Dry powder inhalant for anesthesia and preparing method thereof

A dry powder inhaler and powder technology, applied in the field of anesthetized dry powder inhaler and its preparation, can solve the problems of increased medication risk, large dose, poor stability, etc., and achieve simple and easy preparation process, good content uniformity, powder good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A dry powder inhaler for anesthesia, prepared according to the following steps:

[0025] Element

Dosage (parts by weight)

1 copy

Ketamine hydrochloride

800 copies

2250 copies

1450 copies

2350 copies

1900 copies

110 copies

[0026] Preparation process:

[0027] 1. Pretreatment of raw and auxiliary materials: mix the dexmedetomidine hydrochloride, ketamine hydrochloride, and β-cyclodextrin in the prescribed amount after sterilization, and then put them in an airflow ultrafine pulverizer, and pulverize them into particles with a particle size of less than 5 μm. powder, obtain powder 1, and set aside; take another sterilized prescription amount of lactose, mannitol, and sodium carbonate, mix them, place them in an airflow ultrafine pulverizer, and pulverize them into powders with a ...

Embodiment 2

[0066] A dry powder inhaler for anesthesia, prepared according to the following steps:

[0067] Element

Dosage (parts by weight)

1 copy

Ketamine hydrochloride

700 copies

2200 copies

1300 copies

2200 copies

1800 copies

100 copies

[0068] Preparation process: prepared according to the preparation process of Example 1.

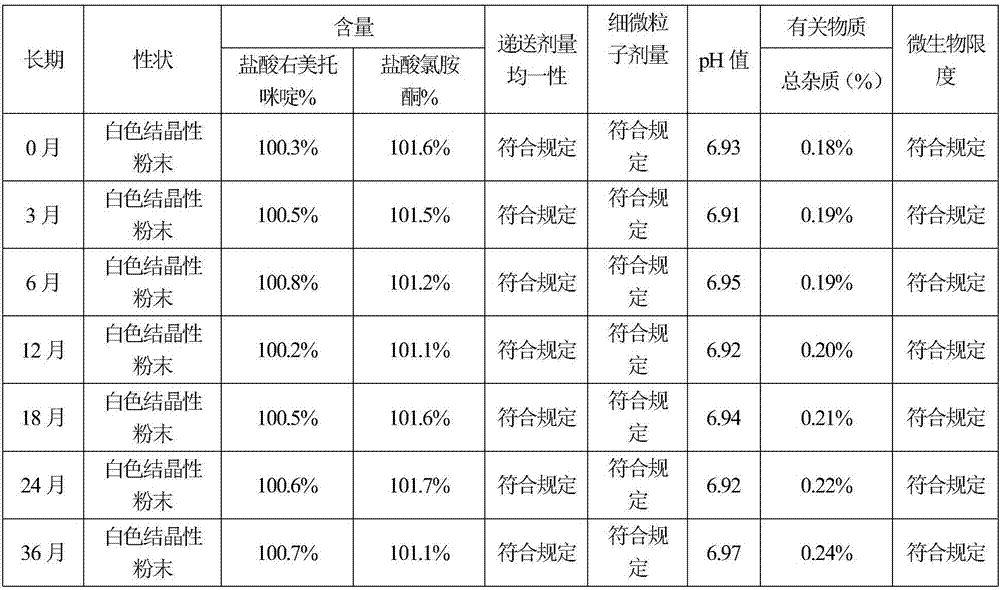

[0069] According to the test method of embodiment 1, the sample stability test result of embodiment 2 shows that the sample quality is stable in accelerating June, and the quality is stable in 36 months for a long time, so the validity period of this product is at least 36 months; The angle is less than 39°, which shows that the powder of Example 2 has good fluidity; the content uniformity measurement test result shows that the RSD of this product is less than 1%, which...

Embodiment 3

[0071] A dry powder inhaler for anesthesia, prepared according to the following steps:

[0072] Element

Dosage (parts by weight)

1 copy

Ketamine hydrochloride

900 copies

lactose

2300 copies

1500 copies

β-cyclodextrin

2500 copies

2000 copies

Sodium carbonate

120 copies

[0073] Preparation process: prepared according to the preparation process of Example 1.

[0074] By the test method of embodiment 1, the sample stability test result of embodiment 3 shows that the sample quality is stable in accelerating June, and the quality is stable in 36 months for a long time, so this product is valid for at least 36 months; The angle is less than 39°, which shows that the powder of Example 3 has good fluidity; the content uniformity measurement test result shows that the RSD of this product is less than 1%, which shows that this produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com