Electroplating method of carrying out La-TiO2-Ag layer cyanide-free composite electroplating on surface of steel base material

A base material surface, composite plating technology, applied in superimposed layer plating, metal material coating process, coating, etc., can solve the problems of slow electrodeposition, high hardness, insufficient purity of the coating, etc., and achieve corrosion resistance Improvement, uniform surface and simple electroplating process

- Summary

- Abstract

- Description

- Claims

- Application Information

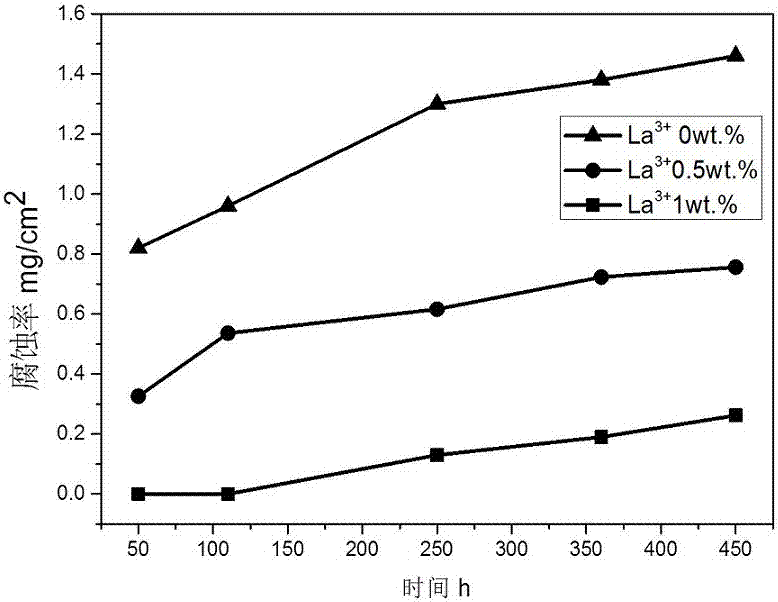

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A Cyanide-free Composite La-TiO Plating on the Surface of a Steel Substrate 2 -The electroplating method of Ag layer, comprises the steps:

[0022] (1) Pretreatment of the steel substrate: polishing, degreasing, acidification, and activation steps are carried out in sequence, wherein the polishing is to use a polishing machine to polish the workpiece, the grinding belt speed is 0.5-1m / s, and the abrasive It is one or more mixtures of 200-280 mesh alumina, silicon carbide or zirconia. The degreasing is an alkaline degreasing agent composed of sodium carbonate, sodium phosphate, sodium silicate and emulsifier. The degreasing temperature is 60 o C, acidification is to use 20wt.% mixed acid to remove residual lye and excess oxides on the surface, mixed acid includes hydrofluoric acid and nitric acid, the volume ratio is 0.5:1, and the activation step is to use VHCl:VH 2 SO 4 =1:2 5wt.% mixed acid for activation. The activation process includes auxiliary steps such as stir...

Embodiment 2

[0027] A Cyanide-free Composite La-TiO Plating on the Surface of a Steel Substrate 2 -The electroplating method of Ag layer, comprises the steps:

[0028] (1) Pretreatment of the steel base material: polishing, degreasing, acidification, and activation steps are carried out in sequence, wherein the polishing is to use a polishing machine to polish the workpiece, the grinding belt speed is 0.5-1m / s, and the abrasive It is one or more mixtures of 200-280 mesh alumina, silicon carbide or zirconia. The degreasing is an alkaline degreasing agent composed of sodium carbonate, sodium phosphate, sodium silicate and emulsifier. The degreasing temperature is 63 o C, acidification is to use 30wt.% mixed acid to remove residual lye and excess oxides on the surface, mixed acid includes hydrofluoric acid and nitric acid, the volume ratio is 0.5:1.3, and the activation step is to use VHCl:VH 2 SO 4 =1:2 composition of 6.5wt.% mixed acid for activation. The activation process includes auxil...

Embodiment 3

[0033] A Cyanide-free Composite La-TiO Plating on the Surface of a Steel Substrate 2 -The electroplating method of Ag layer, comprises the steps:

[0034] (1) Pretreatment of the steel base material: polishing, degreasing, acidification, and activation steps are carried out in sequence. The polishing is to use a polishing machine to polish the workpiece, and the speed of the grinding belt is 0.5-1m / s. The abrasive is one or more mixtures of 200-280 mesh alumina, silicon carbide or zirconia. The degreasing agent is an alkaline degreasing agent composed of sodium carbonate, sodium phosphate, sodium silicate and emulsifier. The degreasing temperature 65 o C, acidification is to use 40wt.% mixed acid to remove residual lye and excess oxides on the surface, mixed acid includes hydrofluoric acid and nitric acid, the volume ratio is 0.5:1.5, and the activation step is to use VHCl:VH 2 SO 4 =1:2 8wt.% mixed acid for activation. The activation process includes auxiliary steps such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com