Layered distribution short-fiber reinforced porous phenolic composite material and preparation method thereof

A technology of short fiber reinforcement and composite materials, which is applied in the field of phenolic resin composite materials and its preparation, can solve the problems of high thermal conductivity, density, and limitation, and achieve the effects of uniform tissue composition, low density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

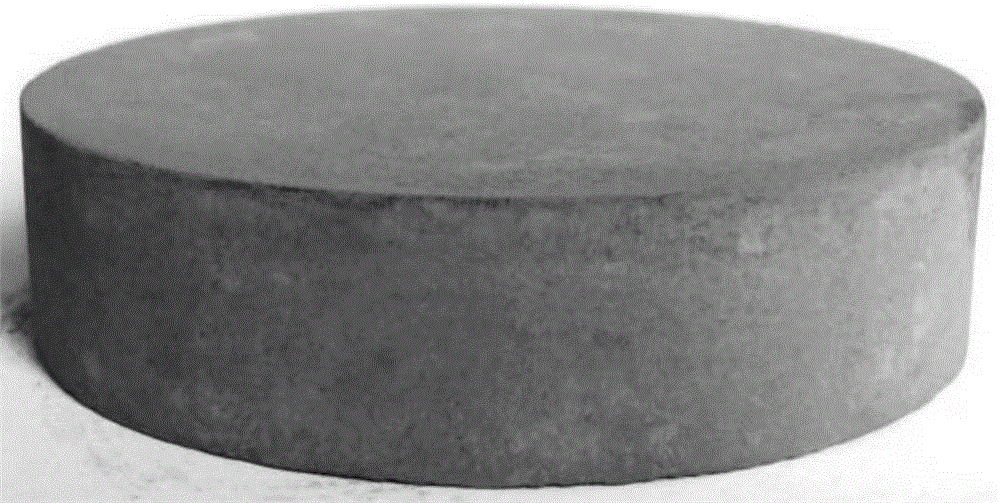

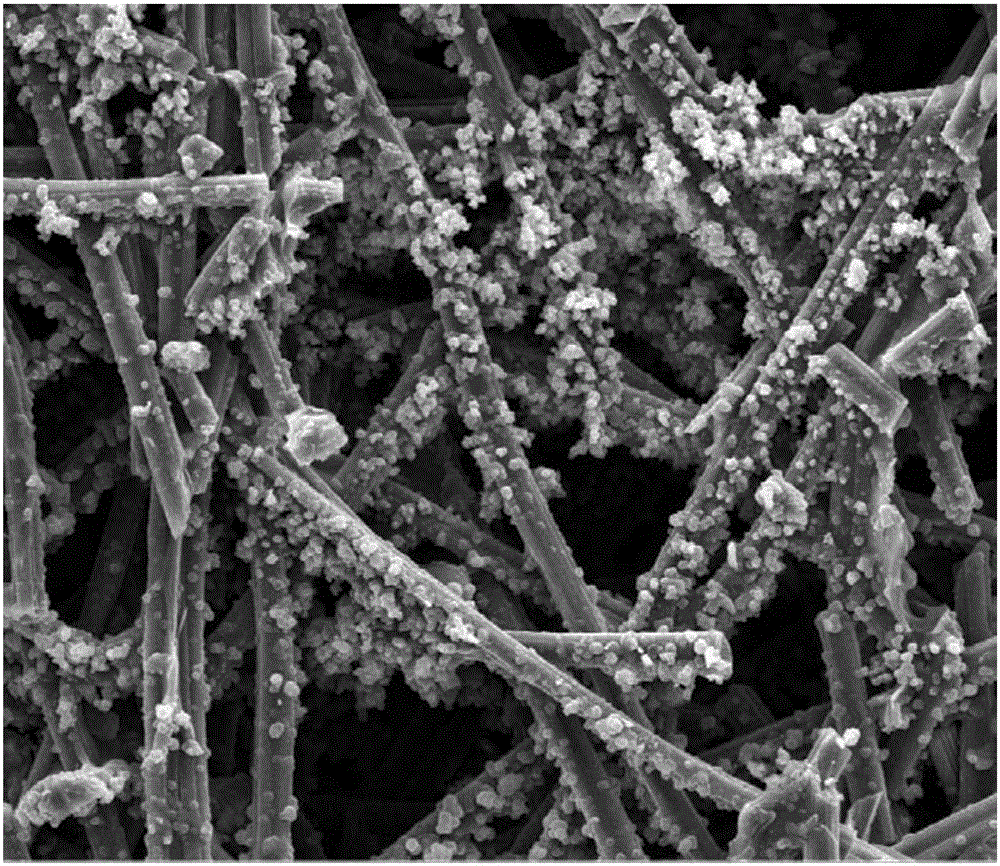

[0022] Specific Embodiment 1: In this embodiment, the layered distributed short fiber reinforced porous phenolic composite material is composed of 20% to 80% phenolic resin and the rest of short fibers according to the mass percentage; the short fibers are distributed in the layered short fiber reinforced porous phenolic composite material Medium-layered distribution, layered distribution A large number of nanopores or micron-sized pores are evenly distributed in the short fiber reinforced porous phenolic composite material.

specific Embodiment approach 2

[0023] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the short fibers are glass fibers, high silica fibers or carbon fibers with a length of 0.5-10 mm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0024] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the layered distributed short fiber reinforced porous phenolic composite material consists of 30% to 70% phenolic resin and the rest of short fibers by mass percentage. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com