Multi-heat treatment process for AQ80M magnesium alloy heavy ingot billet composition homogenization

A technology of composition homogenization and magnesium alloy, applied in the field of magnesium alloy heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

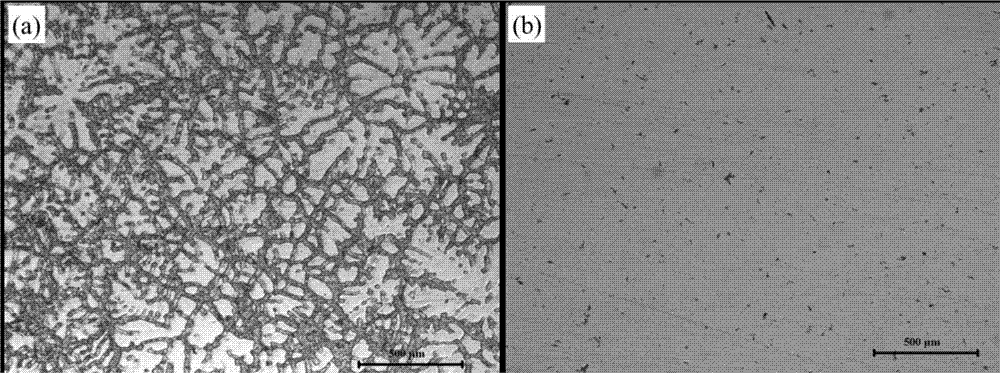

Image

Examples

Embodiment 1

[0019] Put high-purity magnesium-aluminum-zinc ingots and MnCl in the smelting furnace in sequence 2 Granules, Mg-RE, Mg-Ca intermediate alloys and high-purity silver, the melting temperature is controlled at 660-790 °C; after the materials are melted, the slag is removed, and the bottom of the melt is filled with argon gas to stir and refine for 10 minutes; after refining, let it stand and cool down to 690 ℃, keep warm for 1h; press the melt into the electromagnetic mold, wait for the melt above the ingot to solidify and crystallize and the liquid level is 65mm from the vertical height of the upper surface of the mold, start the electromagnetic coil in the mold and start the casting machine at the same time to vertically For ingot pulling, the furnace temperature is 680-685°C during stable casting, the melt temperature in the splitter plate is 646-650°C, the ingot pulling speed is 36mm / min, and the cooling water flow rate is 26m 3 / h, the electromagnetic frequency applied by ...

Embodiment 2

[0021] Put high-purity magnesium-aluminum-zinc ingots and MnCl in the smelting furnace in sequence 2 Granules, Mg-RE, Mg-Ca intermediate alloys and high-purity silver, the melting temperature is controlled at 665-800 °C; after the materials are melted, the slag is removed, and the bottom of the melt is filled with argon gas for stirring and refining for 12 minutes; after refining, let stand and cool down to 688 ℃, keep warm for 1.5h; press the melt into the electromagnetic crystallizer, when the melt above the ingot head solidifies and crystallizes and the liquid level is 50mm vertically from the upper surface of the mold, start the electromagnetic coil in the mold and start the casting machine at the same time Vertical ingot pulling, the temperature in the furnace is 682-688°C during stable casting, the melt temperature in the splitter plate is 648-653°C, the ingot pulling speed is 36mm / min, and the cooling water flow rate is 34m 3 / h, the electromagnetic frequency applied by...

Embodiment 3

[0023] Put high-purity magnesium-aluminum-zinc ingots and MnCl in the smelting furnace in sequence 2 Granules, Mg-RE, Mg-Ca intermediate alloy and high-purity silver, the melting temperature is controlled at 670-780 °C; after the material is melted, the slag is removed, and the bottom of the melt is filled with argon gas for stirring and refining for 12 minutes; after refining, let it stand and cool down to 690 ℃, keep warm for 1h; press the melt into the electromagnetic crystallizer, when the melt above the ingot head is solidified and crystallized and the vertical height of the liquid level from the upper surface of the mold is 40mm, start the electromagnetic coil in the mold and start the casting machine at the same time to vertically For ingot pulling, the temperature in the furnace is 685-688°C during stable casting, the melt temperature in the splitter plate is 656-660°C, the ingot pulling speed is 21mm / min, and the cooling water flow rate is 40m 3 / h, the electromagneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com