Method for regulating and controlling structure uniformity of cross section of ultra-wide aluminum alloy sheet

A technology for aluminum alloy sheet and uniform structure, applied in the field of aluminum alloy sheet processing, can solve the problem of increasing the difficulty of casting and rolling production of high-quality ultra-wide aluminum alloy sheet, uneven structure of aluminum alloy sheet cross-section, and uneven temperature field distribution and other problems, to achieve the effect of fine grains, uniform distribution of the second phase, and uniform temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

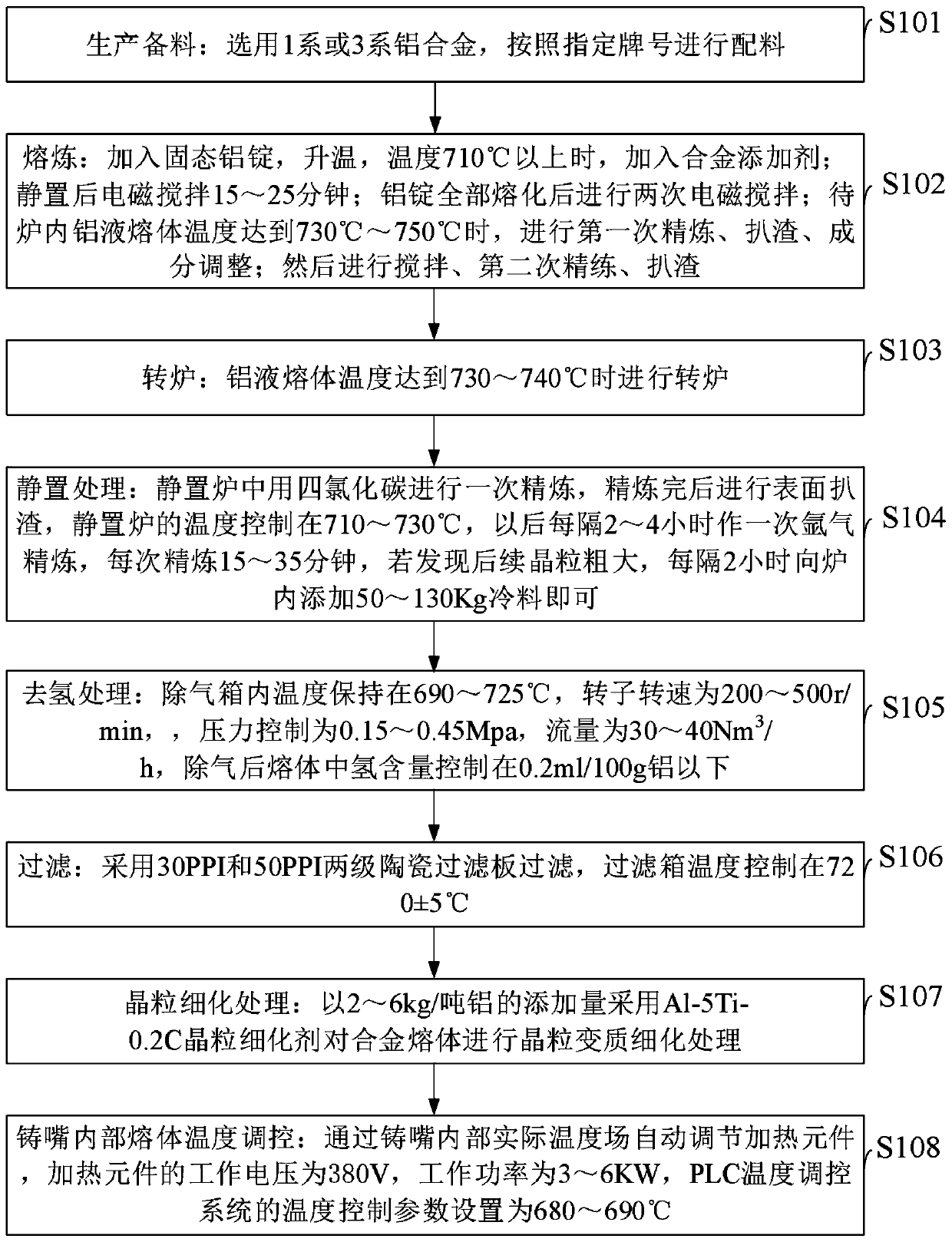

Image

Examples

Embodiment 1

[0082] Step 1: Preparation of raw materials for production: select 1060A aluminum alloy, make ingredients according to the designated grade, and use solid aluminum ingots with high purity. The percentages of Fe and Si are required to be controlled at 0.4-0.55 and 0.2-0.4 respectively;

[0083] Step 2: Melting: Add solid aluminum ingots and heat up. When the temperature reaches above 710°C, add alloy additives evenly according to the designated brand; after standing for 25-35 minutes, carry out electromagnetic stirring for 15-25 minutes; when the aluminum ingots are completely melted, carry out Electromagnetic stirring twice, stirring once every 15-35 minutes, 15-25 minutes each time; when the temperature of the molten aluminum in the furnace reaches 730°C-750°C, carry out the first argon powder spraying refining, tetrachloride The amount of carbon used is 2-3kg / ton of aluminum, and the refining time is 20-35 minutes. During refining, the wave height of the melt is controlled to...

Embodiment 2

[0092] Such as figure 2 and image 3 As shown, as a further improvement to Embodiment 1, in this embodiment, one more step should be added after Step 7 of Embodiment 1, that is, the temperature control of the melt inside the nozzle.

[0093] The specific steps are as follows: firstly, install and fix the serial thermal sensor 9 and the heating element 10 at the tail of the casting nozzle 13 sequentially and evenly, and then connect the terminals of the thermal sensor and the heating element to the terminals of the PLC temperature control system 11 Connect, and finally turn on the power supply 12 circuits, wherein the number of heating element terminals is required to be the same as that of the thermal sensor and the number of heating elements, then start the power supply of the temperature control device, and set the temperature control parameters of the PLC temperature control system to 683°C. And select the working voltage and power of the heating element, so that the temp...

Embodiment 3

[0100] In order to conduct a comparative analysis of temperature control parameters with Example 2, in this example, the temperature control parameters of the PLC temperature control system were set to 685° C. and 688° C. respectively. The specific comparison of the lateral temperature field distribution inside the nozzle in the test can be shown in Table 2:

[0101] Table 2 The specific comparison of the distribution of the lateral temperature field inside the nozzle

[0102]

[0103] result:

[0104] In fact, for the temperature control parameters of the PLC temperature control system, the test results show that the transverse temperature field inside the casting nozzle is generally distributed around 685°C, and 685°C presents the main trend. Therefore, while setting the temperature control parameters of the PLC temperature control system to 680-690°C, 685°C is preferred.

[0105] The alloy provided in the embodiment of the present invention is 1060A aluminum alloy.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com