Multi-oxygen burner and combustion method thereof

A technology of multi-oxygen combustion and combustion method, applied in combustion methods, burners, gas fuel burners, etc., can solve problems such as waste of energy and environmental pollution, and achieve the effect of ensuring safety, low quality requirements, and changing combustion methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

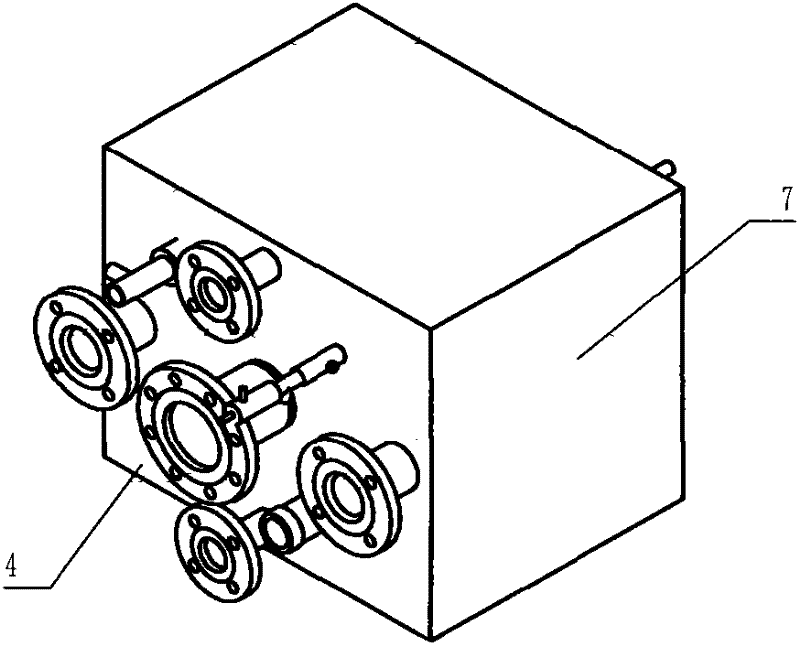

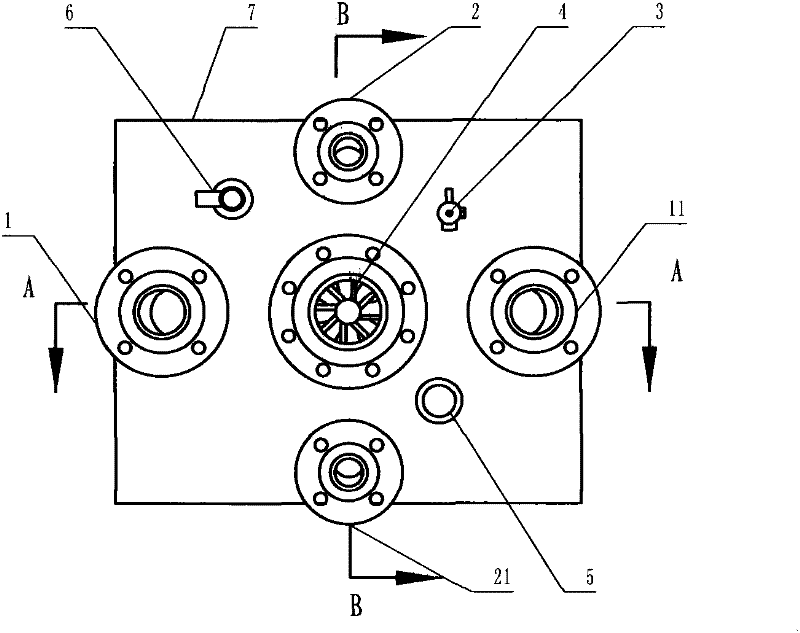

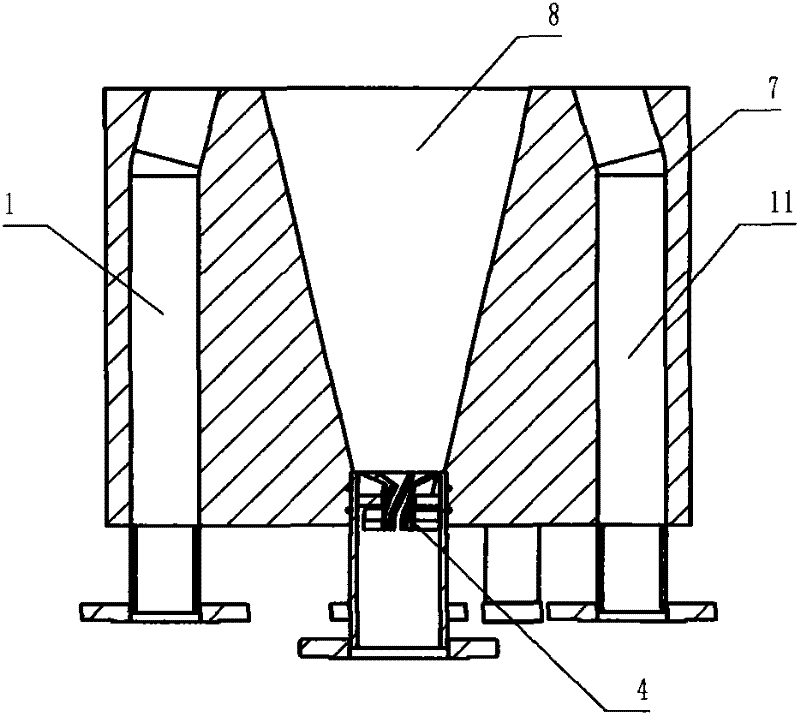

[0038] The present invention will be further described below in conjunction with accompanying drawing and embodiment, embodiment: referring to accompanying drawing, multi-oxygen burner is provided with burner body 7, and this burner body is made of refractory material, and shape is circular or square, In the middle of the burner body, there is a flame vent 8, which is straight or bell-shaped, and the large end of the flame port, that is, the rear end, has an opening angle of 30°, that is, when the angle between the opening and the axis is 0°, it is straight. , when it is greater than 0°, it is bell-shaped; the small end of the crater, that is, the front end, is provided with a straight barrel section, and a fuel cyclone 4 is arranged in the straight barrel section; several oxygen nozzles are arranged around the crater, among which there is a primary oxygen nozzle 2 pieces 2, 21 and 2 pieces 1, 11 of the secondary main combustion oxygen nozzle; an igniter 3, a flame monitor hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com