Active artificial cornea and preparation method thereof

An artificial cornea and active technology, applied in the field of active artificial cornea and its preparation, can solve the problems of complicated operation method, thinning and dissolving of precorneal stroma, and discharge of artificial cornea, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in further detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

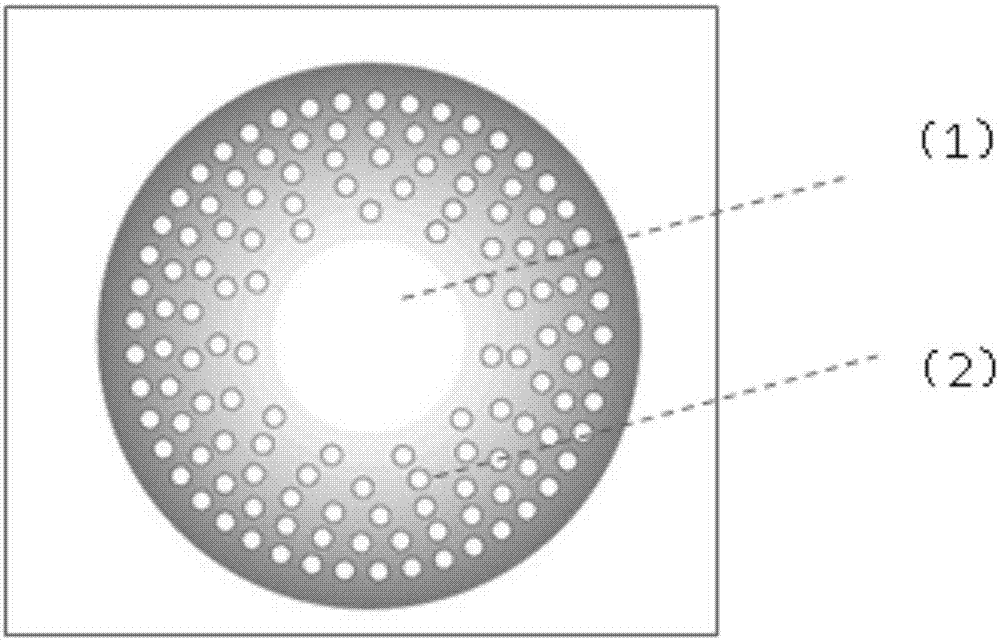

[0058] Using acrylic acid, methyl methacrylate and hydroxyethyl methacrylate as raw materials, adding a photoinitiator, and preparing an artificial corneal substrate with gradient hydrogel properties through a layered gradient ultraviolet light irradiation polymerization technology, the substrate's The central part (which fits with the pupil of the human eye, with a diameter of 5 mm) is pure PMMA, and the periphery expands with the radius. For every 0.5 mm increase, the content of PMMA components decreases by 15%, and the content of P(HEMA-AAS) increases by 15%. The P(HEMA-AAS) content is 100% until the PMMA component content of the outer portion is zero. Then, a polyvinylidene fluoride coating is performed on the central part (inner and outer surfaces) of the artificial c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com