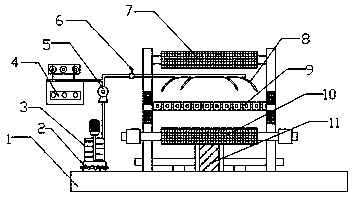

A drug application device for wet wipes with the effect of preventing and treating allergic rhinitis

A technology for allergic rhinitis and wet wipes is applied in the field of drug application devices for wet wipes. Reasonable and reasonable structural design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 A kind of Chinese medicine extract with the effect of preventing and treating allergic rhinitis and its preparation method

[0023] A traditional Chinese medicine extract with the effect of preventing and treating allergic rhinitis, comprising the following raw materials: 3g cicada, 10-90g typhoid grass, 1g Fangfeng, 0.2g goose not eating grass, 0.2g dodder seed, 0.3g raw ephedra, 2g cocklebur , 0.1g fishy, 0.5g vitex, 0.4g burdock, 0.8g calamus, 1g notopterygium, 1g Alisma, 0.3g ligusticum, 0.8g Xu Changqing, 0.1g tea tree essential oil, 0.8g tallow leaf , Euphorbia narrowleaf 0.6g and deionized water 220g.

[0024] A preparation method of a traditional Chinese medicine extract having the effect of preventing and treating allergic rhinitis comprises the following steps: a, taking cicada, windproof, goose does not eat grass, dodder, raw ephedra, cocklebur, vitex, burdock, Shichangpu and notopterygium are mixed and crushed in a ball mill, and crushed into...

Embodiment 2

[0028] Embodiment 2 A kind of paint for roller shaft surface and preparation method thereof

[0029] A kind of paint for the surface of rollers, which includes the following raw materials: 50g of polyester resin, 3g of alkylphenol polyoxyethylene ether, 6g of PAN-based carbon fiber, 0.5g of pe pearlescent purple masterbatch, 0.5g of pearlescent golden yellow powder, pe Black masterbatch 0.3g, pe yellow masterbatch 0.4g, polyaluminum sulfate 5g, zinc naphthenate 2g, polyvinyl butyral 3g, hydroxyethyl cellulose 0.5g, expanded vitrified microbeads 0.5g, nano copper 0.4g, natural jade powder 4g, gum arabic 18g.

[0030] A method for preparing the paint for the surface of the roller shaft is as follows: weighing each raw material, placing it in a ball mill, and using wet pulverization, stirring at a temperature of 55°C for 60 minutes, heating to 85°C in a water bath, stirring for 20 minutes, and then Ultrasonic treatment was carried out for 10 minutes, the ultrasonic power was 100...

Embodiment 3

[0031] Embodiment 3 A kind of roller shaft and preparation method thereof

[0032] A roller shaft is made of hard alloy material, including the following raw materials in mass percentage: 0.08% carbon, 2% zinc, 7% silicon oxide, 1% copper, 0.02% antimony trioxide, 0.6% nano ceramic powder, sulfuric acid Barium 0.09%, Cerium Oxide 0.2%, Diphenylsulfonylimide 1%, Aluminum 11%, Nano Titanium Dioxide 0.9%, Potassium Titanate Whiskers 3%, Chromium 0.01%, Manganese 0.6%, Nickel 0.3%, Cobalt 0.1% , dysprosium 0.08%, scandium 0.03%, the balance is iron and unavoidable impurities.

[0033]A preparation method of a roller shaft is as follows: put all the constituent raw materials into the crucible of a vacuum melting furnace, evacuate to 8.8×10-2Pa, start from 120°C, raise the temperature at 20°C / s, and wait until the temperature rises to 820°C , stop vacuuming and fill the vacuum melting furnace with argon to 3.5×104Pa; then continue to heat up to 1020°C, after the components are comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com