Graphene paint preparation process

A preparation process, graphene technology, applied in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve problems that affect the service life, reduce the protection of walls or door panels, and immersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

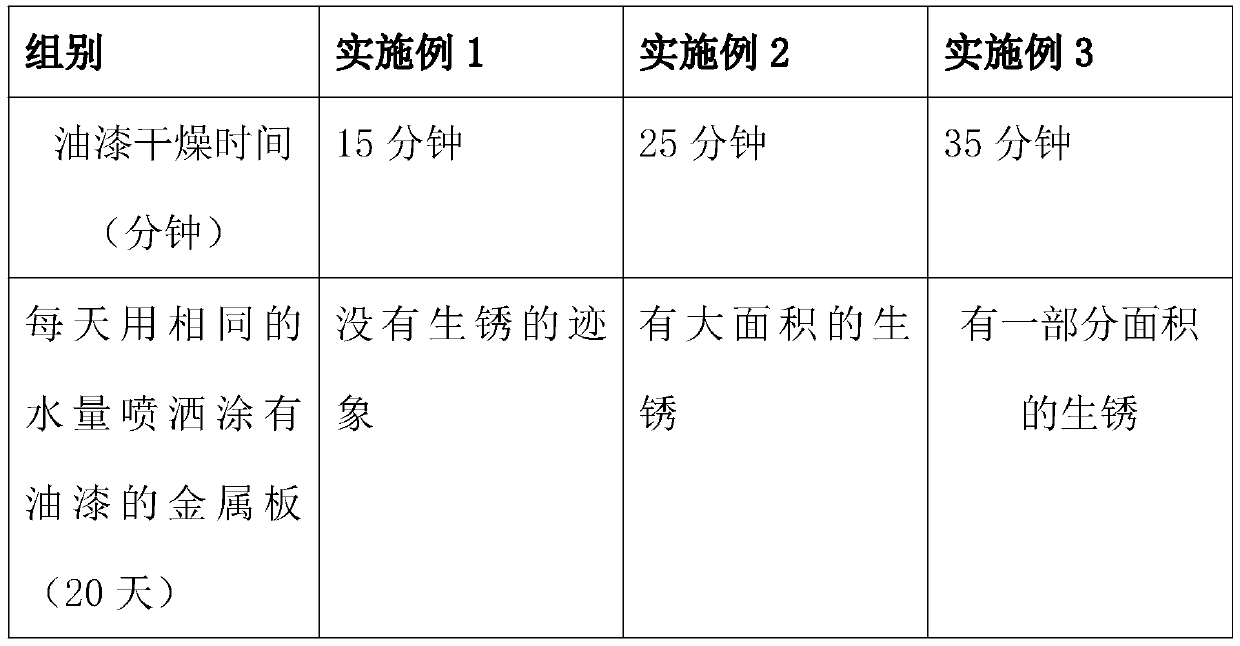

Embodiment 1

[0018] S1. Select 60 parts of water-based resin, 55 parts of epoxy resin, 55 parts of high-temperature-resistant silicone resin, 40 parts of silicone resin and 35 parts of nano-zinc oxide, and use the selected water-based resin, epoxy resin, high-temperature-resistant silicone resin, and organic silicon The resin and nano-zinc oxide are put into the mixer for stirring, the stirring speed is 350 rpm, the stirring time is 15 minutes, the stirring temperature is controlled at 55°C, after the stirring is completed, the water-based resin, epoxy resin, high temperature resistant silicone resin , Silicone resin and nano-zinc oxide are poured into a grinder for grinding, the grinding time is 25 minutes, and the particle size is 3500 mesh, and the mixed powder can be obtained;

[0019] S2. Select 35 parts of polyester polyol and 25 parts of chlorinated paraffin, pour the selected polyester polyol and chlorinated paraffin into the mixer for stirring, control the stirring time at 15 minut...

Embodiment 2

[0022] S1. Select 50 parts of water-based resin, 45 parts of epoxy resin, 45 parts of high-temperature-resistant silicone resin, 30 parts of organic silicon resin and 25 parts of nano-zinc oxide. Put the resin and nano-zinc oxide into the mixer for stirring, the stirring speed is 300 rpm, the stirring time is 10 minutes, the stirring temperature is controlled at 45°C, after the stirring is completed, the water-based resin, epoxy resin, high temperature resistant silicone resin , Silicone resin and nano-zinc oxide are poured into a grinder for grinding, the grinding time is 20 minutes, and the particle size is 3000 mesh, and the mixed powder can be obtained;

[0023]S2. Select 30 parts of polyester polyol and 20 parts of chlorinated paraffin, pour the selected polyester polyol and chlorinated paraffin into the mixer for stirring, control the stirring time at 10 minutes, raise the stirring temperature to 50°C, and control the stirring rate At 100 rpm, then add 15 parts of stabil...

Embodiment 3

[0026] S1. Select 70 parts of water-based resin, 65 parts of epoxy resin, 65 parts of high-temperature-resistant silicone resin, 50 parts of organic silicon resin and 45 parts of nano-zinc oxide. Put the resin and nano-zinc oxide into the mixer for stirring, the stirring speed is 400 rpm, the stirring time is 20 minutes, the stirring temperature is controlled at 65°C, after the stirring is completed, the water-based resin, epoxy resin, high temperature resistant silicone resin , Silicone resin and nano-zinc oxide are poured into a grinder for grinding, the grinding time is 30 minutes, and the particle size is 4000 mesh, and the mixed powder can be obtained;

[0027] S2. Select 40 parts of polyester polyol and 30 parts of chlorinated paraffin, pour the selected polyester polyol and chlorinated paraffin into the mixer for stirring, control the stirring time at 20 minutes, raise the stirring temperature to 70°C, and control the stirring rate At 200 rpm, then add 25 parts of stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com