A kind of preparation method of graphene modified waterborne polyurethane

A water-based polyurethane and graphene modification technology, which is applied in the preparation and application of new materials and functional polymer materials, can solve the problems of unreported modified water-based polyurethane, difficult large-scale industrial production, and complicated preparation processes, and achieves a combination of Tight, not easy to separate, good wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

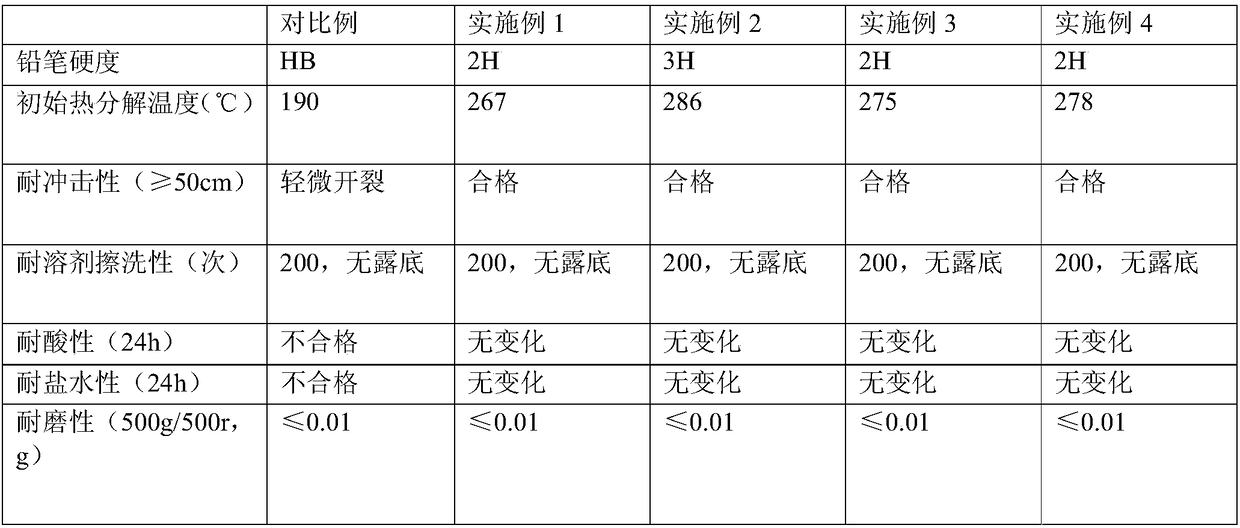

Examples

Embodiment 1

[0040] (1) Add 40 g of polyethylene adipate with a molecular weight of 1000 into the reaction flask, distill under reduced pressure at 100°C for 30 minutes, cool down to 60°C, add 20g of toluene diisocyanate, 0.2g of dibutyltin dilaurate, and heat up React at 70°C for 4 hours;

[0041] (2) Cool down to 60°C, add 2g of 1,4-butanediol and 2g of 2,2-dimethylolpropionic acid, raise the temperature to 70°C and react for 4 hours until the NCO content reaches the theoretical value;

[0042] (3) cooling to 40° C., and after reducing the viscosity with 10 g of acetone, add 2 g of triethylamine, and react for 30 minutes to obtain a prepolymer of water-based polyurethane;

[0043] (4) Dilute 5g graphene SE1430 with 10g isopropanol, then mix with 10g methyltrimethoxysilane, stir and react at room temperature for 30 minutes to obtain graphene modified by silane coupling agent;

[0044] (5) The prepolymer of the water-based polyurethane obtained in step 3 is added to the graphene modified ...

Embodiment 2

[0046] (1) Add 60g of polytetrahydrofuran diol with a molecular weight of 2000 into the reaction flask, distill under reduced pressure at 100°C for 30 minutes, cool down to 60°C, add 40g of hexamethylene diisocyanate and 0.5g of stannous octoate, and heat up to 90°C React for 2 hours;

[0047] (2) Cool down to 60°C, add 5g of diethylene glycol and 8g of 2,2-dimethylolbutyric acid, raise the temperature to 90°C and react for 2 hours until the NCO content reaches the theoretical value;

[0048] (3) cooling to 60° C., and after reducing the viscosity with 20 g of butanone, add 5 g of ammonia water and react for 15 minutes to obtain a prepolymer of water-based polyurethane;

[0049] (4) Dilute 20g graphene SE1231 with 20g isopropanol, then mix with 40gKH560, stir and react at room temperature for 30 minutes to obtain graphene modified by silane coupling agent;

[0050] (5) Add the prepolymer of the waterborne polyurethane obtained in step 3 to the graphene modified by the silane ...

Embodiment 3

[0052] (1) Add 40g of polypropylene glycol with a molecular weight of 2000 into the reaction flask, distill under reduced pressure at 100°C for 60 minutes, cool down to 60°C, add 30g of isophorone diisocyanate and 0.3g of dibutyltin dilaurate, and heat up to 80°C React for 2 hours;

[0053] (2) Cool down to 60°C, add 3g of neopentyl glycol and 4g of 2,2-dimethylolpropionic acid, heat up to 80°C and react for 2 hours until the NCO content reaches the theoretical value;

[0054] (3) cooling to 40° C., and after reducing the viscosity with 10 g of tetrahydrofuran, add 3 g of triethanolamine and react for 15 minutes to obtain a prepolymer of water-based polyurethane;

[0055] (4) Dilute 10g graphene G-Powder with 15g isopropanol, then mix with 20g KH570, stir and react at room temperature for 30 minutes to obtain graphene modified by silane coupling agent;

[0056] (5) The prepolymer of the aqueous polyurethane that step 3 obtains is joined in the graphene that the silane couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com