Water-based polyurethane adhesive and preparation method thereof

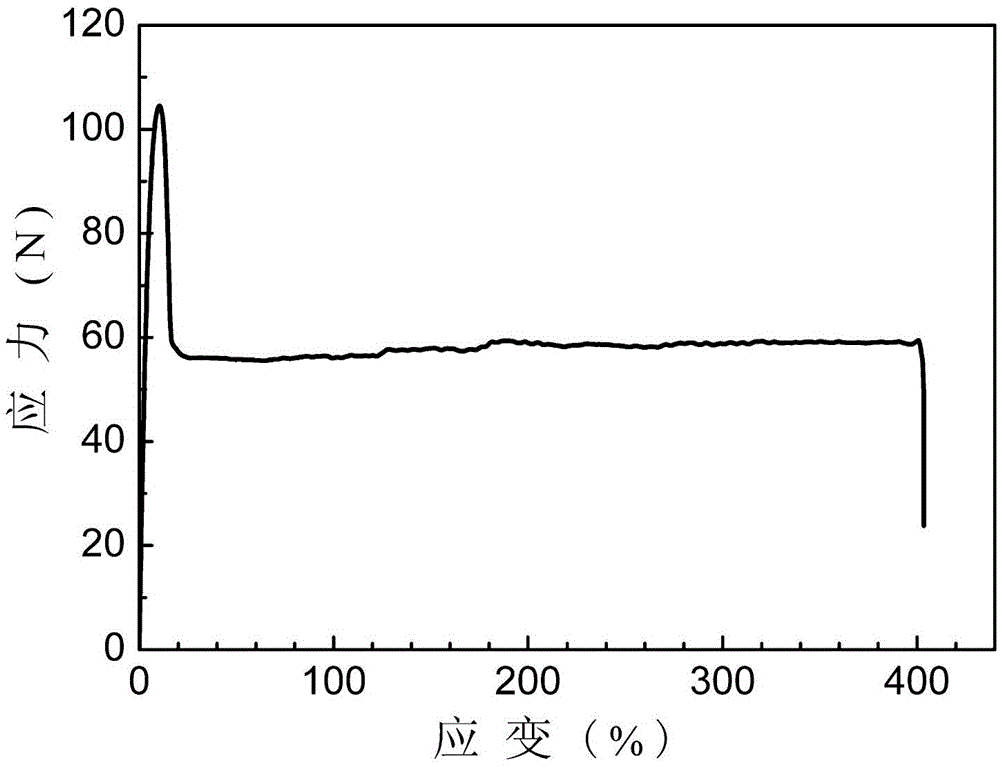

A water-based polyurethane and adhesive technology, applied in the direction of adhesives, polymer adhesive additives, film/sheet adhesives, etc. Simple process, high breaking strength, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 100.00 grams of PEA (M n =3000) into a 500mL three-neck flask, dehydrated at 115°C for 1 hour and then cooled to 60°C. Take 29.70 grams of IPDI into a three-necked flask, stir and react at 90°C for 2 hours, then add 0.05 grams of DBTDL, 6.23 grams of hydrophilic chain extender DMPA, 4.53 grams of HDO and 90.00 grams of methyl ethyl ketone, stir and react at 75°C for 4 hours, then add 3.03 grams of DCP, reacted at 80°C for 3 hours, then added 2.76 grams of DETDA, stirred and mixed evenly, transferred the reaction product to a high-speed shear disperser, added 4.77 grams of TEA under the condition of 3000 rpm, reacted for 5 minutes and then added 325 grams of water, after stirring for 5 minutes, the reaction product was transferred to a rotary evaporator, and the methyl ethyl ketone was removed under 50 ° C and 0.01 MPa vacuum conditions to obtain a water-based polyurethane adhesive emulsion.

Embodiment 2

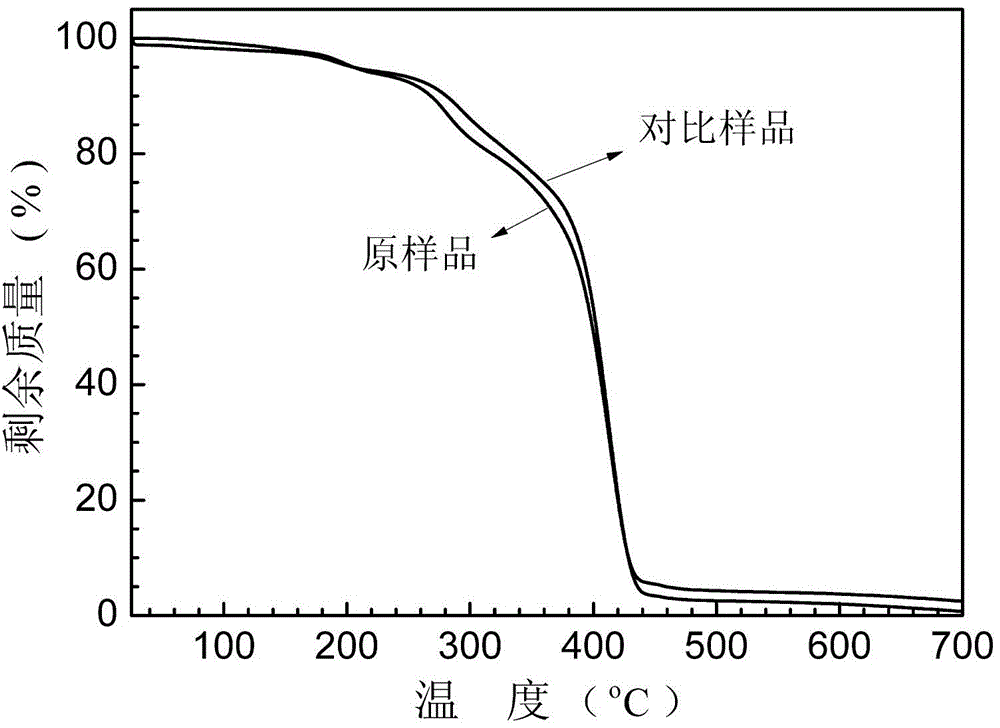

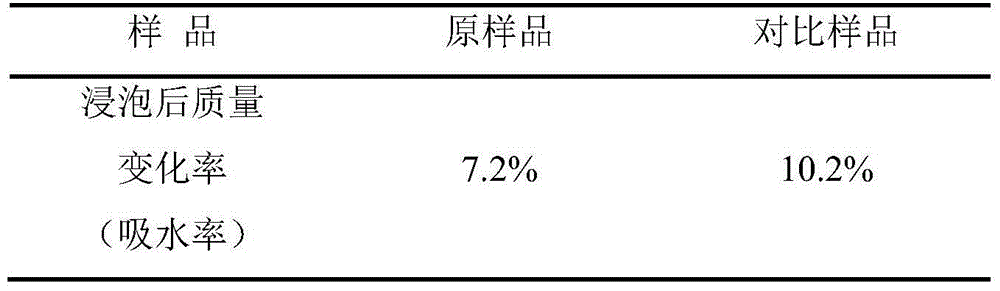

[0038] 50.00 grams of PBA (M n =3200) into a 500mL three-neck flask, dehydrated at 110°C for 1 hour and then cooled to 50°C. Take 11.00 grams of TDI and add it to a three-necked flask, stir and react at 80°C for 2 hours, then add 0.03 grams of DBTDL, 3.00 grams of hydrophilic chain extender DMPA, 0.94 grams of BDO and 55.00 grams of methyl ethyl ketone, stir and react at 70°C for 4 hours, then add 1.63 grams of PHE, reacted at 80°C for 3 hours, then added 1.2 grams of DCP, stirred and mixed evenly, transferred the reaction product to a high-speed shear disperser, added 2.27 grams of TEA under the condition of 3000 rpm, reacted for 5 minutes and then added 155 grams of water, after stirring for 5 minutes, the reaction product was transferred to a rotary evaporator, and butanone was removed at 50° C. and 0.01 MPa vacuum conditions to obtain an aqueous polyurethane adhesive emulsion (original sample).

[0039] Do a comparison sample at the same time, the reaction steps are as fo...

Embodiment 3

[0041] 2 kg of PCL (M n =2000) into the reactor, dehydrated at 110°C for 1 hour and then cooled to 50°C. Take 700.7 grams of TDI and put it into a three-necked flask, stir and react at 80°C for 2 hours, then add 0.03 grams of DBTDL, 139.47 grams of hydrophilic chain extender DMBA, 150.53 grams of DEG and 0.9L of acetone, stir and react at 70°C for 4 hours, then add 75 1 gram of PHE, reacted at 80°C for 3 hours, then added 142.6 grams of DMTDA, stirred and mixed evenly, transferred the reaction product to a high-speed shear disperser, added 96 grams of TEA under the condition of 3000 rpm, and added 7L after 5 minutes of reaction water, after stirring for 5 minutes, transfer the reaction product to a rotary evaporator, and remove acetone at 40°C and 0.01MPa vacuum to obtain a water-based polyurethane adhesive emulsion.

[0042] If other conditions of this embodiment remain unchanged, and DEG is replaced with EG, water-based polyurethane adhesive emulsion can also be obtained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com