Water-based extinguishing agent with solidification and foaming characteristics and preparation method

A technology for solidifying foaming and fire extinguishing agents, which can be used in fire prevention equipment, etc. It can solve the problems of low burning resistance, limited liquid analysis time, and high price, and achieve the effects of long burning resistance, good application prospects, and stable storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

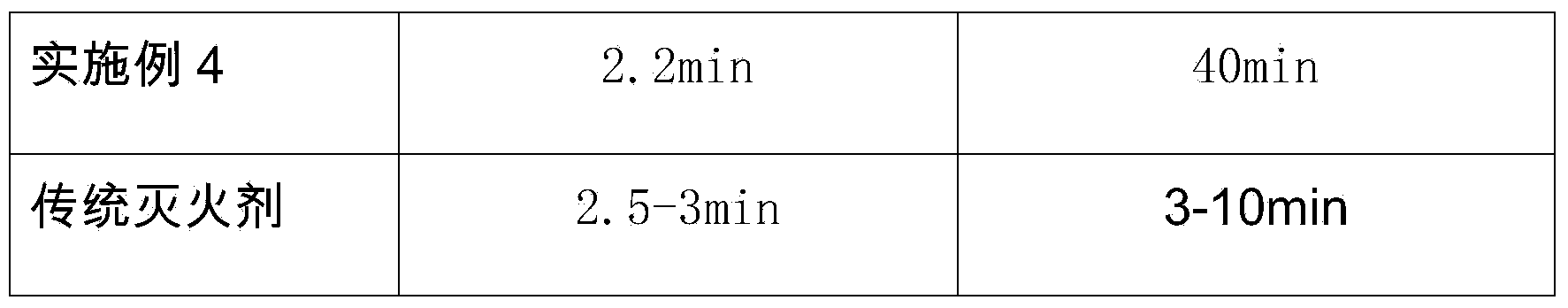

Examples

Embodiment 1

[0012] Embodiment 1 (all are parts by mass in the formula)

[0013] Expandable graphite 10, mica 10;

[0014] Sodium lauryl sulfate 0.95, perfluoroalkyl benzyl quaternary ammonium salt fluorocarbon surfactant 0.05;

[0015] Methyl hydroxypropyl cellulose 0.7;

[0016] Water: 78.3.

[0017] Grind 10 parts of expandable graphite and 10 parts of mica to 1250 mesh in a pulverizer, and grind 10 parts of expandable graphite, 10 parts of mica and 0.95 parts of sodium lauryl sulfate in a high-speed disperser, 0.05 Parts of perfluoroalkylbenzyl quaternary ammonium salt fluorocarbon surfactants were mixed and dispersed for 10 minutes to obtain a mixture, dissolved in 78.3 parts of water in a stirring tank, and 0.7 parts of methyl hydroxypropyl cellulose was added to the mixture obtained above, stirred and mixed evenly Get fire extinguisher. According to the national standard GB15308-2006 "foam fire extinguishing agent", the fire extinguishing experiment was carried out. The fire ex...

Embodiment 2

[0018] Embodiment 2 (all are parts by mass in the formula)

[0019] Expandable graphite 10, boron modified phenolic resin 15, zinc borate 10;

[0020] Alkyl glycoside APG12161.75, perfluorobetaine fluorocarbon surfactant 0.05;

[0021] Sodium polyacrylate 0.5;

[0022] Water: 62.7.

[0023] Grind 10 parts of expandable graphite, 15 parts of boron-modified phenolic resin, and 10 parts of zinc borate to 1250 mesh in a pulverizer, and grind 10 parts of expandable graphite, 15 parts of boron-modified Phenolic resin, 10 parts of zinc borate, 1.75 parts of alkyl glycoside APG1216, and 0.05 parts of perfluorobetaine fluorocarbon surfactant were mixed and dispersed for 10 minutes to obtain a mixture, and 0.5 parts of sodium polyacrylate was dissolved in 62.7 parts of water in a stirring tank and then added to the above-mentioned In the mixture, stir and mix evenly to obtain the fire extinguishing agent. According to the national standard GB15308-2006 "foam fire extinguishing agent...

Embodiment 3

[0024] Embodiment 3 (all are parts by mass in the formula)

[0025] Boric acid 10, boron modified phenolic resin 10, ammonium polyphosphate 10;

[0026] Polyether modified silicone oil 0.1, perfluoroalcohol polyoxyethylene ether 0.1;

[0027] Xanthan gum 0.3;

[0028] Water: 69.5

[0029] Grind 10 parts of boric acid, 10 parts of boron-modified phenolic resin, and 10 parts of ammonium polyphosphate to 1250 mesh in a pulverizer, and grind 10 parts of boric acid and 10 parts of boron-modified phenolic resin in a high-speed disperser, 10 parts of ammonium polyphosphate, 0.1 part of polyether modified silicone oil, and 0.1 part of perfluoroalcohol polyoxyethylene ether were mixed and dispersed for 10 minutes to obtain a mixture. Dissolve 0.3 part of xanthan gum in a stirring tank with 69.5 parts of water and add the mixture obtained above , stir and mix evenly to obtain a fire extinguishing agent. According to the national standard GB15308-2006 "foam fire extinguishing agent",...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com