Expansion type fire-retardant coating

A kind of technology of fireproof coating and expansion type, which is applied in the direction of fireproof coating, epoxy resin coating, coating, etc. It can solve the problems of poor thermal stability and other problems, and achieve the effect of good decoration, good salt corrosion resistance and stable storage

Active Publication Date: 2012-10-03

TIANCHANG YINHU PAINT

View PDF8 Cites 41 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide an intumescent fireproof coating with excellent comprehensive performance, which solves the shortcomings of poor thermal stability of current fireproof coatings, and has very excellent fireproof performance and thermal stability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

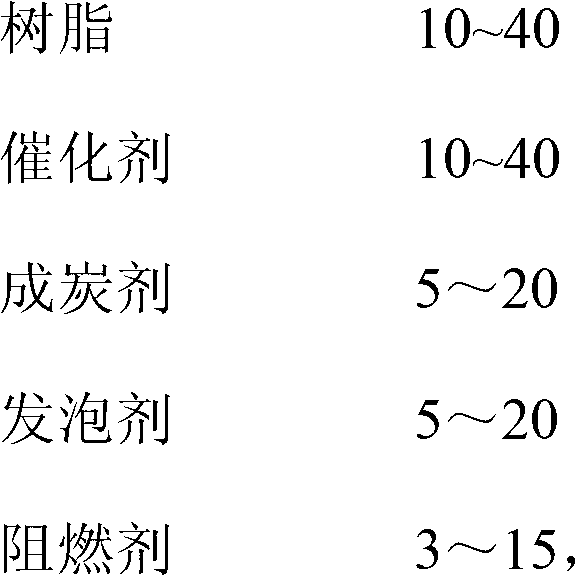

[0035] Described coating comprises by weight parts:

[0036]

Embodiment 2

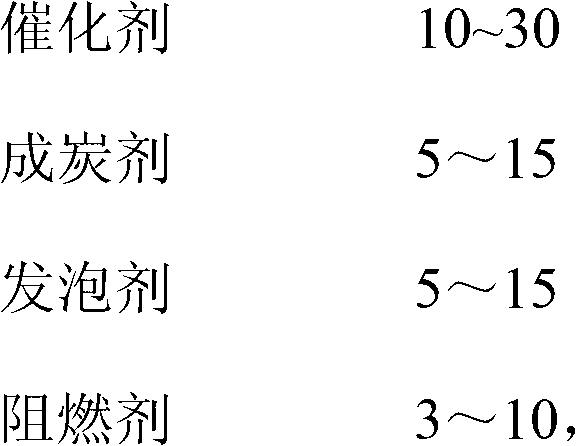

[0038] Described coating comprises by weight parts:

[0039]

Embodiment 3

[0041] Described coating comprises by weight parts:

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an expansion type fire-retardant coating which contains organic silicon resin, and particularly comprises the components in part by weight: 10-40 parts of resin, 10-40 parts of catalyst, 5-20 parts of charcoal forming agent, 5-20 parts of foaming agent, and 3-15 parts of flame retardant, wherein the resin is selected from one or more of epoxy resin, phenolic resin, and acrylic resin as well as organic silicon resin. According to the invention, the shortcoming that the traditional fire-retardant coating is poor in heat stability is overcome; the coating has the characteristics of good fireproofing heat-insulating property, good bonding force, high strength, capability of bearing high and low-temperature circulation influence, excellent water resistance, acid resistance and salt corrosion resistance of coating layer, difficult in falling, stability in storage, good decoration property, convenience for construction and the like; during combustion, no smog or little smog is generated; and the coating is particularly suitable to be used as a fire-resistant coating for ultra-thin steel structures, veneer type fire-retardant coating and cable fire-retardant coating.

Description

technical field [0001] The invention relates to a fireproof paint, in particular to an intumescent fireproof paint, which can be used as a fireproof paint for steel structures, a decorative surface fireproof paint, and a fireproof paint for cables. Background technique [0002] In terms of fire prevention mechanism, fire retardant coatings are generally divided into two types: intumescent and non-intumescent. Non-intumescent fire retardant coatings rely on their own high flame retardancy or non-combustibility to achieve the purpose of flame retardant and fire prevention. To achieve a good fire prevention effect, it must be coated very thickly, and a large amount of halogen, nitrogen, phosphorus and other flame retardants are added to produce Large quantities of toxic gas. Intumescent fireproof coating means that the coating film expands when heated to form a honeycomb carbonized layer, which isolates the heat of the flame and reduces or slows down the transfer to the substr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D183/00C09D183/10C09D183/12C09D183/04C09D163/00C09D161/06C09D133/00C09D5/18C09D7/12

Inventor 祝盆鑫

Owner TIANCHANG YINHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com