Low temperature solid oxide fuel cell and its preparation method

A solid oxide and fuel cell technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

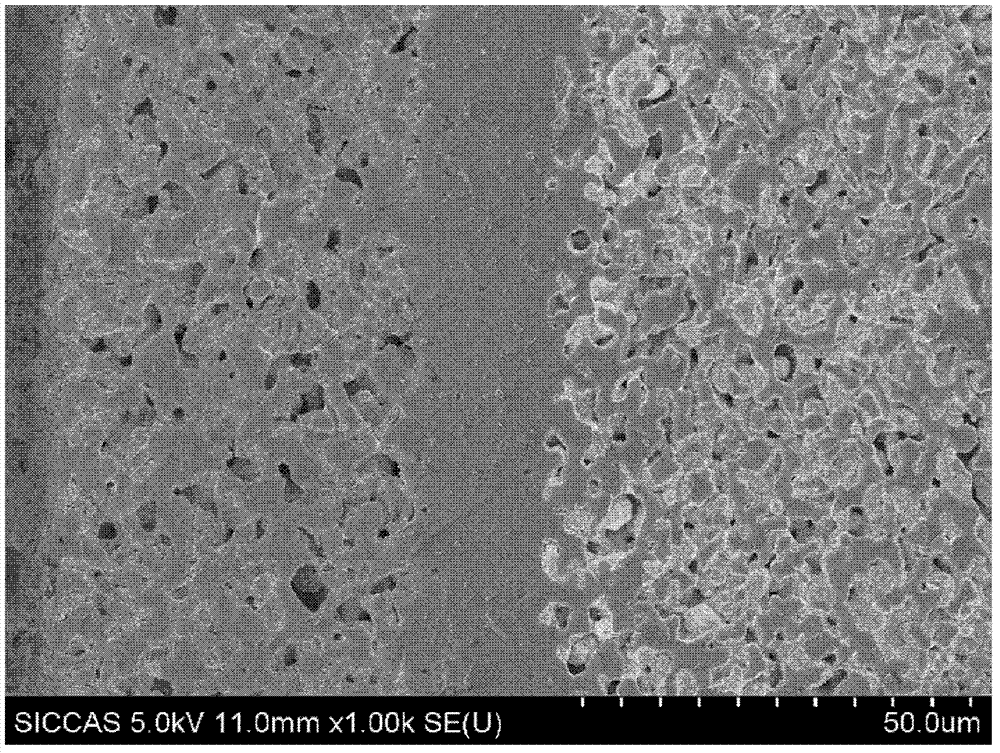

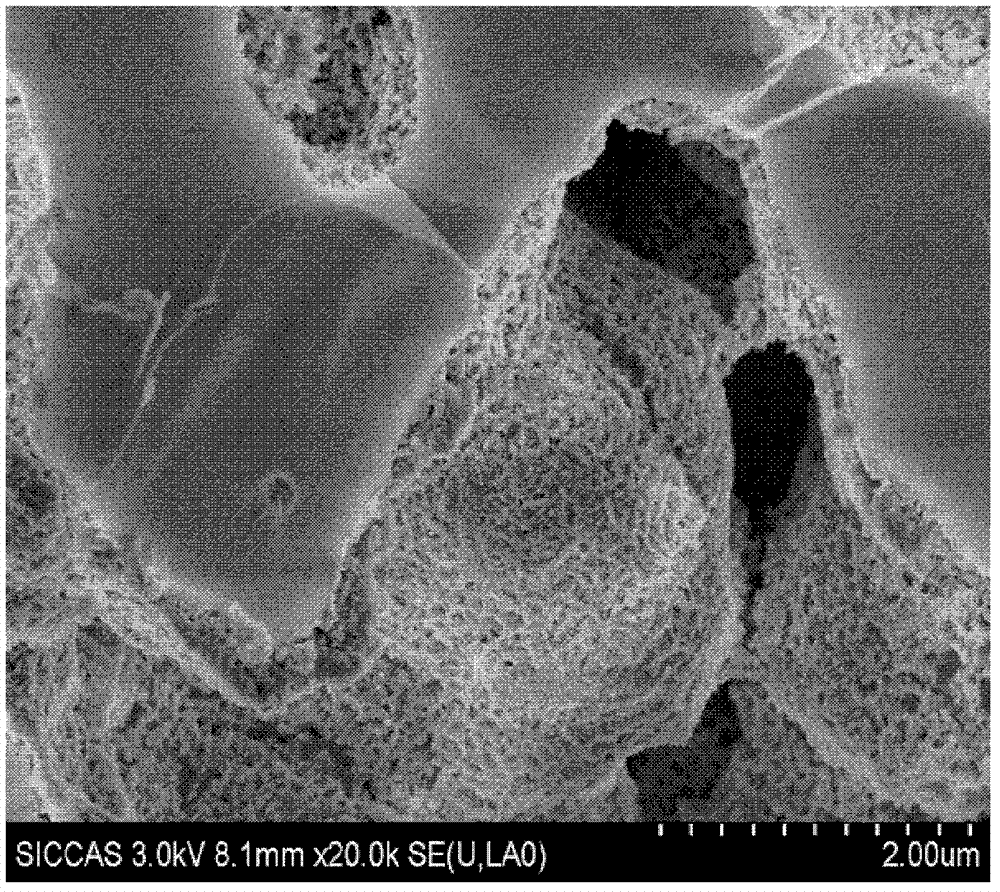

[0034] In the second aspect of the present invention, a kind of preparation method of novel low-temperature LSGM thin-film electrolyte fuel cell is provided, and this method comprises: at first adopting traditional ceramic forming process (such as casting, extruding, coating etc.) and high-temperature co-sintering technology Develop LSGM composite membranes, that is, porous LSGM|dense LSGM|porous LSGM; secondly, use chemical liquid phase immersion coating technology to deposit the cathode film and the anode film on the inner walls of the porous LSGM pores on both sides, thereby forming nanometer and micrometer double-scale Structured porous composite electrodes and single cells.

[0035] In the present invention, the preparation method of novel low temperature LSGM thin film electrolyte fuel cell specifically comprises the following steps:

[0036] (i) Mix LSGM powder with an organic solvent and add a dispersant, a binder, and a plasticizer to prepare a slurry; mix and ball mi...

Embodiment 1

[0050] Embodiment 1: the preparation of LSGM composite membrane

[0051] 1. Casting preparation of dense LSGM electrolyte membrane

[0052] The LSGM powder (La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 2.85 , 40 g), solvent (ethanol (EtOH) and methyl ethyl ketone (MEK), 50 g each), dispersant (triethanolamine (TEA), 2.5 g) were mixed and ball milled for 24 hours, and then the binder (polyvinyl alcohol Butyraldehyde (PVB), 2.5 grams), plasticizers (dibutyl phthalate (DOP) and polyethylene glycol (PEG), 0.9 grams each) continued ball milling for 24 hours. Vacuum defoaming for 15 minutes after the slurry is filtered, and then casting according to the required thickness (30-75 microns) to obtain a dense LSGM electrolyte membrane green body.

[0053] 2. Preparation of porous LSGM substrate film by tape casting

[0054] The LSGM powder (La 0.9 Sr 0.1 Ga 0.8 Mg 0.2 o 2.85 , 40 grams), pore-forming agent (graphite, 20 grams), solvent (ethanol (EtOH) and butanone (MEK), each 75 grams), ...

Embodiment 2

[0057] Example 2: Preparation of flat nano-microstructure low-temperature SOFC

[0058] According to the LSGM composite membrane prepared in Example 1, the chemical liquid phase immersion deposition of the cathode film and the anode film was carried out.

[0059] 1. Chemical liquid phase immersion deposition of cathode film

[0060] a) Preparation of precursor solution

[0061] Selected Oxygen-Ion-Electron Mixed Conductor Sm 0.5 Sr 0.5 CoO 3 (SSC) as cathode thin film material. The starting material is Sm(NO 3 ) 3 , Sr(NO 3 ) 2 , Co(NO 3 ) 3 , Nitrate was dissolved in deionized water according to the stoichiometric ratio of SSC, and a homogeneous, stable and rheologically suitable precursor solution was obtained after stirring for 1 hour.

[0062] b) Chemical liquid phase immersion deposition of SSC in porous LSGM substrate

[0063] The precursor solution of SSC is introduced on the surface of the porous substrate. Driven by the wetting power, the solution flows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com