Ultra high speed preparation method for ultra thick diamond-like coating

A diamond coating, ultra-high-speed technology, applied in metal material coating process, coating, ion implantation plating, etc., can solve the problems of ultra-thick diamond-like coating, large internal stress, poor bonding of film base, etc. Achieve the effect of simple process and good controllability of coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

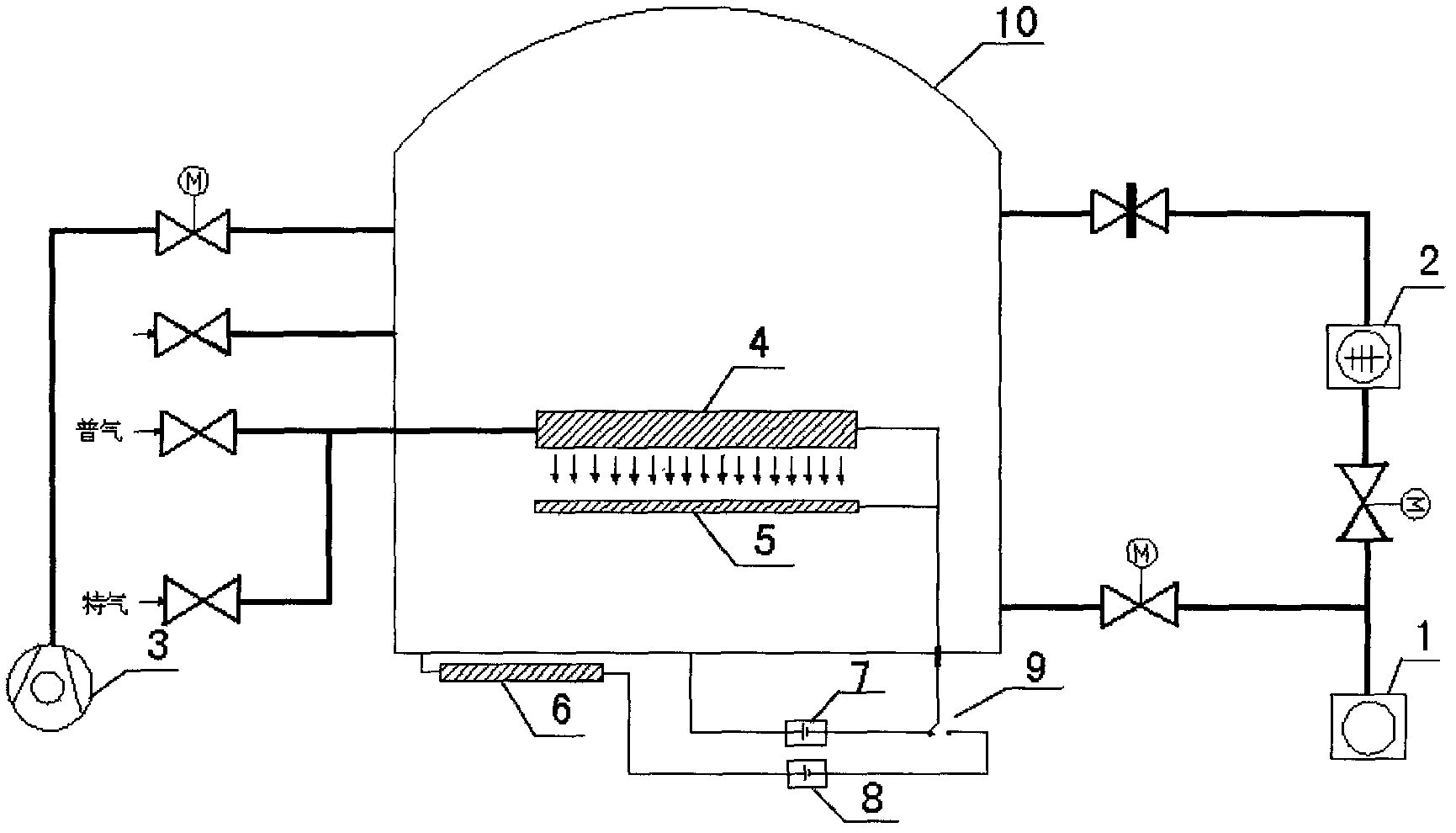

Method used

Image

Examples

Embodiment 1

[0021] The sample base is a P(100) silicon wafer of 6cm×6cm×0.5mm.

[0022] 1. Place the silicon wafer after ultrasonic cleaning with acetone and alcohol in the vacuum chamber of the integrated injection and deposition equipment, and pump the background vacuum to 2×10 -1 After Pa, argon gas is introduced, and a negative pulse bias voltage of 5KV is applied on the silicon wafer by using a high-voltage DC pulse power supply. The pulse frequency is 1.4KHz, the duty cycle is 30%, and the vacuum degree is kept at 1.3Pa. plasma cleaning and activation.

[0023] 2. Introduce nitrogen gas according to the mixing ratio of argon gas and nitrogen gas 1.8:1, adjust the negative pulse bias voltage to 25KV, keep the vacuum degree at 2.5Pa, and implement nitrogen element implantation into the silicon wafer for 20min.

[0024] 3. Introduce acetylene and silane according to the mixing ratio of argon, silane and acetylene 1:1:3, apply a negative pulse bias voltage of 700V on the silicon wafer ...

Embodiment 2

[0028] The sample base is a steel sheet (1Cr18Ni9Ti) of 60cm×60cm×1mm.

[0029] 1. Utilize the method for embodiment 1 step 1 to implement pretreatment to steel sheet.

[0030] 2. Introduce silane gas according to the mixing ratio of argon and silane 1.5:1, adjust the negative pulse bias voltage to 25KV, keep the vacuum at 2Pa, and inject silicon element into the steel sheet for 30min.

[0031] 3. Introduce acetylene and silane according to the mixing ratio of argon, silane and acetylene 1:1:3, and apply a negative pulse bias voltage of 650V on the steel sheet with a low-voltage DC pulse power supply, the pulse frequency is 800Hz, and the duty cycle is 50%. , keeping the vacuum degree at 3.5Pa, and depositing diamond-like carbon with low doped silicon content for 15 minutes.

[0032]4. According to the mixing ratio of argon, silane and acetylene 2:1:5, reduce the silane and increase the flow of argon, adjust the negative pulse bias voltage on the steel sheet to 800V, and depo...

Embodiment 3

[0035] The sample base is an aluminum alloy sheet (6061) of 30cm×30cm×2.5mm.

[0036] 1. Using the method and parameters in Step 1 of Example 1 to perform pretreatment on the aluminum alloy sheet.

[0037] 2. Introduce nitrogen gas according to the mixing ratio of argon gas and nitrogen gas 1.8:1, adjust the negative pulse bias voltage to 30KV, keep the vacuum degree at 2.5Pa, and inject nitrogen element into the aluminum alloy sheet for 30min.

[0038] 3. Introduce acetylene and silane according to the mixing ratio of argon, silane and acetylene 1:1:4, apply a negative pulse bias voltage of 500V on the aluminum alloy sheet with a low-voltage DC pulse power supply, the pulse frequency is 800Hz, and the duty cycle is 50 %, keep the vacuum at 3.8Pa, and deposit diamond-like carbon with low doped silicon content for 10 minutes.

[0039] 4. According to the mixing ratio of argon, silane and acetylene 2:1:6, reduce silane and increase the flow rate of argon, adjust the negative pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com