High-entropy alloy binder phase-based nitrogen-containing hard alloy and preparation method thereof

A technology of high-entropy alloys and hard alloys, applied in the field of hard alloys, to achieve good corrosion resistance, improve comprehensive mechanical properties, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

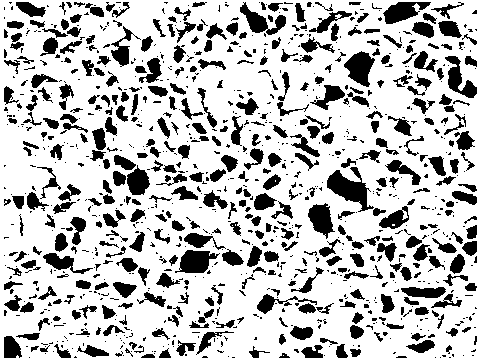

Image

Examples

Embodiment 1

[0035] The raw materials used in this embodiment and the processing steps are as follows:

[0036] Weigh 74g WC powder, 20g (Ti, 5Nb, 5Mo, 0.2Cr, 0.5Y, 0.5Nd) (C 0.9 , N 0.1 ) solid solution powder and 6g high-entropy alloy binder phase, wherein the high-entropy alloy binder phase raw material powder components and proportioning are iron, cobalt, nickel, chromium metal elemental powder, according to the molar ratio of iron, cobalt, nickel, chromium elements 1 :1:1:1 formulation. Then put them into the ball milling tank together, put the balls into the balls according to the ratio of 8:1 ball to material, and pour in an appropriate amount of alcohol, and ball mill for 24 hours to obtain the mixed powder, which is dried and then added into the rubber forming agent according to the ratio of 1wt%. Sieve, granulate. Then the mixed raw materials are weighed to a certain weight and loaded into the mold cavity for compression molding. Then put the prepared sample into a low-pressu...

Embodiment 2

[0038] The raw materials used in this embodiment and the processing steps are as follows:

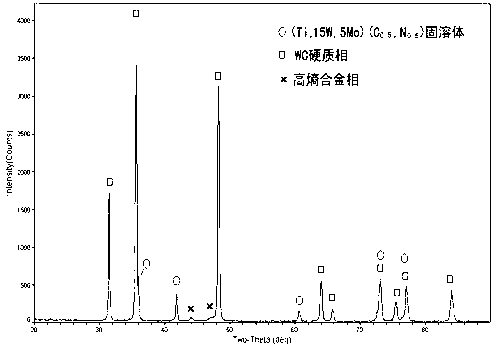

[0039] Weigh 82g μm WC powder, 5g (Ti, 15 W, 5Mo, 0.2V) (C 0.7 , N 0.3 ) solid solution powder, 5gTi(C 0.5 , N 0.5 ) solid solution powder and 8g high-entropy alloy binder phase raw materials, wherein the high-entropy alloy binder phase raw material powder components and proportioning are titanium-iron alloy powder, chromium-nickel alloy powder, iron powder, copper powder, vanadium powder and manganese powder, according to The molar ratio of iron, cobalt, nickel, chromium, titanium, copper, vanadium and manganese is 1:1:1:1:1:1:1:1. Then put them into the ball mill jar together, put the balls into the ball according to the ratio of ball to material of 6:1, and pour in an appropriate amount of alcohol, and ball mill for 72 hours to get the mixed powder. After it was dried, a paraffin wax molding agent was added in a proportion of 0.5 wt%, sieved, and granulated. Then the mixed raw mat...

Embodiment 3

[0042] The raw materials used in this embodiment and the processing steps are as follows:

[0043] Weigh 60g WC powder, 30g (Ti, 15W, 5Mo) (C 0.5 , N 0.5 ) solid solution powder and 10g high-entropy alloy binder phase raw material, wherein the high-entropy alloy binder phase raw material powder is iron powder, nickel powder, cobalt powder, aluminum powder and manganese powder, according to the mole of iron, nickel, nickel, aluminum, manganese Formulated in a ratio of 1:1:1:1:1. Then put them together into a ball mill jar, put them into the balls according to the ball-to-material ratio of 4:1, pour in an appropriate amount of alcohol, and ball mill for 36 hours to obtain a mixed powder. After it is dried, polyethylene glycol molding agent is added according to the proportion of 2wt%, sieved, and granulated. Then the mixed raw materials are weighed to a certain weight and loaded into the mold cavity for compression molding. Then put the prepared sample into a low-pressure si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com