Method for removing iron and aluminum by autoxidation of iron-based waste material containing high-value elements

A natural oxidation, high-value technology, applied in the direction of process efficiency improvement, etc., can solve the problems of long reaction time, large acid consumption, temperature maintenance, etc., achieve the effect of simple process and equipment, mild reaction conditions, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

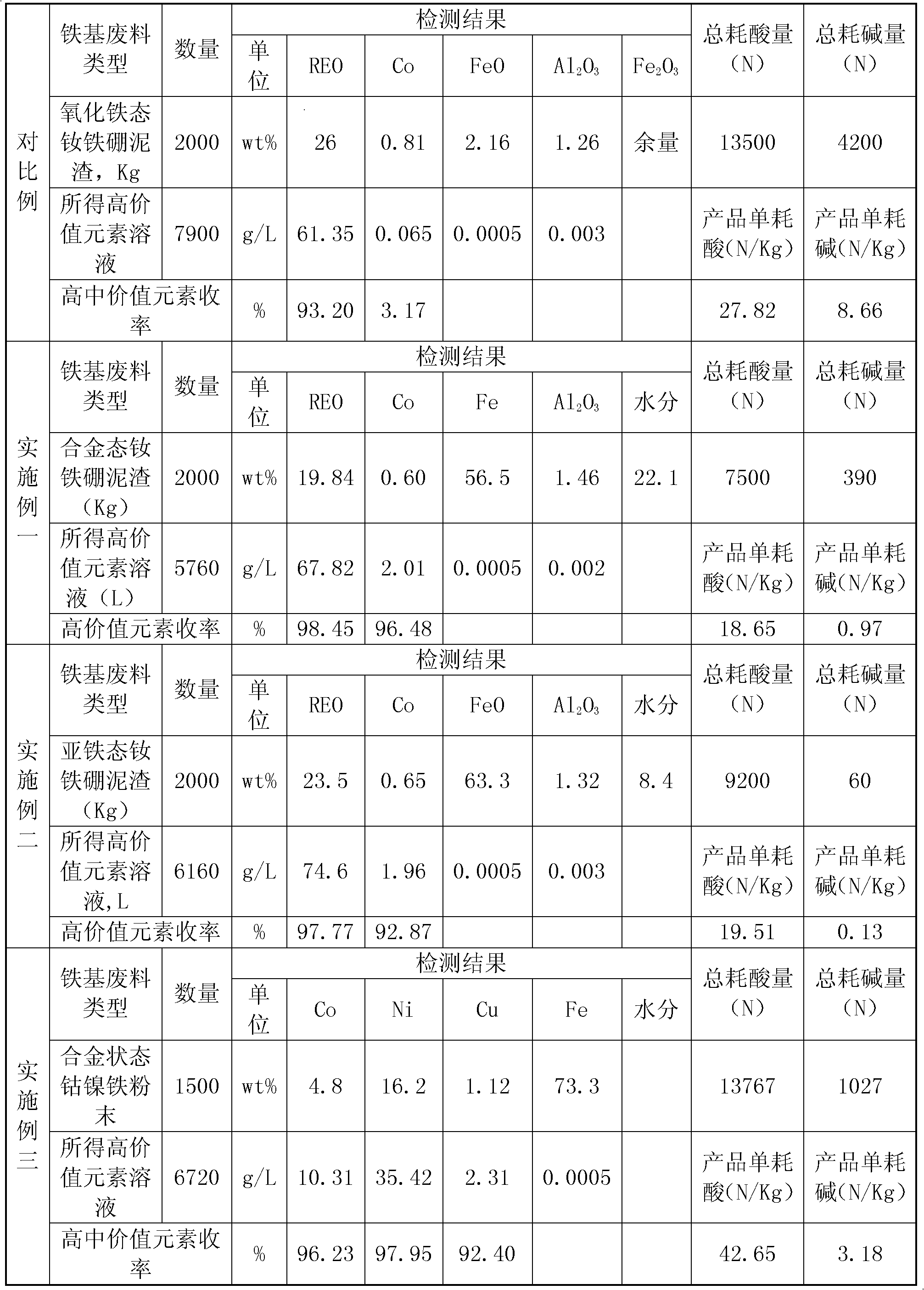

Embodiment 1

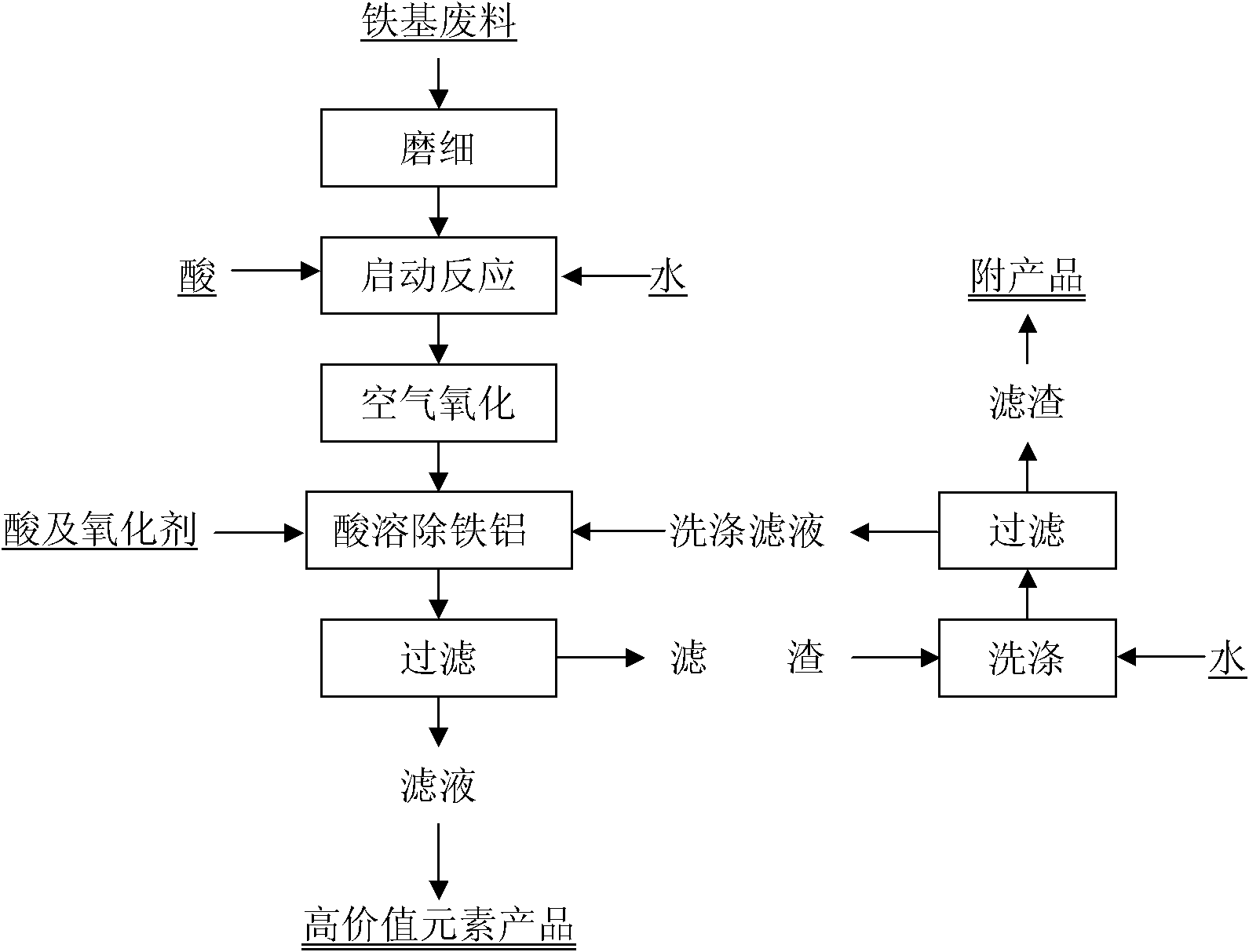

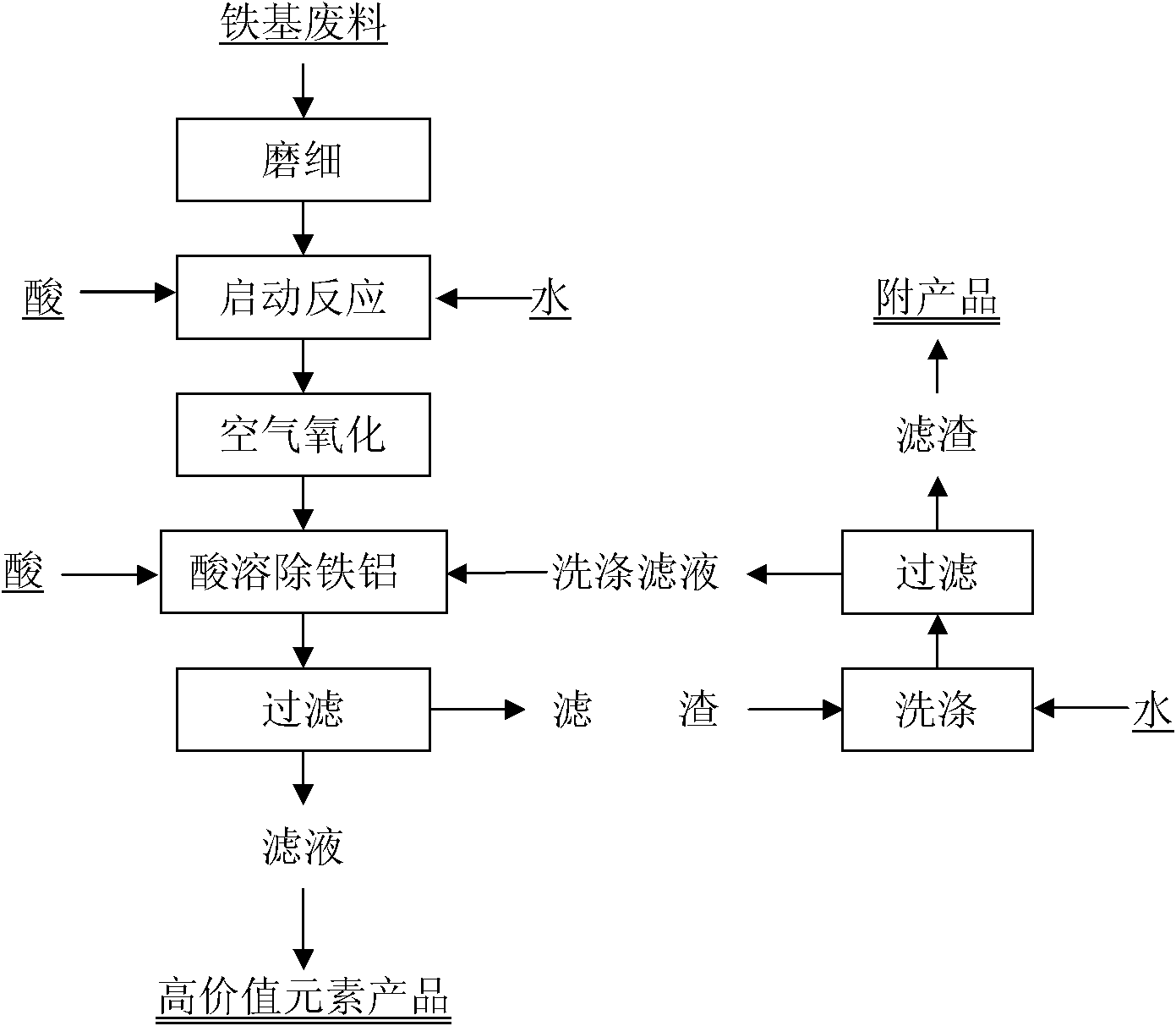

[0046] see figure 1 .

[0047] Get 2000Kg through wet ball milling to-40 order (0.425mm) neodymium-iron-boron alloy waste mud slag (wherein REO 19.84wt%, Co 0.60wt%, Fe 56.5wt%, Al 2 o 3 1.46wt%, 22.1% water, and other substances), put 1900L water and 60L 10N hydrochloric acid into the reaction pot to stir and mix the reaction, and then spread the materials in the pot in a clean and non-leaking acid-resistant shallow pit, turn over Several times, and spray water to keep the material in a semi-dry and wet state until the percentage of ferrous iron in the total iron is reduced to 5.3wt%, and it is measured that the percentage of soluble REO in the total REO is 8.2wt%.

[0048] Acid-soluble oxidation hydrolysis: put 3000L water and the materials obtained in the above steps into the reaction pot, keep the temperature at 70-90°C, keep stirring, add hydrochloric acid and 27.5% industrial hydrogen peroxide in stages, until the acidity of the solution no longer rises to pH=3 When ...

Embodiment 2

[0054] see figure 1 .

[0055] A batch of NdFeB alloy waste in the state of sludge is spontaneously ignited in the air to convert the iron into a ferrous state, and then wet ball milled into -60 mesh material. Take 2000Kg of this iron-based waste material, and it is detected that REO23.5wt%, Co 0.65wt%, FeO 63.3wt%, Fe 2 o 3 1.47wt%, Al 2 o 3 1.32wt%, water 8.4wt%, the rest is other substances, put into the reaction pot with 750L of water and 360L of 5N hydrochloric acid to stir and mix the reaction, spread the materials in the pot on the clean and non-leaking acid-resistant ground, and turn it several times , and spray water to keep the material in a semi-dry and wet state until the percentage of ferrous iron in the total iron is reduced to 17.6%, and it is measured that soluble REO accounts for 12.6% of the total REO percentage at this time.

[0056] Acid-soluble oxidation hydrolysis: Put the material obtained in the above steps and 3000L water into the reaction pot, ...

Embodiment 3

[0071] see figure 1 .

[0072] The cobalt-nickel-iron alloy obtained through the process of "electric furnace depletion" and "cobalt matte magnetic separation" from nickel-smelting converter slag is dry-ground to -100 mesh by jaw crusher and tested to contain Co 4.8wt%, Ni 16.2 wt%, Cu1.12wt%, Fe 73.3wt%, and the rest are other substances.

[0073] Take 1500Kg of the above material, put it into the reaction pot with 1200L water and 75Kg98% sulfuric acid to mix and react, spread the material in a clean and non-leaking shallow container, turn it over several times, and spray water to keep the material in a semi-dry and wet state until Ferrous iron accounts for 7.2wt% of total iron.

[0074] Acid-soluble oxidation hydrolysis: put the material obtained in the above steps and 3000L water into the reaction pot under stirring, slowly add 2460L of 5N sulfuric acid and 180Kg of calcium hypochlorite with 60% available chlorine, keep the temperature at 70-90°C, and finish adding sulfur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com