Absorption radiation boron-doped diamond compound film and method for producing the same

A boron-doped diamond, radiation absorbing technology, applied in the fields of thermal radiation absorption and heat exchange membranes and their preparation, can solve the problems of unstable glow, falling off growth layer, etc., so as to improve the measurement accuracy and sensitivity, and shorten the measurement period , the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

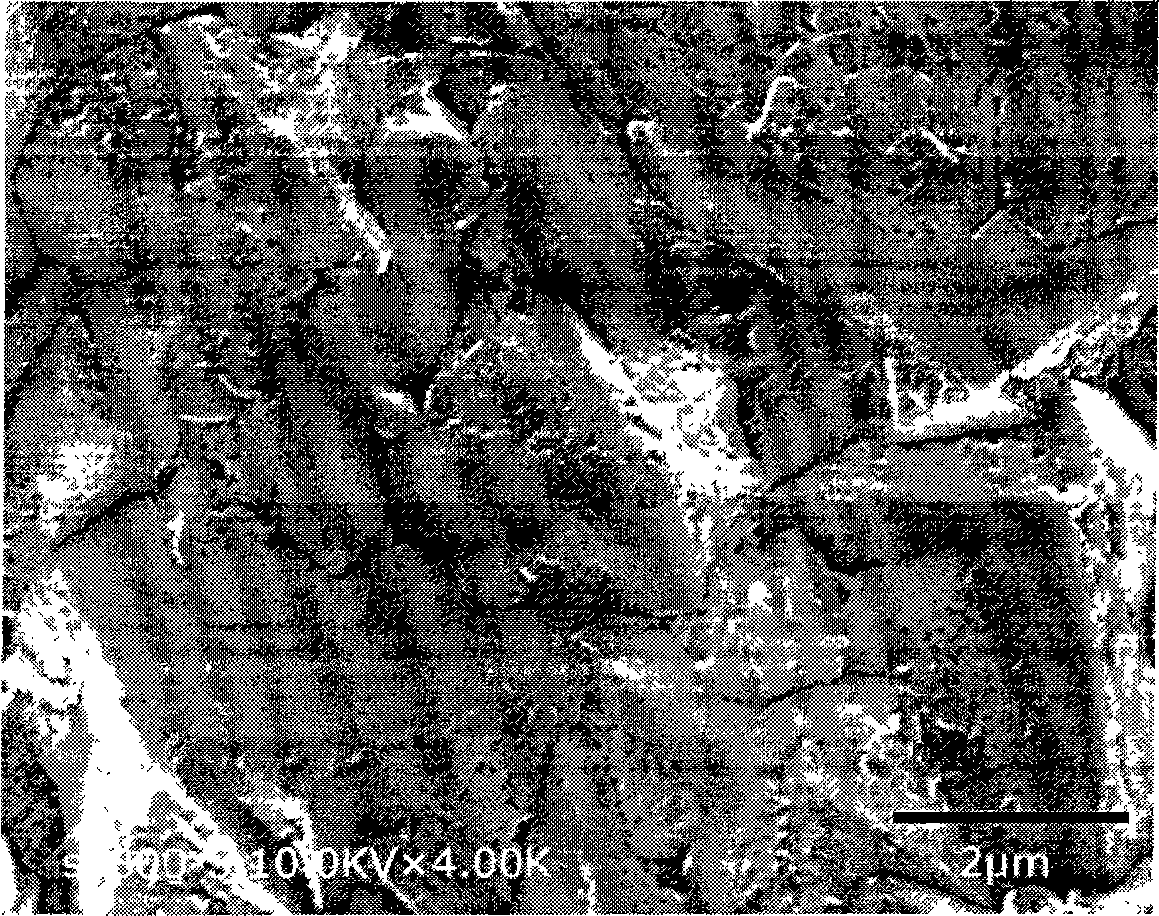

Image

Examples

Embodiment 1

[0022] The preparation method of the radiation-absorbing boron-doped diamond composite film of the present invention comprises the following steps:

[0023] (1) A pure diamond sheet was prepared as a heat sink material by chemical vapor deposition.

[0024] The heat sink diamond sheet is prepared by MW-PCVD microwave plasma chemical vapor deposition system, which belongs to the electrodeless discharge method, and high-quality high-purity transparent diamond film can be obtained under relatively low pressure. Metal molybdenum plate was used as the substrate during deposition, and the substrate treatment method was to grind with diamond abrasive paste for 30 minutes, and then ultrasonically treat with acetone and alcohol for 10 minutes respectively. Both hydrogen and methane are controlled by mass flow meters, H 2 The flow rate is 200sccm, CH 4 The flow rate is 3sccm, the microwave power is 4.2KW, the deposition pressure is 11KPa, the substrate temperature is 850°C, and the gr...

Embodiment 2

[0035] Prepare the radiation-absorbing boron-doped diamond composite film in the same manner as in Example 1, the only difference being:

[0036] (1) The process condition of a chemical vapor deposition heat sink diamond sheet is: H 2 The flow rate is 200sccm, CH 4 The flow rate is 1sccm, the microwave power is 3.8KW, the deposition pressure is 17KPa, the substrate temperature is 950°C, and the growth rate is about 1μm / h. The obtained diamond diaphragm has a thermal conductivity of 18W / K cm and a resistivity of 10 15 Ω·cm.

[0037] (2) The process conditions of secondary chemical vapor deposition of black boron-doped diamond film are: the flow rate of hydrogen and methane is: H 2 =170 sccm, CH 4 =5sccm, the flow rate of trimethyl borate is 8sccm; the temperature in the deposition chamber is 780°C; the gas pressure in the deposition chamber is 125Torr; the applied bias voltage is 710V, the current is 8.3A, and the deposition time is 4 hours. The surface of the black boron-...

Embodiment 3

[0039] Prepare the radiation-absorbing boron-doped diamond composite film in the same manner as in Example 1, the only difference being:

[0040] (1) The process condition of a chemical vapor deposition heat sink diamond sheet is: H 2 The flow rate is 200sccm, CH 4 The flow rate is 2sccm, the microwave power is 4KW, the deposition pressure is 13KPa, the substrate temperature is 750°C, and the growth rate is about 2μm / h. The thermal conductivity of the prepared diamond sheet is 17W / K cm, and its resistivity is 10 14 Ω·cm.

[0041] (2) The process conditions of secondary chemical vapor deposition of black boron-doped diamond film are: the flow rate of hydrogen and methane is: H 2 =170 sccm, CH 4 =7sccm, the flow rate of trimethyl borate is 10sccm; the temperature in the deposition chamber is 850° C.; the gas pressure in the deposition chamber is 130 Torr; the bias voltage is 740V, the current is 8.7A, and the deposition time is 4 hours. The surface of the black boron-doped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com