Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "With scratches" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

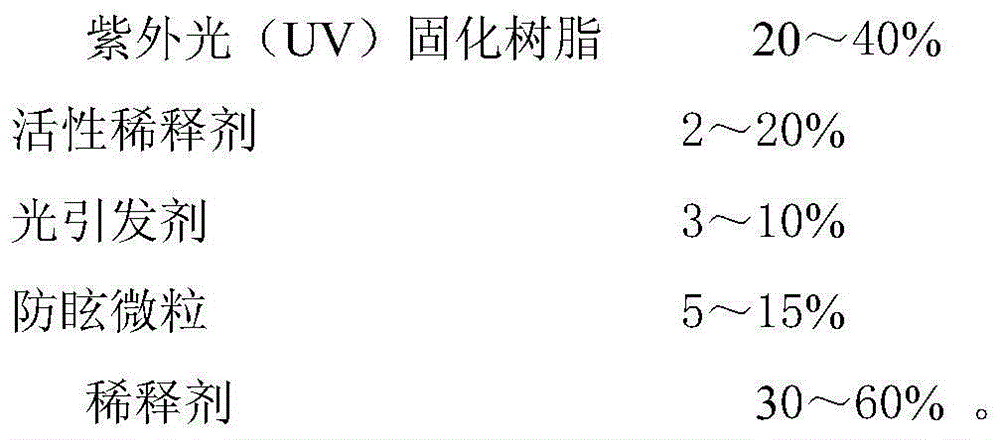

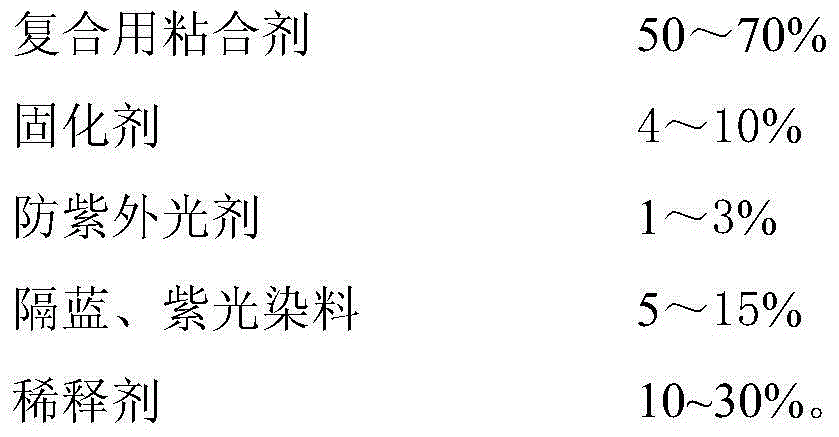

Blue-light-barrier anti-dazzle optical film and preparation method therefor

ActiveCN105524563AProtect from scratchesReduce blue lightFilm/foil adhesivesPolyureas/polyurethane adhesivesFilm materialBlue light

The invention relates to a blue-light-barrier anti-dazzle optical film and a preparation method therefor. The blue-light-barrier anti-dazzle optical film comprises a transparent substrate which is formed through laminating two layers of transparent films with the thickness of 20-200 microns, wherein a laminating interlayer is a composite adhesive layer, which contains an anti-ultraviolet agent and a blue and purple light barrier dye and has the thickness of 10-30 microns, one face of the transparent substrate is coated with an anti-dazzle and scratch-resistant coating layer with the thickness of 2-10 microns, the other face of the transparent substrate is coated with a pressure-sensitive adhesive, i.e., a binder with the thickness of 5-40 microns, and the surface of the pressure-sensitive adhesive is covered with a release film. The film material plays roles in preventing dazzle, cutting off blue light, reducing visual fatigue and protecting vision and further has the function of protecting a LCD screen from scratch.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY +1

Easy-to-clean nano antifouling antibacterial paint and preparation method thereof

ActiveCN108384444AImprove bindingWide choiceAntifouling/underwater paintsPaints with biocidesDiacetone alcoholSodium Bentonite

The invention discloses an easy-to-clean nano antifouling antibacterial paint and a preparation method thereof. The paint comprises the following raw materials by weight: 2-20 parts of nano titanium dioxide, 5-20 parts of bentonite, 3-8 parts of silica aerogel, 0.5-20 parts of modified rare earth, 5-20 parts of nano graphene, 5-20 parts of isophorone, 1-20 parts of diacetone alcohol, 1-10 parts ofan antifoulant, 6-20 parts of modified organic silicon resin, 2-20 parts of ethylene glycol butyl ether / propylene glycol butyl ether, and 6-30 parts of butyl acetate. The modified rare earth is modified nano cerium oxide and nano lanthanum oxide in a weight ratio of 0.35:1, and a titanate coupling agent is employed for modification treatment of nano cerium oxide and lanthanum oxide, the modifiedrare earth has a particle size of 1-100nm, and the nano graphene has a particle size of 3-5nm. The paint prepared by the technical scheme adopted by the invention can achieve the following effects after application to a substrate surface: 1. good anti-fouling effect; 2. easy cleaning; 3. good antibacterial effect; 4. strong adhesion; and 5. high hardness.

Owner:张积喜

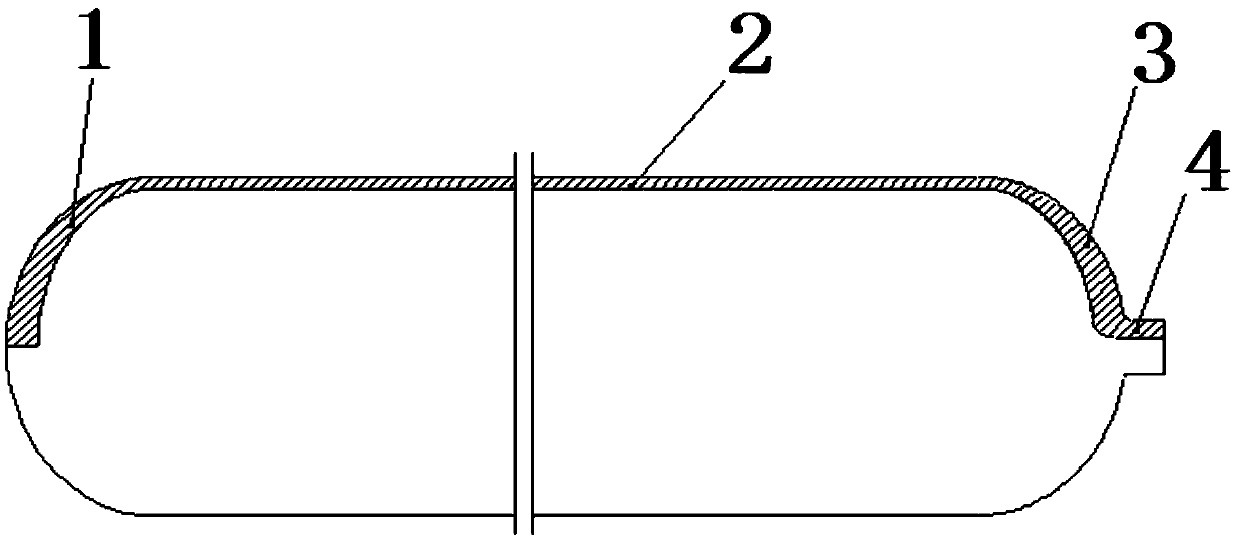

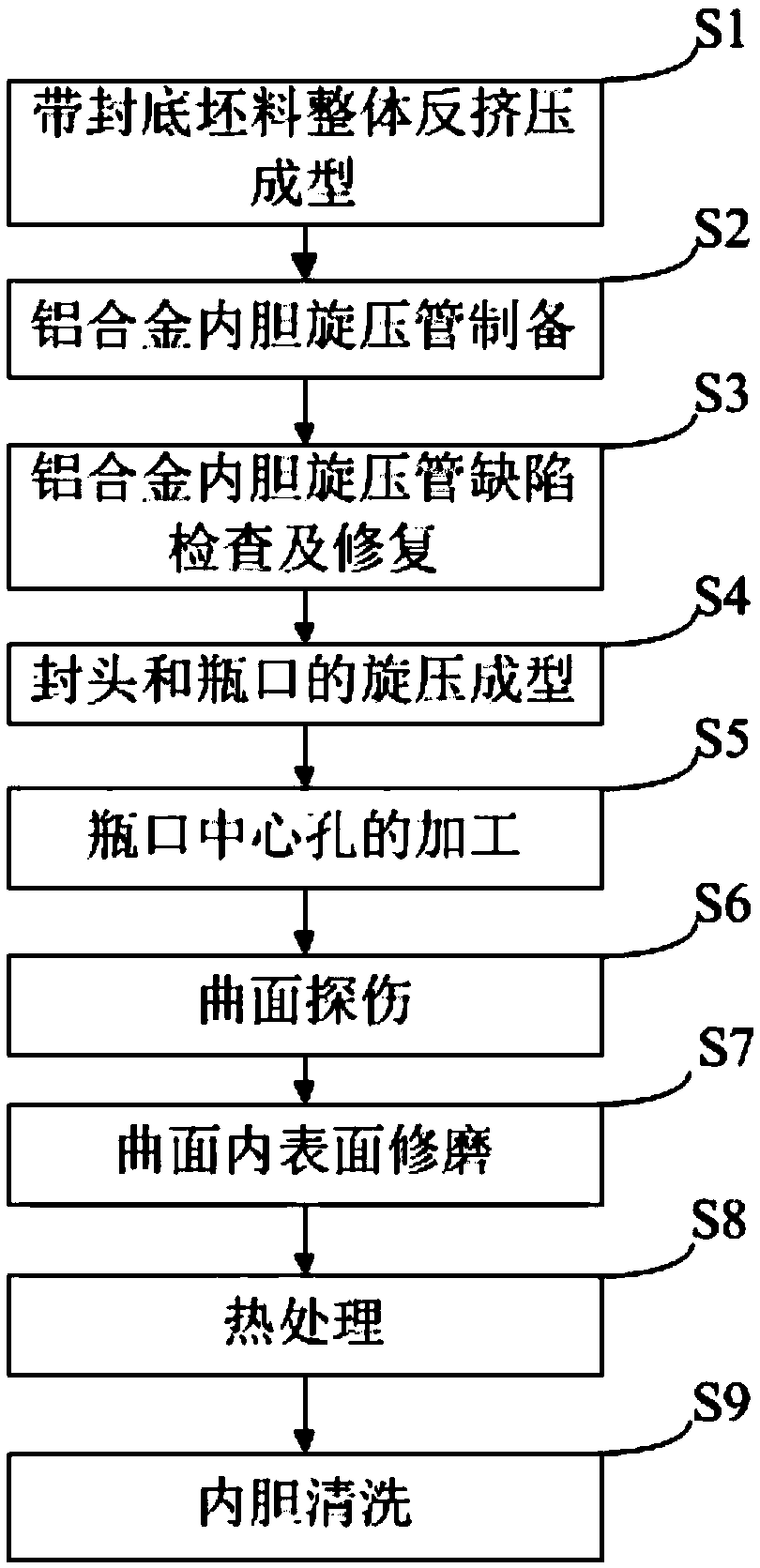

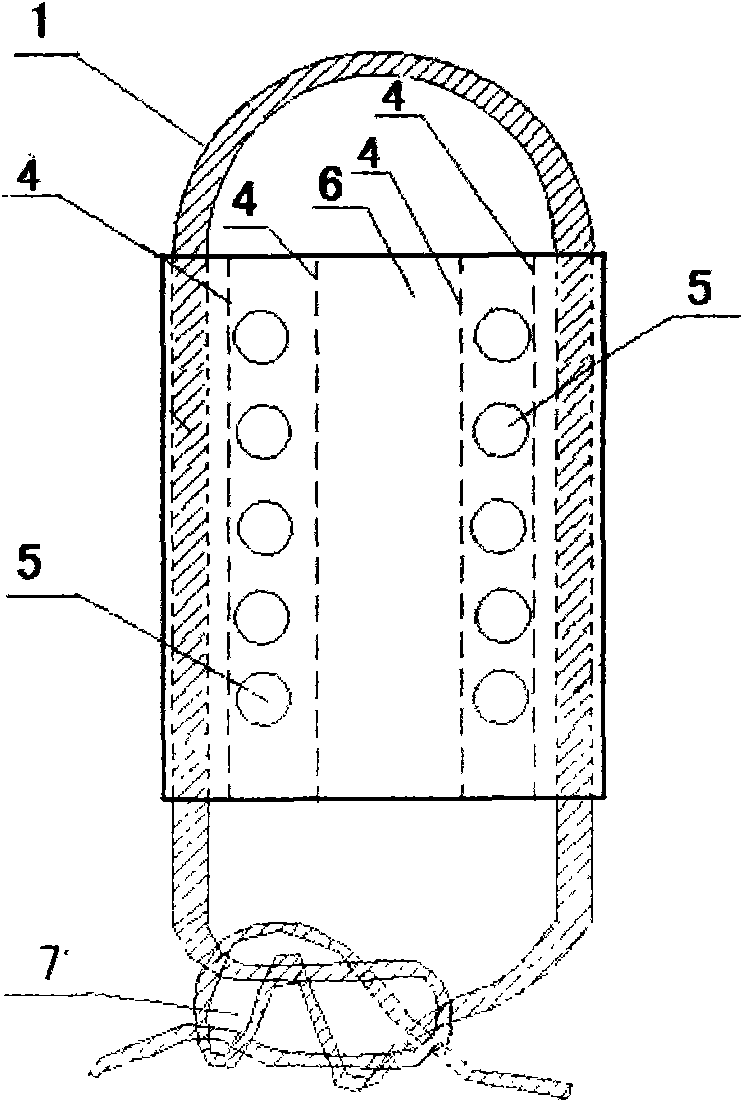

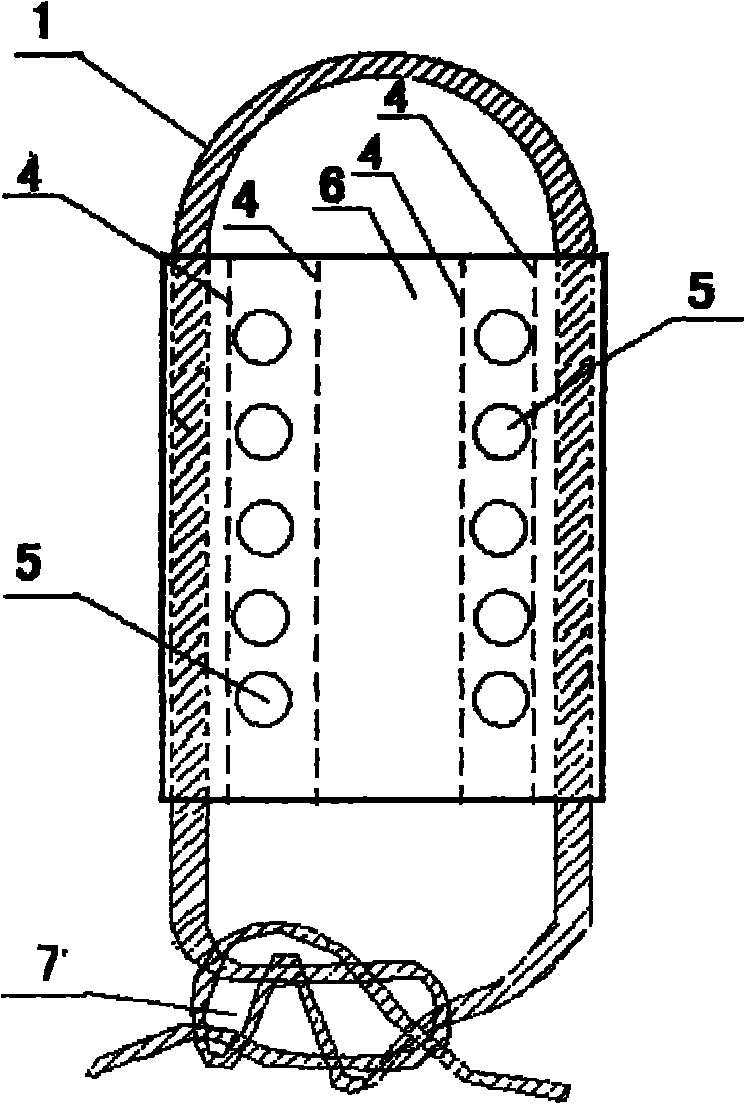

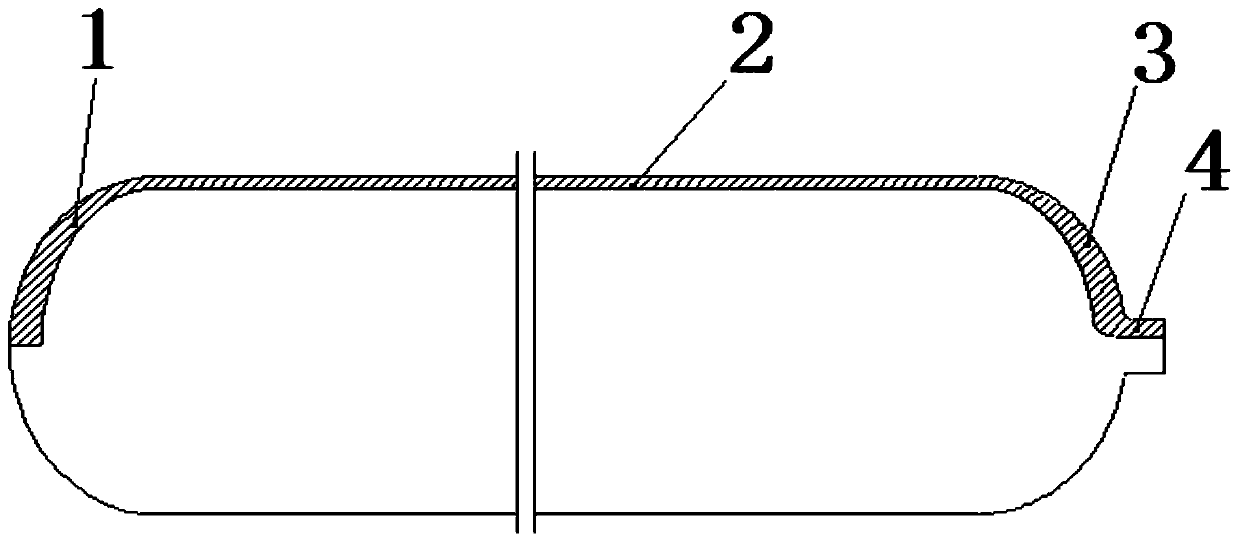

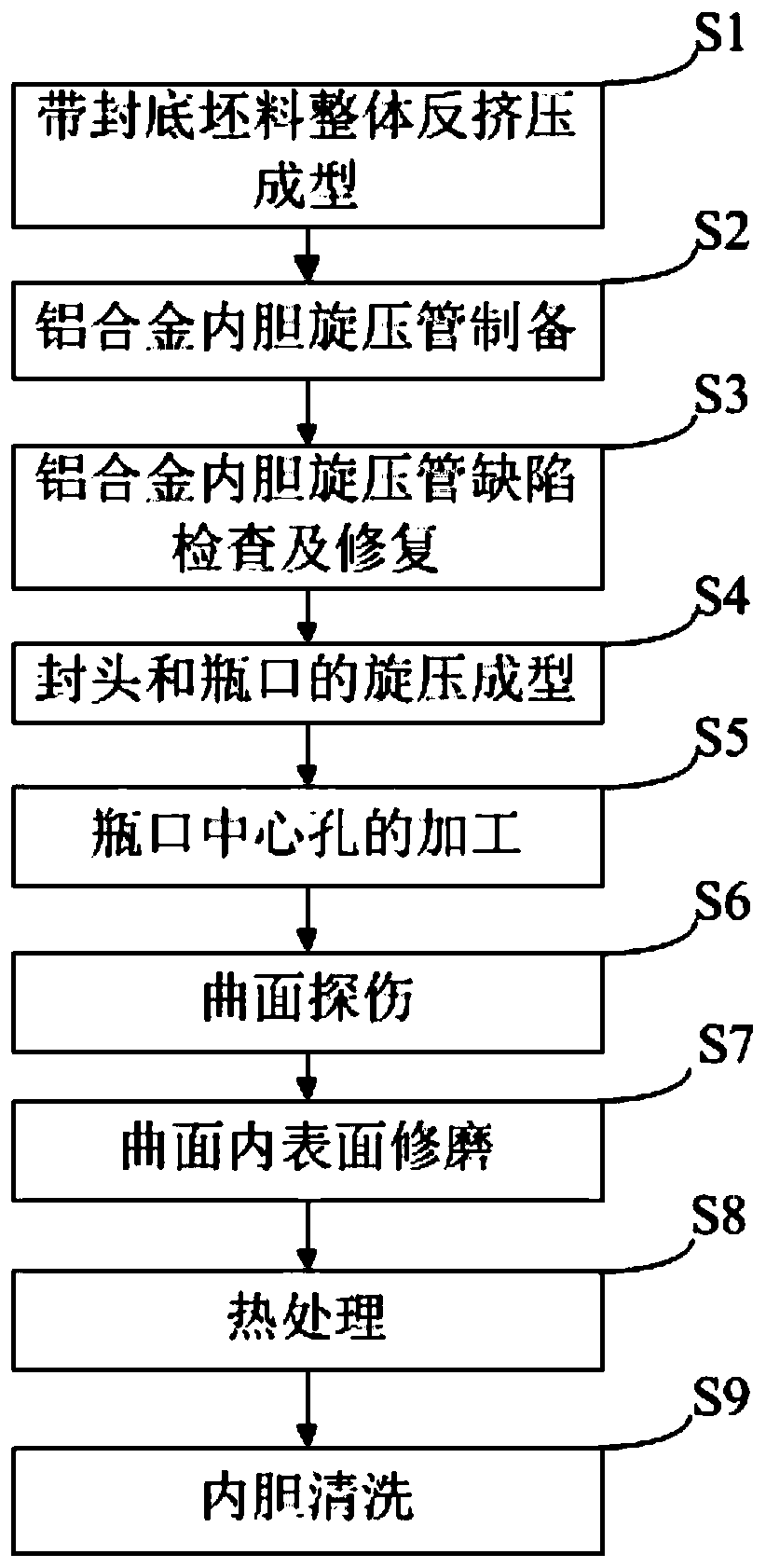

Large-scale ultrahigh-pressure gas cylinder liner and manufacturing method thereof

ActiveCN109668051AReduce lossLow costVessel manufacturingVessel geometry/arrangement/sizeEngineeringUltra high pressure

The invention provides a large-scale ultrahigh-pressure gas cylinder liner and a manufacturing method thereof. The large-scale ultrahigh-pressure gas cylinder liner is characterized in that on end ofthe liner is bottom sealed, and the other end of the liner is formed a sealing head and a bottle opening by closing, and the liner is an integrated seamless structure of a aluminum alloy liner, the liner comprises a straight cylinder section, a sealing bottom and a sealing head, wherein the sealing bottom and the sealing head are located at the two ends of the straight cylinder section respectively, the bottle opening is located on the sealing head; and the length of the aluminum alloy liner is 5-13m, the nominal outside diameter of the straight cylinder section is Phi 300-Phi 500 mm, the nominal pressure of the ultrahigh-pressure gas cylinder is 35-70 Mpa. According to the method, a slab is adopted as a raw material, a spinning method is adopted overall, the product does not have a weld joint, the preparation process is simple, the operation is convenient, the energy consumption is low, the pollution is small, the loss of raw materials in the manufacturing process is less, and the rawmaterial cost is saved. The aluminum alloy liner processed by the manufacturing method has the advantages of being huge in size, high in reliability, thin in wall, and light in weight; the internal material is uniform and compact in structure and excellent in overall strength effect, and has the characteristics of ultrahigh pressure resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

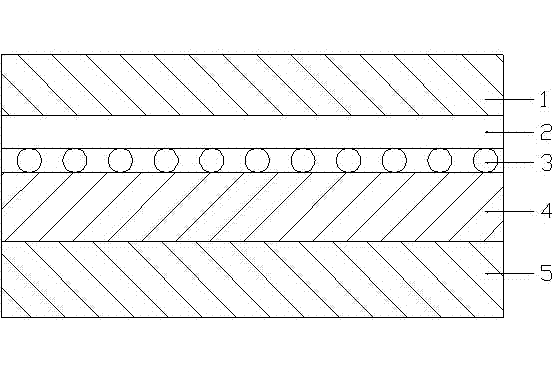

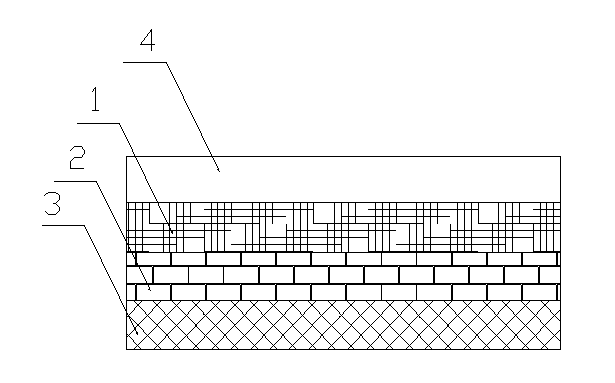

Odor-resistant and sun-resistant layered composite fabric

InactiveCN104249498AGood sun protectionImprove barrier propertiesSynthetic resin layered productsWoven fabricsEngineeringSilk fabric

The invention relates to odor-resistant and sun-resistant layered composite fabric. The odor-resistant and sun-resistant layered composite fabric sequentially comprises a sun-resistant layer (1), a fiber layer (2), a woven fabric layer (3), a polyurethane film layer (5) and a knitted fabric layer (4) from the outside to the inside, wherein a basal layer is compounded on the back surface of the knitted fabric layer; the basal layer comprises an infiltration-proof layer, and adopts the specific structure as follows: the infiltration-proof layer and a raising layer are compounded on the upper surface and the lower surface of the permeability-proof layer respectively; the infiltration-proof layer is made of silk fabric; the permeability-proof layer is made of an elastic rubber film. The odor-resistant and sun-resistant layered composite fabric has a sun-resistant function, has good air permeability, and has the characteristics of water resistance, air permeability, good elasticity and scratch resistance.

Owner:JIANGYIN ZEWAN TRADE

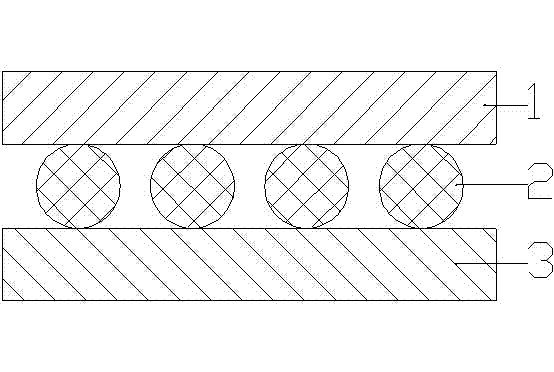

Anti-bacterial layered compound fabric

InactiveCN104339754AEnhanced inhibitory effectGood killing effectWoven fabricsProtective garmentFiberEngineering

The invention relates to an anti-bacterial layered compound fabric, which comprises a base layer (2) and an anti-bacterial layer (1); the anti-bacterial layer (1) is made of warps (11) and wefts (12) in a connecting manner; the warps (11) and the wefts (12) are made of nano-silver fibres in a weaving manner; the base layer is made of a fabric; the fabric comprises an anti-infiltration layer and has the specific structure as follows: the anti-infiltration layer and a raising layer are compounded on the upper and lower surfaces of an anti-permeation layer, respectively; a mercerization fabric is adopted in the anti-infiltration layer; and the anti-permeation layer is made of an elastic adhesive film. The invention provides the anti-bacterial layered compound fabric having the relatively good anti-bacterial effect. The anti-bacterial layered compound fabric disclosed by the invention has the characteristics of being water-proof, breathable, good in elasticity and scratch-resistant.

Owner:JIANGYIN FANRONG YARN DYE FABRIC

Antibacterial layered composite fabric

InactiveCN104275869AAntibacterial hasHas antibacterial functionProtective garmentMetal layered productsPermeationScratching

The invention relates to an antibacterial layered composite fabric which comprises a basic cloth layer (1) and a fabric layer (2), wherein an antibacterial layer (3) is arranged between the basic cloth layer (1) and the fabric layer (2) and consists of a silver ion antibacterial agent; the silver ion antibacterial agent is adhered between the basic cloth layer (1) and the fabric layer (2); the basic cloth layer comprises an anti-wetting layer, and the specific structure of the basic cloth layer is that the anti-wetting layer and a flocking layer are respectively composited on the upper surface and the lower surface of an anti-permeation layer; the anti-wetting layer is made of a mercerizing fabric; the anti-permeation layer consists of an elastic rubber film. The antibacterial layered composite fabric has antibacterial and sterilization functions, achieves an antibacterial effect and has the characteristics of water resistance, breathability, high elasticity and scratching prevention.

Owner:WUXI BALAS LIGHTING ELECTRONICS

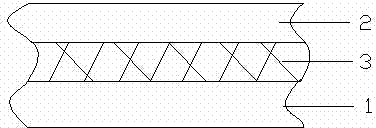

Connection method for adjacent meshes of copper alloy trapezius net

InactiveCN102085547AThe method of operation is reasonable and reliableReduce chafingBinding endsClimate change adaptationBraidCopper alloy

The invention discloses a connection method for adjacent meshes of a copper alloy trapezius net, relating to a connection method for a mesh of an aquaculture net cage. In the connection method for the adjacent meshes of the copper alloy trapezius net, a cylindrical braid, a rope, a suture line and a tarpaulin ring are adopted. The connection method is characterized in that a soft connecting piece is arranged between two copper alloy trapezius nets, and ring plates manufactured by the tarpaulin ring on the soft connecting piece correspond to screens on the copper alloy trapezius net one by one; one end of a polyethylene rope is fixed on one net knot at one side of the trapezius net, and the other end of the polyethylene rope successively passes through the tarpaulin ring on the soft connecting piece and screens on the copper alloy trapezius net until the other end of the polyethylene rope passes through all the ring plates on the same side of the soft connecting piece and all the screens on the trapezius net; the other end of the polyethylene rope is fixed on one net knot of the copper alloy trapezius net; and the soft connecting piece is connected with the other copper alloy trapezius net with the same method. The connection method is used for connecting the adjacent meshes of the copper alloy trapezius net.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI +1

Radiation preventing layered composite fabric

InactiveCN104260494AImprove radiation protection performanceImprove the protective effectClothingsMetal layered productsFiberOptoelectronics

The invention relates to a radiation preventing layered composite fabric. The composite fabric comprises a base layer (1), wherein a layer of aluminium alloy film (2) is bonded on the upper surface of the base layer (1) via an adhesive; an antistatic layer (3) is arranged on the aluminium alloy film (2) and is formed by scions with conductive fibers; the base layer is made from a fabric; the fabric comprises an anti-infiltration layer; the upper and lower sides of an anti-permeation layer are respectively composited with the anti-infiltration layer and a raised layer; the anti-infiltration layer is formed by a mercerized fabric; the anti-permeation layer is formed by an elastic adhesive film. The fabric reduces harms of radiation to human bodies. The fabric has the characteristics of water resistance, breathability, good elasticity and scratch resistance.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Anti-fouling, mosquito-repelling and layered composite shell fabric

InactiveCN104275896ASuperamphiphobicWaterproofSynthetic resin layered productsClothingsEngineeringLower face

The invention relates to an anti-fouling, mosquito-repelling and layered composite shell fabric. The shell fabric comprises a first anti-fouling coating layer (1), a mosquito-repelling protective layer (2), a small-scale-shaped knit layer (3), a first base fabric layer (4) and a second anti-fouling coating layer (5) from outside to inside, wherein the first base fabric layer (4) is made from nano-antifoulant-containing warps and nano-antifoulant-containing wefts through cross arrangement, and both the first anti-fouling coating layer (1) and the second anti-fouling coating layer (5) are polytetrafluoroethylene layers; the back face of the second anti-fouling coating layer is laminated with a second base fabric layer, the second base fabric layer comprises an anti-wetting layer and has the specific structure that the upper and lower faces of an impermeable layer are respectively laminated with the anti-wetting layer and a raising layer, the anti-wetting layer is made from a mercerized shell fabric, and the impermeable layer is made from an elastic glue film. The shell fabric can effectively prevent fouling; due to the mosquito-repelling function of the shell fabric, the trouble to people caused by mosquitoes in summer can be avoided. The shell fabric has the characteristics of water resistance, air permeability, good elasticity and scratch resistance.

Owner:JIANGYIN NEW QUANSHENG TEXTILE PRINTING & DYEING

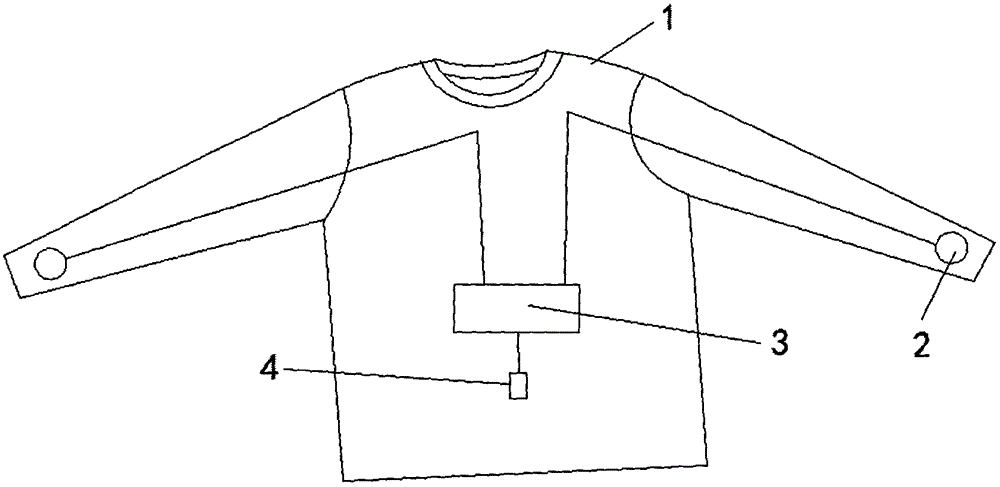

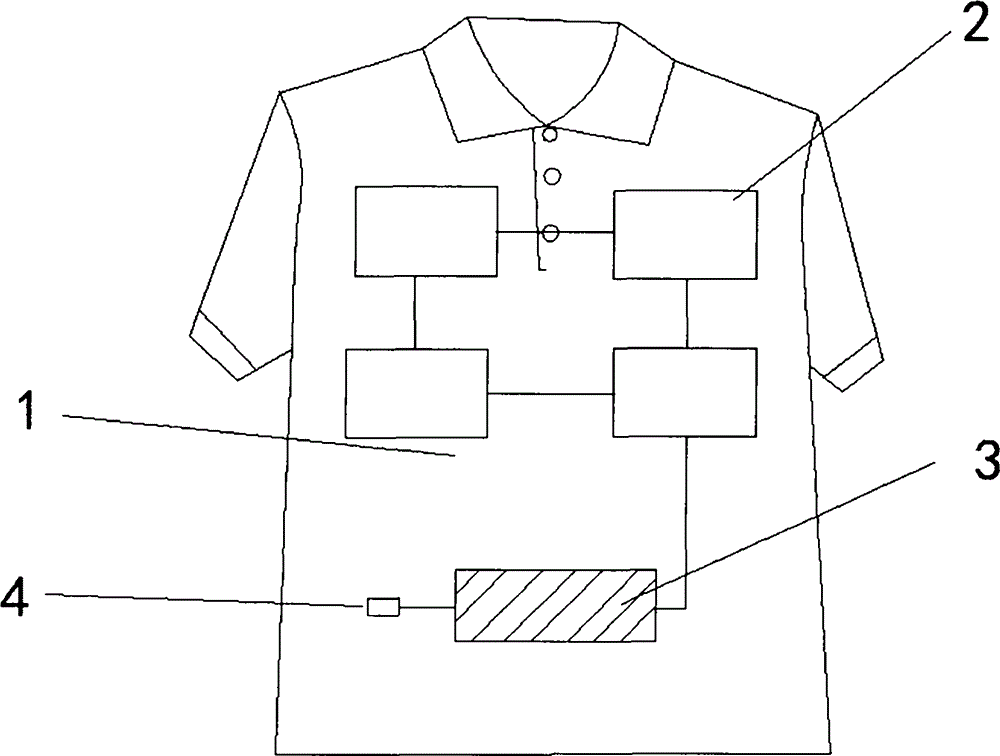

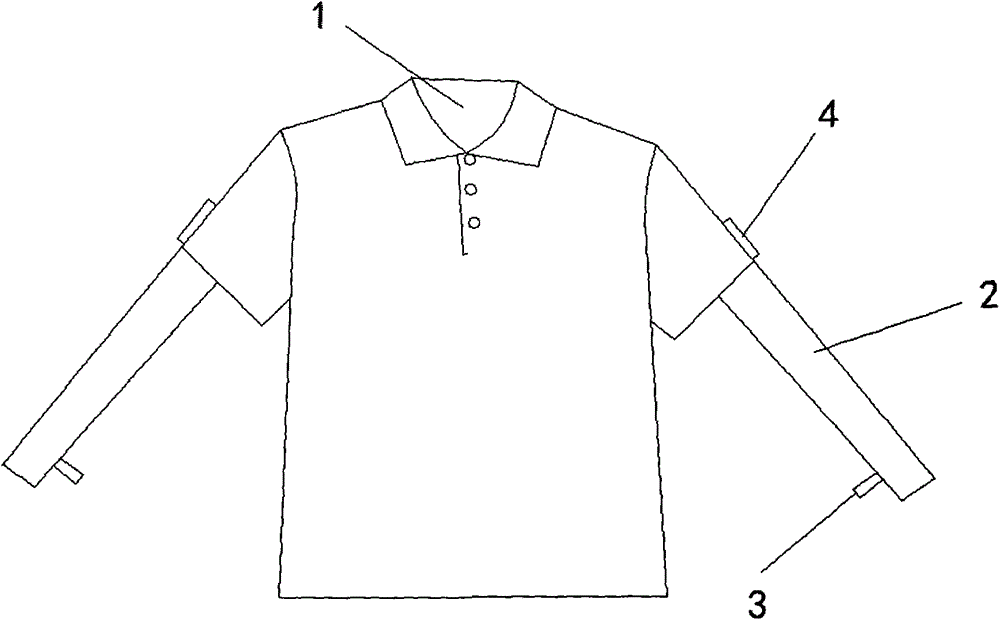

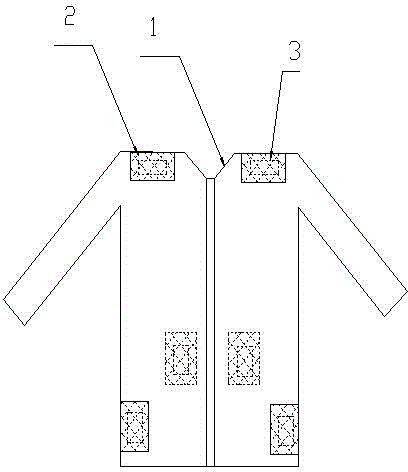

Layered composite-fabric garment with cellphone charging function

The invention relates to a layered composite-fabric garment with a cellphone charging function, comprising a garment body (1). Each cuff of the garment body (1) is provided with a miniature generator (2); a front part of the garment body (1) is provided with a lithium battery (3); the miniature generators (2) are connected to the lithium battery (3) through wires; a terminal of the lithium battery (3) is connected with a USB (universal serial bus) interface (4). The garment body is made of shell fabric. The shell fabric comprises a wet-proof layer, specifically, the wet-proof layer and a nap layer are attached to upper and lower surfaces of a non-permeable layer, the wet-proof layer is made of mercerized fabric, and the non-permeable layer is made of elastic adhesive film. The layered composite-fabric garment is capable of charging a cellphone and has the advantages of watertightness, breathability, good elasticity and scratch resistance.

Owner:夏宏希

Layered composite color-variable fabric

InactiveCN105437707AMeet needsAchieve color changing effectLayered productsColor changesBiomedical engineering

Owner:黄文平

Layered composite fabric clothing with urine storage bag

InactiveCN104664889AEasy urinationBreathableProtective garmentSpecial outerwear garmentsEngineeringGuide tube

The invention relates to layered composite fabric clothing with a urine storage bag. The layered composite fabric clothing comprises a clothing body (1), the urine storage bag (2) is arranged on one leg of the clothing body, a triangular storage bag (3) is arranged at the crotch of the clothing body (1), two contraction bands (4) are arranged on the storage bag (3), and the urine storage bag (2) is connected with the storage bag (3) through a guide tube (5). The clothing body is made of fabric comprising an anti-wetting layer; the fabric is specifically structurally characterized in that the anti-wetting layer and a raising layer are respectively composited to the upper and lower sides of an impermeable layer, the anti-wetting layer is made of mercerized fabric, and the impermeable layer is made of an elastic adhesive film. The layered composite fabric clothing can allow a user to urinate easily and has the advantages of waterproofness, breathability, good elasticity and scratch prevention.

Owner:夏宏希

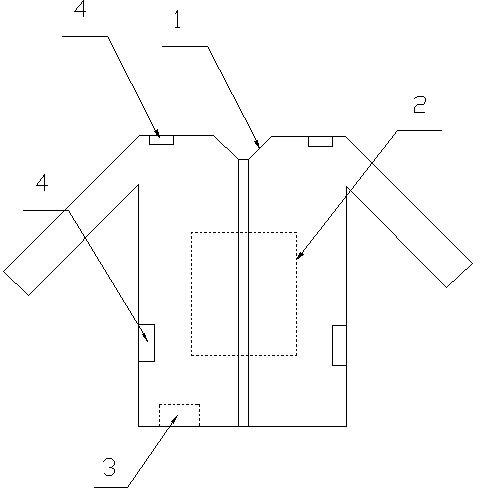

Laminar composite fabric garment capable of relieving fever

InactiveCN104687455ATo achieve the effect of physical coolingBreathableGarment special featuresTherapeutic coolingTemperature controlEngineering

The invention relates to laminar composite fabric garment capable of relieving fever. The laminar composite fabric garment comprises a garment body (1), wherein a water guide pipe (2) is distributed in the whole garment body (1); a temperature controller (3) is arranged in the front body of the garment body (1) and consists of a power supply, a heater and a temperature control circuit breaker; the temperature controller (3) is connected with the water guide pipe (2) through a temperature control valve (4); the garment body is made of a fabric; the fabric comprises a wetting-resistant layer, and the specific structure is that the wetting-resistant layer and a raising layer are respectively compounded on the upper surface and the lower surface of an anti-permeation layer; the wetting-resistant layer adopts a silky fabric; the anti-permeation layer consists of an elastic rubber film. According to the garment, deformation and creasing of the neckline which is washed for multiple times can be prevented. The garment disclosed by the invention achieves a physical fever reduction effect and has the characteristics of water resistance, breathability, high elasticity and scratching resistance.

Owner:曹寅

Multifunctional lamellar composite fabric clothes

InactiveCN104223490AImprove work efficiencyBreathableProtective garmentSpecial outerwear garmentsBiochemical engineeringSolar cell

The invention relates to multifunctional lamellar composite fabric clothes. The multifunctional lamellar composite fabric clothes comprises a clothes body (1), wherein a solar cell panel (2) is arranged on the back of the clothes body (1) and is connected with a storage battery (3), and the storage battery (3) is connected with an indicator light (4); the clothes body is made of a fabric comprising an anti-wetting layer; the fabric has the specific structures that the anti-wetting layer and a gigging layer are respectively compounded on the upper surface and the lower surface of an anti-infiltration layer, the anti-wetting layer is made of a mercerized fabric, and the anti-infiltration layer is made of an elastic adhesive film. The multifunctional lamellar composite fabric clothes realize illumination by arranging the light on the clothes body, so that the working efficiency is improved. The multifunctional lamellar composite fabric clothes has the characteristics of waterproofness, air permeability, good elasticity and scratch resistance.

Owner:JIANGYIN TIANCHENG TEXTILE

Composite layered fabric warm clothing applicable to wearing in winter

InactiveCN104223482AGuaranteed warmthReduce the amount of wearBatteries circuit arrangementsOhmic-resistance heatingEngineeringBreathing

The invention relates to composite layered fabric warm clothing applicable to wearing in winter. The composite layered fabric warm clothing comprises a clothing body (1), wherein a solar panel (2) is arranged on the back of the clothing body (1), the solar panel (2) is connected with a storage battery (3), a plurality of infrared heat conduction devices (4) are arranged in an interlayer of the clothing body (1), and the infrared heat conduction devices (4) are connected with the storage battery (3); the clothing body is made of fabric, the fabric comprises an anti-infiltration layer, the specific structure of the fabric is as follows: the upper layer and the lower layer of the anti-infiltration layer are respectively provided with an anti-infiltration layer and a napping layer, the anti-infiltration layer adopts a mercerizing fabric, and the anti-infiltration layer is formed by an elastic rubber film. By adopting the composite layered fabric warm clothing, a warn effect of the clothing can be guaranteed in winter. The composite layered fabric warm clothing has characteristics of water resistance, ventilation, good elasticity and scratch resistance.

Owner:JIANGYIN KEHAO GARMENT & YARN DYE WEAVING

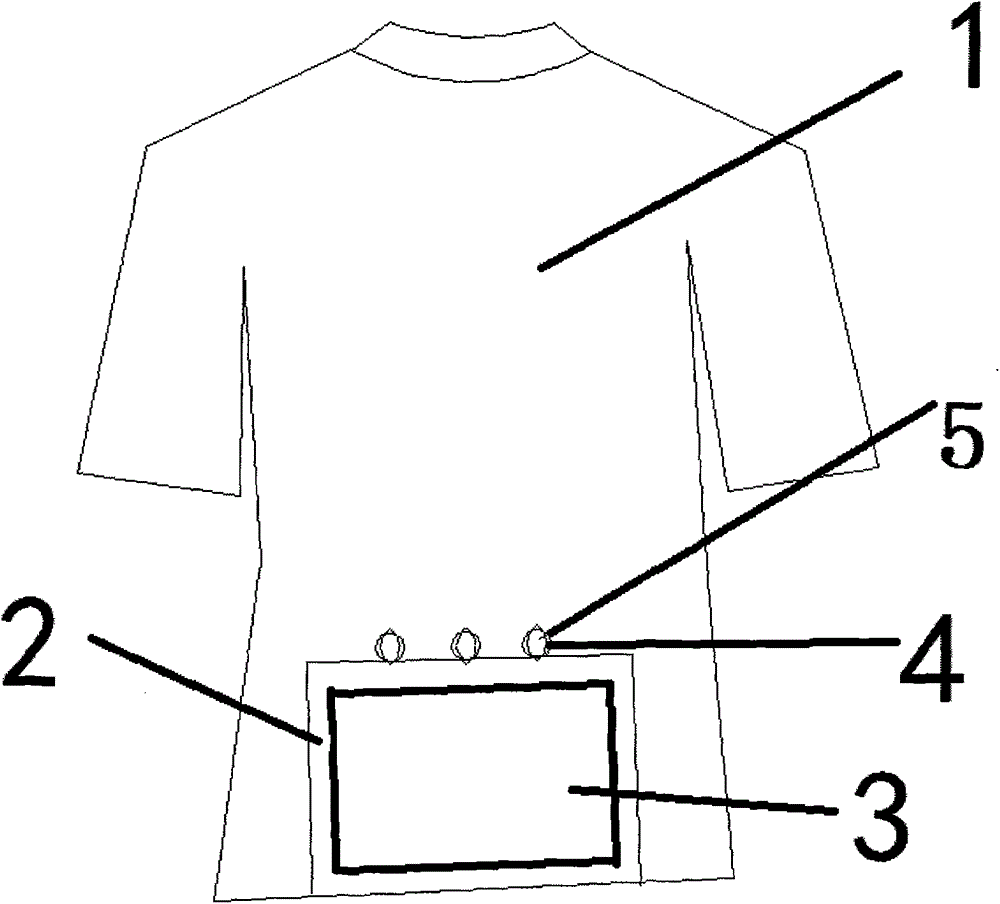

Layered composite fabric garment with water cushion

InactiveCN104687393AEasy to carryAvoid direct contactProtective garmentSpecial outerwear garmentsCushionEngineering

The invention relates to a layered composite fabric garment with a water cushion. The layered composite fabric garment comprises a garment body (1), wherein a water cushion (2) is sewn to the back lower hem of the garment body (1), a seal mat (3) is formed in the middle of cloth at the periphery of the water cushion (2), the seal mat (3) is filled with water, a button (4) is arranged at the position opposite to the sewing part between the water cushion (2) and the garment body (1), and a button (5) is also arranged at the back waist part of the garment body; the garment body is made of fabric, the fabric comprises an infiltration preventing layer, the specific structure of the fabric is as follows: the infiltration preventing layer and the raising layer are respectively compounded with the upper side and the lower side of a permeation preventing layer, the infiltration preventing layer adopts mercerizing fabric, and the permeation preventing layer is made of an elastic rubber film. The layered composite fabric garment with the water cushion is convenient to carry and has the characteristics of being waterproof and breathable, good in elasticity and scratch-proof.

Owner:张焕良

Garment provided with urethral catheter and made of layered combined fabrics

InactiveCN104664942ASolve urination problemsBreathableProtective garmentSpecial outerwear garmentsButtocksContraction bands

The invention relates to a garment provided with a urethral catheter and made of layered combined fabrics. The garment comprises a garment body (1). A storage sleeve (2) is arranged at a crotch of the garment body (1), two contraction bands (3) are arranged on the storage sleeve (2), the long flexible catheter (4) is arranged at the bottom of the storage sleeve (2), an opening (5) is formed in a buttock of the garment body, and the flexible catheter (4) penetrates the garment via the opening (5). The garment body is made of the fabrics, the fabrics comprise wetting preventive layers; particular structures of the fabrics include that each wetting preventive layer and a napping layer are respectively combined with the upper surface and the lower surface of a permeation preventive layer, the wetting preventive layers are made of mercerized fabrics, and the permeation preventive layers are made of elastic rubber films. The garment has the advantages that urine of patients can be conveniently drained by the aid of the garment, and the garment is waterproof, breathable and scratching-preventive and is good in elasticity.

Owner:顾建坤

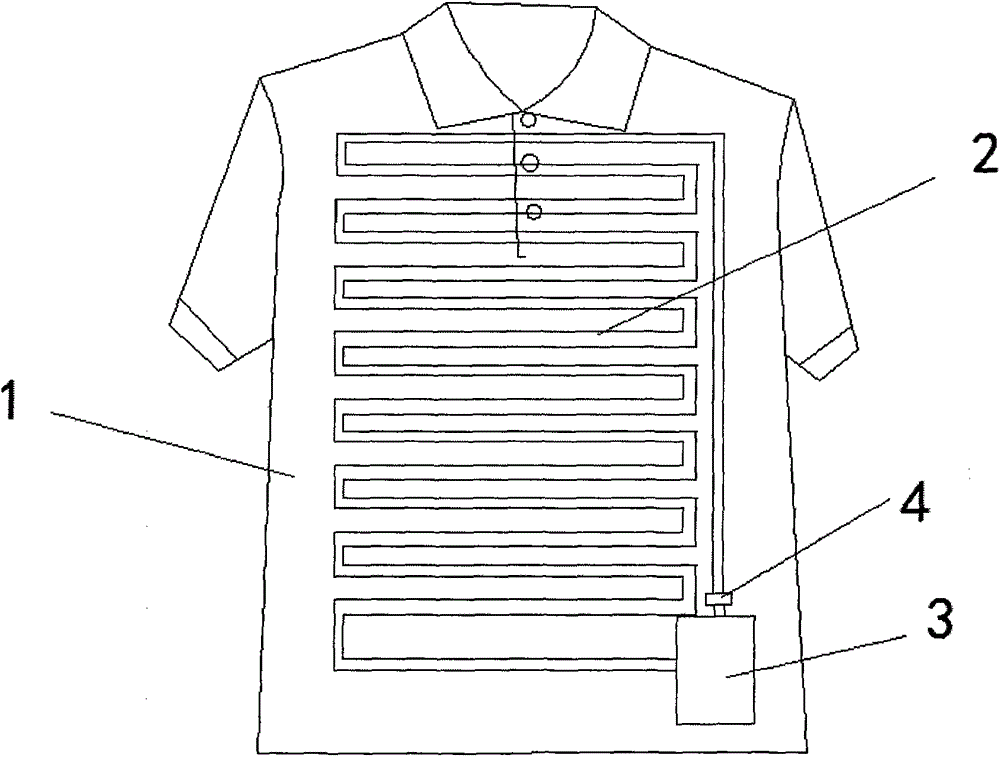

Layered composite fabric clothing with electricity storage function

InactiveCN104664806ABreathableWith scratchesProtective garmentSpecial outerwear garmentsElectricitySurface layer

The invention relates to layered composite fabric clothing with an electricity storage function. The layered composite fabric clothing comprises a clothing body (1), a plurality of solar panels (2) are arranged on the front body of the clothing body (1), each solar panel (2) is connected with a lithium battery (3), and a USB (universal serial bus) interface (4) is connected to the terminal of each lithium battery (3); the clothing body is made of fabrics including a surface layer, an inner layer and an infiltration prevention layer, and the fabrics are characterized in that the infiltration prevention layer and a raising layer are respectively composited on the upper and lower surfaces of a permeating prevention layer, the infiltration prevention layer is made of silk fabrics, and the permeating prevention layer is formed by an elastic membrane. By the arrangement, electronic products can be charged, and the layered composite fabric clothing has the advantages of being water resistible and breathable, good in elasticity and scratch prevention.

Owner:李士清

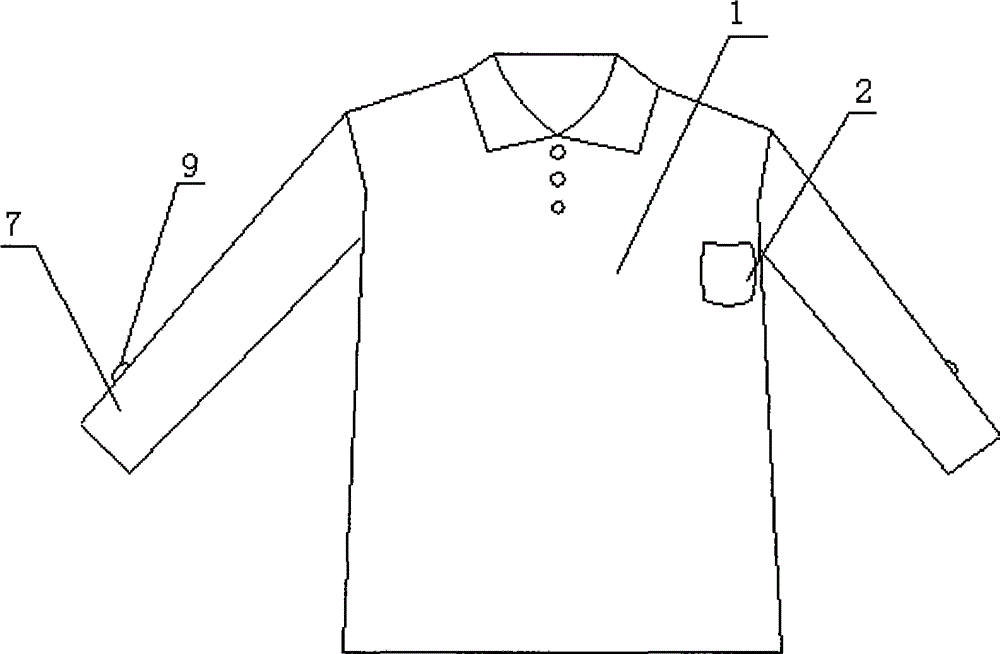

Going-out laminar composite fabric clothes for old people

InactiveCN104664664AConvenient careAvoid dangerous accidentsLayered productsVisible signalling systemsComputer moduleEngineering

The invention relates to going-out laminar composite fabric clothes for old people. The going-out laminar composite fabric clothes comprise a clothes body (1), wherein a chest pocket (2) is opened in the clothes body (1); a GPS (Global Position System) positioning module (3) is fixed in the chest pocket (2); the GPS positioning module (3) is connected with a CPU (Central Processing Unit) (5) through an AD (Analogue / Digital) conversion module (4); the CPU (5) is connected with a GSM (Global System for Mobile Communications) transmitting module (6); a through hole (8) is formed in the outer side of each sleeve (7) of the clothes body (1); LED (Light Emitting Diode) light-emitting lamps (9) are fixed on the through holes (8); the clothes body is made of a fabric; the fabric comprises an anti-wetting layer; the specific structure is that the anti-wetting layer and a raising layer are compounded on the upper and lower surfaces of an anti-permeation layer; the anti-wetting layer adopts a mercerized fabric; the anti-permeation layer is composed of an elastic rubber film. By the aid of the going-out laminar composite fabric clothes for the old people, the position of the old people can be known in real time. The going-out laminar composite fabric clothes have the characteristics of water prevention and air permeability, good elasticity and scratching resistance.

Owner:李士清

Waterproof insulation layered composite fabric

InactiveCN104256980AGood warmth retentionGuaranteed warmthSynthetic resin layered productsProtective garmentInsulation layerEngineering

The invention relates to a waterproof insulation layered composite fabric which sequentially comprises an outer layer (1), a middle layer (2) and an inner layer (3), wherein the outer layer (1) and the middle layer (2) are in press fit, the outer layer (1) is a windproof and waterproof breathable film, the inner layer (3) is an insulation layer and fitted with the middle layer (2), and the middle layer is made of fabrics including an anti-infiltration layer. The composite fabric is particularly and structurally characterized in that the anti-infiltration layer and a fleecy layer are compounded on the upper surface and the lower surface of an anti-permeation layer respectively, the anti-infiltration layer is made of mercerized fabrics, and the anti-permeation layer is made of elastic adhesive films. The composite fabric has waterproof and insulation effects and has the advantages of waterproof property, breathability, fine elasticity and scratch prevention.

Owner:JIANGYIN SHANGFENG TEXTILE

Waterproof, air-permeable and layered composite shell fabric

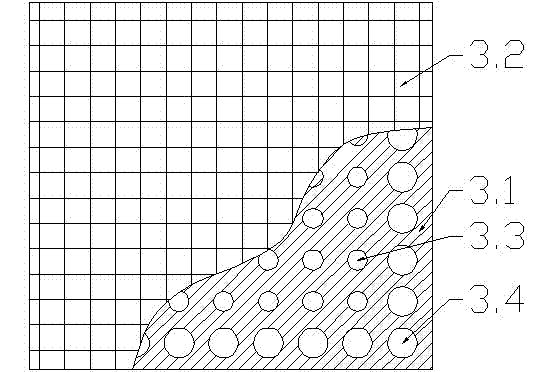

The invention relates to a waterproof, air-permeable and layered composite shell fabric. The shell fabric comprises an outer-layer splashing shell fabric (1), a middle-layer sol layer (2) and an inner-layer air-permeable layer (3), wherein the air-permeable layer (3) comprises a bamboo charcoal fiber shell fabric (3.1), the bamboo charcoal fiber shell fabric (3.1) is wrapped with a layer of non-woven fabric (3.2), a plurality of first shell fabric blocks (3.3) are arranged at the middle part between the bamboo charcoal fiber shell fabric (3.1) and the non-woven fabric (3.2), and a plurality of second shell fabric blocks (3.4) are arranged at the edge part between the bamboo charcoal fiber shell fabric (3.1) and the non-woven fabric (3.2); a base layer is laminated to the back face of the air-permeable layer, comprises an anti-wetting layer and has the specific structure that the upper and lower faces of an impermeable layer are respectively laminated with the anti-wetting layer and a raising layer. The shell fabric is waterproof and air-permeable and has strong layered feeling. The shell fabric is scratch-resistant.

Owner:JIANGYIN HULIAN DYEING & FINISHING

Sun protective laminar compound fabric short-sleeve garment

InactiveCN104687564AUV protectionTo achieve the effect of sun protectionProtective garmentSpecial outerwear garmentsEngineeringLower face

The invention relates to a sun protective laminar compound fabric short-sleeve garment which comprises a garment body (1), wherein a silver plaster strip (2) is connected to the upper cloth margin at each short-sleeve cuff of the garment body (1); an elastic cord (3) is arranged at the bottom end of each silver plaster strip (2); a storage pocket (4) with a zipper is arranged at each short-sleeve cuff of the garment body. The garment body is made of a fabric which comprises an infiltration-preventing layer, and the specific structure of the fabric is that the infiltration-preventing layer and a raising layer are respectively compounded on the upper face and the lower face of a permeation-preventing layer; the infiltration-preventing layer adopts a mercerized fabric, and the permeation-preventing layer is made of an elastic rubber film. According to the garment provided by the invention, the silver plaster strips can be accommodated in the storage pockets. The garment provided by the invention has the characteristics of being waterproof and air-permeable, and good in elasticity and scratch-resistance.

Owner:曹君华

Multifunctional layered composite-fabric physiotherapeutic garment

InactiveCN105495723ARelieve sorenessBreathableProtective garmentSpecial outerwear garmentsAirbagPermeation

The invention relates to a multifunctional layered composite-fabric physiotherapeutic garment, comprising a garment body (1). All garment linings of the garment body (1) at neck and waist parts of the back surface are provided with inflatable airbags (2), the garment inner sides of the neck and waist parts of the back surface of the garment body (1) are fitted with electromagnetic vibrators (3), and a controller (4) is disposed on the lower side of a front part of the garment body (1); the garment body is made of shell fabric that comprises an anti-infiltration layer, and the specific structure thereof is: the anti-infiltration layer and a flocked layer are composited to upper and lower surfaces of an anti-permeation layer, respectively, the anti-infiltration layer is made of mercerized fabric, and the anti-permeation layer is made of elastic film. The garment enables a wearer to get relaxed and massaged while feeling sores in cervical vertebra and waist. The garment has the characteristics of water repellency, breathability, good elasticity and scratch resistance.

Owner:顾方钟

Laminar composite fabric garment capable of reducing temperature of human body

InactiveCN104687481AReduce the temperatureSlow down the flowGarment special featuresProtective garmentWhole bodyEngineering

The invention relates to laminar composite fabric garment capable of reducing the temperature of a human body. The laminar composite fabric garment comprises a garment body (1), wherein a water guide pipe (2) is distributed in the whole body of the garment body (1); a mini water extractor (3) is arranged at a pocket; a cooling box (4) is arranged in the front body; the garment body is made of a fabric; the fabric comprises a wetting-resistant layer, and the specific structure is that the wetting-resistant layer and a raising layer are respectively compounded on the upper surface and the lower surface of an anti-permeation layer; the wetting-resistant layer adopts a silky fabric; the anti-permeation layer consists of an elastic rubber film. The garment disclosed by the invention can achieve an effect of reducing the temperature of the human body and has the characteristics of water resistance, good breathability, high elasticity and scratching resistance.

Owner:陆荣耀

A kind of blocking blue light anti-glare optical film and preparation method thereof

ActiveCN105524563BProtect from scratchesReduce blue lightPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsFilm materialBlue light

The invention relates to a blue-light-barrier anti-dazzle optical film and a preparation method therefor. The blue-light-barrier anti-dazzle optical film comprises a transparent substrate which is formed through laminating two layers of transparent films with the thickness of 20-200 microns, wherein a laminating interlayer is a composite adhesive layer, which contains an anti-ultraviolet agent and a blue and purple light barrier dye and has the thickness of 10-30 microns, one face of the transparent substrate is coated with an anti-dazzle and scratch-resistant coating layer with the thickness of 2-10 microns, the other face of the transparent substrate is coated with a pressure-sensitive adhesive, i.e., a binder with the thickness of 5-40 microns, and the surface of the pressure-sensitive adhesive is covered with a release film. The film material plays roles in preventing dazzle, cutting off blue light, reducing visual fatigue and protecting vision and further has the function of protecting a LCD screen from scratch.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY +1

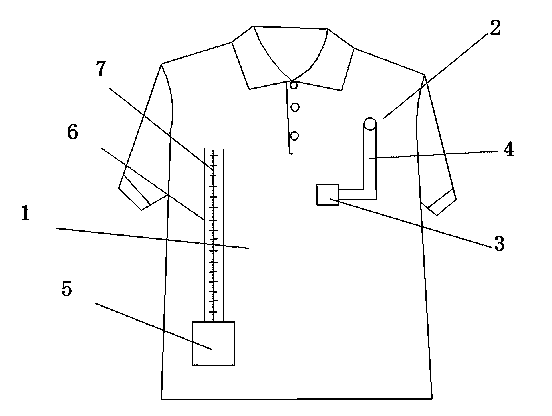

Layered composite fabric garment convenient for use of mobile phone

InactiveCN104223435AAvoid sorenessBreathableProtective garmentSpecial outerwear garmentsEngineeringMechanical engineering

The invention relates to layered composite fabric garment convenient for use of a mobile phone. The layered composite fabric garment comprises a garment body (1), wherein a plastic gear (2) is arranged at the upper side of the front body of the garment body (1) and is connected with a bracket (3); the bracket (3) is connected with a mobile-phone supporting frame (4); a mobile-phone pocket (5) is sewn under the front body of the garment body (1); an earphone pipe (6) is arranged above the mobile-phone pocket (5); a zipper (7) is arranged on the earphone pipe (6); the garment body is made of fabric; the fabric comprises an infiltration-preventing layer and the specific structure is as follows: the upper surface and the lower surface of a permeation-preventing layer are respectively composited with the infiltration-preventing layer and a gigging layer; the infiltration-preventing layer adopts mercerized fabric; the permeation-preventing layer is formed by elastic adhesive films. The layered composite fabric garment can enable the two hands to be free and avoid the aching pain of the hands, and has the characteristics of good waterproof and breathable effects, good elasticity and good scratch-proof effect.

Owner:JIANGYIN TOPWAY TEXTILE

A kind of easy-to-clean nano antifouling and antibacterial coating and preparation method thereof

ActiveCN108384444BImprove bindingWide choiceAntifouling/underwater paintsPaints with biocidesDiacetone alcoholCerium

The invention discloses an easy-to-clean nano antifouling antibacterial paint and a preparation method thereof. The paint comprises the following raw materials by weight: 2-20 parts of nano titanium dioxide, 5-20 parts of bentonite, 3-8 parts of silica aerogel, 0.5-20 parts of modified rare earth, 5-20 parts of nano graphene, 5-20 parts of isophorone, 1-20 parts of diacetone alcohol, 1-10 parts ofan antifoulant, 6-20 parts of modified organic silicon resin, 2-20 parts of ethylene glycol butyl ether / propylene glycol butyl ether, and 6-30 parts of butyl acetate. The modified rare earth is modified nano cerium oxide and nano lanthanum oxide in a weight ratio of 0.35:1, and a titanate coupling agent is employed for modification treatment of nano cerium oxide and lanthanum oxide, the modifiedrare earth has a particle size of 1-100nm, and the nano graphene has a particle size of 3-5nm. The paint prepared by the technical scheme adopted by the invention can achieve the following effects after application to a substrate surface: 1. good anti-fouling effect; 2. easy cleaning; 3. good antibacterial effect; 4. strong adhesion; and 5. high hardness.

Owner:张积喜

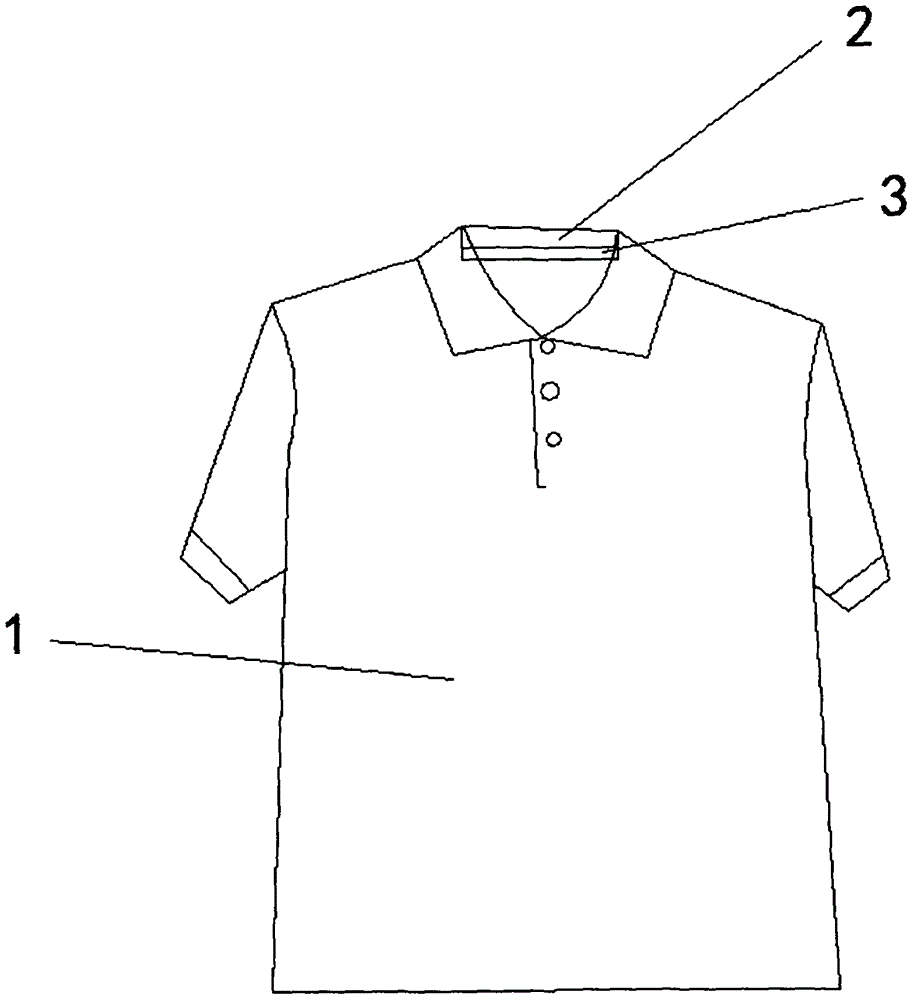

Laminated composite fabric garment with stain-resistant collar

InactiveCN104687602AWon't get dirtyEasy to removeProtective garmentSpecial outerwear garmentsEngineeringPermeation

The invention relates to a laminated composite fabric garment with a stain-resistant collar. The laminated composite fabric garment comprises a garment body (1), wherein a filter layer (2) is arranged at the collar of the garment body (1), the filter layer (2) is a filtering membrane, and a collection layer (3) is arranged under the filter layer (2); the garment body is made of a fabric, the fabric comprises an anti-permeation layer, and the specific structure of the anti-permeation layer is as follows: an anti-infiltration layer and a napping layer are compounded on the upper surface and the lower surface of the anti-permeation layer respectively, the anti-infiltration layer adopts a mercerized fabric, and the anti-permeation layer is made of an elastic rubber film. The collar of the garment cannot be stained. The laminated composite fabric garment has the characteristics of being water resistible and breathable, good in elasticity and scratch-proof.

Owner:秦曦蕾

Large ultra-high pressure gas cylinder liner and manufacturing method thereof

ActiveCN109668051BHigh pressure resistantReduce lossVessel manufacturingVessel geometry/arrangement/sizeUltra high pressureSpinning

The invention provides a large-scale ultrahigh-pressure gas cylinder liner and a manufacturing method thereof. The large-scale ultrahigh-pressure gas cylinder liner is characterized in that on end ofthe liner is bottom sealed, and the other end of the liner is formed a sealing head and a bottle opening by closing, and the liner is an integrated seamless structure of a aluminum alloy liner, the liner comprises a straight cylinder section, a sealing bottom and a sealing head, wherein the sealing bottom and the sealing head are located at the two ends of the straight cylinder section respectively, the bottle opening is located on the sealing head; and the length of the aluminum alloy liner is 5-13m, the nominal outside diameter of the straight cylinder section is Phi 300-Phi 500 mm, the nominal pressure of the ultrahigh-pressure gas cylinder is 35-70 Mpa. According to the method, a slab is adopted as a raw material, a spinning method is adopted overall, the product does not have a weld joint, the preparation process is simple, the operation is convenient, the energy consumption is low, the pollution is small, the loss of raw materials in the manufacturing process is less, and the rawmaterial cost is saved. The aluminum alloy liner processed by the manufacturing method has the advantages of being huge in size, high in reliability, thin in wall, and light in weight; the internal material is uniform and compact in structure and excellent in overall strength effect, and has the characteristics of ultrahigh pressure resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Layered combined fabric garment with self-cleaning function

InactiveCN105455272AImprove air qualityKeep healthyProtective garmentSpecial outerwear garmentsSurface layerEngineering

The invention relates to a layered combined fabric garment with a self-cleaning function. The garment comprises a garment body (1), wherein the surface layer of the garment body (1) is an anti-static fabric, breathable dust-filtering fabric bags (2) are arranged on the shoulder, waist and back portions of the surface of the garment body (1), and a carbon package (3) is arranged in each breathable dust-filtering fabric bag (2). The garment body is made of the fabric which comprises an anti-wetting layer. According to the specific structure of the garment body, the anti-wetting layer and a raising layer are combined with the upper surface and the lower surface of an anti-permeating layer respectively, the anti-wetting layer is a mercerized fabric, and the anti-permeating layer is made of an elastic adhesive film. The layered combined fabric garment ensures health of a human body and has the advantages of being waterproof, breathable, good in elasticity and resistant to scratches.

Owner:杨洪兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com