Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Stable and reliable clamping force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

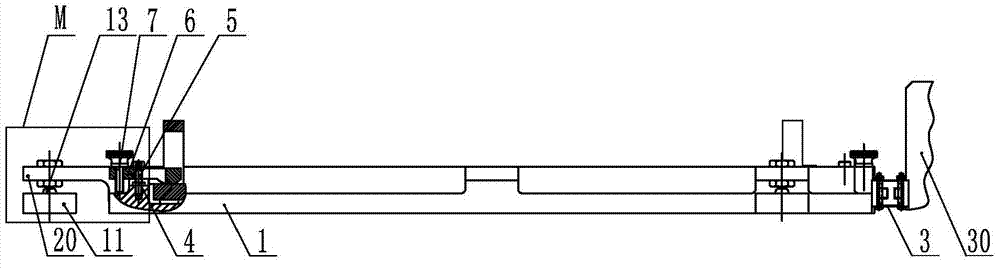

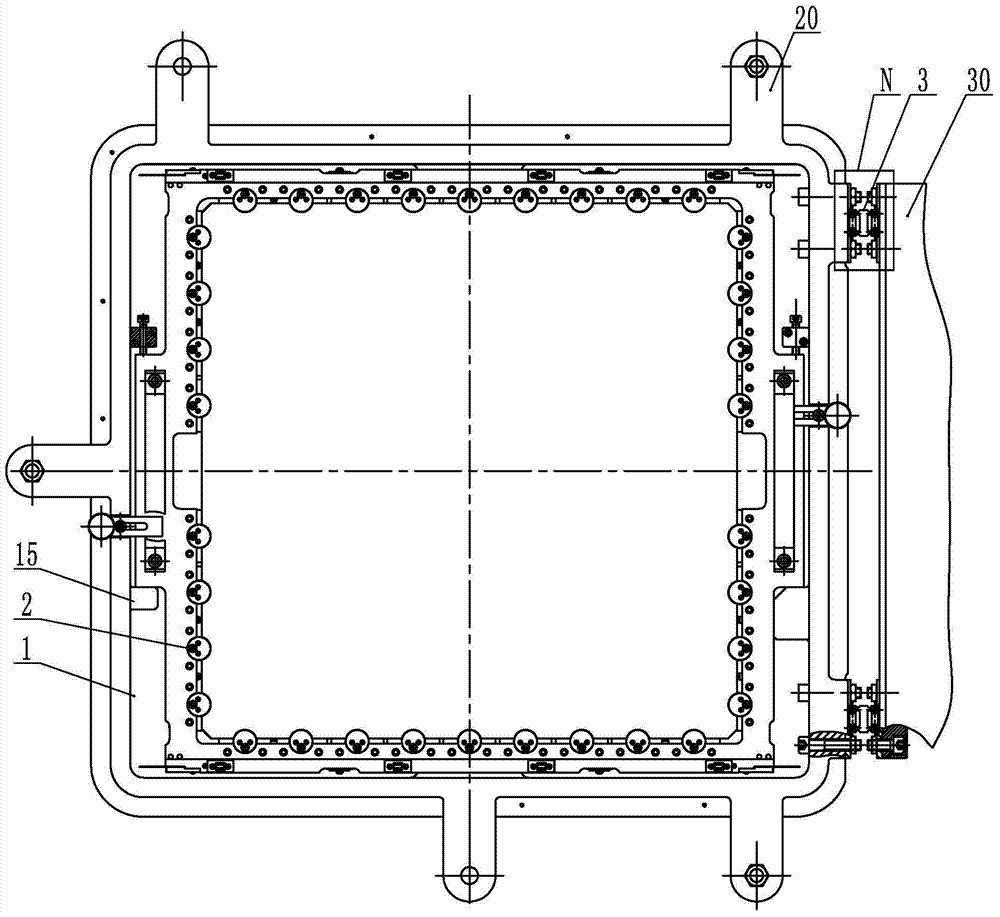

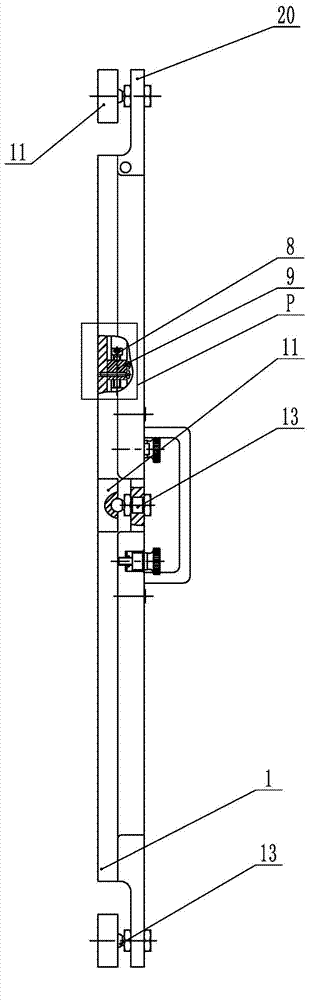

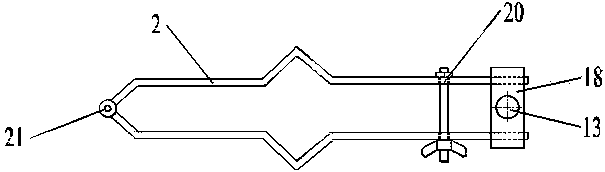

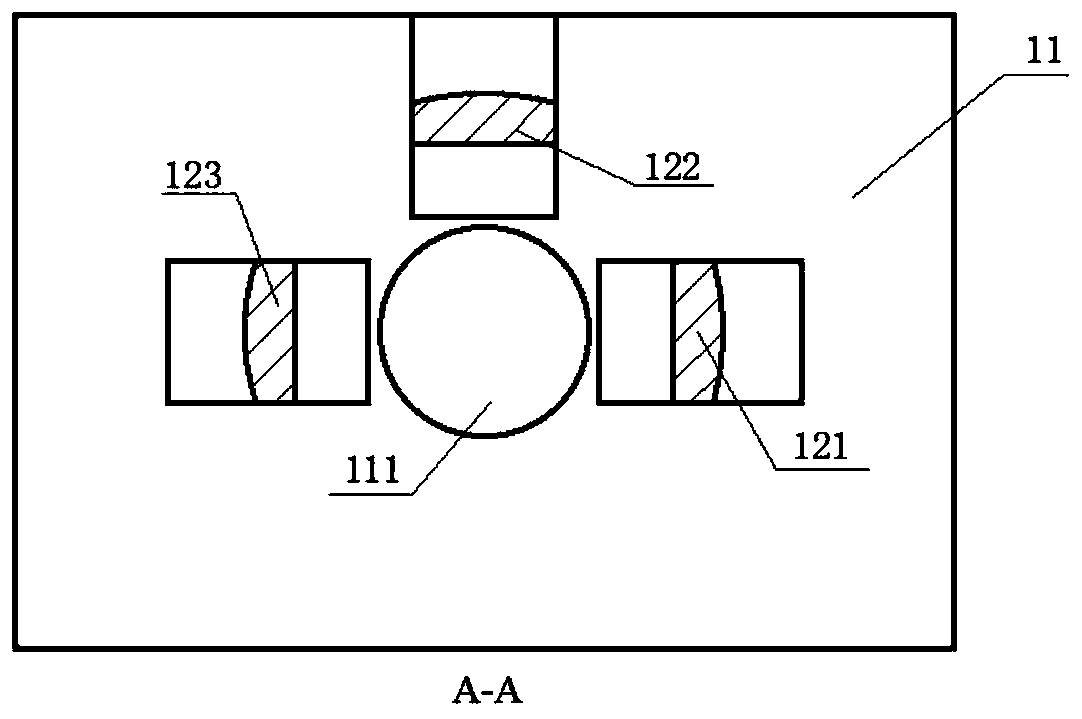

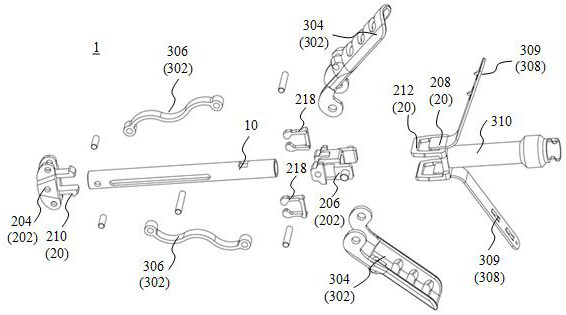

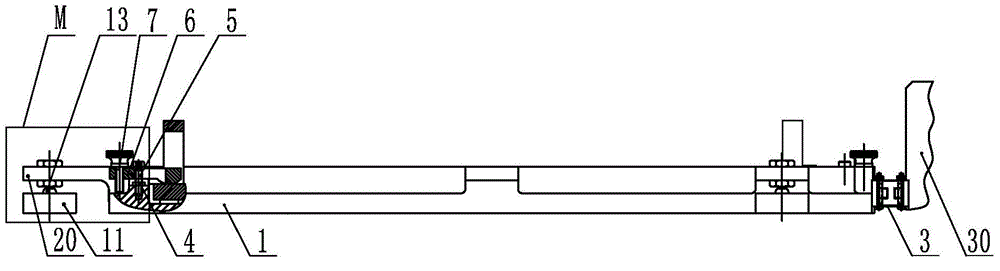

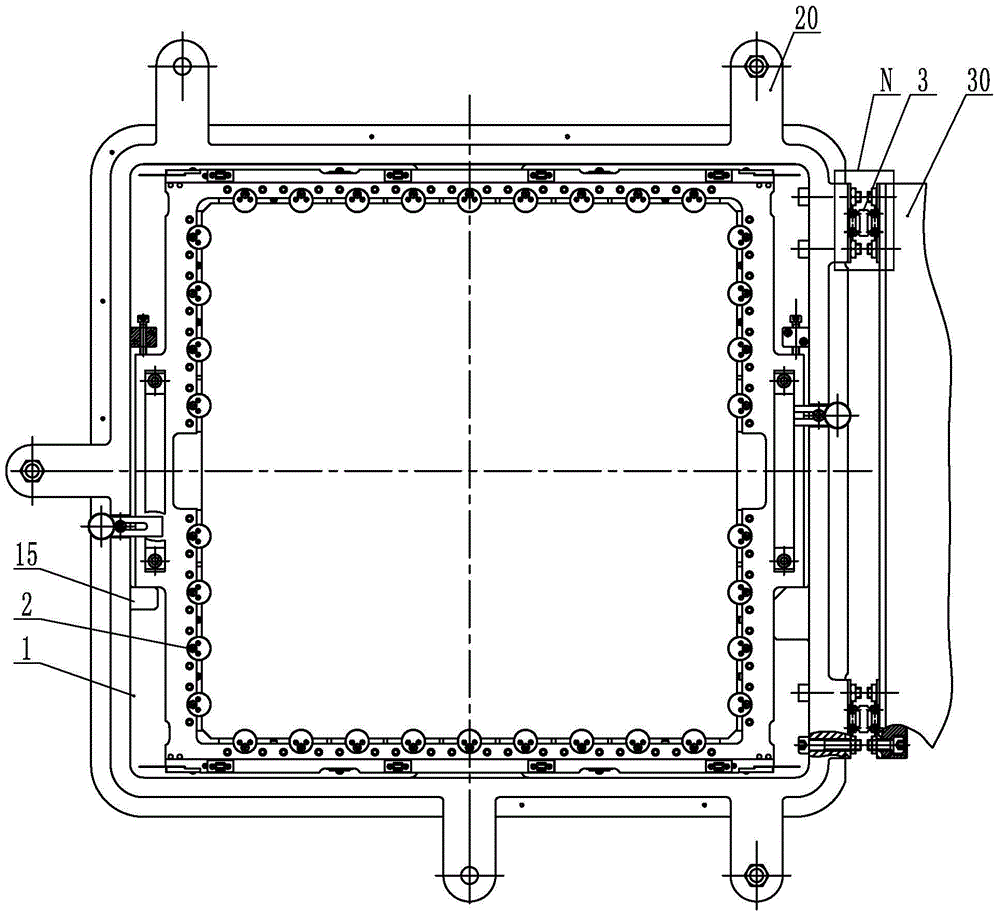

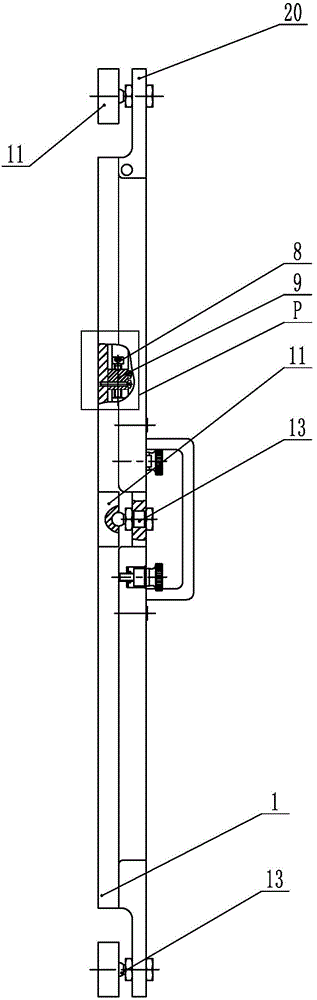

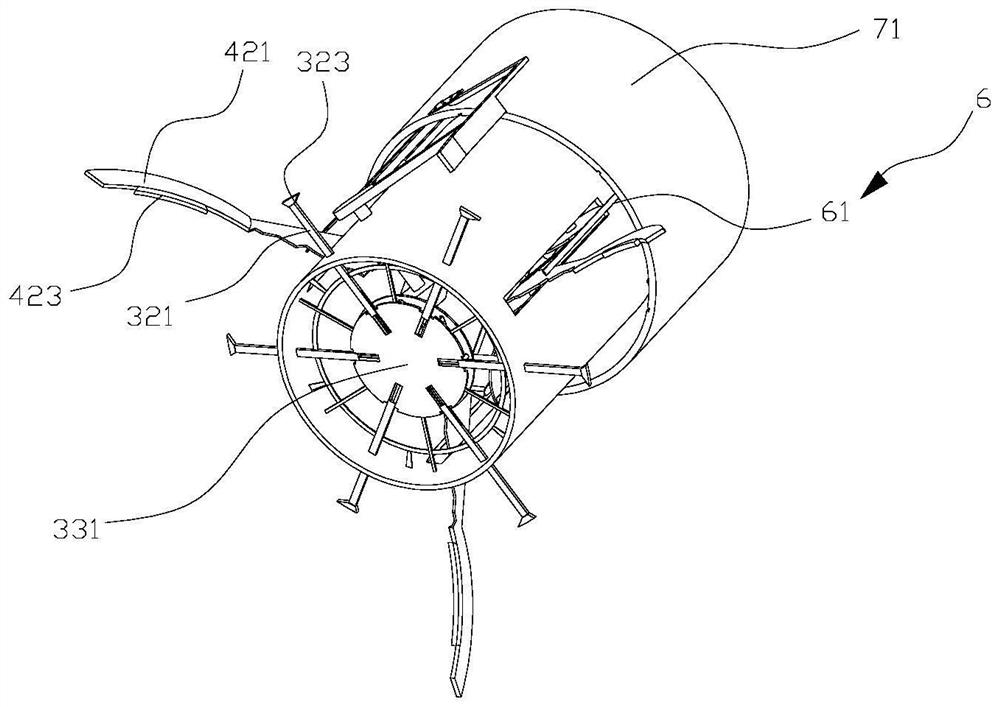

Flexible hinge and floating frame matched clamping and positioning device for optical component

ActiveCN103753449AGuaranteed uptimeMeet the requirements of precision restorationWork holdersEngineeringMechanical engineering

The invention discloses a flexible hinge and floating frame matched clamping and positioning device for an optical component. A flexible hinge and a floating frame are matched to be used for clamping and positioning the optical component, so that a large-caliber optical component is provided with the low-stress-strain reliable clamping capacity in the horizontal plane, moreover, the floating frame and two-dimensional large stroke are in flexible connection, so that the parallelism between the optical element surface and the work table plane is guaranteed. The flexible hinge is fixedly connected with a crystal frame, connection lugs are fixed on the crystal frame, positioning blocks are fixed in the crystal frame, and the optical component is disposed in the crystal frame integrally and positioned through the positioning blocks. Locking blocks are fixed in the crystal frame, first positioning screws are screwed in the locking blocks, and the optical component is pre-clamped and fixed between the first positioning screws and the positioning blocks. Compression blocks are fixedly connected with the crystal frame, and the optical component is compressed and fixed vertically through the compression blocks. Spherical hinge studs are fixedly connected with connection lugs and are in contact with air floating pads. The device is used for clamping and positioning of optical elements during micro-defect rapid searching and repairing.

Owner:HARBIN INST OF TECH

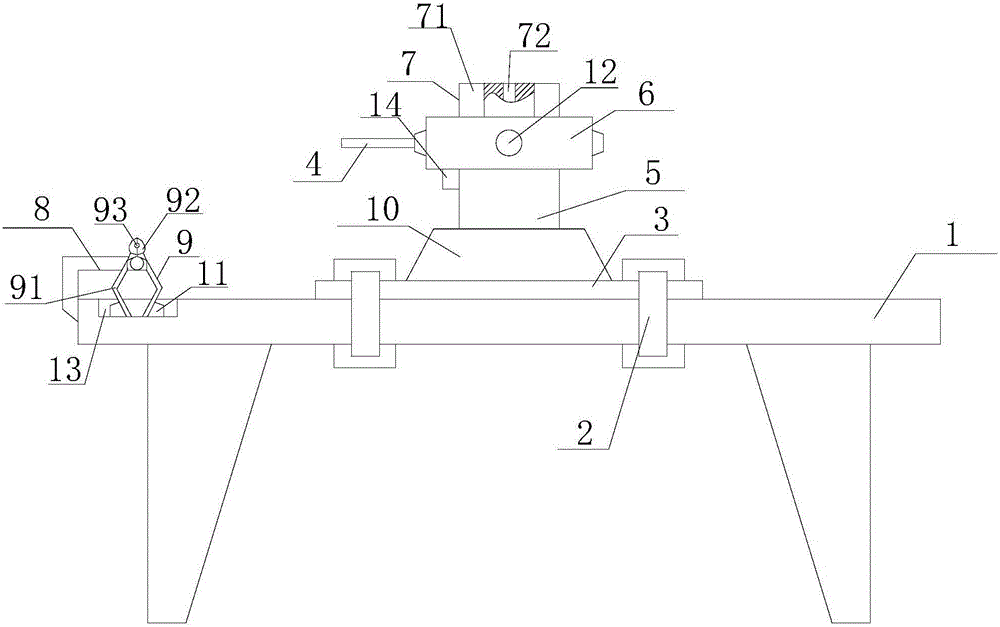

Lever type online safety valve checking device

InactiveCN103822776AReduce the required powerReduce volumeMachine part testingHydraulic cylinderHydraulic pump

The invention discloses a lever type online safety valve checking device. One end of a V-type lower rod and one end of the other V-type lower rod are hinged to each other, the two ends of a supporting rod adjusting nut are supported by one end of an upper rod and one end of each lower rod, a groove in a supporting rod upper bolt is hinged to one end of the upper rod, a tension sensor is arranged on the middle point of the upper rod, an iron chain and a clamping device with clamping heads provided with transverse tooth-shaped patterns are hung below the upper rod, a manual hydraulic pump is connected with a single-action hydraulic cylinder, the hydraulic cylinder is located on the open end of the lower rods through a hydraulic cylinder holding board, a hydraulic cylinder ejector rod is in contact with the upper rod, a displacement sensor is installed at the bottom of the hydraulic cylinder, a safety valve body is arranged in protruding V shapes of two pressing rods, and a valve neck of a safety valve is clamped by a locking device; the clamping device can clamp a valve rod of the safety valve, the valve rod of the safety valve and the tension sensor are coaxially arranged, and the displacement sensor and the tension sensor are connected with a data processor through data cables. According to the lever type online safety valve adjusting device, the valve rod is lifted according to the lever principle, the power and the size of a lifting mechanism are effectively reduced, checking is rapid and accurate, the application range is wide, and the checking efficiency can be effectively improved.

Owner:HANGZHOU SPECIAL EQUIP INSPECTION & RES INST

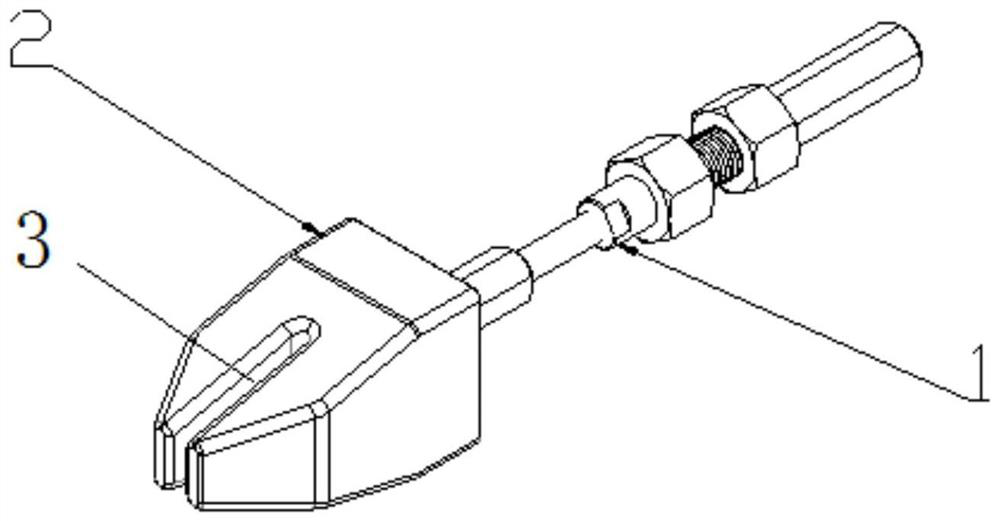

Negative-pressure blocking miniature soft gripper

InactiveCN111872971AImprove protectionLocation determinationGripping headsEngineeringMechanical engineering

The invention discloses a negative-pressure blocking miniature soft gripper which comprises a connecting piece with one end connected with a transmission device and a flexible clamping piece connectedto the other end of the connecting piece; and a clamping opening is formed in the flexible clamping piece, the clamping opening is in a U shape, an inner cavity surrounding the clamping opening is formed in the flexible clamping piece, outer cavities are symmetrically formed in the two sides of the inner cavity, the outer cavities are filled with shaping particles, and the outer cavities are connected with air pressure adjusting equipment through air pipes. The negative-pressure blocking miniature soft gripper is good in part protectiveness, and due to the fact that the negative-pressure blocking miniature soft gripper is made of a flexible material, indentations cannot be left on the machining face of a part; the grabbing precision is high, opening and closing of the clamping opening inthe flexible clamping piece are a gradual process, the operable space is large in the grabbing process, the position of the part can be better determined, and the possibility of misoperation is reduced; and the clamping effect is good, the rigidity of the clamping opening in the flexible clamping piece is gradually increased in the closing process, and reliable clamping force is provided while constraint is provided for the part.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

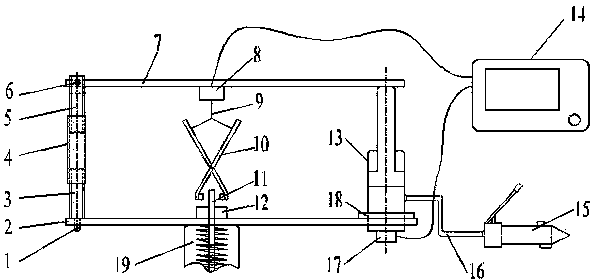

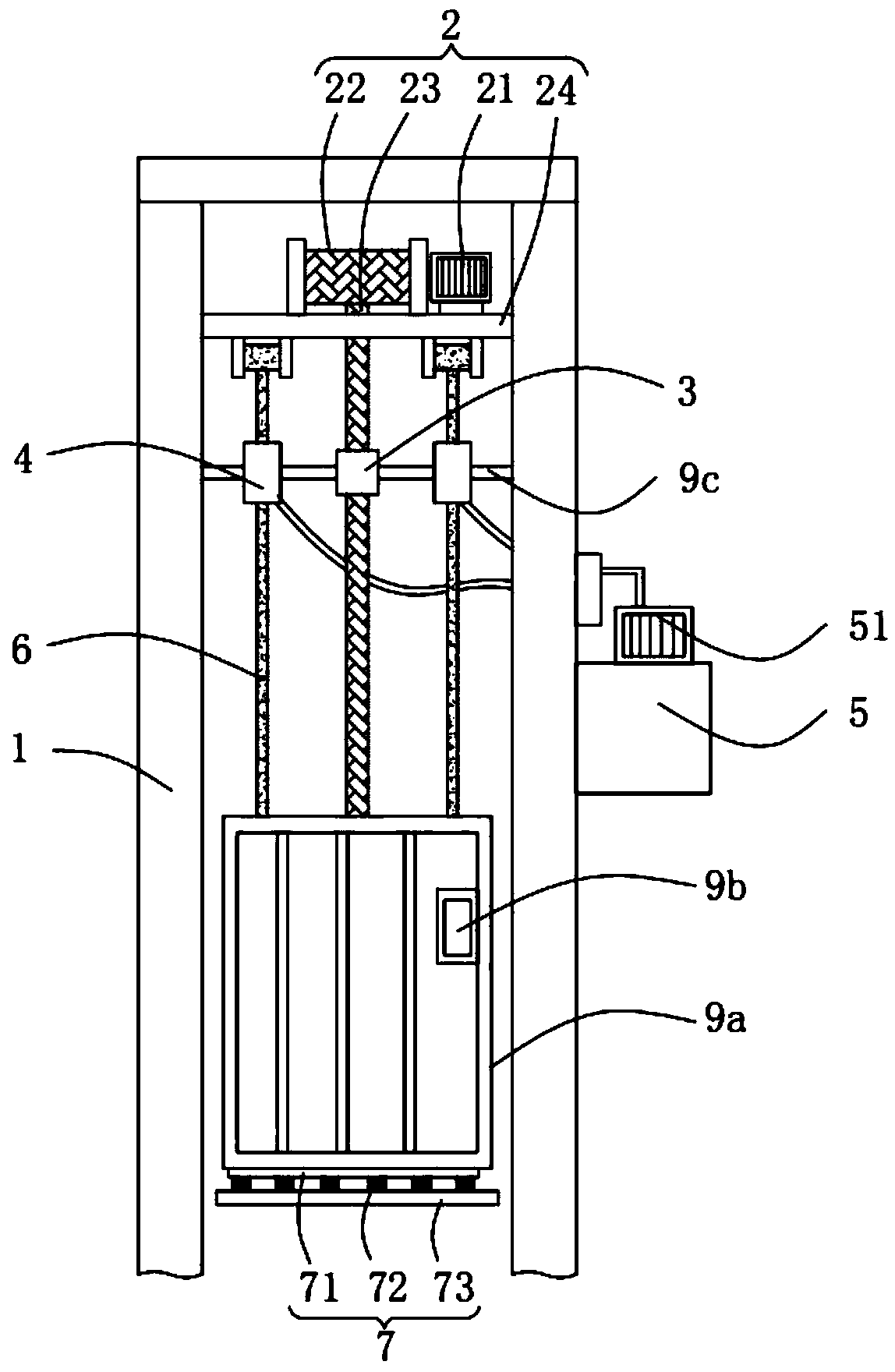

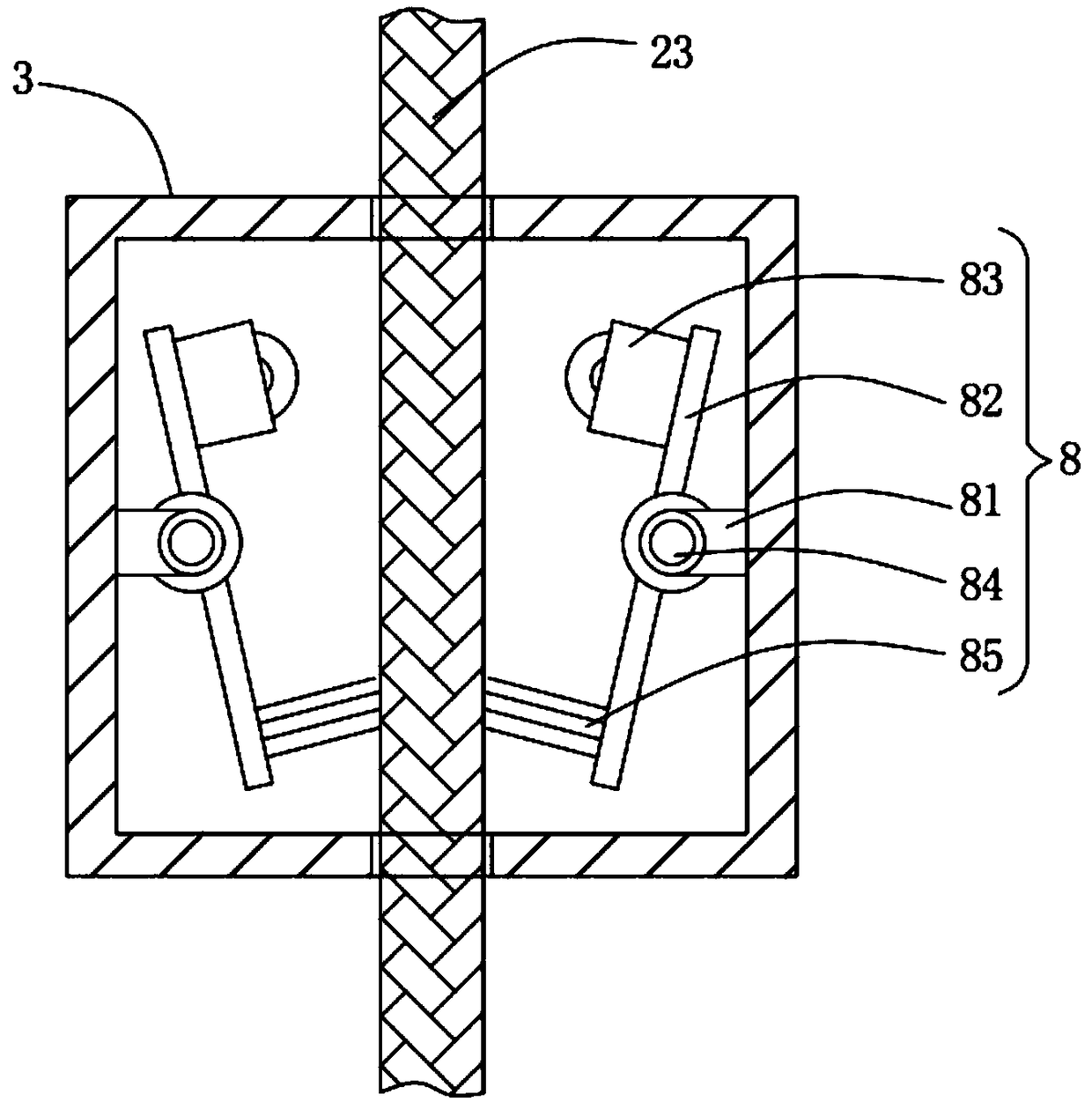

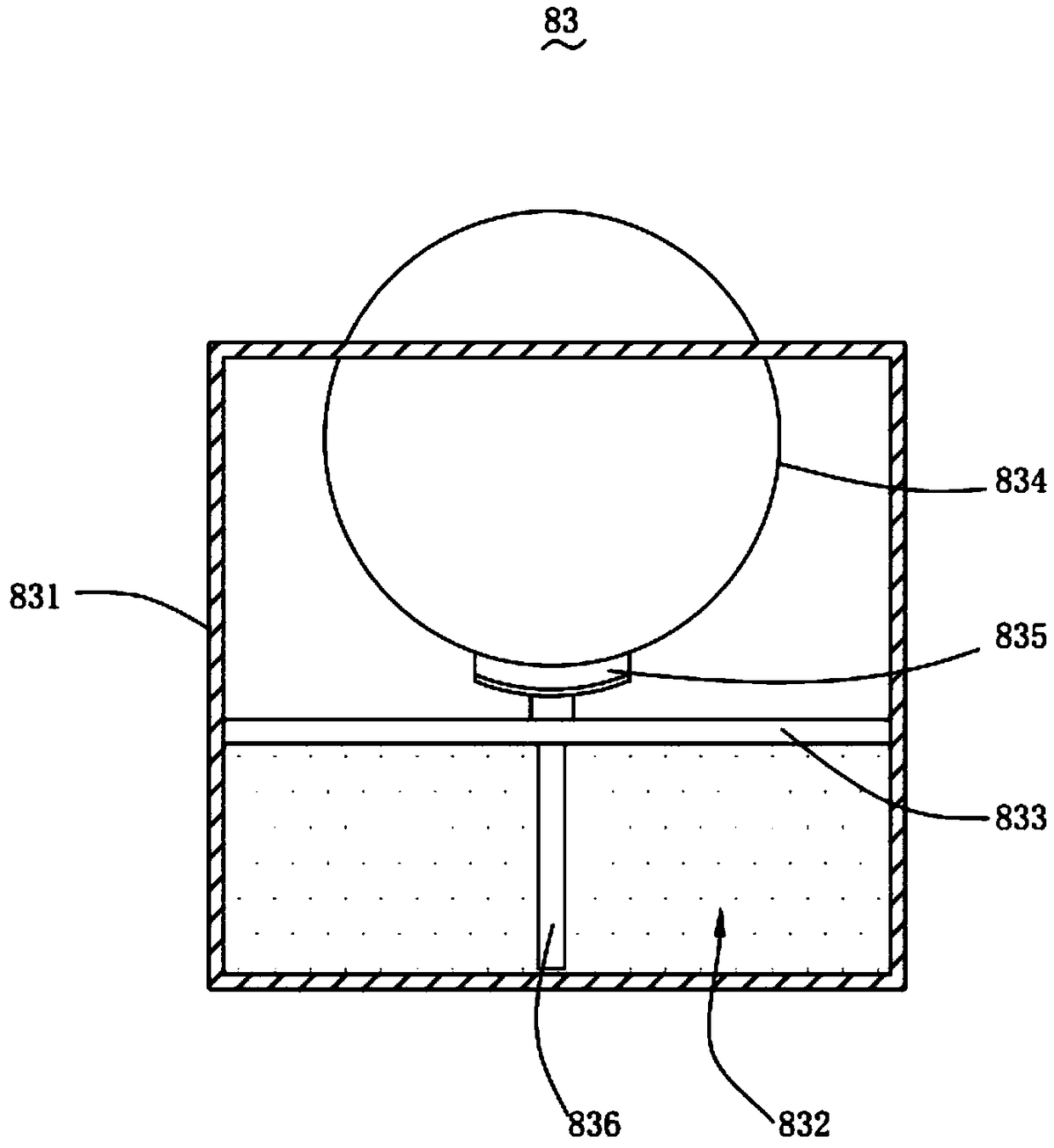

Safety protection method of mining lifting cage

ActiveCN109019221ASimple structureStable and reliable clamping forceElevatorsBuilding liftsFall protectionEngineering

The invention relates to the technical field of mining protection equipment, in particular to a safety protection method of a mining lifting cage. The safety protection method comprises the followingsteps that S1, an elastic rubber airbag is mounted at the bottom of a channel of the lifting cage, and the elastic rubber airbag is filled with water; and S2, a safety protection rope is connected tothe top of the lifting cage based on step S1. According to the safety protection method, the lifting cage drives a pressing plate to move through hydraulic oil, so that an auxiliary rope is clamped and limited to achieve rapid anti-falling protection; rubber heads are distributed on the surface of the pressing plate, so that the friction force is improved; and the pressing plate is of an inward concave arc-surface structure and thus can be attached to the auxiliary rope more closely, so that the protection effect is improved, and the clamping force is larger; and main ropes can be cleaned through brushes, so that the friction between the main ropes is reduced, aging of the main ropes is delayed, rusting of the main ropes is avoided, and breakage of the main rope is prevented fundamentally.

Owner:苏州理合文科技有限公司

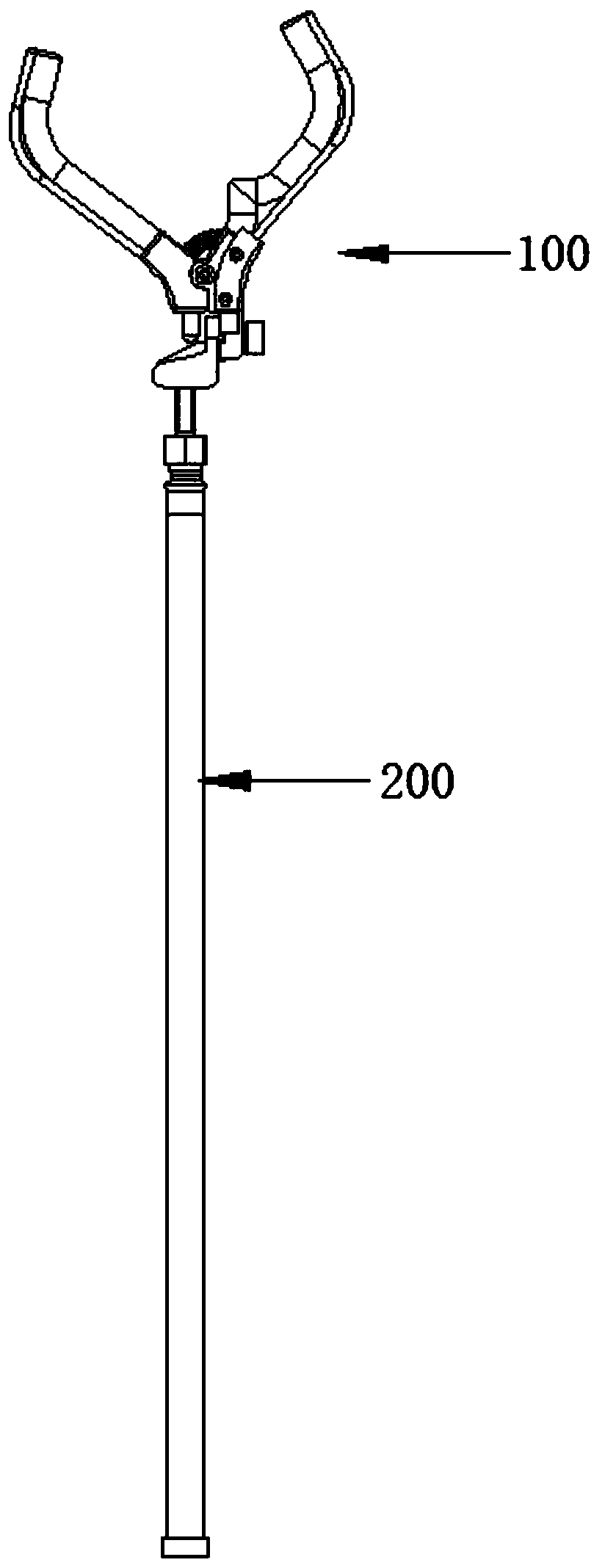

Clamping tool for insulator replacement and application method thereof

InactiveCN110535063AAvoid shakingShorten the opening and closing timeApparatus for overhead lines/cablesEngineeringBottle

The invention discloses a clamping tool for insulator replacement and an application method thereof. The clamping tool comprises a clamping fitting body and an insulating quick insertion rod, and theclamping fitting body comprises a jaw part used for being clamped on a porcelain bottle or an insulator groove part, a transmission part used for being inserted on the insulating quick insertion rod and a connecting part used for connecting the jaw part and the transmission part; when the clamping tool is in use, the jaw part of the clamping fitting body is clamped at the groove part of a porcelain bottle or an insulator to support the insulator chain to be overhauled or replaced, then the lifting screw rod of the transmission part is driven to rotate by rotating the insulating quick insertionrod, and then the lifting screw rod of the transmission part drives the inclined sliding block of the connecting part to slide up and down, so that a jaw supporting column is touched to enable the jaw to be clamped or loosened. The clamp has the advantages of being simple in structure, easy and convenient to operate, rapid, convenient to assemble and disassemble, capable of saving time and labor,stable in clamping force, good in using effect, capable of being rapidly opened and closed, capable of avoiding the complex disassembling process, capable of effectively shortening the opening and closing time of an insulator and a porcelain insulator and high in working efficiency.

Owner:ZHEJIANG ZHONGXIN POWER ENG CONSTR CO LTD +2

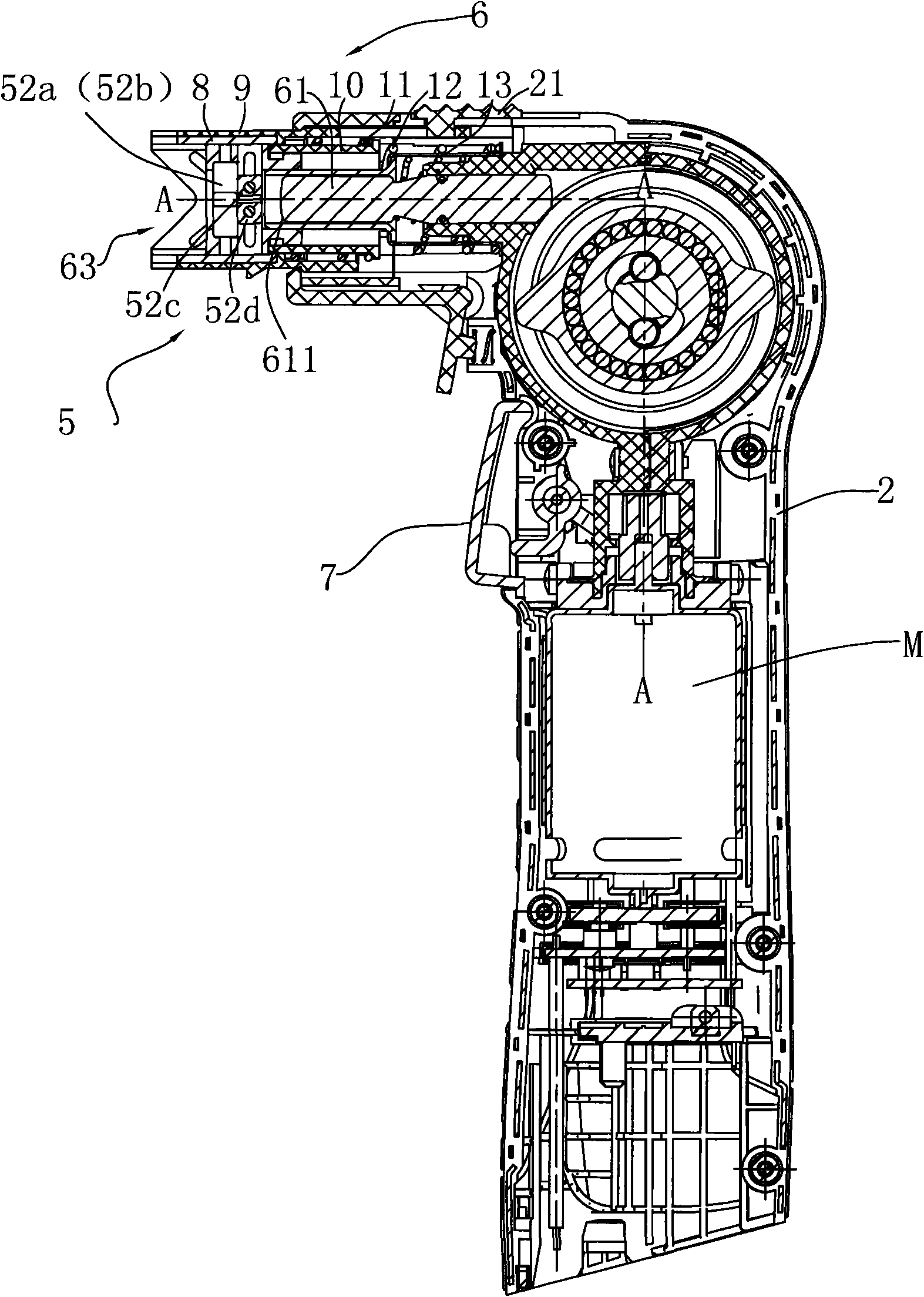

Charger, wearable equipment and charging system

PendingCN110571893AEasy to chargeFirmly connectedBatteries circuit arrangementsCoupling device detailsBattery chargerElectrical and Electronics engineering

The invention provides a charger, wearable equipment and a charging system, and relates to the technical field of wearable equipment charging. The charger comprises a base, a first clamping piece anda second clamping piece, wherein the first clamping piece and the second clamping piece are movably arranged on the base, and the first clamping piece and the second clamping piece are oppositely arranged and used for clamping the wearable equipment. The base is provided with a circuit board and charging terminals electrically connected with the circuit board, wherein the charging terminals are arranged on two sides of the base and used for being electrically connected with wearable equipment. The charger has the characteristics of reliable clamping during charging, stable connection, good charging contact and the like.

Owner:SHENZHEN DO INTELLIGENT TECH CO LTD

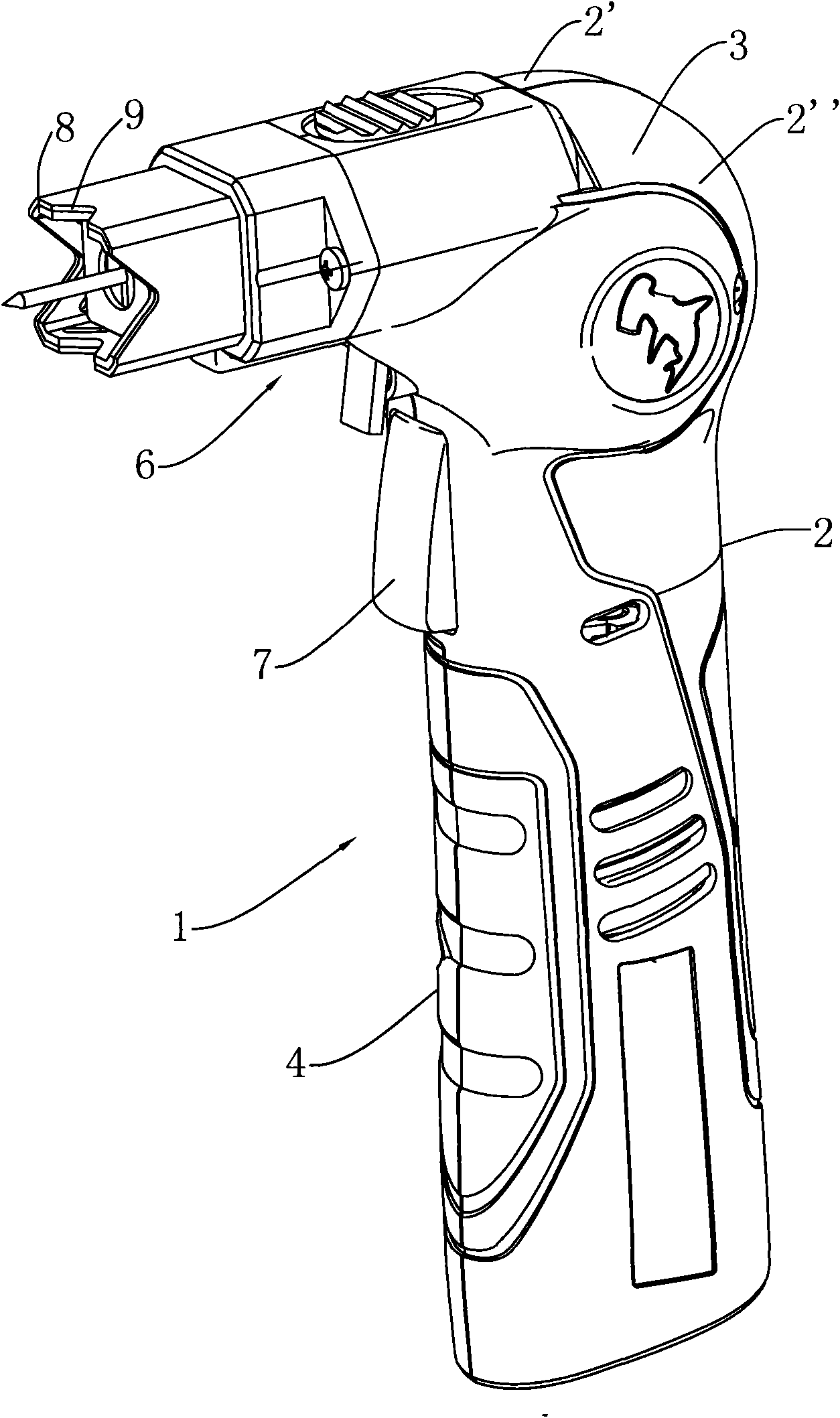

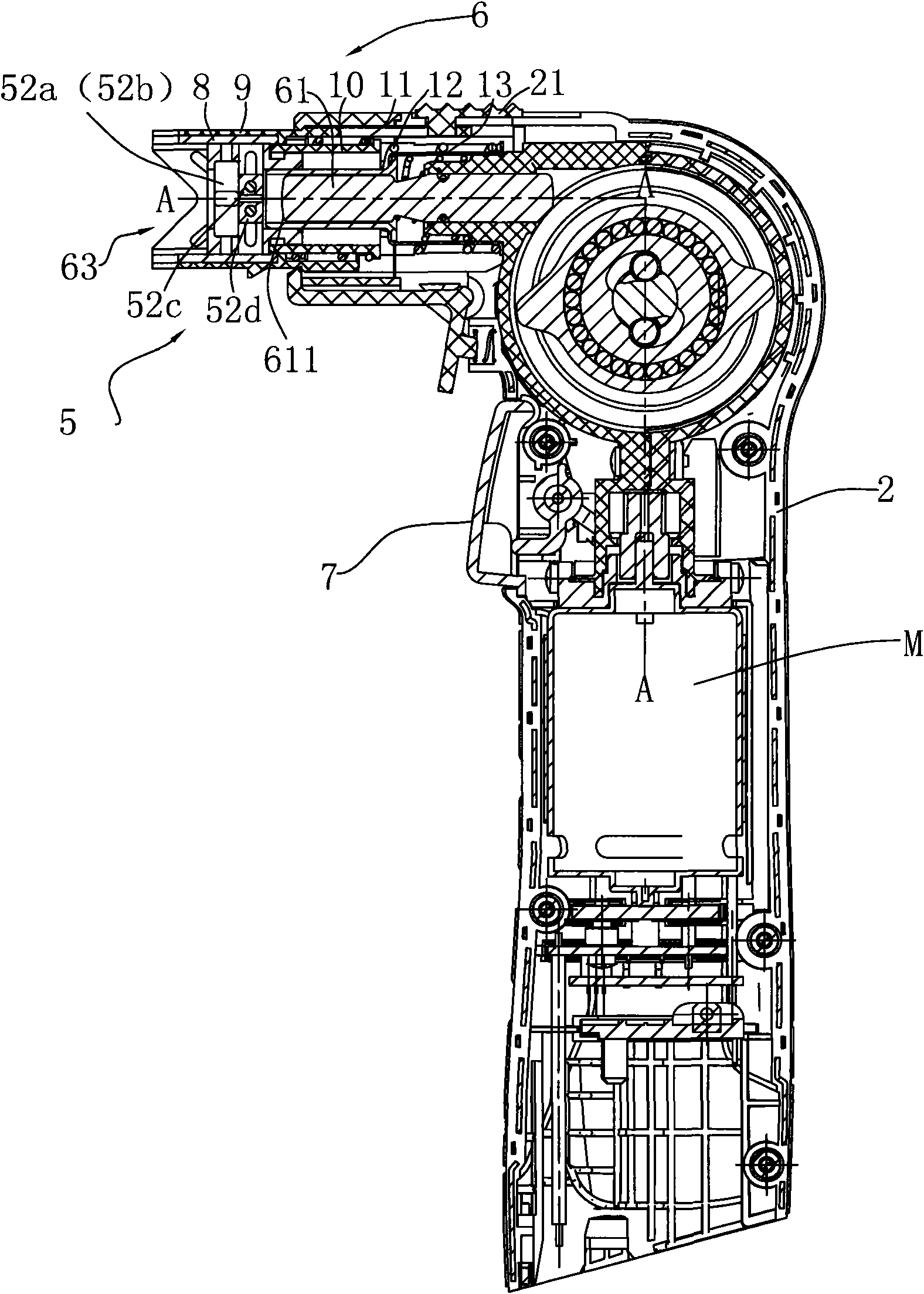

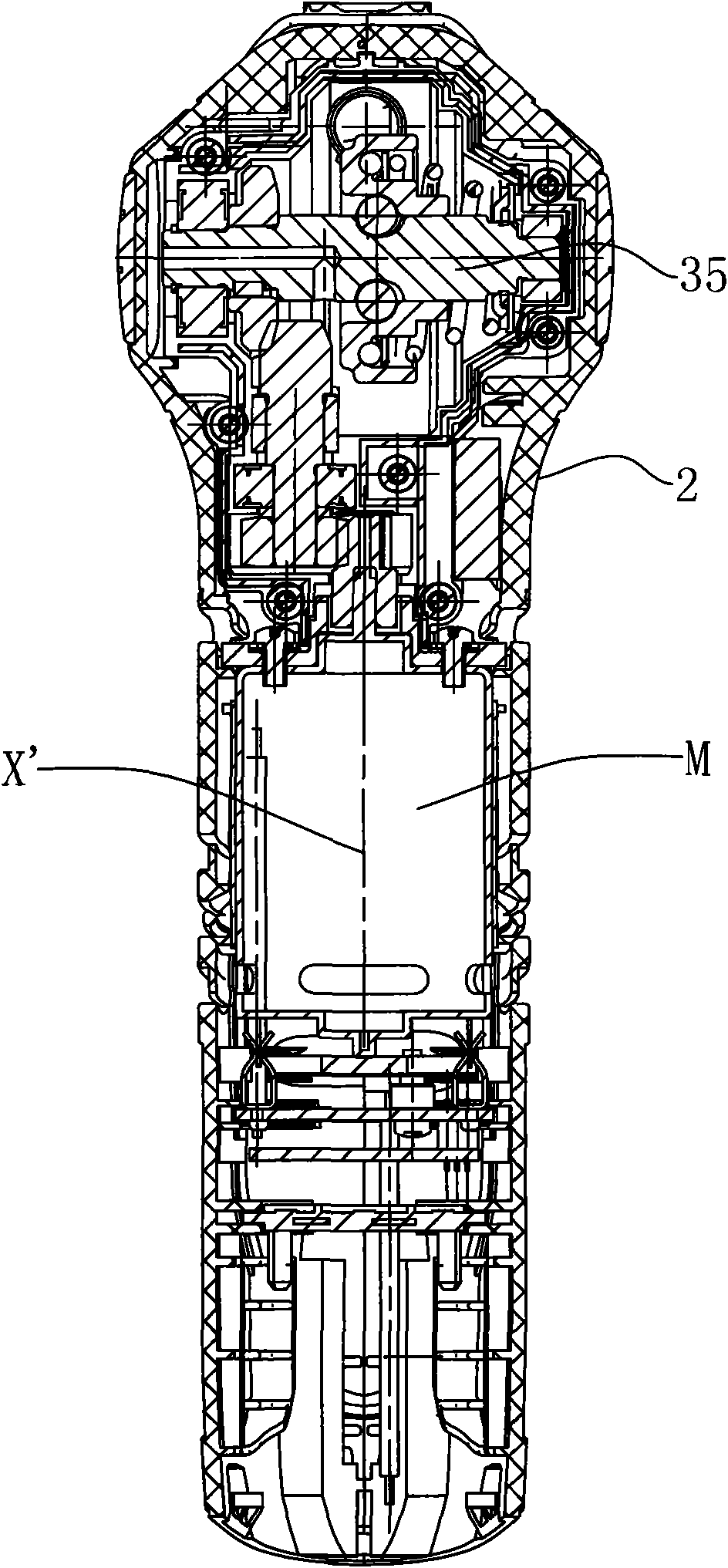

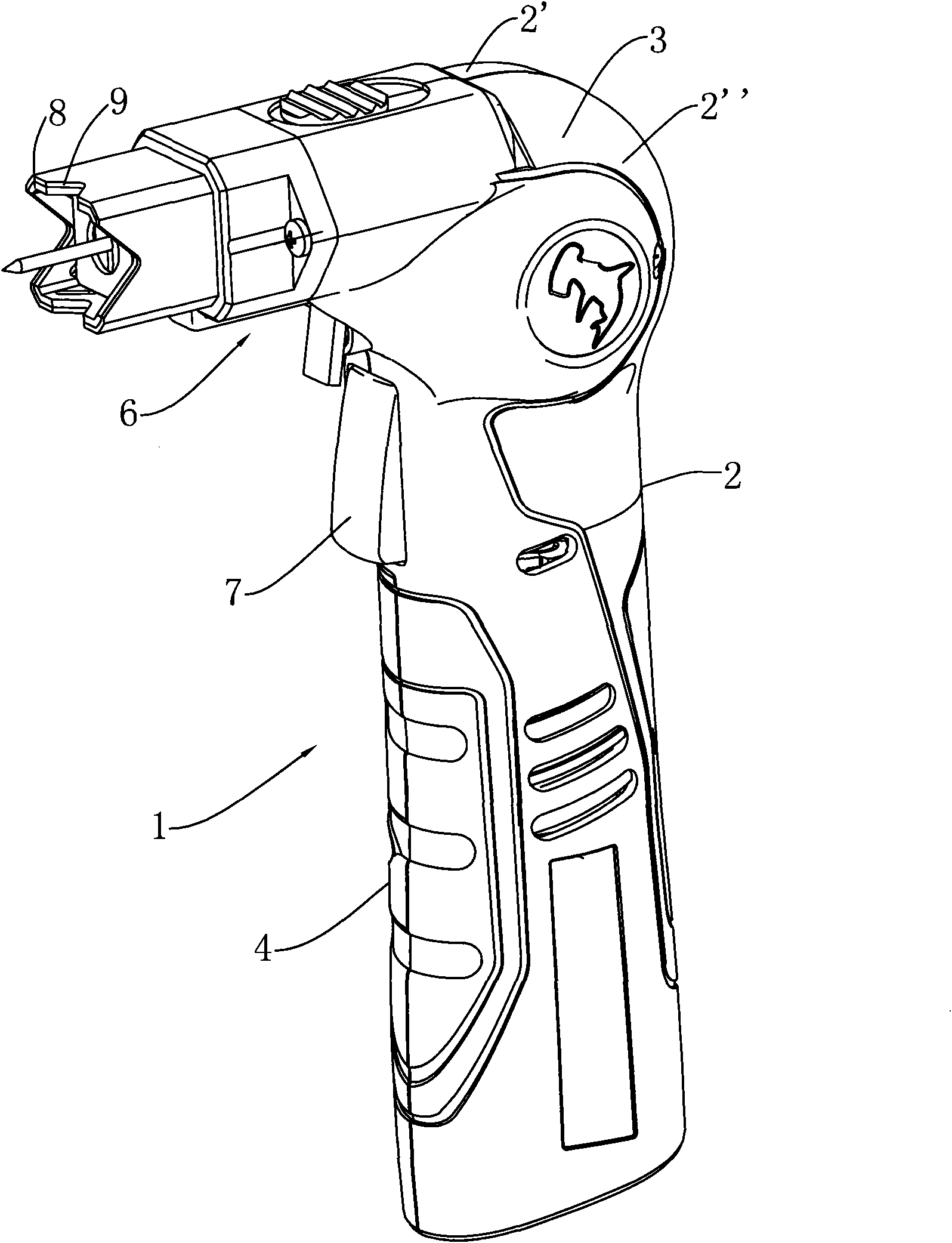

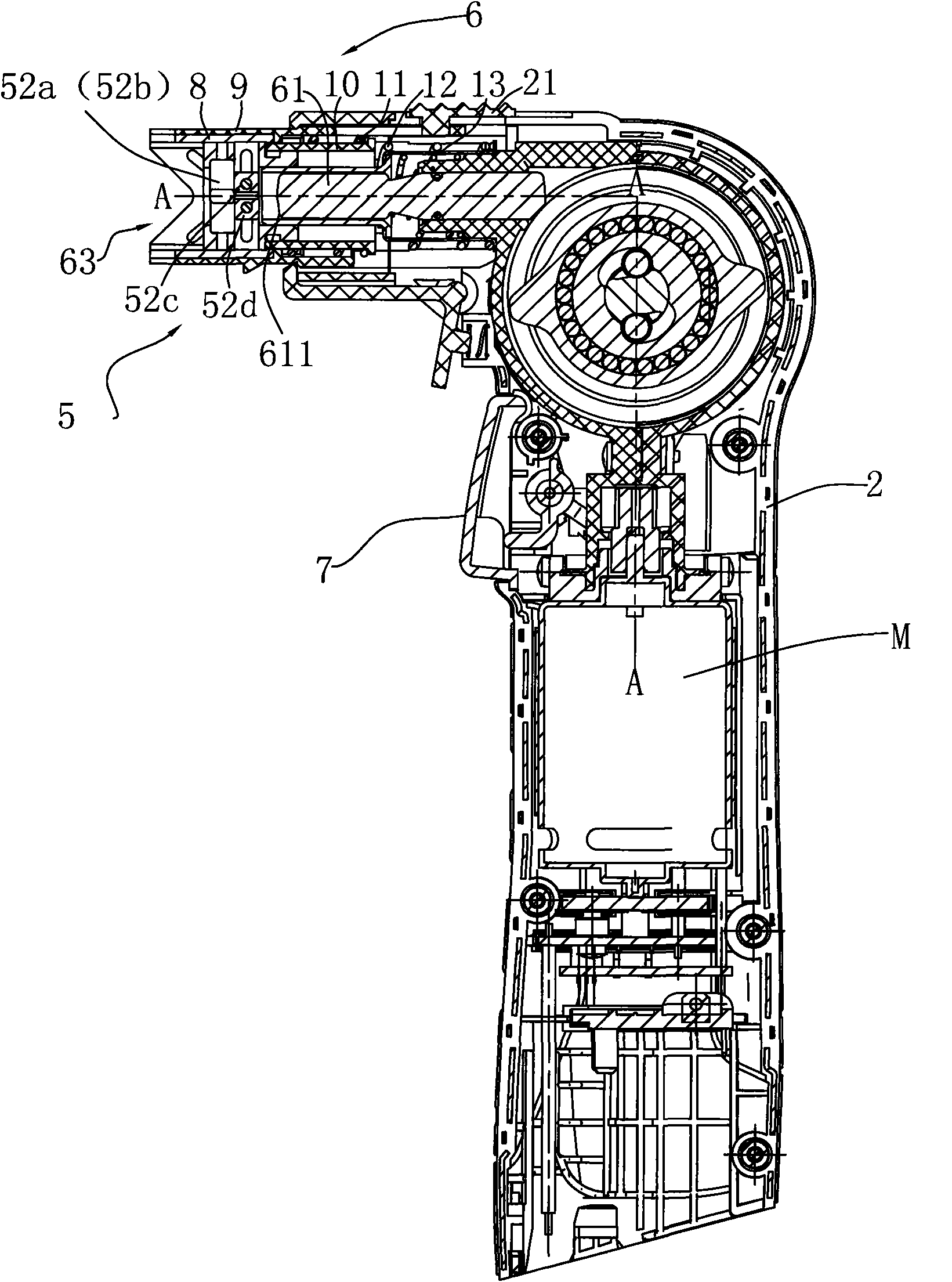

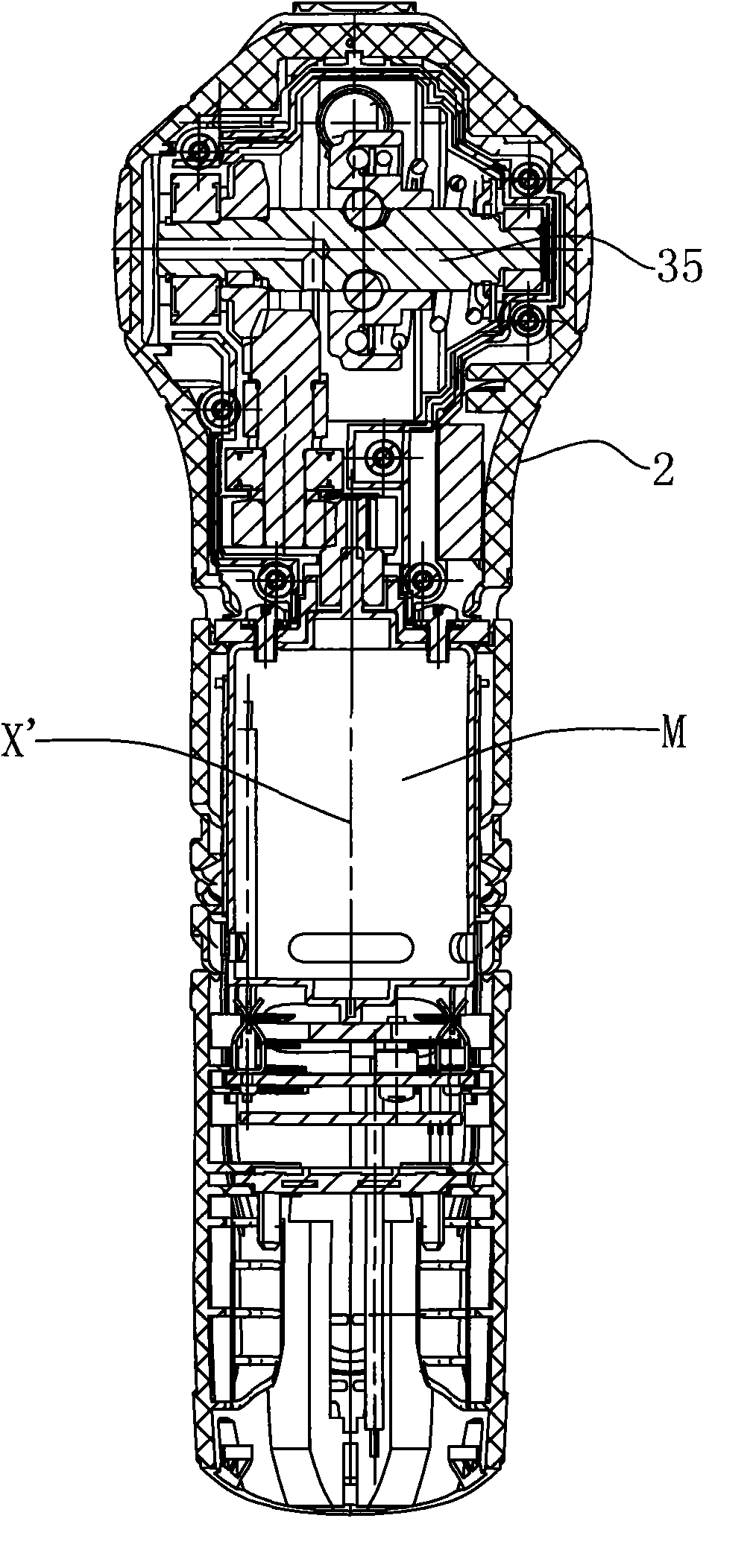

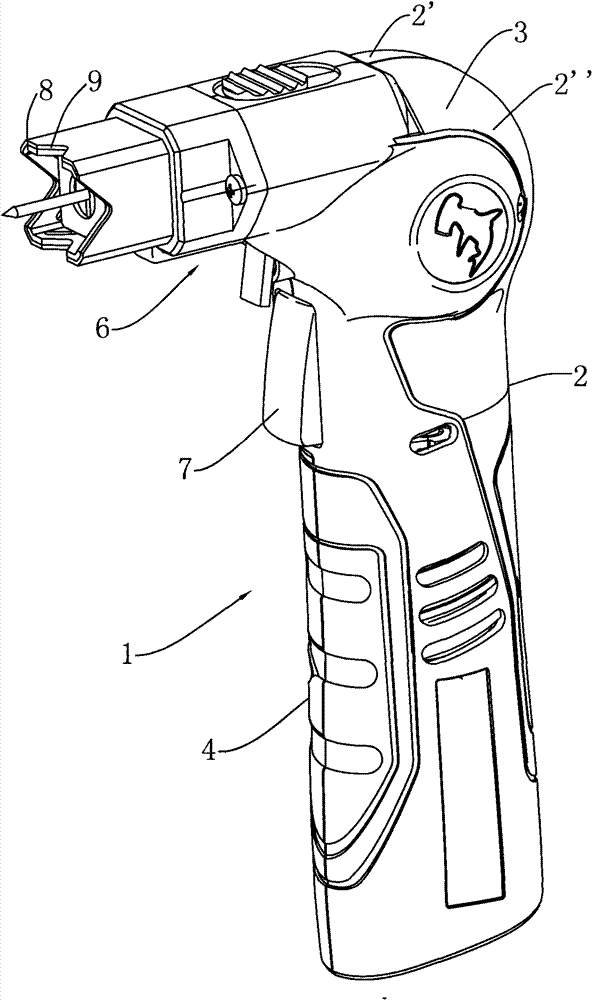

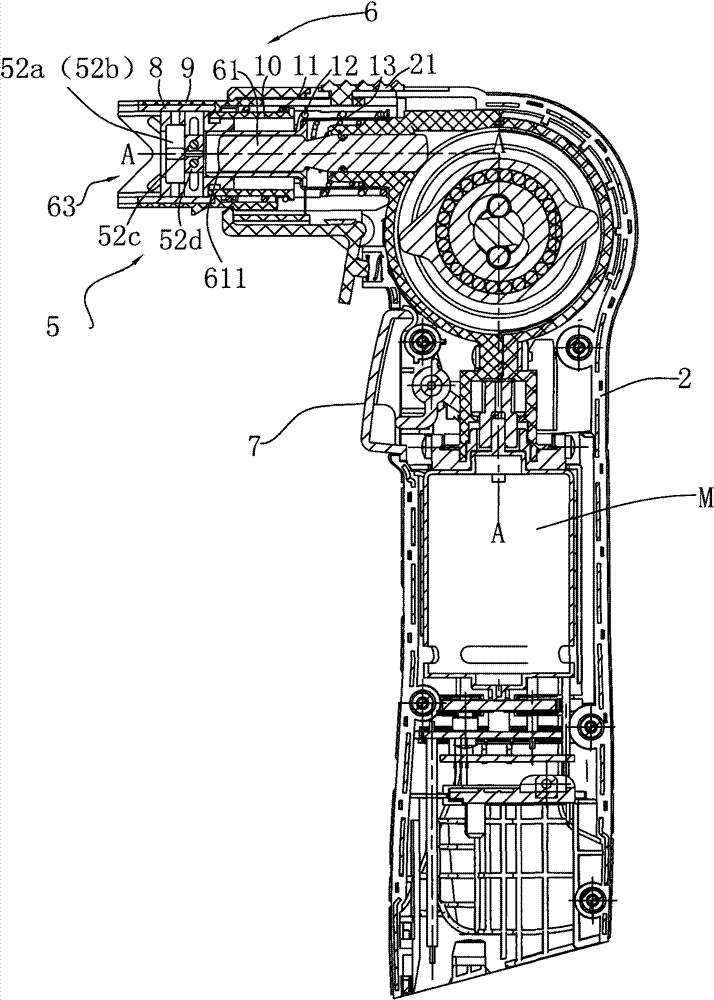

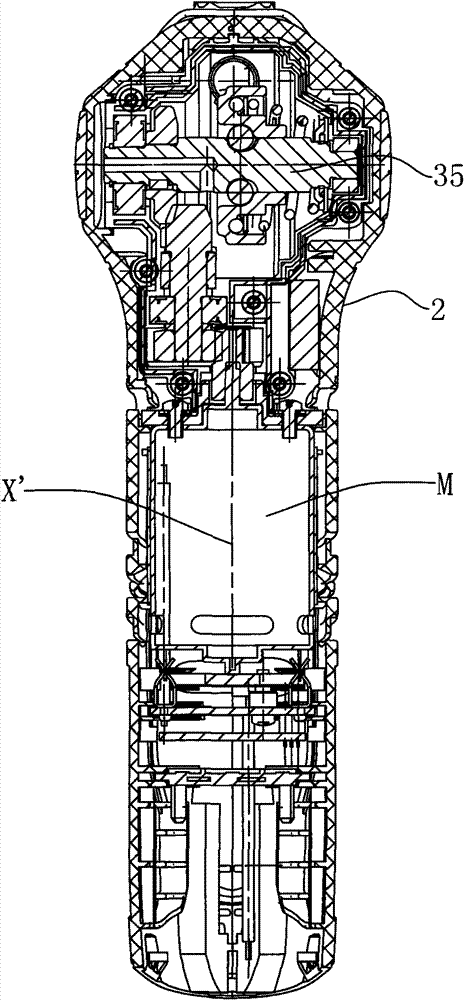

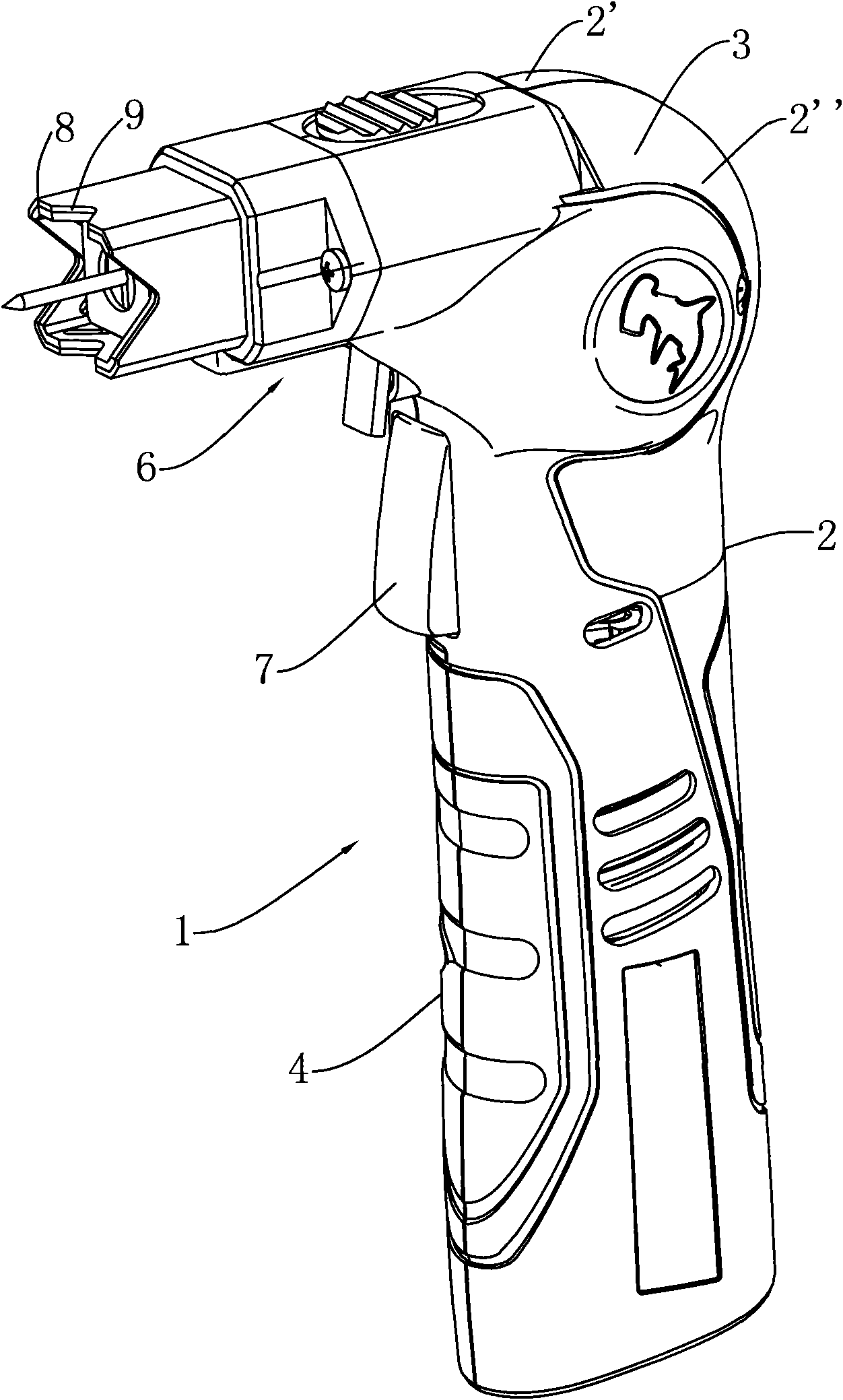

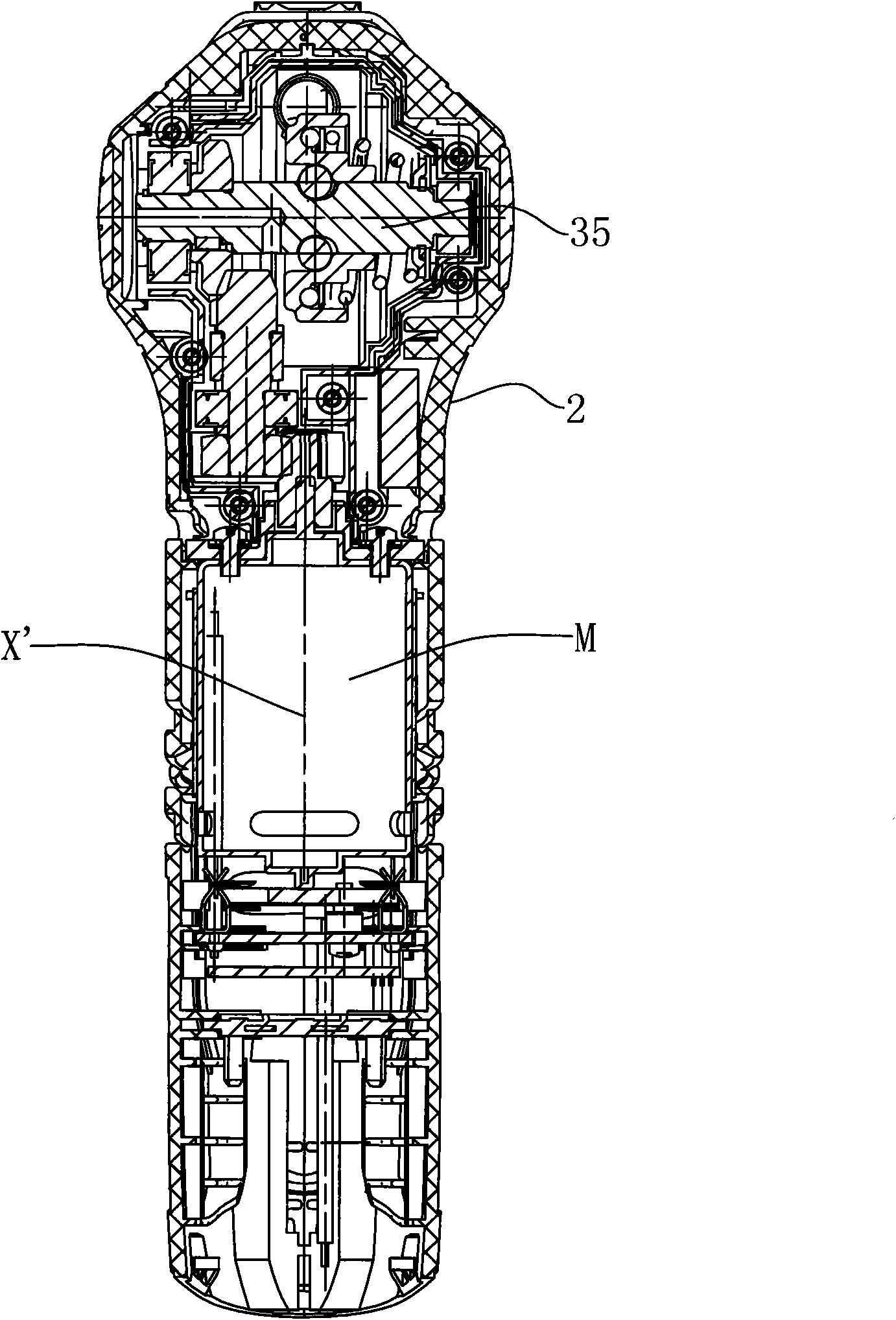

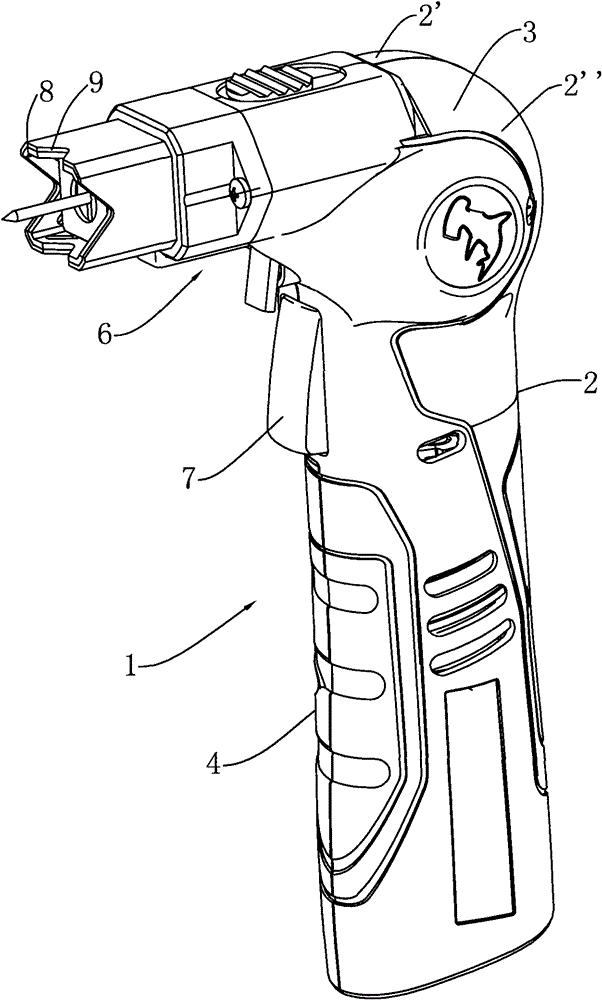

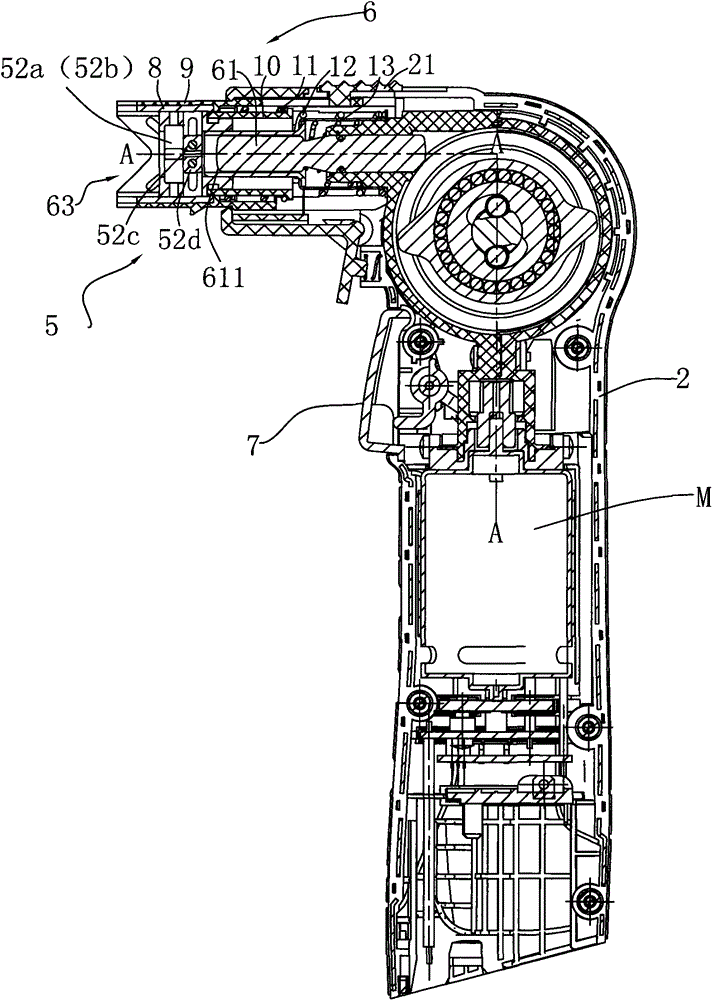

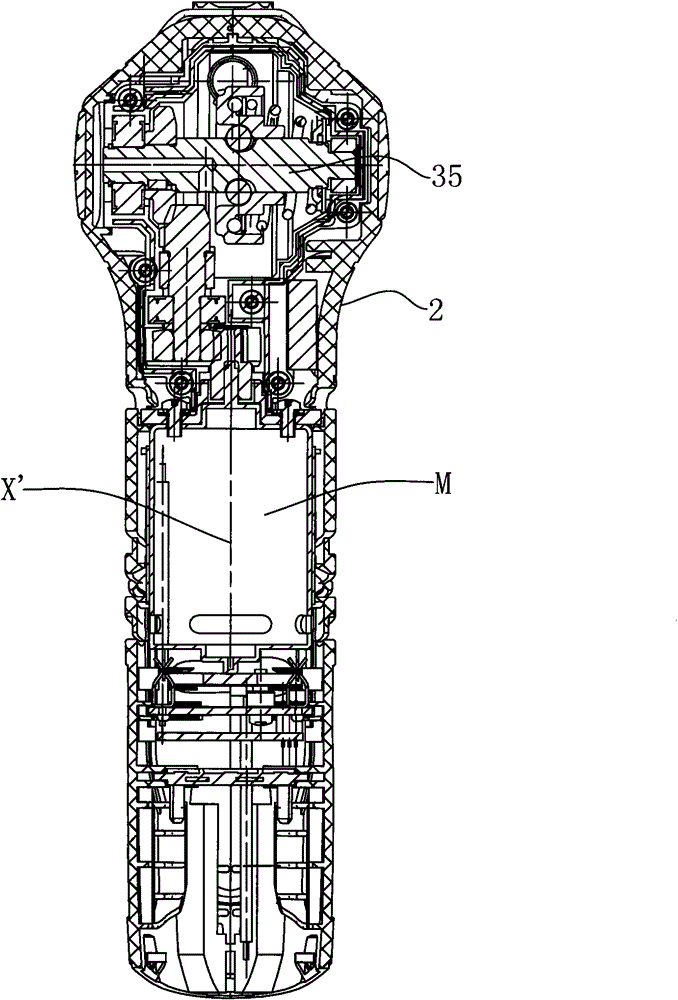

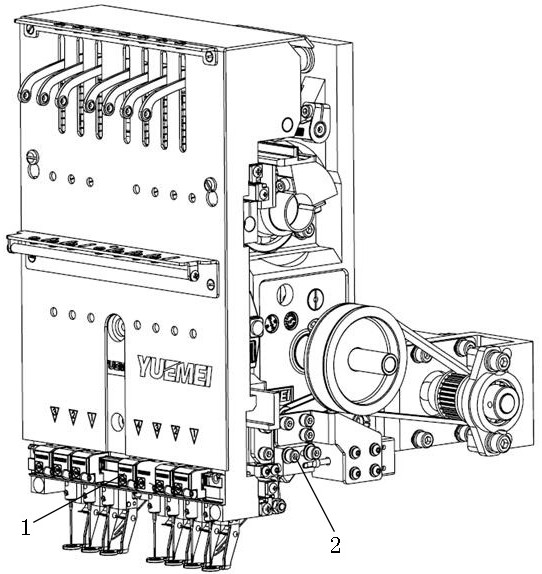

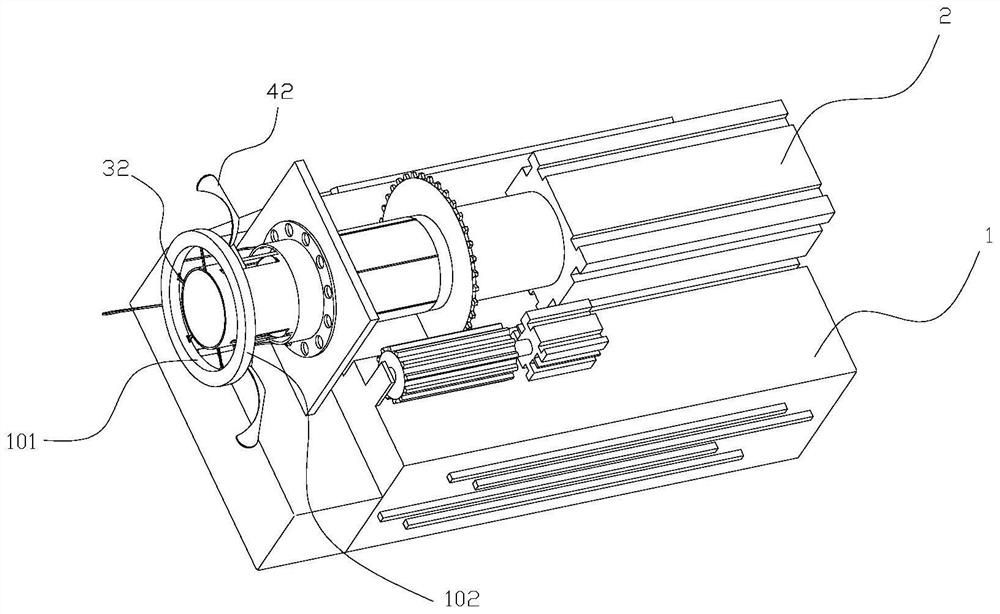

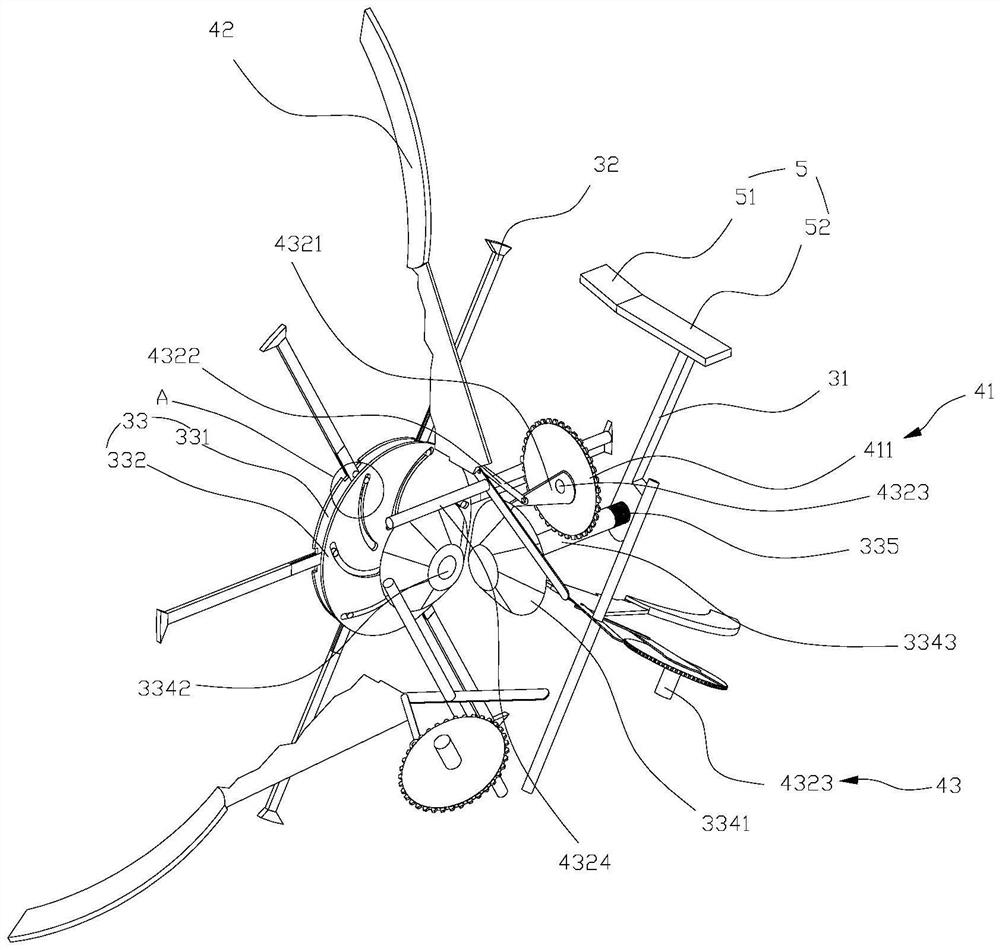

Electric hammer

InactiveCN102069478AShorten the sliding strokeCompact structurePortable percussive toolsGear driveDevice form

The invention relates to an electric hammer which comprises a shell, a motor, a transmission mechanism, an impacting assembly, a striking piece and a clamping mechanism, wherein the motor is vertically arranged in the shell; the transmission mechanism is used for converting rotary motions of the motor into impacting motions to the striking piece through bevel gear transmission and the impacting assembly; the impacting assembly comprises an impacting block in contact with an impacted part of the striking piece; the clamping mechanism comprises a sleeve, clamping pieces and an offsetting device; and the sleeve is used for driving the clamping piece to move between an opening position and a closing position. The electric hammer also comprises a holding part and a striking device formed by forwards protruding, wherein the striking device comprises a striking piece capable of linearly striking on a nail or other elements back and forth; and the striking device also comprises a clamping mechanism used for clamping the nail and other elements. The electric hammer has the advantages of compact structure and convenient operation and can be used for better clamping nails or other elements so as to prevent the nails or other elements from being deflected.

Owner:NANJING CHERVON IND

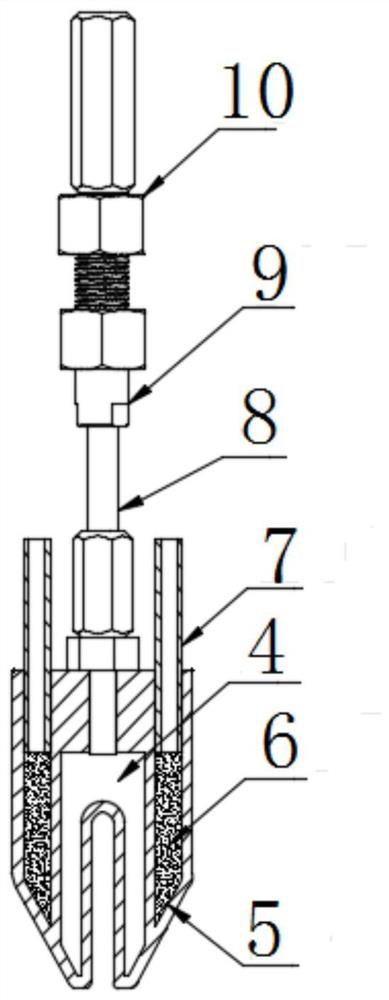

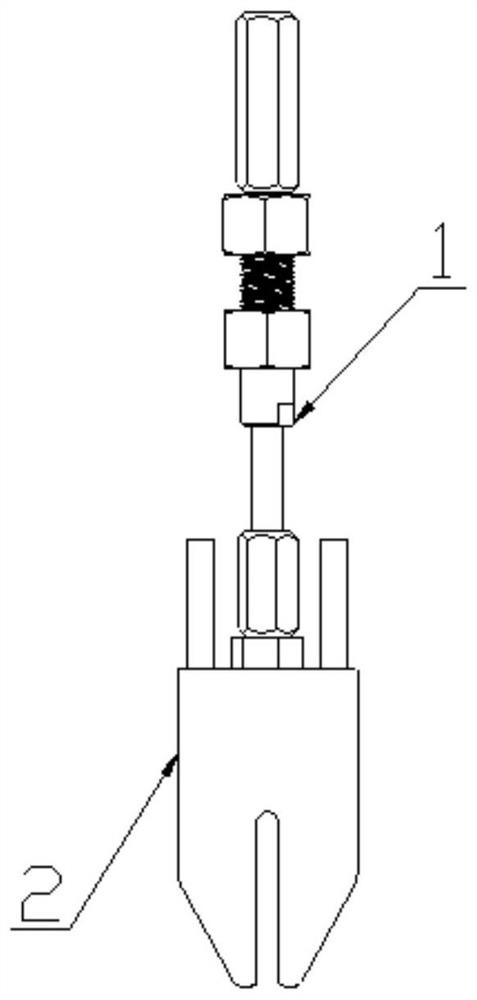

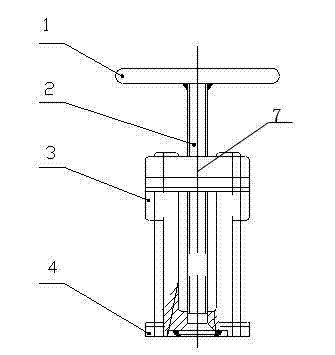

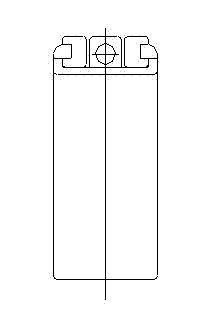

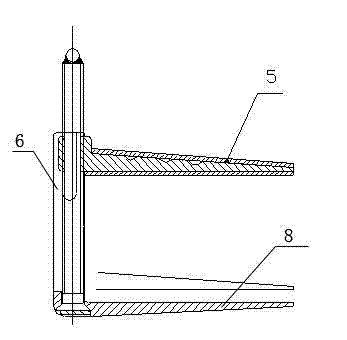

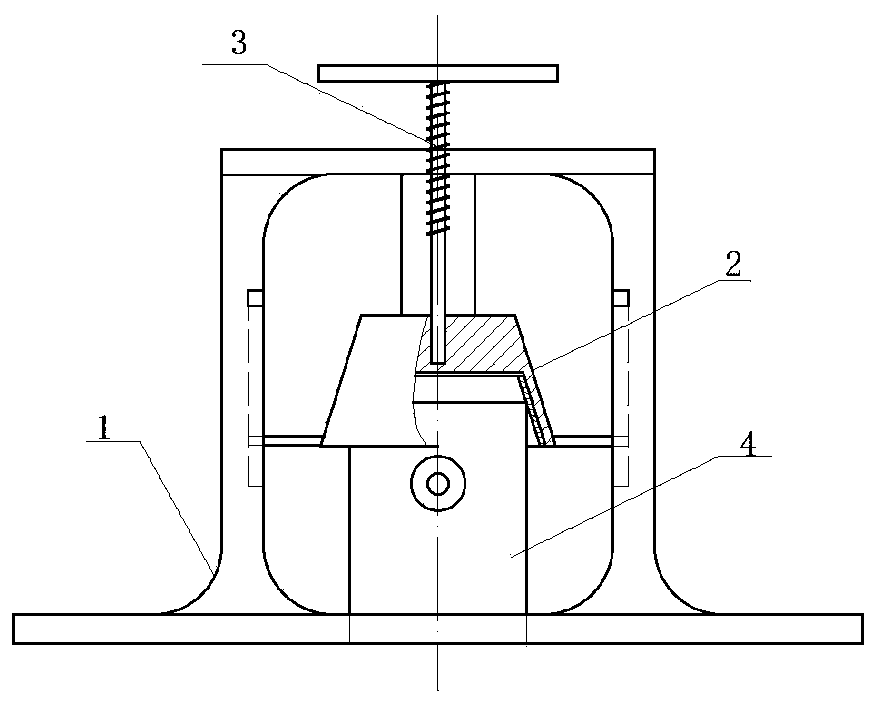

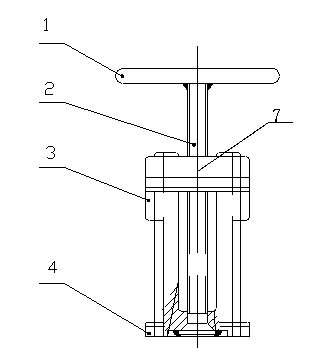

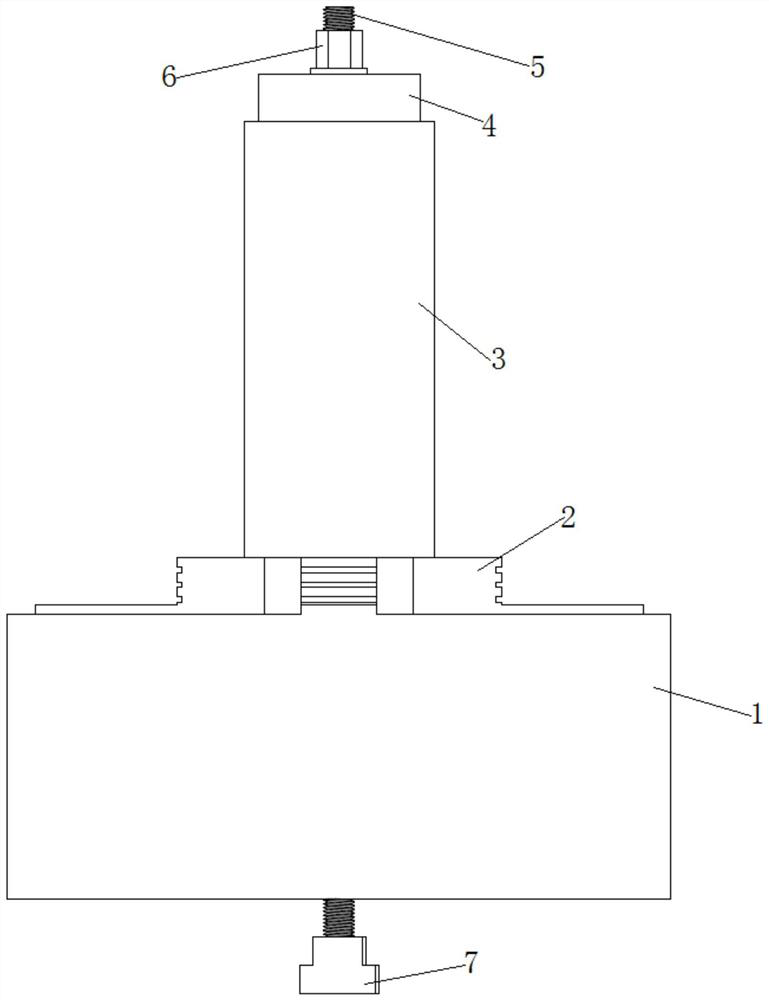

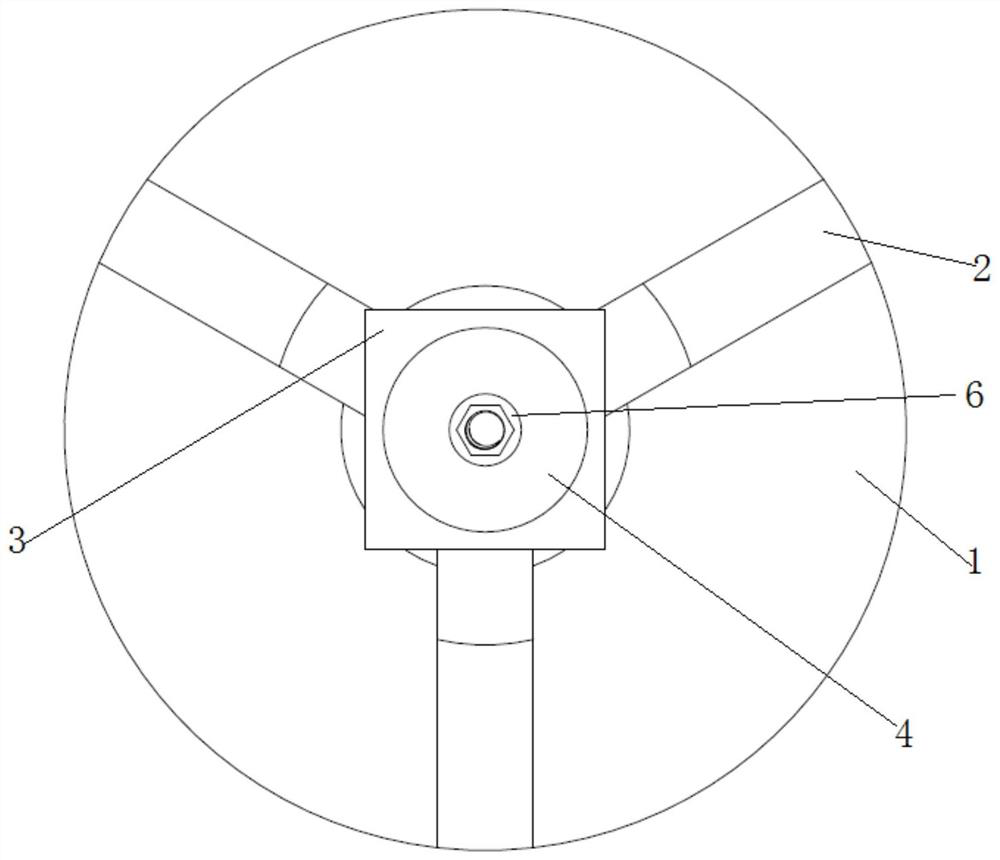

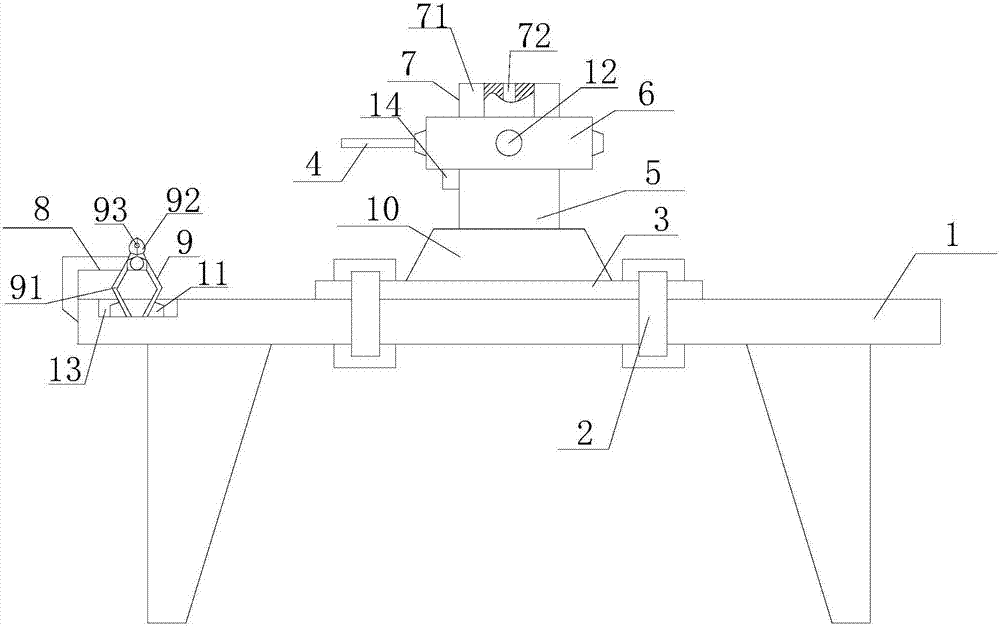

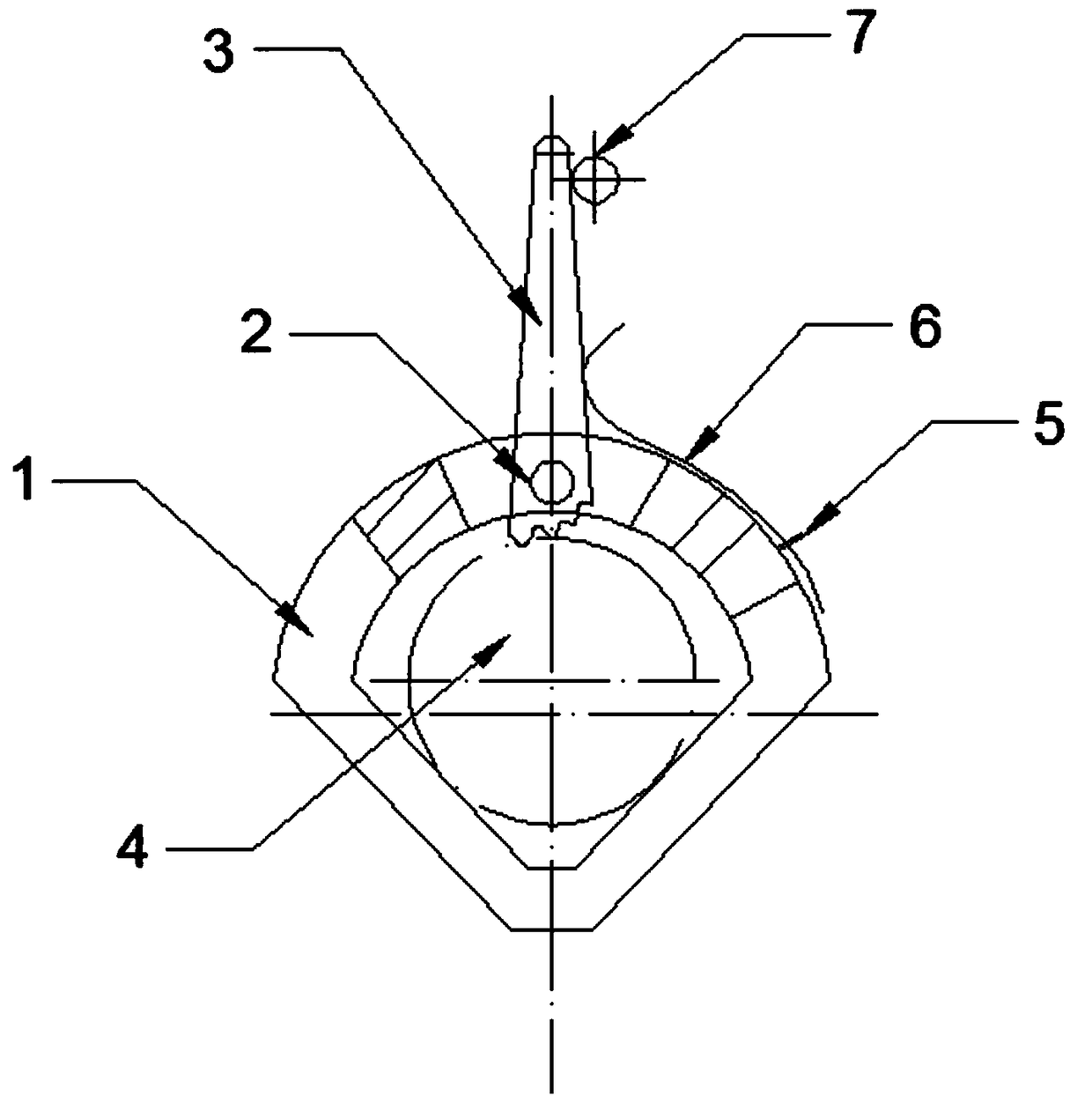

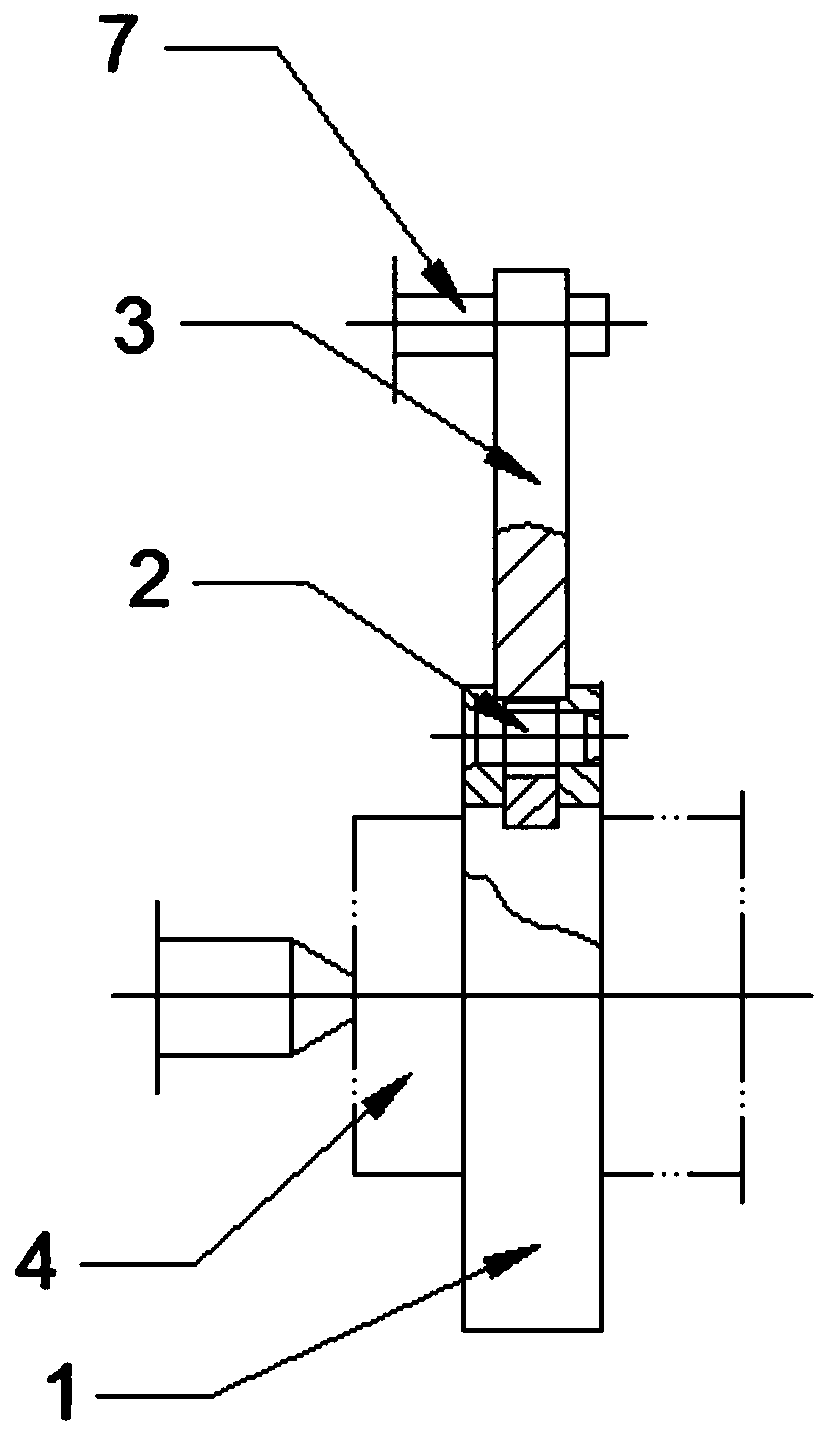

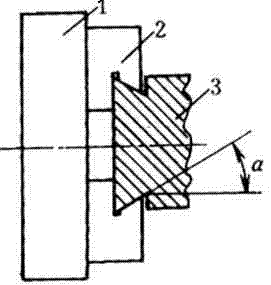

Cake type coil fixture

InactiveCN102496452AEliminate the phenomenon of easy falling off and lossSmooth slidingCoils manufactureManufacturing technologyProcess equipment

The invention relates to a cake type coil fixture and particularly relates to process equipment for winding a transformer coil, belonging to the technical field of winding and manufacturing of transformer coils. The invention adopts the technical scheme that the cake type coil fixture comprises a handle (1), a screw rod (2), a sliding clamping plate (3), a basic body (4) and a thermoplastic rubber sleeve (5), wherein the handle is connected with the screw rod; the screw rod is arranged in the basic body; a rail groove (6) parallel to the screw rod is arranged in the lateral surface of the basic body; a screw rod nut (7) in the basic body is connected with the sliding clamping plate; the sliding clamping plate is perpendicular to the screw rod and extends out of the rail groove; a substrate (8) is arranged at the bottom of the basic body and is perpendicular to the basic body; a plane of the substrate is parallel to a clamping surface of the sliding clamping plate; and the thermoplastic rubber sleeve is arranged on the sliding clamping plate. According to the cake type coil fixture disclosed by the invention, the protection for an insulating layer of a lead is facilitated; the coilis enabled to become attractive; the phenomenon that a rivet or a screw is easy to fall off during use is completely eliminated; and quality problems and potential safety hazards generated by fallingof scrap iron are eliminated. The cake type coil fixture disclosed by the invention has the advantages of long service life, low manufacturing cost and stable and reliable clamping force.

Owner:BAODING TIANWEI GRP CO LTD

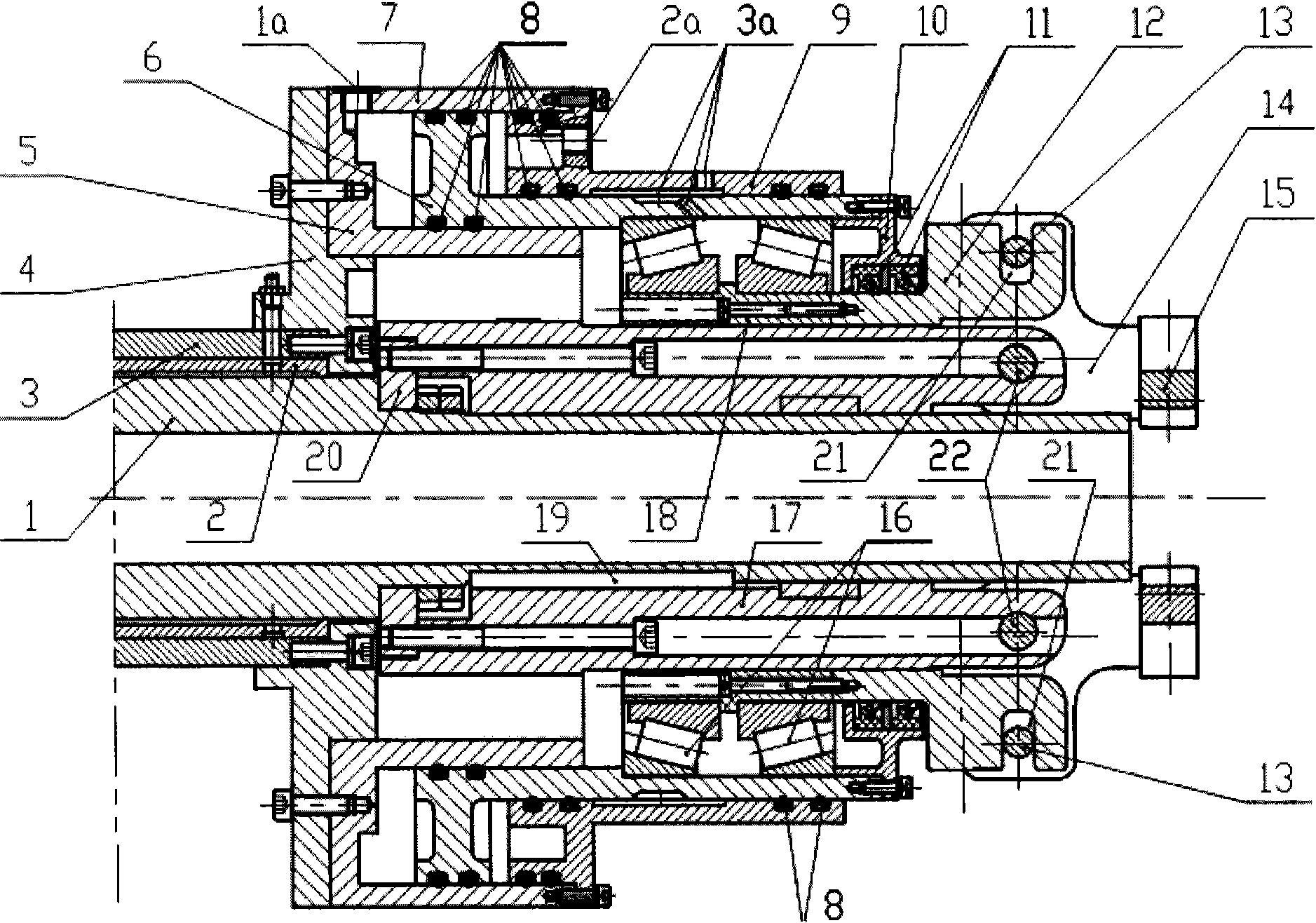

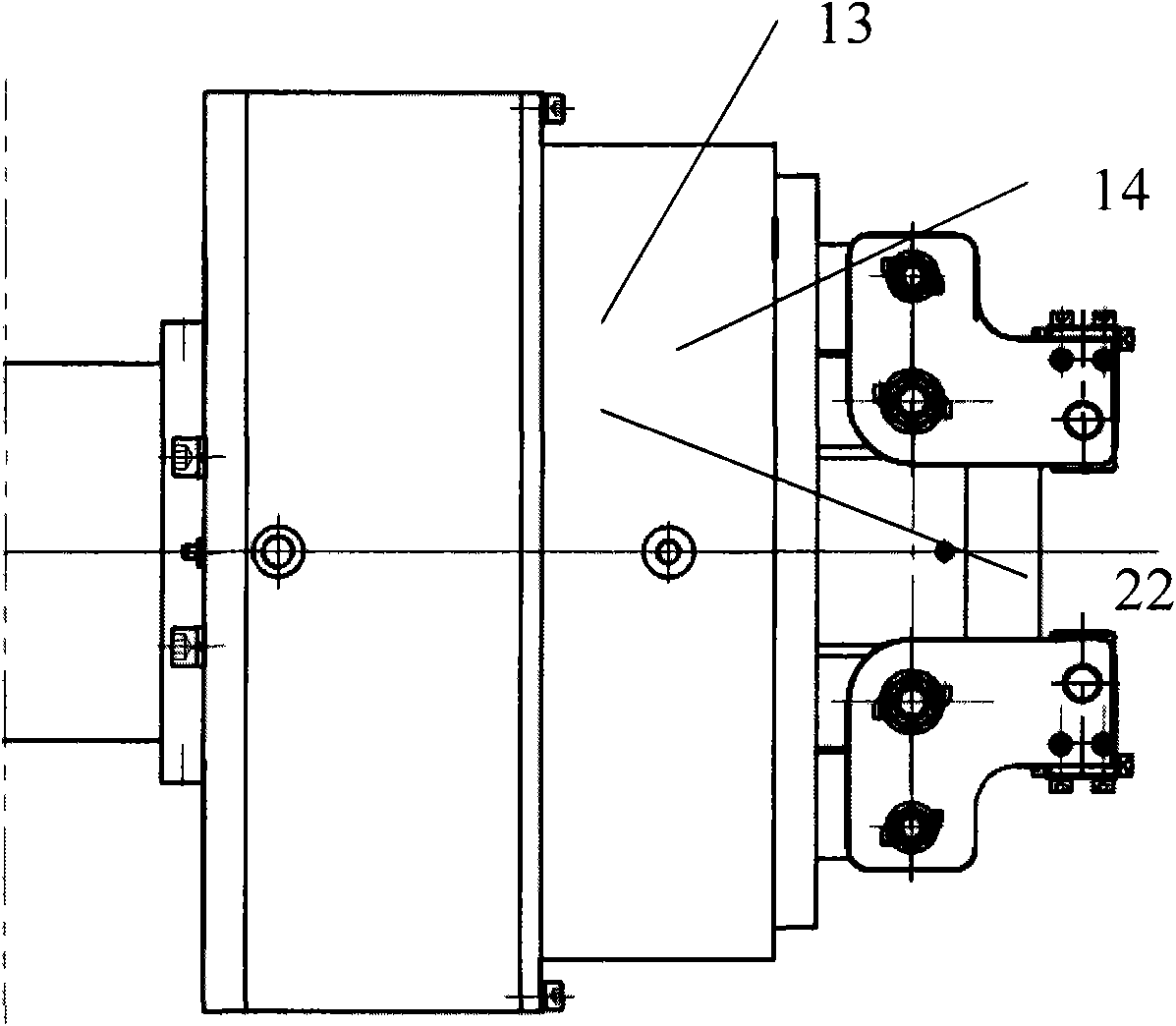

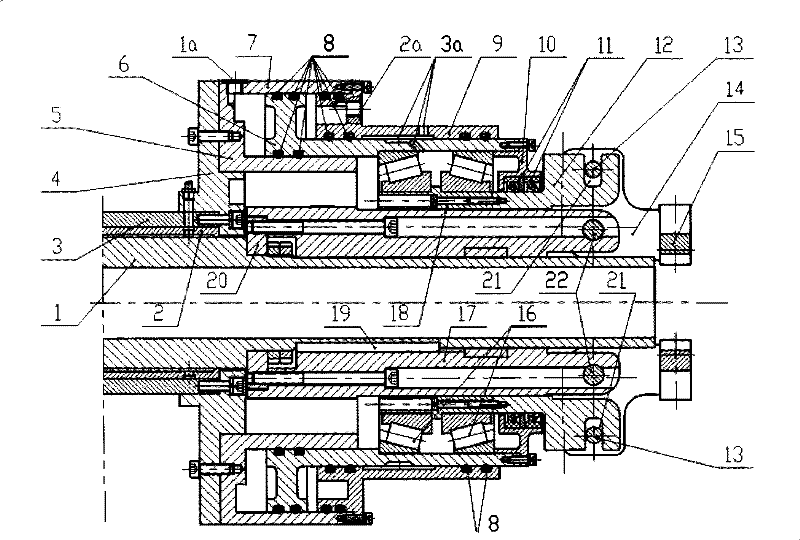

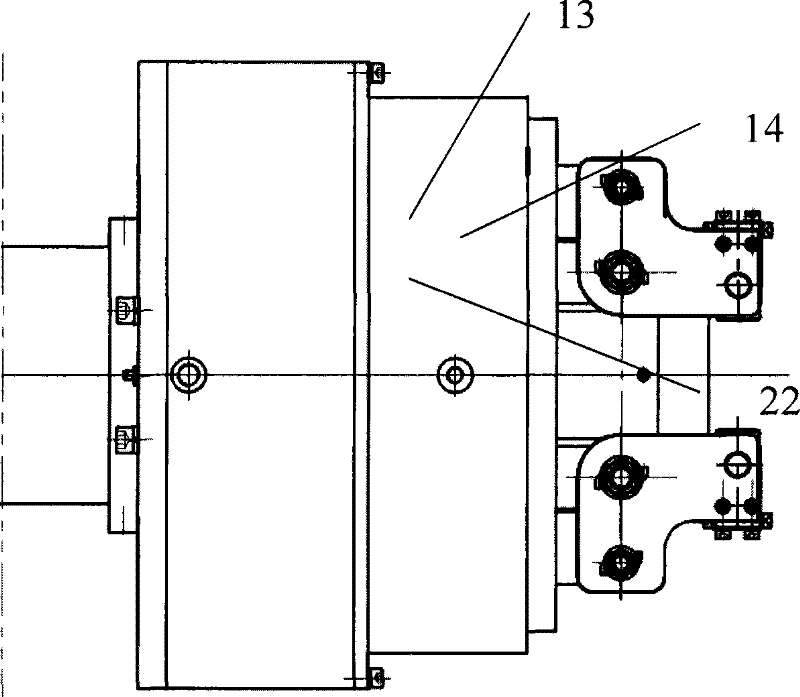

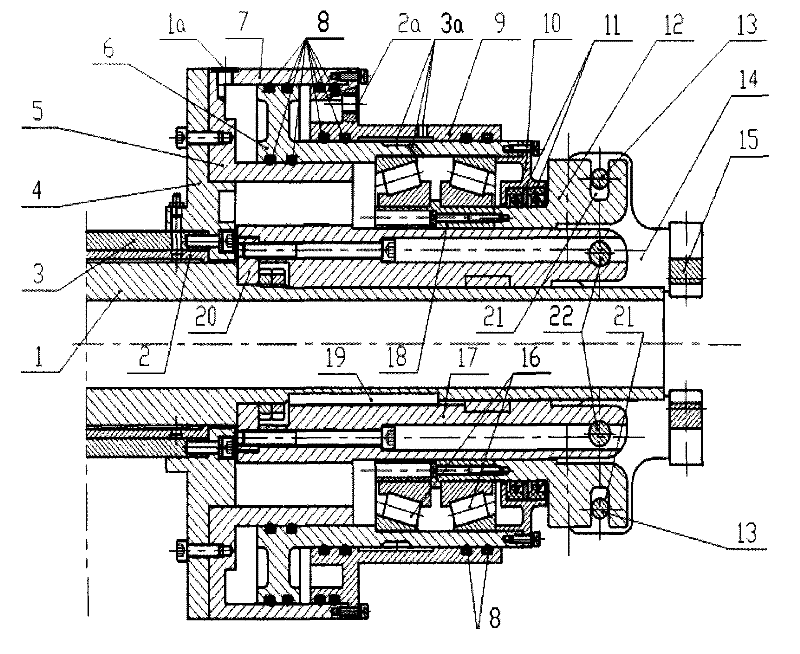

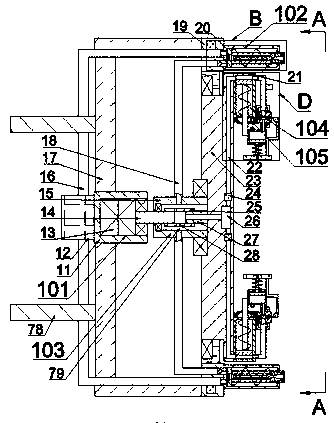

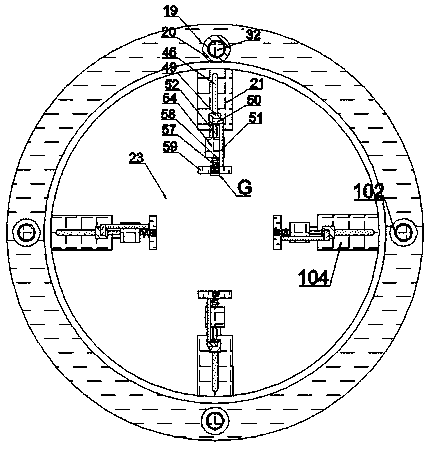

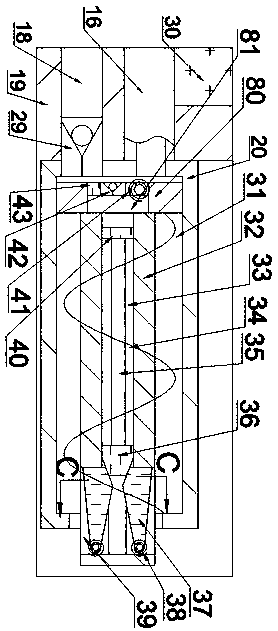

Holding device

InactiveCN101560590AGuaranteed working lifeEffectively withstand axial forcesFurnace typesHeat treatment furnacesDual actionMechanical engineering

The invention relates to a holding device, in particular to the holding device used for holding a long pipe type workpiece in quenching process. The device comprises a hollow main shaft, a supporting sleeve, a dual-action cylinder, a sliding sleeve, a crank plate and a holding claw, wherein the hollow main shaft can rotatably support; the supporting sleeve is coaxially sleeved on the hollow main shaft and axially and fixedly connected with the main shaft; the dual-action cylinder can rotatably support relative to the supporting sleeve; the inner surface of the sliding sleeve can be glidingly supported on the surface of an outer circumference of the supporting sleeve; the crank plate is hinged with the end parts of the supporting sleeve and the sliding sleeve respectively; and the holding claw is fixedly connected with the crank plate.

Owner:北京宜飞航空科技有限公司

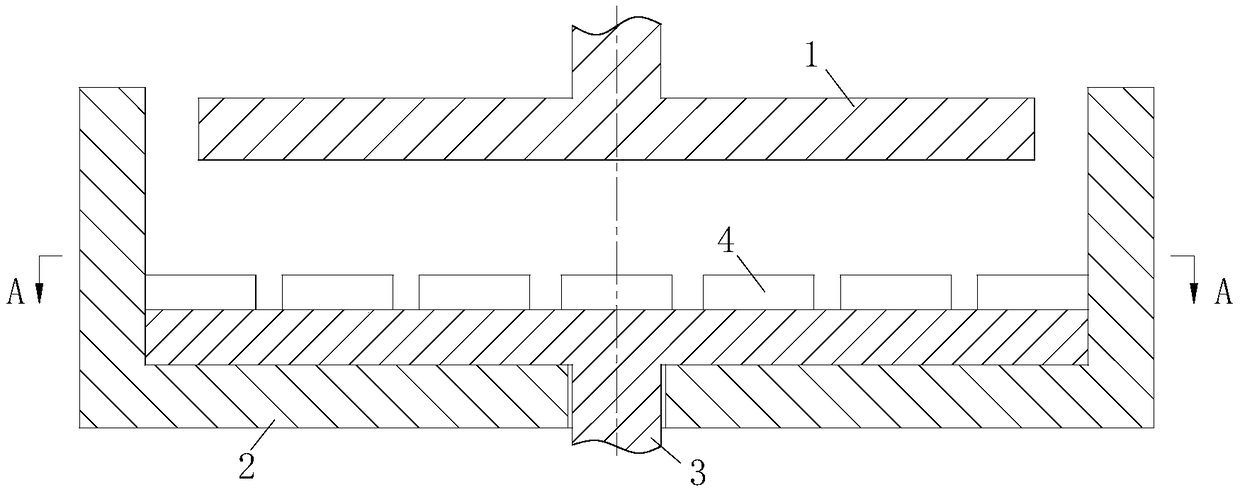

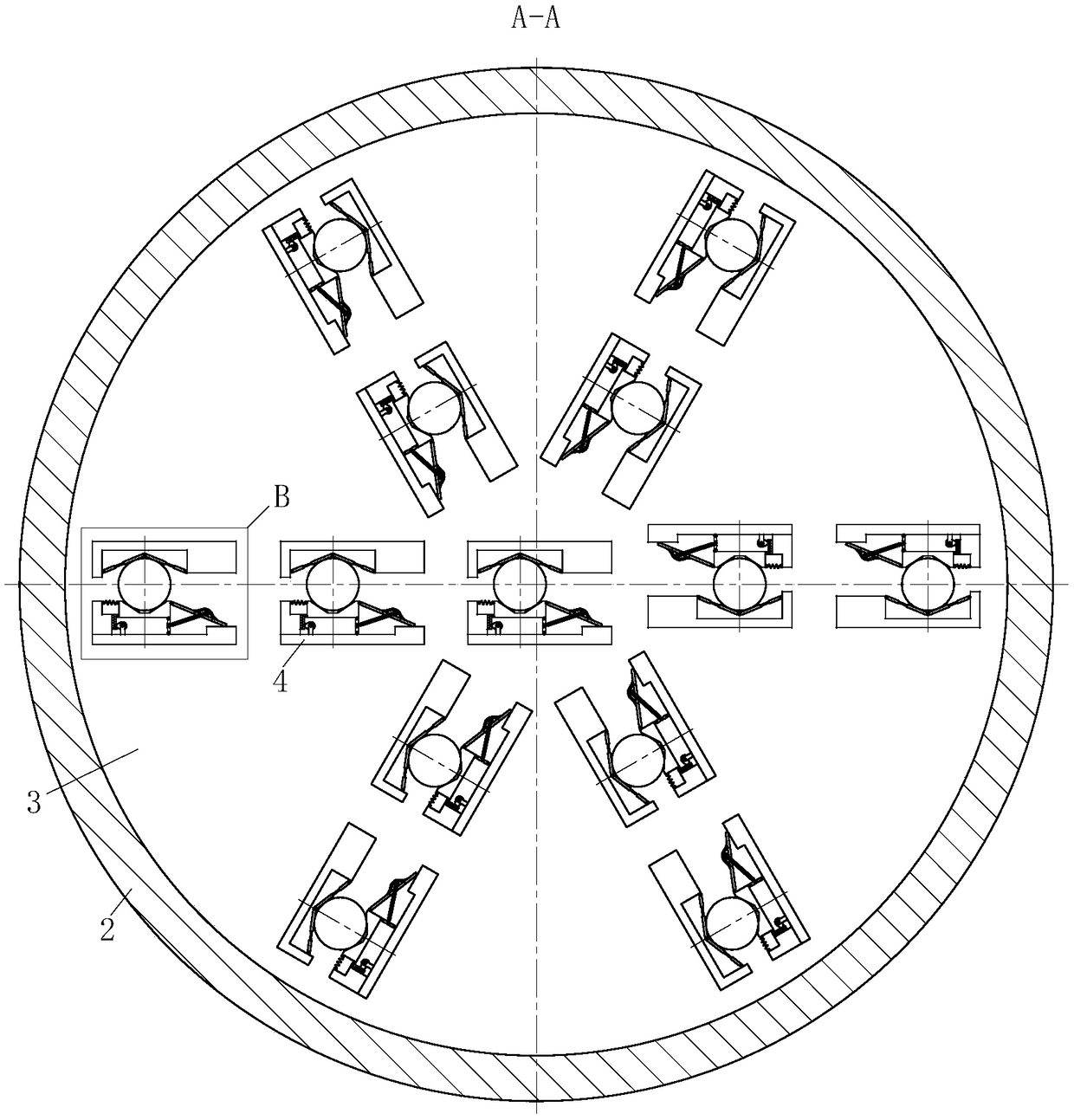

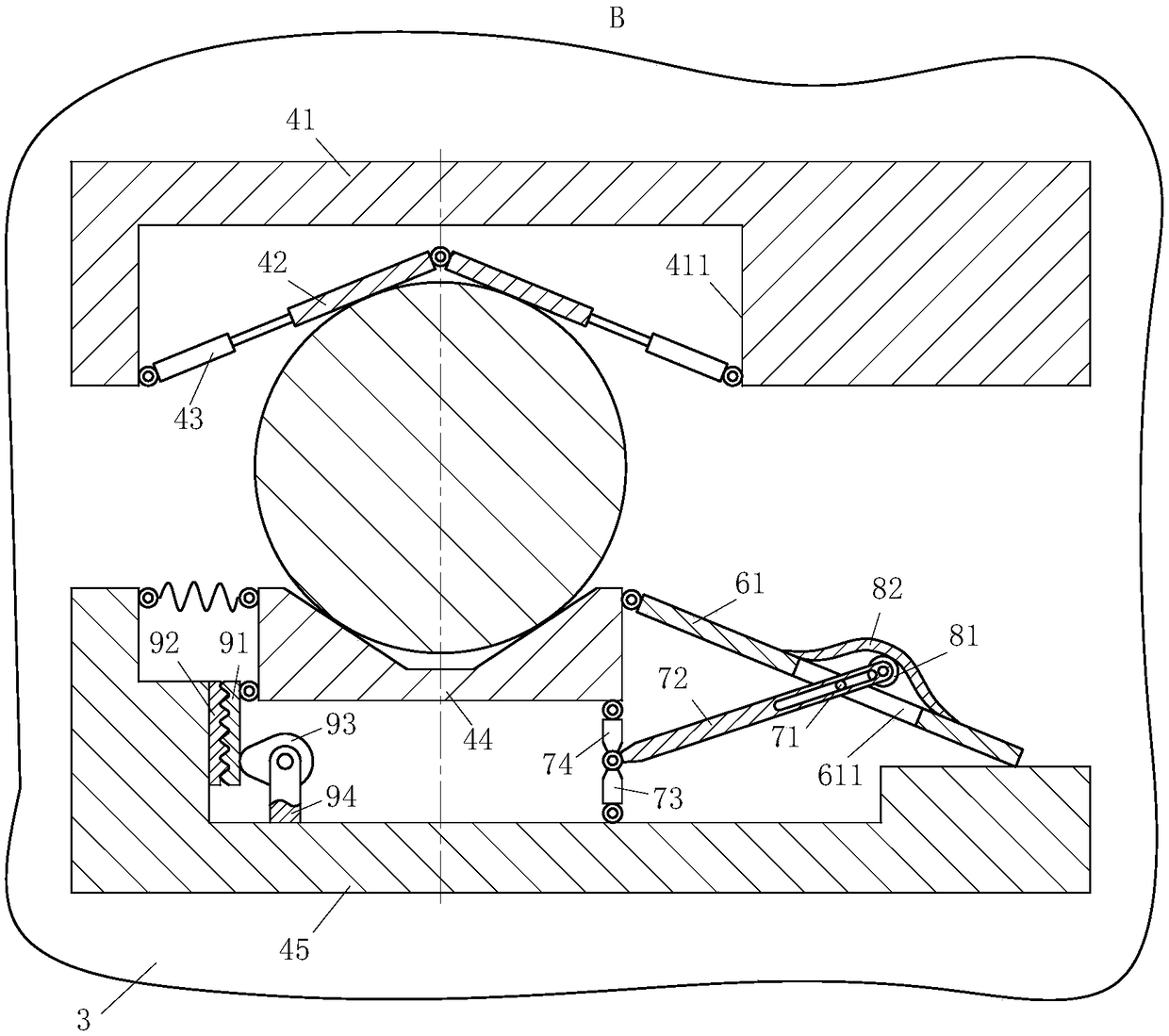

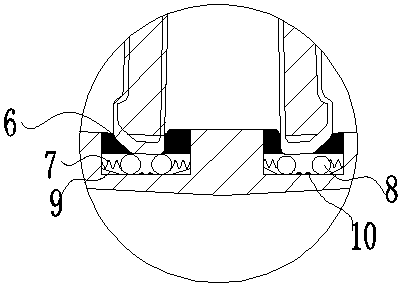

Semiconductor wafer grinding equipment

ActiveCN108838870AEasy accessAchieve lockingLapping machinesWork carriersElastic compressionAir spring

The invention belongs to the technical field of semiconductor manufacturing, and specifically discloses semiconductor wafer grinding equipment. The semiconductor wafer grinding equipment comprises a grinding sheet, a grinding frame, a grinding disc and a clamping device, wherein the clamping device comprises a fixing block, hinge baffles, first air springs, a clamping block and a connection block,and a first rectangular groove is formed in one side of the fixing block; one end of each first air spring is hinged to the opening of the first rectangular groove; the other end of each first air spring is fixedly connected with one end of the corresponding hinge baffle; the other end of one hinge baffle and the other end of the other hinge baffle are mutually hinged; and the clamping block andthe hinge baffles are oppositely arranged, the bottom of one end of the clamping block is hinged to a shoulder at one end of the connection block, and the top of one end of the clamping block is connected with the top of one end of the connection block through a spring. According to the semiconductor wafer grinding equipment, a second air spring is arranged below an elastic compression sheet, thesecond air spring compresses an elastic swing sheet, and clamping for a wafer is realized through the co-action of the second air spring and the spring; and moreover, a soft and reliable clamping force is achieved.

Owner:NANTONG RUISEN OPTICAL CO LTD

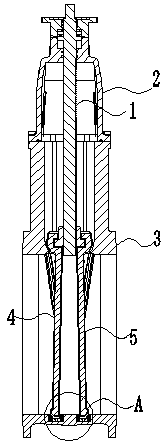

Power hammer

InactiveCN102069476AShorten the sliding strokeCompact structurePortable percussive toolsEngineeringMechanical engineering

The invention relates to a power hammer which comprises a beating device, wherein the beating device comprises a beating piece and a clamping mechanism; the beating piece is used for beating components; the clamping mechanism comprises a clamping piece, a sleeve, a lining and a bias device; the sleeve is provided with a slot; the clamping piece slides in the slot; a first position, which is opposite to the slot, on the clamping piece is closed; a second position, which is opposite to the slot, on the clamping piece is opened; and the bias device is used for biasing the lining towards the beating components of the beating piece. The lining is arranged on the periphery of the beating piece and when nails or other components are beaten, the lining is still maintained at the ends of the nail caps or the other components so as to prevent the nails or the other components from being clamped in the power hammer, especially in a gap generated after the clamping piece is opened. The power hammer provided by the invention is compact in structure and convenient in operation, can better clamp the nails or the other components so as to prevent the nails or the other components from being beaten obliquely.

Owner:NANJING CHERVON IND

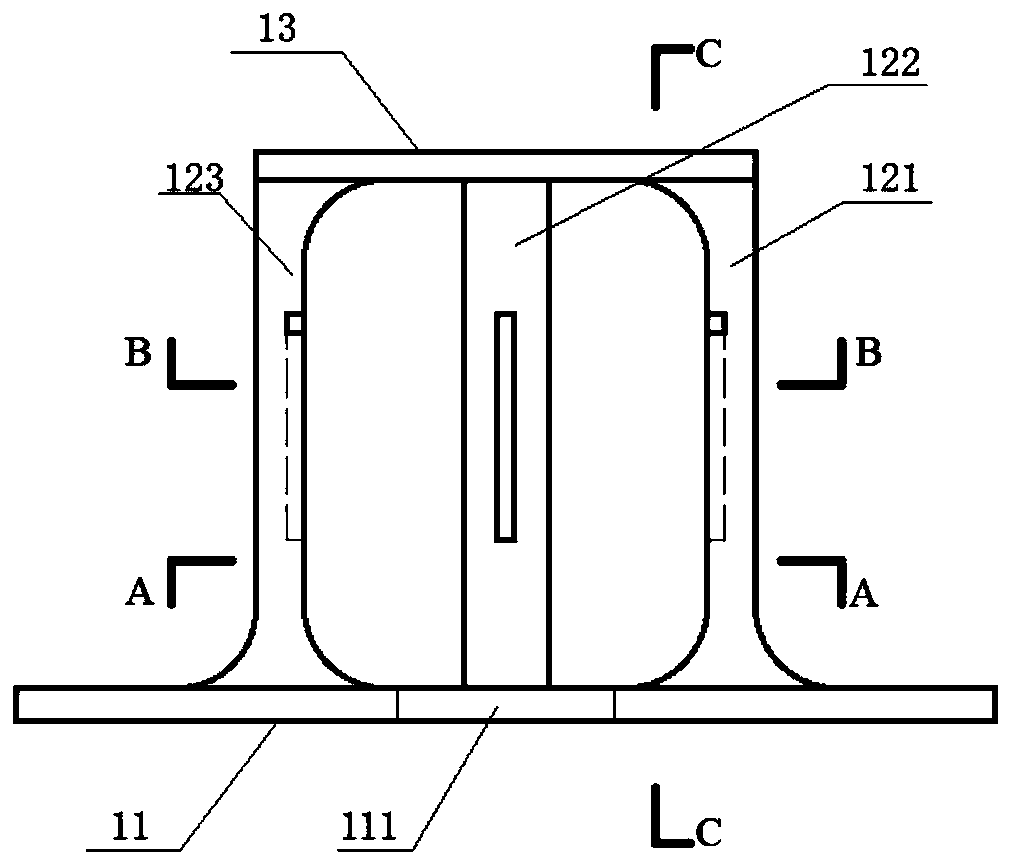

Acoustic emission sensor fixing device and using method thereof

PendingCN111060604AStable and reliable clamping forceAvoid affecting the test effectMaterial analysis using acoustic emission techniquesStrength propertiesAcoustic emissionEngineering

The invention discloses an acoustic emission sensor fixing device and a using method thereof. The device comprises a base frame, a gland and an adjusting bolt, wherein the adjusting bolt is connectedwith the gland, a mounting hole is formed in the base frame, the gland is in a hollow circular truncated cone shape, the adjusting bolt applies force to the gland, the acoustic emission sensor is tightly attached to the surface of a concrete structure, and the gland can limit the circumferential position of the acoustic emission sensor. The using method of the device comprises the following steps:(S1) the base frame is bonded to the surface of a concrete structure; (S2) the gland is pushed into the base frame; (S3) the acoustic emission sensor is placed in the mounting hole and the gland is pressed on the acoustic emission sensor; (S4) a force is applied to the gland by using the adjusting bolt; and (S5) the device and the sensor are recovered according to a process with an opposite installation sequence after the signal acquisition is finished. The device can provide stable circumferential clamping force for the acoustic emission sensor, and is suitable for tests of various loads andactual engineering measurement scenes; and the hoop effect is prevented from being generated to influence the test effect.

Owner:HOHAI UNIV

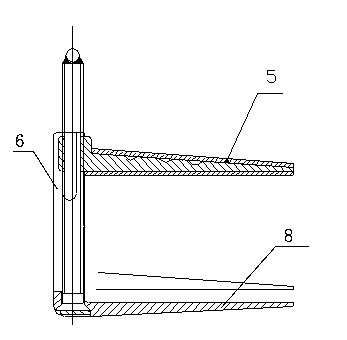

Disassembly and assembly tool for optical fiber connectors

ActiveCN105856149AImprove stabilityImprove reliabilityMetal-working hand toolsDistance detectionEngineering

The invention relates to a disassembly and assembly tool for optical fiber connectors. The disassembly and assembly tool comprises a base, at least one vertical column, a cross beam, a detector and a detection terminal; at least four adjusting bolts are arranged on the lower surface of the base, and a detection platform is arranged on the upper surface of the base; the tail end of the vertical column is perpendicularly connected to the edge position of the upper surface of the base; the tail end of the cross beam is arranged outside the vertical column in a sleeving mode and is connected to the vertical column in a sliding mode, the front end of the cross beam is hinged to the detector through a locating pin, and the cross beam comprises a rod body, a connecting ratchet wheel and an organ type protection cover; the detection terminal is installed right below the detector, is connected to the detector and comprises a test end, a fixed threaded sleeve, a ceramic locating rod and a test head, wherein the top end of the test end is connected to the detector, and the tail end of the test end is connected to the top end of the fixed threaded sleeve. According to the disassembly and assembly tool, the work efficiency and the work quality of the focal distance detection work of the optical fiber connectors can be improved effectively, the replacement efficiency of parts of detection equipment can be improved effectively, the service life of the parts of the detection equipment can be prolonged effectively, and the detection cost can be lowered.

Owner:SUZHOU JIALAN ZHIYUAN ELECTRONICS TECH CO LTD

Implantable medical device

ActiveCN113749822AReliable and stable clamping forceImprove the success rate of surgeryHeart valvesMechanical engineeringMedical device

The invention provides an implantable medical device. The implantable medical device mainly comprises a mandrel, a locking structure and a clamping structure, a main base and an auxiliary base of the locking structure can be coaxially connected through the mandrel and can be switched between a locking state and a non-locking state, when the locking structure is in the non-locking state, the locking structure can be used for adjusting the clamping distance and the clamping angle of the clamping structure, and when the locking structure is in the locking state, the clamping structure can form the shortest clamping distance and the minimum clamping angle. Therefore, the implantable medical device can provide stable and reliable clamping force, and can be suitable for clamping target tissues with different thicknesses.

Owner:SHANGHAI HUIHE MEDICAL CO LTD +1

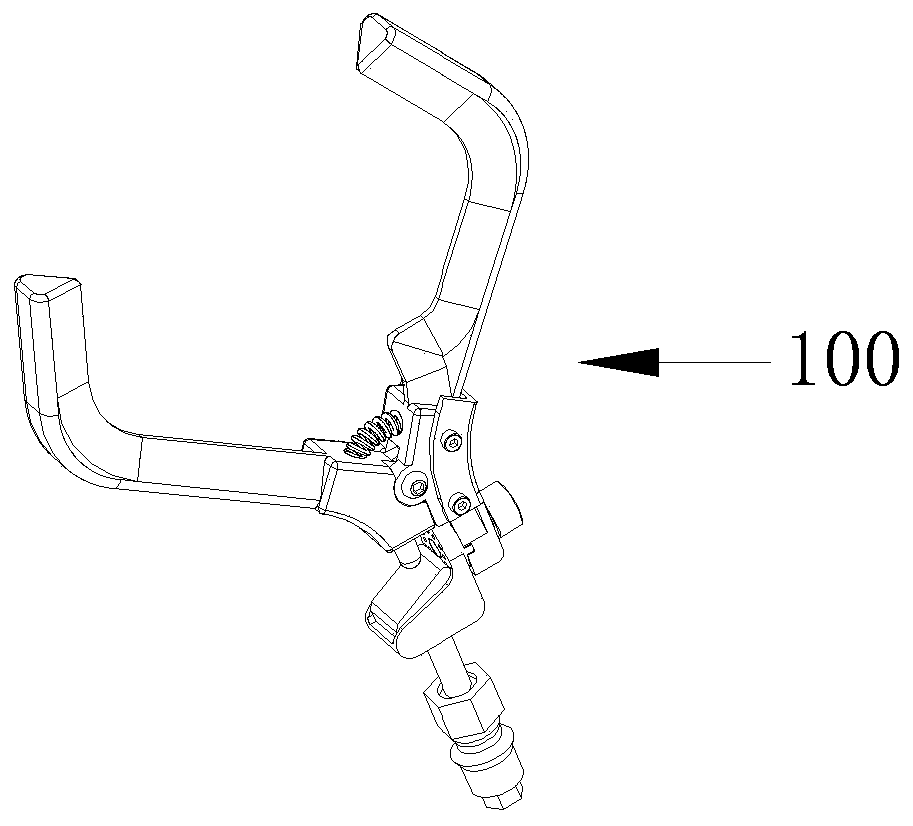

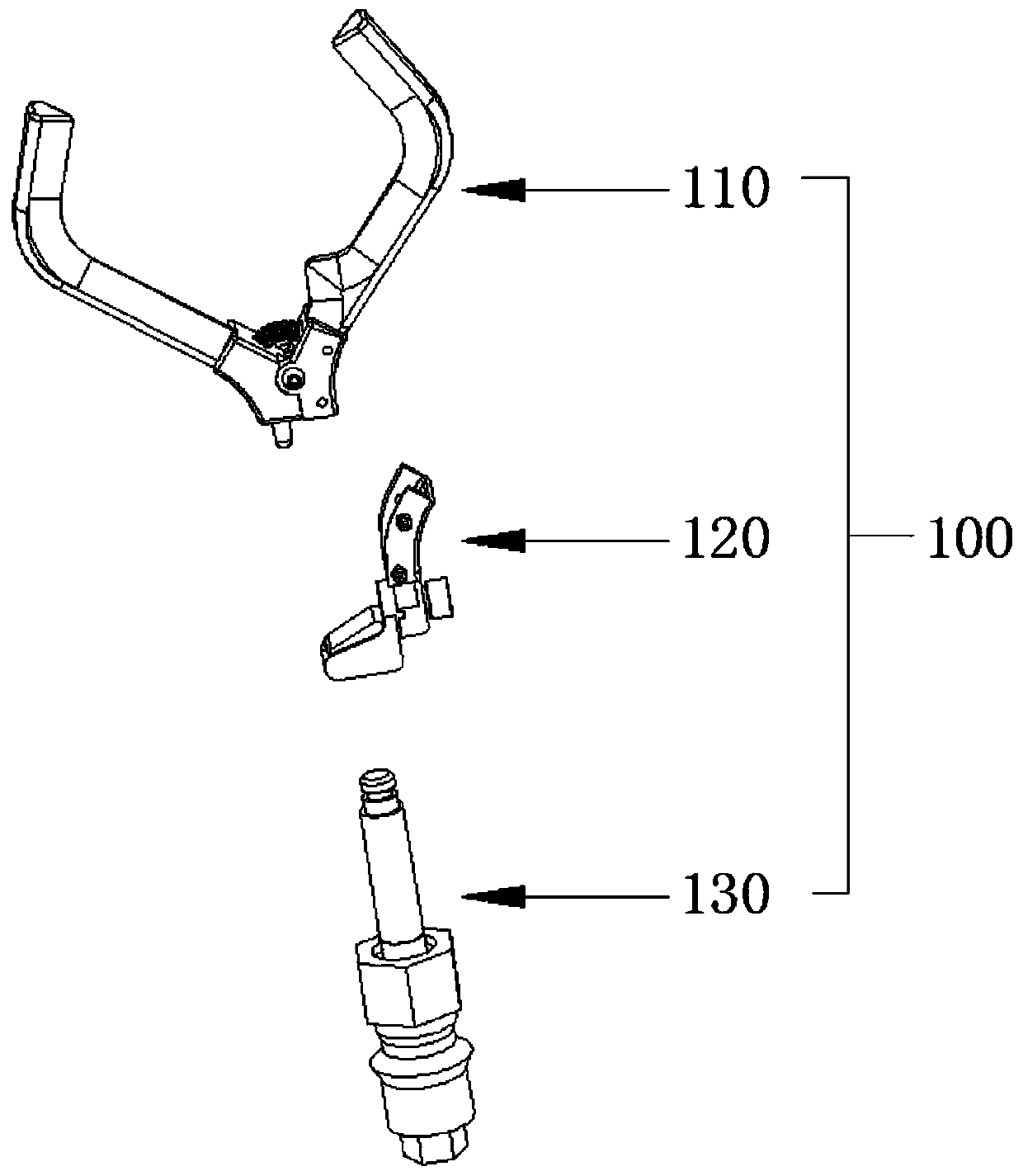

Electric hammer

InactiveCN102069478BStable and reliable clamping forceEasy to holdPortable percussive toolsGear driveDevice form

The invention relates to an electric hammer which comprises a shell, a motor, a transmission mechanism, an impacting assembly, a striking piece and a clamping mechanism, wherein the motor is vertically arranged in the shell; the transmission mechanism is used for converting rotary motions of the motor into impacting motions to the striking piece through bevel gear transmission and the impacting assembly; the impacting assembly comprises an impacting block in contact with an impacted part of the striking piece; the clamping mechanism comprises a sleeve, clamping pieces and an offsetting device; and the sleeve is used for driving the clamping piece to move between an opening position and a closing position. The electric hammer also comprises a holding part and a striking device formed by forwards protruding, wherein the striking device comprises a striking piece capable of linearly striking on a nail or other elements back and forth; and the striking device also comprises a clamping mechanism used for clamping the nail and other elements. The electric hammer has the advantages of compact structure and convenient operation and can be used for better clamping nails or other elements so as to prevent the nails or other elements from being deflected.

Owner:NANJING CHERVON IND

Flexible hinge and floating frame matched clamping and positioning device for optical component

The invention discloses a flexible hinge and floating frame matched clamping and positioning device for an optical component. A flexible hinge and a floating frame are matched to be used for clamping and positioning the optical component, so that a large-caliber optical component is provided with the low-stress-strain reliable clamping capacity in the horizontal plane, moreover, the floating frame and two-dimensional large stroke are in flexible connection, so that the parallelism between the optical element surface and the work table plane is guaranteed. The flexible hinge is fixedly connected with a crystal frame, connection lugs are fixed on the crystal frame, positioning blocks are fixed in the crystal frame, and the optical component is disposed in the crystal frame integrally and positioned through the positioning blocks. Locking blocks are fixed in the crystal frame, first positioning screws are screwed in the locking blocks, and the optical component is pre-clamped and fixed between the first positioning screws and the positioning blocks. Compression blocks are fixedly connected with the crystal frame, and the optical component is compressed and fixed vertically through the compression blocks. Spherical hinge studs are fixedly connected with connection lugs and are in contact with air floating pads. The device is used for clamping and positioning of optical elements during micro-defect rapid searching and repairing.

Owner:HARBIN INST OF TECH

Power hammer

InactiveCN102069477AShorten the sliding strokeCompact structurePortable percussive toolsEngineeringClosest relatives

The invention relates to a power hammer, which comprises a striking device. The striking device comprises a striking element and a clamping mechanism, wherein the striking element is used for repeatedly striking components; the clamping mechanism comprises a clamping element, a casing pipe, a first skewing device and a second skewing device; the casing pipe is provided with slots; the clamping element slides in the slots; the clamping element is closed relative to the first positions of the slots; the clamping element is opened relative to the second positions of the slots; the first skewing device is used for skewing the casing towards the direction of the striking element striking the components; the clamping mechanism also comprises a cutting ferrule; and the second skewing device is used for acting on the cutting ferrule towards the direction of the striking element striking the component to skew the clamping element. The power hammer has a compact structure, is convenient to operate and can be used for well clamping nails or other components so as to avoid that the nails or other components are struck to incline.

Owner:NANJING CHERVON IND

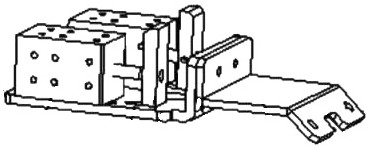

a clamping device

InactiveCN101560590BStable and reliable clamping forceSimple structureFurnace typesHeat treatment furnacesEngineeringQuenching

The invention relates to a clamping device, in particular to a clamping device for clamping a long tubular workpiece during quenching treatment. The device comprises a rotatably supported hollow main shaft; a support sleeve coaxially sleeved on the hollow main shaft and axially fixedly connected with it; a double-acting cylinder, which is rotatably supported relative to the support sleeve; a sliding sleeve, the inner surface of the sliding sleeve is slidably supported on the outer peripheral surface of the supporting sleeve; a crank plate, the crank plate is hingedly connected with the ends of the supporting sleeve and the sliding sleeve respectively; Jaws fixedly connected to the crank plate.

Owner:北京宜飞航空科技有限公司

Cake type coil fixture

InactiveCN102496452BEliminate the phenomenon of easy falling off and lossSmooth slidingCoils manufactureManufacturing technologyProcess equipment

The invention relates to a cake type coil fixture and particularly relates to process equipment for winding a transformer coil, belonging to the technical field of winding and manufacturing of transformer coils. The invention adopts the technical scheme that the cake type coil fixture comprises a handle (1), a screw rod (2), a sliding clamping plate (3), a basic body (4) and a thermoplastic rubber sleeve (5), wherein the handle is connected with the screw rod; the screw rod is arranged in the basic body; a rail groove (6) parallel to the screw rod is arranged in the lateral surface of the basic body; a screw rod nut (7) in the basic body is connected with the sliding clamping plate; the sliding clamping plate is perpendicular to the screw rod and extends out of the rail groove; a substrate (8) is arranged at the bottom of the basic body and is perpendicular to the basic body; a plane of the substrate is parallel to a clamping surface of the sliding clamping plate; and the thermoplastic rubber sleeve is arranged on the sliding clamping plate. According to the cake type coil fixture disclosed by the invention, the protection for an insulating layer of a lead is facilitated; the coilis enabled to become attractive; the phenomenon that a rivet or a screw is easy to fall off during use is completely eliminated; and quality problems and potential safety hazards generated by fallingof scrap iron are eliminated. The cake type coil fixture disclosed by the invention has the advantages of long service life, low manufacturing cost and stable and reliable clamping force.

Owner:BAODING TIANWEI GRP CO LTD

Power hammer

The invention relates to a power hammer, which comprises a striking device. The striking device comprises a striking element and a clamping mechanism, wherein the striking element is used for repeatedly striking components; the clamping mechanism comprises a clamping element, a casing pipe, a first skewing device and a second skewing device; the casing pipe is provided with slots; the clamping element slides in the slots; the clamping element is closed relative to the first positions of the slots; the clamping element is opened relative to the second positions of the slots; the first skewing device is used for skewing the casing towards the direction of the striking element striking the components; the clamping mechanism also comprises a cutting ferrule; and the second skewing device is used for acting on the cutting ferrule towards the direction of the striking element striking the component to skew the clamping element. The power hammer has a compact structure, is convenient to operate and can be used for well clamping nails or other components so as to avoid that the nails or other components are struck to incline.

Owner:NANJING CHERVON IND

Anti-displacement soft sealing gate valve and using method thereof

ActiveCN111022671AStable and reliable clamping forcePrevent lateral displacementSlide valveValve housingsPhysicsLeft valve

The invention discloses an anti-displacement soft sealing gate valve which comprises a valve rod (1), a valve cover (2), a valve body (3) and a valve plate. The valve plate comprises a left valve plate (4) and a right valve plate (5) which are connected with the valve rod, a certain gap is reserved between the left valve plate and the right valve plate, and elastic meshing mechanisms are arrangedon valve body channels below the left valve plate and a right valve plate; each elastic meshing mechanism comprises an opening groove capable of accommodating the left valve plate / the right valve plate, wherein the opening groove is divided into an upper layer elastic filling body (6) and a lower layer cavity part, two end walls of the lower layer cavity part are respectively connected with sliding blocks (8) through elastic connecting pieces (7), and the sliding blocks are located on the two sides of the left valve plate / the right valve plate. The anti-displacement soft sealing gate valve has the beneficial effects that when the left valve plate and the right valve plate move downwards, the left valve plate and the right valve plate are in contact with the elastic meshing mechanisms, theupper elastic filling bodies are deformed in a V shape, the two sides of the left valve plate and the right valve plate are meshed, reliable clamping force is provided, and lateral displacement of the valve plate is prevented.

Owner:铜陵天海流体控制股份有限公司

Refractory material product machining clamp and machining method based on refractory material product machining clamp

The invention discloses a refractory material product machining clamp and a machining method based on the refractory material product machining clamp. The refractory material product machining clamp comprises a chuck, the bottom end face of the chuck is a base, the top end face of the chuck is a clamping face, the base of the chuck is fixedly connected with a clamping block, the clamping block is connected with a connecting rod, and the connecting rod penetrates through a central inner cavity of the chuck. The connecting rod is further sleeved with a plug. When the workblank is arranged on the connecting rod in a sleeving mode, one end of the workblank abuts against the clamping face of the chuck, and the other end of the workblank abuts against the plug. The shape machining of a product is completed through one-time clamping, the coaxiality of the workblank is determined by the chuck, the plug and the connecting rod at the same time, and therefore the coaxiality consistency of the inner cylindrical face and the outer cylindrical face of the product is good, the outer diameter consistency of the upper end and the lower end is good, the positioning precision is high, the machining precision is high, and the use requirement of the product is met.

Owner:IRICO

Disassembly tooling for optical fiber connector

ActiveCN105856149BImprove stabilityImprove reliabilityMetal-working hand toolsDistance detectionEngineering

Owner:SUZHOU JIALAN ZHIYUAN ELECTRONICS TECH CO LTD

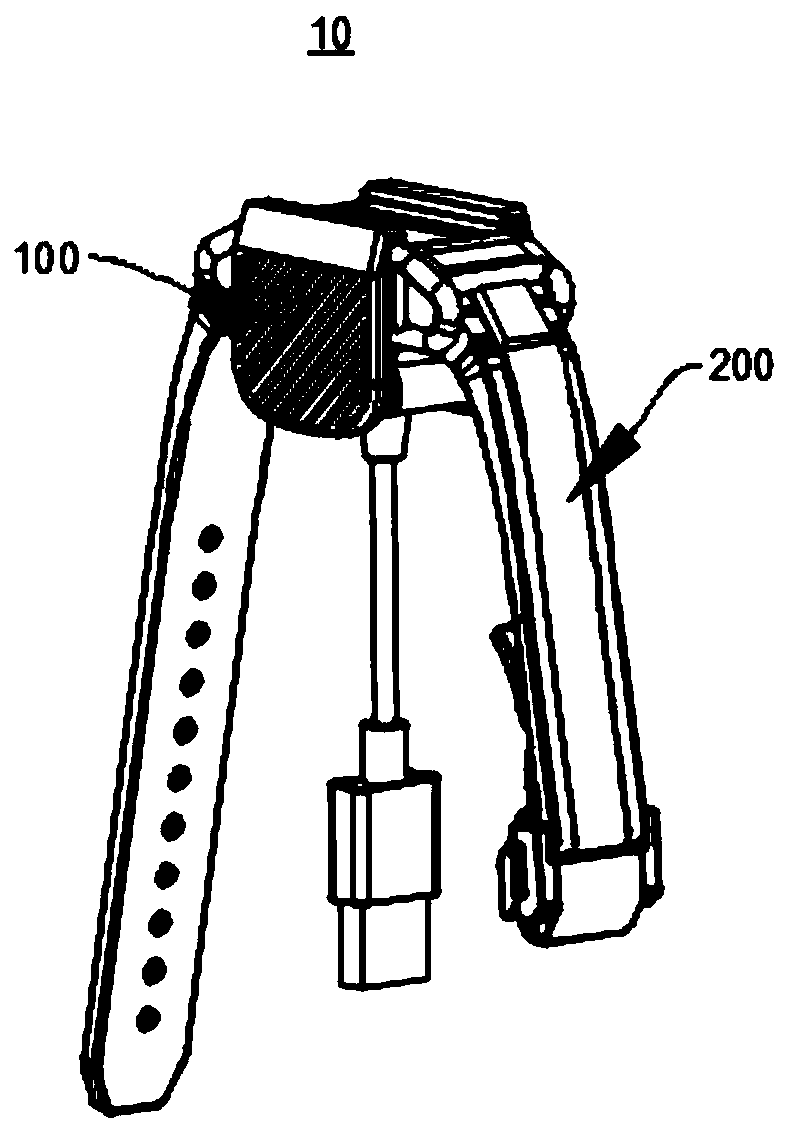

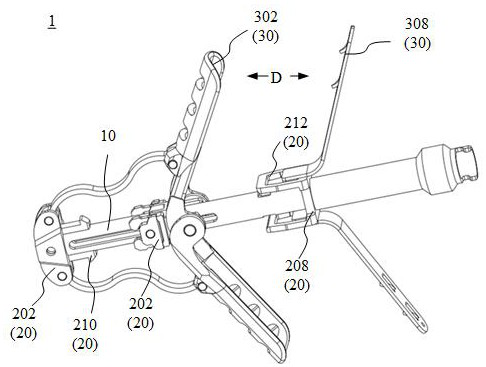

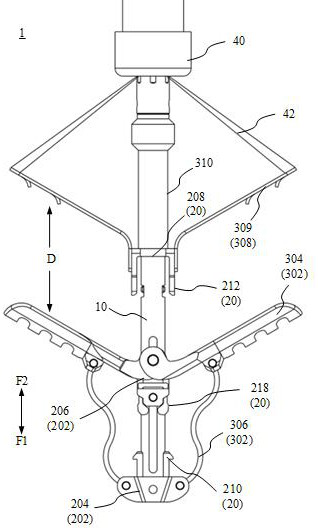

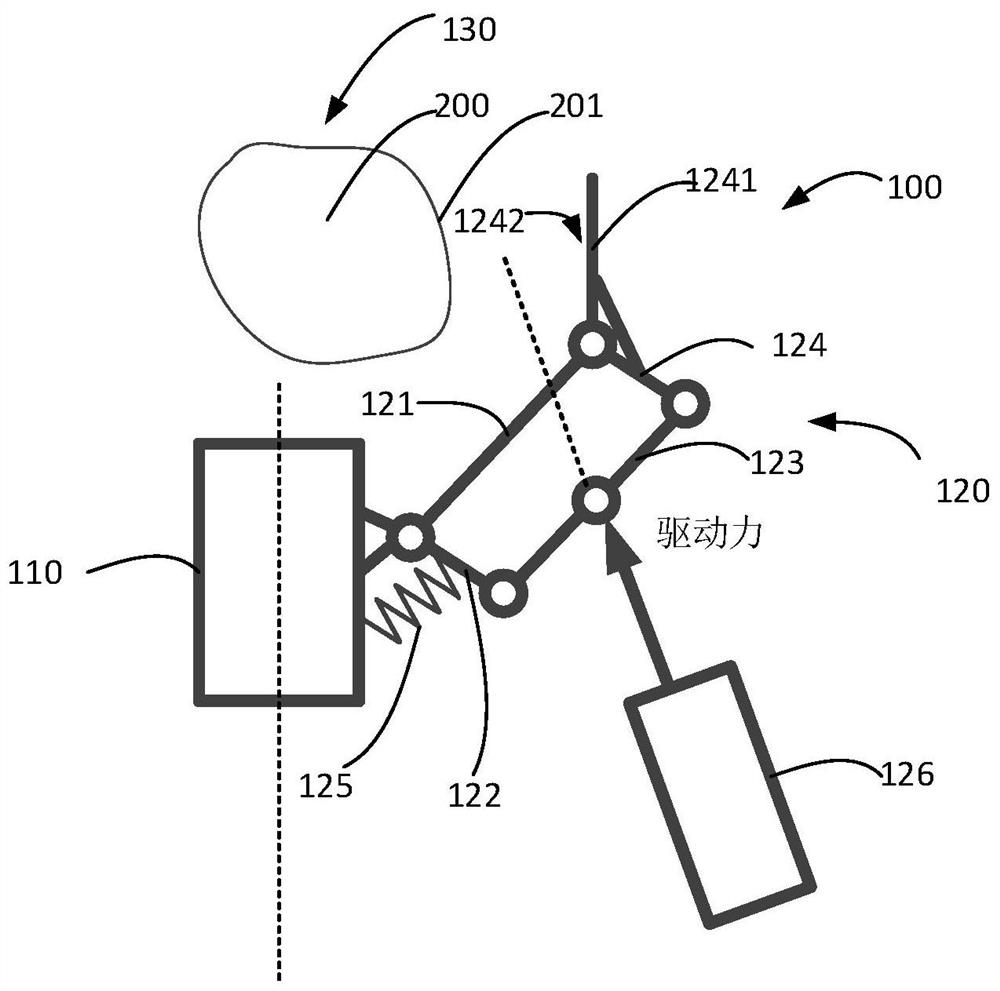

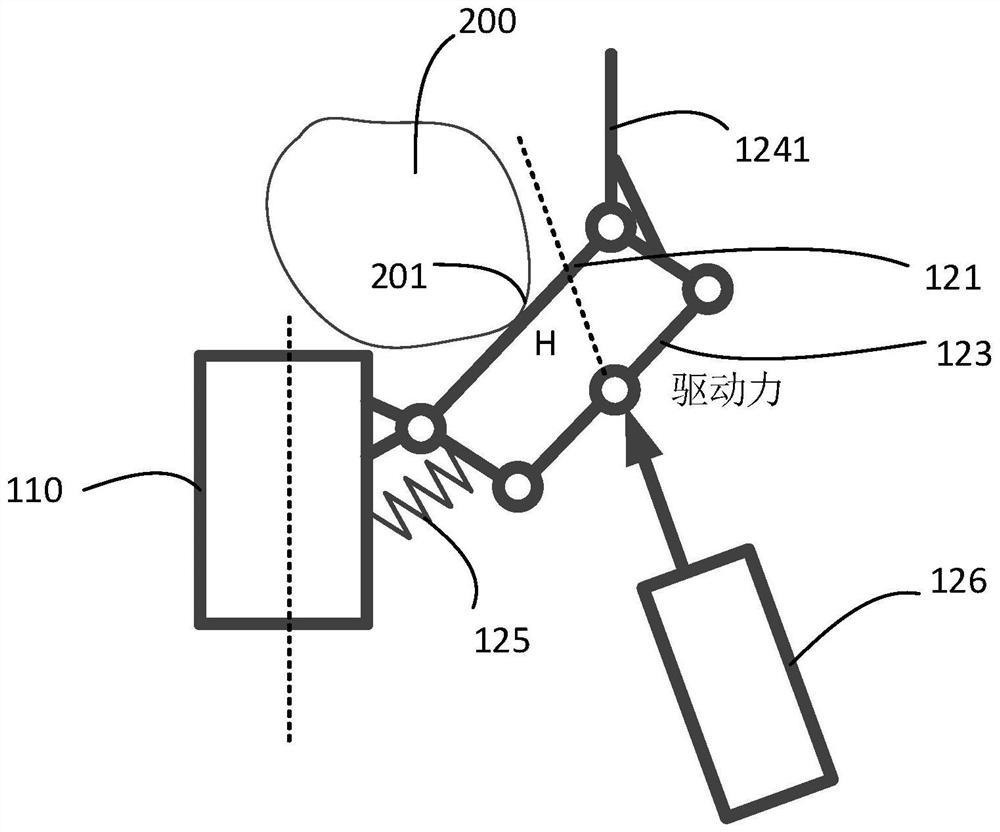

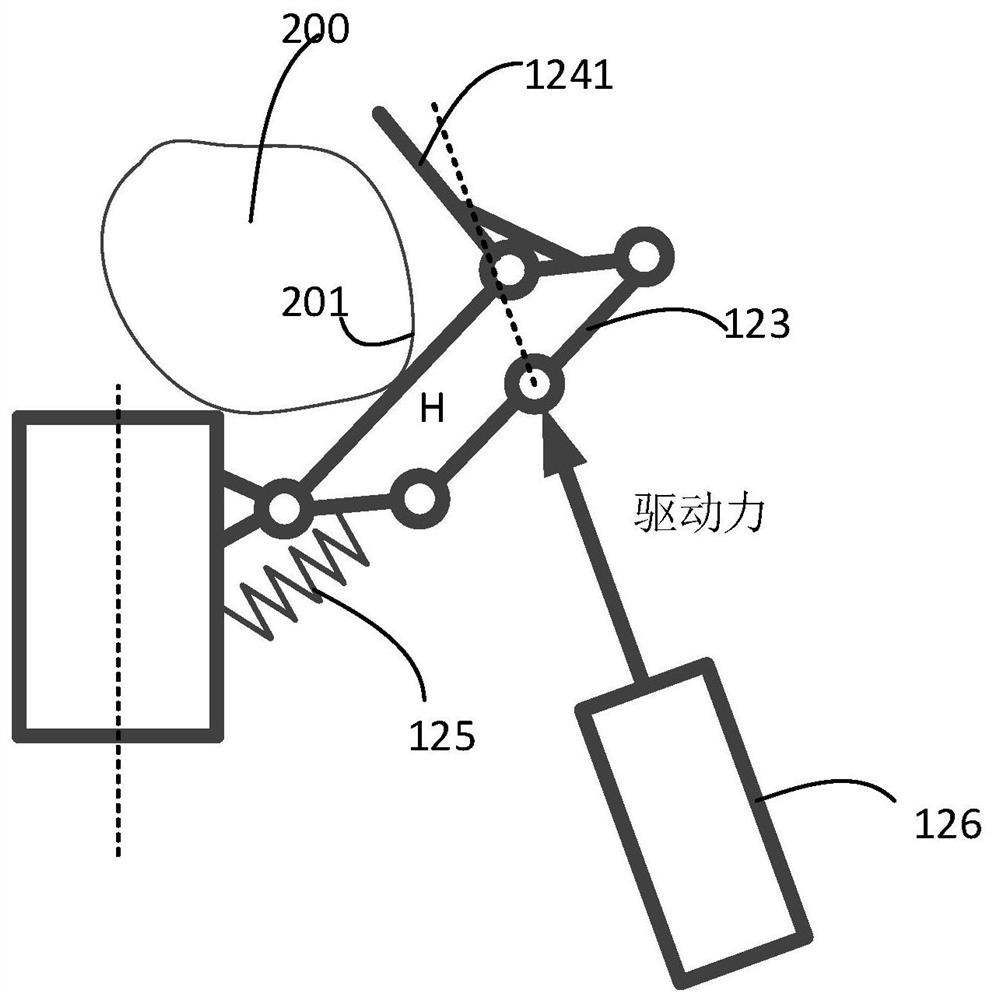

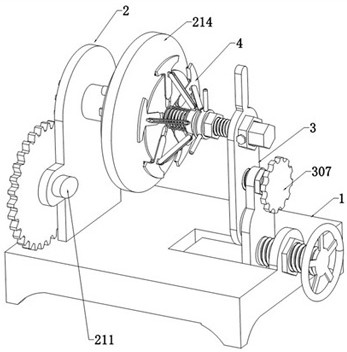

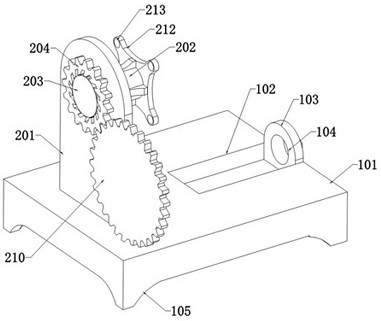

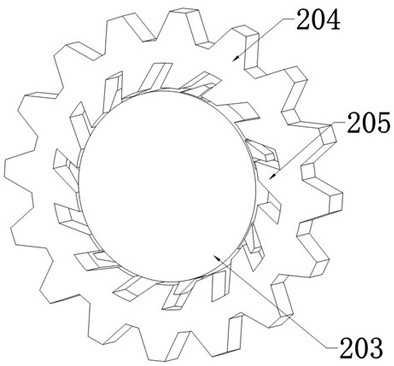

Under-actuated clamping device, robot and method for clamping object

PendingCN113696204AStable and reliable clamping forceInhibit sheddingGripping headsControl engineeringStructural engineering

The invention relates to an under-actuated clamping device which comprises a machine frame, and further comprises a clamping finger driving assembly, an elastic assembly and a driving assembly. The clamping finger driving assembly comprises a first connecting rod, a second connecting rod, a third connecting rod and a clamping finger rod, wherein the first connecting rod, the second connecting rod, the third connecting rod and the clamping finger rod form a parallel four-rod structure. The elastic assembly is restrained between the machine frame and the second connecting rod. The driving assembly is used for driving the third connecting rod to move when the under-actuated clamping device executes a clamping task. The invention further relates to a robot and a method for clamping an object. Self-adaption of flat clamping and wrapping clamping can be achieved.

Owner:清瑞博源智能科技河北有限责任公司

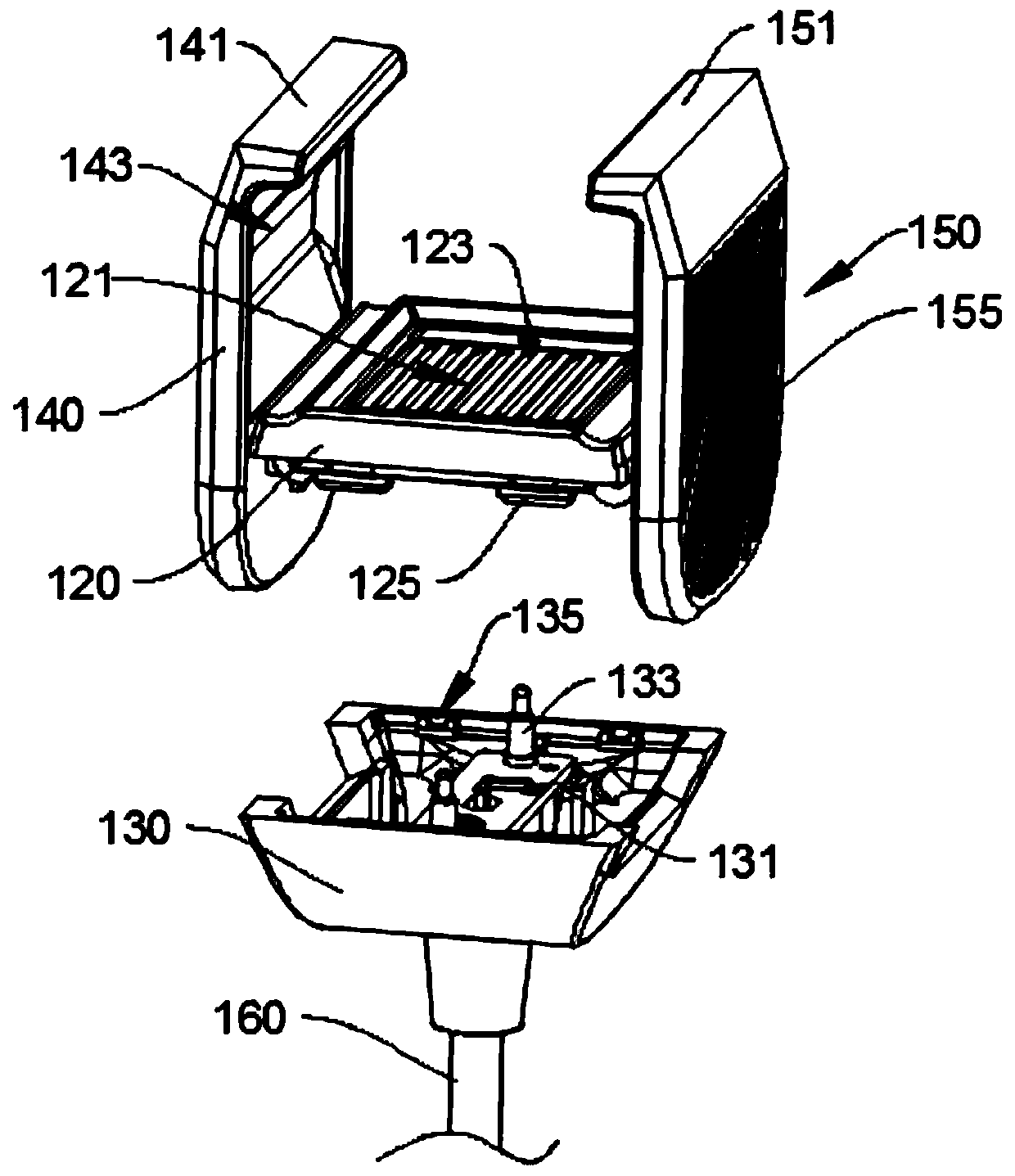

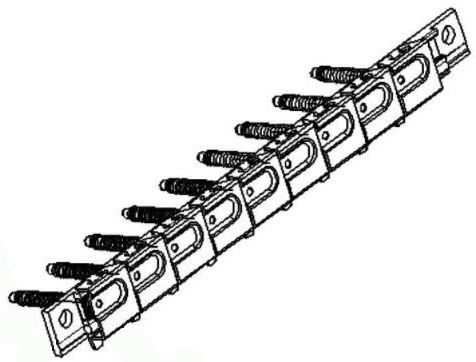

Upper thread clamping mechanism of double-needle embroidery machine

ActiveCN114411349AStable and reliable clamping forceEmbroidering machines apparatusEngineeringMechanical engineering

The invention relates to the technical field of double-needle embroidery machines, in particular to a double-needle embroidery machine upper thread clamping mechanism which comprises a lower thread passing assembly and an upper thread clamping and loosening assembly. The lower thread passing assembly comprises a pressing strip aluminum seat which is detachably connected with the needle rod frame, and a first mounting hole is formed in the pressing strip aluminum seat; the thread pressing spring seat is detachably connected with the pressing strip aluminum seat, and the thread pressing spring seat is provided with a thread penetrating groove allowing an upper thread to penetrate through from top to bottom; the first elastic ends of the wire pressing springs are connected with the corresponding wire pressing spring seats, and each wire pressing spring seat is connected with at least two wire pressing springs; and the wire pressing sheet is connected with the second elastic end of the wire pressing spring on the corresponding wire pressing spring seat. According to the upper thread clamping mechanism, by arranging the thread loosening connecting rod piece, the two thread loosening push rods can push the corresponding thread passing ejector rods to synchronously move forwards / backwards, and by arranging the at least two thread pressing springs, stable and reliable upper thread clamping force is provided for the thread pressing piece, so that two faces of threads can be stably, reliably and synchronously loosened or clamped.

Owner:ZHEJIANG YUELONG SEWING EQUIP

Quick self-clamping heart-shaped fixture

InactiveCN108857516AFirmly connectedAvoid chippingPositioning apparatusGrinding work supportsEngineeringCircular surface

The invention discloses a quick self-clamping heart-shaped fixture. The heart-shaped fixture comprises a heart-shaped fixture body, the upper end of the heart-shaped fixture body is hinged with a lever through a pin shaft, and a workpiece is clamped in the middle of the heart-shaped fixture body, the lower end of the lever is in a zigzag shape and in beveling with the outer circular surface of theworkpiece, a leaf spring is fixed to the outer circular surface of the heart-shaped fixture body through a screw, and the other end of the leaf spring abuts against the lever. According to the fixture, instantaneously when a machine tool starts, reliable connection between the heart-shaped fixture and the workpiece can be kept, and the clamping force is more reliable.

Owner:徐州昊隆工具股份有限公司

Device for testing friction performance of clutch friction plate

ActiveCN114878391ADetect frictionConvenient detection workMachine part testingWork holdersPhysicsClutch

The invention discloses a clutch friction plate friction performance testing device, and relates to the technical field of clutch accessory detection, and the clutch friction plate friction performance testing device comprises a supporting assembly and a rotating assembly, and the two ends of the upper surface of the supporting assembly are provided with the rotating assembly and an adjusting assembly respectively; a clamping assembly is arranged between the rotating assembly and the adjusting assembly; the clamping assembly comprises a clamping seat, one end of the clamping seat is fixedly connected with a stud, one end of the stud is fixedly connected with a fixing disc, and the outer side of the stud is connected with a positioning sleeve in a sleeving mode; by arranging the clamping assembly, the clutch friction plate can be supported and fixed, the movable arm is arranged on one side of the clamping block, the movable sleeve is arranged at one end of the movable arm, and the movable sleeve can adjust the position of the clamping block, so that the device can clamp and fix the clutch friction plates of various specifications.

Owner:EASTERN GANSU UNIVERSITY

Dovetail groove type clamping jaw

The invention discloses a dovetail groove type clamping jaw. The dovetail groove type clamping jaw comprises a three-jaw chuck and a clamping jaw body and is characterized in that a dovetail groove is formed in the clamping jaw body, and a dovetail clamp is arranged in the dovetail groove in a matched manner; and the dovetail inclination angle of the dovetail clamp ranges from 20 degrees to 30 degrees. The dovetail groove type clamping jaw has the beneficial effects that the dovetail clamp is arranged on the clamping jaw body, and the dovetail clamp is connected with the clamping jaw through the dovetail groove, so that reliable clamping force is provided; the clamping jaw body is made of flexible materials, and is not prone to being damaged; and shaking in the process of machining a workpiece is relieved.

Owner:铜陵市永生机电制造有限责任公司

A water conservancy construction plugging cover removal device

ActiveCN110549103BRealize flexible clampingReduce work intensityMetal working apparatusEngineeringStructural engineering

Owner:穿梭边界线(河北)科技有限公司

Clamping-adjustable automobile annular part mounting platform and mounting method

PendingCN114131527AImprove continuityRealize staggered realizeSpraying apparatusWork holdersStructural engineeringMachining

The invention discloses a clamping-adjustable automobile annular part mounting platform which is characterized in that only inner ring clamping, simultaneous inner ring clamping and outer ring clamping and only outer ring clamping are performed in sequence in the extension movement process of a telescopic end from back to front; inner ring clamping occurs in the process that the multiple inner supporting clamping blocks slide to abut against the inner wall of the automobile annular part, and outer ring clamping occurs in the process that the multiple outer pressing clamping rods rotate to abut against the outer wall of the automobile annular part. The invention further discloses an annular part mounting method. The clamping device has the beneficial effects that on the premise that the technology is continuous and uninterrupted, staggered clamping of the inner wall and the outer wall of the annular part is achieved, and the industrial machining continuity is improved.

Owner:杨鸿安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com