Refractory material product machining clamp and machining method based on refractory material product machining clamp

A technology of refractory materials and processing methods, applied in the direction of chucks, etc., can solve problems such as unstable clamping and poor processing accuracy, and achieve the effects of convenient product clamping, good outer diameter consistency, and good positioning and supporting functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

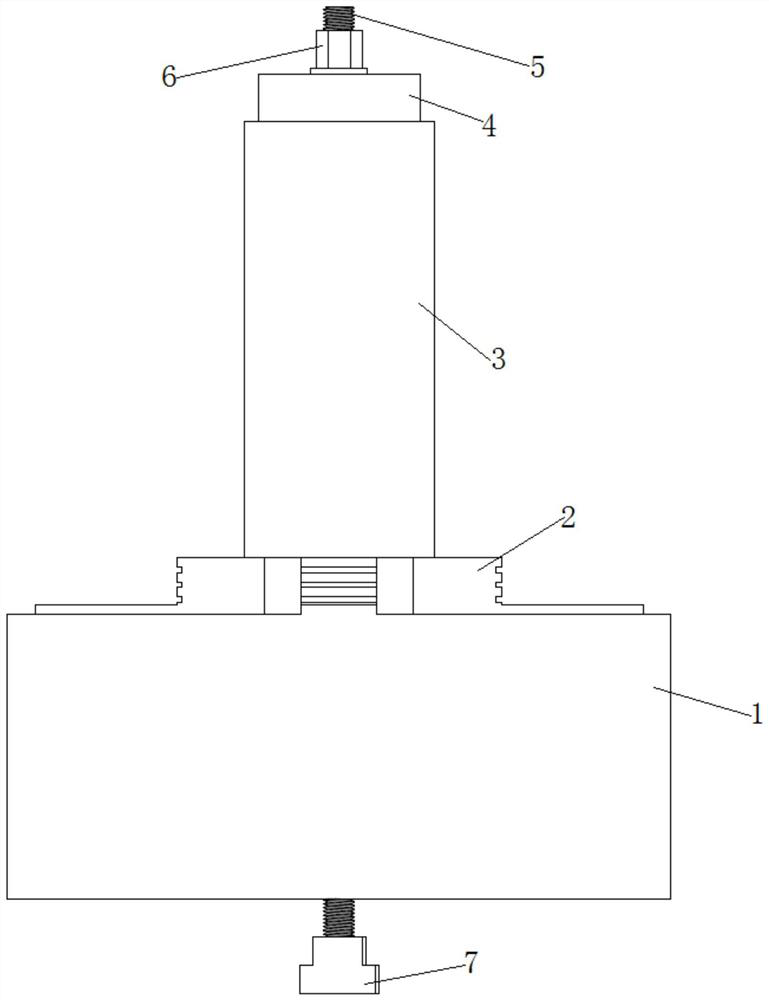

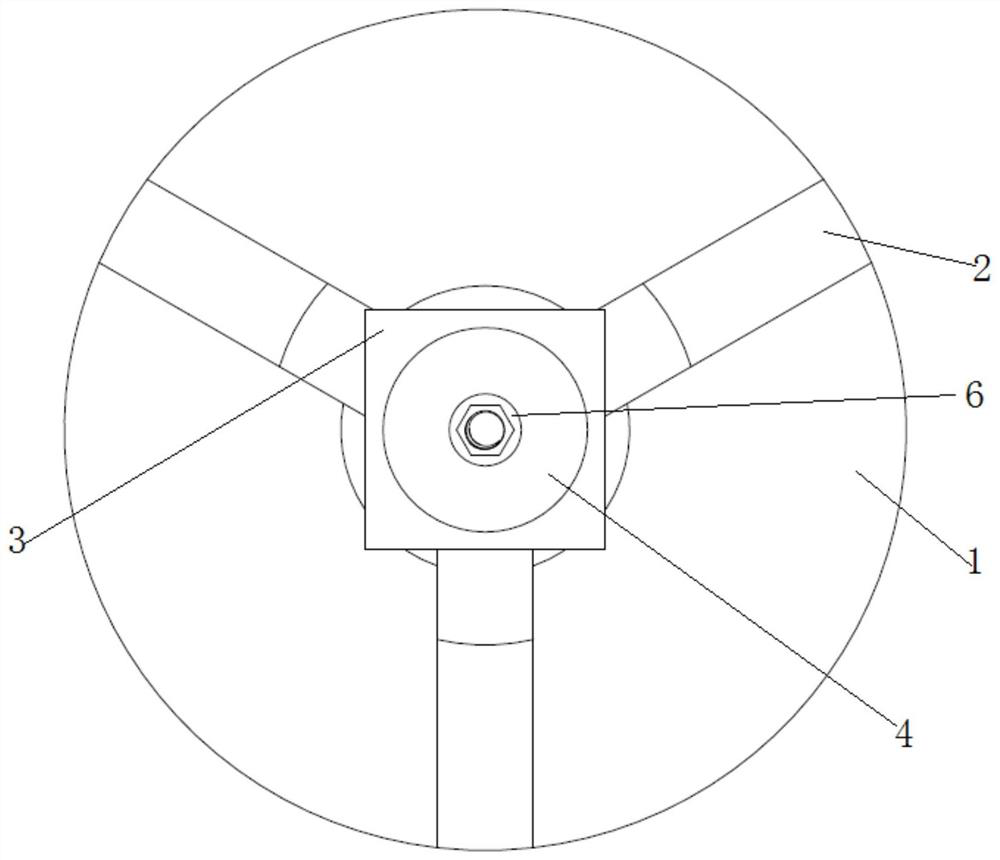

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0033] The present invention provides a refractory material product processing fixture, aiming at the currently processed refractory material blank 3, which has an outer square inner circle structure, the product is frequently used on the production line, the shape structure is similar to a ring, and the wall is thin (outer diameter 88mm, The inner diameter is 82mm, the thickness is only 3mm) and the length is 100mm, 130mm, and 230mm in three specifications (different product models, different application lengths). For the processing of thin-walled long tube parts, on the numerical control equipment, the clamping method and processing technology must be adjusted accordingly, in order to process products with qualified quality and requirements;

[0034] Such as figure 1 and figure 2 As shown, in this embodiment, the refractory material is a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com