Stent and method for manufacturing same

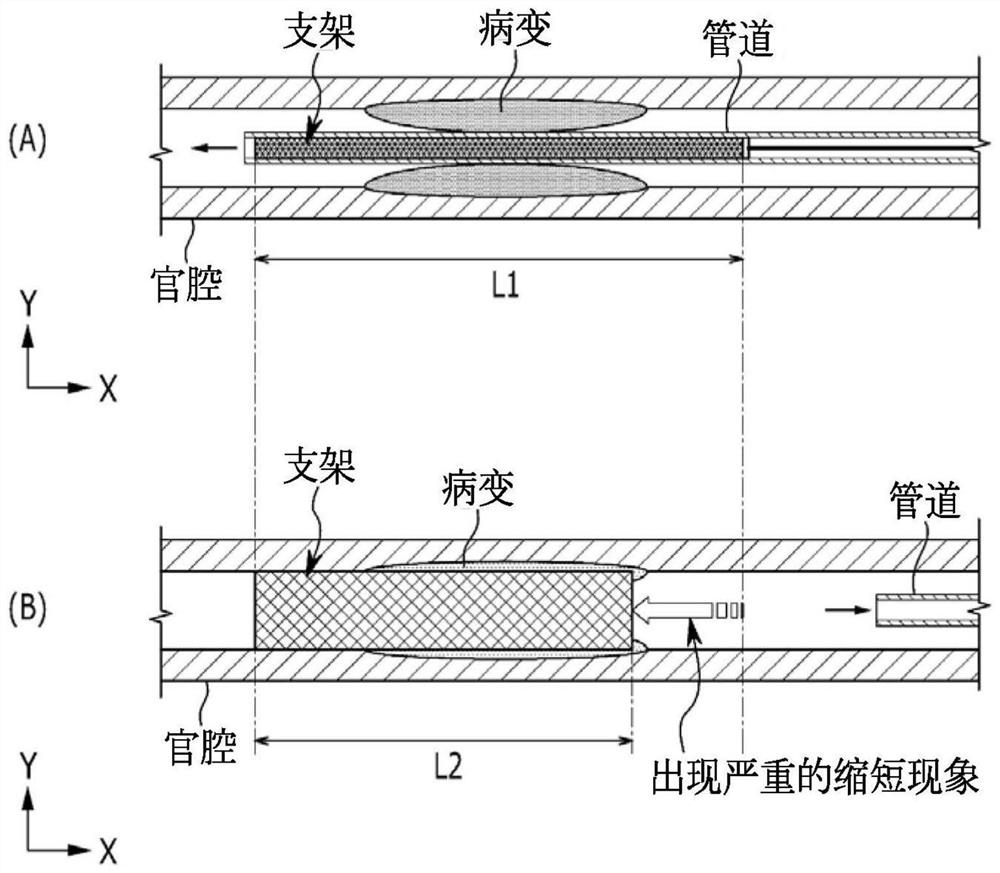

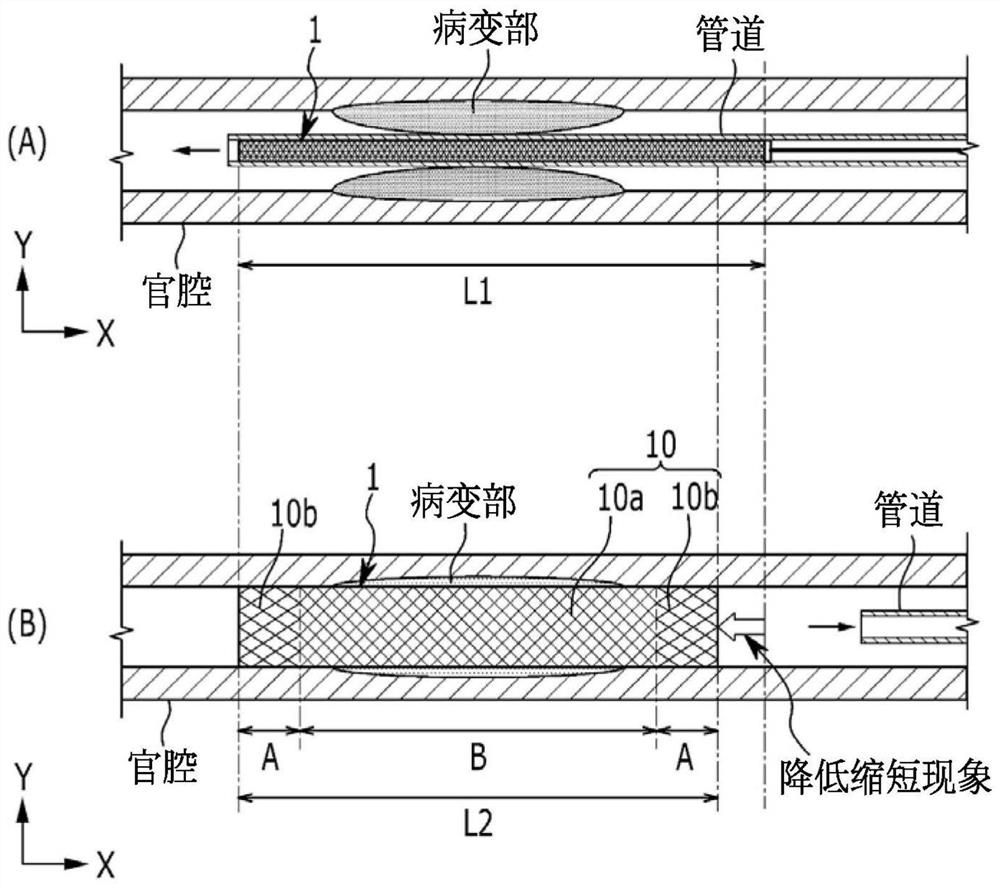

A technology of circumferential direction and pattern, applied in the field of stent and stent manufacturing, can solve the problems of restenosis, reduced function, shortening, etc., and achieve the effect of reducing stent activity, improving expansion force, and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

[0089] Figure 7 The structure of the bracket of the second embodiment of the present invention is shown.

[0090] refer to Figure 7 The stent 1 of the second embodiment of the present invention can be applied in the same way as the above-mentioned first embodiment, but the only difference here is that the coating member 20 and the anti-movement members 31 and 32 are additionally used. Therefore, repeated descriptions will be omitted below, and descriptions will be given mainly for additional structures.

[0091] The stent 1 is coated with a coating member 20 such as polyurethane, which is used to cover the inner and outer surfaces of the stent 1, so that blood or Food etc. can flow smoothly.

[0092] The coating member 20 described above can be coated on the outer surface of the stent 1 while being heated to a predetermined temperature. In addition, the coating member 20 is formed by immersing the stent 1 in a melted tank and then cooling it to form a coating.

[0093] ...

no. 3 example

[0100] on the other hand, Figure 8 The grid structure of the stent of the third embodiment of the present invention is shown.

[0101] refer to Figure 8 , the stent 1 of the third embodiment of the present invention is similar to the above-mentioned embodiment, the difference lies in that it is configured to repeat the A-type prismatic pattern and the B-shaped prismatic pattern along the overall length direction Y with a predetermined interval and cycle. grid structure. That is, the stent 1 does not distinguish between the central part and both ends of the above-mentioned embodiment, but repeatedly forms the A section of the A-shaped prism pattern and the B section of the B-shaped prism pattern in the overall longitudinal direction Y. Morphological representation. Here, the predetermined interval and period are not limited to Figure 8 , but can be fabricated according to the arrangement design of the pins P of the jig 100 to change the structure.

[0102] Therefore, th...

no. 4 example

[0104] on the other hand, Figure 9 The grid structure of the stent of the fourth embodiment of the present invention is shown.

[0105] refer to Figure 9 , the stent 1 of the fourth embodiment of the present invention is similar to the above-mentioned embodiments, the difference lies in the grid structure formed in a continuous B-shaped prism pattern along the overall length direction Y. This has the effect of constituting a lattice structure capable of reducing the phenomenon of shortening of the stent 1 in an optimal state. Alternatively, with the Figure 4 to Figure 6 As explained above, the stent 1 is self-shrinkable and expandable, has flexibility, and forms the first unit part 11 and the second unit part 12 of the unit length respectively. The first turn and the second turn of the zigzag are respectively synthesized and woven to form a tight structure. pattern, so the expansion force can be maintained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com