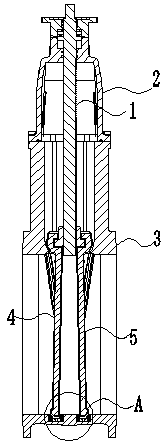

Anti-displacement soft sealing gate valve and using method thereof

A soft-sealing, displacement technology, applied in sliding valves, valve details, valve devices, etc., can solve problems such as lateral displacement of large-diameter gate valves, and achieve the effect of preventing lateral displacement and reliable clamping force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

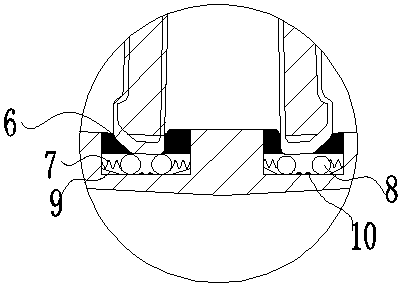

[0018] Embodiment 1: The elastic occlusal mechanism under the left valve plate can be called the left elastic occlusal mechanism, the upper elastic filling body is called the left upper elastic filling body, the lower cavity part is called the left lower cavity part, There is a first slider and a second slider in the cavity of the first layer. Similarly, the elastic occlusal mechanism under the right valve plate can be called the right elastic occlusal mechanism, and the upper elastic filling body is called the upper right elastic filling body. , the lower cavity part is called the right lower cavity part, and the third slider and the fourth slider are arranged in the right lower cavity part.

[0019] A preferred example of the present invention is that both ends of the lower cavity part are further provided with a guide slope 9 located below the elastic connector, and the highest end of the guide slope is fixedly connected to the end wall of the lower cavity part. The role of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com