Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Reduce assembly volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

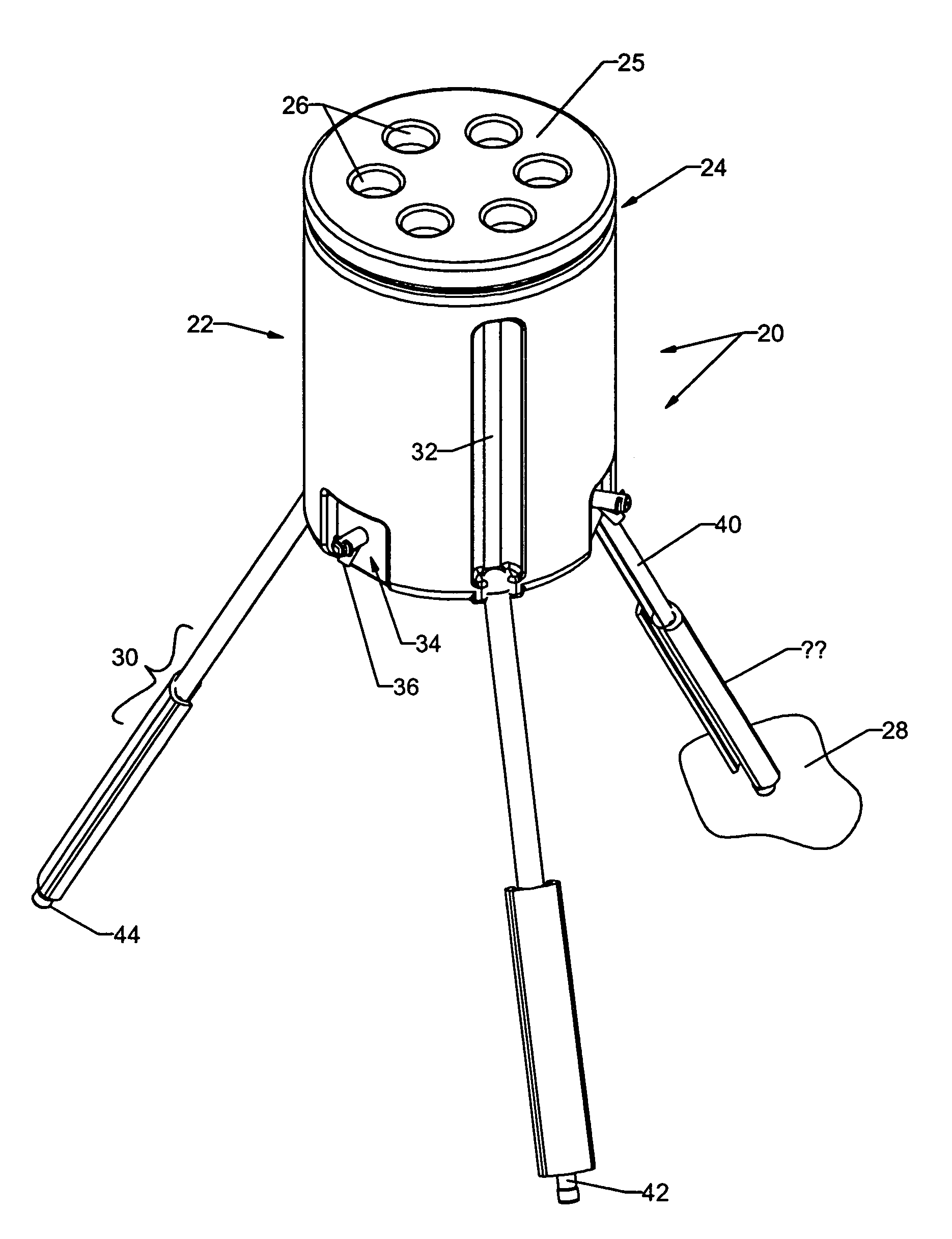

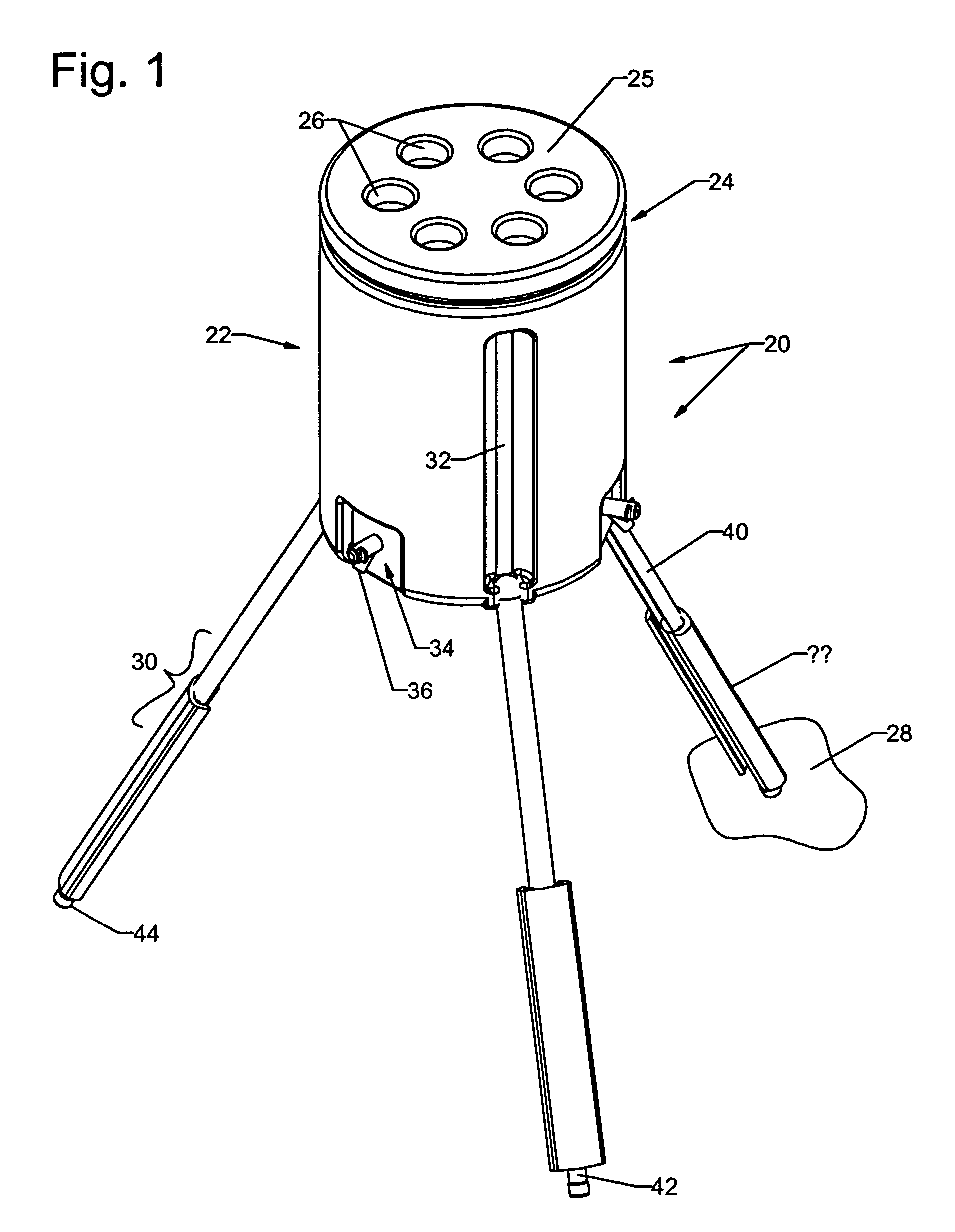

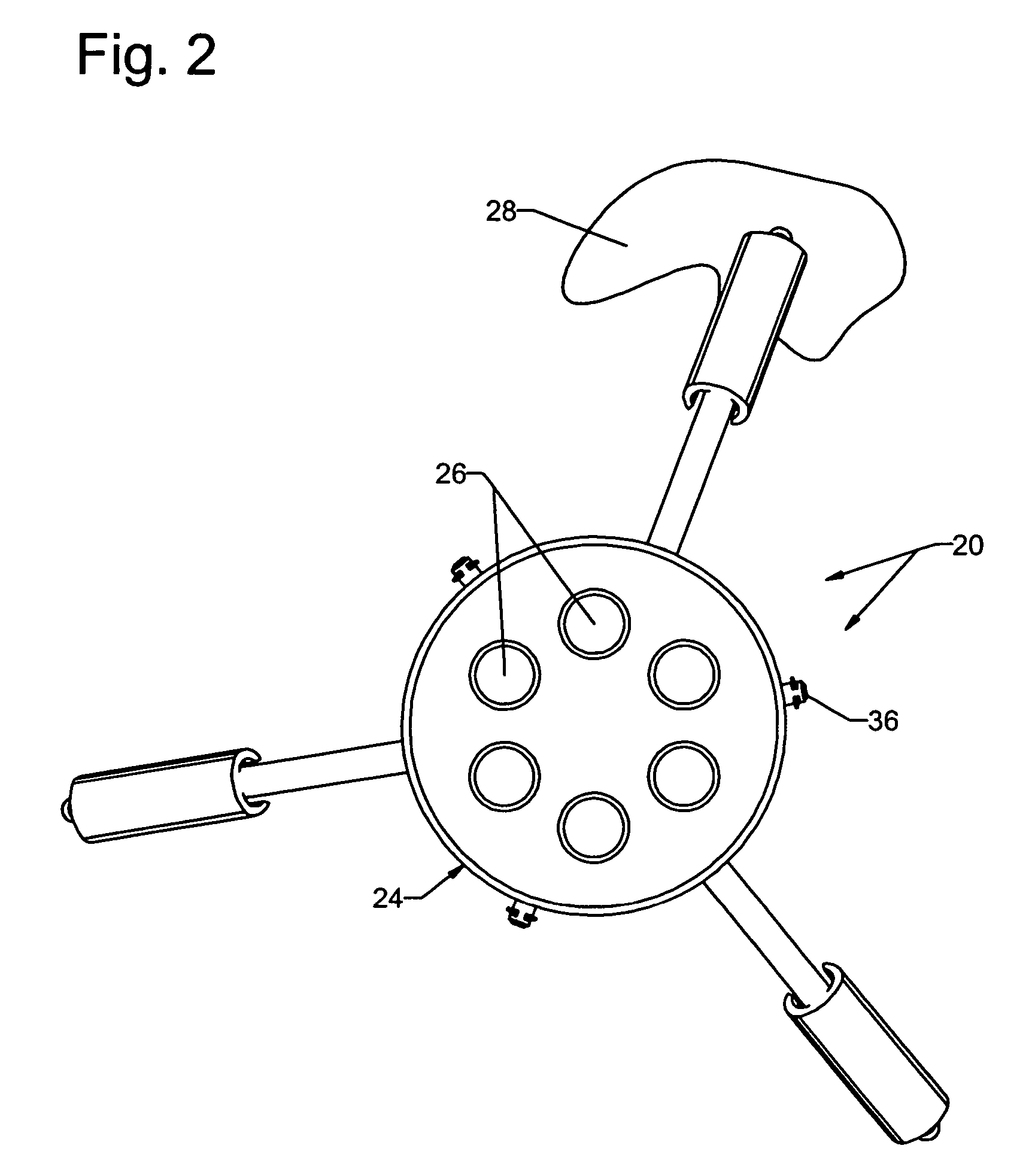

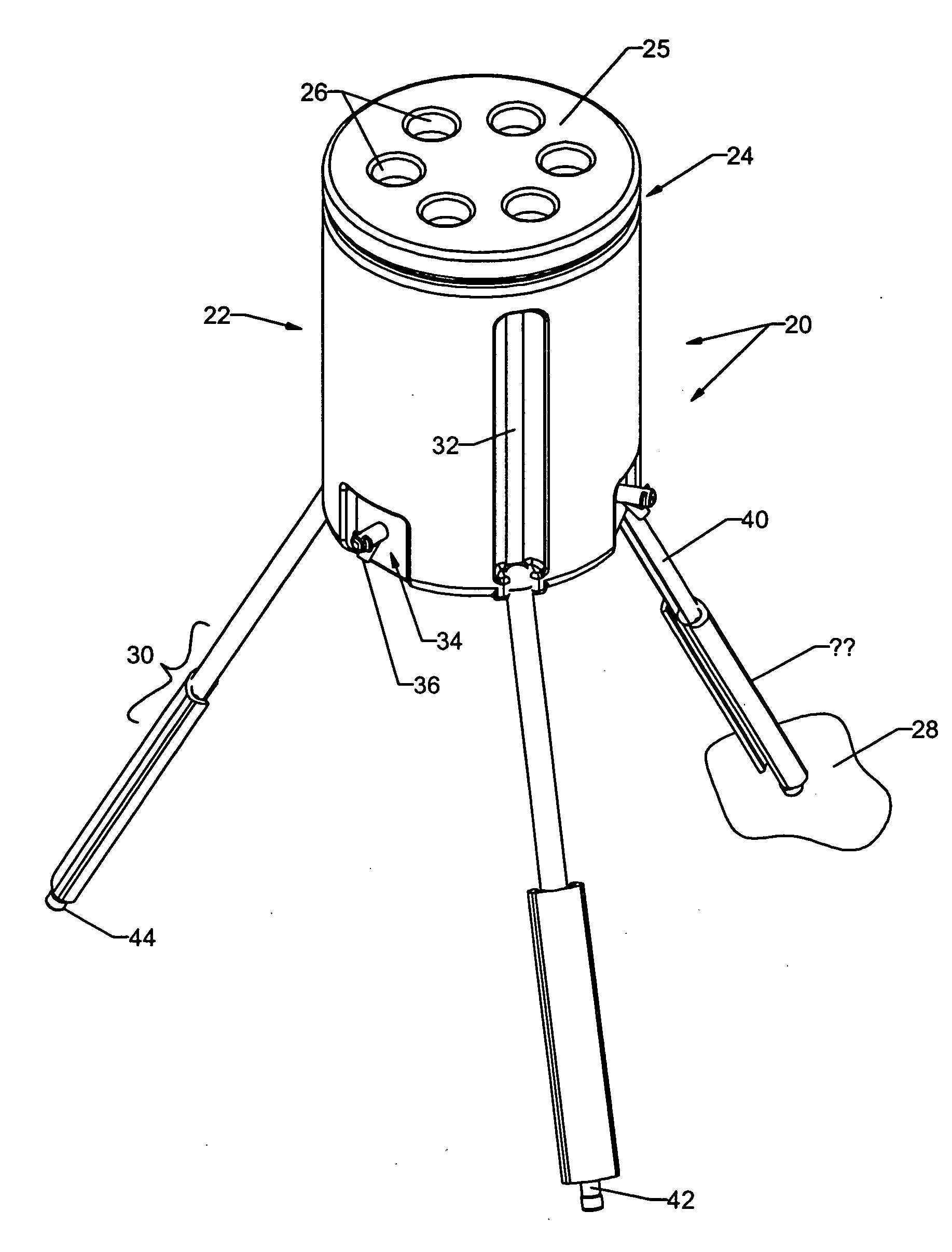

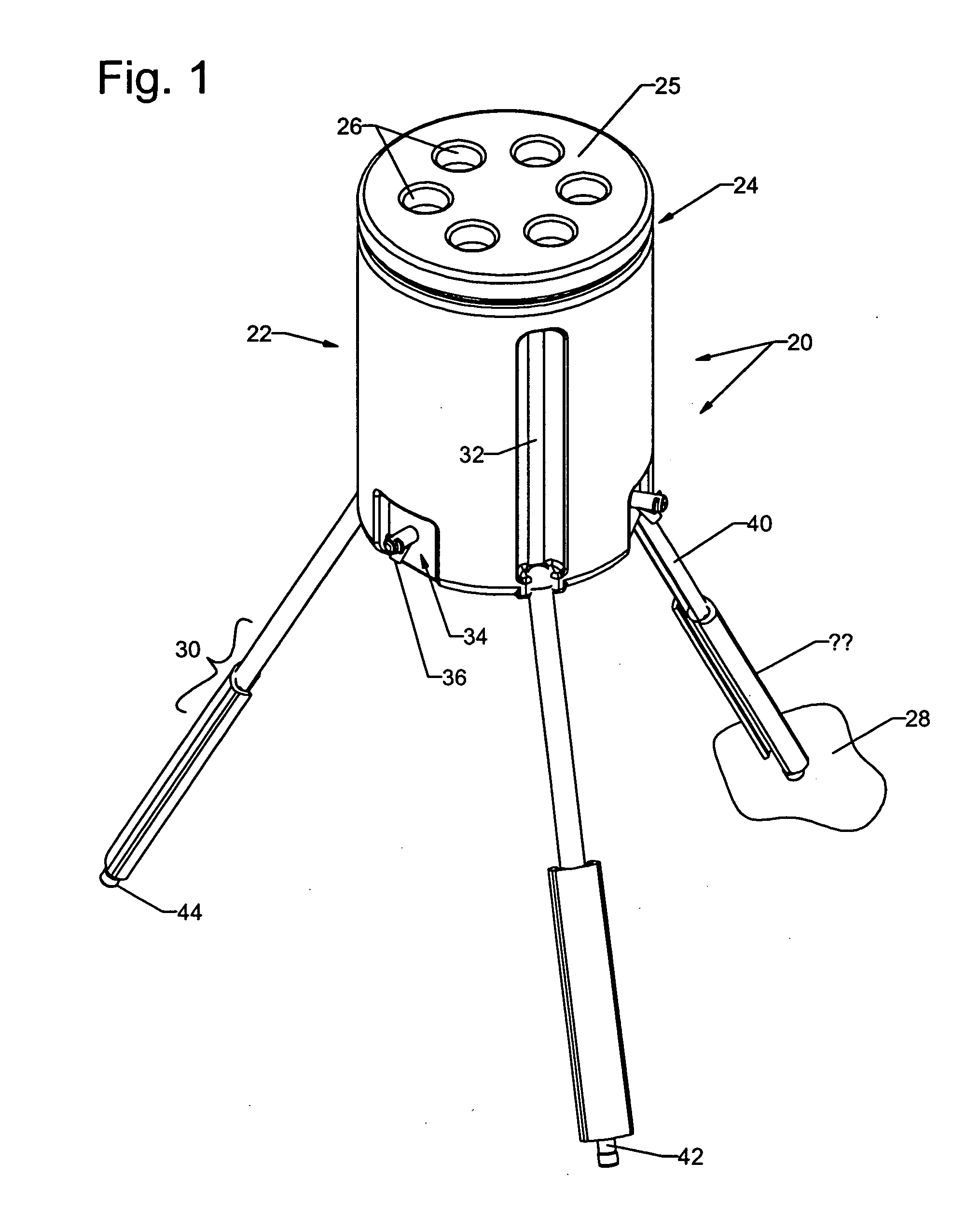

Multi-user transformable water cooler

ActiveUS7350671B2Easy to transportLess likely to collide with other objectLiquid flow controllersLiquid transferring devicesEngineeringMechanical engineering

Owner:HOSPITEC

Multi-user transformable water cooler

ActiveUS20060283883A1Easy to transportLess likely to collide with other objectLiquid flow controllersLiquid transferring devicesMechanical engineeringWater cooler

Owner:HOSPITEC

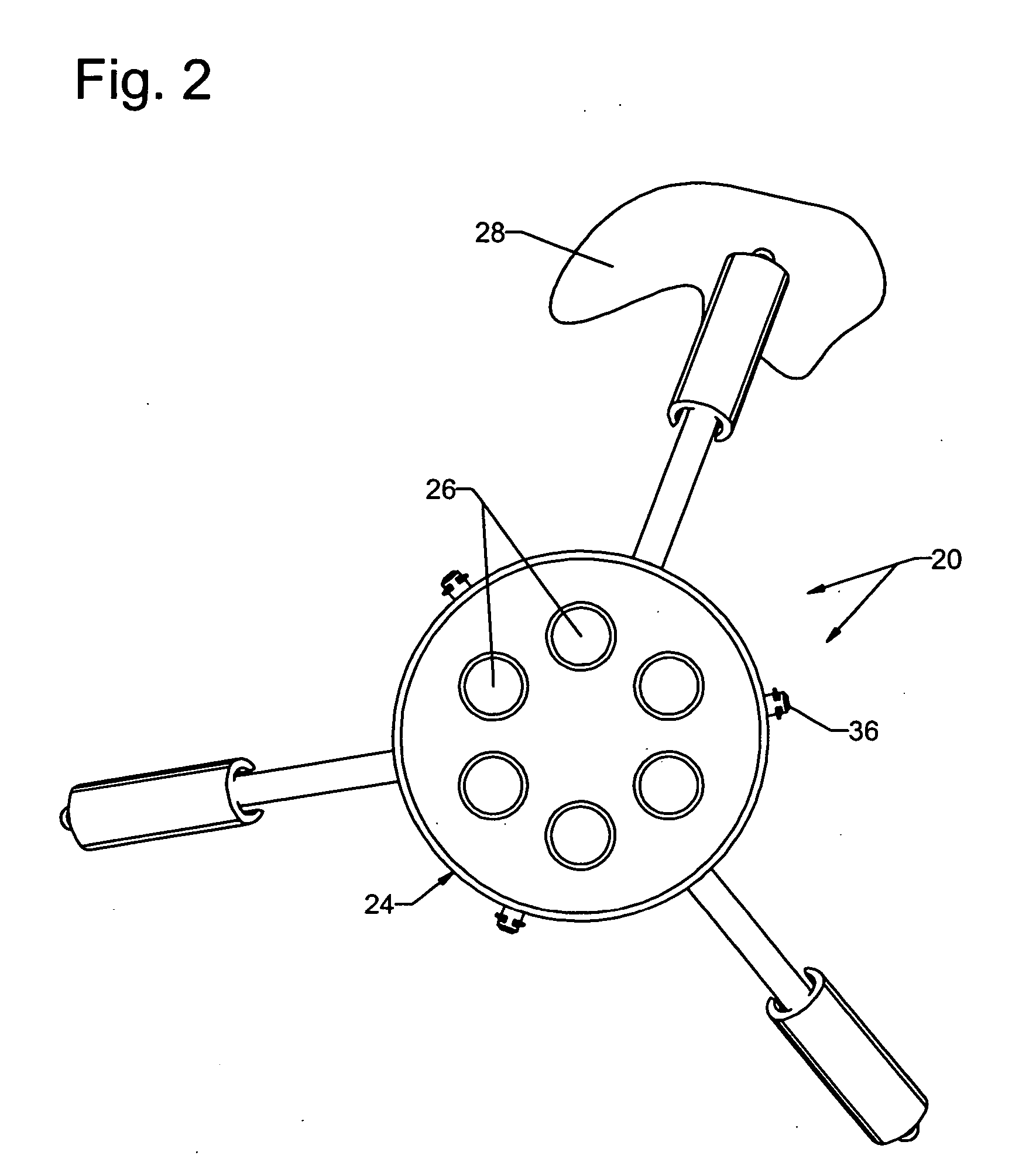

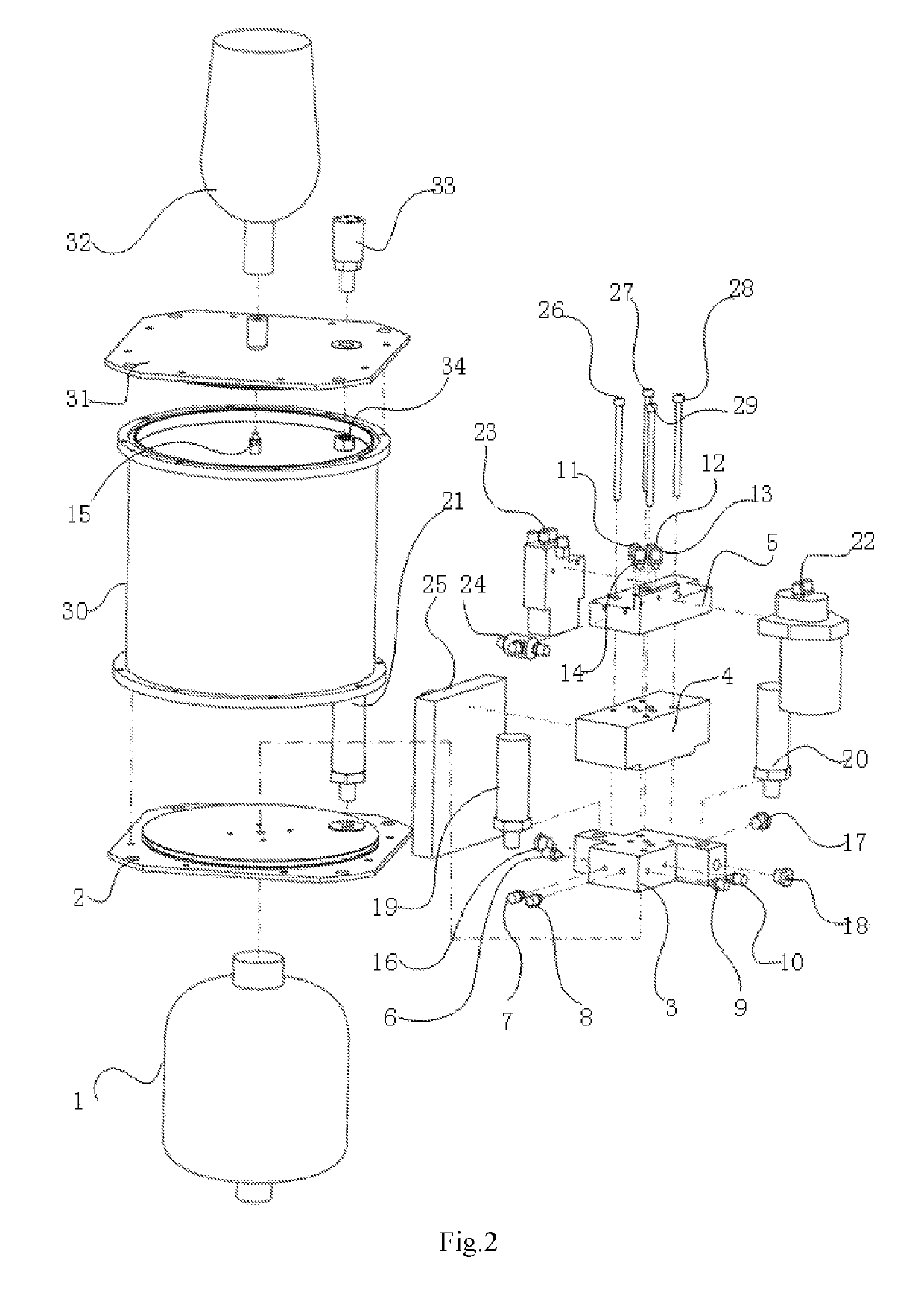

Self-draining oil buoyancy regulating device for underwater robots

ActiveUS20180208284A1Easy to controlQuick switchPump controlPositive-displacement liquid enginesHydraulic pumpCheck valve

The present invention provides a self-draining oil buoyancy regulating device for underwater robots, wherein the accumulator, lower hatch cover, hatch trunk, upper hatch cover and bladder are fixedly connected in sequence; the water-proof connector is fixed on the upper hatch cover; the depth-pressure sensor is settled on the lower hatch cover to check the underwater pressure; the upper valve block, hydraulic-operated check valve and lower valve block are connected though piping in sequence; the lower valve block is fixed on the lower hatch cover; the pump outlet pressure sensor and the accumulator pressure sensor are settled on the lower valve block; the directional valve and the upper valve block are connected through piping; the hydraulic pump motor assembly and the relief valve are both connected with the lower valve block through piping; the depth-pressure sensor, pump outlet pressure sensor and accumulator pressure sensor are all connected with the control panel; the control panel is connected with the external power supply and the host computer respectively by the water-proof connector; The present invention adopts a whole hydraulic plan which performs active oil drain and passive oil return; the design of overlay valve blocks has advantages of compact structure, reliable and energy-saving.

Owner:ZHEJIANG UNIV

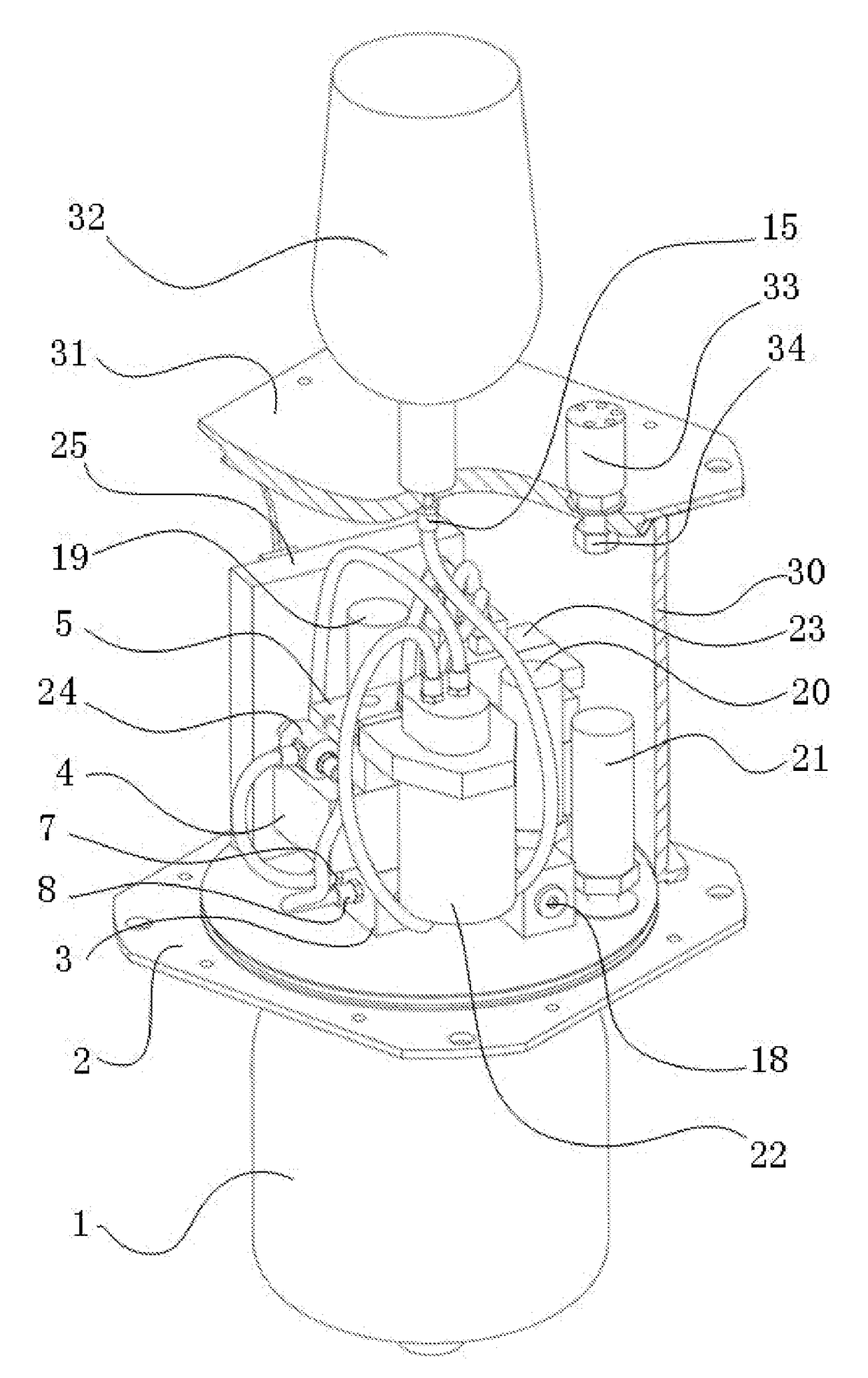

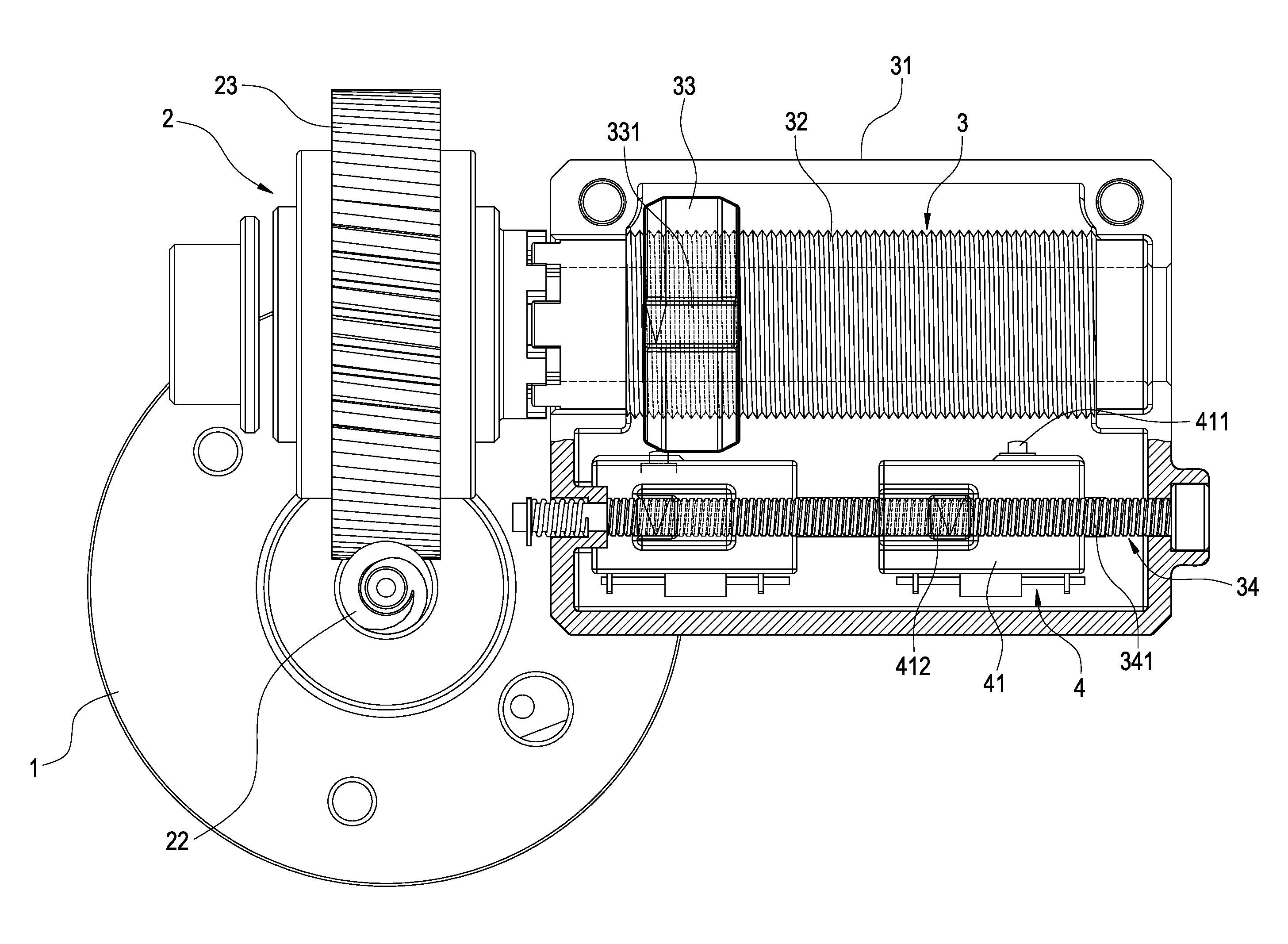

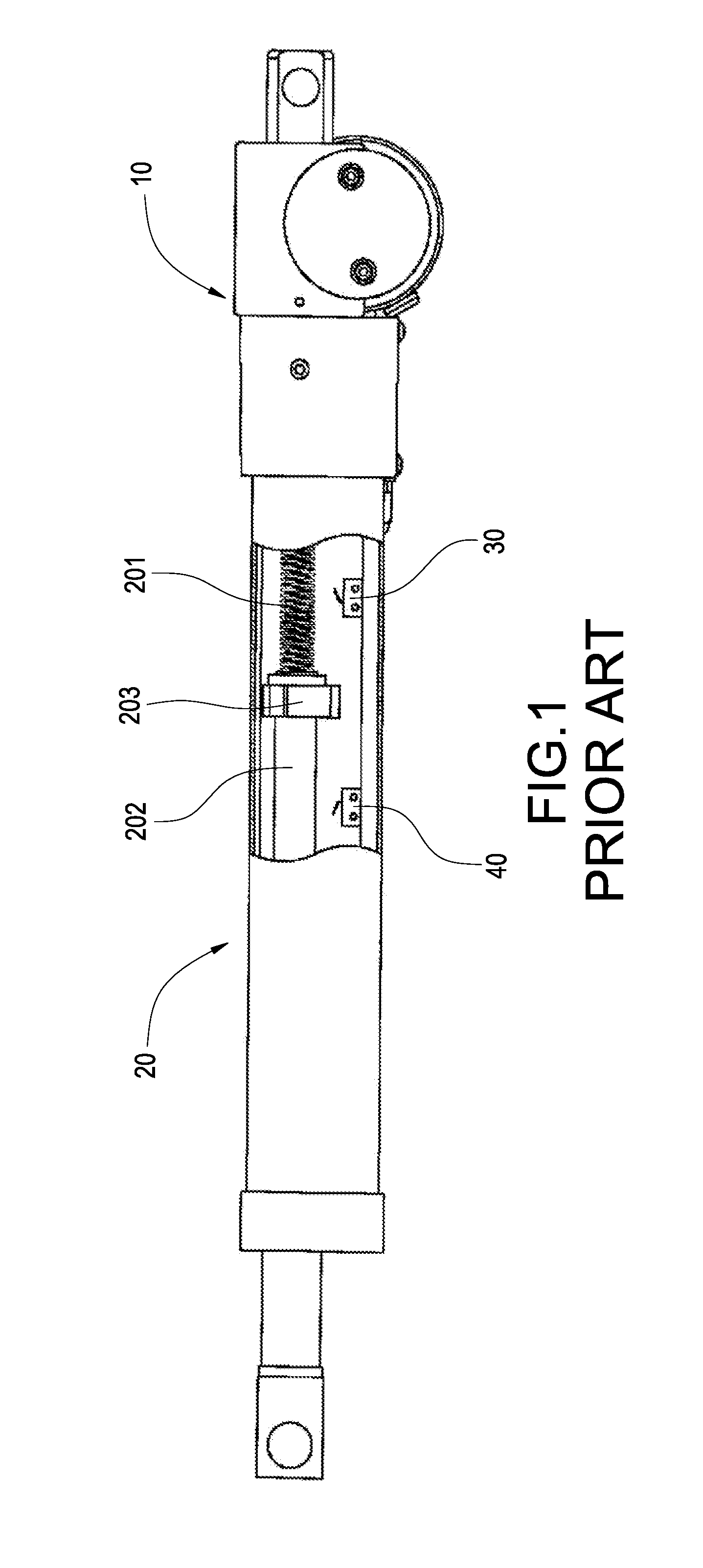

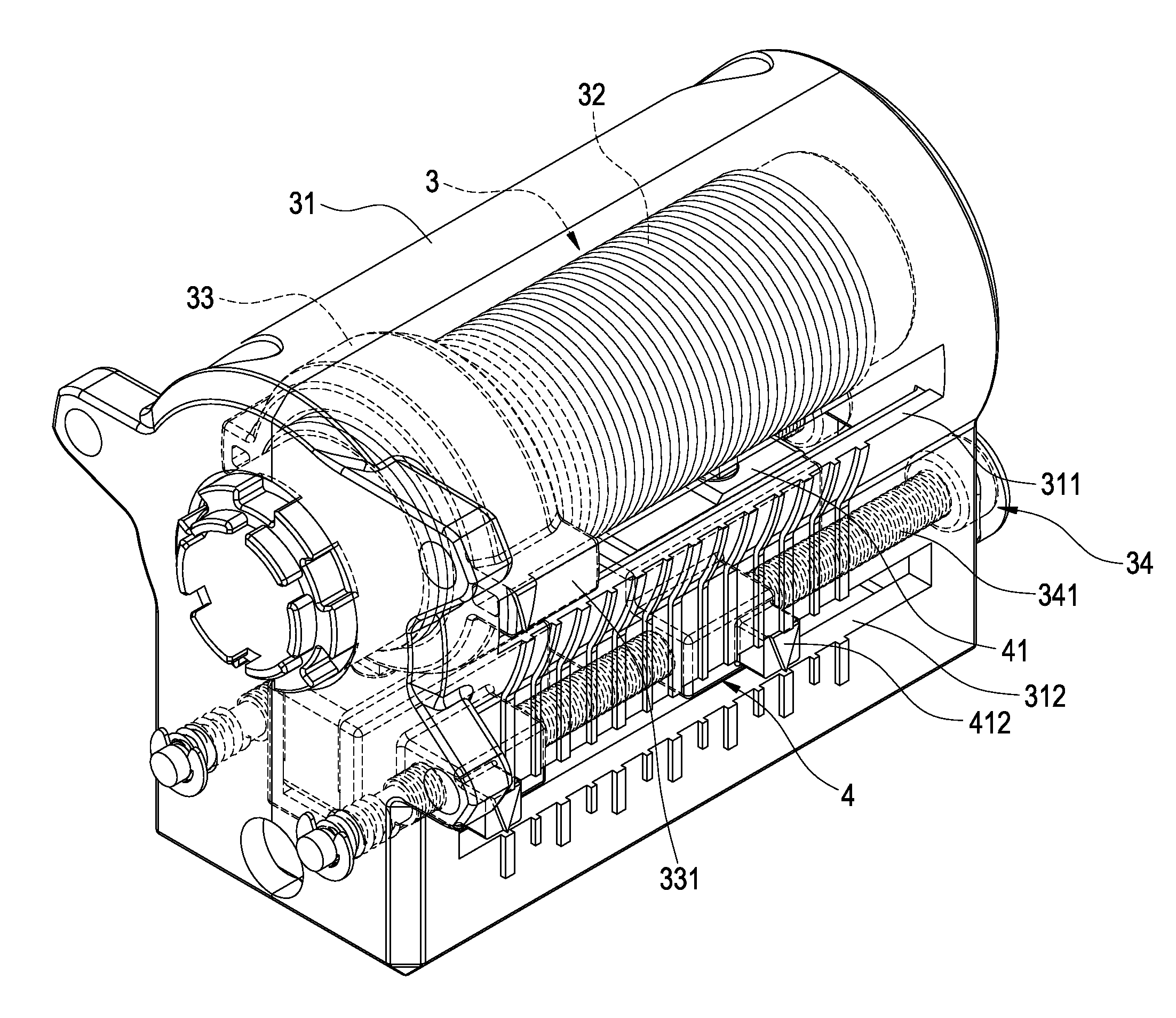

Gear motor having safety mechanism

ActiveUS8794087B2Reduce MechanismsReduce volumeToothed gearingsPortable liftingLeadscrewTouch switch

A gear motor having a safety mechanism includes a motor body, a speed reduction mechanism, a transmission mechanism, and a touch switch. The speed reduction mechanism includes a worm and a worm wheel drivingly engaged with the worm. The transmission mechanism includes a base fixed to the speed reduction mechanism, a lead screw rod pivotally connected to the base and rotatably driven by the worm wheel, and a nut threadedly connected to the lead screw rod. The touch switch is electrically connected to the motor body and provided aside the lead screw rod, thereby stopping the motor body when the nut contacts the touch switch. Thus, the gear motor not only controls the operation of the driven mechanism, but also allows various driven mechanisms to be mounted thereon. The assembled volume of the gear motor and the driven mechanism is reduced.

Owner:TIMOTION TECH CO LTD

Gear motor having safety mechanism

ActiveUS20130327168A1Increase safetyInspect and adjust easilyToothed gearingsTouch switchElectric motor

A gear motor having a safety mechanism includes a motor body, a speed reduction mechanism, a transmission mechanism, and a touch switch. The speed reduction mechanism includes a worm and a worm wheel drivingly engaged with the worm. The transmission mechanism includes a base fixed to the speed reduction mechanism, a lead screw rod pivotally connected to the base and rotatably driven by the worm wheel, and a nut threadedly connected to the lead screw rod. The touch switch is electrically connected to the motor body and provided aside the lead screw rod, thereby stopping the motor body when the nut contacts the touch switch. Thus, the gear motor not only controls the operation of the driven mechanism, but also allows various driven mechanisms to be mounted thereon. The assembled volume of the gear motor and the driven mechanism is reduced.

Owner:TIMOTION TECH CO LTD

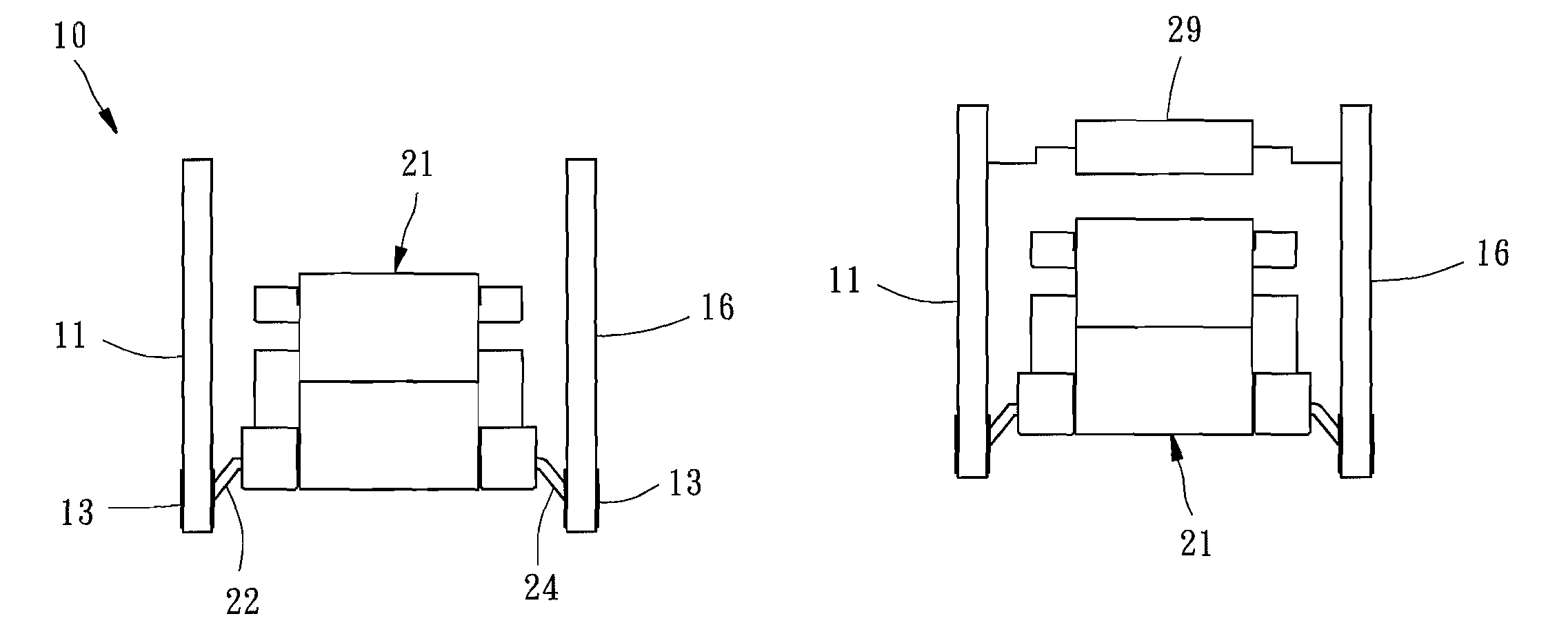

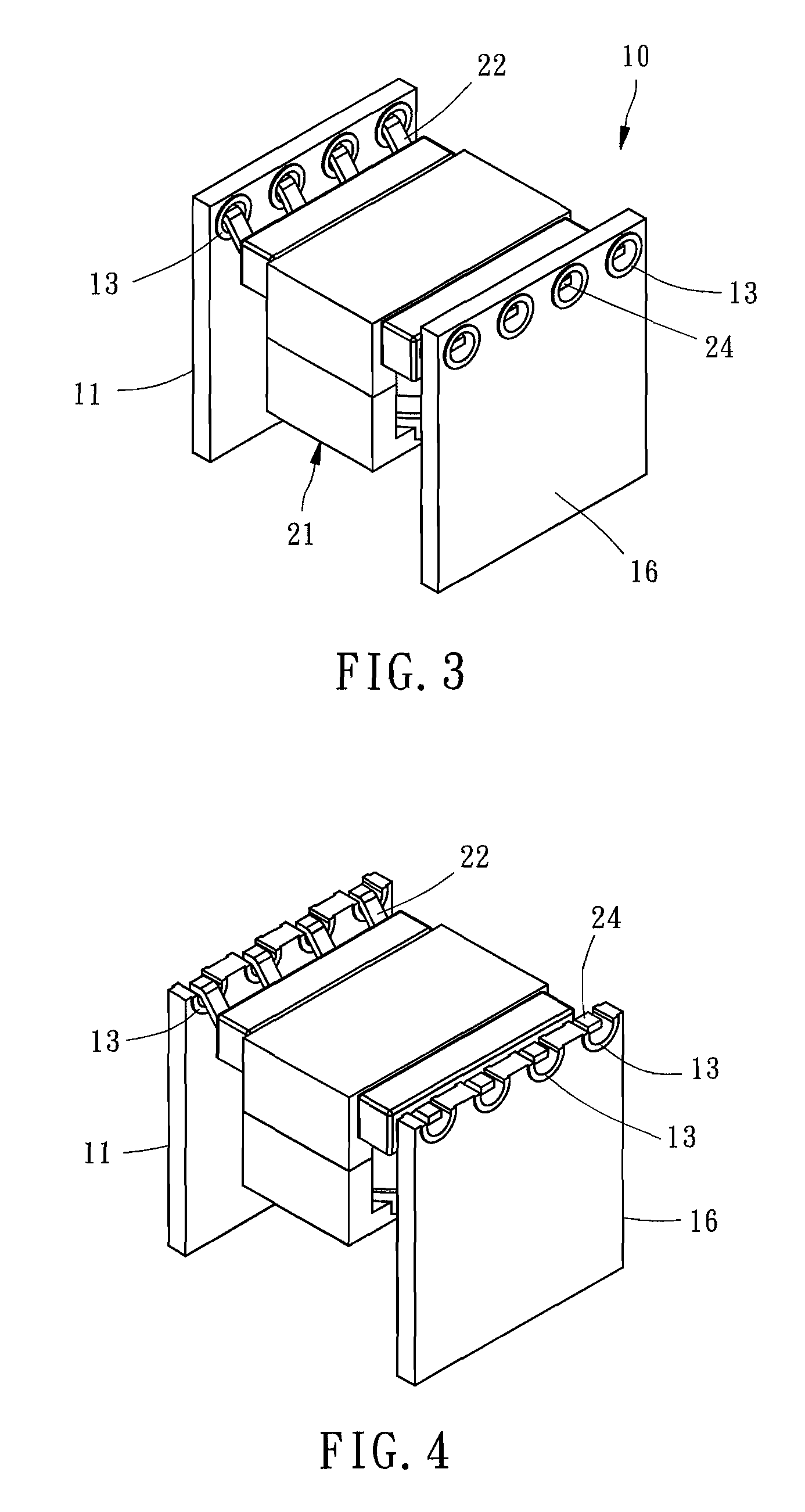

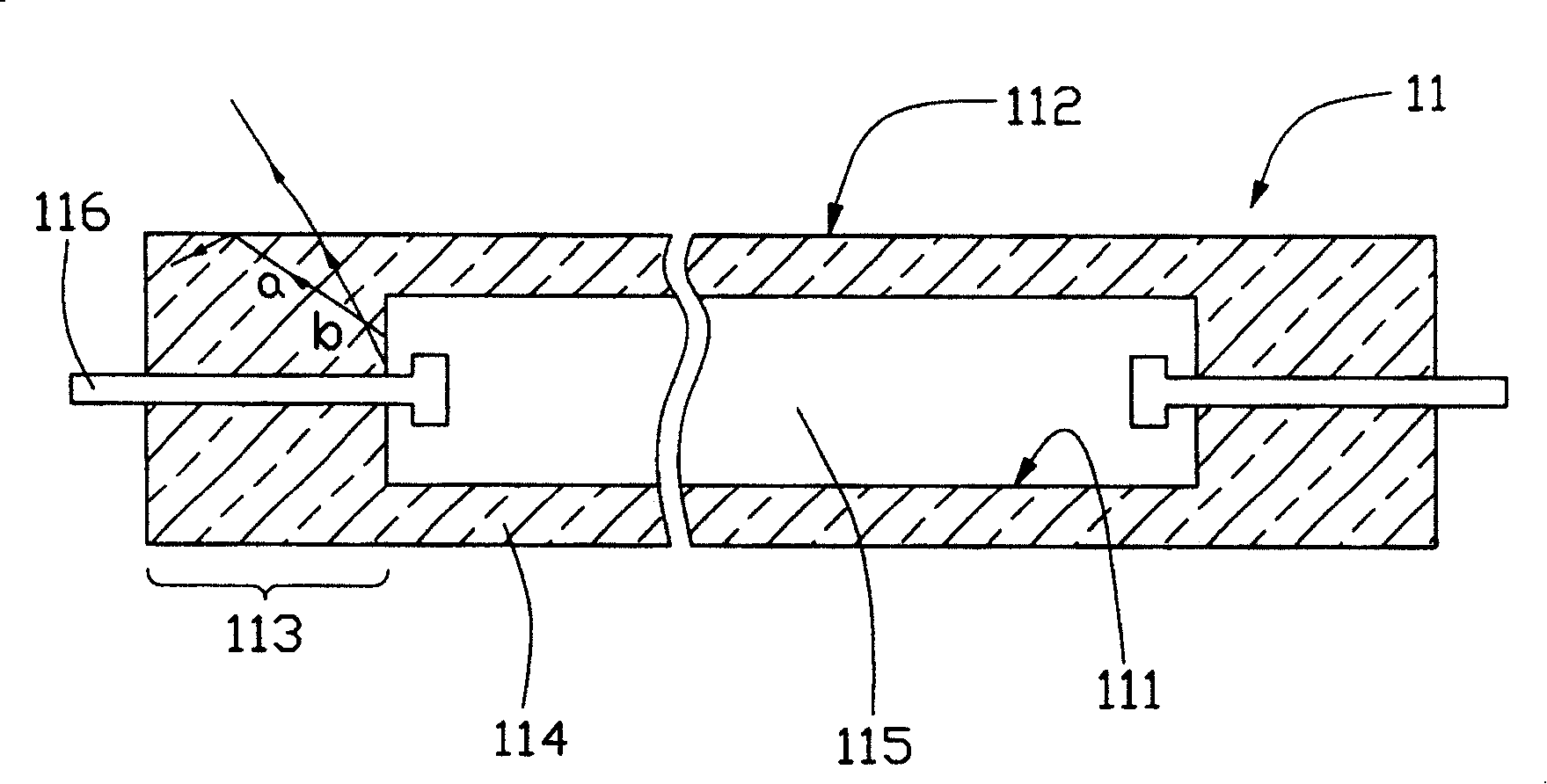

Miniaturize voltage-transforming device

ActiveUS9148066B2Reduce assembly volumeConversion constructional detailsTransformers/inductances coils/windings/connectionsElectricityMiniaturization

A miniaturized voltage-transforming device includes a first circuit board and a second circuit board parallel to and separated from each other by a predetermined distance so that there is no physical connection therebetween, and a transformer having a plurality of primary-side pins and a plurality of secondary-side pins, wherein the transformer is located beside the first circuit board and the second circuit board, and has its primary-side pins and secondary-side pins directly or indirectly connected to the first circuit board and the second circuit board physically, so that the transformer is electrically connected to the first circuit board and the second circuit board via the primary-side pins and the secondary-side pins.

Owner:POWER MATE TECH CO LTD

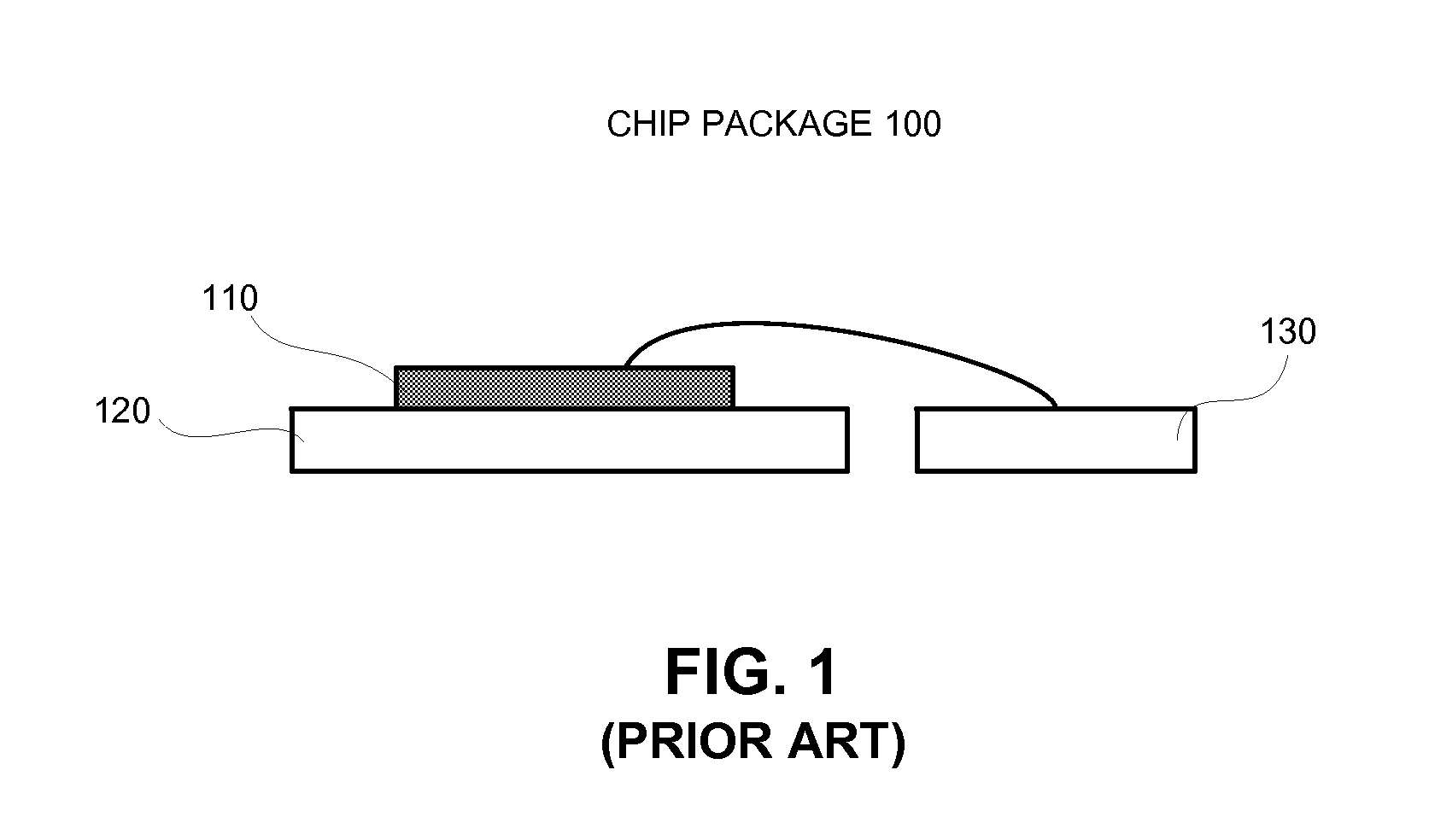

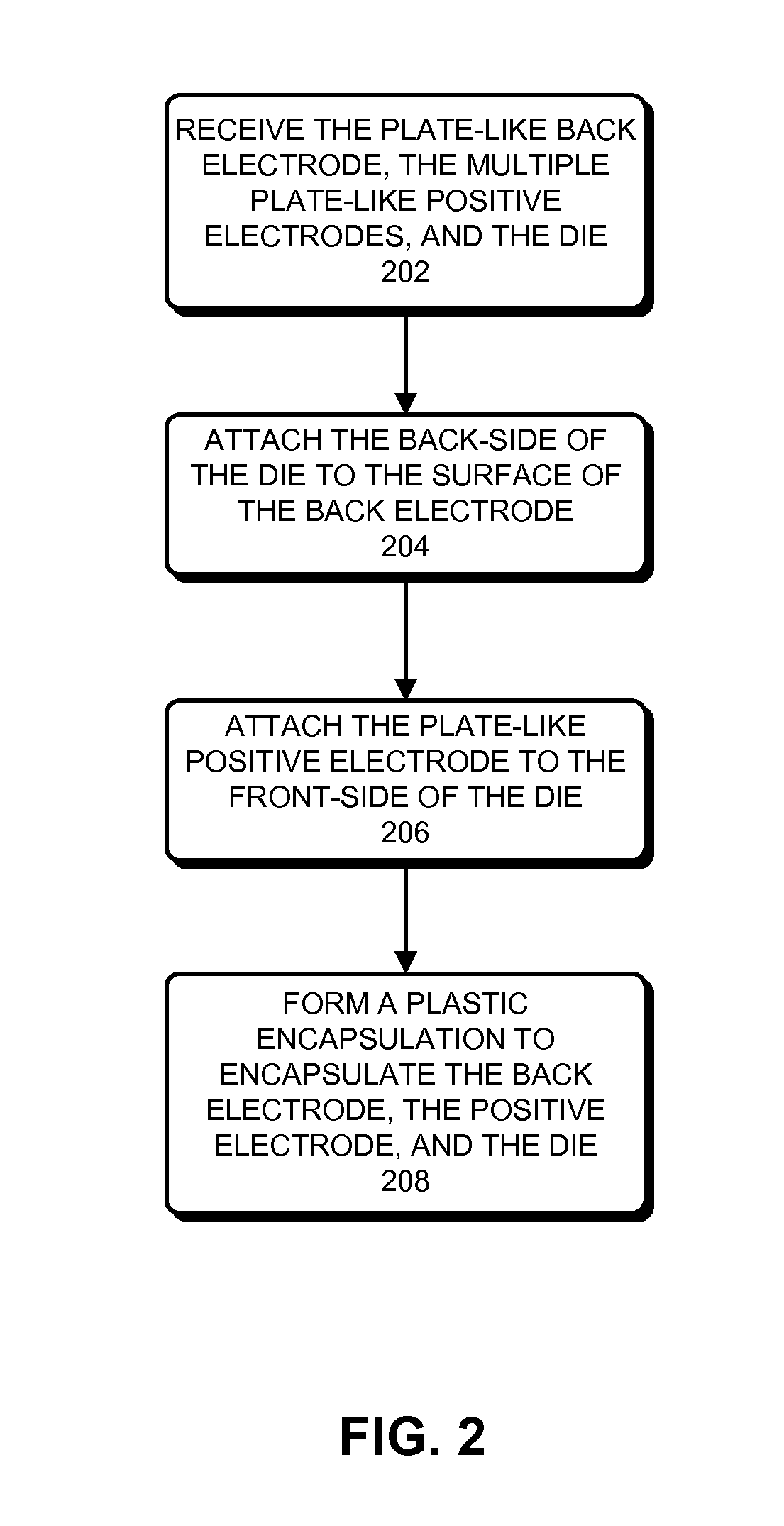

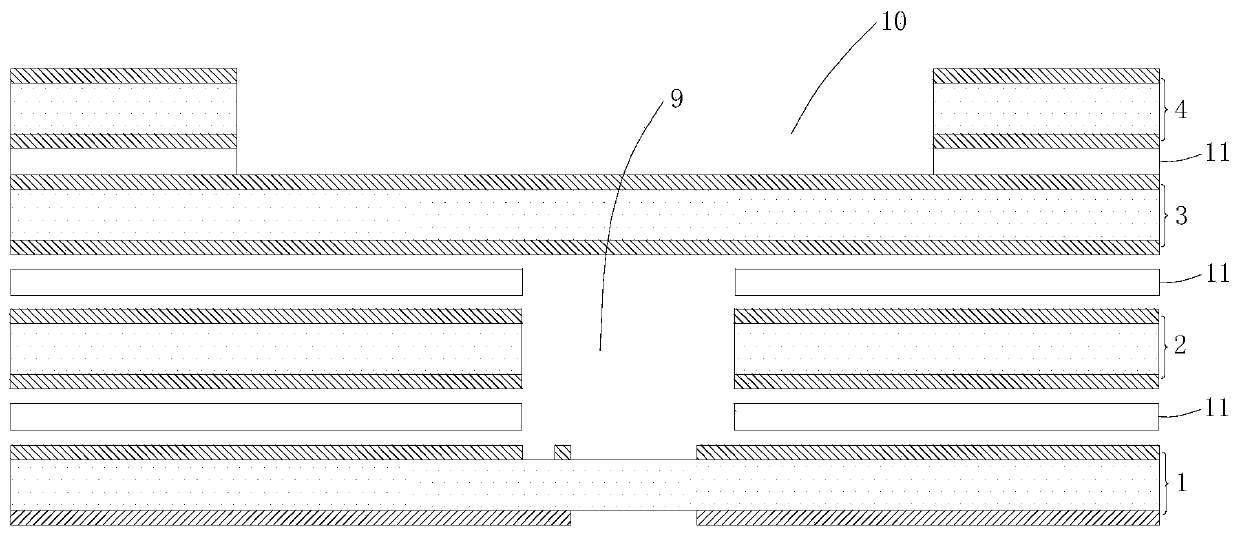

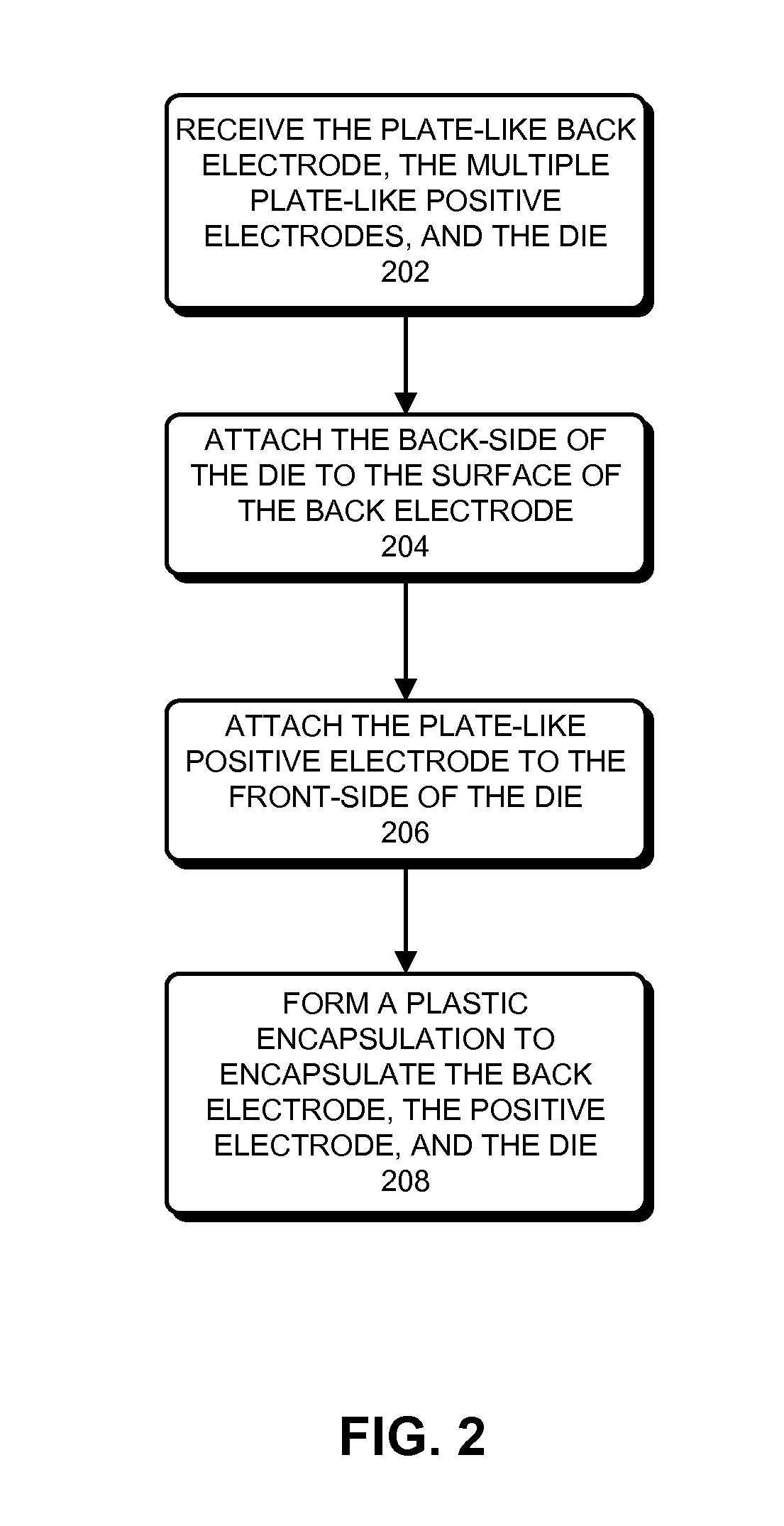

Ultra-small chip package and method for manufacturing the same

ActiveUS20130147029A1Lower the volumeSmall volumeSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

Some embodiments of the present disclosure provide the design and manufacture of an ultra-small chip assembly. The ultra-small chip assembly comprises a die, a plate-like back electrode disposed on the back-side of the die, and one or more plate-like positive electrodes disposed on the front-side of the die. The ultra-small chip assembly is configured such that one end of the plate-like back electrode extends beyond a first side of the die, and each of the one or more plate-like positive electrodes includes an end which extends beyond a second side of the die. By attaching both the plate-like back electrode and the plate-like positive electrodes on the surfaces of the die, and directly using the exposed ends of the plate-like electrodes as the lead-out electrodes for the chip assembly, the electrical connections outside of the die only occupy a very small volume.

Owner:DIODES INC

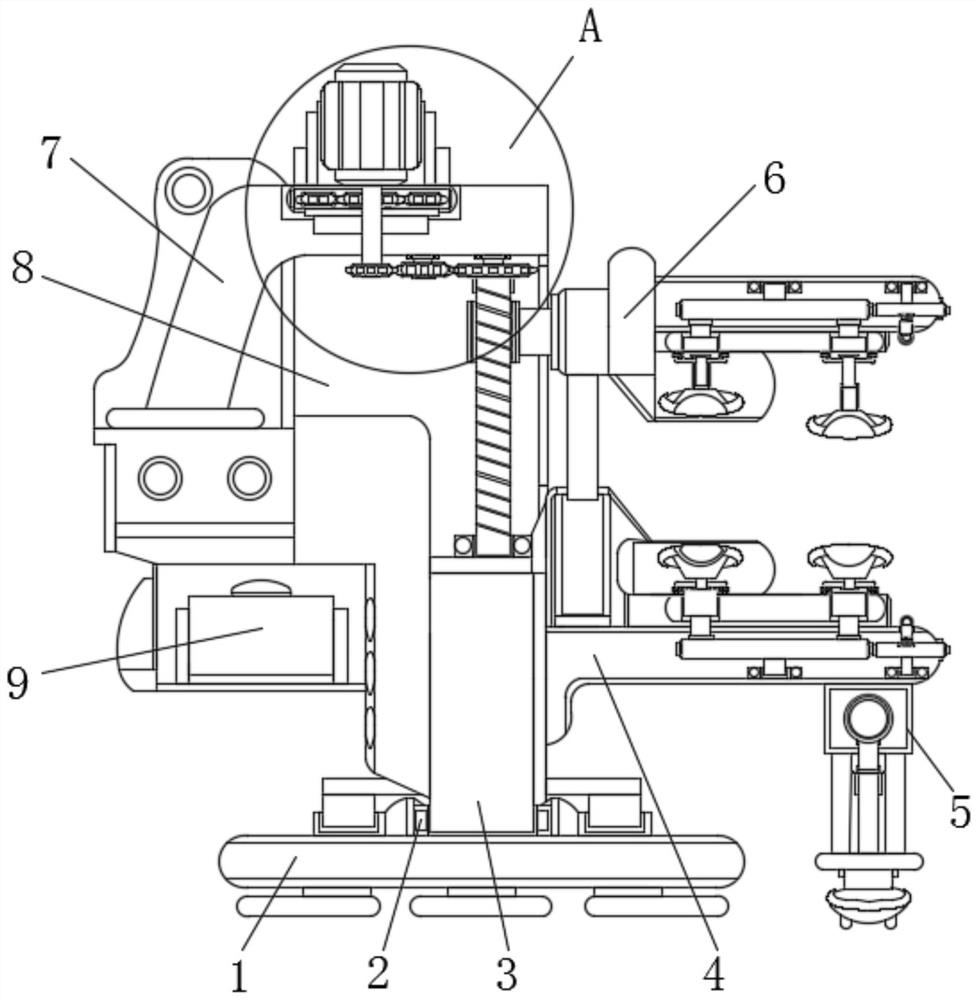

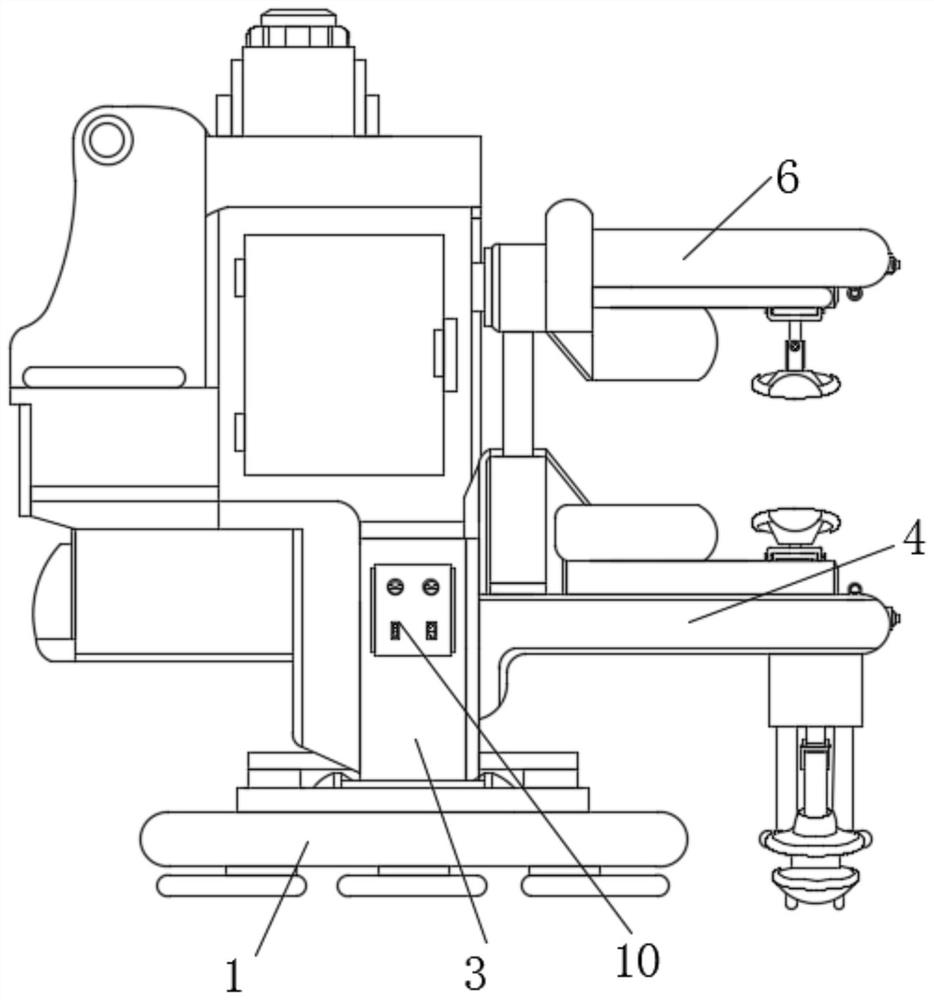

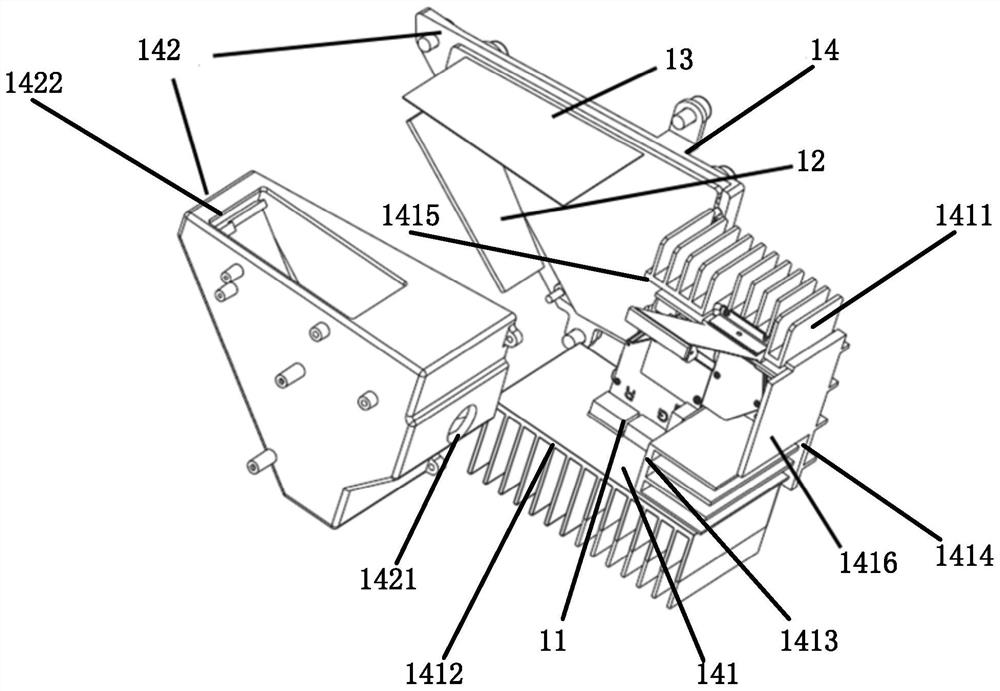

Cable connection crimping machine and crimping method

PendingCN113422274APrevent flaws in the connectionReduce adhesionLine/current collector detailsElectric cablesDC motor

The invention discloses a cable connection crimping machine and a crimping method. The cable connection crimping machine comprises a base, wherein the middle position of the top part of the base is provided with a rotating disc, the inner side of the rotating disc is sleeved with a mounting base, the top part of the mounting base is provided with a machine body, one side of the machine body is provided with a connecting frame, the top part of one side of the base is provided with a lower crimping table, and a low-voltage DC motor is arranged on one side of the top part of the machine body. According to the cable connection crimping machine, through mutual cooperation of crimping adjusting assemblies, two different types of continuous cable molds are assembled at the corresponding positions of the lower crimping table and an upper crimping table, and angle adjustment is carried out on a slide block by utilizing stirring of a stirring wheel and a stirring disc, such that a first crimping die set or a second crimping die set can be adjusted to a corresponding position for press-fit and continuation, and when the first crimping die set and the second crimping die set are not used, the first crimping die set and the second crimping die set can be hidden and protected in semi-arc-shaped hidden grooves, so that dust adhering to the surfaces of parts is reduced.

Owner:华容县星星营销传媒中心

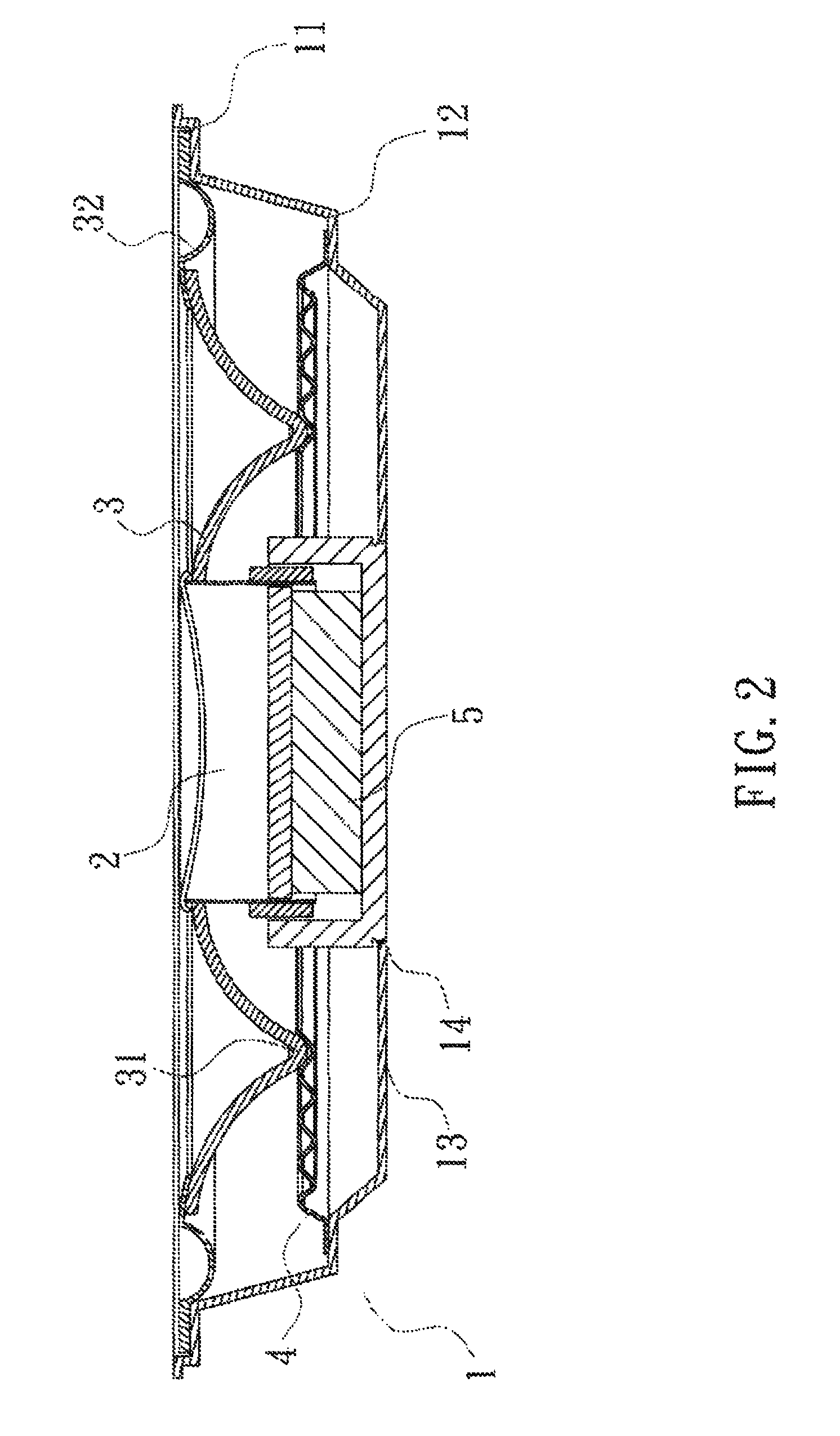

Slim speaker

InactiveUS8428294B2Easy to installSmooth vibrationTransducer detailsNon-planar diaphragms/conesResonanceEngineering

Owner:LIU CHUN I

Self-draining oil buoyancy regulating device for underwater robots

ActiveUS10308334B2Easy to controlQuick switchPump controlPositive-displacement liquid enginesHydraulic pumpCheck valve

Owner:ZHEJIANG UNIV

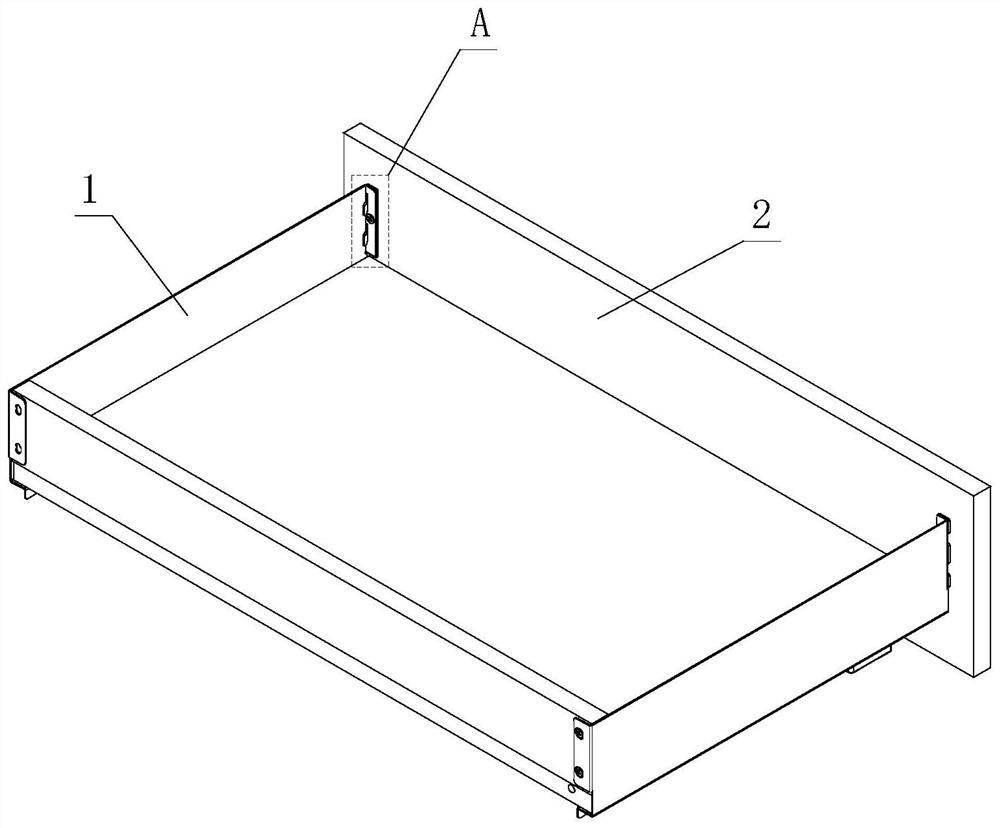

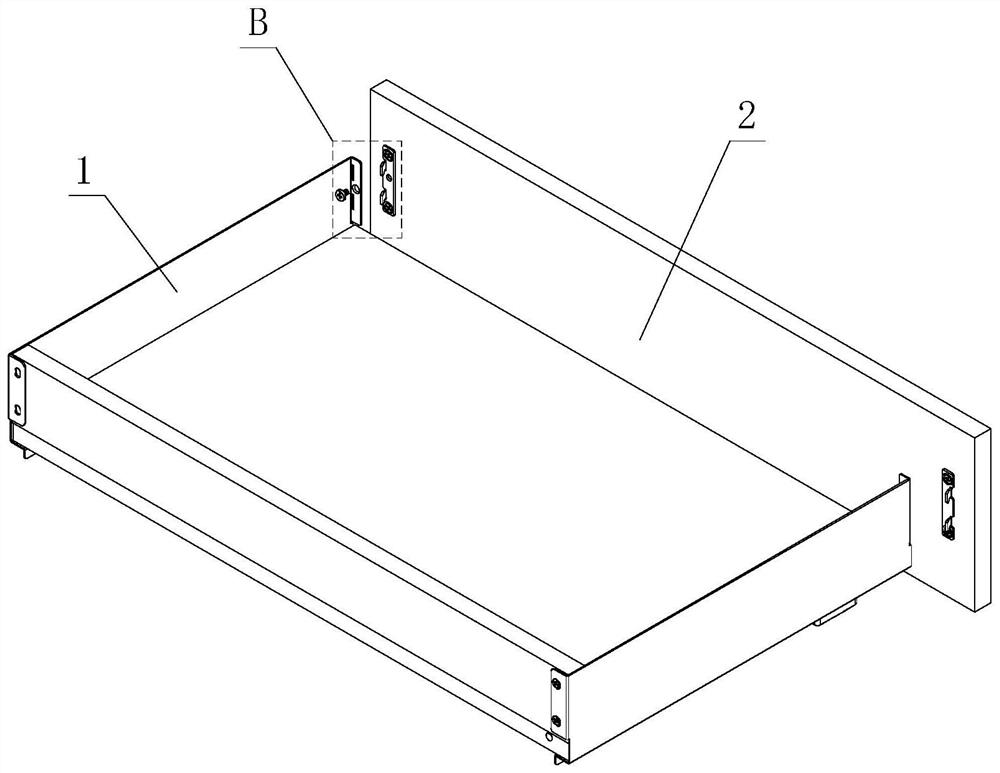

Convenient disassembly and assembly structure for furniture drawer

PendingCN112656148AReduce assembly volumeIncreased internal storage spaceDrawersStructural engineeringAssembly structure

A convenient disassembly and assembly structure for a furniture drawer comprises a side plate and a connecting piece. The side plate is a sheet metal part, and a clamping part is arranged at the front end of the side plate; and a clamping matching part is arranged on the connecting piece, and the connecting piece is detachably clamped on the clamping part through the clamping matching part. Through the improvement of the structure, the side plate is made of the sheet metal part, so that the overall assembly size of the drawer is reduced, the internal storage space of the drawer is increased, meanwhile, the clamping part is arranged at the front end of the side plate, the connecting piece is provided with the clamping matching part, and the connecting piece is detachably clamped on the clamping part through the clamping matching part. The clamping structure is simple, thus the assembly and disassembly operation is easy, meanwhile, a panel is assembled on the connecting piece, the convenient, quick and efficient disassembly and assembly effect between the side plate and the panel can be finally realized, a series of problems of difficulty in disassembly and assembly, inconvenience in operation and the like caused by the fact that the panel in the prior art can be fixed with the front bent part of the side plate only by adopting a fastener are solved, and the use experience of a user is improved.

Owner:GUANGDONG DTC HARDWARE PRECISION MFG CO LTD

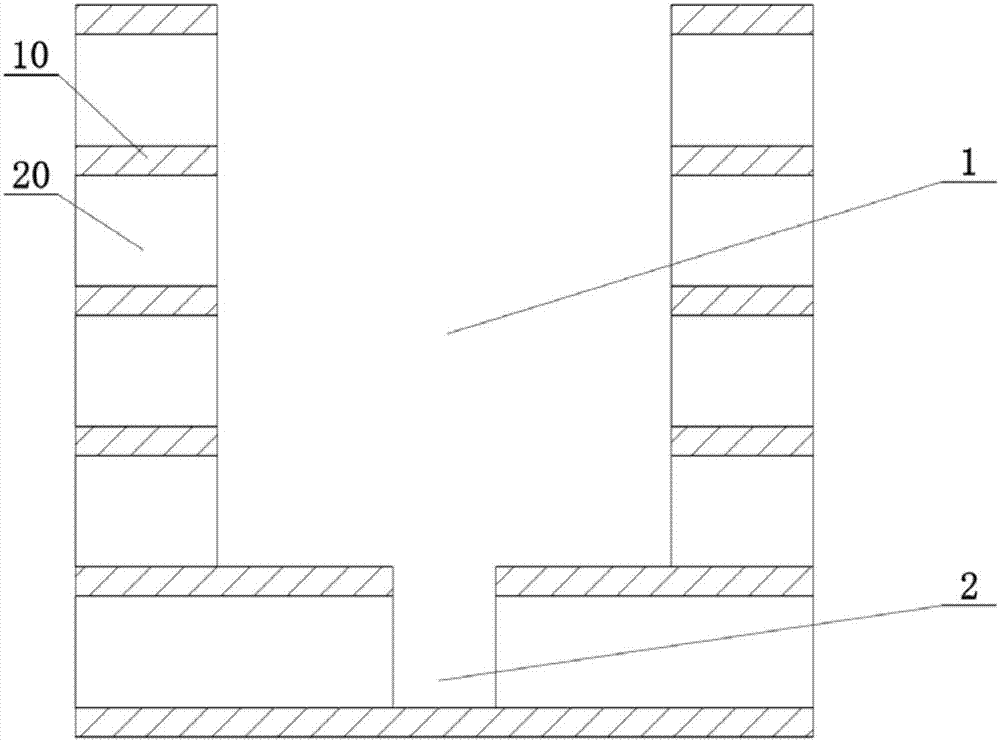

Preparation method of PCB with step groove

InactiveCN108012465ATake advantage ofReduce assembly volumePrinted circuit aspectsMultilayer circuit manufactureBiochemical engineeringPrinted circuit board

Owner:DONGGUAN SHENGYI ELECTRONICS

Telescopic structure, selfie stick, lamp holder and photography tripod

PendingCN113137412AEasy to operateSimple structureRod connectionsStands/trestlesEngineeringTripod (photography)

The invention discloses a telescopic structure which comprises an inner pipe, an outer pipe, a telescopic assembly connected with the inner pipe and a driving surface arranged on the outer pipe, wherein the telescopic assembly comprises an elastic piece and a protruding part, one end of the protruding part abuts against the elastic piece, the other end of the protruding part extends out of the side wall of the inner pipe, an inclined surface is formed on the protruding part, the driving surface and the end face of the outer pipe are located at different horizontal heights, when the inner pipe moves towards the outer pipe, the driving surface extrudes the convex part to move inwards along the inclined surface, and then the outer pipe continuously extrudes the convex part along the inclined surface, so that the convex part is propped against the inner wall of the outer pipe to translate, and the inner pipe and the outer pipe are overlapped and shrunk along the axial direction. The invention further discloses a selfie stick, a lamp holder and a photography tripod. The matching structure of the telescopic assembly and joints is simple, and the assembly size is reduced; and the adjacent pipe bodies can contract automatically without independent operation, operation is easy and convenient, and the length control flexibility is high.

Owner:陈庆元

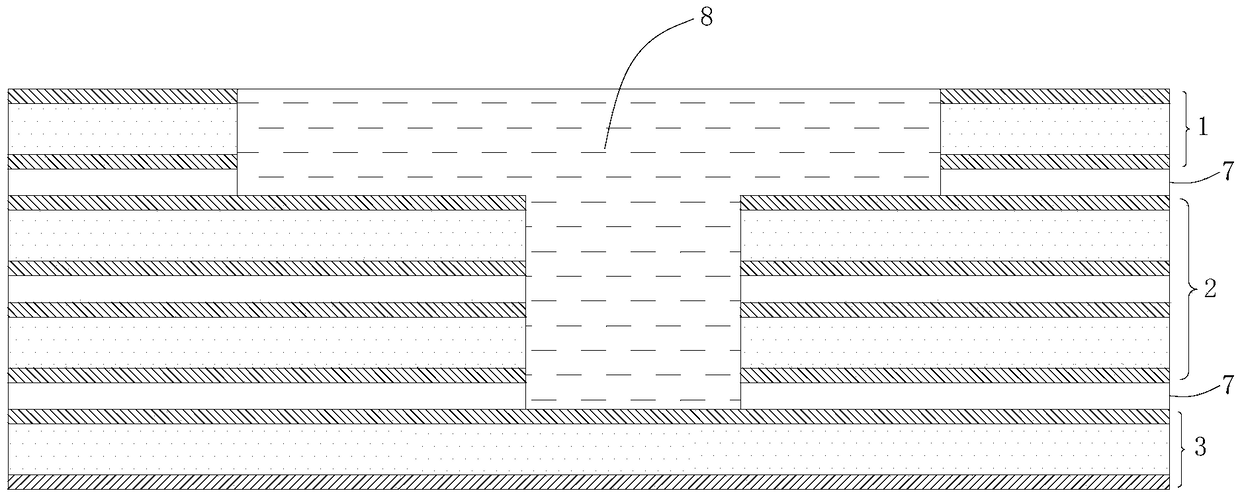

PCB with step groove

InactiveCN108012404ATake advantage ofReduce assembly volumePrinted circuit aspectsPrinted circuit non-printed electric components associationPrinted circuit boardBiochemical engineering

The invention belongs to the technical field of printed circuit boards and discloses a PCB with a step groove. A first groove is formed in the PCB; a second groove is formed in the bottom of the firstgroove; the cross section area of the second groove is smaller than that of the first groove; the first groove is matched with the second groove to form the step groove; a side wall of the first groove is a nonmetallic side wall; and a circuit pattern is arranged at the bottom of the first groove. According to the PCB with the step groove, through the arrangement of the second groove in the bottom of the first groove, the space in the step groove is more fully utilized; and components of multiple specifications can be arranged in the step groove, so that the assembly volume of the PCB is reduced.

Owner:DONGGUAN SHENGYI ELECTRONICS

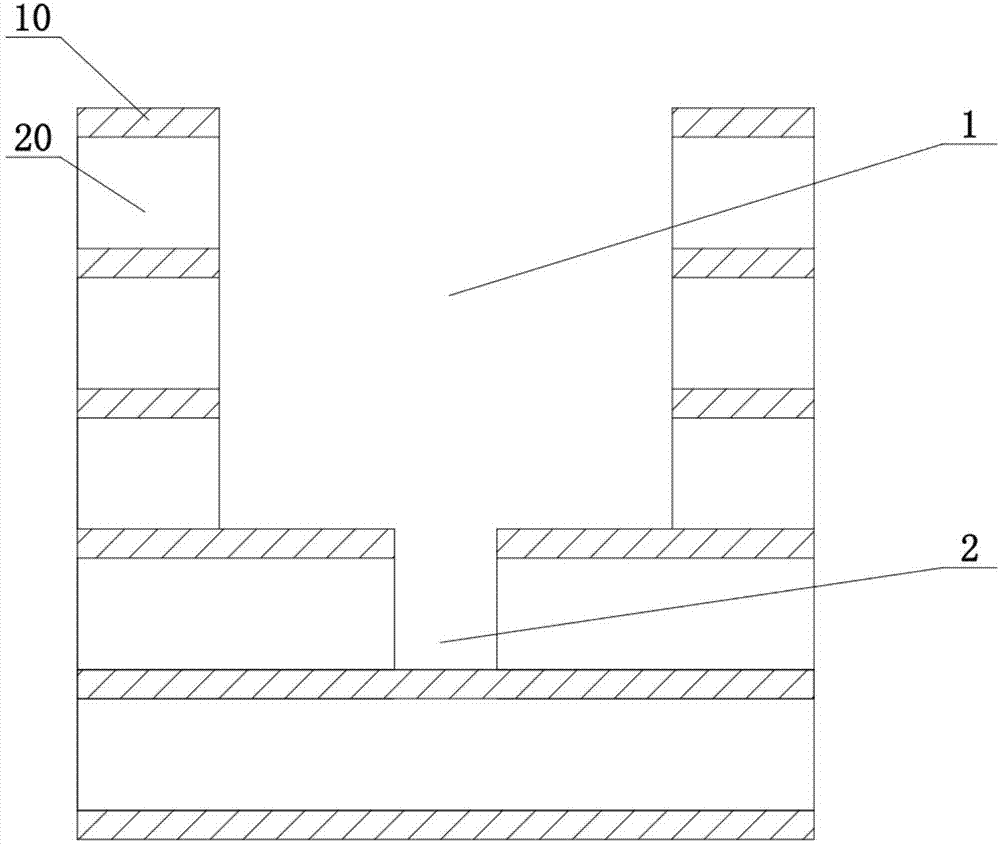

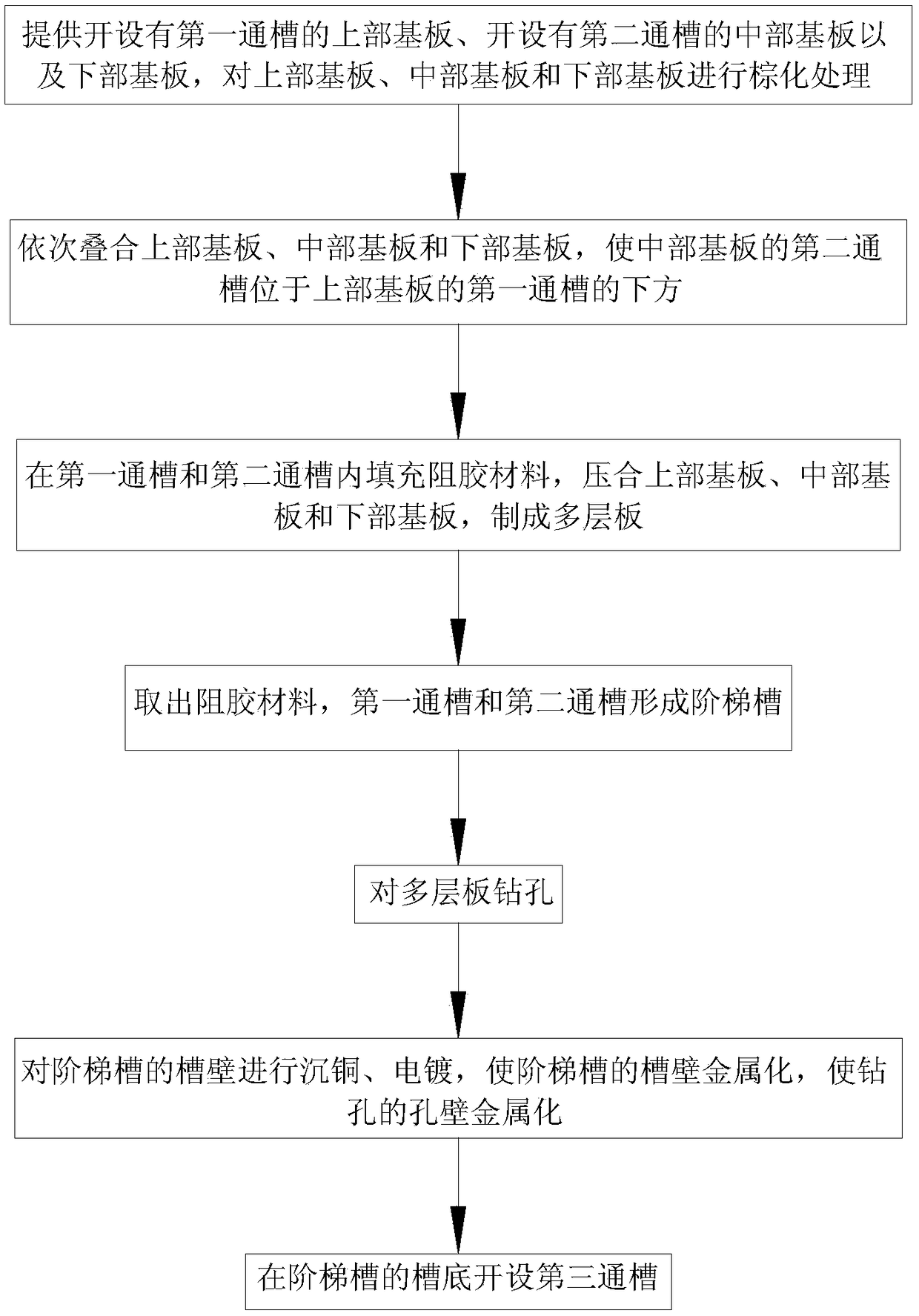

PCB manufacturing method

ActiveCN108882568ARealize submerged installationEasy to placePrinted circuit aspectsMultilayer circuit manufactureEngineeringMultiple layer

The invention relates to the technical field of circuit board production, and discloses a PCB manufacturing method. The method comprises the steps of: S1, providing an upper substrate with a first through groove opened, a middle substrate with a second through groove opened and a lower substrate, and sequentially stacking the upper substrate, the middle substrate and the lower substrate so that the second through groove of the middle substrate is located below the first through groove of the upper substrate; S2, filling the glue blocking material in the first through groove and the second through groove, and pressing the upper substrate, the middle substrate and the lower substrate to form a multilayer board; S3, taking out the glue blocking material, and forming a step groove by the firstthrough groove and the second through groove; S4, carrying out copper deposition and electroplating on the groove wall of the step groove, and metalizing the groove wall of the step groove; and S5, opening a third through groove on the bottom of the groove of the step groove. According to the PCB manufacturing method of the invention, the mounting of the special-shaped component and different sizes of component are realized by forming a step groove with multiple layers of steps on the PCB, thereby reducing the occupied space of the PCB.

Owner:DONGGUAN SHENGYI ELECTRONICS

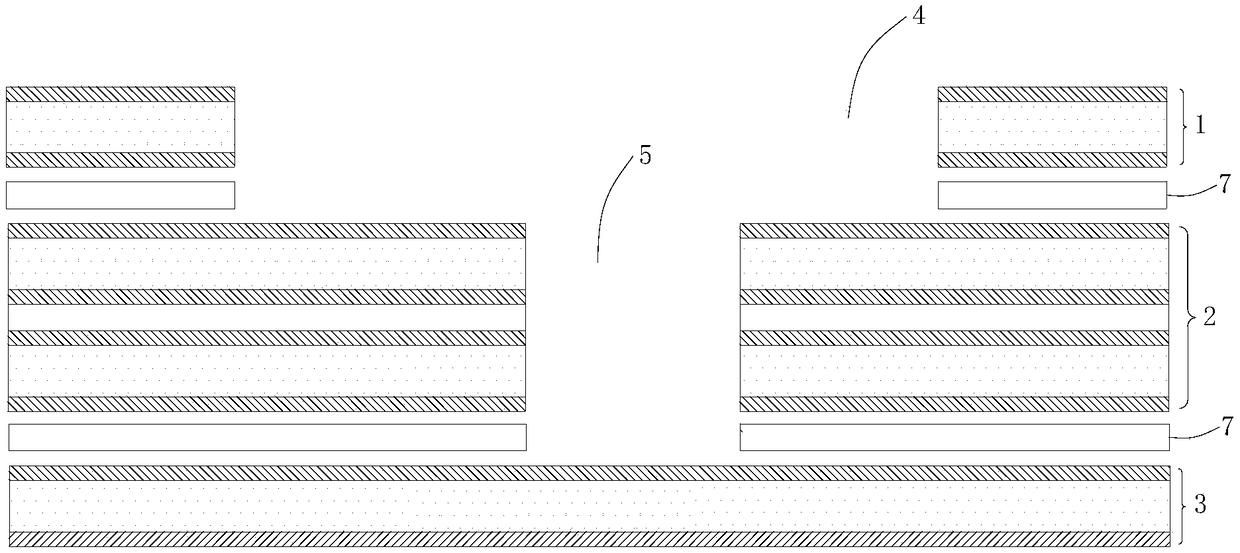

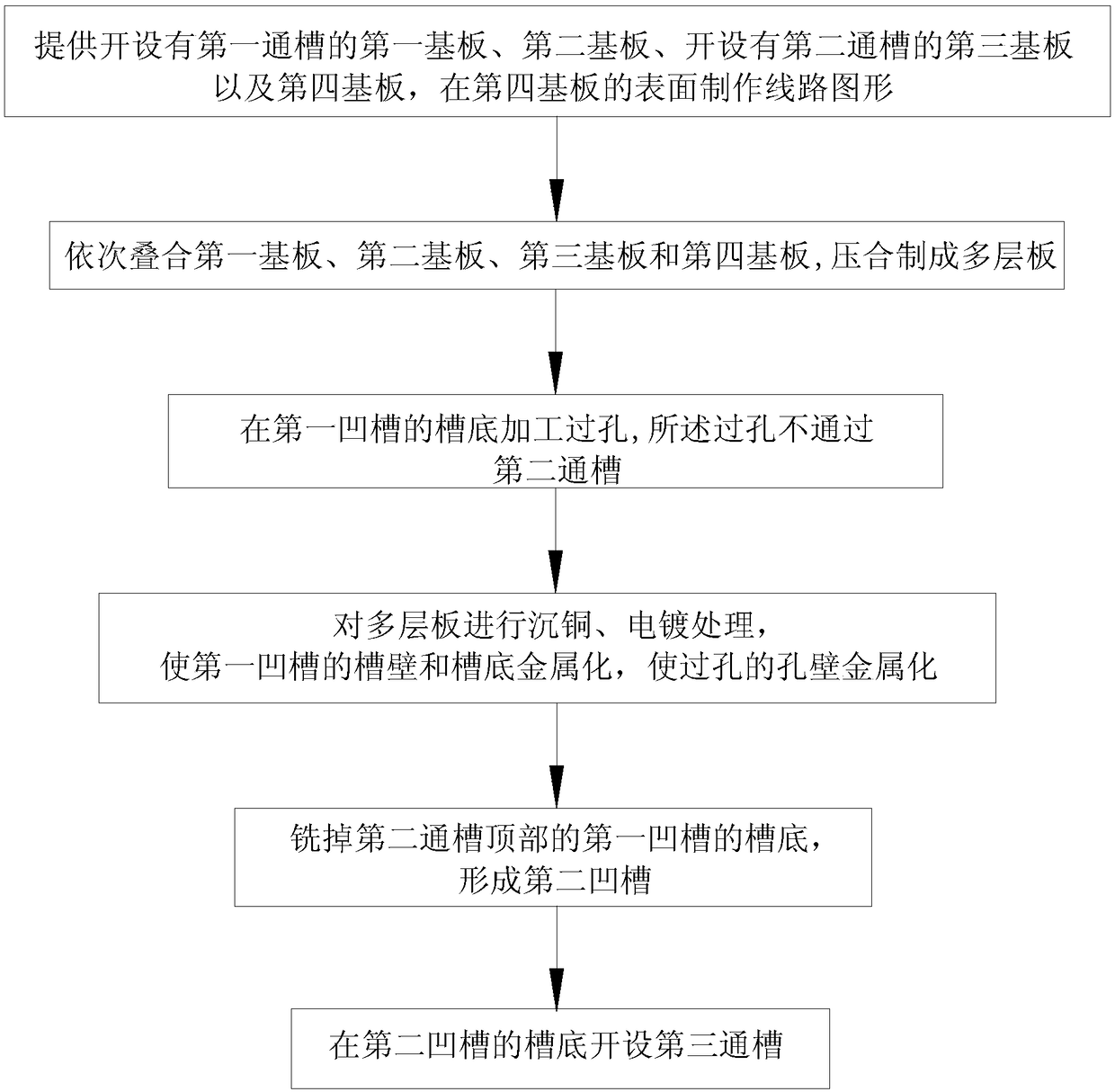

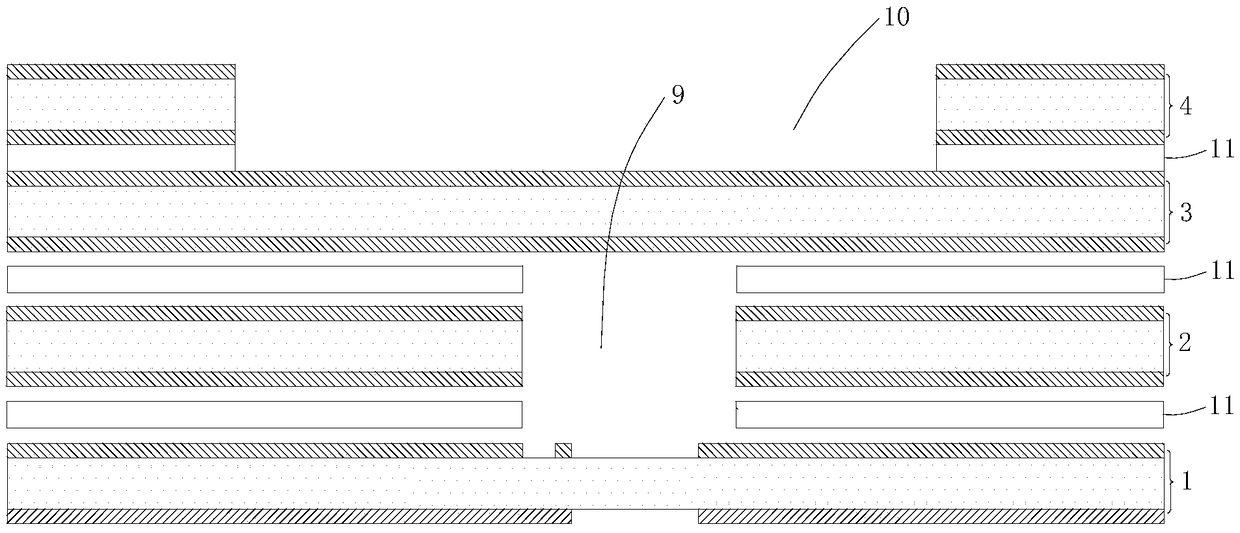

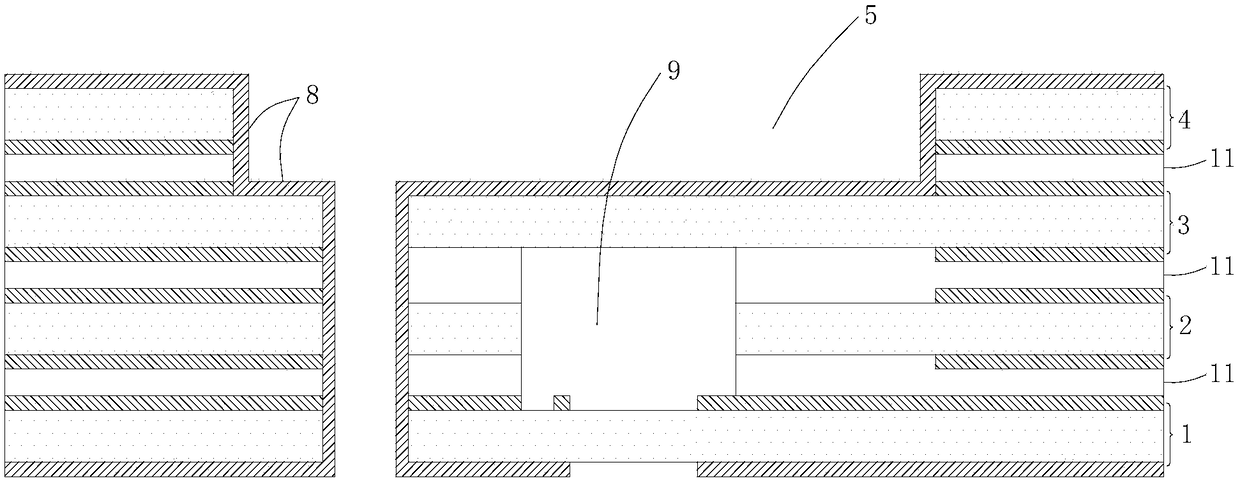

Manufacturing method of PCB

ActiveCN108834336AEasy to placeSave installation spacePrinted circuit assemblingCross-talk/noise/interference reductionBiochemical engineeringMiniaturization

The invention relates to the technical field of circuit board production, and discloses a manufacturing method of a PCB, comprising the following steps: S1, providing a first substrate having a firstthrough groove, a second substrate, a third substrate having a second through groove and a fourth substrate, and forming a circuit pattern on the surface of the fourth substrate; S2, sequentially laminating the first substrate, the second substrate, the third substrate and the fourth substrate, and forming a multilayer board by compression; S3, subjecting the multilayer board to copper immersion and electroplating to metallize the groove wall and the groove bottom of a first groove; S4, milling the groove bottom of the first groove at the top of the second through groove to form a second groove; and S5, forming a third through groove in the groove bottom of the second groove. The manufacturing method of the PCB according to the present invention realizes the mounting of the special-shapedcomponent and a plurality of components of different sizes, reduces the occupied space of the PCB, and forms a circuit pattern at the groove bottom of the stepped groove, which is beneficial to further miniaturization of the PCB.

Owner:DONGGUAN SHENGYI ELECTRONICS

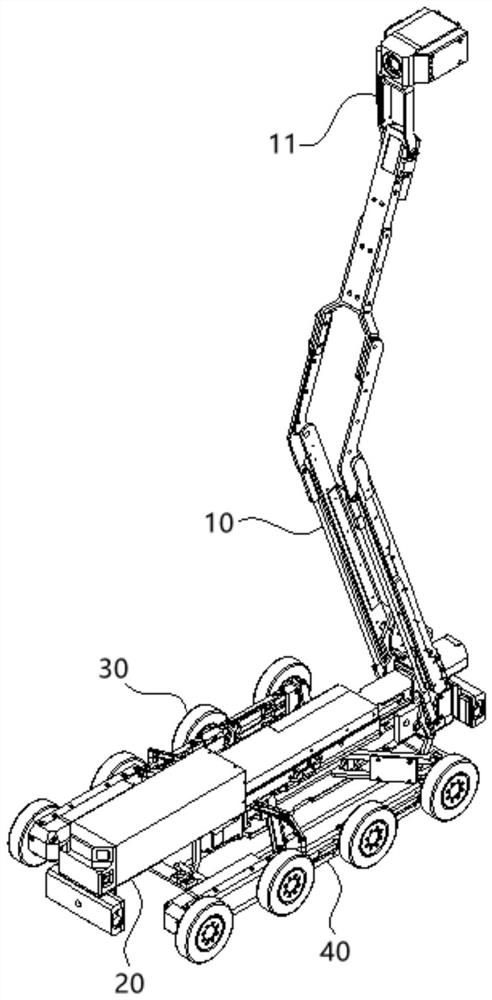

Inspection robot camera lifting platform and cable trench inspection robot

PendingCN114102631ARealize the controllable function of lifting heightMiniaturizationTelevision system detailsChecking time patrolsStructural engineeringWork unit

The invention discloses an inspection robot camera lifting platform and a cable trench inspection robot, and relates to the technical field of cable inspection, and the inspection robot camera lifting platform comprises a working unit, a four-bar linkage assembly and a straight stroke driving mechanism; the working unit comprises a camera and a pitching mechanism, and the pitching mechanism can drive the camera to generate pitching action; the four-connecting-rod assembly comprises an upper long connecting rod, a lower long connecting rod, a head-end short connecting rod and a tail-end short connecting rod, and the head-end short connecting rod, the upper long connecting rod, the tail-end short connecting rod and the lower long connecting rod are sequentially hinged through a horizontal shaft; the straight-stroke driving mechanism comprises a straight-stroke driving source, the four-connecting-rod assembly is hinged to the straight-stroke driving source through a hinged shaft of a head-end short connecting rod and an upper-portion long connecting rod, and the working end of the straight-stroke driving source is in sliding fit with the upper-portion long connecting rod and the head-end short connecting rod. The cable trench has the advantage of being capable of better adapting to the narrow and cramped cable trench environment.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

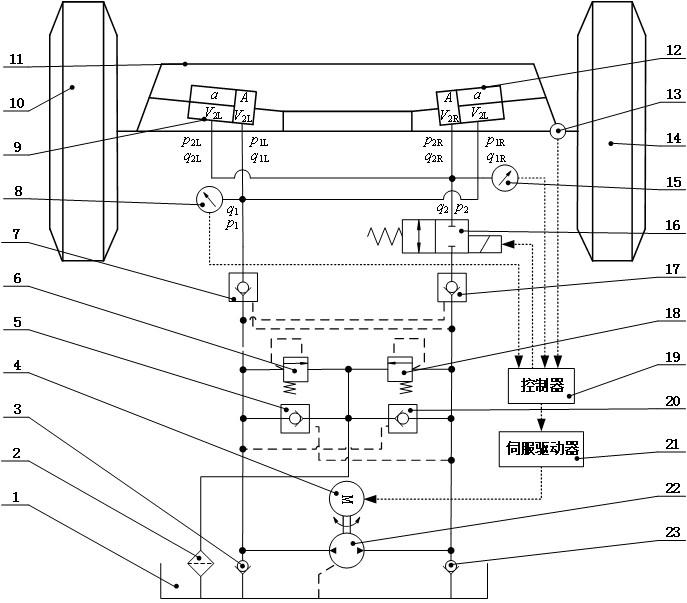

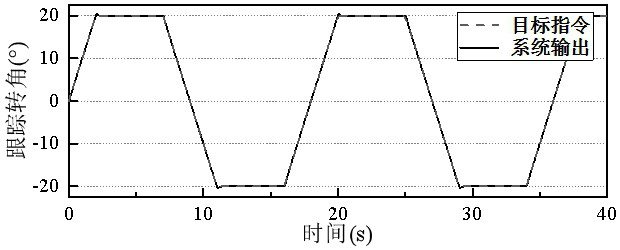

Heavy vehicle electro-hydraulic servo steering system and control method capable of suppressing overshoot

ActiveCN114655306ASave hardware costSave maintenance costFluid steeringAdaptive controlLoop controlSteering wheel

The invention relates to a heavy vehicle electro-hydraulic servo steering system and a control method capable of suppressing overshoot. The heavy vehicle electro-hydraulic servo steering system comprises a hydraulic subsystem, a mechanical subsystem, a data acquisition subsystem and a controller. The data acquisition subsystem is used for acquiring the actual turning angle of a steering wheel and the pressure of each pressure sensor; the controller calculates and outputs control voltage of the servo driver according to the target rotating angle of the system, the actual rotating angle of the steering wheel and the pressure of each pressure sensor so as to control the hydraulic subsystem. According to the invention, corner closed-loop control of the system can be realized, and system overshoot can be reduced while high-dynamic tracking control of the system can be realized.

Owner:FUZHOU UNIV

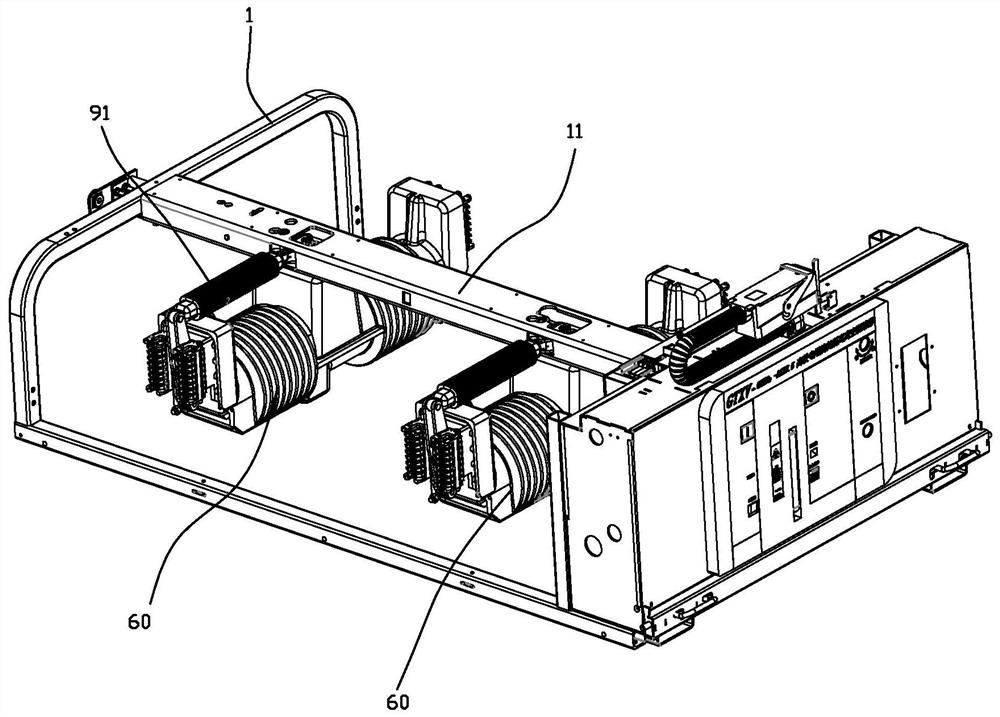

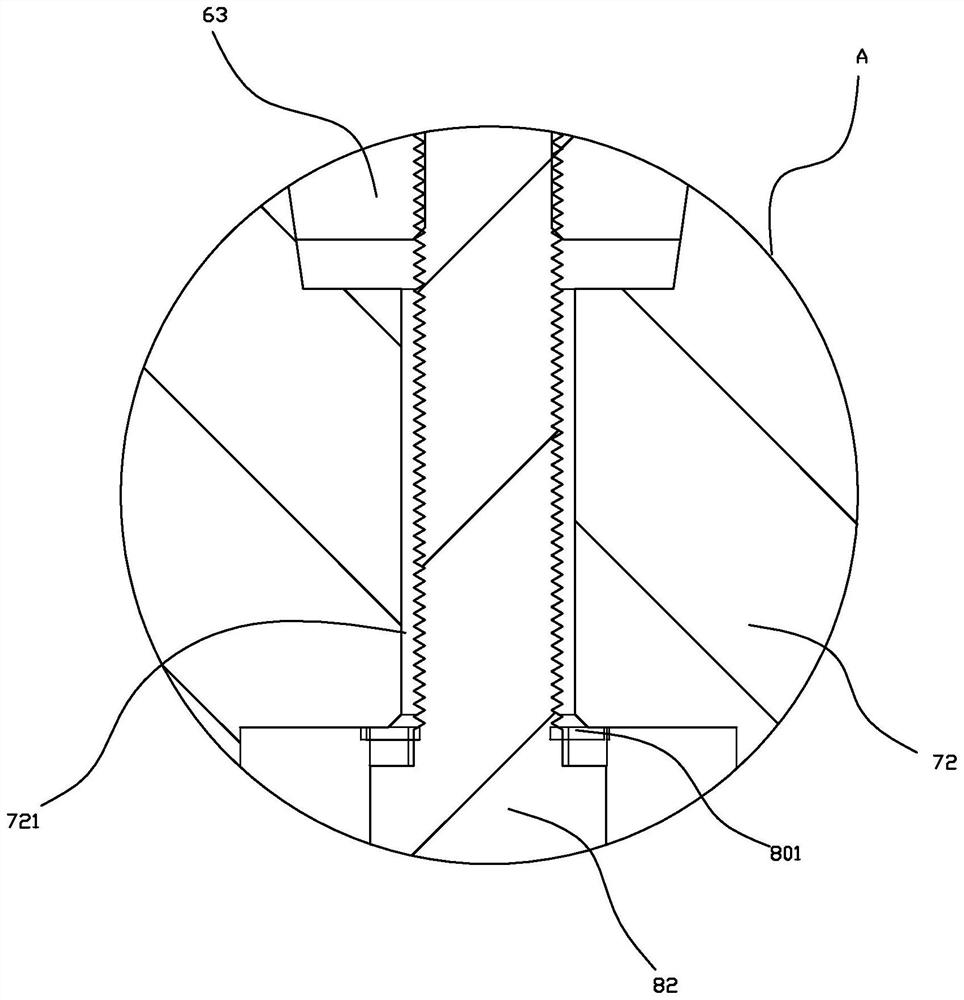

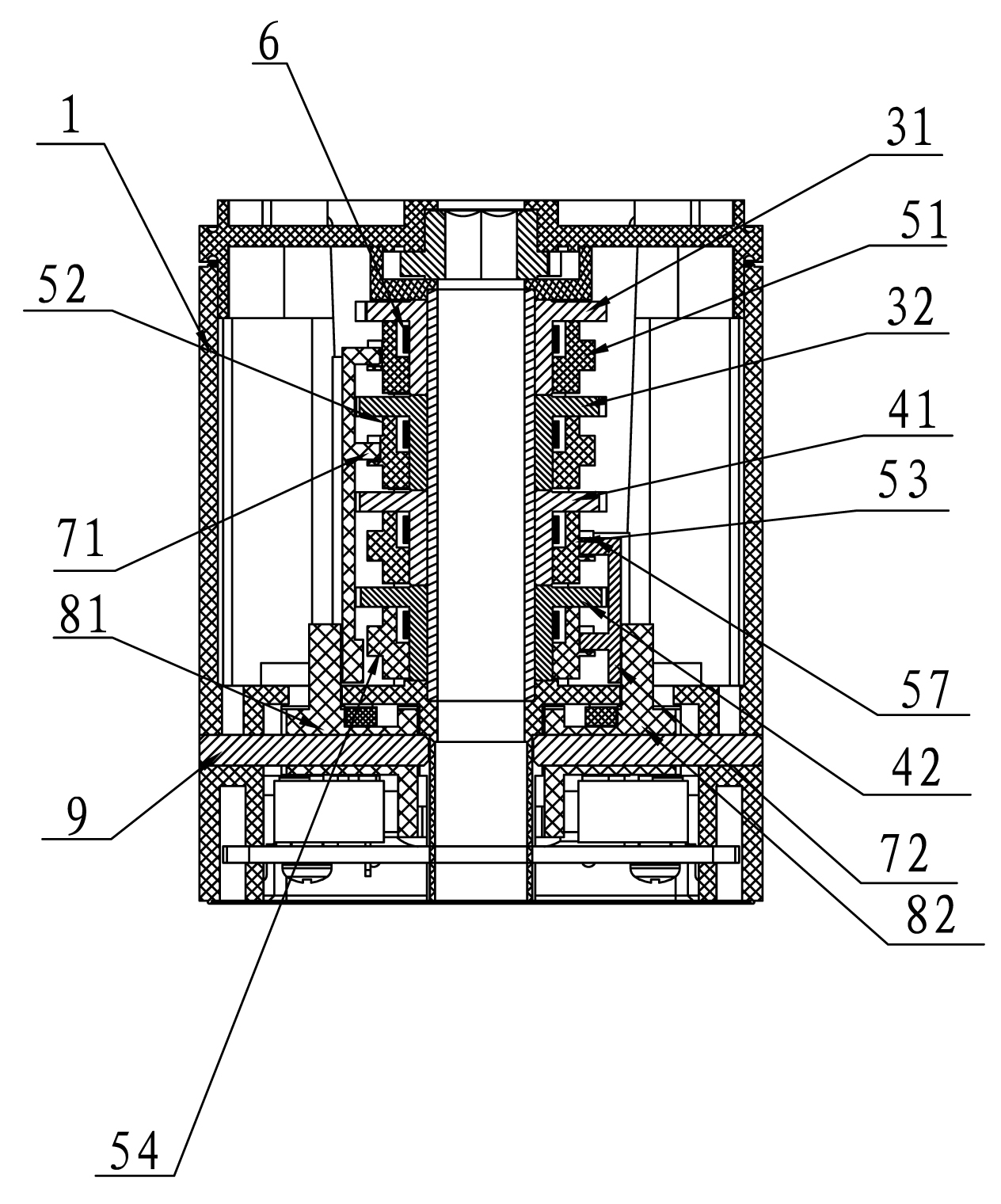

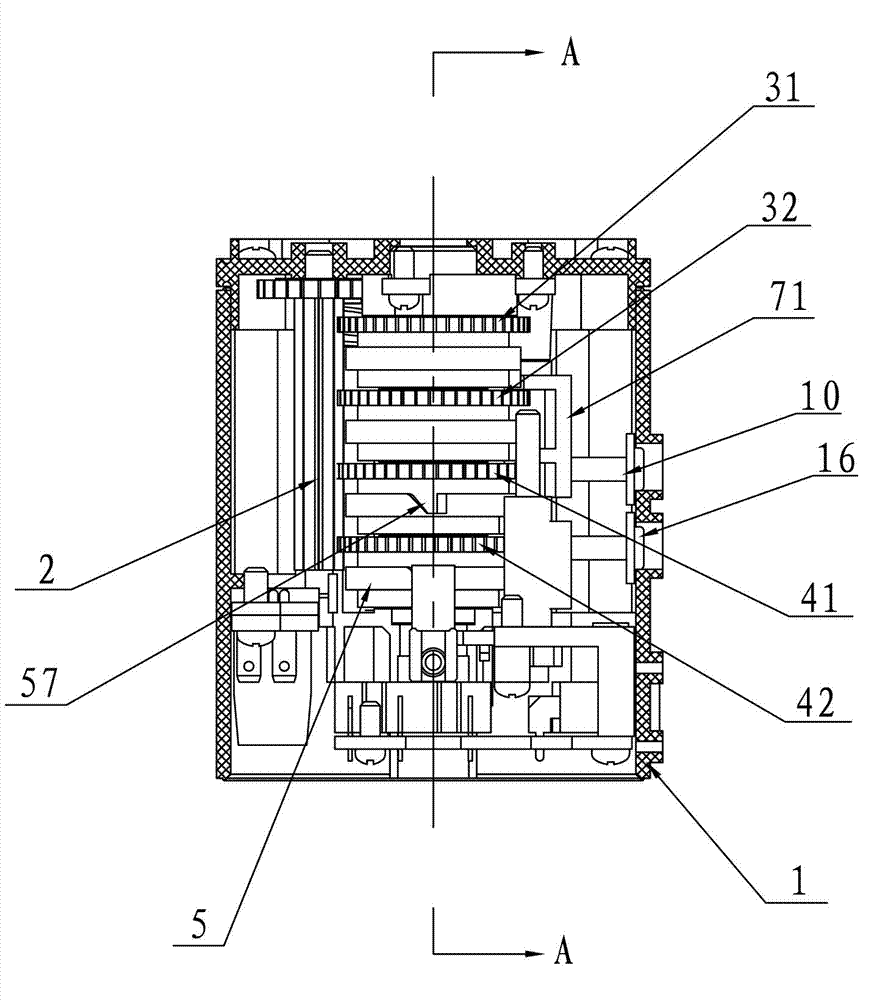

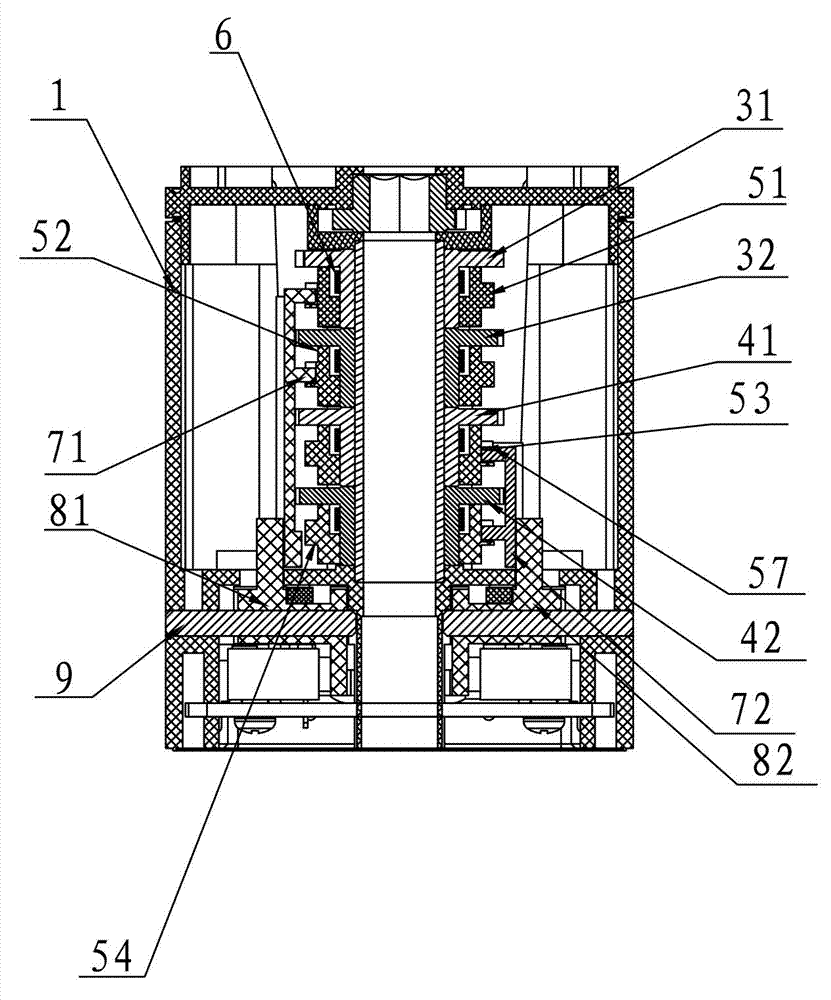

a circuit breaker

ActiveCN108899244BStable structureEasy to assembleHigh-tension/heavy-dress switchesAir-break switchesElectrical conductorElectrical connection

The invention provides a circuit breaker. The movable end of the vacuum interrupter of the pole is fixedly electrically connected to a movable conductive rod, and a lower outlet seat is provided in the accommodating cavity, and the movable conductive rod forms a sliding electrical connection with the lower outlet seat. When the movable end of the vacuum interrupter moves, it drives the movable conductive rod to move at the same time, and the movable conductive rod forms a sliding electrical connection with the lower outlet seat to replace the direct connection between the movable end of the vacuum interrupter and the soft conductor in the prior art. The lead-out circuit can be realized by directly connecting the hard copper bar with the lower outlet seat rigidly, with stable structure, easy assembly and low cost. The pole is set on the channel steel, and the channel steel is driven to rotate by the channel steel rotation drive mechanism. The rotation of the channel steel drives the pole to turn over, so that the pole is between the working state of connecting the external power supply end and the power consumption end and the detached storage state switch to realize the function of the isolating switch, save the isolating switch and related components, reduce the assembly volume, and simplify the assembly.

Owner:SUCTRN TECH

Positioning device based on mechanical counting of motor

ActiveCN102025219AEffectively adjust the internal structureReduce assembly volumeMechanical energy handlingTooth numberEngineering

The invention discloses a positioning device based on mechanical counting of a motor, comprising a shell. The shell is internally provided with a driving gear, a clockwise gear set and an anticlockwise gear set, wherein the clockwise gear set and the anticlockwise gear set are fit with the driving gear; the clockwise gear set comprises a pair of differential gears which are arranged at the same axis and have different tooth numbers; the anticlockwise gear set comprises a pair of differential gears which are coaxially arranged and have different tooth numbers; the shell is also internally provided with a clockwise stroke regulating mechanism and an anticlockwise stroke regulating mechanism which are fit with the clockwise gear set and the anticlockwise gear set respectively; and the clockwise gear set and the anticlockwise gear set are arranged at the same axis. By using the positioning device based on the mechanical counting of the motor, the inner structure of the device can be effectively regulated, so that the inner structure is more compact, simultaneously, and the whole volume of the positioning device can be effectively reduced. The positioning device disclosed by the invention can be used in the positioning field of curtain machines.

Owner:GUANGDONG RAEX INTELLIGENT TECH CO LTD

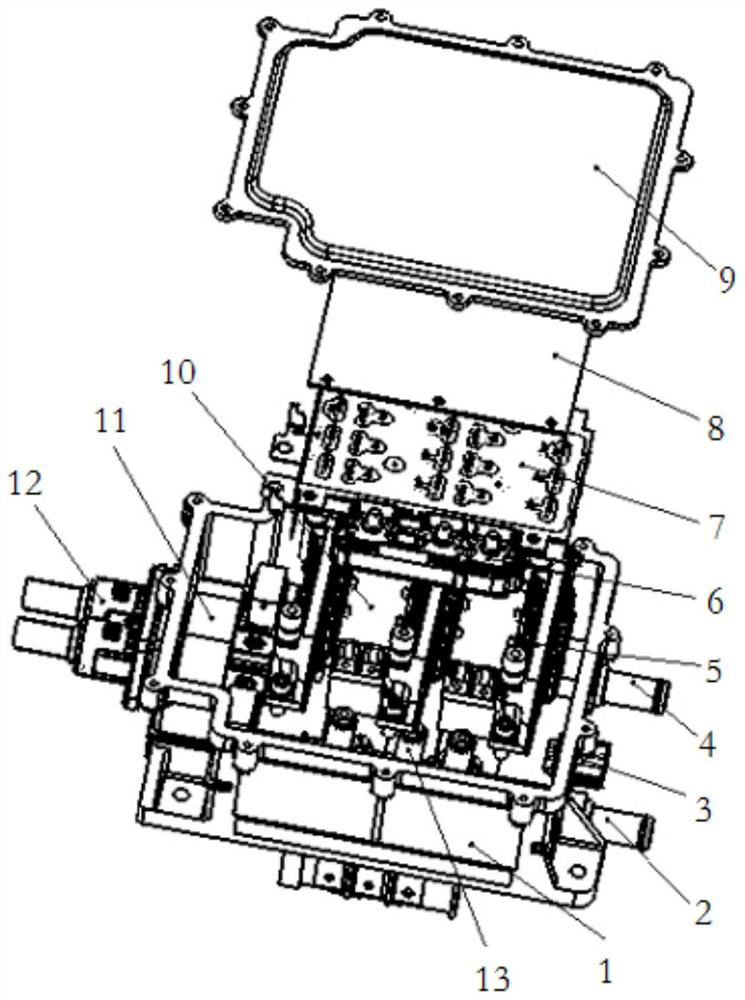

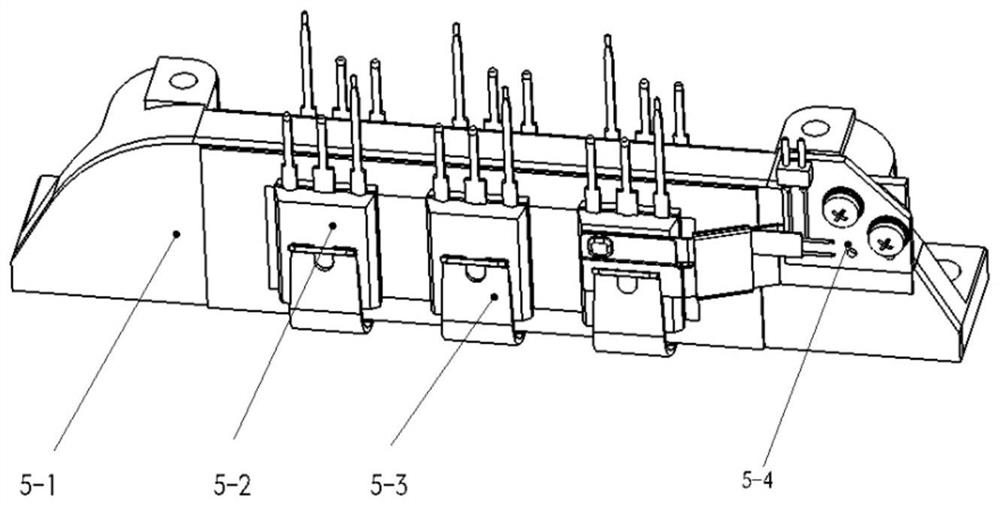

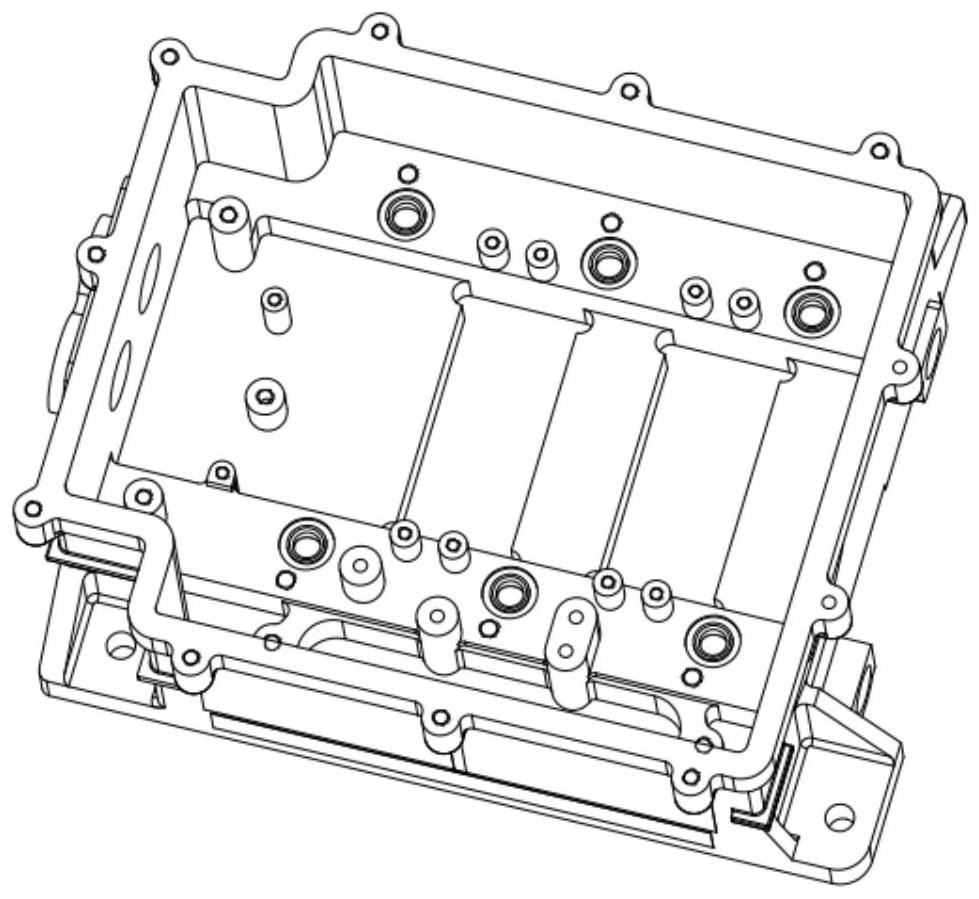

Electric vehicle controller based on single-tube parallel connection

PendingCN112994580AMeet cooling needsLow cost requirementsSpeed controllerElectric motor controlCapacitanceCurrent transducer

The invention relates to an electric vehicle controller based on single-tube parallel connection. The electric vehicle controller comprises a box body and a box cover; a thin-film capacitor, a magnetic ring assembly, a current sensor assembly, a composite busbar and a PCBA control panel are arranged in the box body; and the thin-film capacitor is connected with the composite busbar; a single-tube heat dissipation assembly and a three-phase plastic-coated polar plate are also arranged in the box body; the single-tube heat dissipation assembly comprises a radiator and a single-tube IGBT (Insulated Gate Bipolar Translator) and a temperature sensor which are arranged on the radiator; the single-tube IGBT is respectively connected with the thin-film capacitor and the PCBA control panel; the input end of the three-phase plastic-coated polar plate is electrically connected with the three-phase output end of the composite busbar, and the output end of the three-phase plastic-coated polar plate extends out of the box body and is electrically connected with the three-phase input end in the motor. Compared with the prior art, the single-tube IGBTs are adopted, so that a complex packaging process is avoided; the single-tube IGBTs are clamped on the two sides of the radiator for heat dissipation, so that the heat dissipation requirement of the controller can be well met; and the controller has the advantages of being high in integration, low in inductance, low in cost and high in vibration resistance.

Owner:SHANGHAI EDRIVE +2

PCB having multi-step ladder grooves

InactiveCN108834312ASave installation spaceReduce assembly volumePrinted circuit non-printed electric components associationCircuit thermal arrangementsEngineering

Owner:DONGGUAN SHENGYI ELECTRONICS

Positioning device based on mechanical counting of motor

ActiveCN102025219BEffectively adjust the internal structureReduce assembly volumeMechanical energy handlingTooth numberEngineering

The invention discloses a positioning device based on mechanical counting of a motor, comprising a shell. The shell is internally provided with a driving gear, a clockwise gear set and an anticlockwise gear set, wherein the clockwise gear set and the anticlockwise gear set are fit with the driving gear; the clockwise gear set comprises a pair of differential gears which are arranged at the same axis and have different tooth numbers; the anticlockwise gear set comprises a pair of differential gears which are coaxially arranged and have different tooth numbers; the shell is also internally provided with a clockwise stroke regulating mechanism and an anticlockwise stroke regulating mechanism which are fit with the clockwise gear set and the anticlockwise gear set respectively; and the clockwise gear set and the anticlockwise gear set are arranged at the same axis. By using the positioning device based on the mechanical counting of the motor, the inner structure of the device can be effectively regulated, so that the inner structure is more compact, simultaneously, and the whole volume of the positioning device can be effectively reduced. The positioning device disclosed by the invention can be used in the positioning field of curtain machines.

Owner:GUANGDONG RAEX INTELLIGENT TECH CO LTD

Packaging structure of microphone

PendingCN113891200AImprove stabilityImprove acoustic performanceElectrostatic transducer microphonesMouthpiece/microphone attachmentsMiniaturizationEngineering

The embodiment of the invention discloses a packaging structure of a microphone. The packaging structure of the microphone comprises an ASIC chip, an MEMS chip, a first rewiring layer and a second rewiring layer, wherein the ASIC chip is provided with a first rewiring layer distributed along the surface of the ASIC chip, and the ASIC chip is provided with a first silicon through hole penetrating through the thickness direction; the MEMS chip is provided with a second rewiring layer distributed along the surface of the MEMS chip, and the MEMS chip is provided with a second silicon through hole penetrating through the thickness direction; the ASIC chip is arranged on the MEMS chip in an overlapping manner; and the ASIC chip is connected with the MEMS chip through the first rewiring layer, the first through silicon via, the second rewiring layer and the second through silicon via. The packaging structure of the microphone is simple in structure and beneficial to miniaturization design of the microphone.

Owner:QINGDAO GOERTEK INTELLIGENT SENSOR CO LTD

A method of manufacturing a pcb

ActiveCN108882568BRealize submerged installationEasy to placePrinted circuit aspectsMultilayer circuit manufactureEngineeringMechanical engineering

The invention relates to the technical field of circuit board production, and discloses a PCB manufacturing method. The method comprises the steps of: S1, providing an upper substrate with a first through groove opened, a middle substrate with a second through groove opened and a lower substrate, and sequentially stacking the upper substrate, the middle substrate and the lower substrate so that the second through groove of the middle substrate is located below the first through groove of the upper substrate; S2, filling the glue blocking material in the first through groove and the second through groove, and pressing the upper substrate, the middle substrate and the lower substrate to form a multilayer board; S3, taking out the glue blocking material, and forming a step groove by the firstthrough groove and the second through groove; S4, carrying out copper deposition and electroplating on the groove wall of the step groove, and metalizing the groove wall of the step groove; and S5, opening a third through groove on the bottom of the groove of the step groove. According to the PCB manufacturing method of the invention, the mounting of the special-shaped component and different sizes of component are realized by forming a step groove with multiple layers of steps on the PCB, thereby reducing the occupied space of the PCB.

Owner:DONGGUAN SHENGYI ELECTRONICS

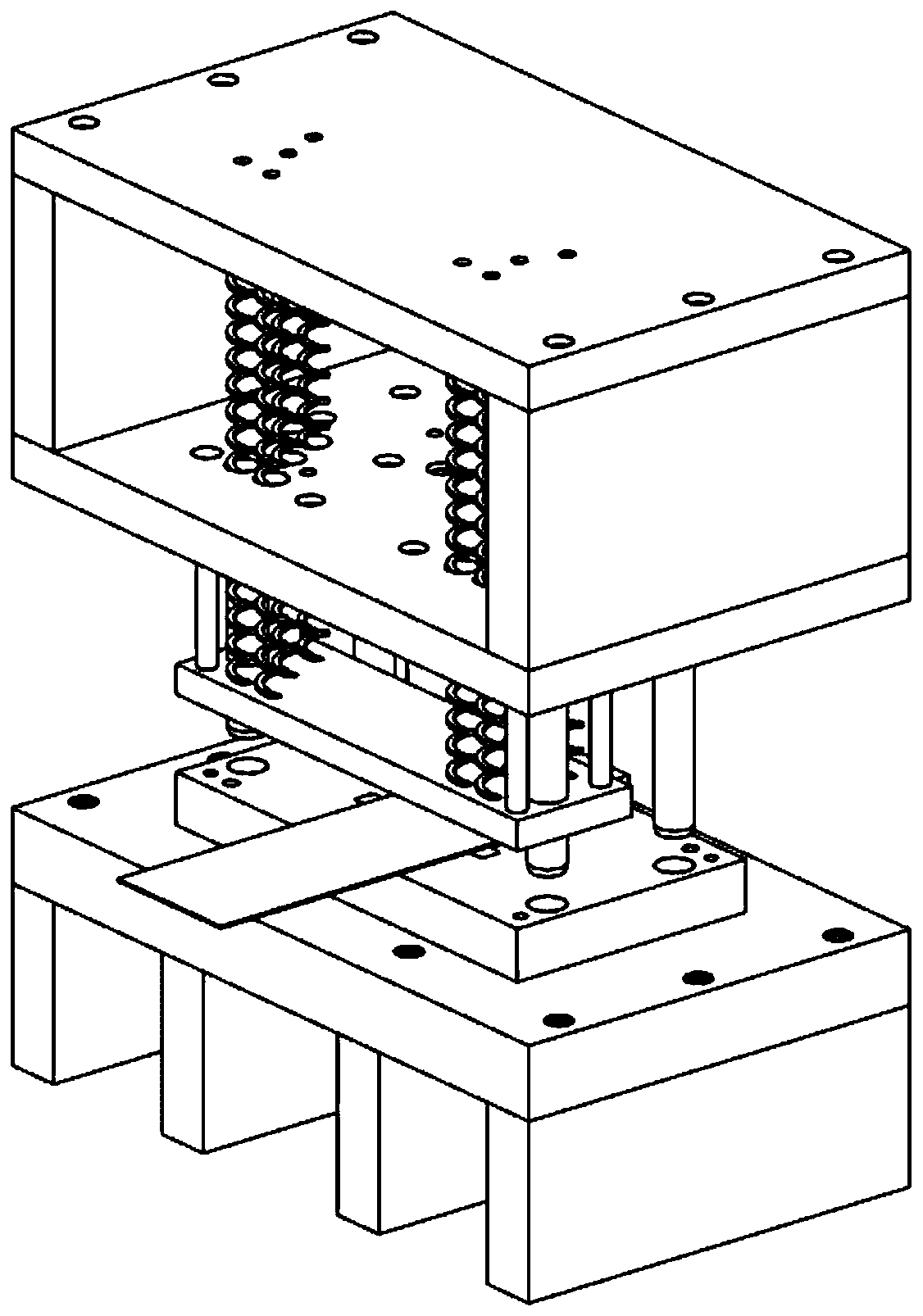

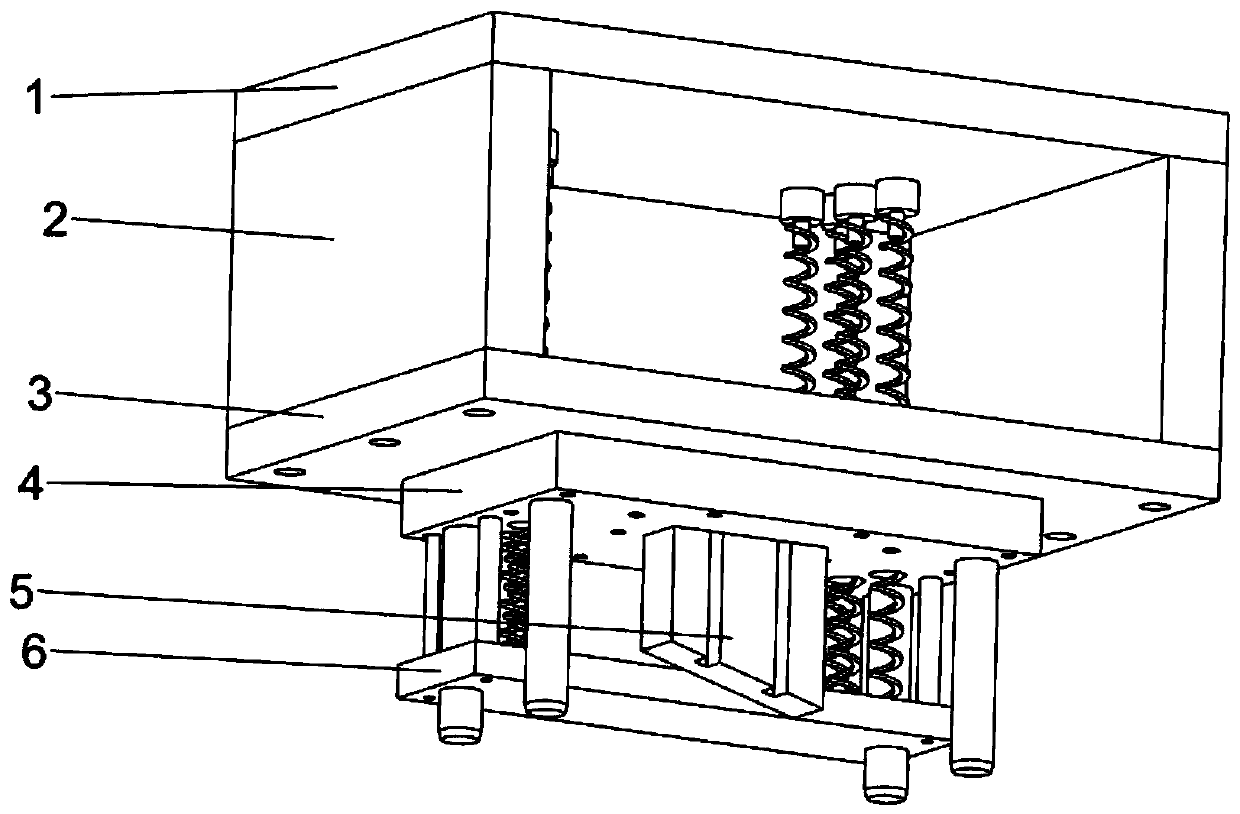

Detachable cutting die with variable process parameters

ActiveCN108817197BHigh precisionLarge adjustment rangeShaping toolsStructural engineeringMechanical engineering

The invention provides a detachable variable-technological-parameter shearing die which comprises an upper die and a lower die. The upper die is provided with an upper cover plate, an upper die base,an upper clamping plate and a stripper plate in sequence from top to bottom, the upper cover plate and the upper die base are installed together through an upper cushion block, the lower surface of the upper cover plate is provided with a plurality of springs, the springs sequentially penetrate through the upper die base and the upper clamping plate to abut against the upper surface of the stripper plate, the lower surface of the upper die base is provided with a replaceable punch knife block which penetrates through a first groove in the middle of the upper clamping plate, and the upper clamping plate and the stripper plate are movably connected through a first isoheight sleeve. The lower die is provided with a lower die plate, a lower die base and a lower cushion block in sequence from top to bottom, the lower die plate is provided with a lower die plate groove, a replaceable lower die knife edge inlet is placed in the lower die plate groove, and the lower die plate groove is locatedin the advancing direction of the punch knife block. The detachable variable-technological-parameter shearing die is simple in overall structure, small in assembling size, low in manufacturing cost and wide in shear sample application range.

Owner:SHANGHAI JIAO TONG UNIV

A method of manufacturing a pcb

ActiveCN108834336BEasy to placeSave installation spacePrinted circuit assemblingCross-talk/noise/interference reductionBiochemical engineeringMiniaturization

The invention relates to the technical field of circuit board production, and discloses a manufacturing method of a PCB, comprising the following steps: S1, providing a first substrate having a firstthrough groove, a second substrate, a third substrate having a second through groove and a fourth substrate, and forming a circuit pattern on the surface of the fourth substrate; S2, sequentially laminating the first substrate, the second substrate, the third substrate and the fourth substrate, and forming a multilayer board by compression; S3, subjecting the multilayer board to copper immersion and electroplating to metallize the groove wall and the groove bottom of a first groove; S4, milling the groove bottom of the first groove at the top of the second through groove to form a second groove; and S5, forming a third through groove in the groove bottom of the second groove. The manufacturing method of the PCB according to the present invention realizes the mounting of the special-shapedcomponent and a plurality of components of different sizes, reduces the occupied space of the PCB, and forms a circuit pattern at the groove bottom of the stepped groove, which is beneficial to further miniaturization of the PCB.

Owner:DONGGUAN SHENGYI ELECTRONICS

Automobile and detection method of head-up display

PendingCN114779472ACompact structureReduce assembly volumeTesting optical propertiesOptical elementsDisplay deviceLight reflection

The embodiment of the invention discloses a head-up display and an automobile, and belongs to the field of image display. According to the embodiment of the invention, the DLP device, the refraction reflector and the imaging diffusion film are packaged in the DLP packaging shell to obtain the DLP display module, and then the DLP packaging shell is connected with the curved surface reflector packaging shell packaged with the first curved surface reflector unit and the second curved surface reflector unit to obtain the head-up display. Through the modular design, the structure of the head-up display is simpler and more compact, and the assembly volume of the head-up display is effectively reduced.

Owner:HISENSE GRP HLDG CO LTD

Ultra-small chip package and method for manufacturing the same

ActiveUS8704344B2Increase the volume ratioReduce assembly volumeSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

Some embodiments of the present disclosure provide the design and manufacture of an ultra-small chip assembly. The ultra-small chip assembly comprises a die, a plate-like back electrode disposed on the back-side of the die, and one or more plate-like positive electrodes disposed on the front-side of the die. The ultra-small chip assembly is configured such that one end of the plate-like back electrode extends beyond a first side of the die, and each of the one or more plate-like positive electrodes includes an end which extends beyond a second side of the die. By attaching both the plate-like back electrode and the plate-like positive electrodes on the surfaces of the die, and directly using the exposed ends of the plate-like electrodes as the lead-out electrodes for the chip assembly, the electrical connections outside of the die only occupy a very small volume.

Owner:DIODES INC

Back light module

The present invention relates to a kind of back light module including one light guiding board and at least one cold cathode fluorescent lamp. The light guiding board includes at least one incident plane, and the cold cathode fluorescent lamp is set opposite to the incident plane of the light guiding board. The cold cathode fluorescent lamp is one closed glass tube with electrodes inserted to its two ends, and glass tube has V-grooves carved on its two ends.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com