Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Realize fully automatic testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

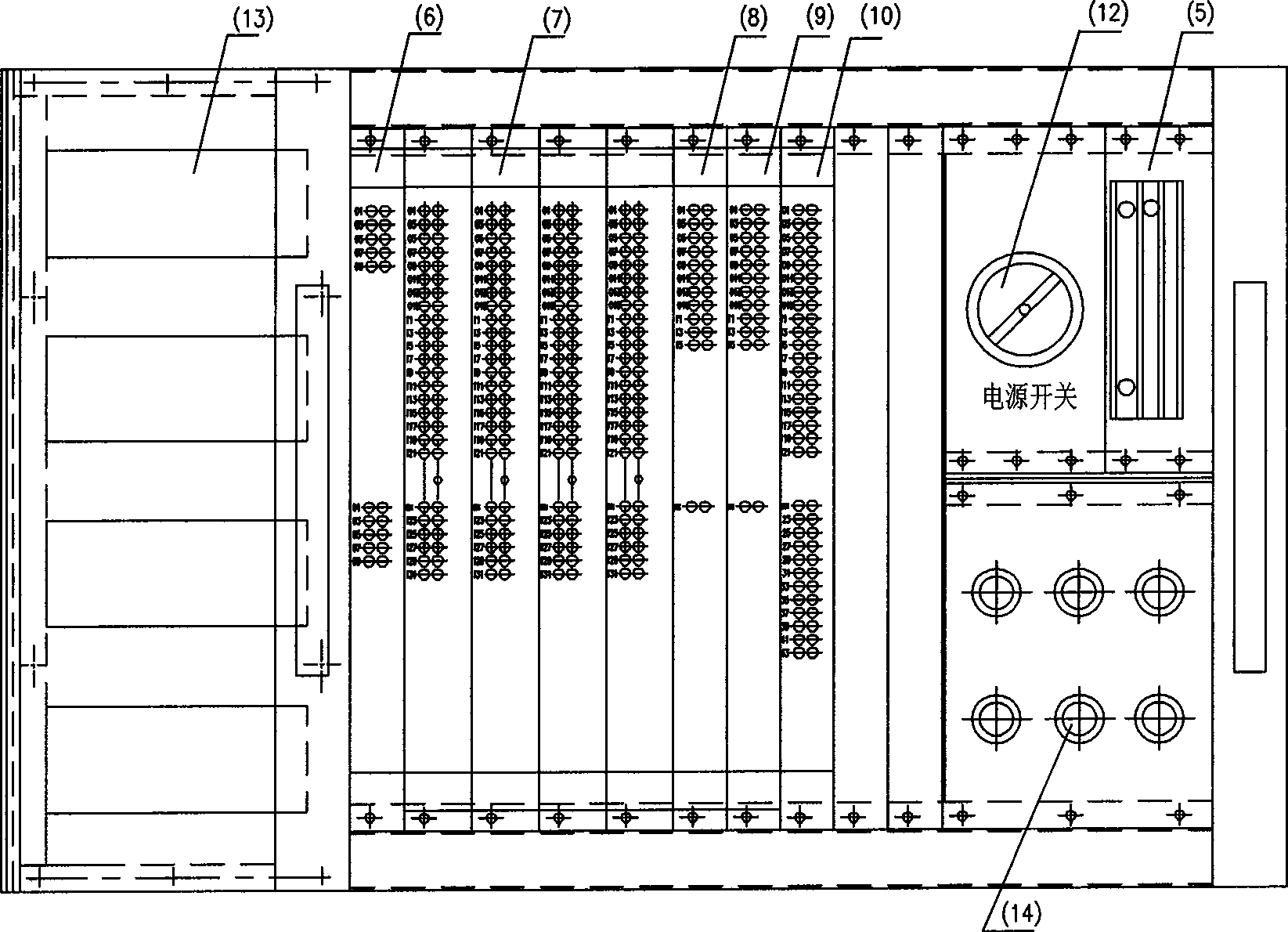

Method and device for testing microcomputer control system of diesel locomotive

InactiveCN101520661AEasy to debugConvenience testElectric testing/monitoringDiesel locomotiveClosed loop

The invention discloses a method and a device for testing a microcomputer control system of a diesel locomotive. A CAN bus or a serial bus is used for communication with an host computer to receive a test command from the host computer, and an inter CAN bus is used to receive the test command and transmits the test command to internal signal generation modules which generate a corresponding test signal according to the test command and transmit the test signal to equipment to be tested through an adapter cable; a signal detection module of a testing device detects an output signal of the equipment to be tested and transmits the output signal to a CPU board through the CAN bus, and the CAN bus or serial bus transmits the output signal to the host computer; and the host computer compares a given signal with the detected signal to realize the fully automatic closed loop test of the equipment to be tested. The fully automatic closed-loop test is a fully automatic loop test of the equipment to be tested which is implemented in a way that: the inside of the testing device adopts a distribution type module based on the CAN bus, the CPU board is connected with a digital quantity input and output board, a frequency board, a constant-current source board and a DA board through the internal CAN bus, and the testing device uses the external CAN bus or serial bus of the CPU board to communicate with the host computer and to realize the automatic circulating test of the equipment to be tested.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

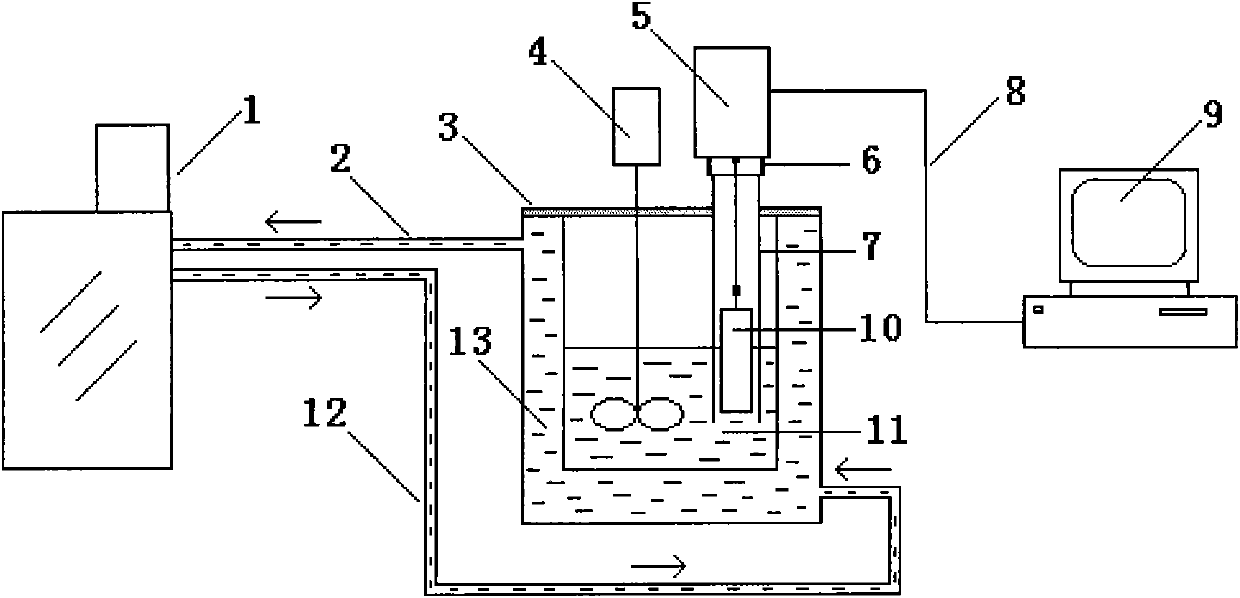

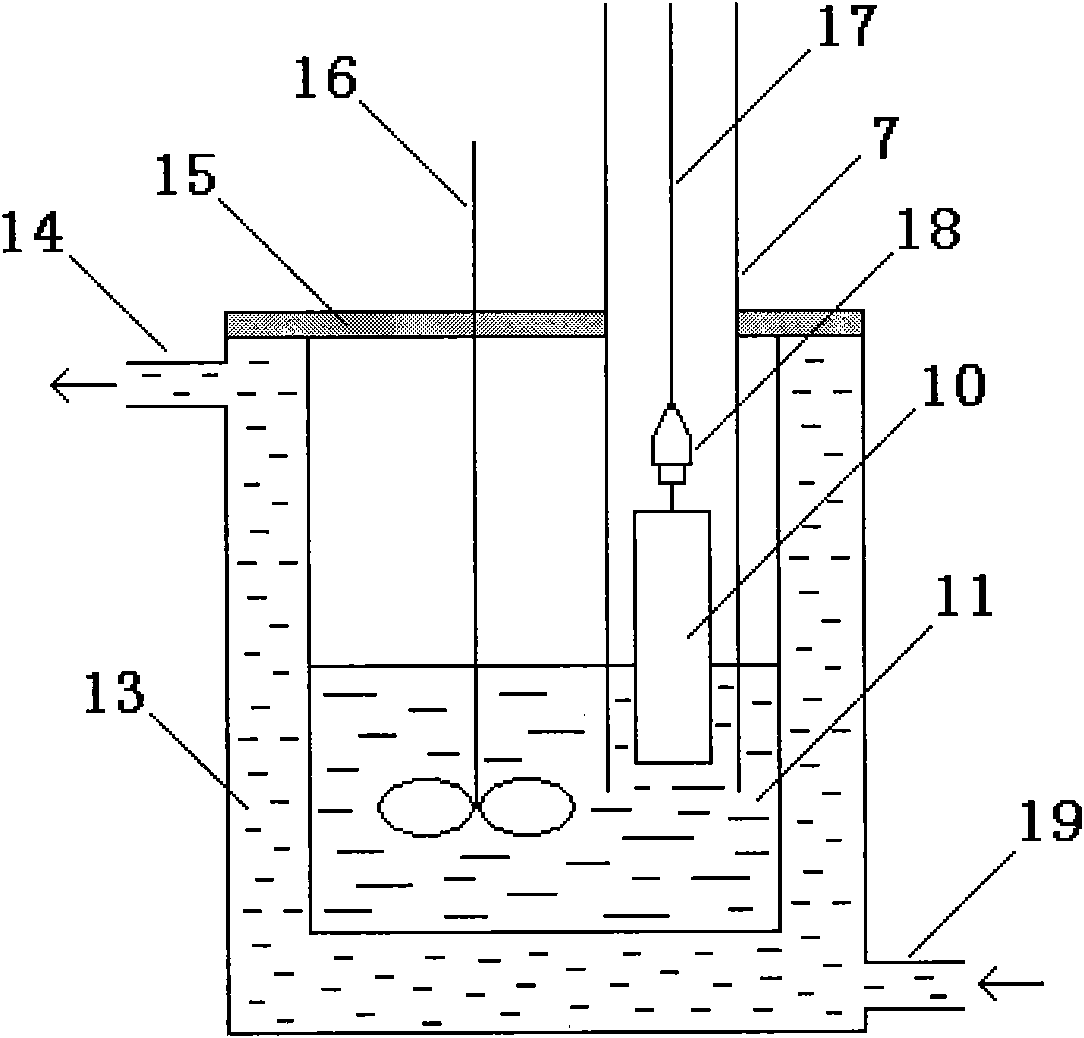

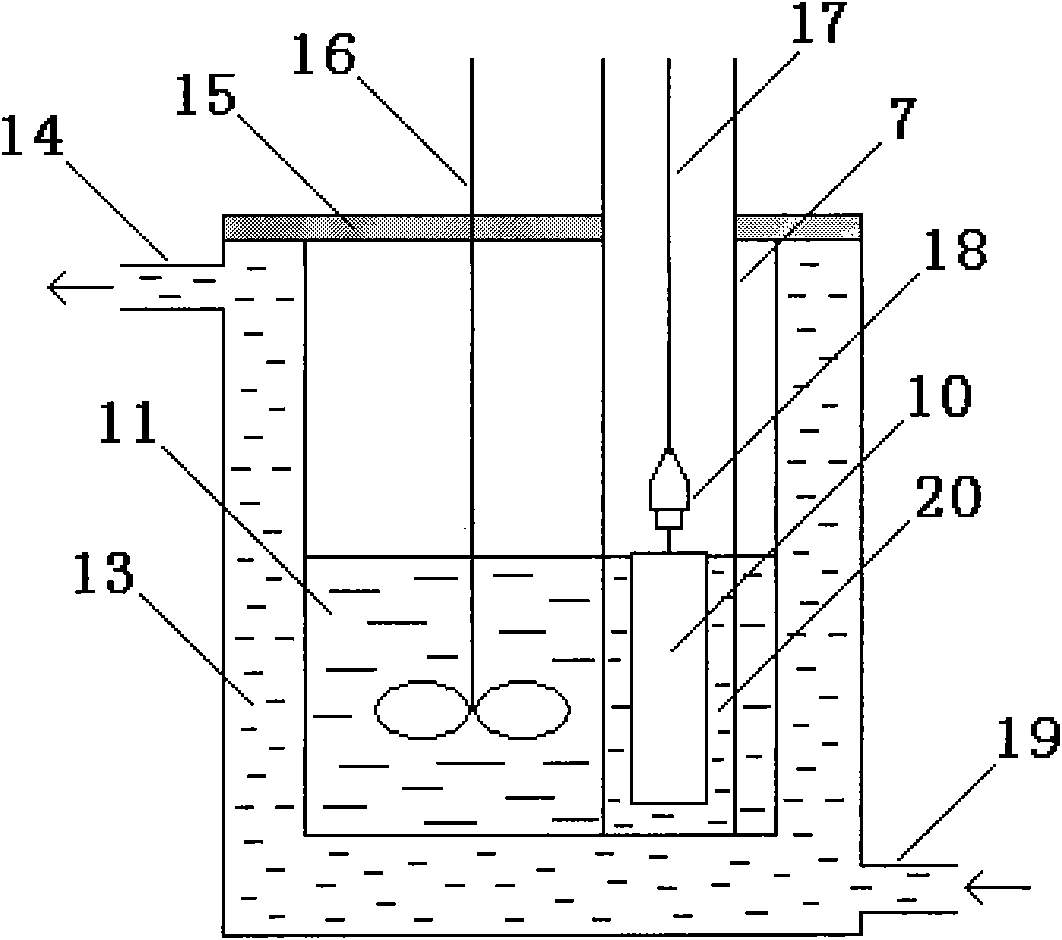

Testing device for crude oil viscosity

ActiveCN102087191AThe influence of temperature history does notImplement testFlow propertiesWater bathsTemperature curve

The invention is a testing device for crude oil viscosity, which is applicable to the determination of crude oil viscosity-temperature curves and the evaluation of heating and agent addition. The testing device comprises a programmable water bath (1), circulating water (13), a water jacket outlet (14), a water jacket inlet (19), a stirring motor (4) and a stirring paddle (16), a viscometer (5) and a rotor (10), and a rotating shaft (17); and the invention is characterized in that the device also comprises a crude oil processing device (3), a sleeve connector (6), a sleeve (7), a data transmission cable (8), a computer (9), a cover (15), and a rotating shaft connector (18). The crude oil processing device (3) is connected with the programmable water bath (1) through a water-bath inlet pipeline (2) and a water-bath outlet pipeline (12); the stirring motor (4) is connected with the stirring paddle (16) which is inserted into the crude oil processing device (3); the viscometer (5) is firstly connected to the sleeve connector (6), and then connected to the sleeve (7) which is inserted into the crude oil processing device (3) containing crude oil (11).

Owner:PIPECHINA SOUTH CHINA CO

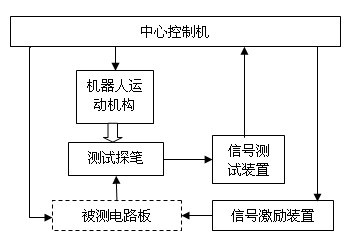

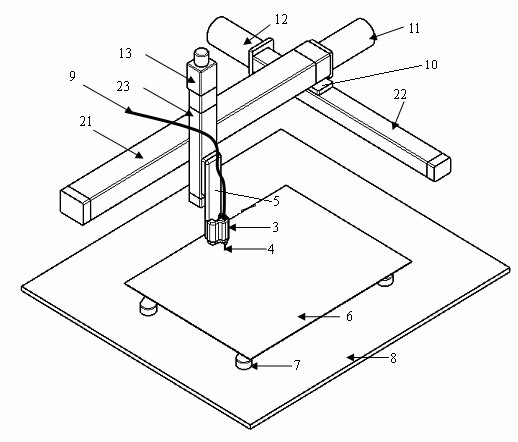

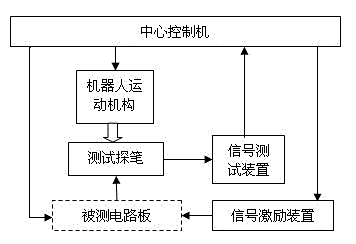

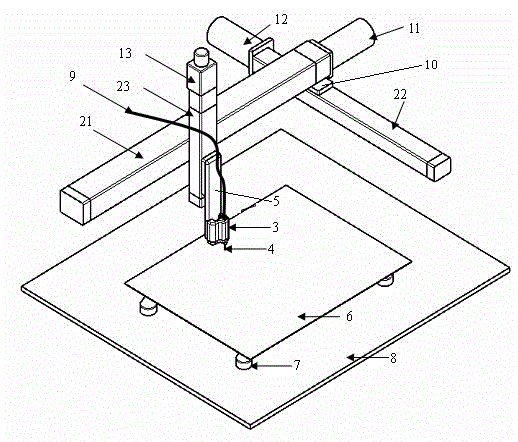

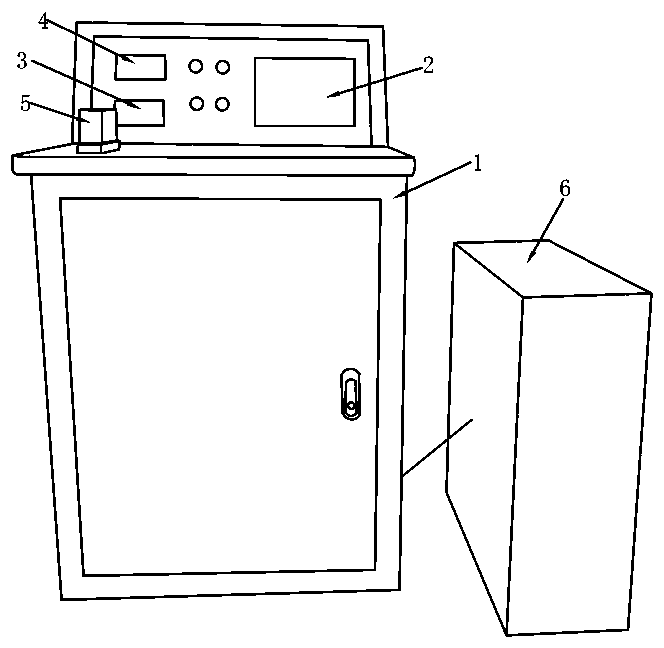

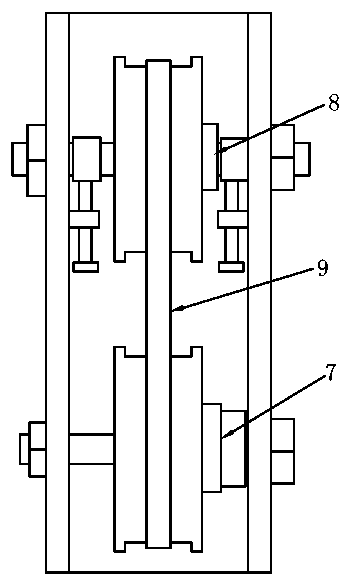

System and method for automatically diagnosing fault of circuit board

InactiveCN102621481AIncrease contactRealize fully automatic testingElectronic circuit testingMachine controlControl signal

The invention discloses a system for automatically diagnosing a fault of a circuit board. The system comprises a testing probe, a signal excitation device, a signal testing device, a central control machine and a robot movement mechanism, wherein the central control machine controls the signal excitation device; the signal excitation device is connected with a signal excitation end of a circuit board; the testing probe acquires data of a tested point of the circuit board to be transmitted to the signal testing device; the signal testing device processes the data and transmits the data to the central control machine; the central control machine controls the robot movement mechanism; the robot movement mechanism is used for controlling the testing probe to move; and the testing probe is used for testing the fault of the circuit board. The robot movement mechanism is controlled to drive the testing probe to move to a target testing point by the central control machine, so that fault diagnosis of the circuit board is fully automatically tested, manual operation is replaced by the robot movement mechanism, and manual labor is saved; and moreover, the fault of the circuit board can be accurately tested, and the system is convenient to use.

Owner:HENAN ZHENGTAIXIN INNOVATION BASE

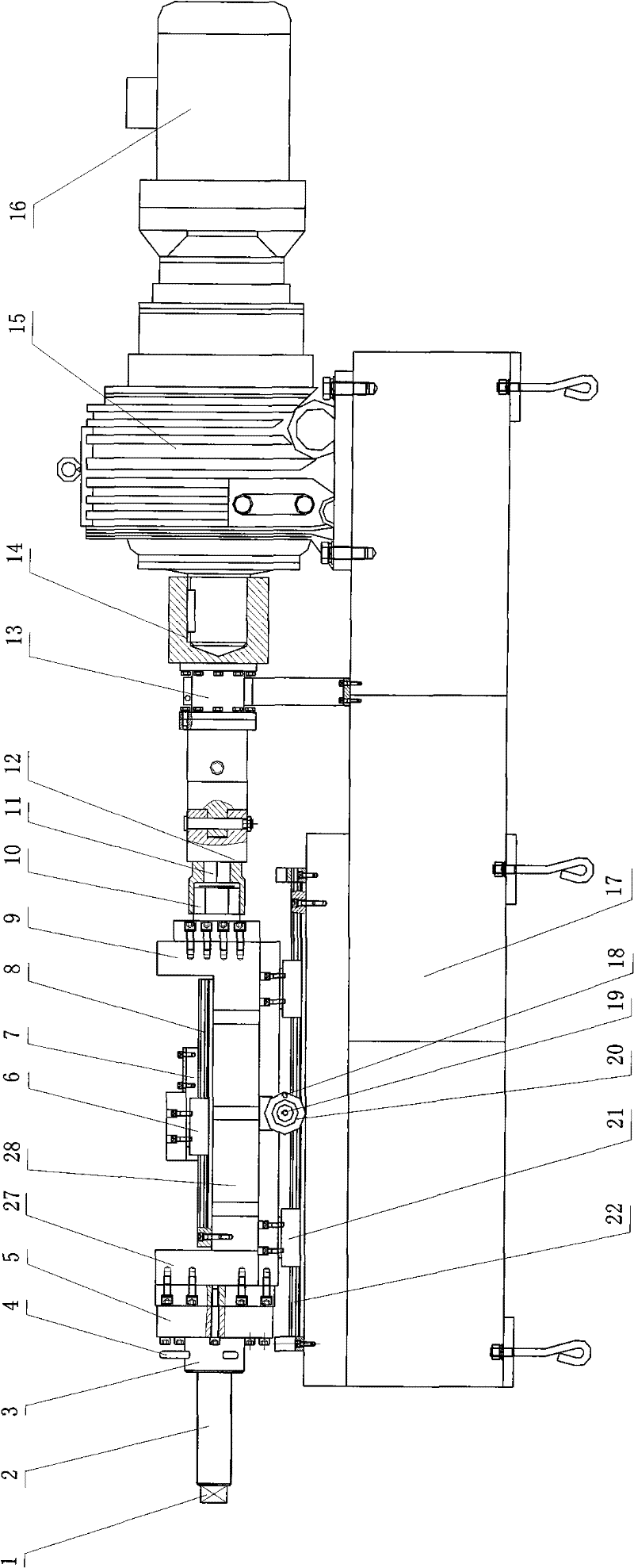

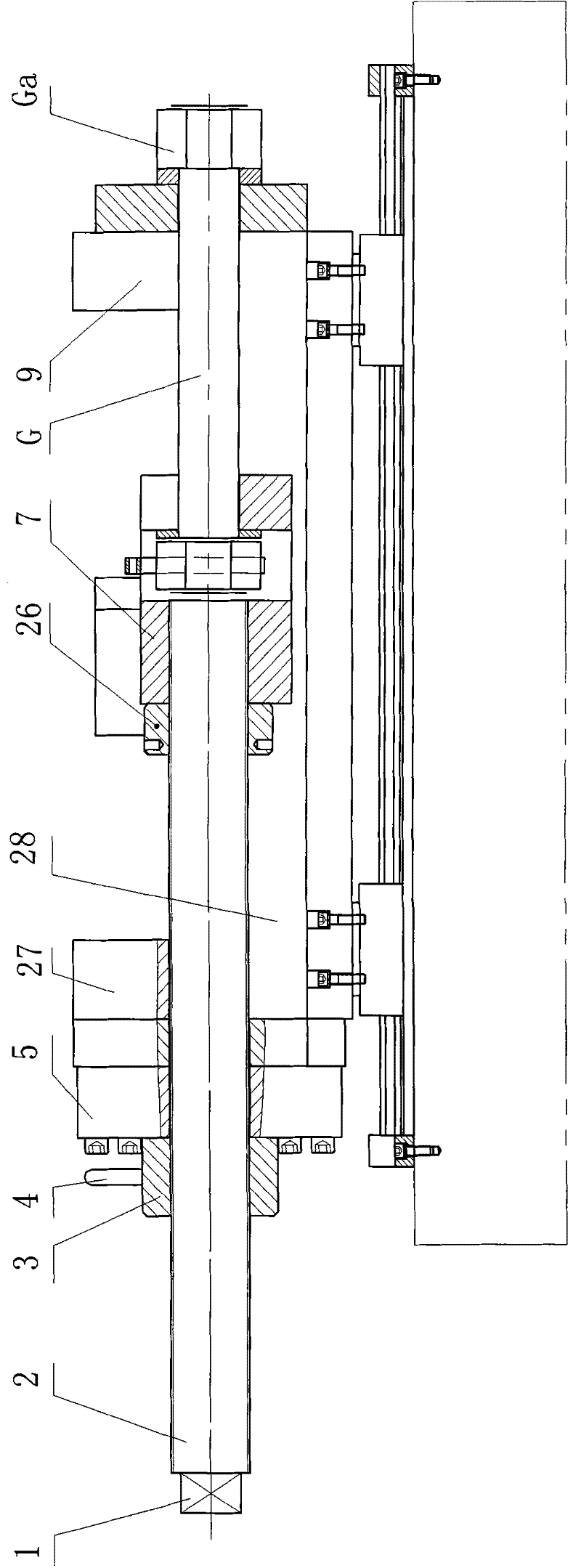

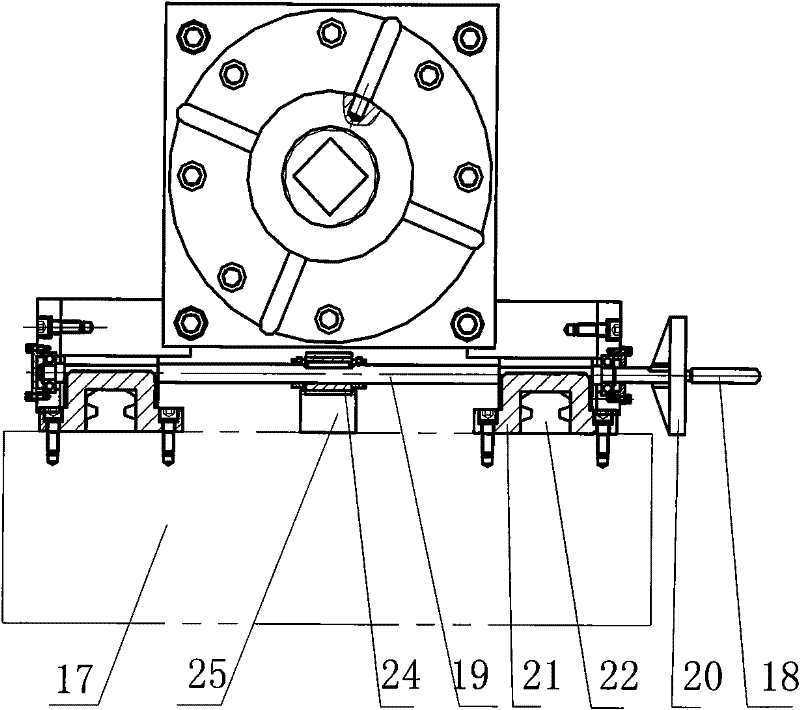

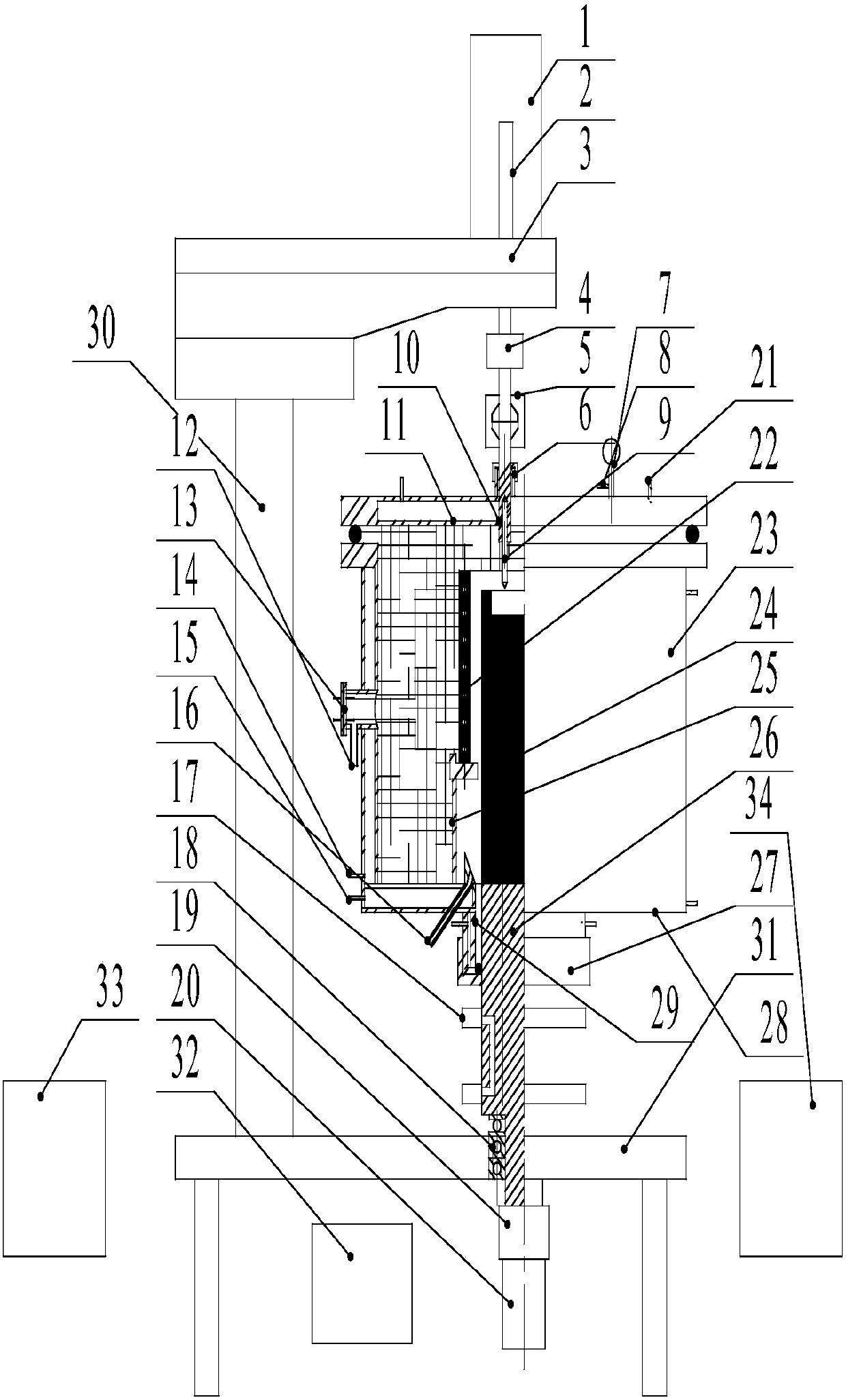

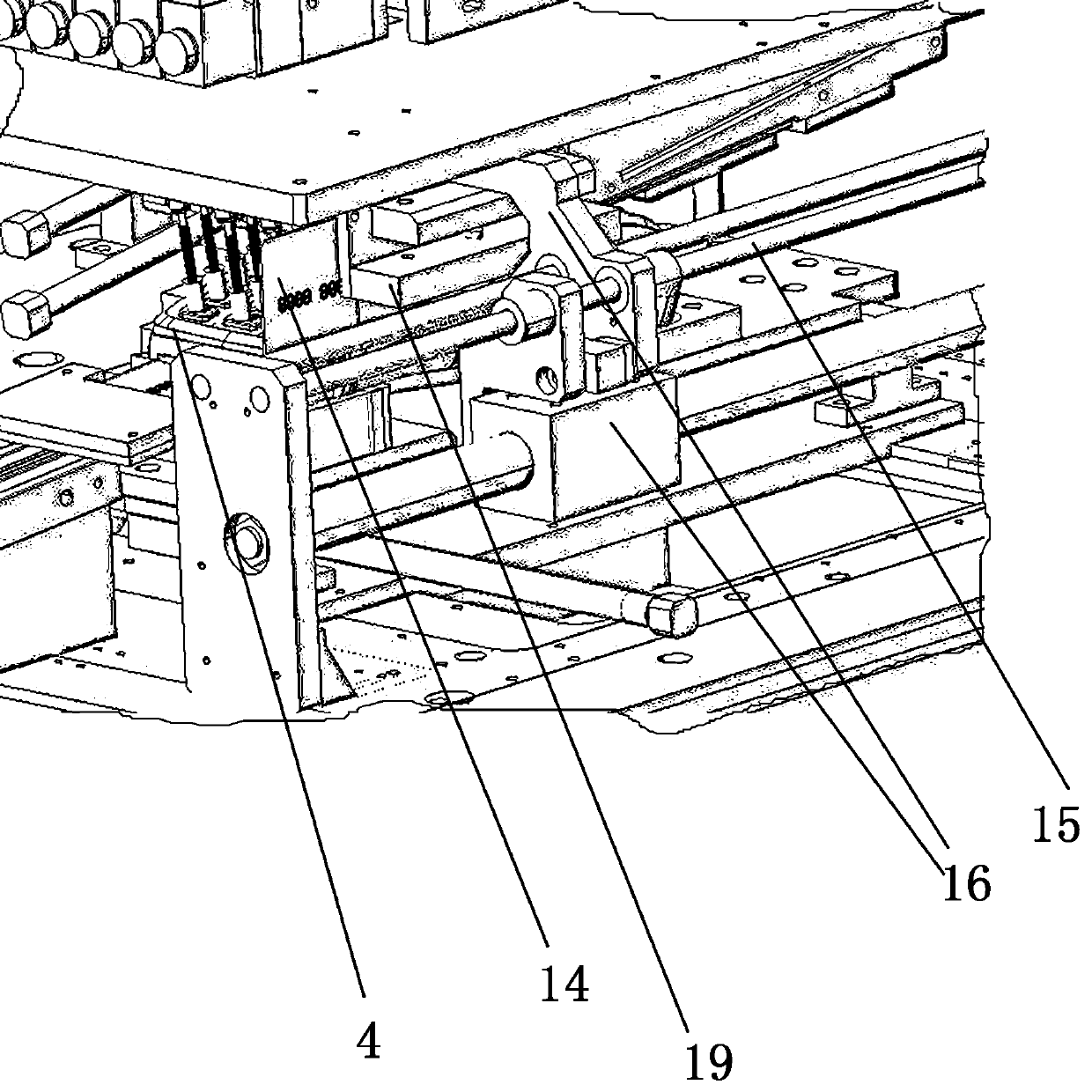

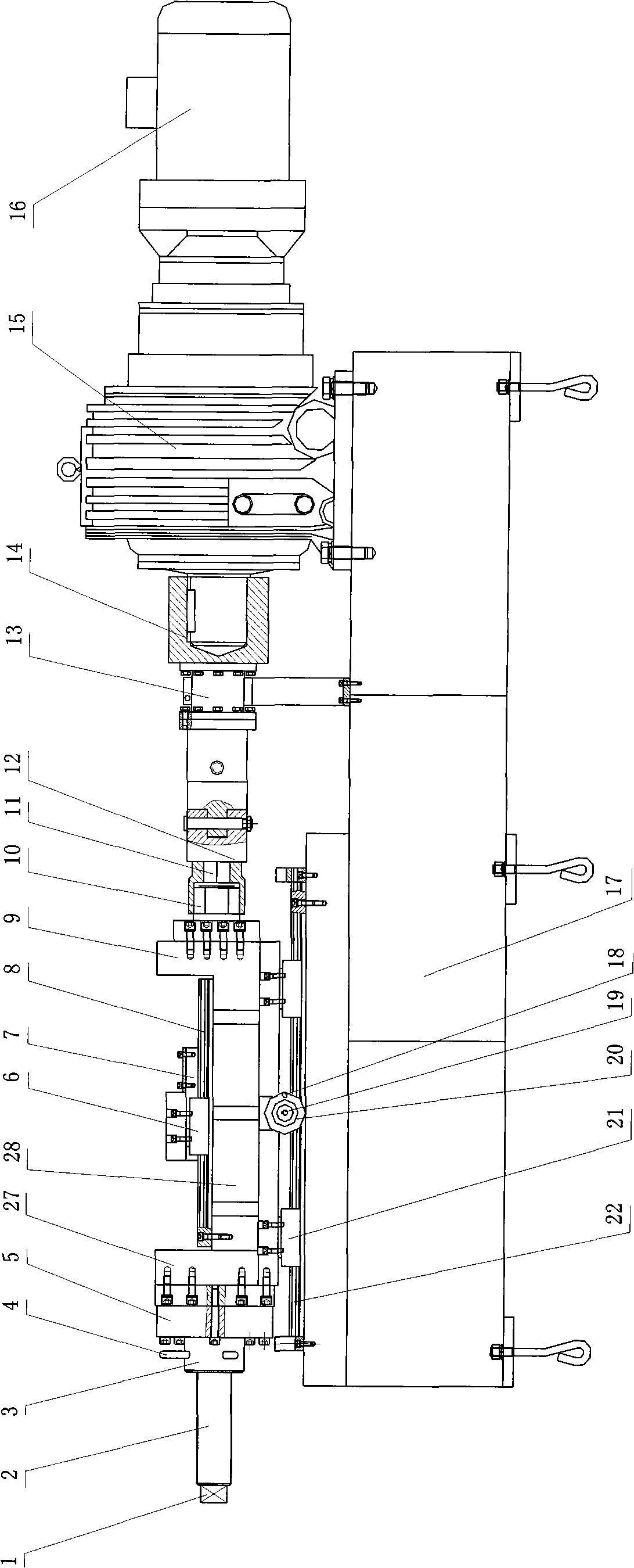

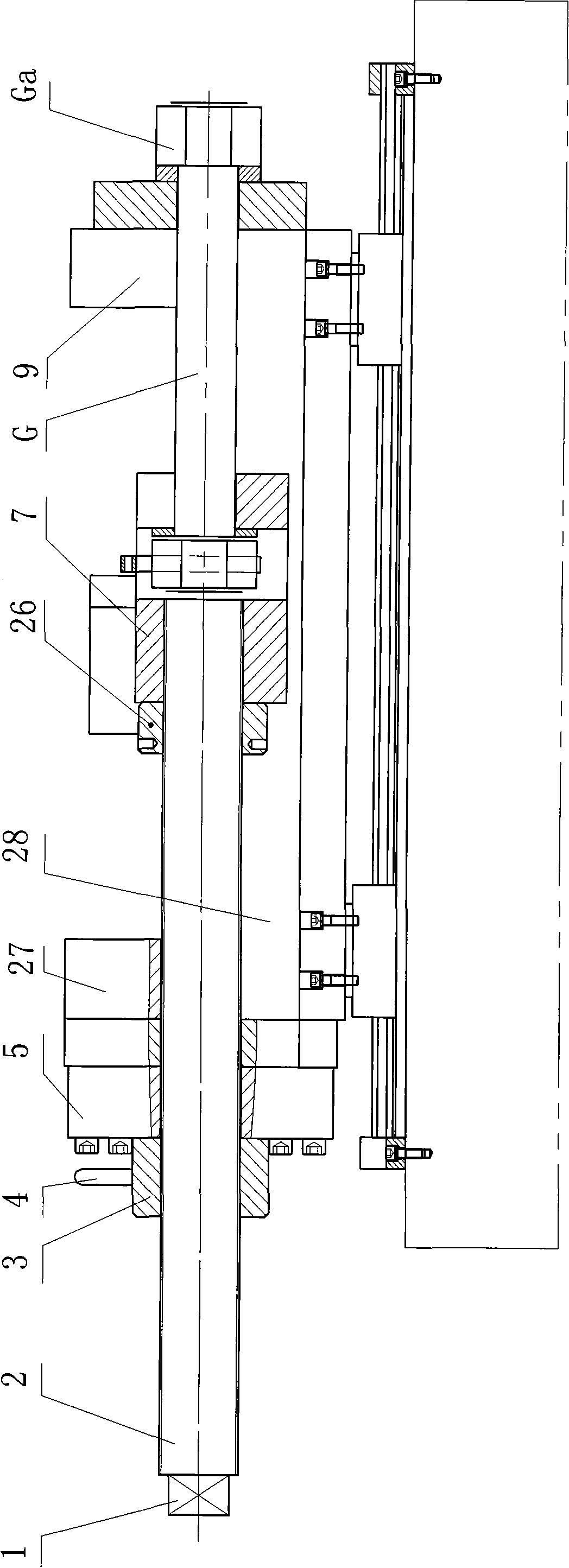

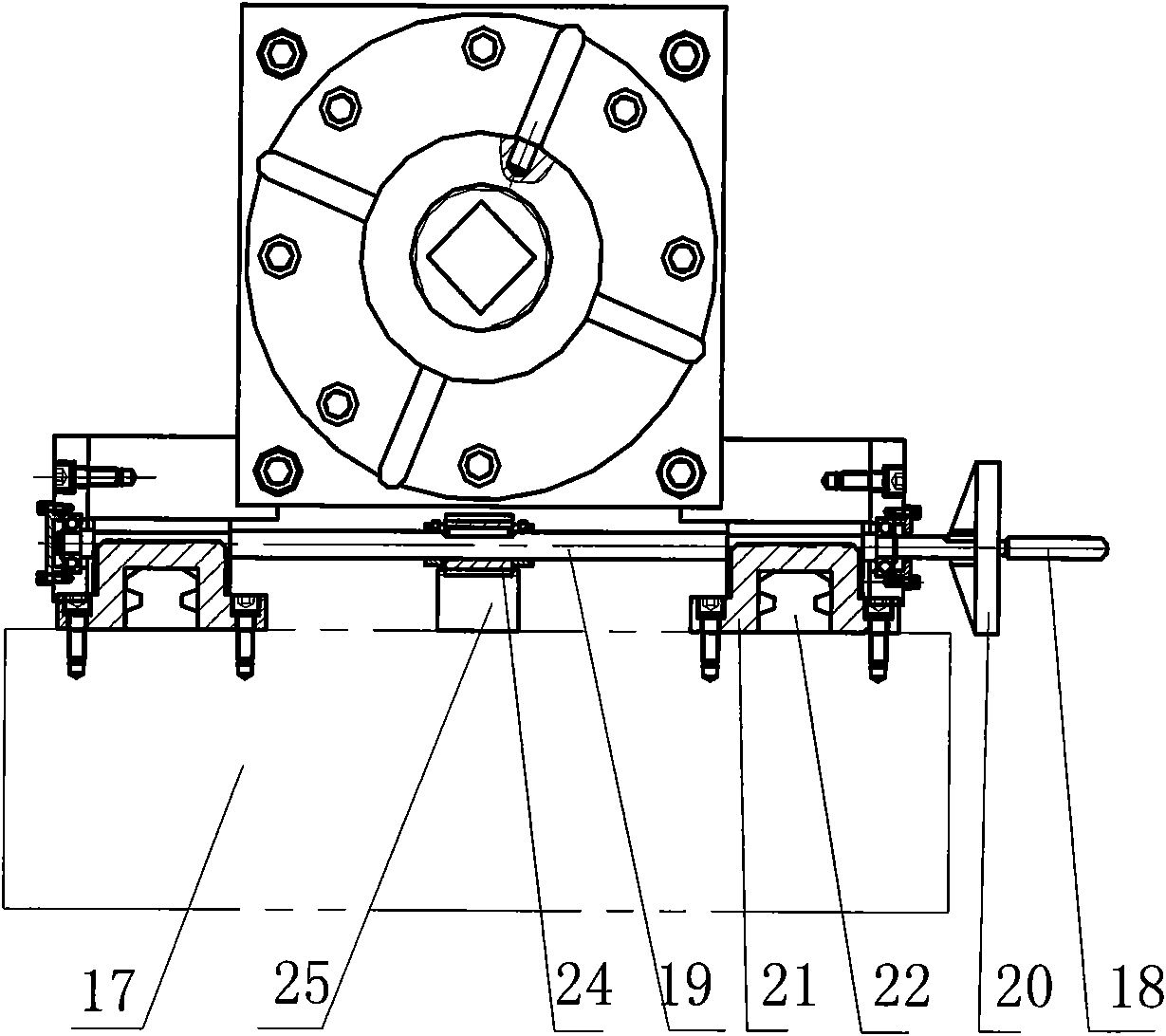

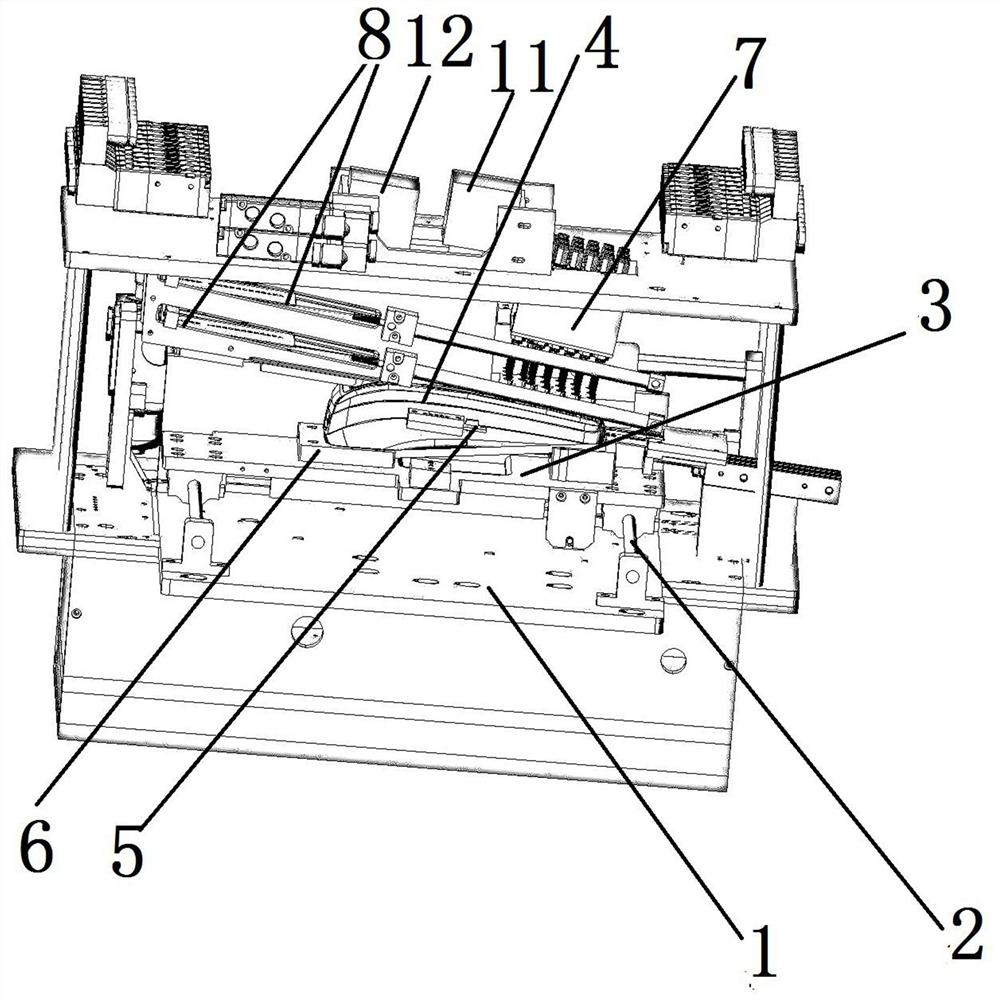

A large-scale bolt torque testing equipment

ActiveCN102262021ARealize fully automatic collectionRealize the display effectMaterial strength using steady torsional forcesCouplingElectric machinery

The invention belongs to experimental and testing devices for mechanical parts, and specifically relates to a torque force testing device for a large-sized bolt. The device comprises a clamping and fixing part and a twisting part; the clamping and fixing part is formed by the way that two guide rails (22) are arranged on a pedestal (17), left and right guide sleeves (21) are arranged on each guide rail (22), a sliding pull base (28) is formed on the four guide sleeves (21), a bolt pull sleeve (7) is placed in an opening cavity of the sliding pull base (28), and two sides of the bolt pull sleeve (7) are sleeved in sliding rails (8) at two sides of the opening cavity of the sliding pull base (28) via sliding sleeves (6); a front end of a tensioning screw (2) is connected with the bolt pull sleeve (7); a locking screw disc (3) is sleeved on the tensioning screw (2); a rack (25) is arranged on the pedestal (17); and a shaft (19) of a wheel gear (24) engaged with the rack penetrates into the sliding pull base (28). The twisting part is orderly composed of a nut sleeve head (10), a rotary special-shaped head (11), a universal coupling (12), a torque sensor (13), a coupling (14), a reducer (15) and a motor (16). The torque force testing device is steady, reliable, accurate, safe and convenient in the test procedure, and can implement automatic test and improve the speed, the efficiency and the accuracy of the test.

Owner:上海宝冶工程技术有限公司 +1

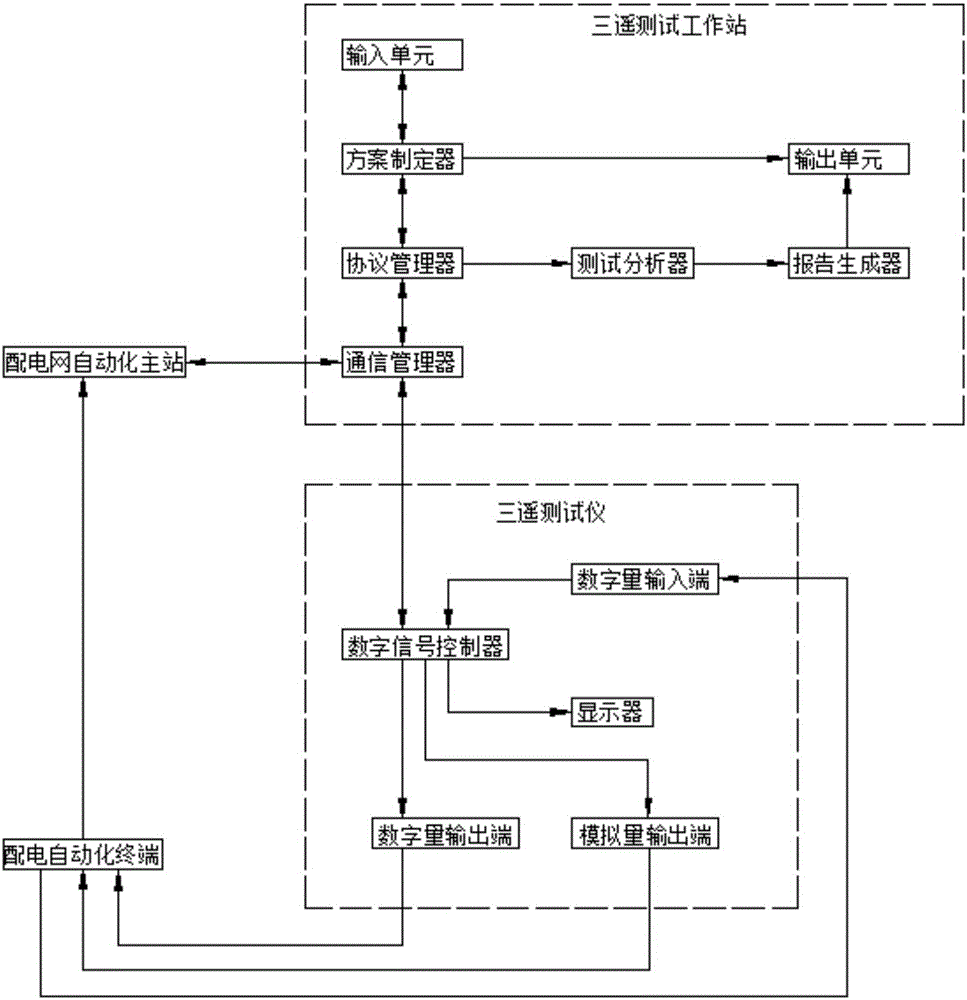

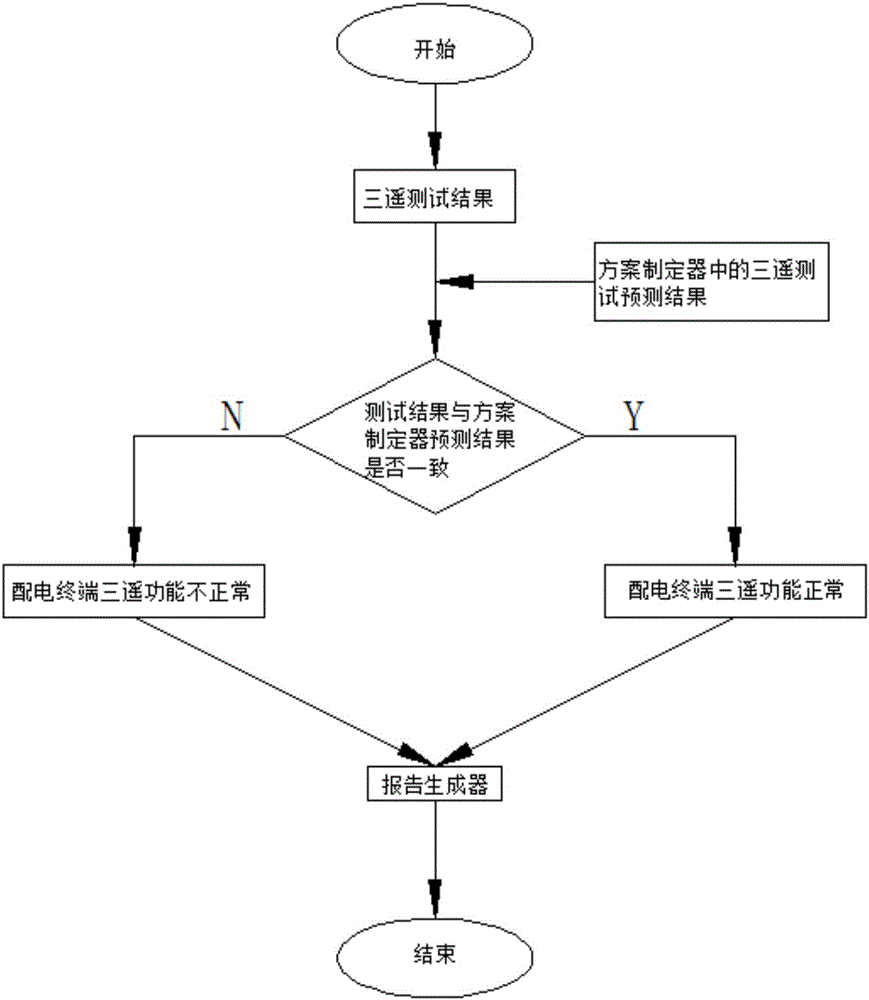

Power distribution automation three-remote function closed-loop test system and method

InactiveCN106444710ALow technical requirementsRealize fully automatic testingElectric testing/monitoringClosed loopMaster station

The invention discloses a power distribution automation three-remote function closed-loop test system and method. The system comprises a three-remote test workstation, a three-remote tester, a power distribution automation terminal and a power distribution network automation master station, wherein the three-remote test workstation is used for acquiring three-remote configuration parameter information from the power distribution network automation master station and transmitting generated three-remote test case parameter information to the three-remote tester, the three-remote tester is used for transmitting on-off state information and analog quantity to the power distribution automation terminal, the power distribution automation terminal generates SOE (sequence of event) information after operation, transmits the SOE information to the power distribution network automation master station, the power distribution network automation master station transmits the SOE information to the three-remote test workstation, the power distribution automation terminal transmits the SOE information to the three-remote tester, the three-remote tester transmits the SOE information to the three-remote test workstation, and finally, the three-remote test workstation generates a three-remote test report. Technical requirements for on-site constructors are reduced, on-site installation and commissioning workload is greatly relieved, and maintenance efficiency is improved.

Owner:STATE GRID CHONGQING ELECTRIC POWER +2

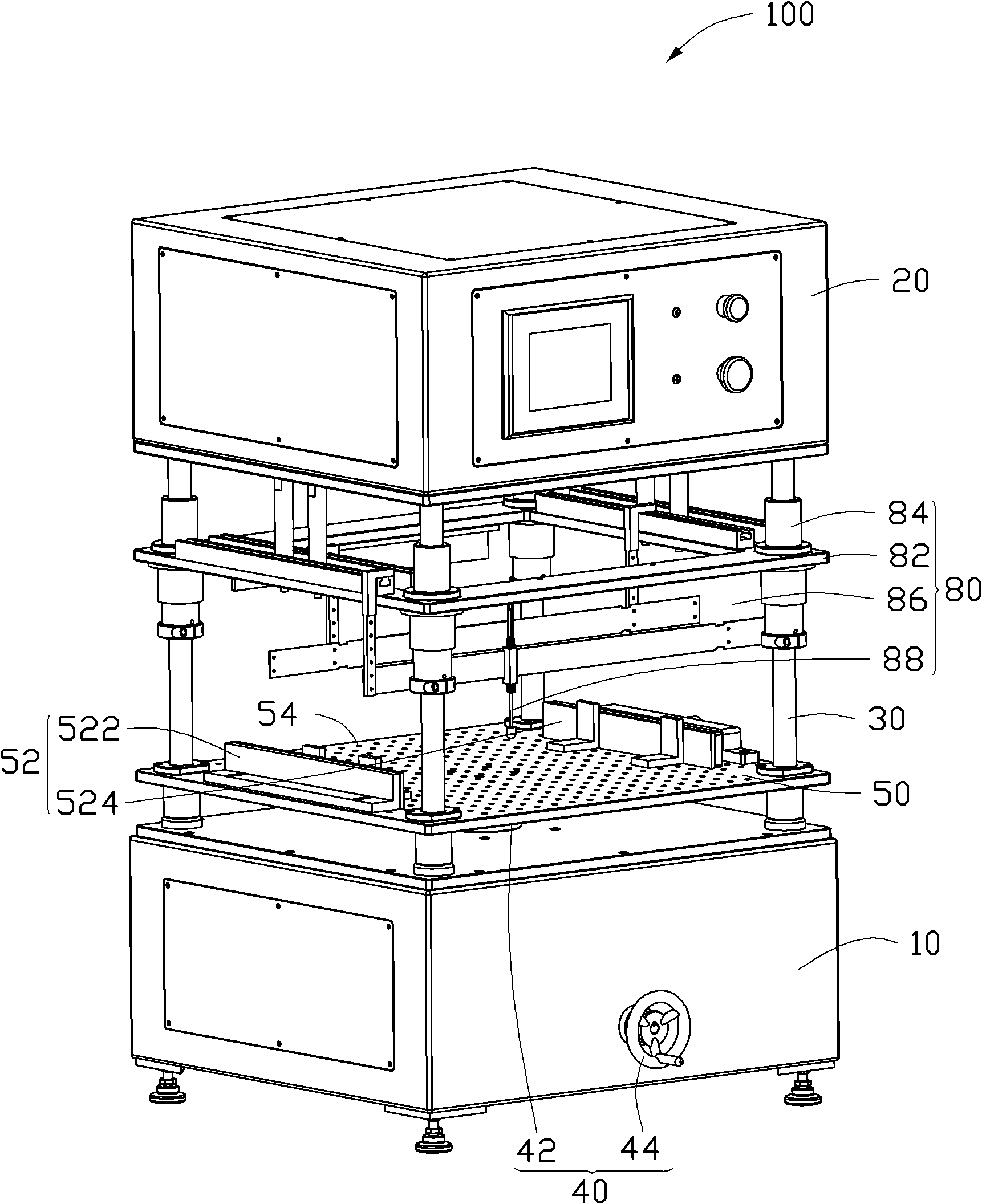

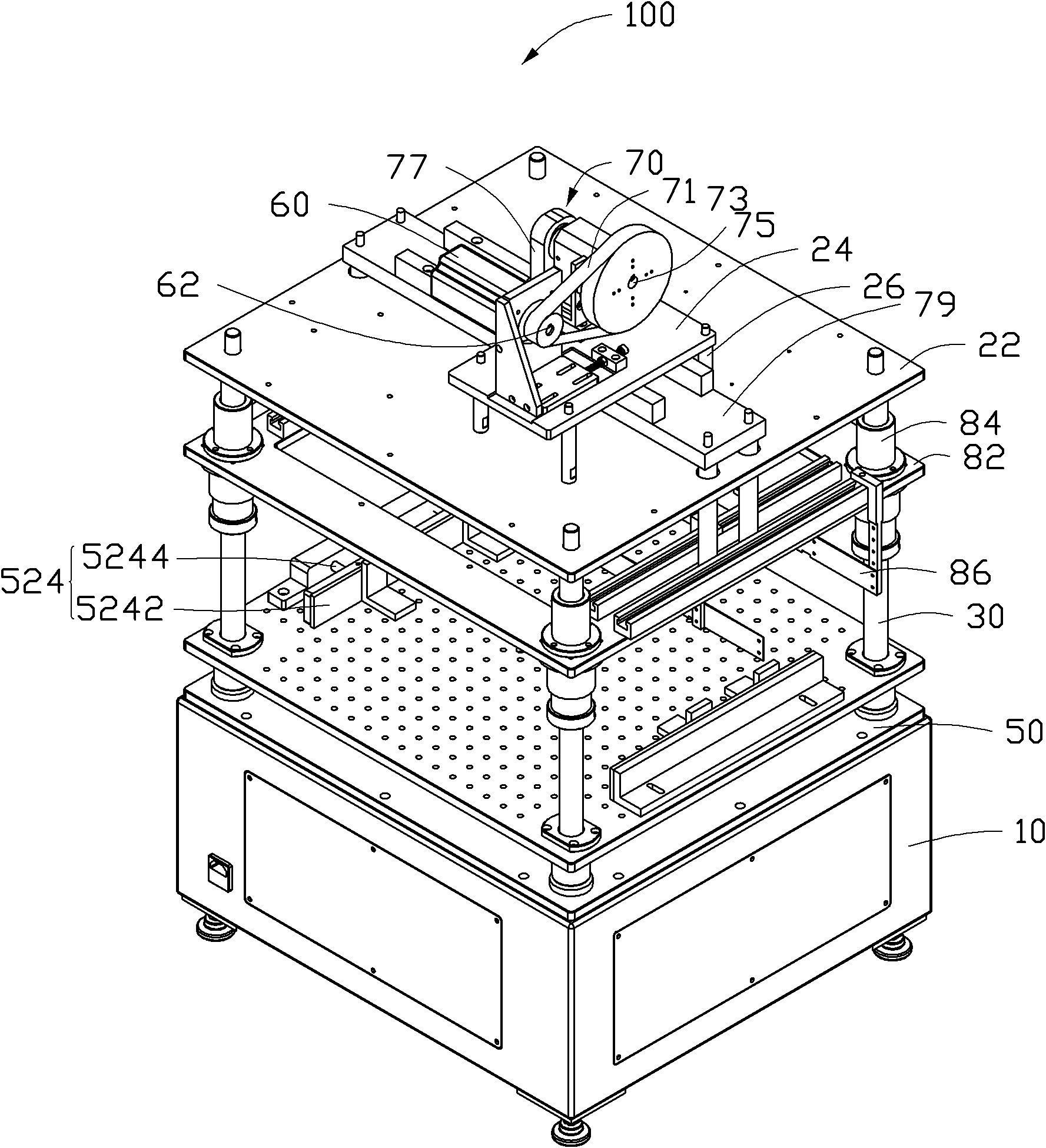

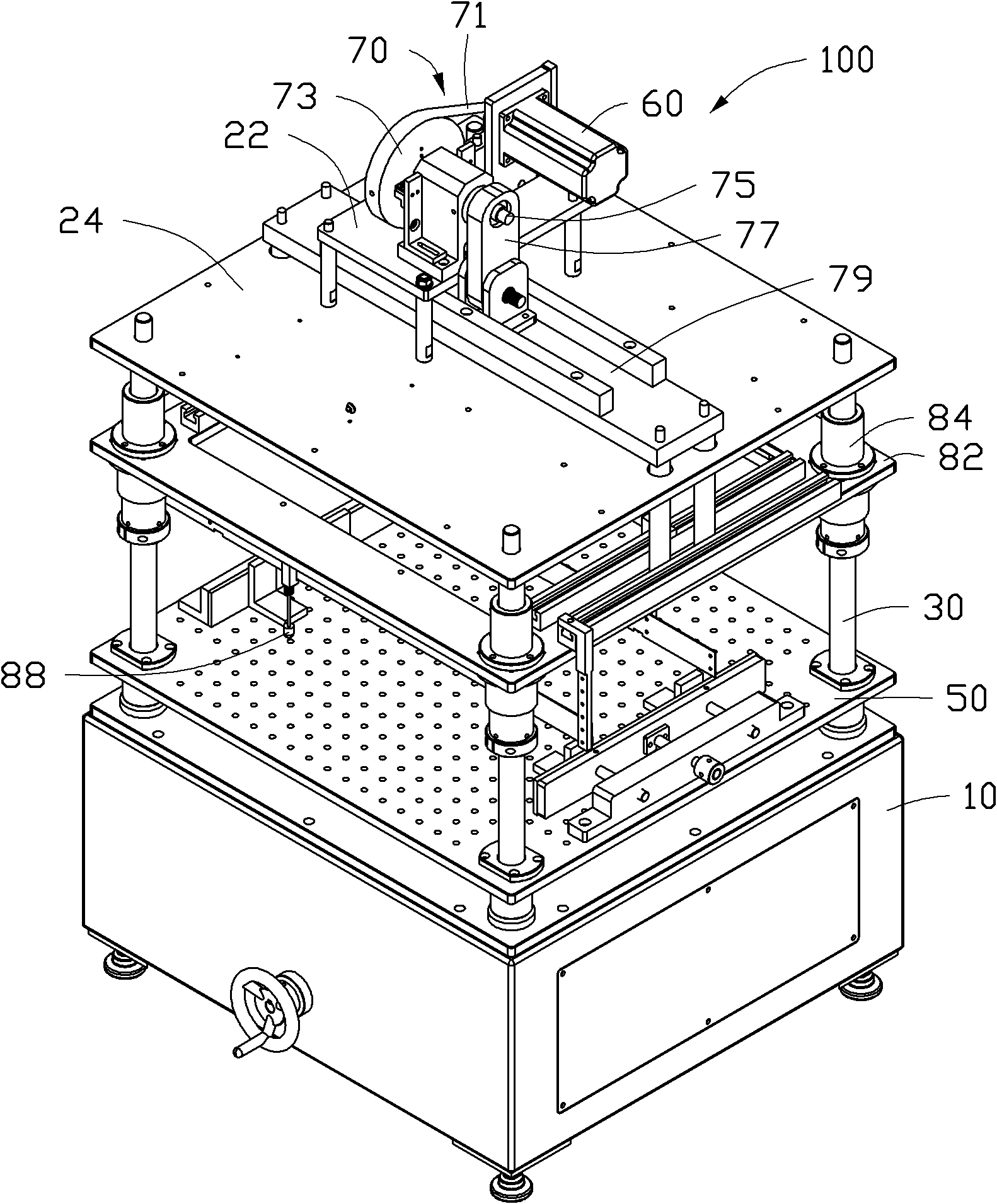

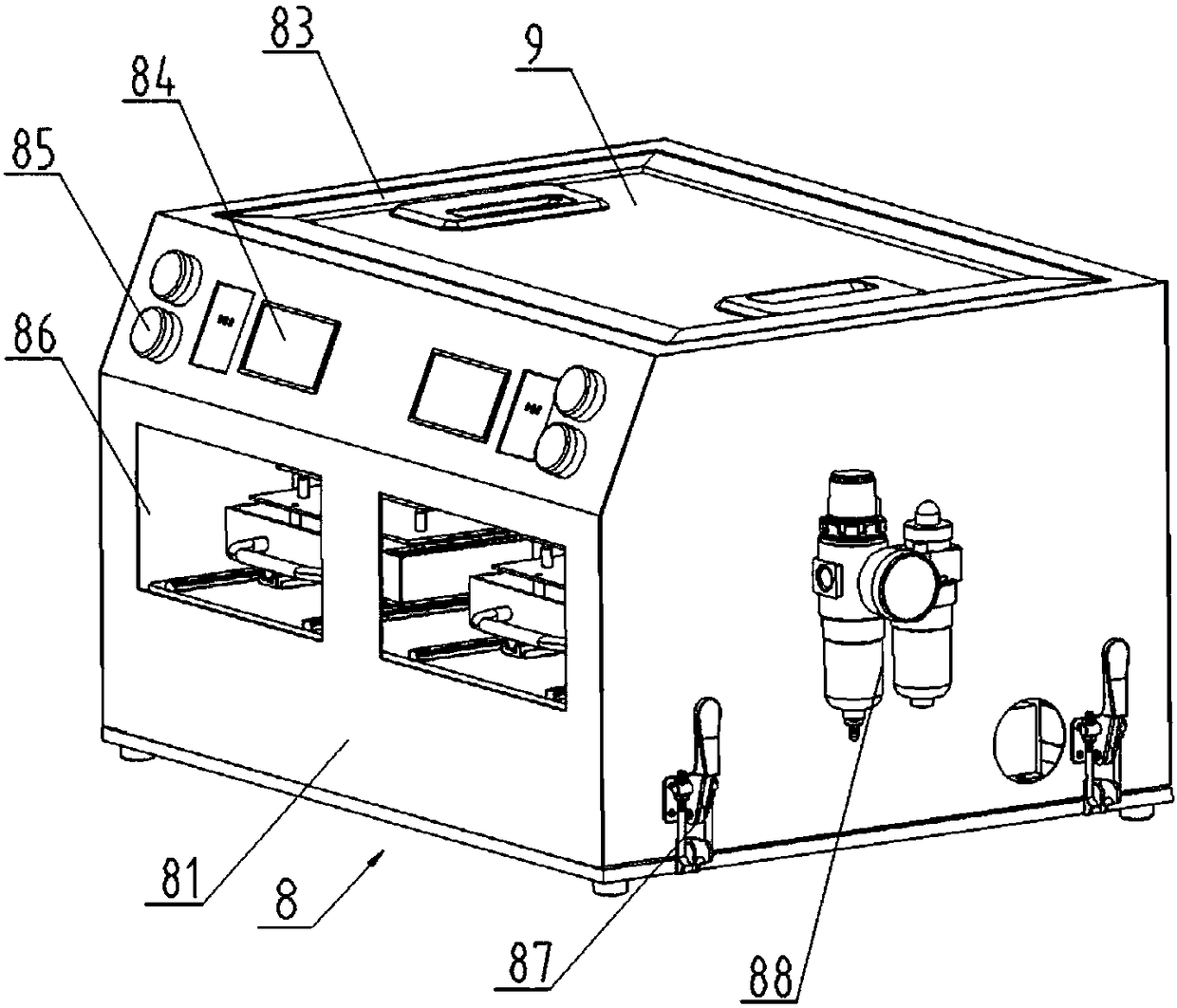

Button durability testing machine

InactiveCN102650562AGuaranteed accuracyRealize fully automatic testingMaterial strength using repeated/pulsating forcesElasticity measurementKey pressingReciprocating motion

A button durability testing machine includes a machine box, a lifting control mechanism and a work table, wherein the lifting control mechanism is mounted on the machine box to drive the work table to vertically reciprocate; the button durability testing machine also includes an electric cabinet, a guide rod, a servo motor, a drive mechanism and a pressing component; the guide rod is fixed between the machine box and the electric cabinet; the work table can be sleeved on the guide rod in a moving way under the control of the lifting control mechanism; both the servo motor and the drive mechanism are mounted in the electric cabinet; and the drive mechanism is used for transmitting the power output by the servo motor to the pressing component and driving the pressing component to vertically reciprocate along the guide rod.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

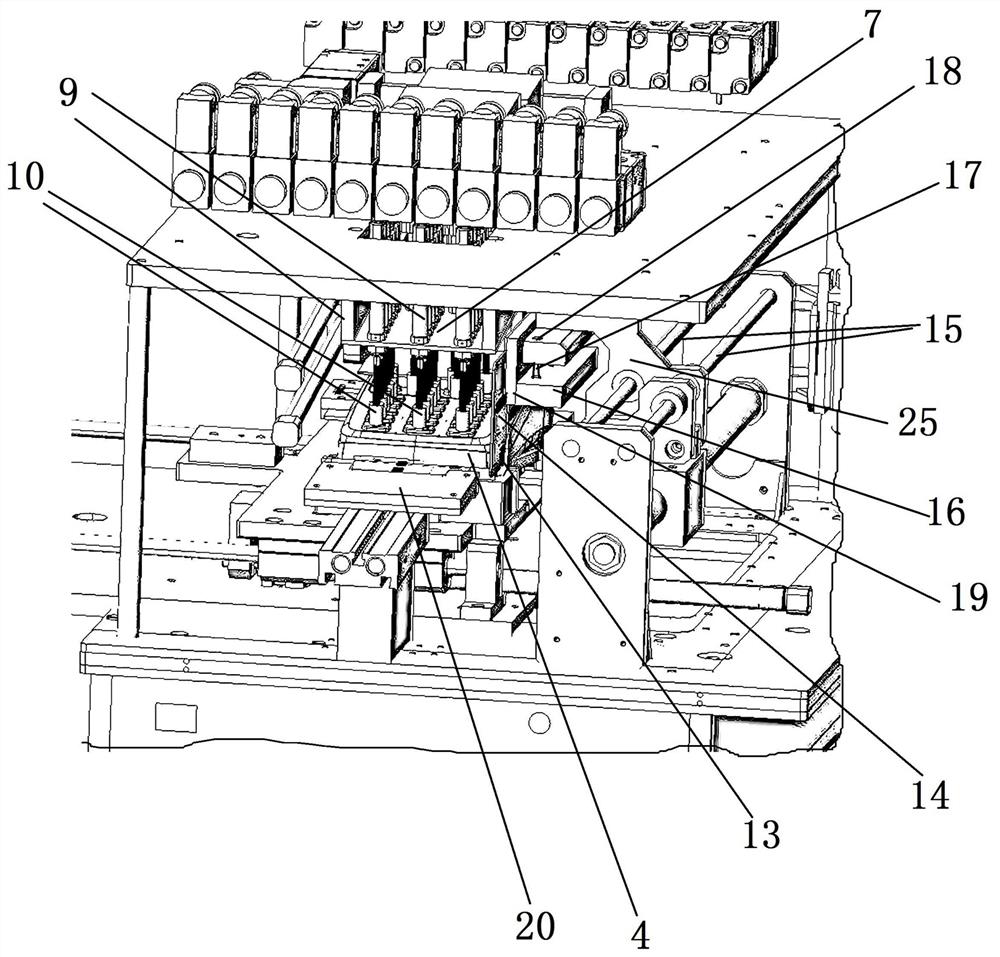

Circuit board function test device

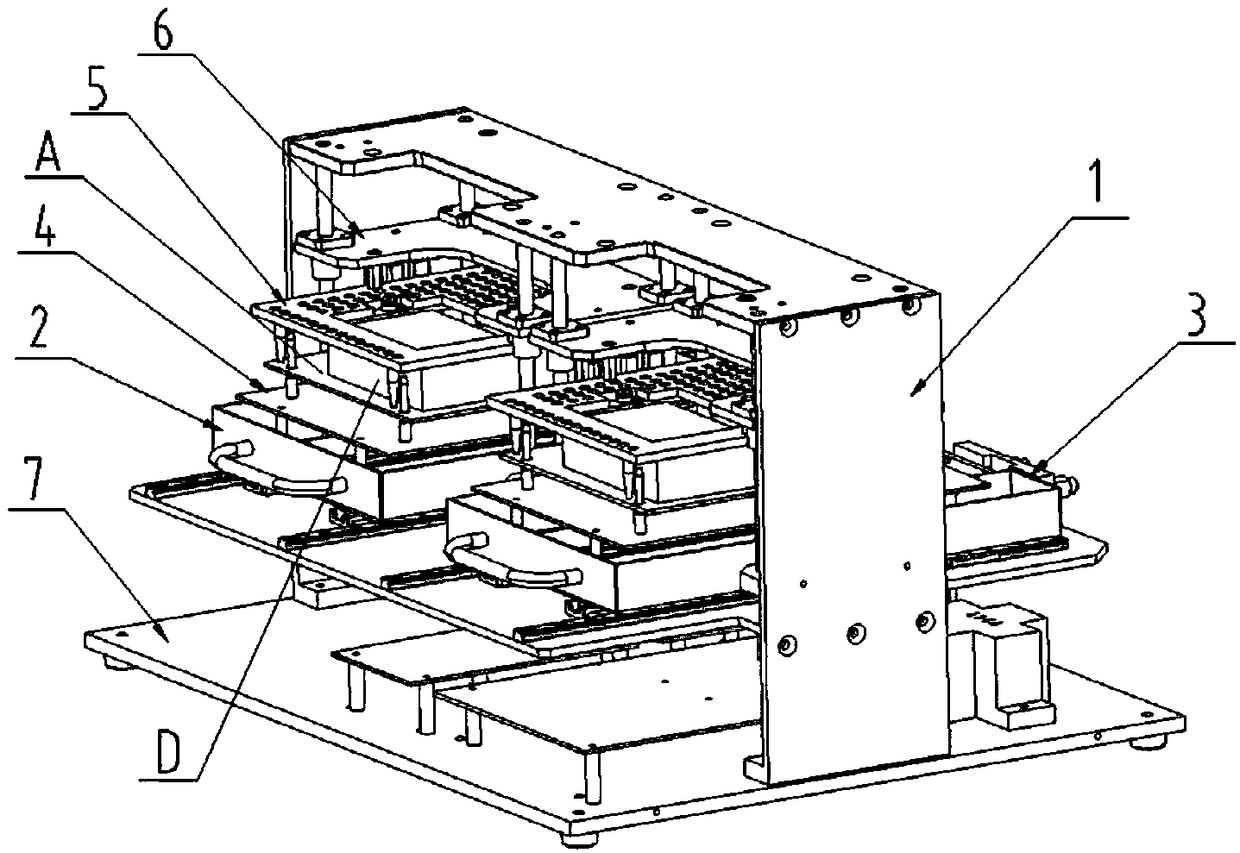

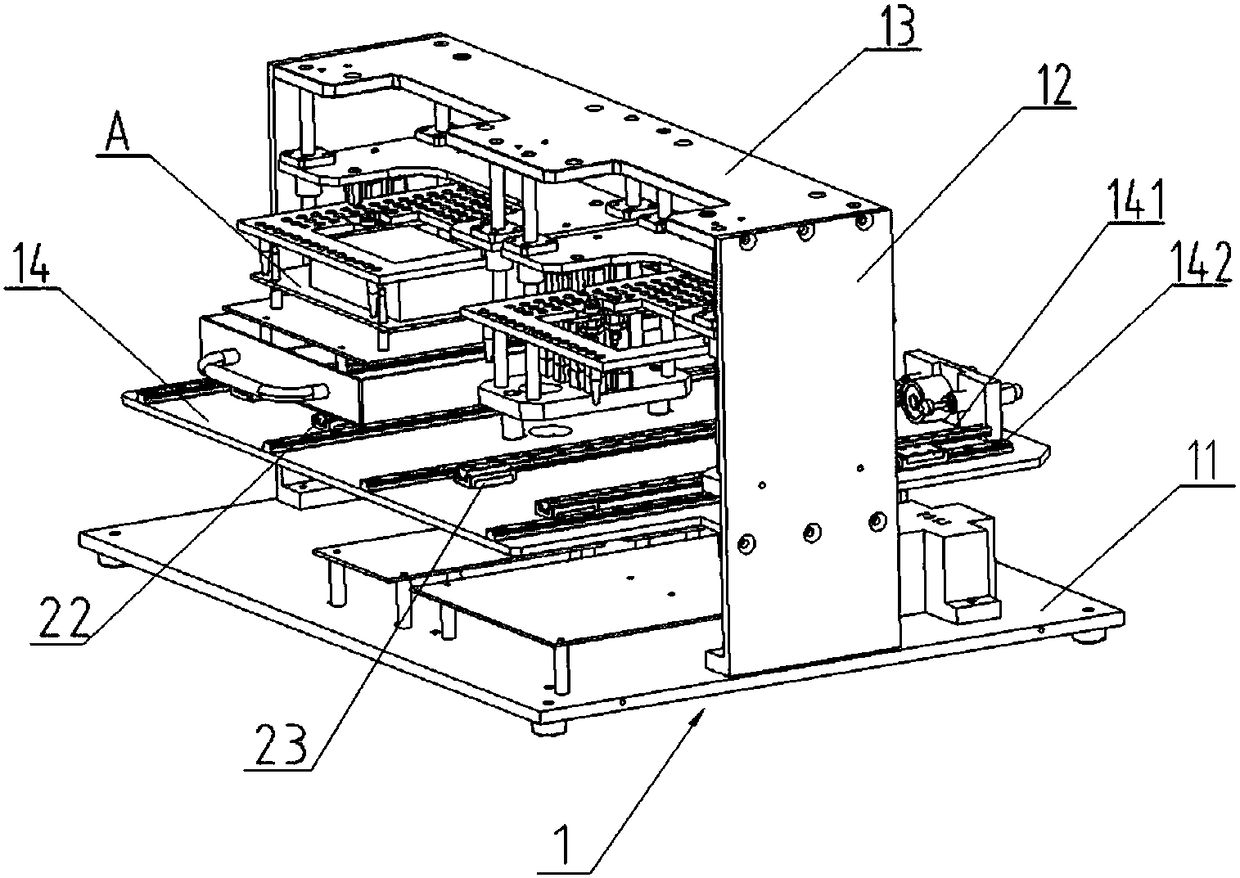

PendingCN108459265AEasy to replaceImplement functional testingPrinted circuit testingMeasurement instrument housingPrinted circuit boardBed boards

The invention discloses a circuit board function test device. The circuit board function test device comprises a main support framework, a tray assembly, a tray limit assembly, a needle bed board assembly, a crimping board assembly, an automatic crimping mechanism and a test bottom board assembly, wherein the main support framework comprises a base board and a support framework connected with thebase board, a lower portion of the support framework is connected with a platform board, a tray of the tray assembly can move on the platform board, the tray limit assembly is used for realizing the limit effect, the needle bed board assembly is connected with the tray, a tested circuit board is mounted on a needle bed board, a crimping board is arranged above the tested circuit board and is connected with an upper end of the automatic crimping mechanism, a lower end of the automatic crimping mechanism is fixed on the platform board, and the test bottom board assembly is arranged below the platform board and is fixed on the base board. A test bottom board of the test bottom board assembly is connected with a power source board, a test circuit board and a wiring terminal seat, the test bottom board is electrically connected with the tested circuit board through the wiring terminal seat and a connection lead, and functional tests on circuit boards in multiple types of model specifications can be carried out.

Owner:WASION GROUP HLDG

Full-automatic function test method and device for new energy automobile controller

PendingCN111258289ARealize fully automatic testingImplement automatic connectionElectric testing/monitoringTest efficiencyFunctional testing

The invention discloses a full-automatic function test method and device for a new energy automobile controller. The method comprises steps of S1, controlling the collected information of a to-be-tested controller for recognition, and recognizing the type output of the to-be-tested controller; S2, according to the identified type of the to-be-tested controller, controlling the to-be-tested controller to be connected with a matched test tool in a pre-constructed test tool database so as to use a matched test tool to realize automatic connection of interfaces required when the to-be-tested controller is tested; and S3, according to the identified type of the to-be-tested controller, controlling a matched test program in the pre-constructed test program database to execute a required functiontest on the to-be-tested controller; the device comprises a type automatic identification module, a tool automatic calling module and a function test automatic execution module. The method has advantages of being simple to implement, high in intelligent degree and test efficiency, low in test cost, capable of being suitable for batch test and the like.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

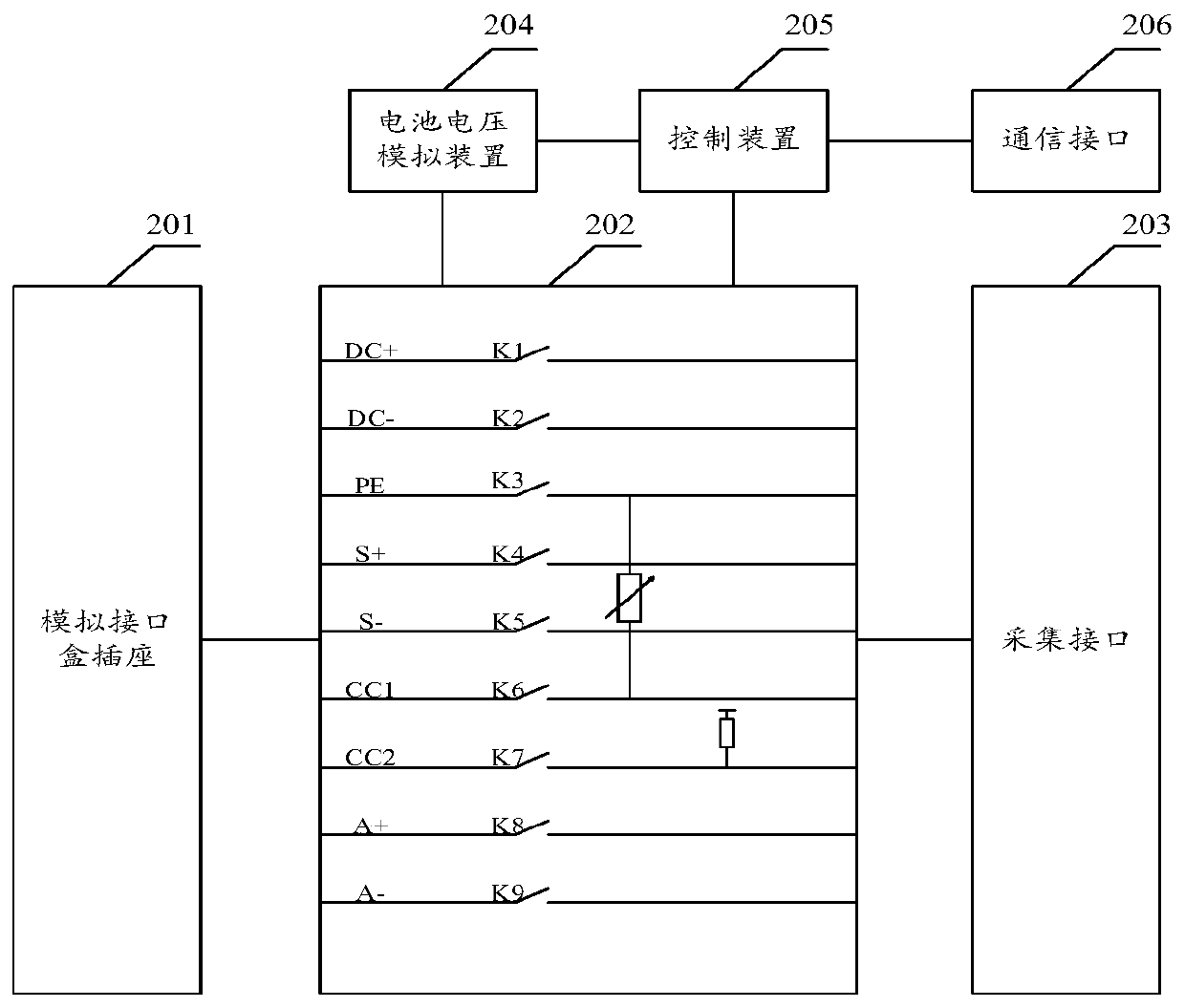

Mobile detection device for on-site detection of DC charging pile

InactiveCN109884438AHighly integratedImprove test securityElectrical testingAnalysis dataData acquisition

The invention discloses a mobile detection device for on-site detection of a DC charging pile. The mobile detection device comprises an upper computer, a DC interface simulation device, a charging simulation device and a data acquisition device, wherein the upper computer is used for issuing a control instruction to the DC interface simulation device and the charging simulation device, receiving and analyzing test parameters of a tested charging pile uploaded by the data acquisition device; the charging simulation device is used for simulating a charging process and regulating output current of the tested charging pile according to the control instruction; the DC interface simulation device is used for simulating various abnormal charging conditions according to the control instruction; the data acquisition device is used for acquiring the test parameters of the tested charging pile under normal charging conditions and the abnormal charging conditions and uploading the test parametersto the upper computer. The mobile detection device can effectively reduce workload of test workers, improve accuracy and traceability of test data and guarantee test safety.

Owner:浙江华云清洁能源有限公司

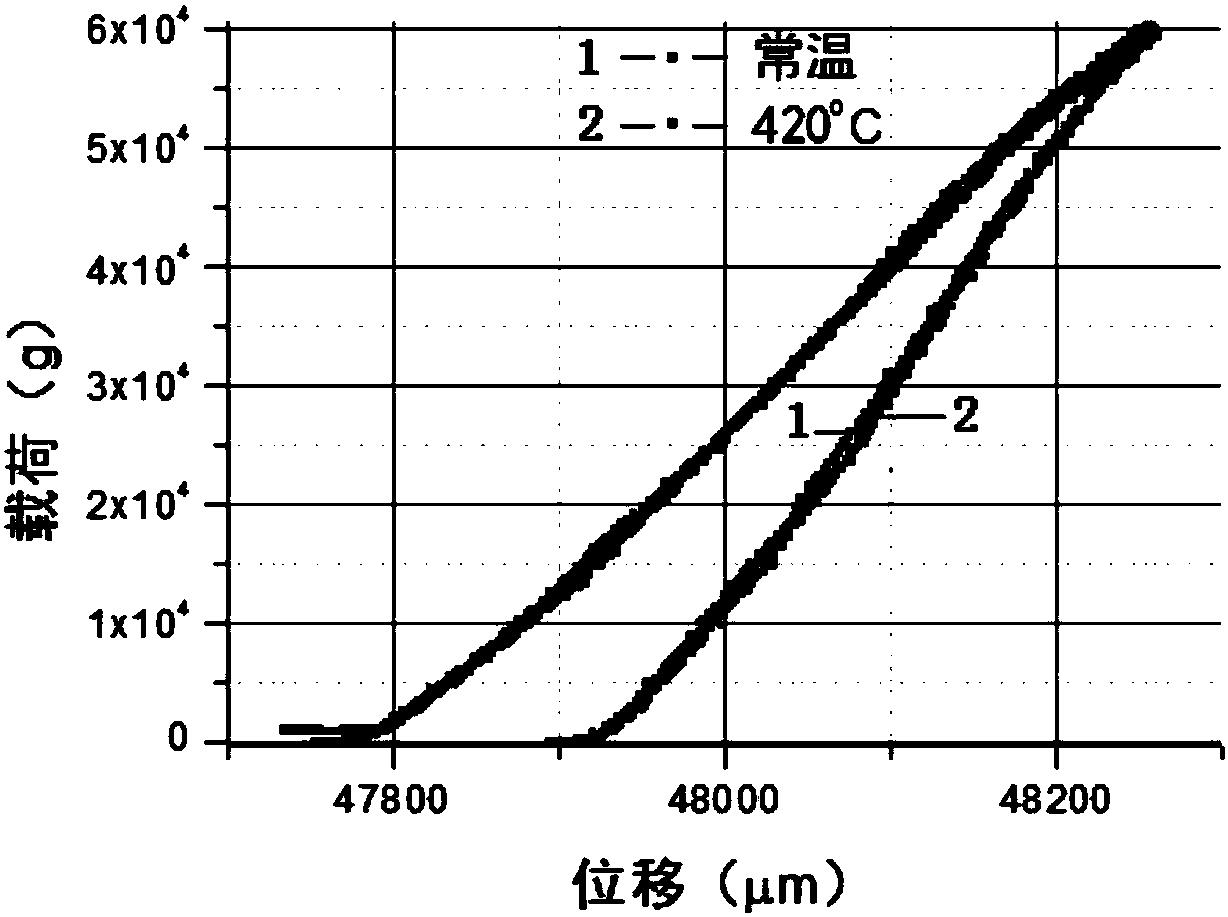

Test instrument for material mechanical properties at ultra-high temperature and high-temperature furnace used thereby

PendingCN108037002AEasy to operateOperational securityInvestigating material hardnessVacuum pumpingAutomatic control

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

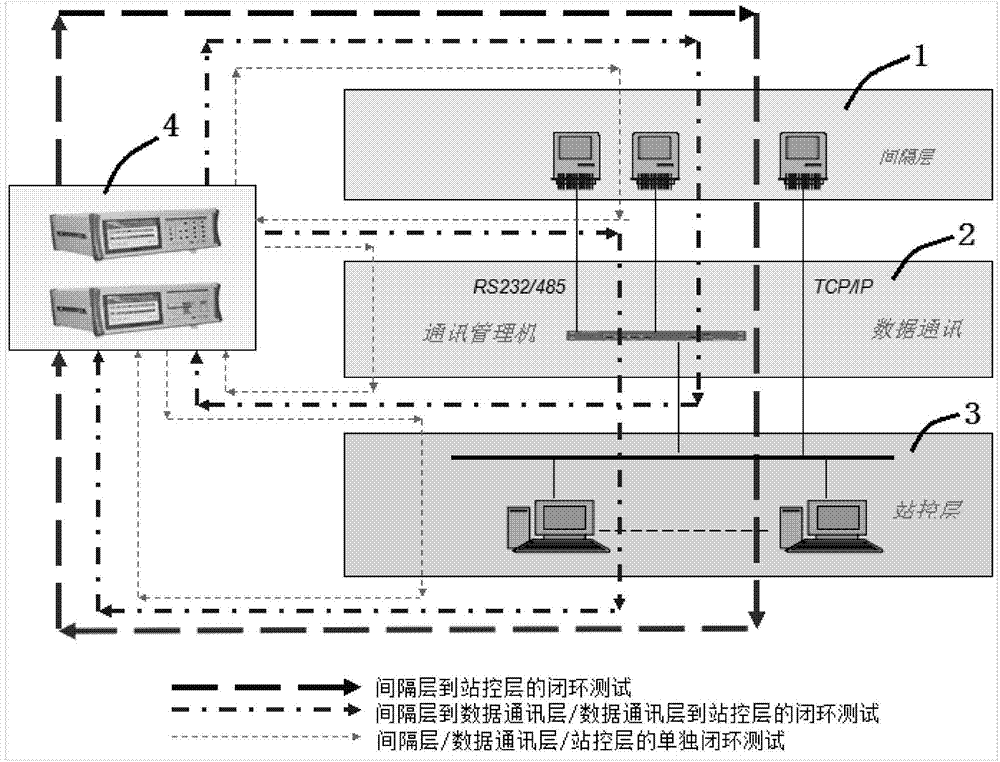

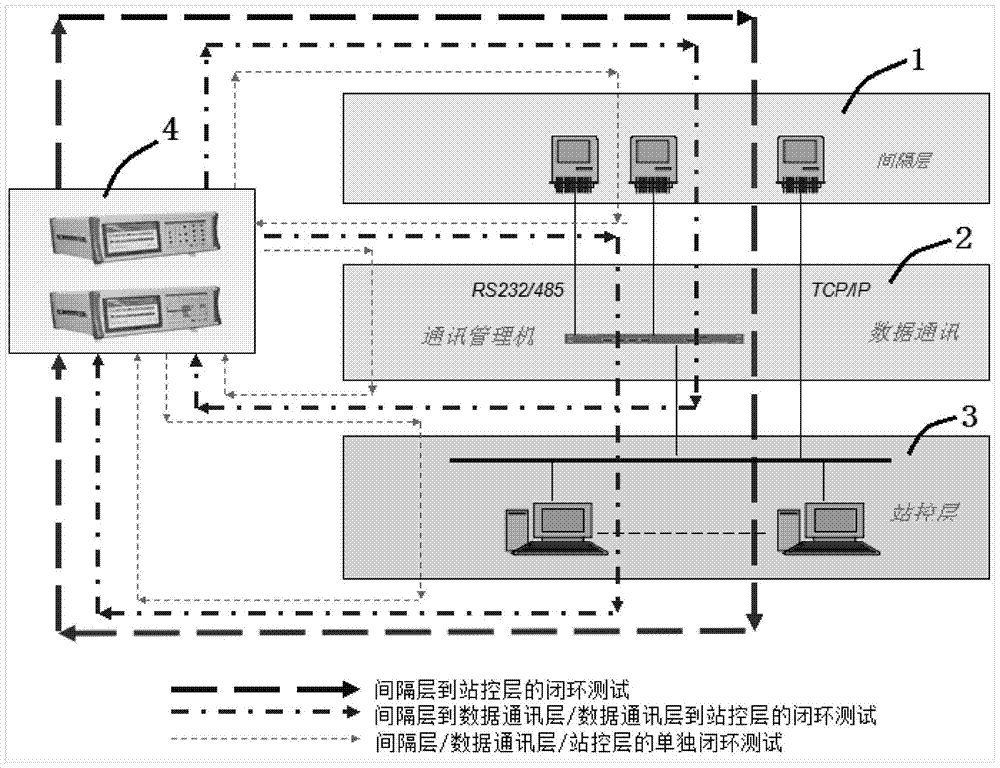

Transformer station integrated automatic test system

ActiveCN104502748ARealize the purpose of comprehensive automatic detectionRealize fully automatic testingElectrical testingMultiple functionTransformer

The invention provides a transformer station integrated automatic test system, and relates to the technical field of transformer station automatic system detection. The transformer station integrated automatic test system comprises a tester, isolation layer equipment, data communication layer equipment and station control layer equipment. An independent closed-loop test is respectively formed by the tester and the isolation layer equipment, the tester and the data communication layer equipment, and the tester and the station control layer equipment. The closed-loop test of the isolation layer to the data communication layer is formed by the tester and the isolation layer equipment and the data communication layer equipment. The closed-loop test of the data communication layer to the station control layer is formed by the tester and the data communication layer equipment and the station control layer equipment. The closed-loop test of the isolation layer to the station control layer is formed by the tester and the isolation layer equipment, the data communication layer equipment and the station control layer equipment. According to the transformer station integrated automatic test system, multiple functions of a protocol analyzer, a data acquisition device, a data simulator, a measurement and control device tester and a GPS time synchronization instrument are integrated as a whole, and various electric power automatic measurement and control equipment, RTU, protection devices and synchronizing devices are tested so as to be multi-purpose.

Owner:STATE GRID CORP OF CHINA +1

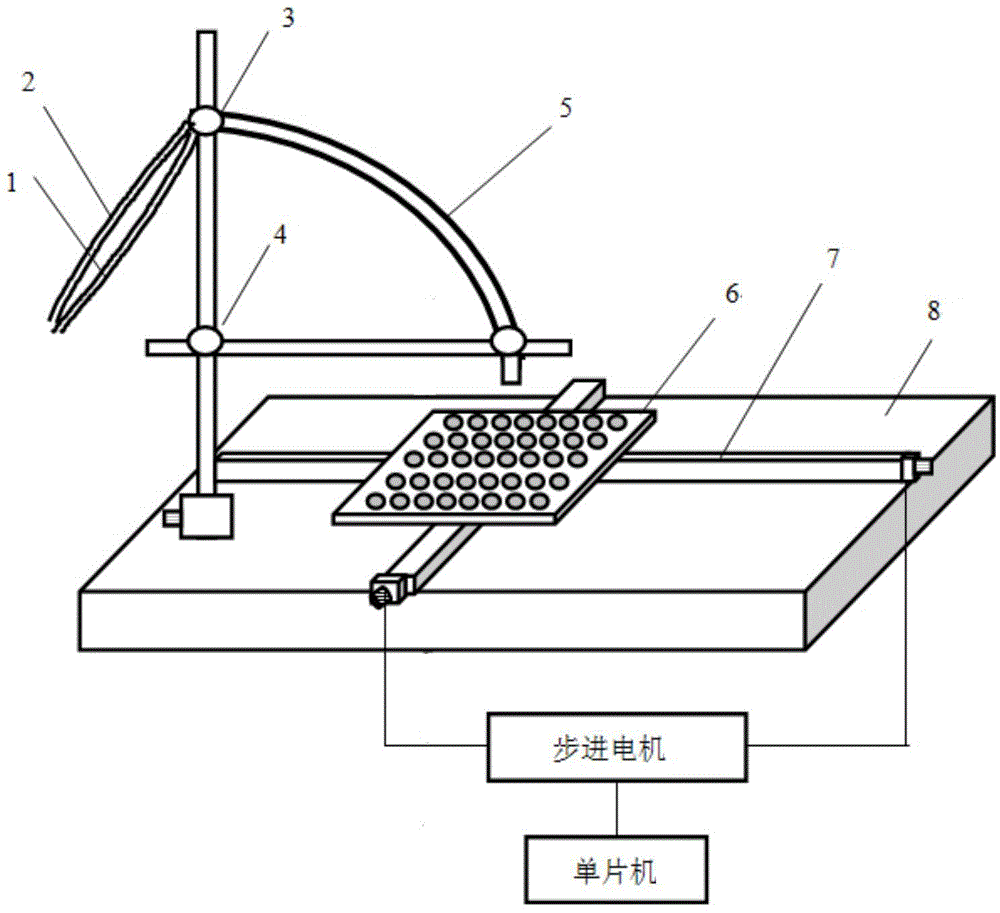

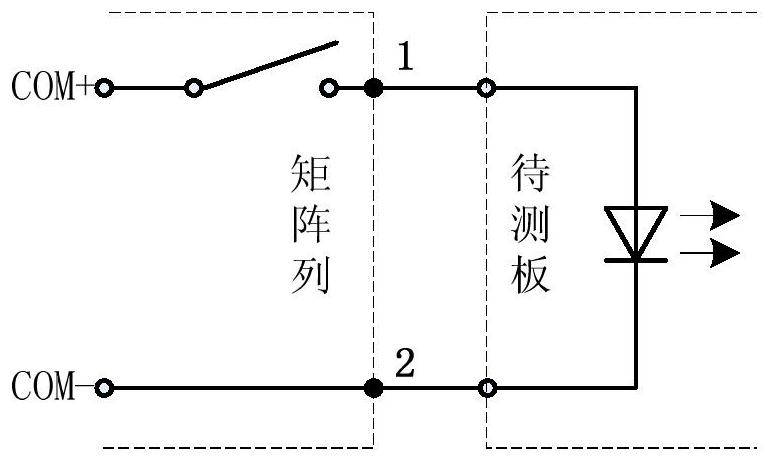

Luminescence property automatic testing system for luminescent material combination sample library

InactiveCN104142318ARealize fully automatic testingFully automatic test fastFluorescence/phosphorescenceMicrocontrollerMicrocomputer

The invention discloses a luminescence property automatic testing system for a luminescent material combination sample library. The system mainly solves the problems that in the prior art, samples in a sample library can not be fully automatically tested, people need to control two computers at the same time, and work efficiency is low. The system comprises an optical panel, a substrate, an X-Y two dimensional movable platform, a lifting support, an optical fiber support, an excitation light transmission optical fiber, an emitted light receiving optical fiber, an optical fiber tube, a single chip microcomputer, a step motor and manual operation interface software, wherein the combination sample library is arranged on the substrate in parallel. The single chip microcomputer controls the step motor to drive the X-Y two dimensional movable platform to move, test the samples on the substrate and record data results obtained through tests, and a manual operation interface controls the whole test process. By means of the system, full-automatic test of the combination sample library is achieved. Luminescence properties of various luminescent materials can be tested by means of the system.

Owner:XIDIAN UNIV

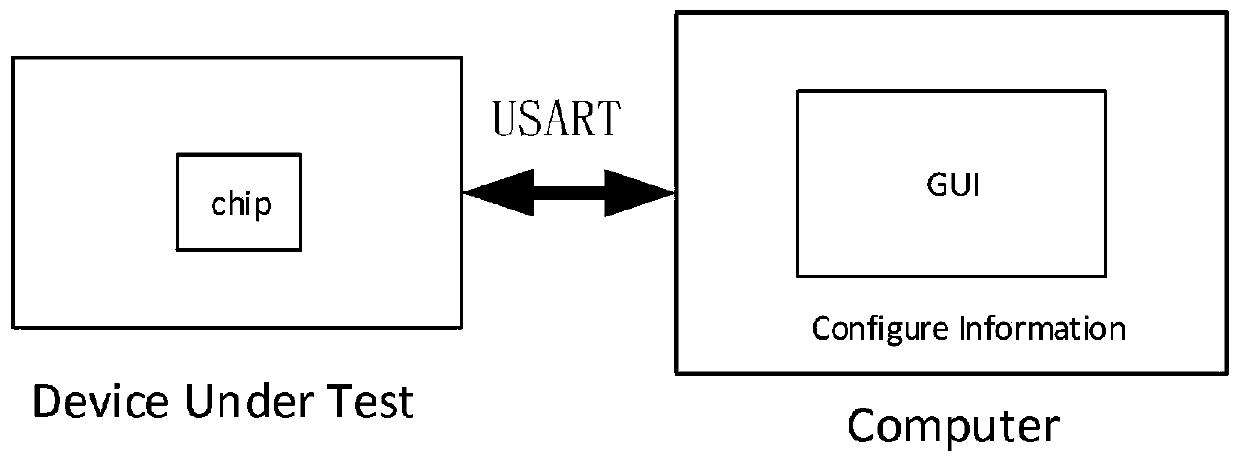

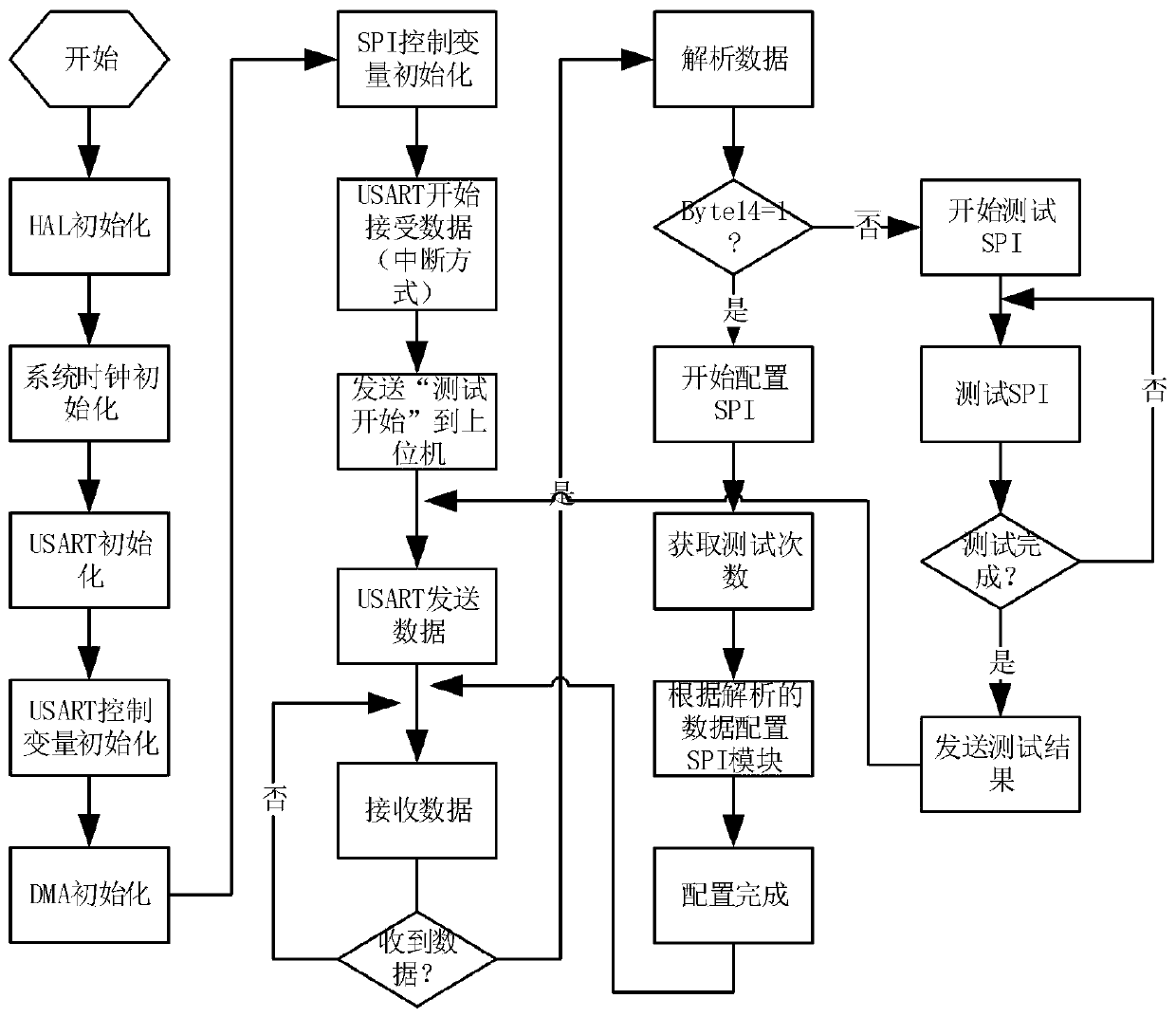

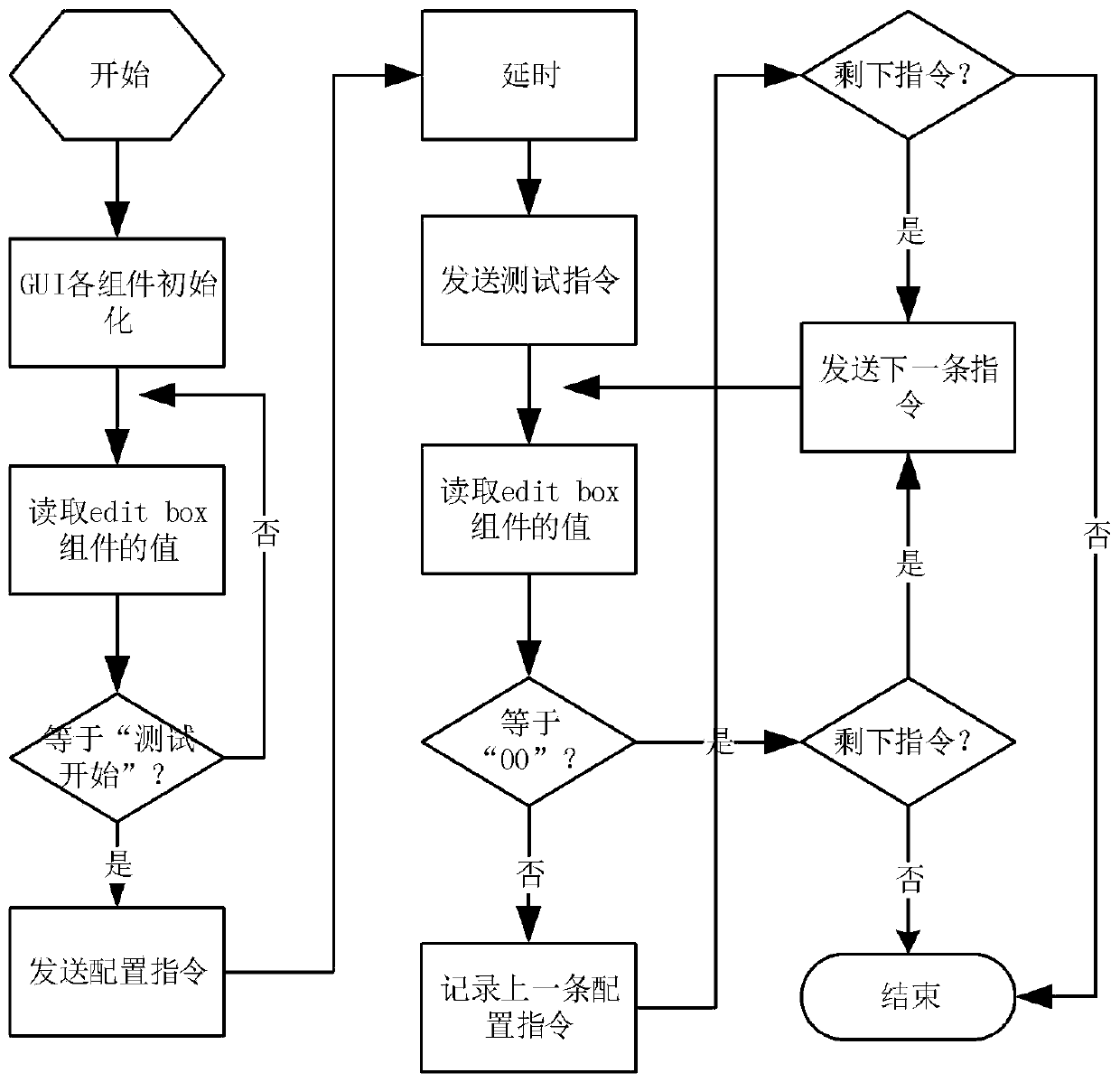

A method for quickly testing an SPI communication module

ActiveCN109885433AShorten the test cycleQuick testDetecting faulty computer hardwareComputer moduleTime cost

The invention discloses a method for quickly testing an SPI (serial peripheral interface) communication module, which is used for the communication based on a serial interface and comprises the following steps of S1, specifying a communication protocol between an upper computer and a lower computer; S2, using the upper computer to automatically configure an SPI module, generate a configuration table of the test case by using the SPI module, and convert the configuration table into a corresponding test instruction; S3, enabling the upper computer to communicate with the lower computer; and S4,after receiving the test instruction, using the lower computer to analyze the configuration instruction, and initialize the SPI of the chip according to the configuration information of the configuration instruction, so that the SPI works in an appointed working mode of the upper computer. According to the test method, nearly 100 thousands of cases of the SPI module can be fully automatically tested, the serial peripheral interface module can be quickly and efficiently tested, the test period of the SPI module is shortened, and the labor cost and the time cost consumed on the SPI module are greatly reduced.

Owner:CHIPSEA TECH SHENZHEN CO LTD

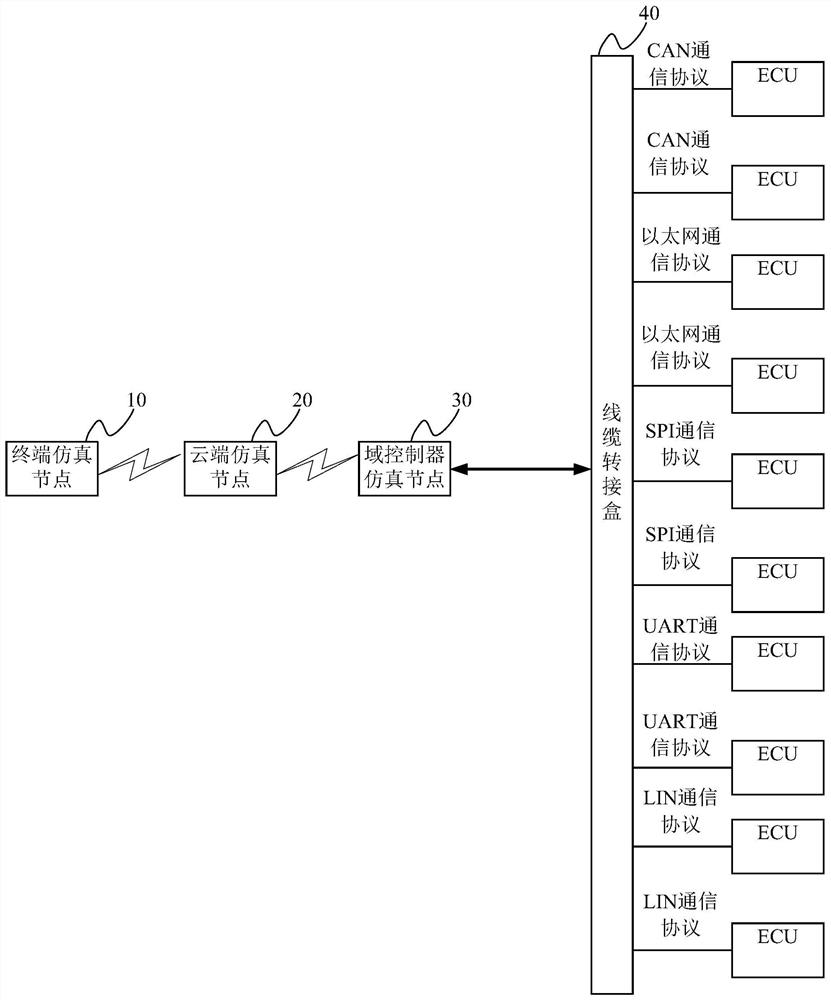

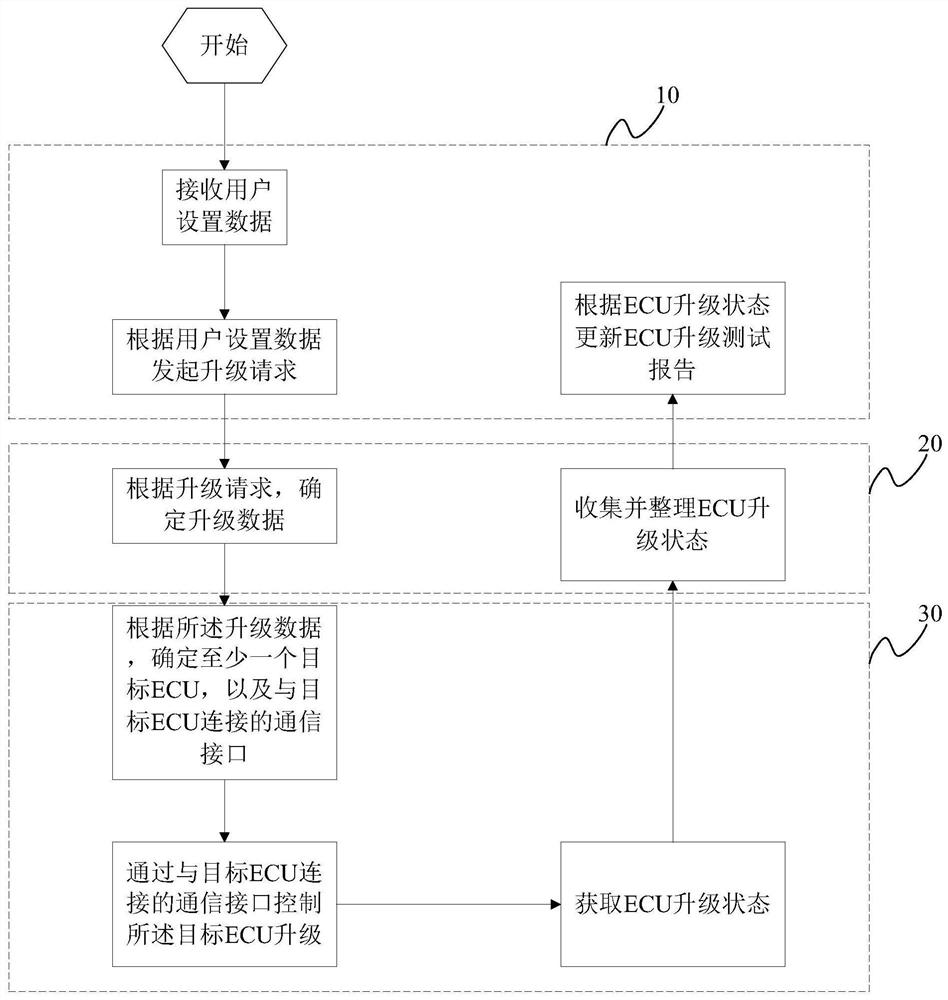

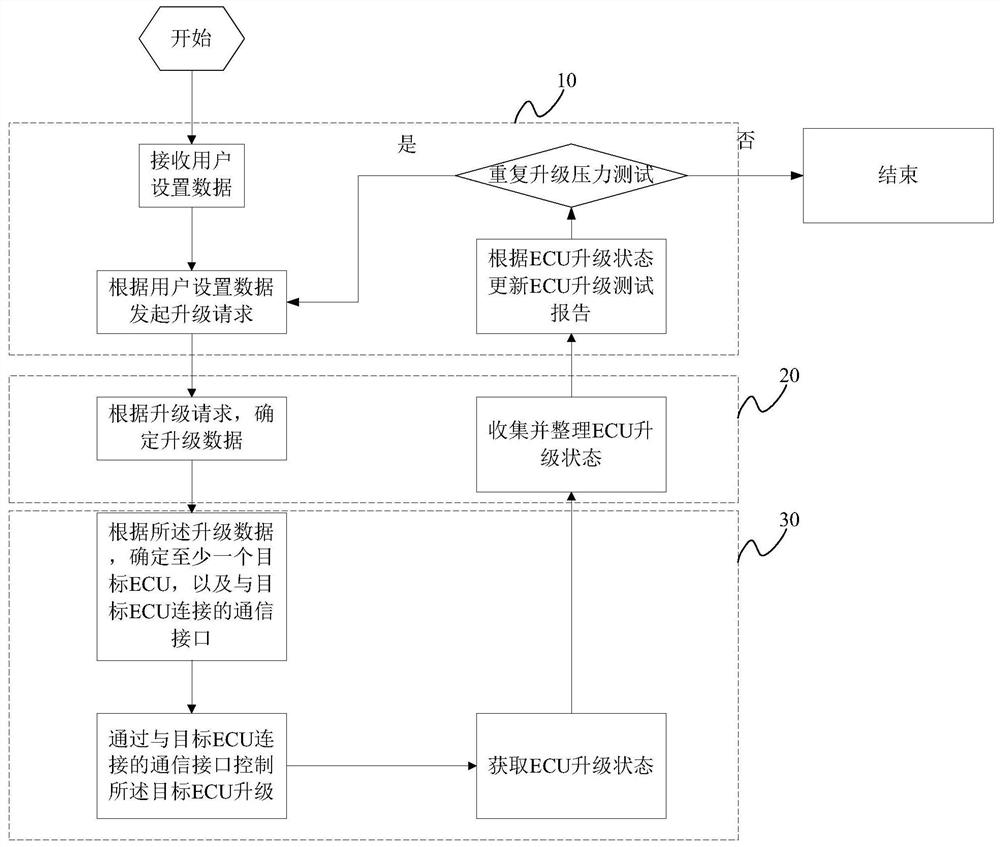

ECU upgrading test system

ActiveCN112698640ARealize fully automatic testingVerify stabilityElectric testing/monitoringMulticore cableCommunication interface

The invention discloses an ECU upgrading test system. The system is composed of a terminal simulation node, a cloud simulation node, a domain controller simulation node and a cable switching box; the domain controller simulation node is connected with the cable switching box through a multi-core cable; the cable switching box comprises multiple types of communication interfaces, therefore, the connection with various ECUs is realized. According to the ECU upgrading test system, the nodes and the cable switching box are utilized to simulate the whole process from initiating an upgrading request by a terminal to upgrading various ECUs; and full-automatic test of different upgrading channels can be realized by operating the domain controller simulation node through interaction between the terminal simulation node and the cloud simulation node, and therefore, the stability and reliability of the function of remote ECU upgrading of the domain controller are verified; and moreover, the ECU upgrading test system can realize upgrading test of a plurality of same or different types of ECUs at the same time, so that the ECU upgrading test efficiency is greatly improved.

Owner:SAIC MOTOR

Automatic testing device for complete machine function

ActiveCN109085003AShorten development timeShorten the development cycleMachine part testingElectrical testingX-machineTest station

The invention provides an automatic testing device for a complete machine function, comprising a control module, an image recognition module, a communication module, a key testing station, a screen testing station, a printing test station, a card swiping test station, a tray for fixing a POS machine to be tested, an machine placement area and an machine testing area. A plurality of telescopic keyboard point pressing rods are arranged at the key testing station; a first camera used for shooting a POS machine screen is arranged at the screen testing station; a second camera used for shooting thePOS machine printing bill is arranged at the printing test station; the first camera and the second camera are connected with the image recognition module; the pressing point of keyboard point pressing rods is close to the keyboard of the POS machine after the POS machine is fed into the machine testing area; The first camera faces the POS machine screen; the second camera faces the printout endof the POS machine; the card swiping test station is close to the side edge of the POS machine; The control module is connected with the POS machine through the communication module to obtain the working data of the POS machine. According to the automatic testing device for complete machine function, full-automatic integrated testing can be performed on the POS machine.

Owner:FUJIAN NEWLAND PAYMENT TECH

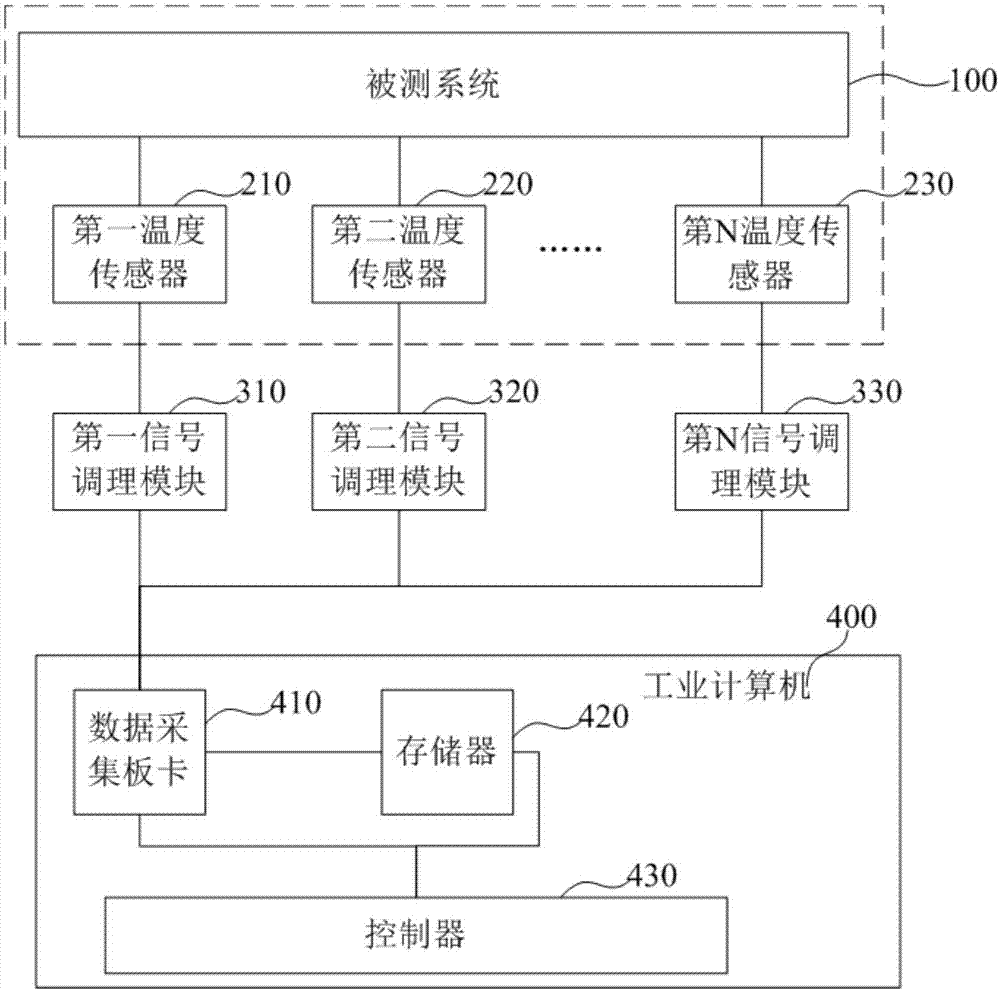

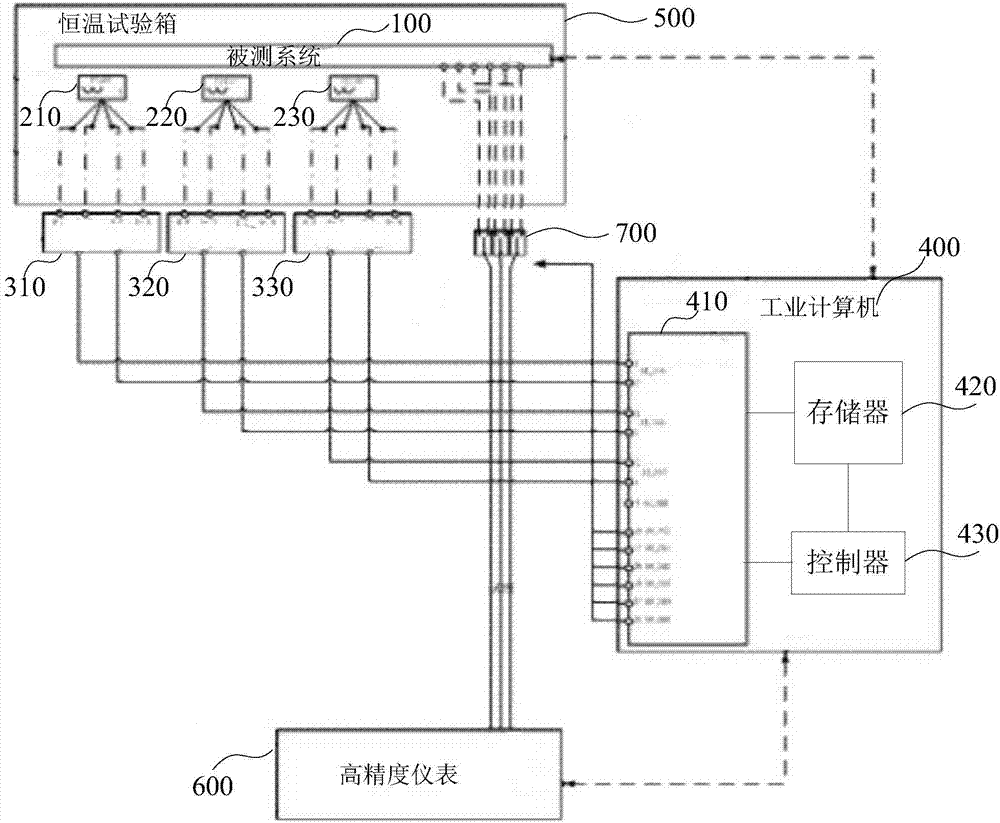

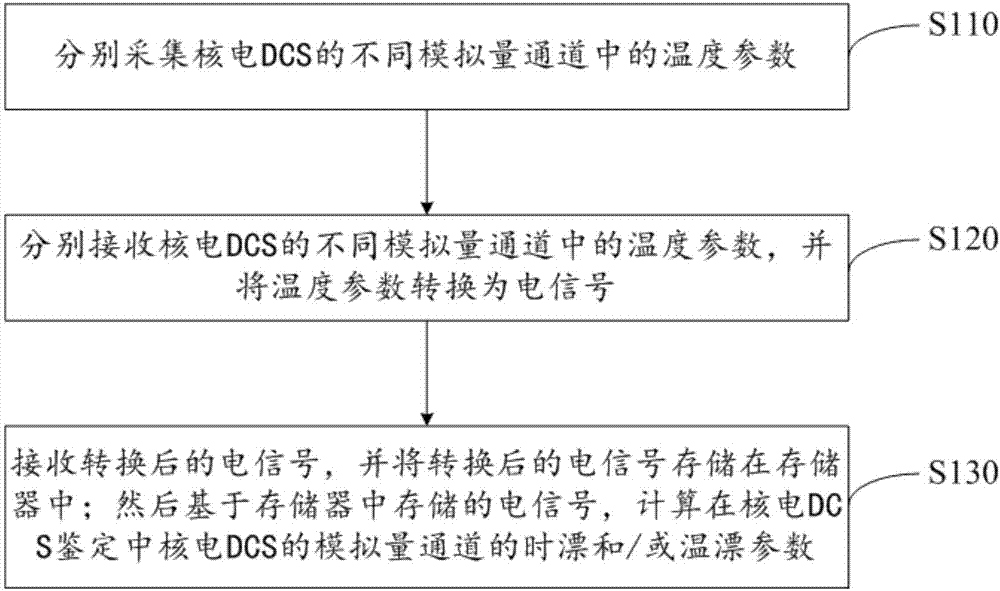

Automatic analog quantity testing device and method in nuclear power DCS identification

ActiveCN107544478AImprove test efficiencyComprehensive testElectric testing/monitoringSignal conditioningNuclear power

The invention belongs to the technical field of system performance testing in nuclear power DCS, and provides an automatic analog quantity testing device and method in nuclear power DCS identification, wherein the device and method can achieve precision testing and temperature drift and time drift monitoring simultaneously in DCS monitoring; the device comprises multiple temperature sensors, multiple signal conditioning modules and an industrial computer; the temperature sensors are arranged in different analog quantity channels of the nuclear power DCS respectively, and the temperature sensors and the nuclear power DCS are arranged in a constant temperature test chamber together; the signal conditioning modules receive temperature signals of the multiple temperature sensors and convert the temperature signals into electric signals; the industrial computer comprises a data acquisition board card, storage and a controller, the data acquisition board card is arranged to be capable of receiving the electric signals of the multiple signal conditioning modules, and the storage can store the electric signals received by the data acquisition board card; the controller computes time driftand / or temperature drift parameters of analog quantity channels of the nuclear power DCS in nuclear power DCS identification on the basis of the electric signals stored in the storage.

Owner:CHINA TECHENERGY +1

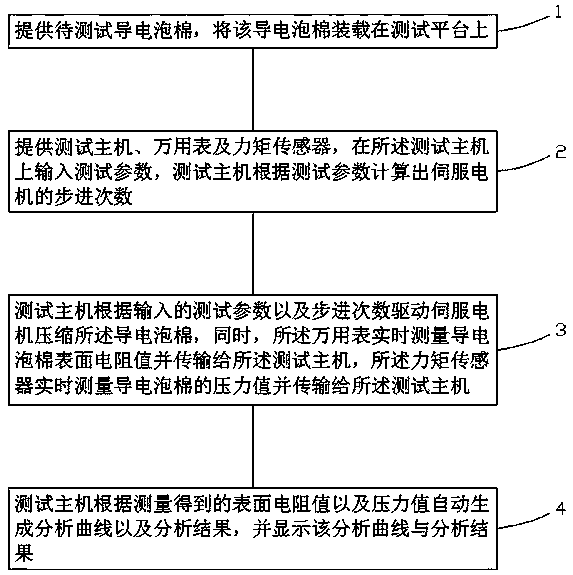

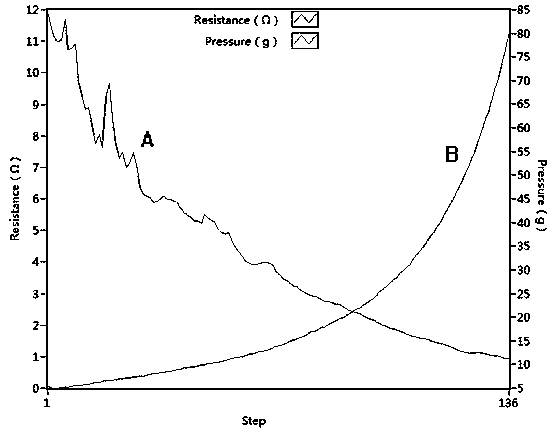

A kind of conductive foam test method

ActiveCN105115547BSimple test operationThe test result interface is simple and clearMeasurement devicesElectrical resistance and conductanceMotor drive

The invention discloses a method for testing conductive foam, comprising: step 1, providing conductive foam to be tested, and loading the conductive foam on a test platform; step 2, providing a test host, a multimeter and a torque sensor, and inputting Test parameters, the test host calculates the step times of the servo motor according to the test parameters; step 3, the test host drives the servo motor to compress the conductive foam according to the input test parameters and step times, and the multimeter measures the surface resistance of the conductive foam in real time and transmits For the test host, the torque sensor measures the pressure value of the conductive foam in real time and transmits it to the test host; step 4, the test host automatically generates an analysis curve and analysis results according to the measured surface resistance value and pressure value, and displays the analysis curve and analysis results. result. The invention tests the pressure value and the resistance value on the same device at the same time, and automatically generates a test curve, the test operation is simple, convenient and quick, and the display interface is simple and clear.

Owner:湖南赫莫尼科技有限公司

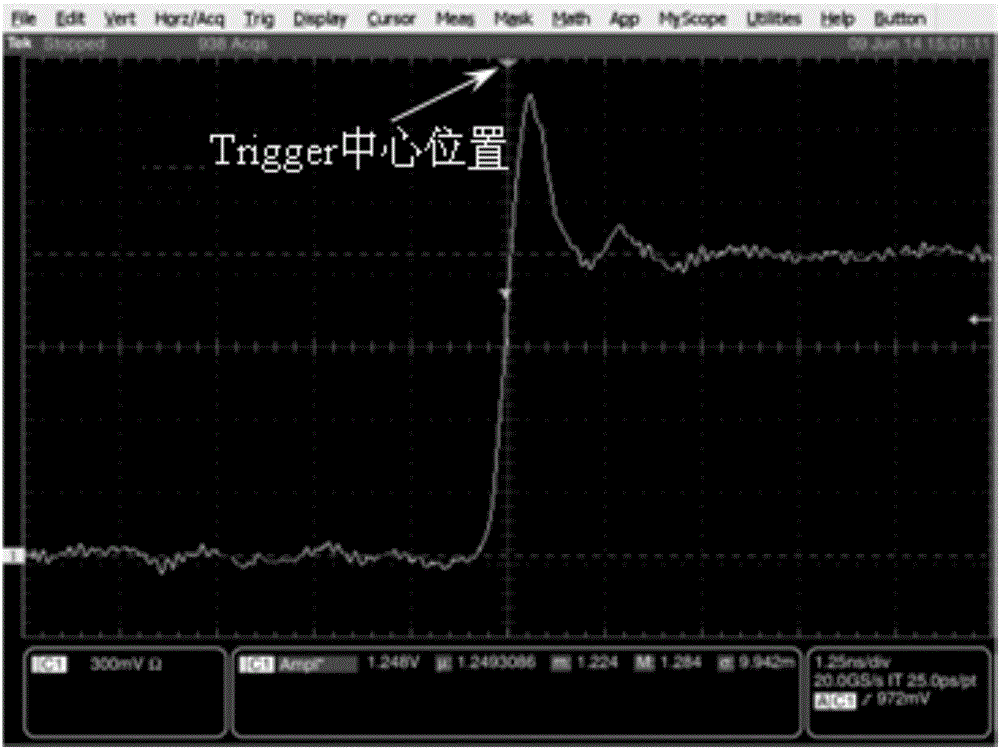

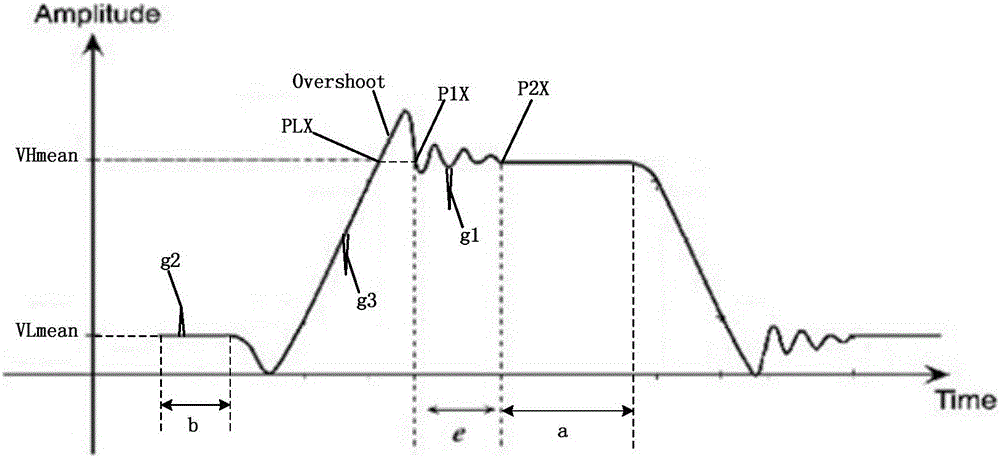

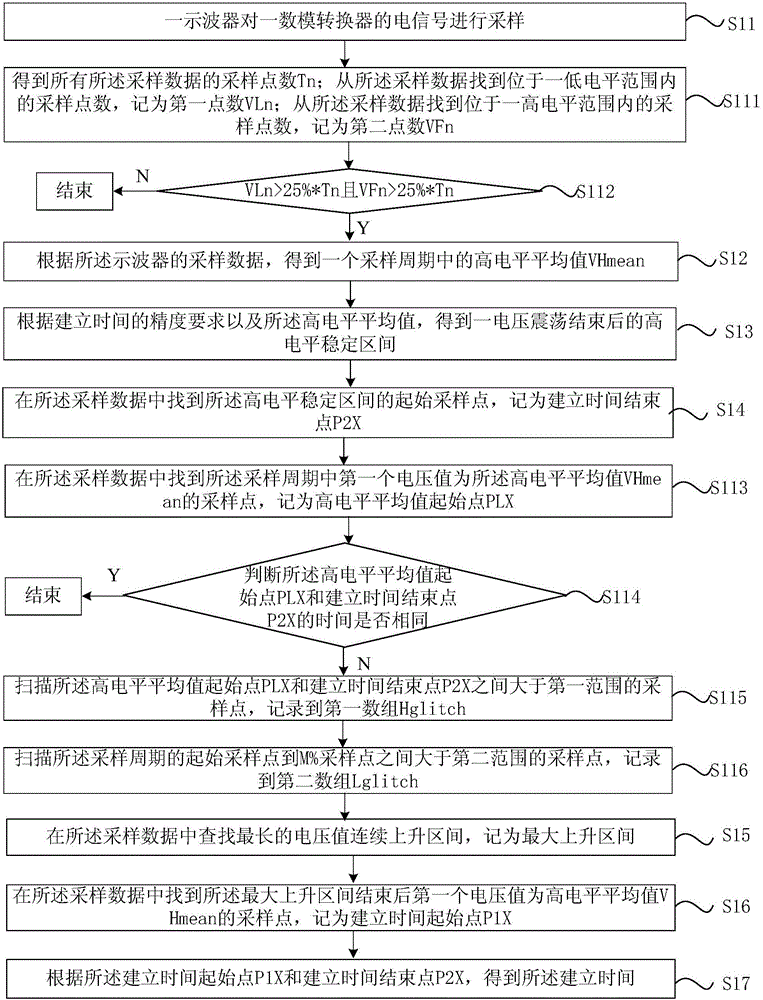

Settling time test method and system for digital to analog converter

ActiveCN107528590ARealize fully automatic testingAnalogue/digital conversion calibration/testingComputer scienceDigital-to-analog converter

The invention discloses a settling time test method for a digital to analog converter. The method comprises the steps of sampling an electrical signal of the digital to analog converter; acquiring an average high level value in a sampling period according to sampled data; acquiring a stable high level section after voltage oscillation ends; finding an initial sampling point of the stable high level section in the sampled data, and recording the initial sampling point as a settling time end point; finding the longest voltage value continuous raising section in the sampled data, and recording the section as a maximum raising section; finding the first sampling point of which the voltage value is the average high level value from the sampled data after the maximum raising section ends, and recording the first sampling point as a settling time initial point; and acquiring settling time according to the settling time initial point and the settling time end point. The invention also provides a settling time test system for the digital to analog converter using the method, and thus the settling time can be automatically tested.

Owner:SEMICON MFG INT TIANJIN +1

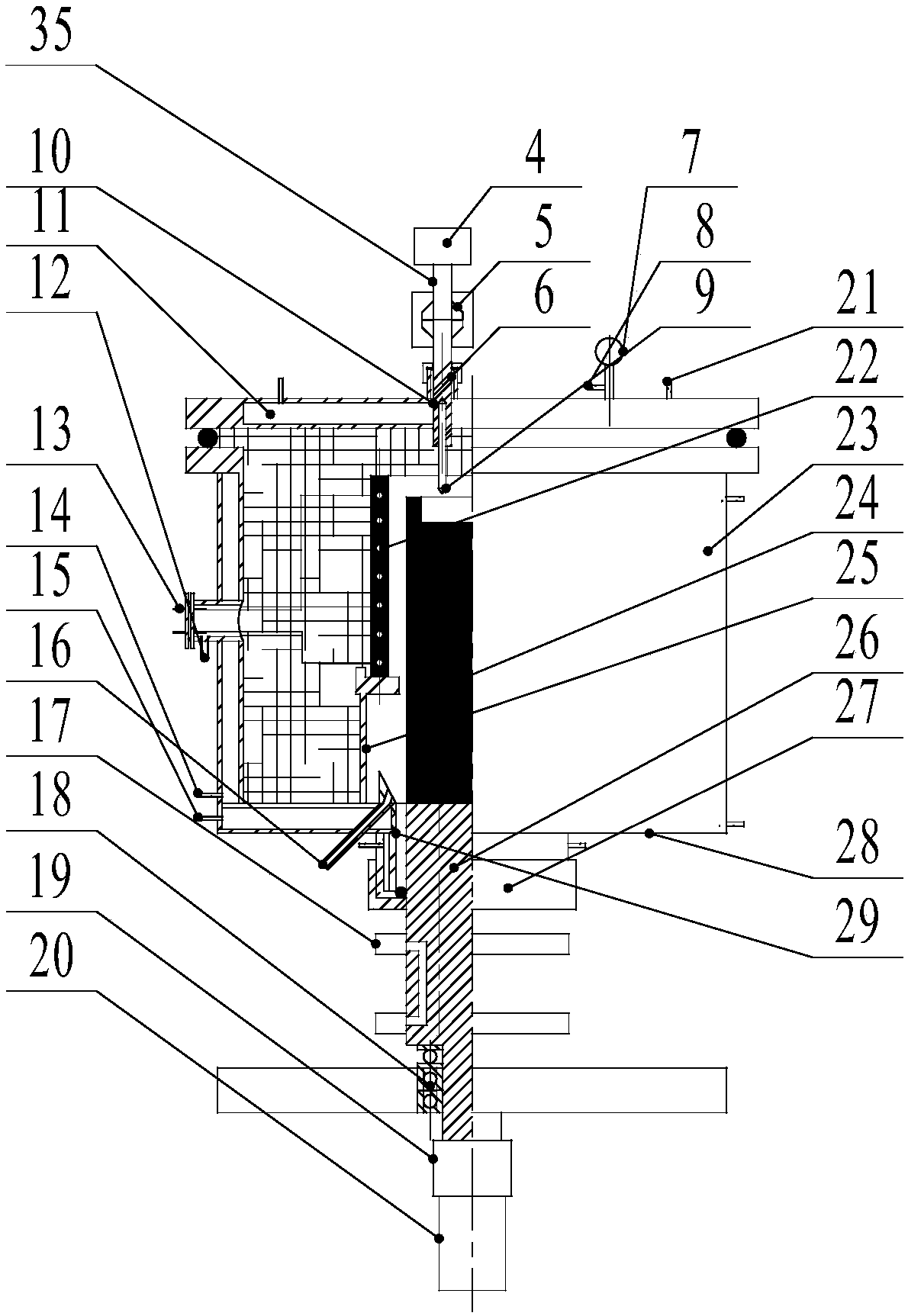

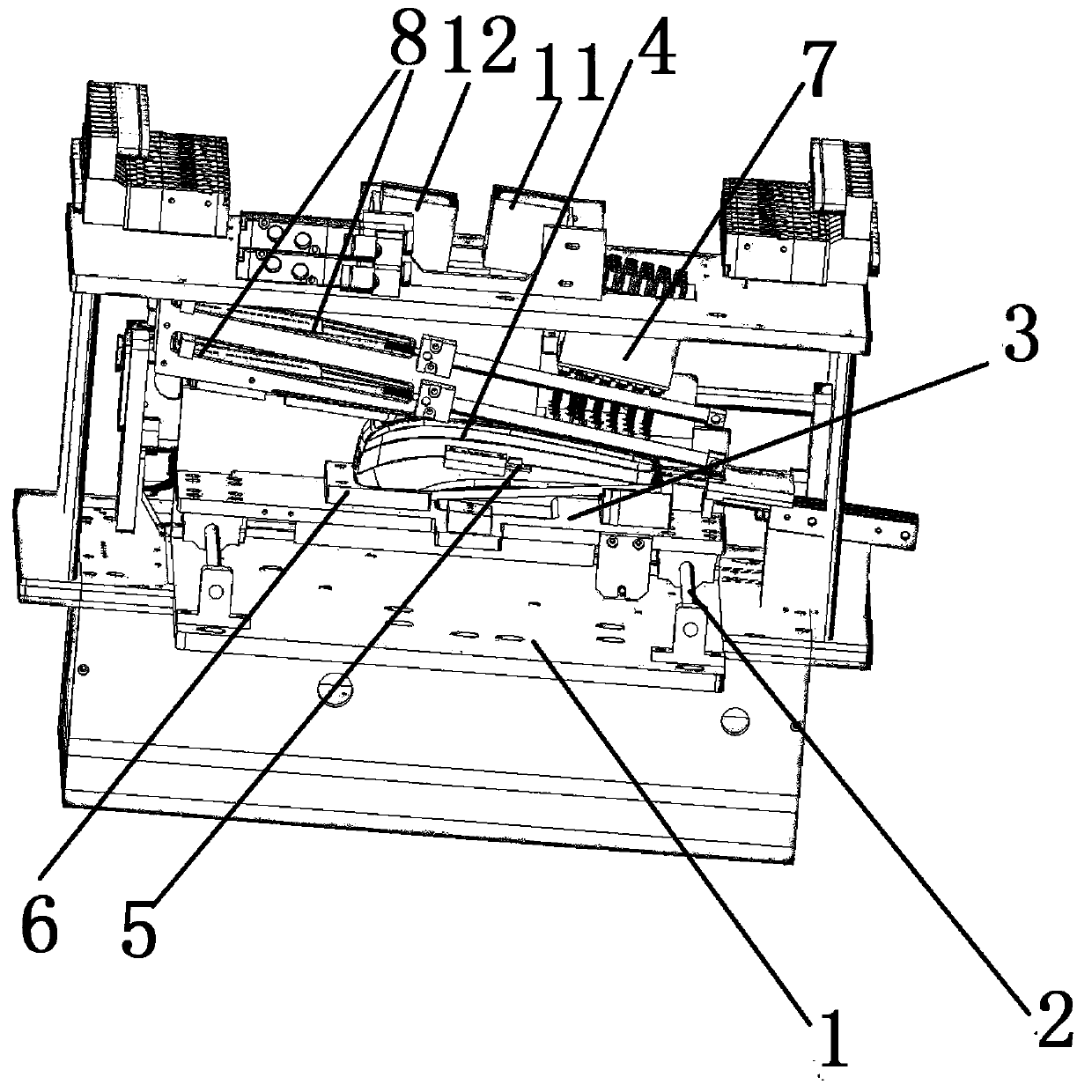

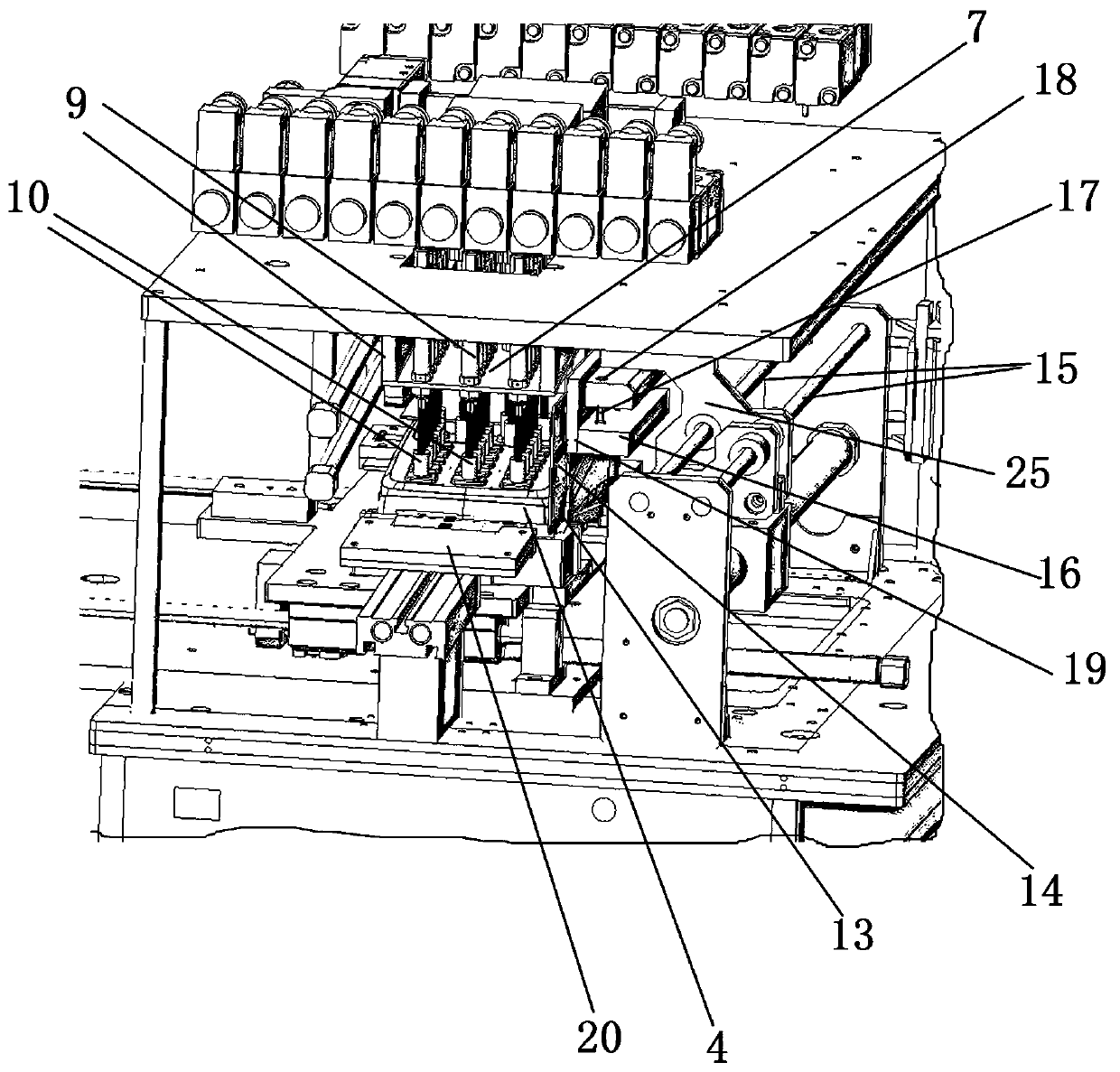

Torque force testing device for large-sized bolt

ActiveCN102262021BRealize fully automatic collectionRealize the display effectMaterial strength using steady torsional forcesCouplingEngineering

The invention belongs to experimental and testing devices for mechanical parts, and specifically relates to a torque force testing device for a large-sized bolt. The device comprises a clamping and fixing part and a twisting part; the clamping and fixing part is formed by the way that two guide rails (22) are arranged on a pedestal (17), left and right guide sleeves (21) are arranged on each guide rail (22), a sliding pull base (28) is formed on the four guide sleeves (21), a bolt pull sleeve (7) is placed in an opening cavity of the sliding pull base (28), and two sides of the bolt pull sleeve (7) are sleeved in sliding rails (8) at two sides of the opening cavity of the sliding pull base (28) via sliding sleeves (6); a front end of a tensioning screw (2) is connected with the bolt pull sleeve (7); a locking screw disc (3) is sleeved on the tensioning screw (2); a rack (25) is arranged on the pedestal (17); and a shaft (19) of a wheel gear (24) engaged with the rack penetrates into the sliding pull base (28). The twisting part is orderly composed of a nut sleeve head (10), a rotary special-shaped head (11), a universal coupling (12), a torque sensor (13), a coupling (14), a reducer (15) and a motor (16). The torque force testing device is steady, reliable, accurate, safe and convenient in the test procedure, and can implement automatic test and improve the speed, the efficiency and the accuracy of the test.

Owner:上海宝冶工程技术有限公司 +1

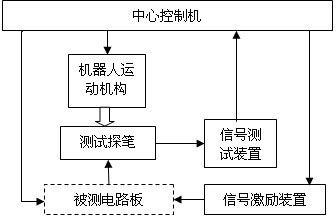

System and method for automatically diagnosing fault of circuit board

InactiveCN102621481BIncrease contactRealize fully automatic testingElectronic circuit testingMachine controlControl signal

Owner:HENAN ZHENGTAIXIN INNOVATION BASE

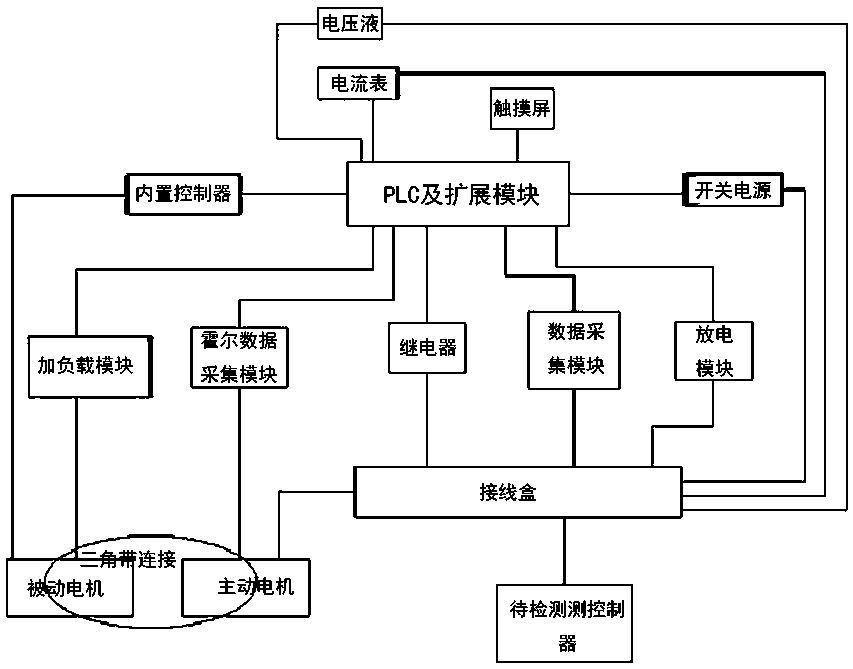

Electric vehicle controller automatic test system

PendingCN110442109AAvoid damageGuarantee quality stabilityElectric testing/monitoringData acquisitionVoltmeter

The invention discloses an electric vehicle controller automatic test system, which relates to the technical field of electric vehicle tests. An auxiliary direct current regulated power supply is connected to a power supply end of a test cabinet. The test cabinet is electrically connected to a test motor set. The test cabinet is provided with a touch screen, an ammeter, a voltmeter and a junctionbox. A pulley of an active motor is connected to a pulley of a passive motor through a belt. An PLC and an expansion module are electrically connected to a built-in controller, a switching power supply, a loading module, a Hall data acquisition module, a relay, a data acquisition module, a discharge module, the touch screen, the ammeter and the voltmeter. The ammeter, the voltmeter, the switchingpower supply, the relay, the data acquisition module, the discharge module and the active motor are electrically connected to the junction box. The built-in controller and the loading module are connected to the passive motor through wires. The electric vehicle controller automatic test system can realize rapid detection, is accurate in detection data and simple in operation, and facilitates the quick connection and can realize automatic discharge.

Owner:张龙

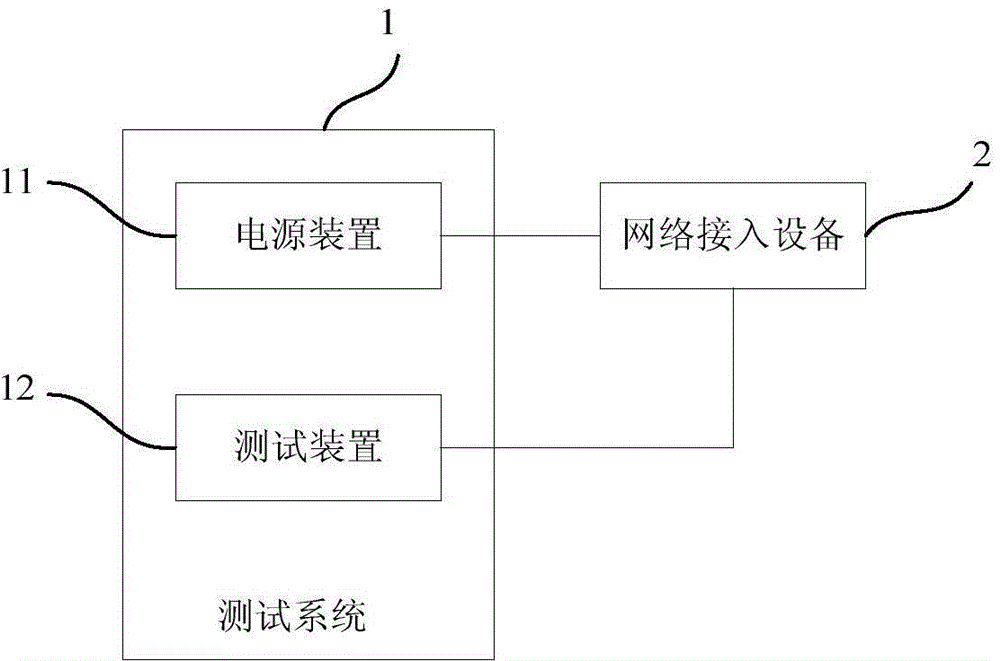

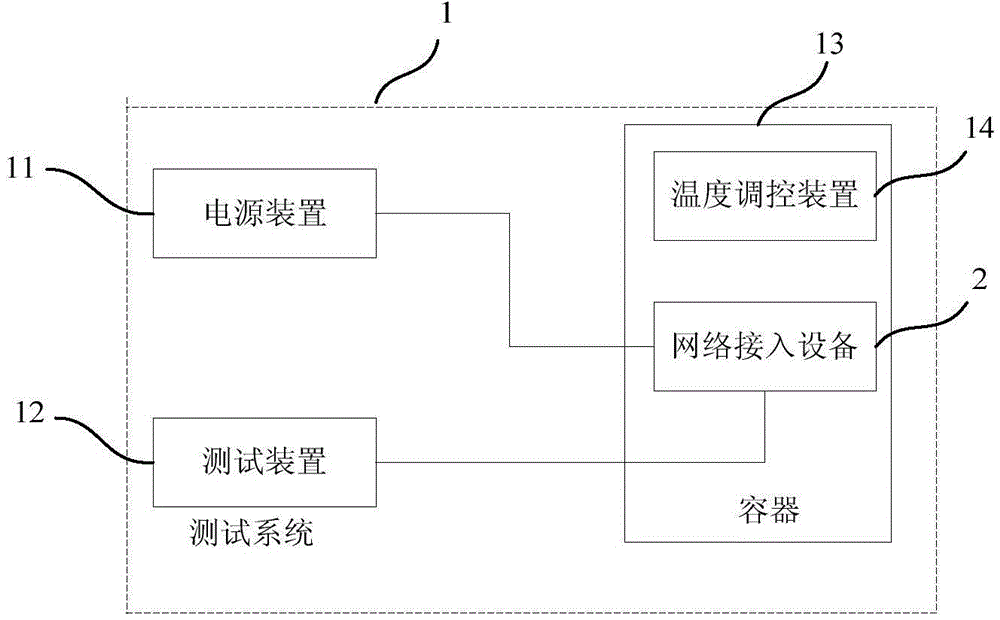

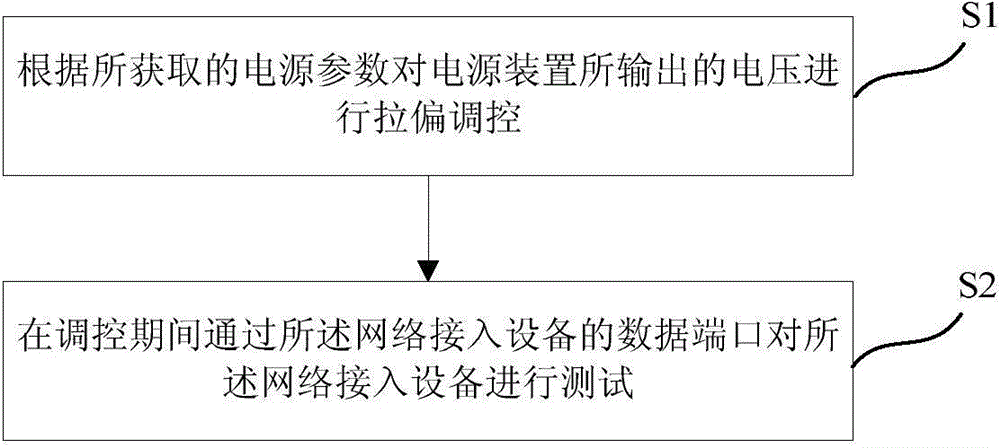

Automatic testing method and automatic testing system for power source drawing deflection

ActiveCN104950265ARealize fully automatic testingEasy to testPower supply testingTest efficiencyEngineering

The invention provides an automatic testing method and an automatic testing system for power source drawing deflection. The testing system comprises a power source device and a testing device. The power source device is connected with a power port of a network access device and is provided with a data interface. The testing device is connected with the data interface of the power source device and a data port of the network access device, and is used for performing drawing deflection regulation on voltages output by the power source device according to acquired power source parameters and testing the network access device through the data port during regulation. The automatic testing method and the automatic testing system have the advantages that the testing device is connected with the data interface of the power source device, so that software can be used for controlling changes of output voltages of the power source device in a drawing deflection area, full-automatic testing of the network access device under the condition of power source drawing deflection can be achieved, and testing efficiency is improved greatly.

Owner:湖州帷幄知识产权运营有限公司

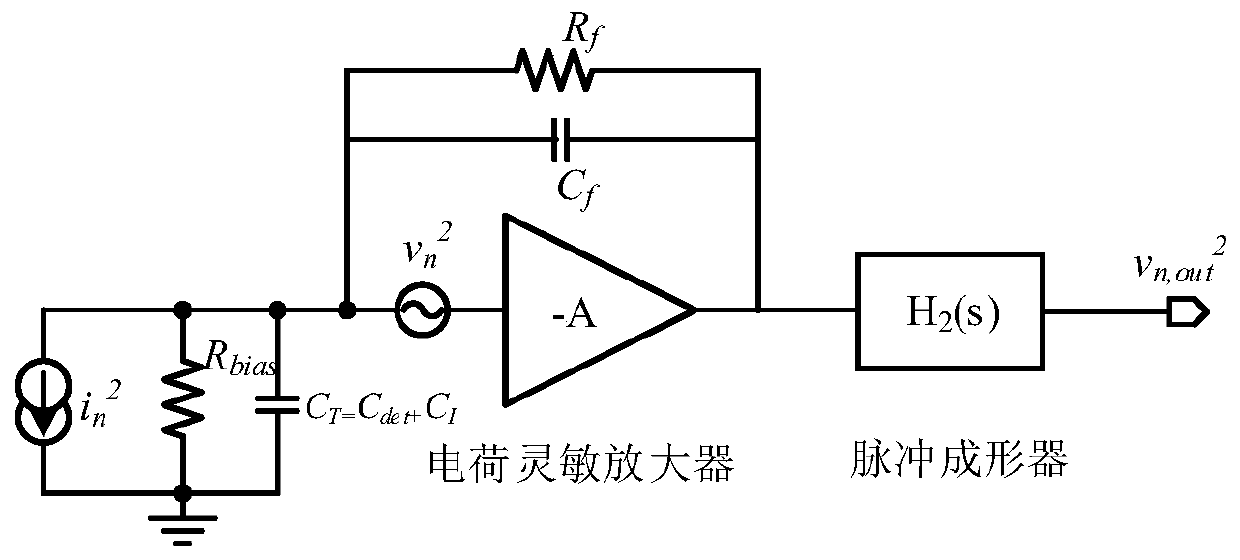

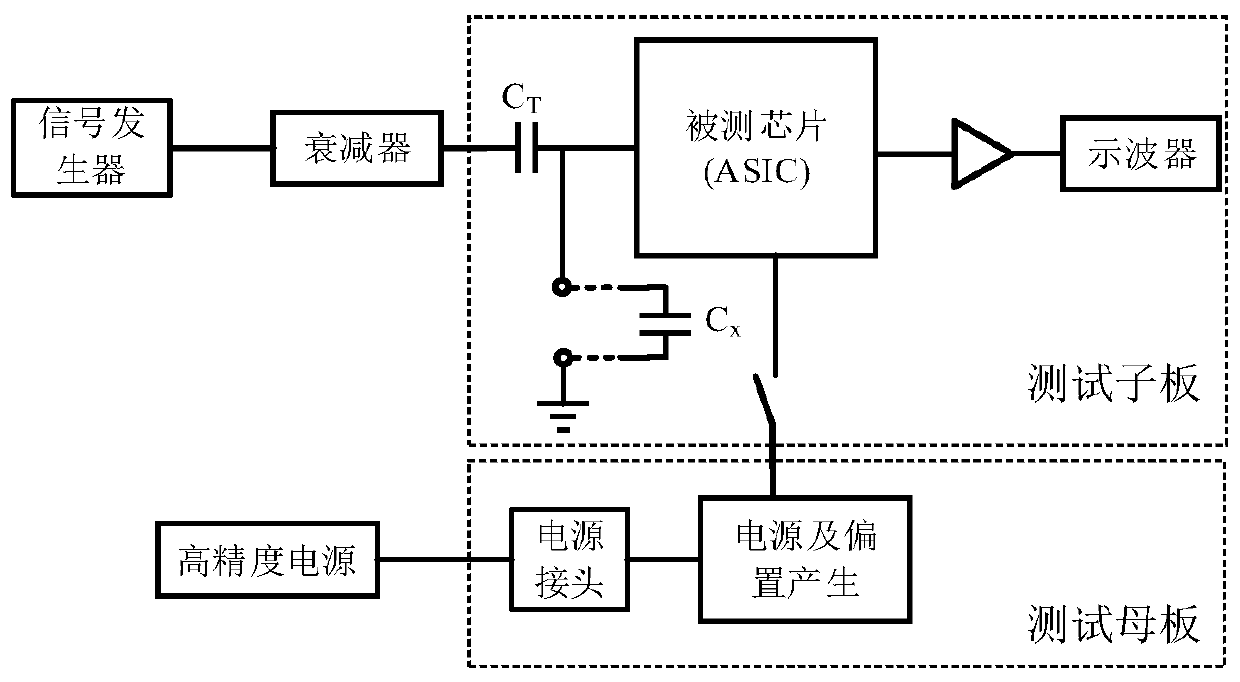

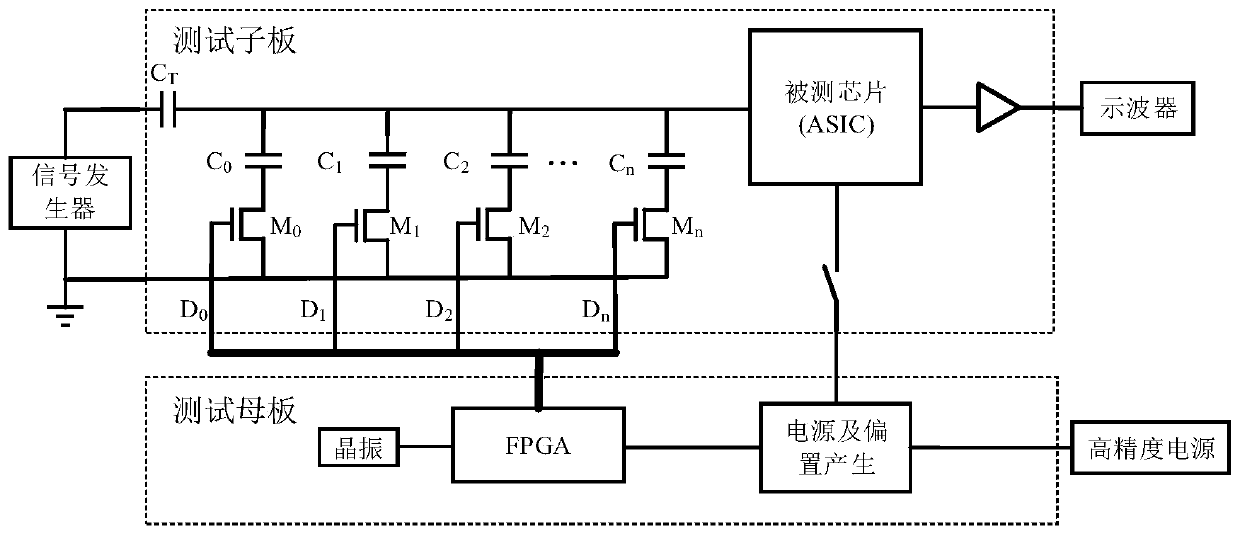

Testing circuit and testing method of equivalent noise charge of front-end readout integrated circuits

InactiveCN110208676ARealize fully automatic testingImprove efficiencyElectronic circuit testingCapacitanceEquivalent noise charge

The invention relates to a testing circuit and a testing method of equivalent noise charge of front-end readout integrated circuits. The testing method comprises the following steps: firstly, placinga front-end readout chip in a measurement system according to a relation between equivalent noise charge and detector capacitance of the front-end readout chip, and completing electrical test preparation; secondly, achieving different detector capacitance values by using the states of an FPGA control switch, measuring equivalent noise charge values under different capacitance values, and calculating equivalent noise slope through linear fitting; thirdly, breaking an input end bound wire and calculating an equivalent noise charge value under the condition of zero input capacitance; and finally,proposing a front-end readout integrated circuit equivalent noise charge formula obtained by testing. The method is capable of achieving full-automatic testing of equivalent noise charge parameters of the front-end readout integrated circuits, is suitable for testing large batches of front-end readout integrated circuits, is high in efficiency and low in cost, and has scientific guiding significance to performance evaluation of the front-end readout integrated circuits.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

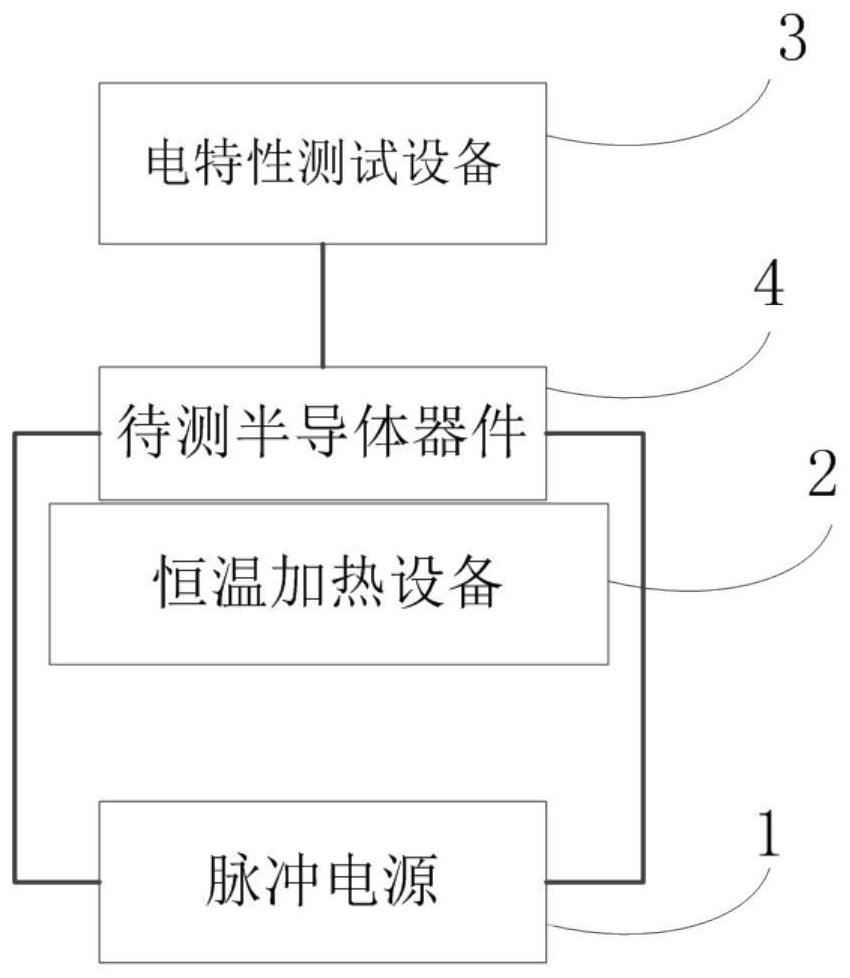

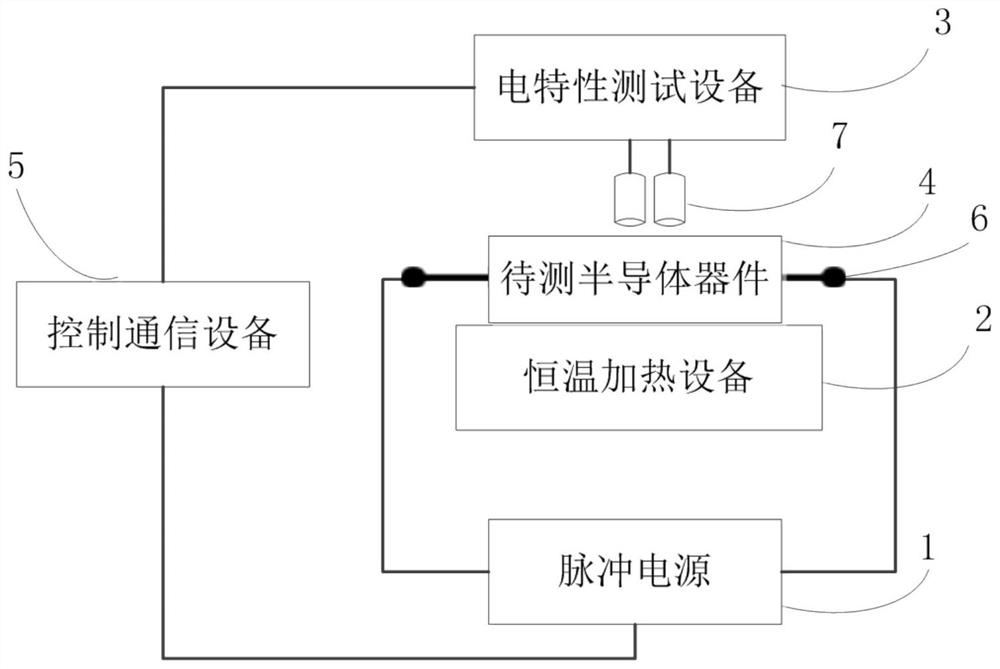

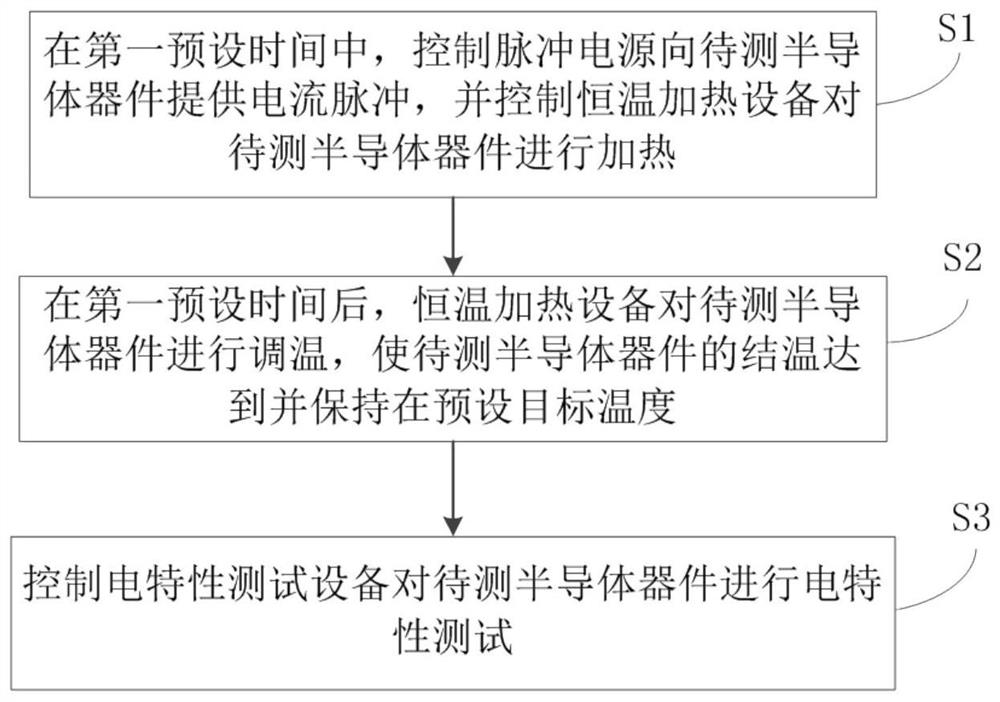

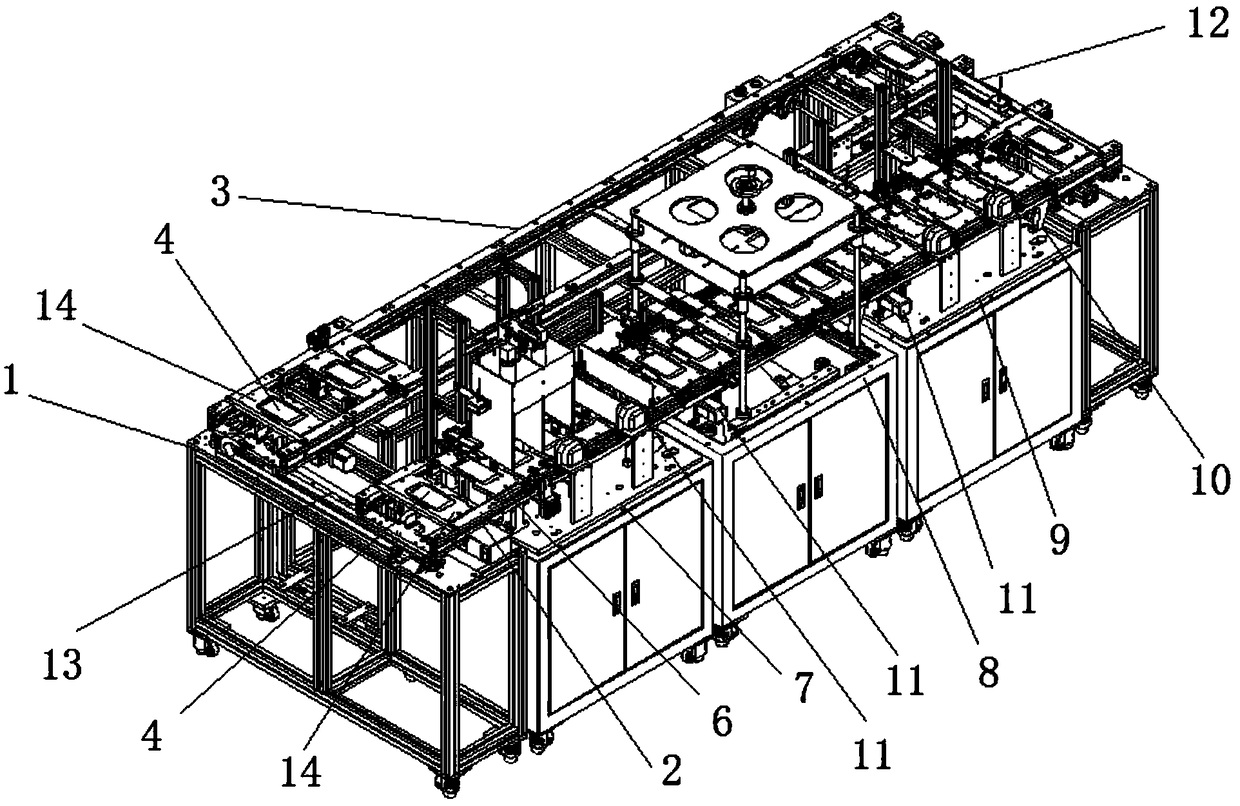

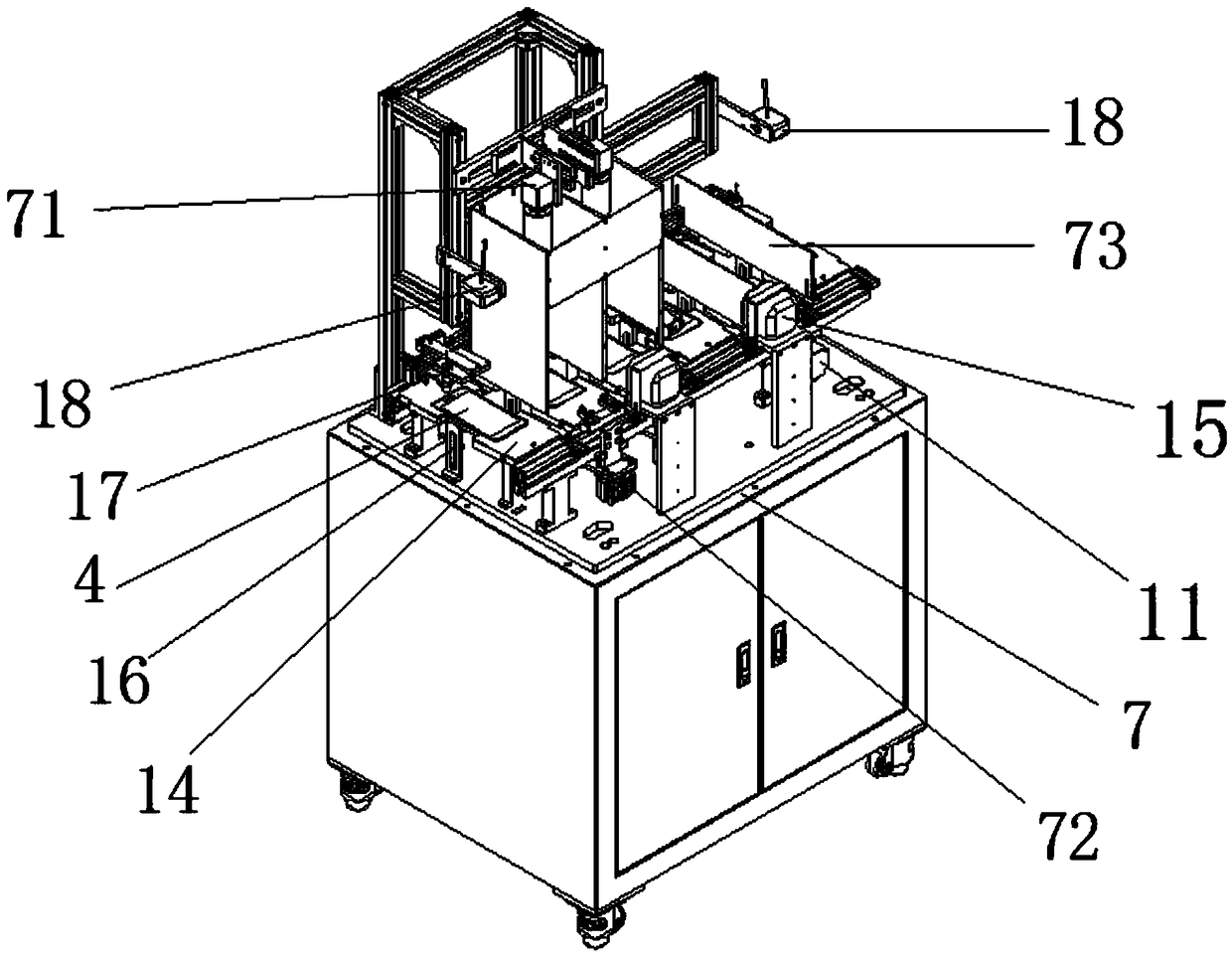

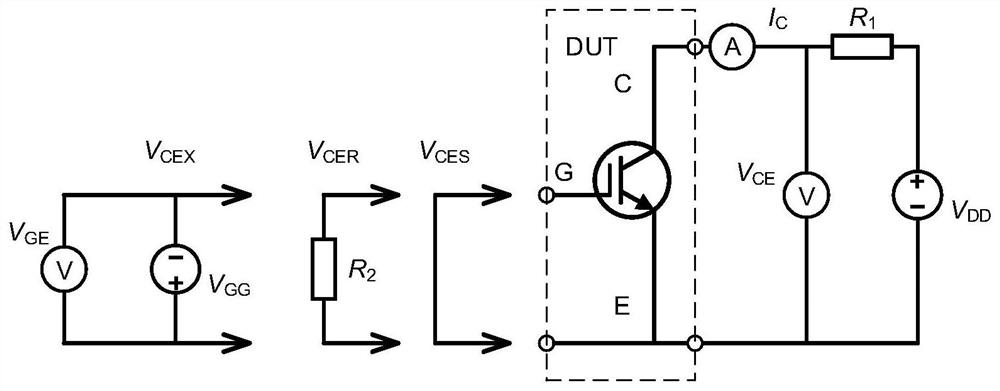

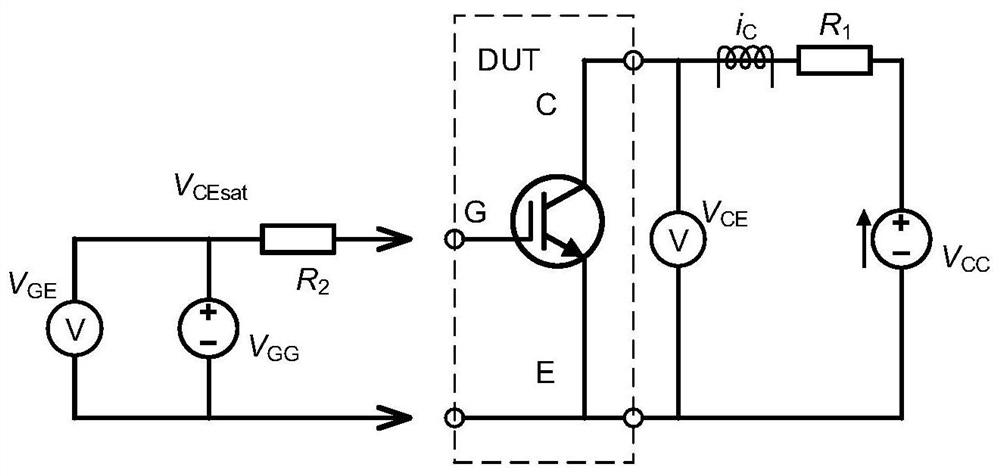

Device and method for testing high-temperature electrical characteristics of semiconductor devices

ActiveCN109212399BFast heatingActual temperature effectIndividual semiconductor device testingThermodynamicsDevice material

The invention discloses a high-temperature electrical characteristic testing device and a method for a semiconductor device. The device comprises a pulse power supply, a constant temperature heating equipment, and an electrical characteristic testing equipment. The method comprises the following steps of during a first preset time, the pulse power supply supplies a current pulse to a device to betested, and the constant temperature heating equipment heats the device to be tested; after the first preset time, the connection between the pulse power source and the device to be tested is disconnected, the constant temperature heating equipment adjusts the temperature of the device to be tested, so that the junction temperature of the device to be tested reaches and maintains the target temperature; the electrical characteristic testing equipment performs a high-temperature electrical characteristic test on the device to be tested. By implementing the high-temperature electrical characteristic testing device and method for semiconductor device, the device to be tested is heated by the combination of its own loss and the constant temperature heating device, the heating rate is fast; theelectrical characteristic testing equipment is not in contact with the device during the temperature rise of the device to avoid being affected by high temperature; the pulse power supply and the electrical characteristic testing equipment are disconnected during the test so as to prevent the two devices from interacting with each other, the testing process is safer and can be quickly and extensively tested in large batches.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD

A fully automatic streamlined mobile phone online testing method and system thereof

ActiveCN105847501BIncrease profitRealize fully automatic testingMeasurement devicesTransmission systemsComputer hardwareStation

The invention discloses a fully automatic streamlined mobile phone online testing method, comprising the following steps: (1) prefabricating an online testing system; (2) implanting APK software in the mobile phone; (3) placing the mobile phone on a test vehicle, Move to the mobile phone information reading station, and transmit the mobile phone identification information to the PC, and the mobile phone moves to the LCM test station; (4) The camera takes pictures of the screen of each color, the PC analyzes the photos, and the mobile phone moves to the Camera test station; (5) Test the near-focus and far-focus functions of the front camera and the rear camera of the mobile phone respectively, the APK software analyzes and calculates the test results from the test information, and the mobile phone moves to the Sensor test station; (7) The mobile phone transmits the test results to the switchboard, and the switchboard judges whether the mobile phone is qualified, and re-tests the unqualified mobile phone . An online testing system is also disclosed.

Owner:广东每通测控科技股份有限公司 +2

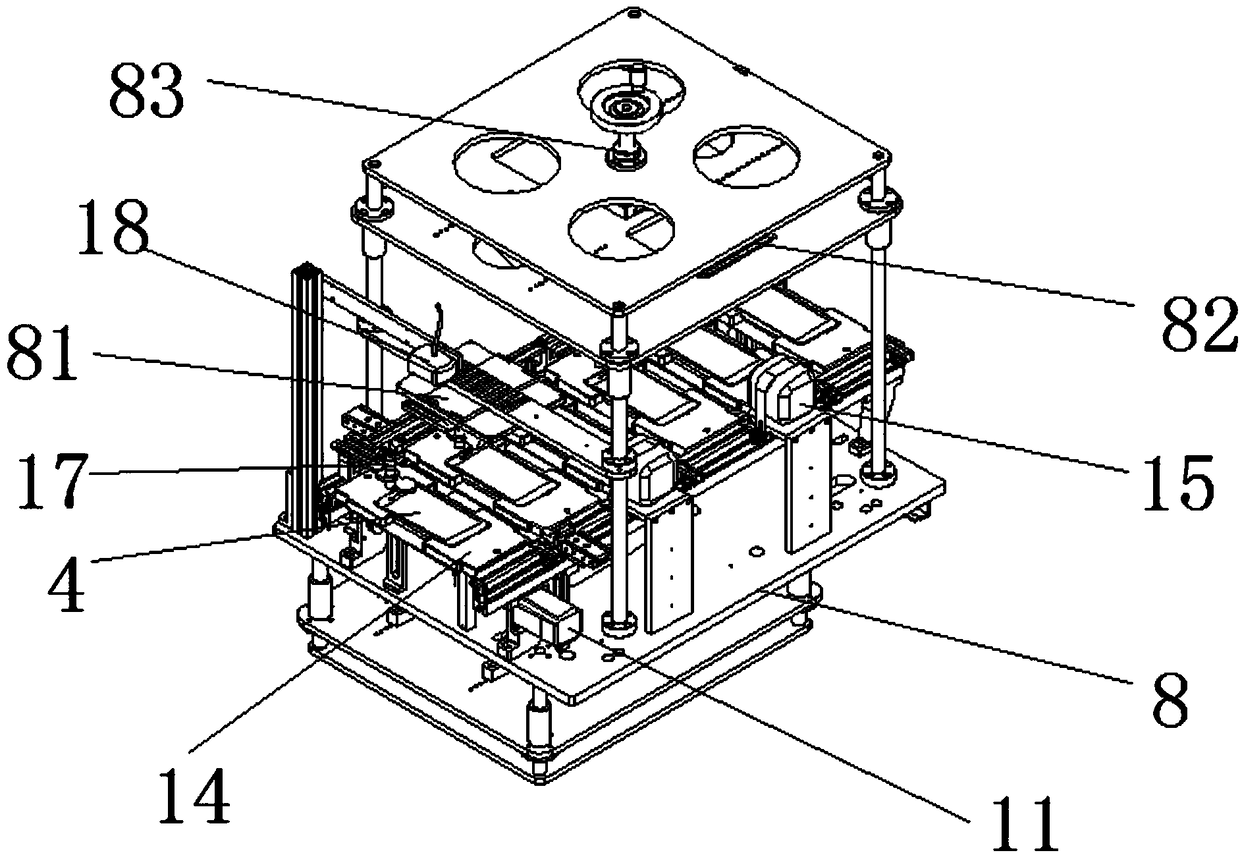

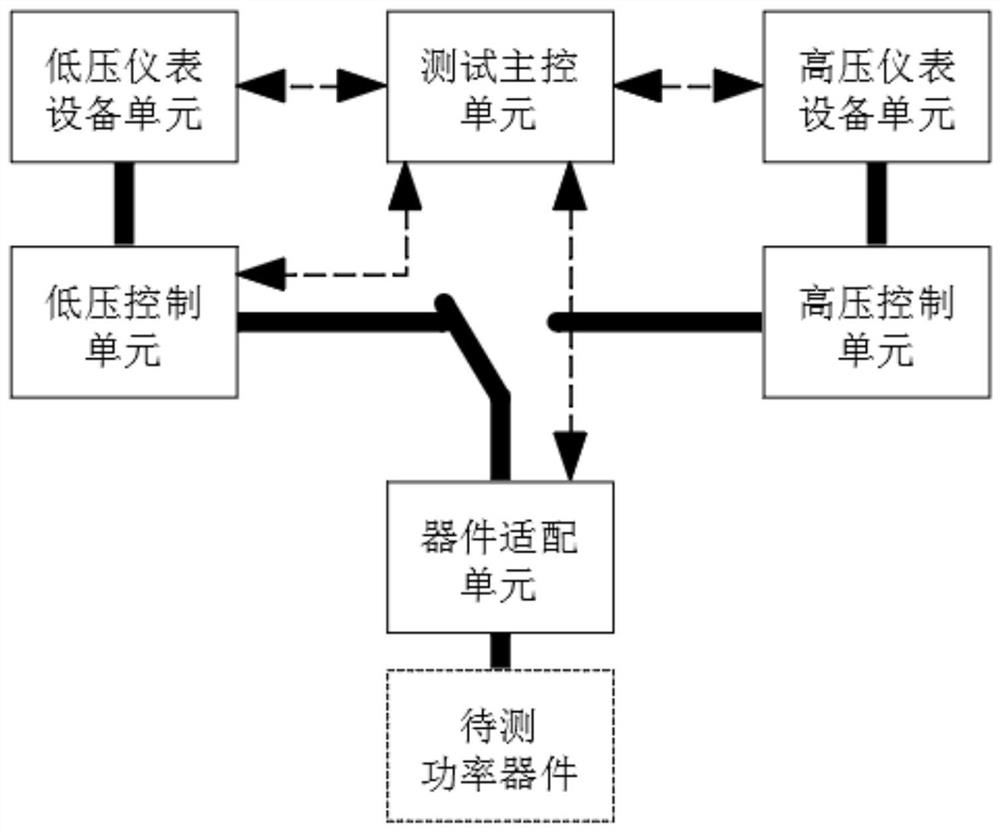

High-low voltage testing equipment for power device

PendingCN112946448AExtended service lifeImprove test accuracyIndividual semiconductor device testingLow voltageVoltage control

The invention belongs to the technical field of power device parameter testing equipment, and particularly relates to high-low voltage testing equipment for a power device. In order to overcome the defects that existing power device testing equipment needs to manually switch connecting wires, is low in testing efficiency and prone to making mistakes, or is large in size, high in cost, short in service life, complex in connection and low in testing accuracy, the invention adopts the following technical scheme that the power device high-low voltage testing equipment comprises: a low-voltage instrument equipment unit; a low-voltage control unit; a high-voltage instrument equipment unit; a high-voltage control unit; a device adaptation unit which comprises a device assembling connector, an adaptation connector, a position controller and a signal processor; and a test main control unit which sends an instruction according to the test requirement. The high-low voltage test equipment for the power device has the beneficial effect that various items can be automatically tested.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Substation Integrated Automatic Test System

ActiveCN104502748BRealize the purpose of comprehensive automatic detectionRealize fully automatic testingElectrical testingData simulationControl layer

The invention provides a comprehensive automatic test system for substations, which relates to the technical field of detection of substation automation systems, including a tester, an interval layer device, a data communication layer device and a station control layer device; The equipment and the station control layer equipment constitute a separate closed-loop test; the tester forms a closed-loop test from the interval layer to the data communication layer with the interval layer equipment and the data communication layer equipment; the tester forms a closed-loop test with the data communication layer equipment and the station control layer equipment A closed-loop test from the data communication layer to the station control layer; the tester, the bay layer equipment, the data communication layer equipment, and the station control layer equipment form a closed-loop test from the bay layer to the station control layer. The substation comprehensive automation test system provided by the present invention integrates multiple functions such as a protocol analyzer, a data collector, a data simulator, a measurement and control device tester, and a GPS timing instrument; it tests various electric power automation measurement and control equipment, RTU, protection device, synchronous device, one machine with multiple functions.

Owner:STATE GRID CORP OF CHINA +1

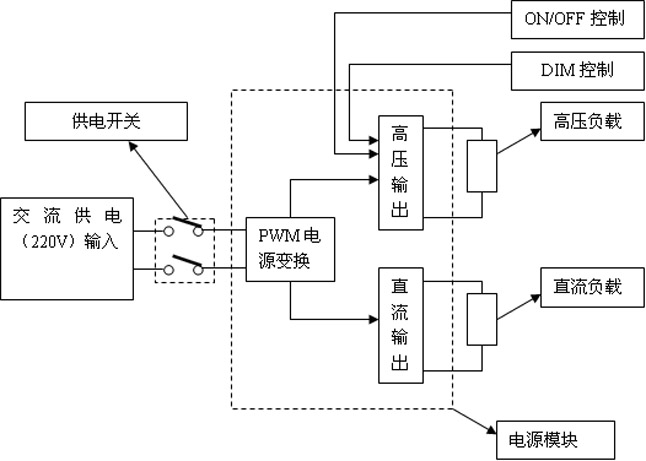

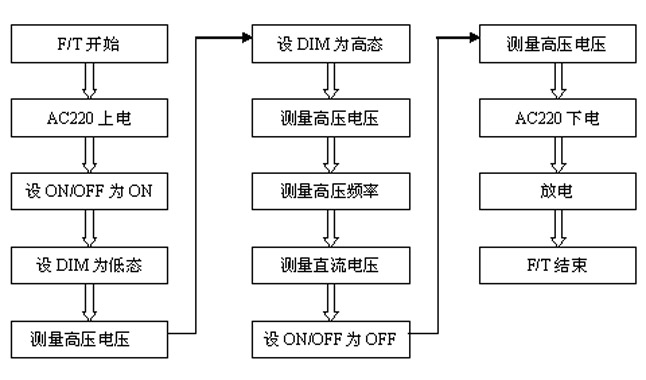

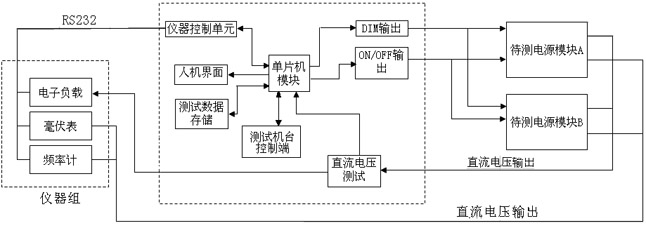

System for automatically testing display and television power modules

InactiveCN102043134ARealize fully automatic testingWithout human interventionPower supply testingTest powerMicrocontroller

The invention relates to a system for automatically testing display and television power modules. The system comprises a testing bench and a tested power module, and is characterized in that: the testing bench comprises a probe for supplying power to the tested power module, a DIM control output probe, an ON / OFF control output probe, a first probe for detecting a direct current output end of the tested power module, and a second probe for detecting an alternating current output end of the tested power module, wherein an input end of the probe for supplying power to the tested power module is connected with 220V alternating current; input ends of the DIM control output probe and the ON / OFF control output probe are connected with a singlechip respectively; and an output control end of the singlechip is connected with a control end of the testing bench. The system can automatically test the power modules, the working efficiency is improved, the action of plugging / unplugging wires is removed, and the testing time, the number of testing instrument and manual labor are reduced.

Owner:TPV ELECTRONICS (FUJIAN) CO LTD

An automatic test device for the whole machine function

ActiveCN109085003BQuick switchShorten the time periodMachine part testingElectrical testingComputer hardwareKey pressing

The invention provides an automatic testing device for a complete machine function, comprising a control module, an image recognition module, a communication module, a key testing station, a screen testing station, a printing test station, a card swiping test station, a tray for fixing a POS machine to be tested, an machine placement area and an machine testing area. A plurality of telescopic keyboard point pressing rods are arranged at the key testing station; a first camera used for shooting a POS machine screen is arranged at the screen testing station; a second camera used for shooting thePOS machine printing bill is arranged at the printing test station; the first camera and the second camera are connected with the image recognition module; the pressing point of keyboard point pressing rods is close to the keyboard of the POS machine after the POS machine is fed into the machine testing area; The first camera faces the POS machine screen; the second camera faces the printout endof the POS machine; the card swiping test station is close to the side edge of the POS machine; The control module is connected with the POS machine through the communication module to obtain the working data of the POS machine. According to the automatic testing device for complete machine function, full-automatic integrated testing can be performed on the POS machine.

Owner:FUJIAN NEWLAND PAYMENT TECH

An automatic test method for power equipment io plug-in suitable for assembly line production

ActiveCN109116133BRealize fully automatic testingMeet flexible production needsElectrical testingDatabase machineElectric power equipment

Owner:NARI TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com