Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Realize direct connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

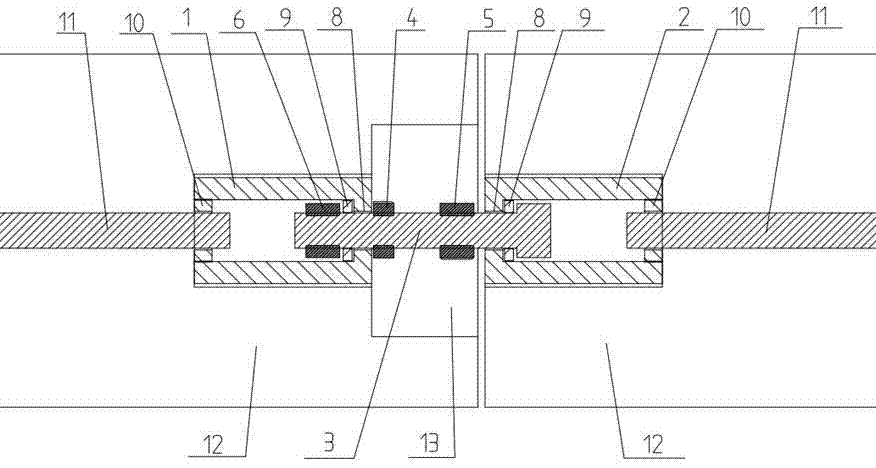

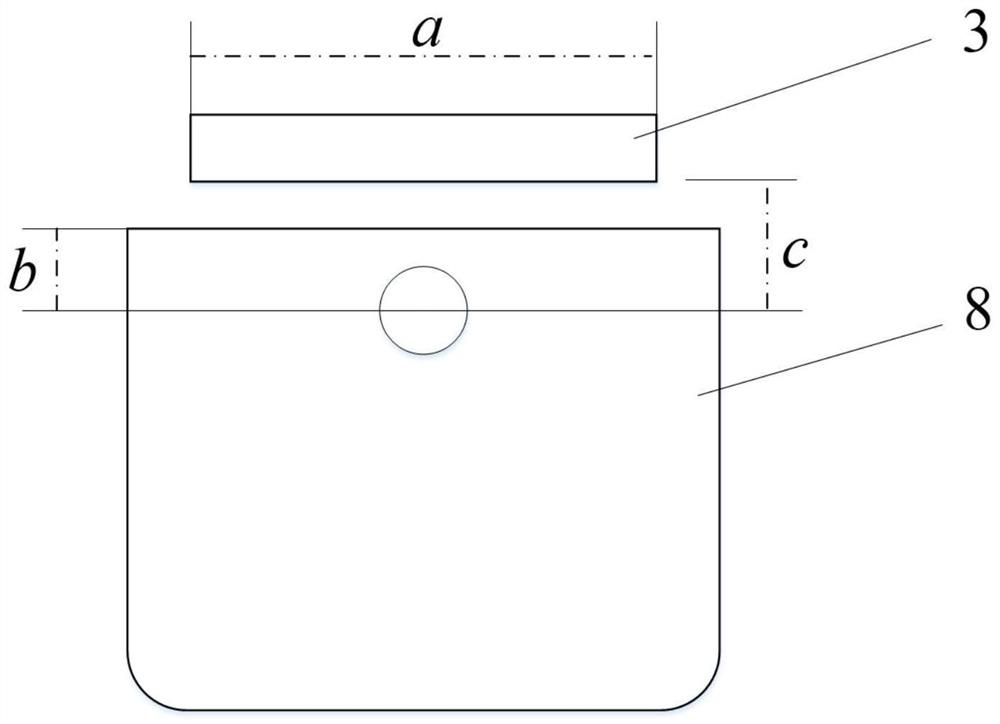

Assembled building connector

InactiveCN107419809AHigh strengthReduced strength impact and damageBuilding constructionsAerospace engineeringEngineering

Owner:SHANDONG YUANBO BUILDING TECH CO LTD

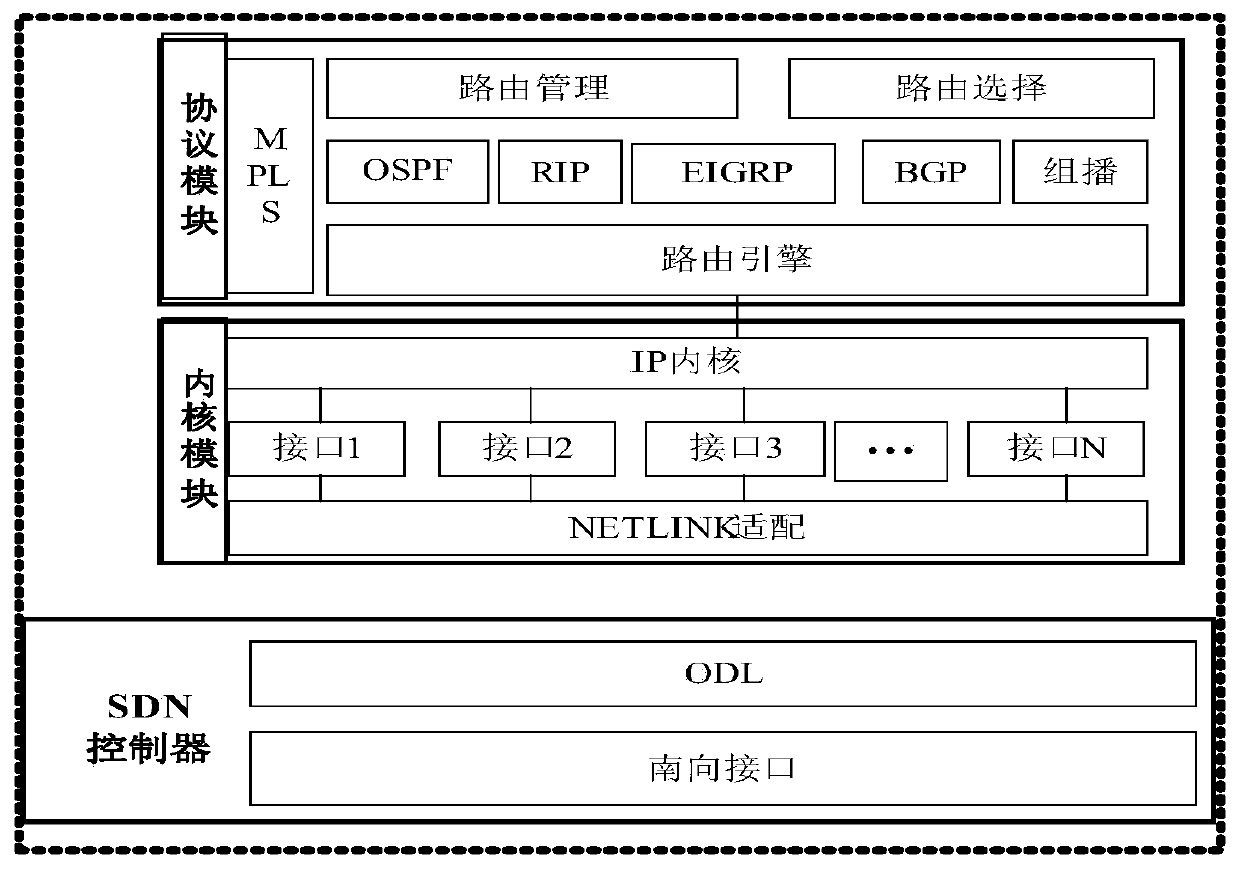

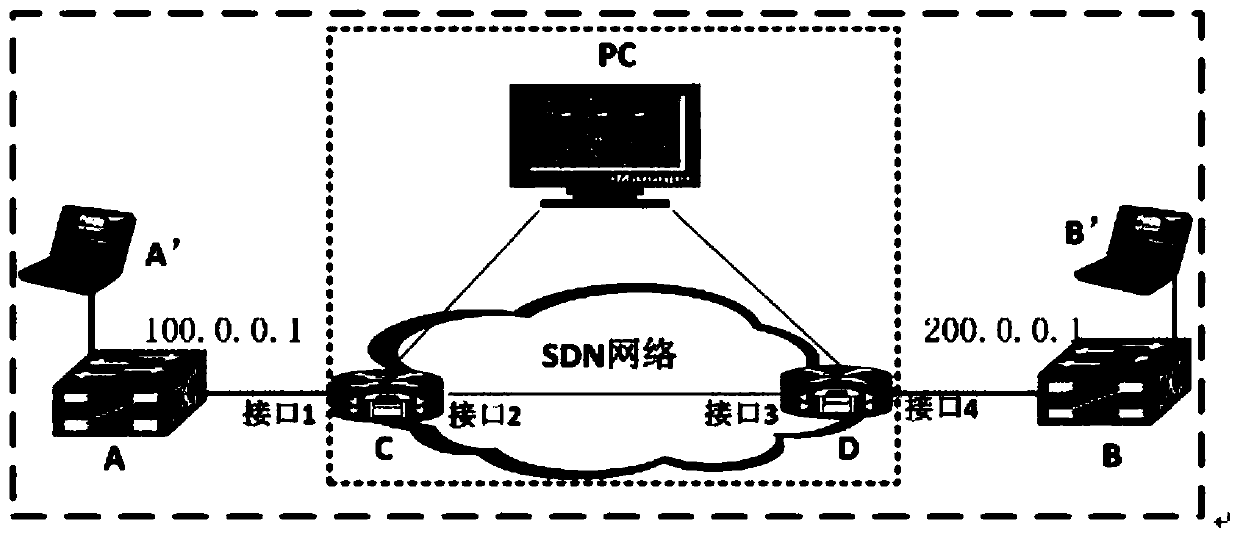

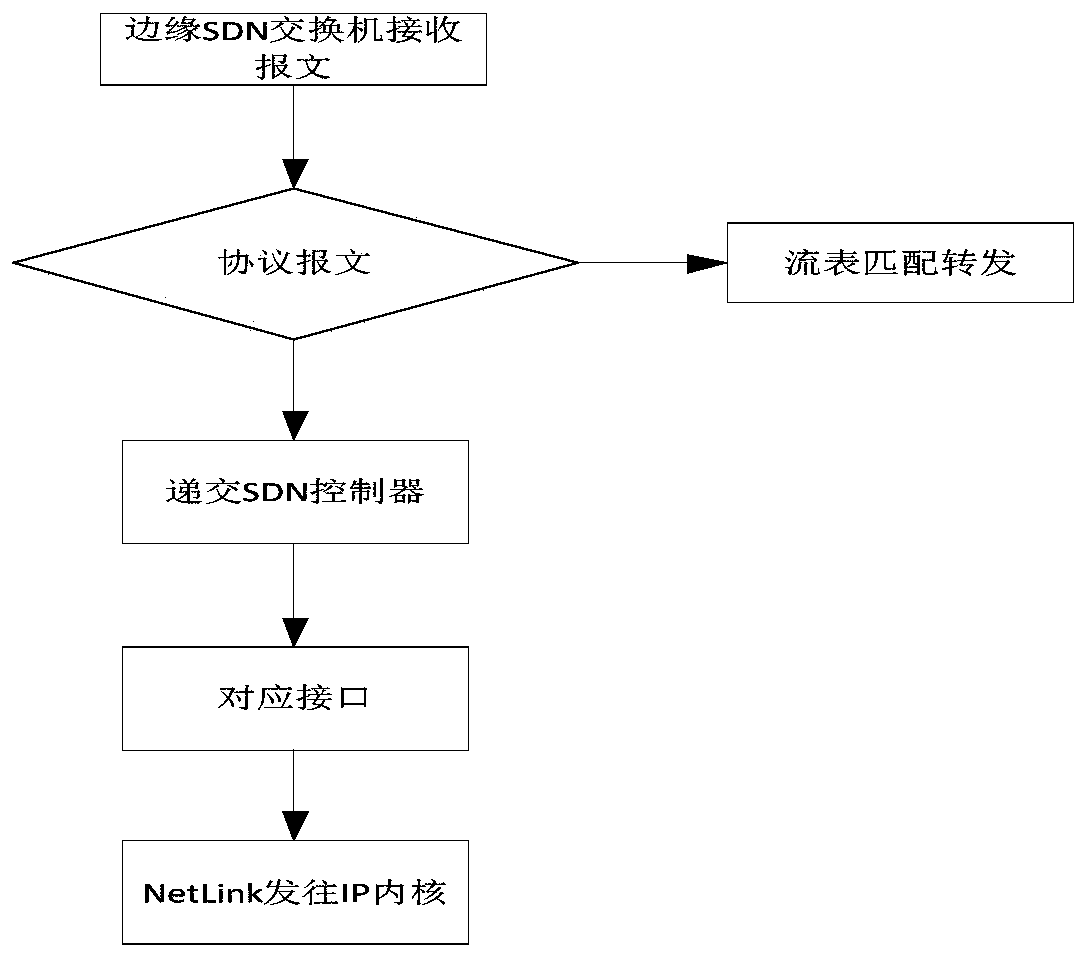

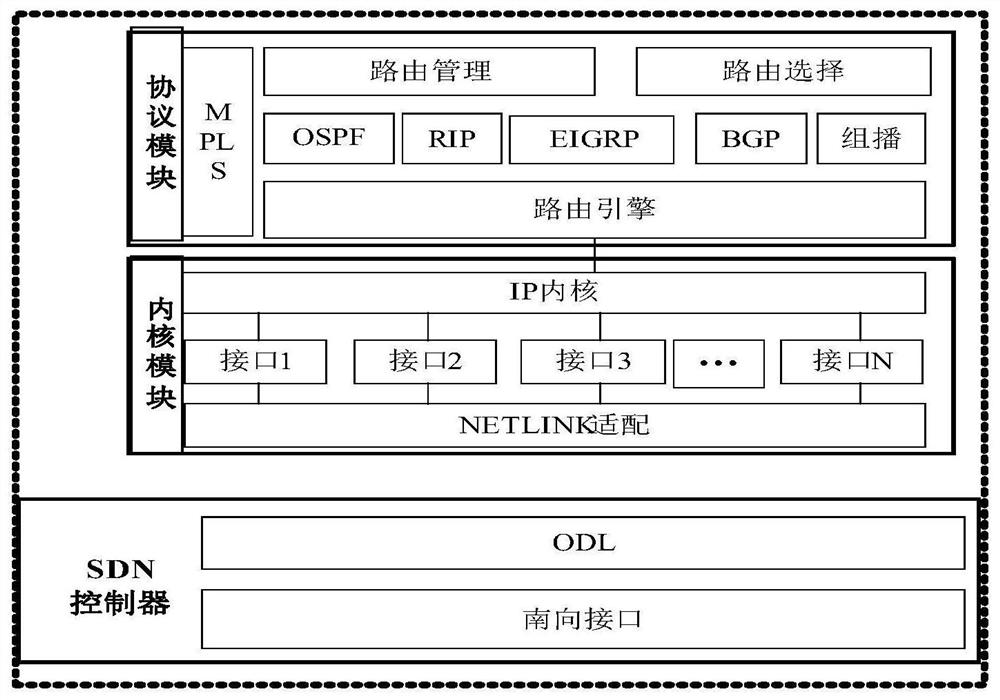

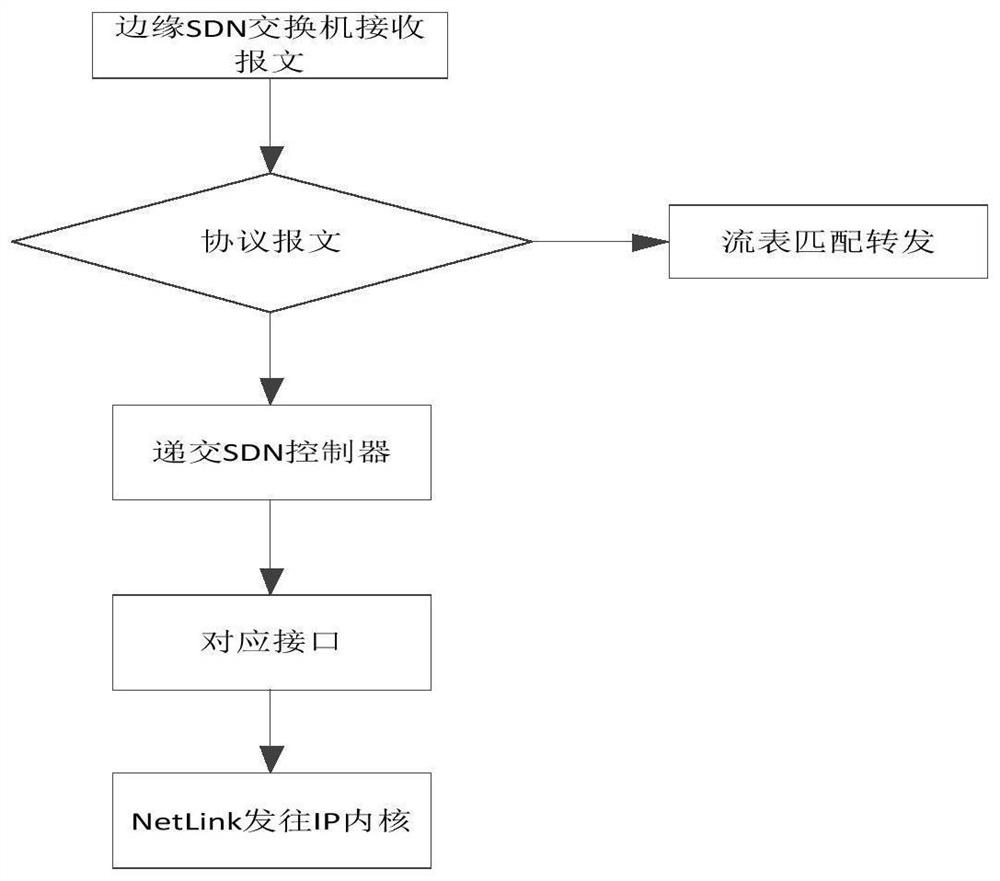

Virtual router and method for realizing interconnection between SDN network and traditional IP network

ActiveCN110430114ARealize direct connectionRealize seamless interoperabilityNetworks interconnectionRouting tableInterconnection

The invention discloses a virtual router. The virtual router is characterized by comprising an SDN controller, a kernel module and a protocol module. The SDN controller is used for providing a standard northbound interface, carrying out OF protocol encapsulation on a flow table configuration instruction of an application and message data of the protocol module through the SDN controller module, and forwarding the flow table configuration instruction of the application and the message data of the protocol module to the corresponding interface for processing. A standard southbound interface is provided downwards. According to the kernel module, a shielding bottom layer provides a standard IP layer and an interface for operation of an upper-layer protocol. The communication adaptation betweenthe IP core message and the SDN controller is completed. The protocol module is used for processing a traditional standard router protocol to form a corresponding routing table and a forwarding tableand informing the SDN controller through the routing engine module. The SDN controller generates a flow table entry according to the routing table and the forwarding table and issues the flow table entry. According to the invention, the interconnection communication between the SDN network and the traditional network can be realized.

Owner:CHINA ELECTRONICS TECH GRP NO 7 RES INST

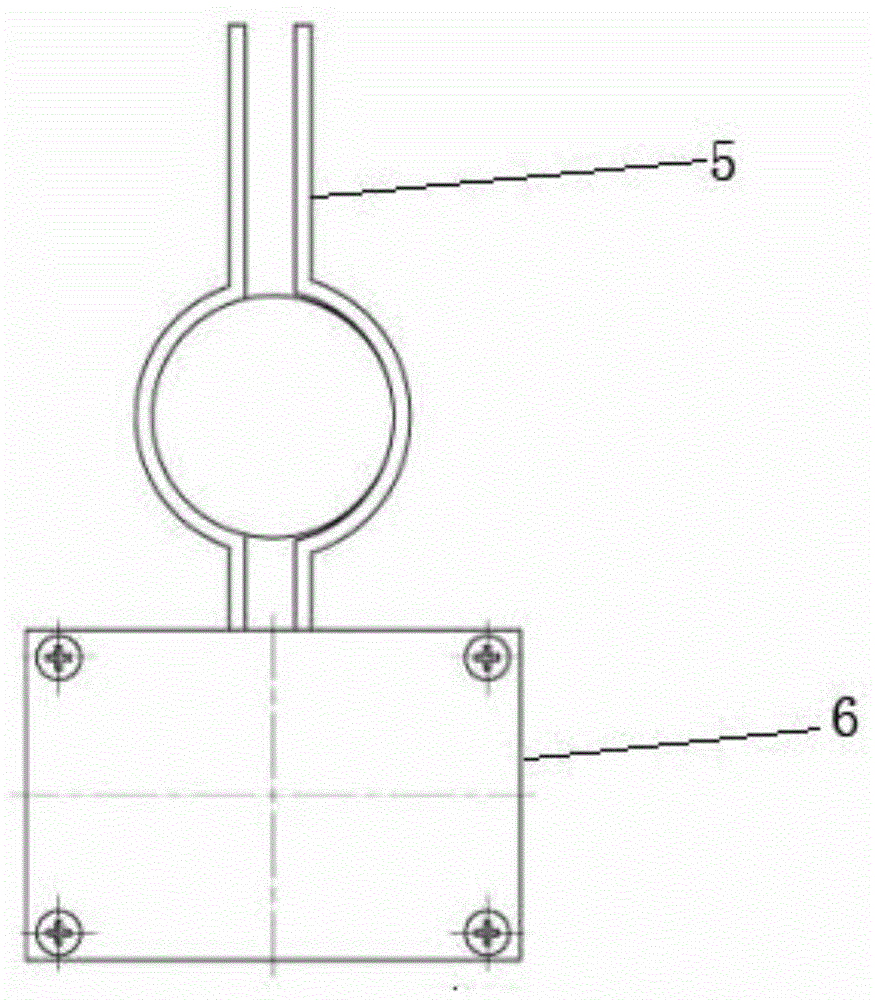

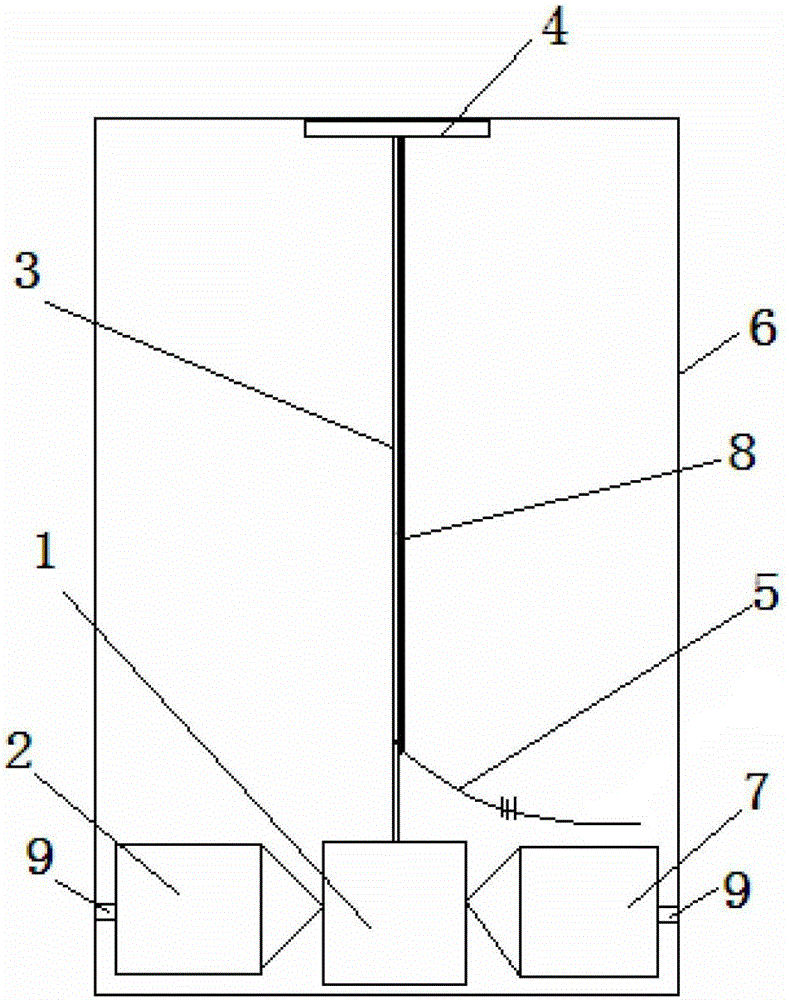

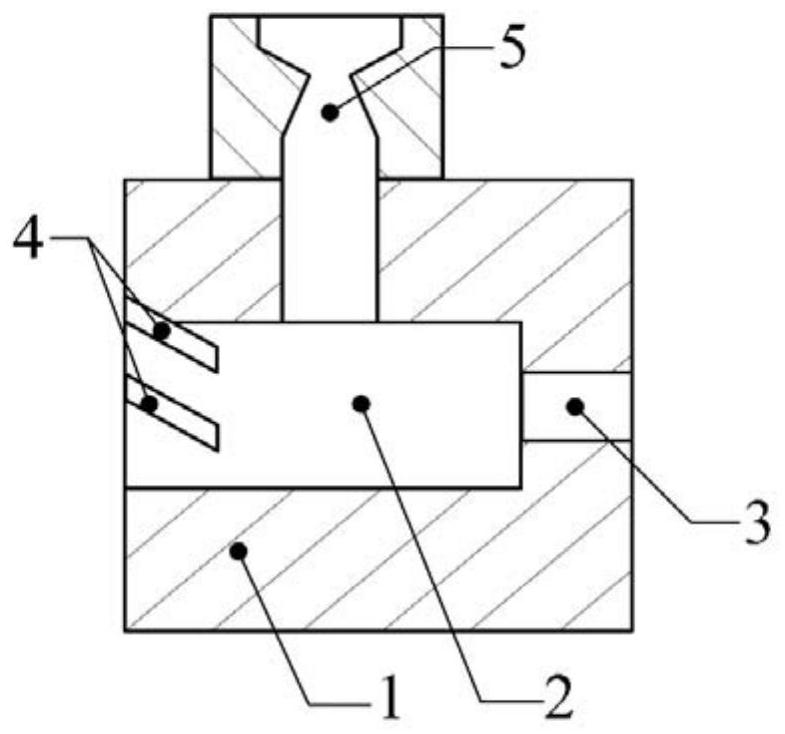

Optical fiber angle transducer for measuring windage yaw angle of insulator

The invention relates to the field of sensors, in particular to an optical fiber angle transducer for measuring a windage yaw angle of an insulator. The optical fiber angle transducer comprises a housing (6), pendulum bobs (1), swinging arms (2), optical fiber rasters (3) and a substrate (4 ), wherein the substrate (4) is fixed in the top of the housing (6); the upper ends of the swinging arms (2) are connected to the substrate (4 ), and the lower ends are connected to the pendulum bobs (1); the optical fiber rasters (3) are integrally fixed on the swinging arms (2); hold hoops (5) are fixed on the side wall of the housing (6), and fittings clamped at the low voltage end of the insulator, of the hold hoops (5) enable the optical fiber rasters (3) inside the hold hoops (5) to be vertical downwardly. The optical fiber angle transducer provided by the invention is free from electromagnetic interference, does not need power supply, is high in measuring accuracy and resolution, is high in respond speed, and can be used in the harsh environment with high temperature, high humidity, chemical erosion and the like.

Owner:STATE GRID CORP OF CHINA +1

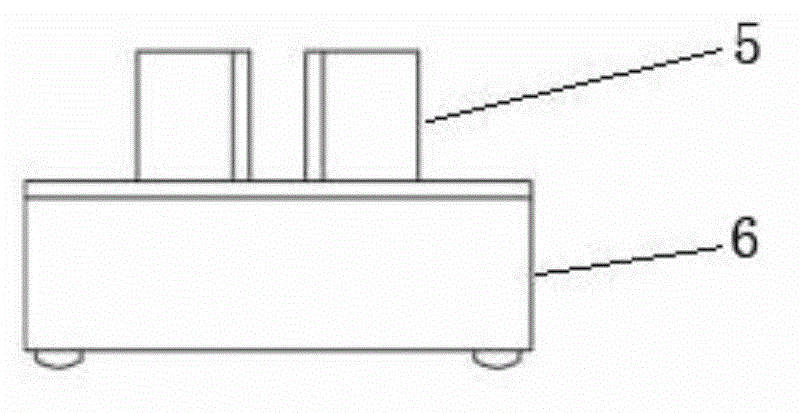

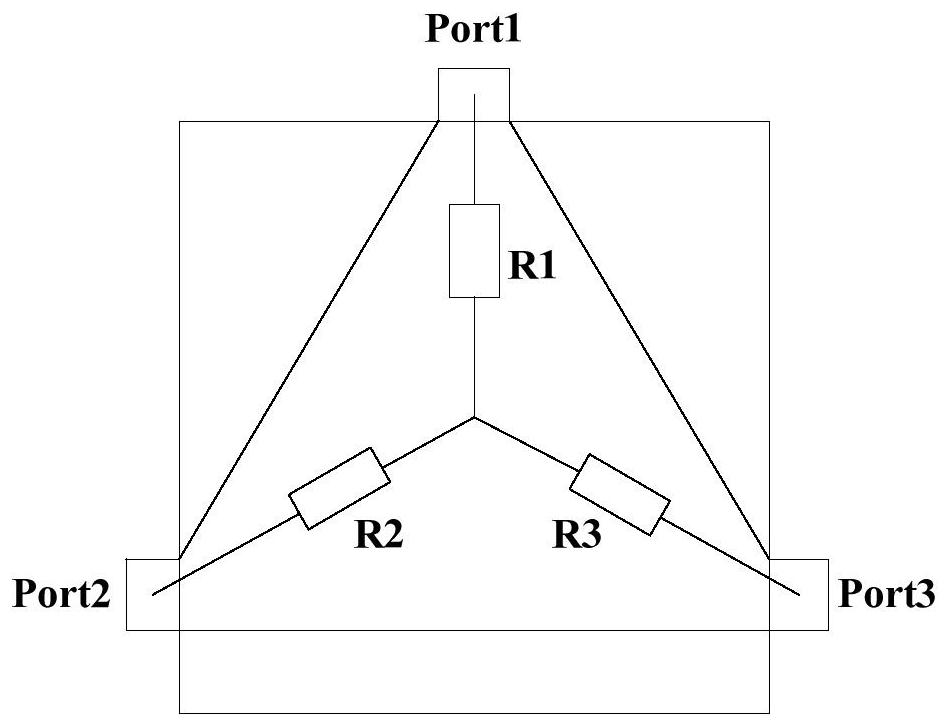

High-speed digital oscilloscope bandwidth calibration test device and test method

ActiveCN111856374ARealize direct connectionImprove accuracyElectrical measurementsPower sensorEngineering

The invention discloses a high-speed digital oscilloscope bandwidth calibration test device and test method, and belongs to the field of oscilloscope bandwidth calibration. The testing device comprises a resistor R1, a resistor R2, a resistor R3 and three testing ports; one end of the resistor R1 is connected with a signal input end port 1, the other end of the resistor R1 is connected with one end of the resistor R2 and one end of the resistor R3, the other end of the resistor R2 is connected with a signal output end port 2, and the other end of the resistor R3 is connected with a signal output end port 3; and the signal input end port 1 is used for being connected with an output port of an analog signal source, the signal output end port 2 is used for being connected with an input port of a power sensor, and the signal output end port 3 is used for being connected with a high-speed digital oscilloscope. According to the test method, only the signal frequency of the analog signal source needs to be adjusted, the output power level of the analog signal source does not need to be adjusted, the power compensation error is reduced, and the accuracy of the bandwidth calibration test isimproved.

Owner:XIAN MICROELECTRONICS TECH INST

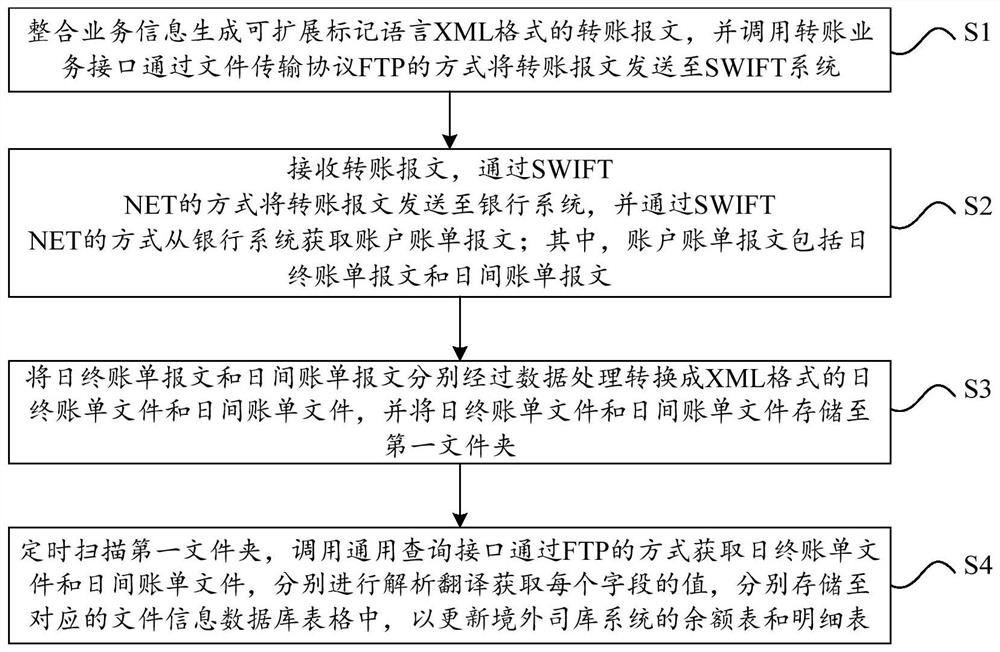

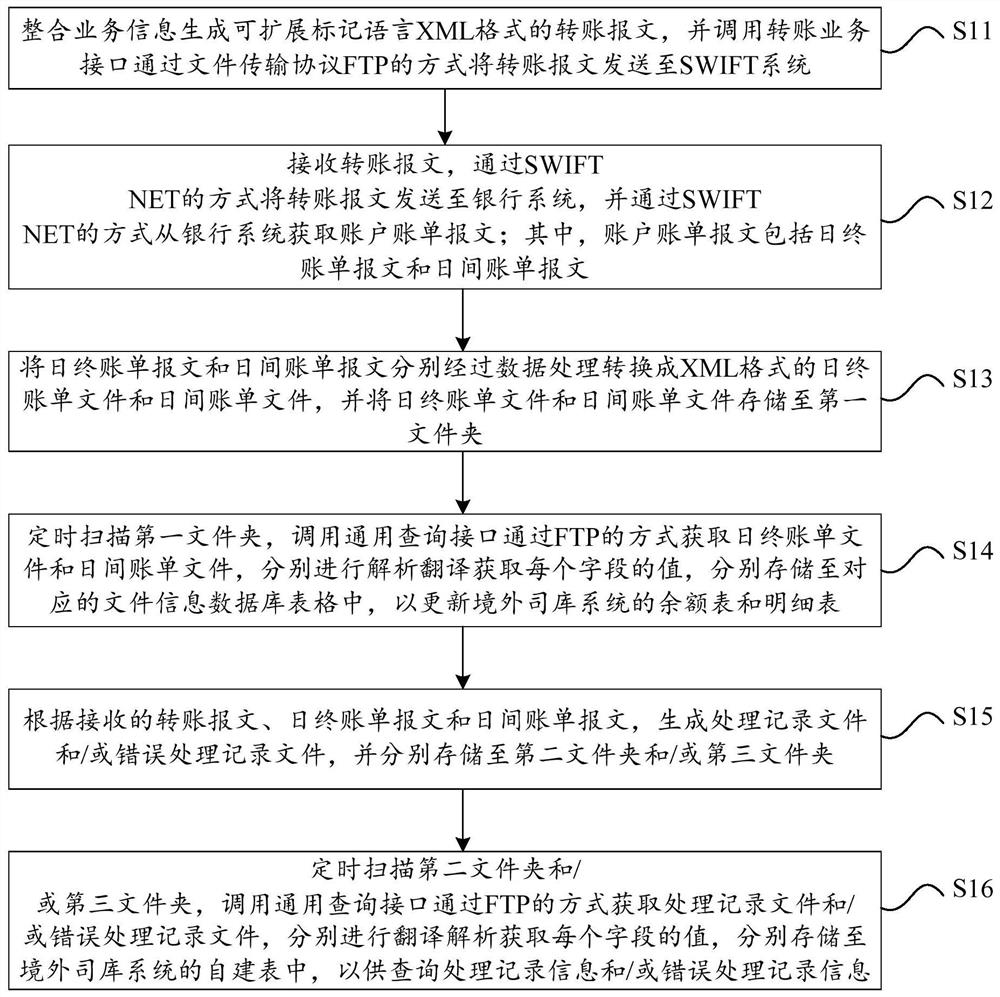

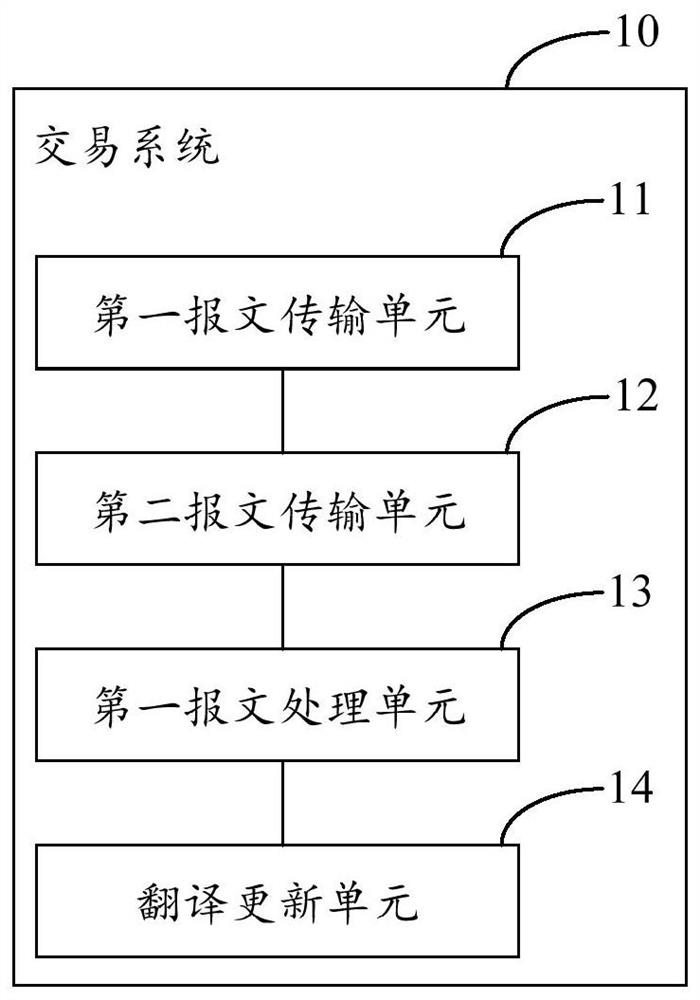

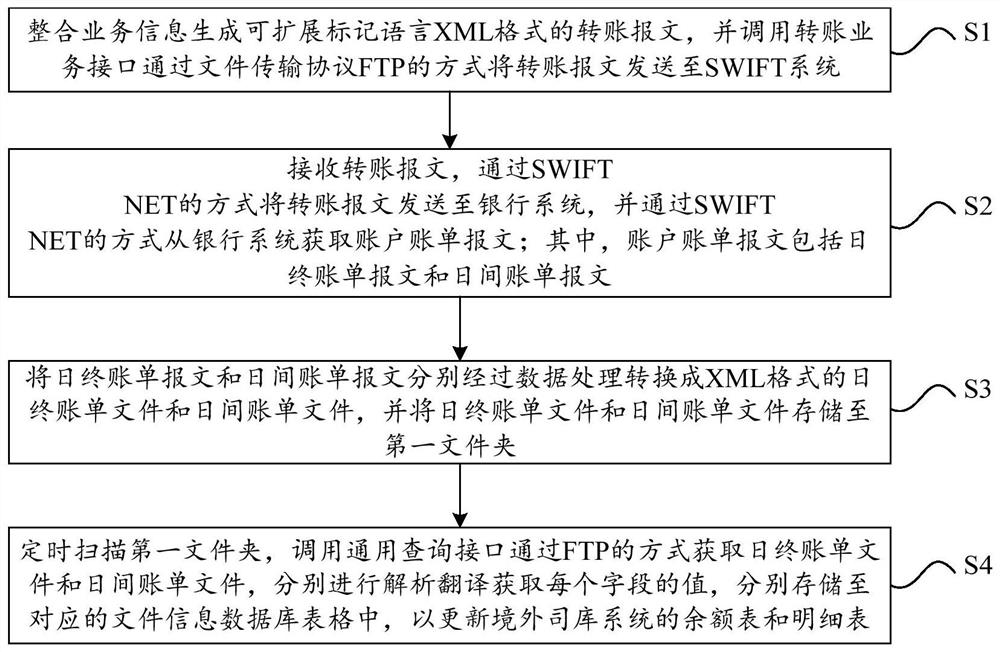

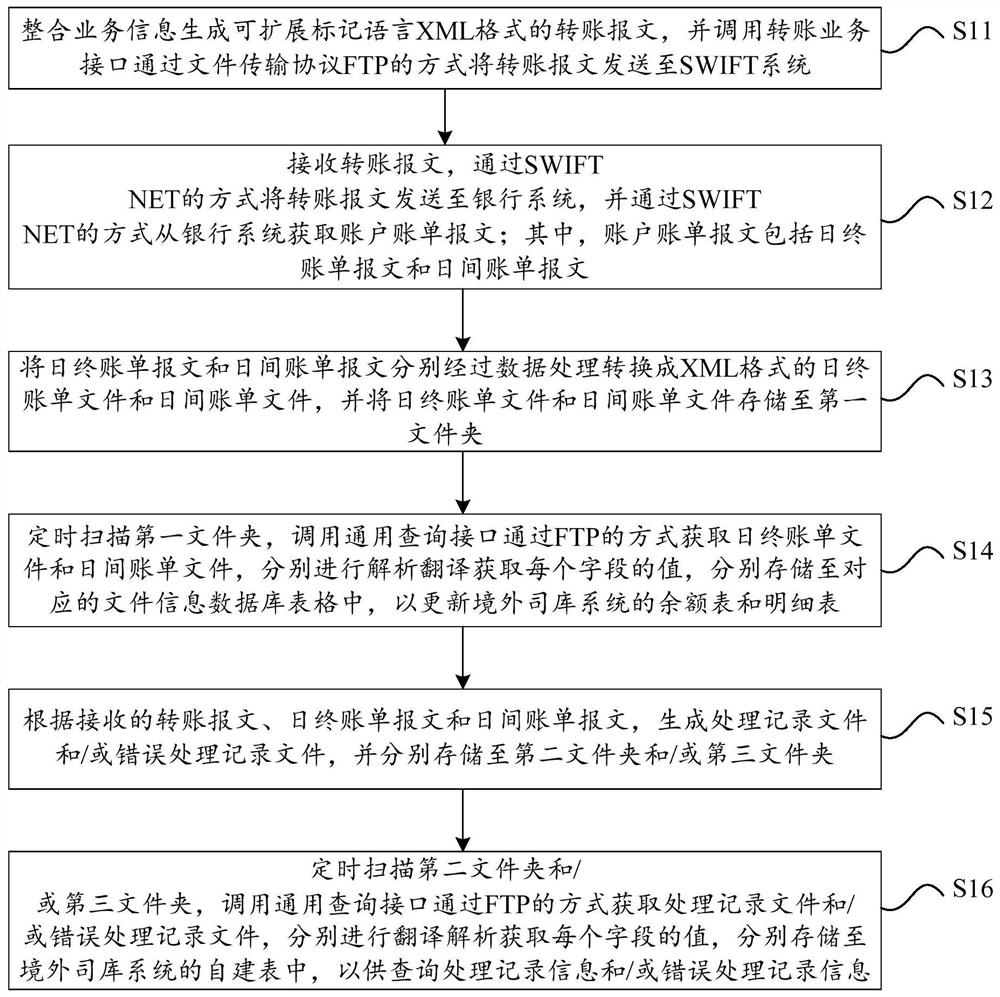

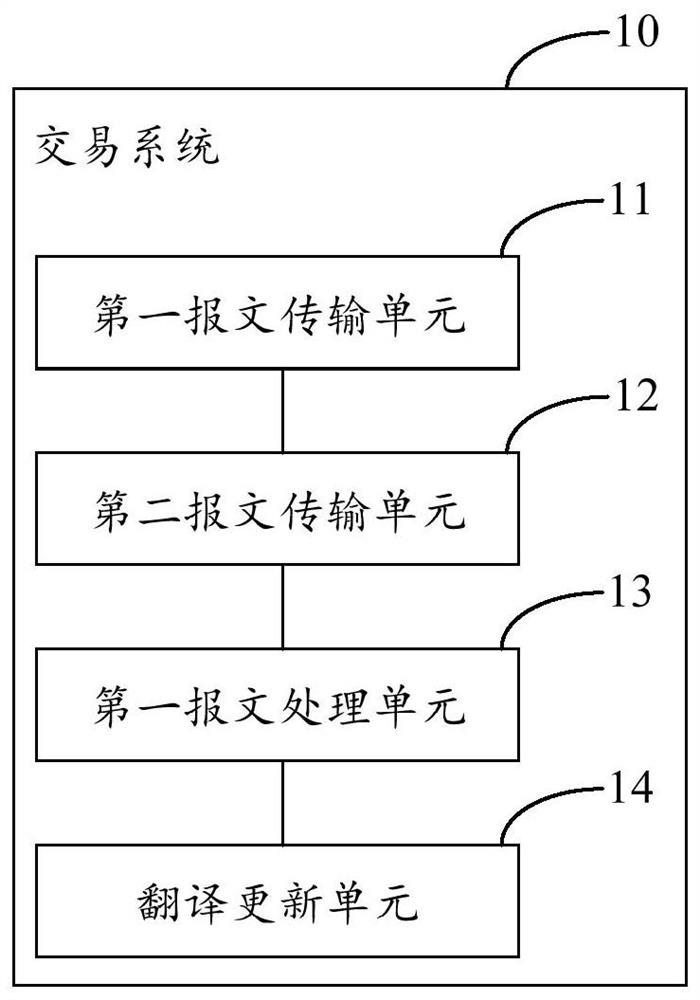

Transaction method and system based on SWIFT system, computer equipment and storage medium

ActiveCN113673978ARealize direct connectionEasy to useDatabase updatingFinanceBusiness enterpriseSoftware engineering

The invention provides a transaction method and system based on a SWIFT system, computer equipment and a storage medium, and the method comprises the steps: generating a transfer message in an extensible markup language (XML) format through integrating business information, and obtaining an account bill message from a bank system through a SWIFT NET mode; respectively converting the day-end bill message and the day-time bill message into a day-end bill file and a day-time bill file in an XML format through data processing, and storing the day-end bill file and the day-time bill file in a first folder; regularly scanning the first folder, obtaining the day-end bill file and the day-to-day bill file, respectively analyzing and translating to obtain a value of each field, storing the value into a corresponding file information database table, and updating a balance table and a detail table of the overseas judicial library system. Therefore, data interaction between the overseas judicial library system and the bank system of the enterprise user can be realized through the SWIFT system, the enterprise user can directly carry out business data processing on the corresponding account in the bank system in the overseas judicial library system, the use of the enterprise user is facilitated, and bank-enterprise direct connection is realized.

Owner:国家电投香港财资管理有限公司

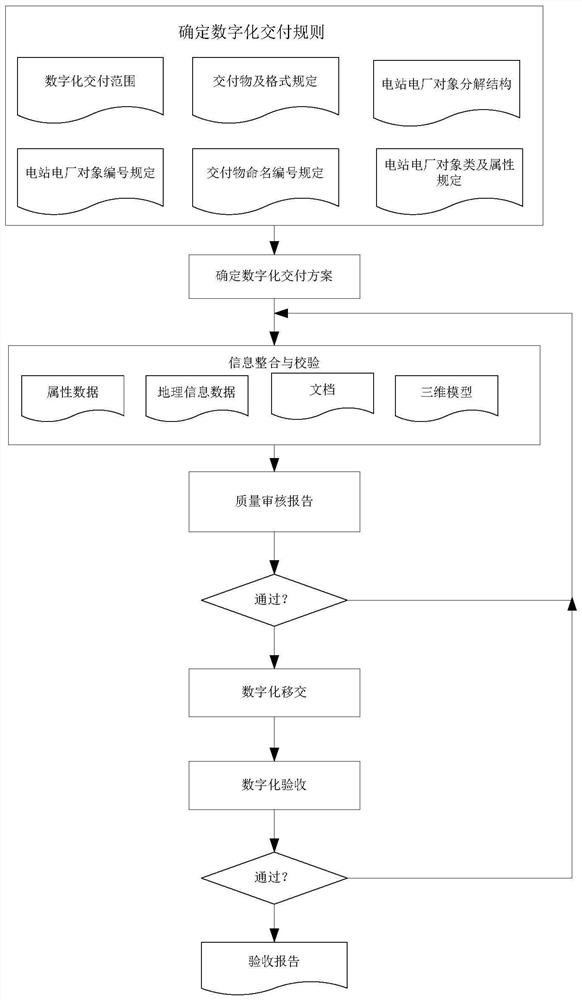

Digital power station delivery method based on BIM and GIS, medium and equipment

InactiveCN112685820AOvercoming inefficienciesOvercoming low accuracyGeometric CADData processing applicationsPower stationDigitization

The invention discloses a digital power station delivery method based on BIM and GIS, a medium and equipment. The method comprises the following steps: determining a digital delivery rule; determining a digital deliverable delivery requirement; determining a digital delivery scheme to establish a BIM, a GIS model or a BIMGIS model of a digital deliverable in the power station; digital delivery information association: determining that a digital deliverable in the power station needs to deliver associated information and associates the associated information to the deliverable; taking the BIM, the GIS model or the BIMGIS model of the deliverable associated with the completed information and the information associated with the deliverable as delivery objects for delivery; and after the delivery is completed, checking the detailed information of the deliverable through the local window. According to the method, paperless digital interaction can be achieved, the technical problems that traditional delivery is low in efficiency and accuracy are solved, a source is provided for digitization of a power station through three-dimensional design, source-to-end direct connection of information is achieved, and it is fundamentally ensured that the information is correct.

Owner:QINGYUAN PUMPED STORAGE POWER GENERATION CO LTD +1

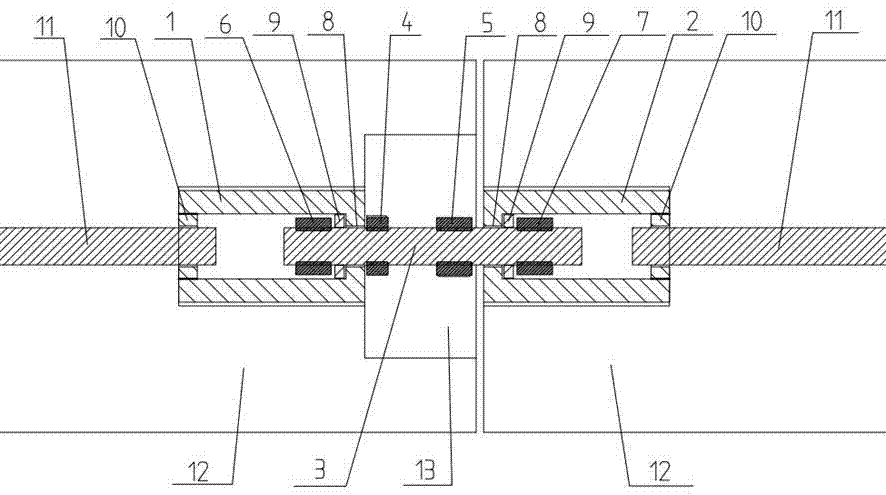

Novel fabricated building connecting piece

PendingCN107476500AHigh strengthRealize direct connectionBuilding reinforcementsConstruction engineeringRebar

Owner:SHANDONG YUANBO BUILDING TECH CO LTD

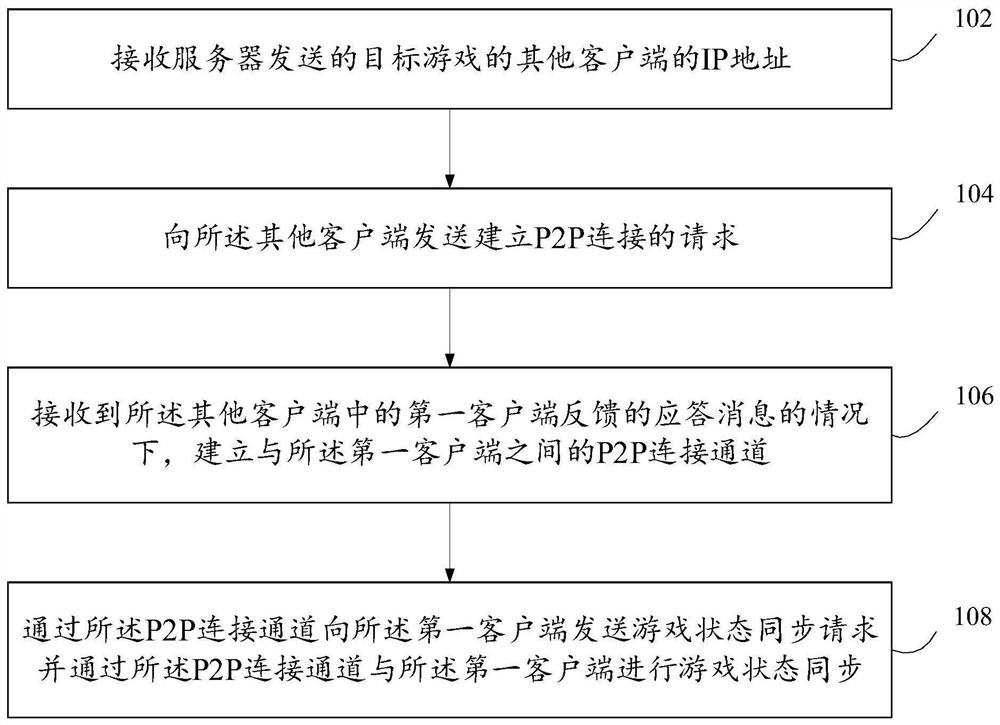

Game interaction method and system

ActiveCN112787995ARelieve pressureRealize direct connectionVideo gamesTransmissionIp addressEngineering

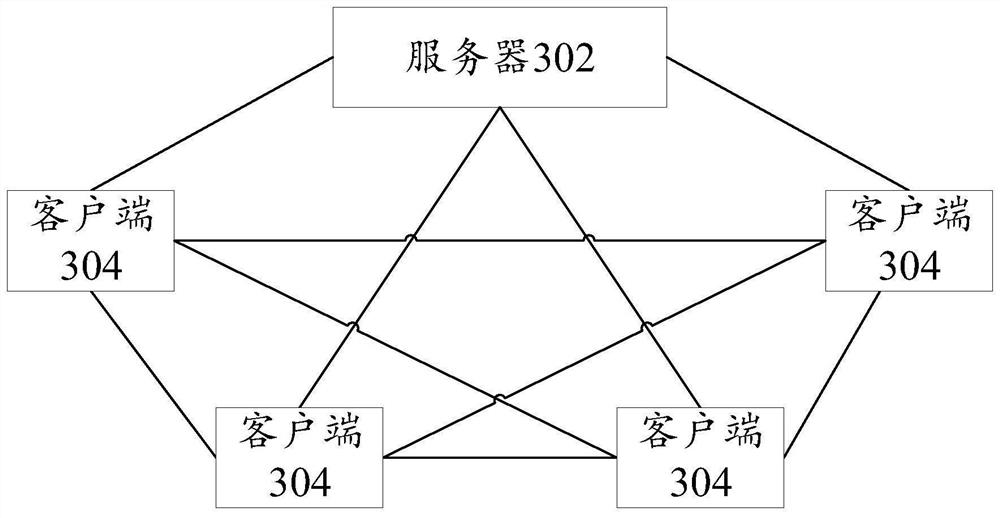

The invention provides a game interaction method and system. The game interaction method comprises the steps that IP addresses, sent by a server, of other clients of a target game are received; sending a request for establishing P2P connection to the other clients; under the condition that a response message fed back by a first client in the other clients is received, establishing a P2P connection channel with the first client; and sending a game state synchronization request to the first client through the P2P connection channel, and performing game state synchronization with the first client through the P2P connection channel. In the game interaction method, the P2P connection channel is established between the clients in the target game, so that direct connection between the clients is realized, and the server does not need to be used as a transfer for data interaction between the clients, so that the pressure of frequent data transmission on the server is reduced and the broadband resources are saved; therefore, the server can be supported to be connected with more players at the same time.

Owner:ZHUHAI SEASUN MOBILE GAME TECH CO LTD

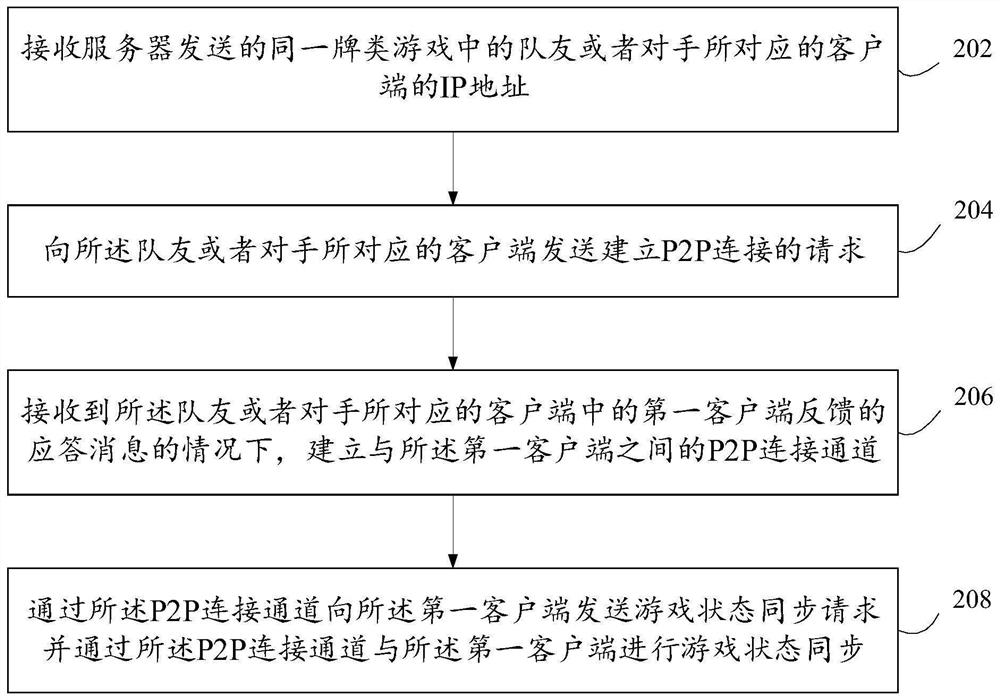

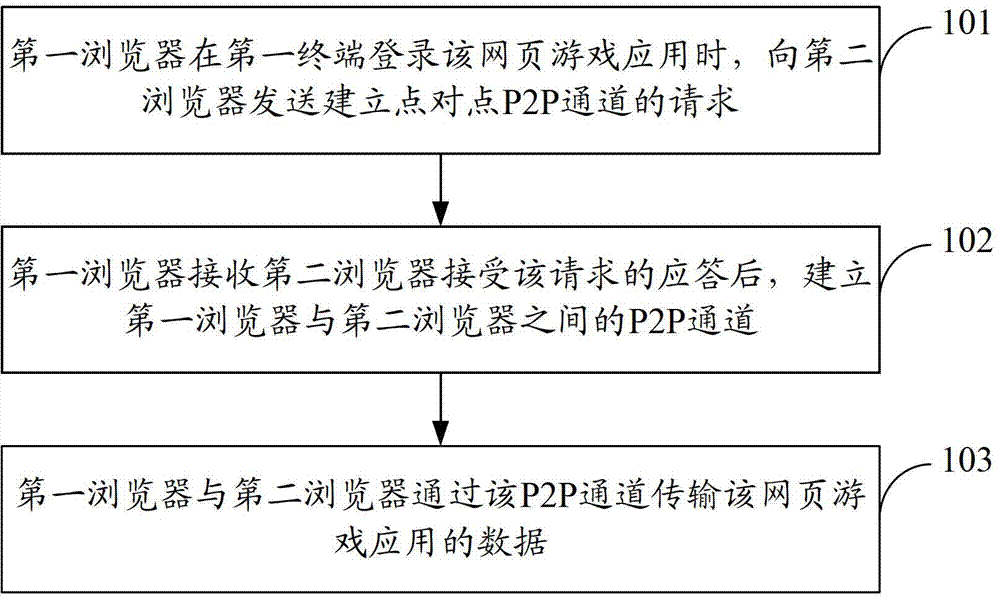

Web-game interaction method, device and system

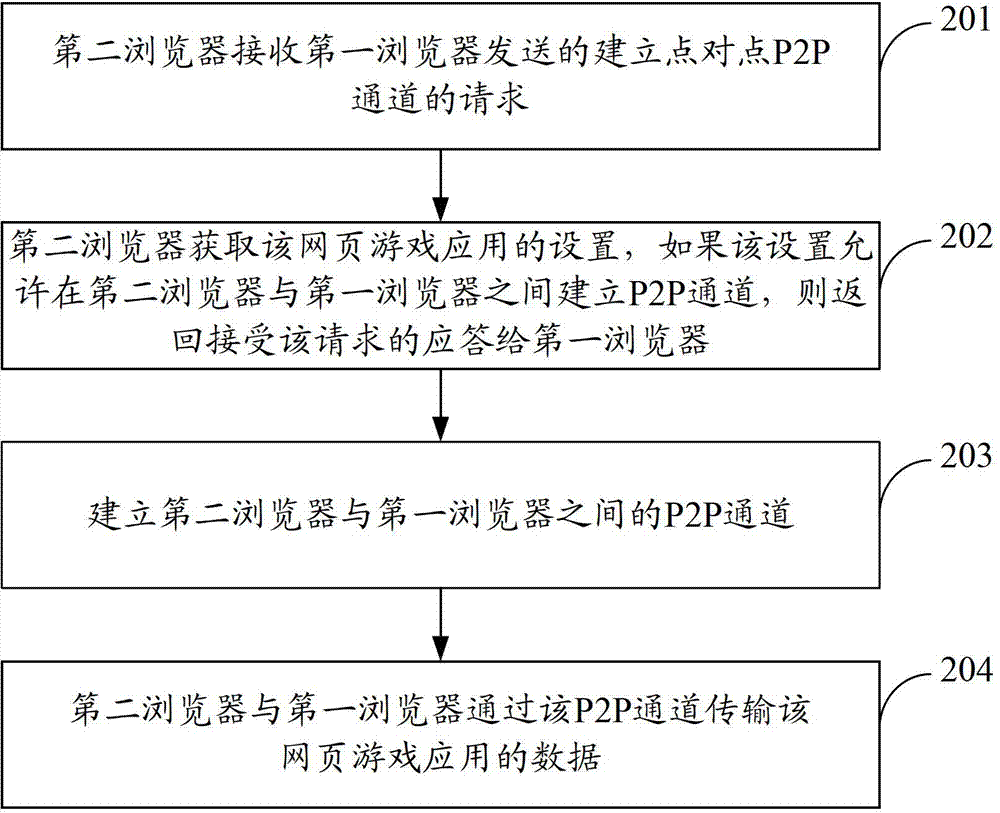

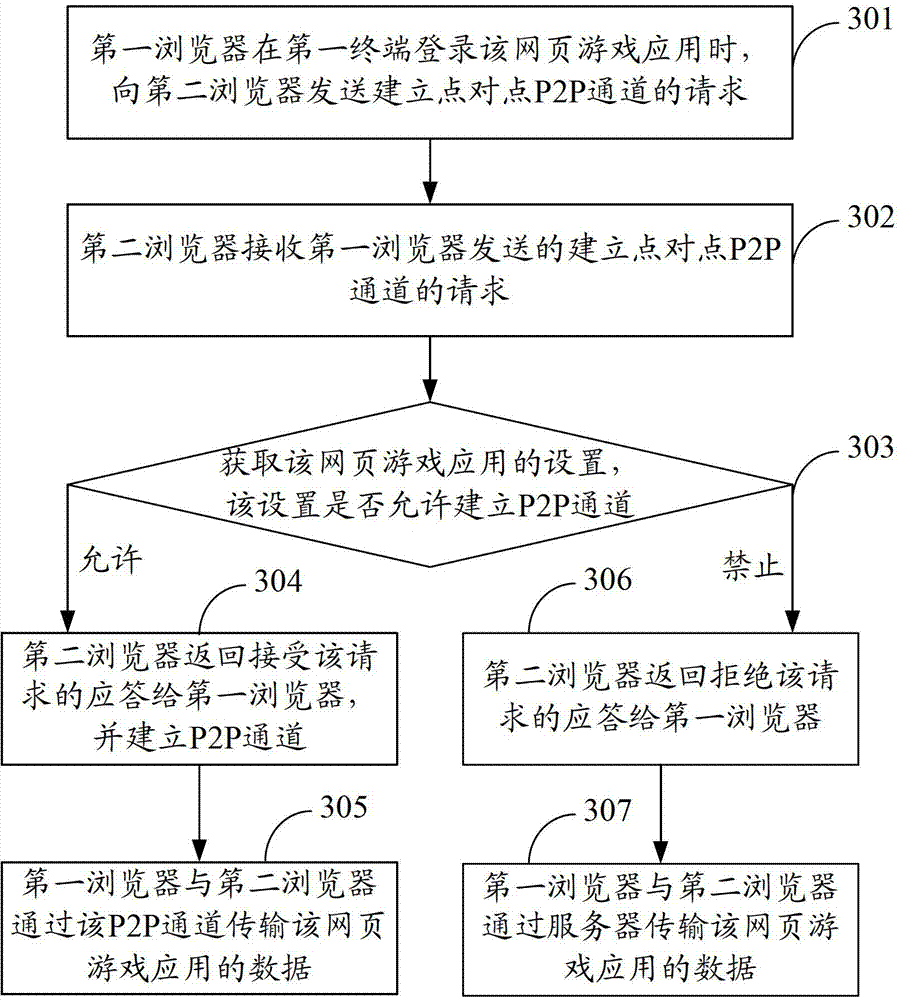

ActiveCN104065692ARealize direct connectionImplement resourcesVideo gamesTransmissionComputer terminalComputer science

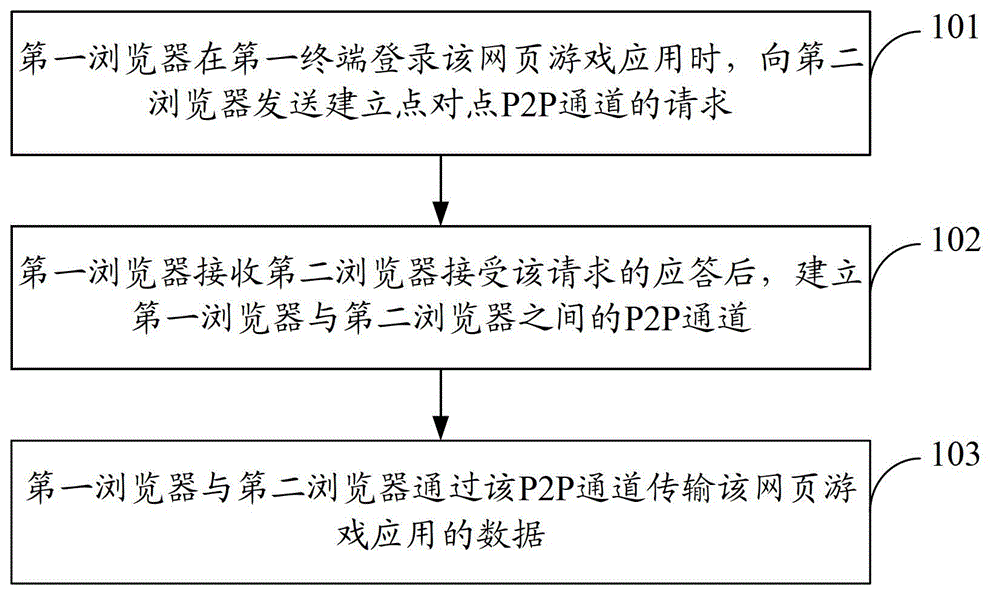

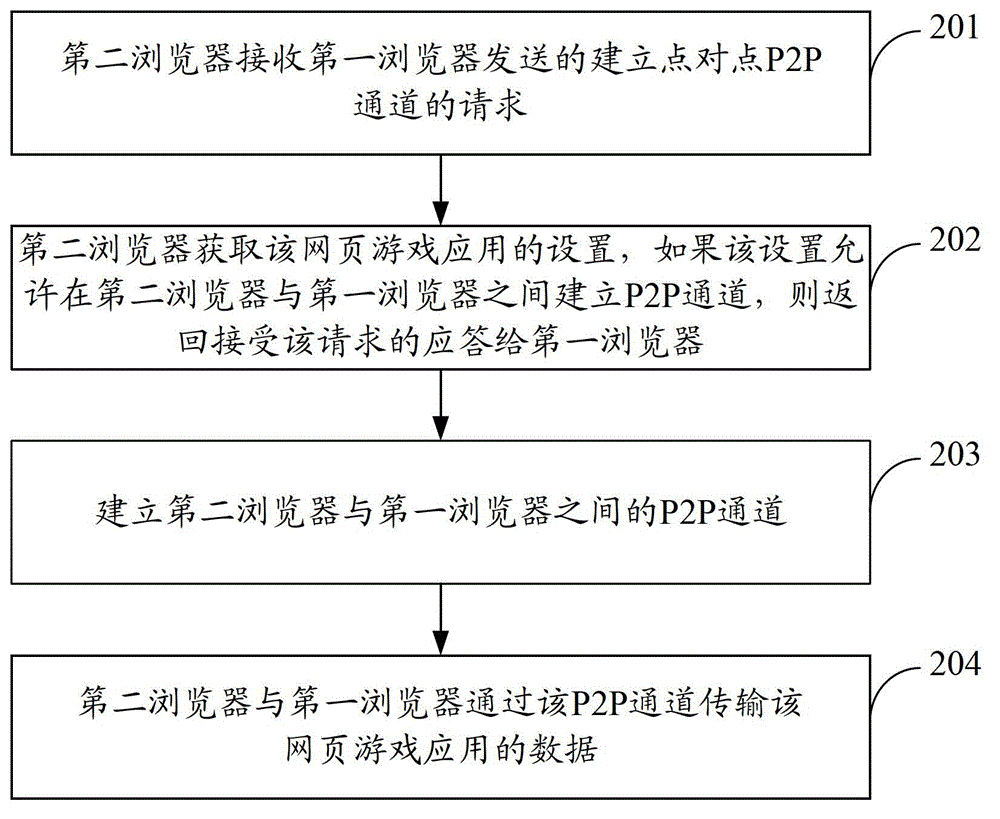

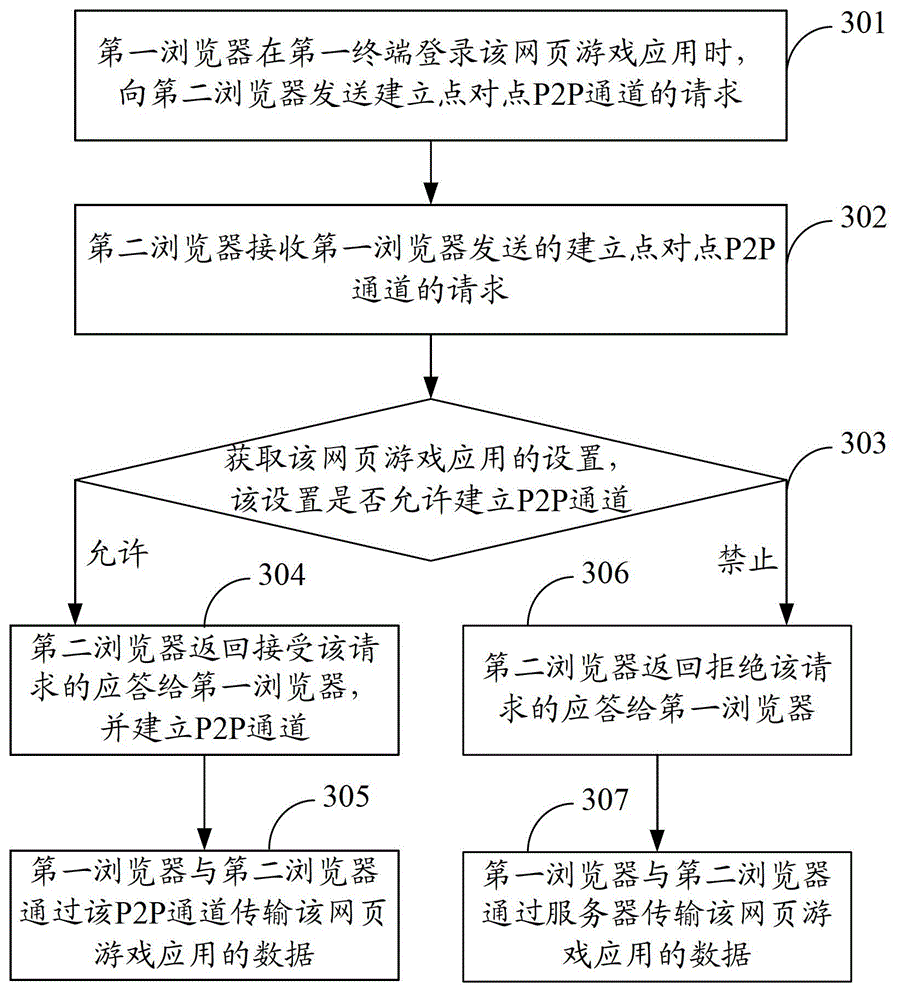

The invention discloses a web-game interaction method, device and system and belongs to the web-game field. The web-game interaction method includes that a first browser sends a P2P channel building request to a second browser when a first terminal logs in a web-game application; the first browser builds a P2P channel between the first browser and the second browser after receiving the request respond from the second browser; the first browser and the second browser transmit data of the web-game application through the P2P channel. The first browser comprises a request module, a building module and a processing module. The second browser comprises a receiving module, an acquiring module, a responding module, a building module and a processing module. The system comprises the first terminal and a second terminal. The web-game interaction method, device and system realize to directly connect with the browser of the web-game without server transfer and realize the resource sharing and point-to-point transmission of the web-game through browsers.

Owner:TENCENT TECH (SHENZHEN) CO LTD

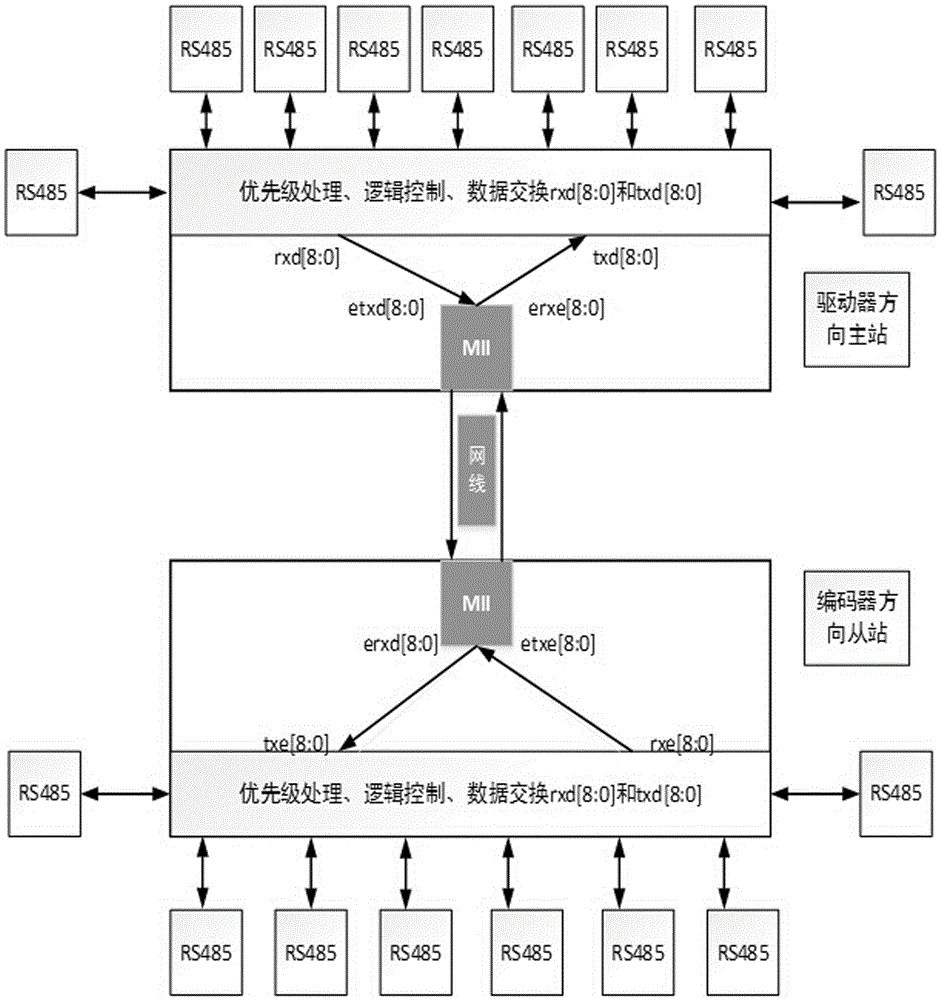

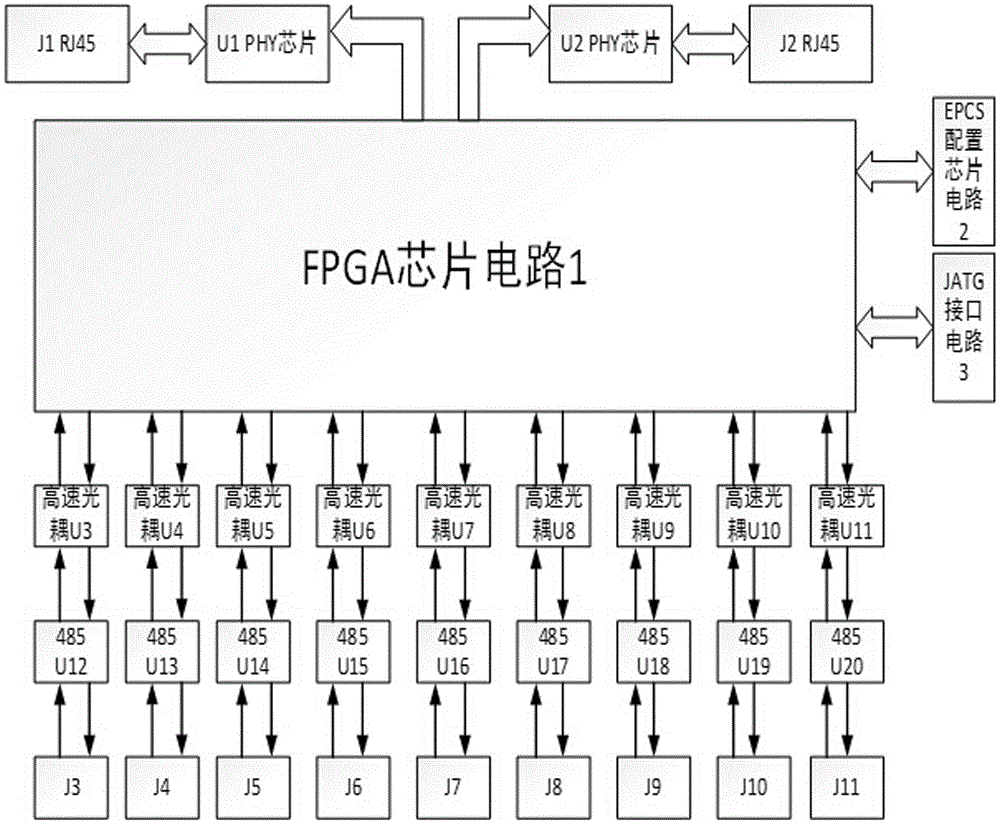

Transmission system for converting 9-channel coder signals into 1000Mbps PHY signals

InactiveCN105554034AIncrease transmission distance and stabilityImprove transmission efficiencyTransmissionPHYTransceiver

The invention relates to a transmission system for converting 9-channel coder signals into 1000Mbps PHY signals, belonging to the technical field of data communication protocol conversion of robots. The transmission system comprises PHY chip circuits U1 and U2, digital photoelectric couplers U3-U11, 485 transceivers U12-U20, RJ45 sockets J1 and J2 with isolation transformers, an FPGA chip circuit, an EPCS configuration chip circuit, a Jtag interface and SM-6P-PCB sockets J3-J11; the two-channel MII digital signal output and input ends of the FPGA chip circuit are respectively connected with the MII digital signal input and output ends of the PHY chip circuits U1 and U2; the differential data signal output and input ends of the PHY chip circuits U1 and U2 are respectively connected onto the RJ45 sockets J1 and J2 with the isolation transformers; and a master station and a slave station are arranged simultaneously. The transmission system provided by the invention satisfies high-stability, low-delay, long-distance and low-cost transmission requirements of industrial robots to coder data communication in a complex electrical environment, and simultaneously satisfies the high-refreshing-speed requirements of a robot controller to the coder data.

Owner:HARBIN BO QIANG ROBOT TECH CO LTD +1

Transaction method, system, computer equipment and storage medium based on swift system

ActiveCN113673978BRealize direct connectionEasy to useDatabase updatingFinanceBusiness enterpriseFinancial transaction

The present disclosure proposes a transaction method, system, computer equipment and storage medium based on the SWIFT system, wherein the method includes: generating a transfer message in the XML format by integrating business information, and sending a transfer message from a bank system by means of SWIFT NET Obtain the account billing message; convert the day-end billing message and the daytime billing message into XML-formatted daily billing file and daytime billing file respectively after data processing, and store them in the first folder; scan the first folder regularly , to obtain the end-of-day bill file and the day-to-day bill file, respectively parse and translate to obtain the value of each field, store it in the corresponding file information database table, and update the balance table and detailed table of the overseas treasury system. In this way, the data exchange between the overseas treasury system and the banking system of the enterprise user can be realized through the SWIFT system, and the enterprise user can directly realize the business data processing of the corresponding account in the banking system in the overseas treasury system, which is convenient for the enterprise user to use and realizes the realization of the banking system. Enterprise direct connection.

Owner:国家电投香港财资管理有限公司

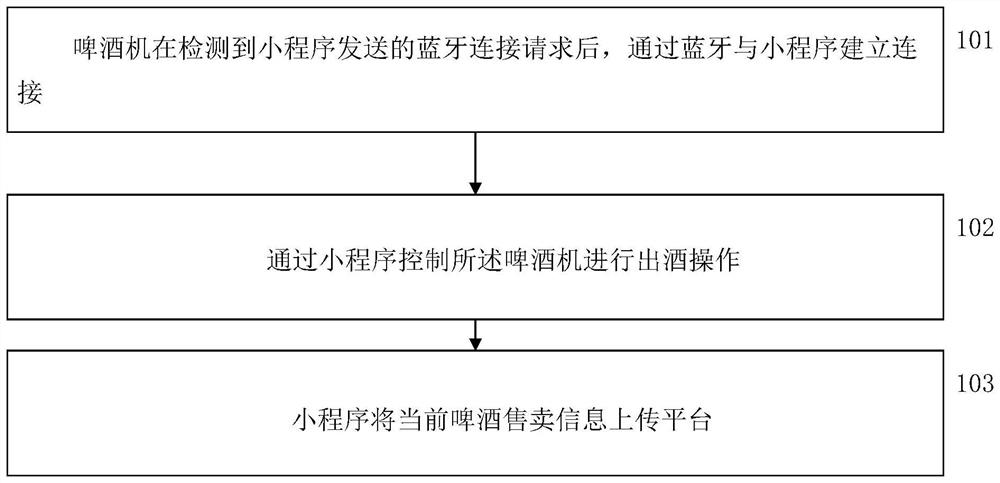

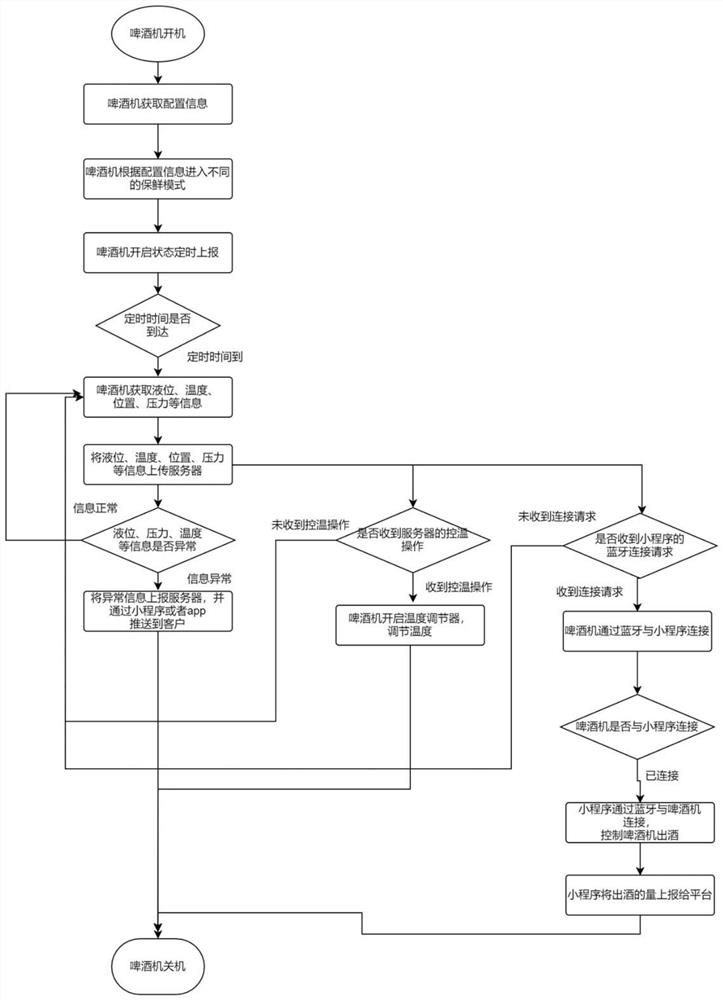

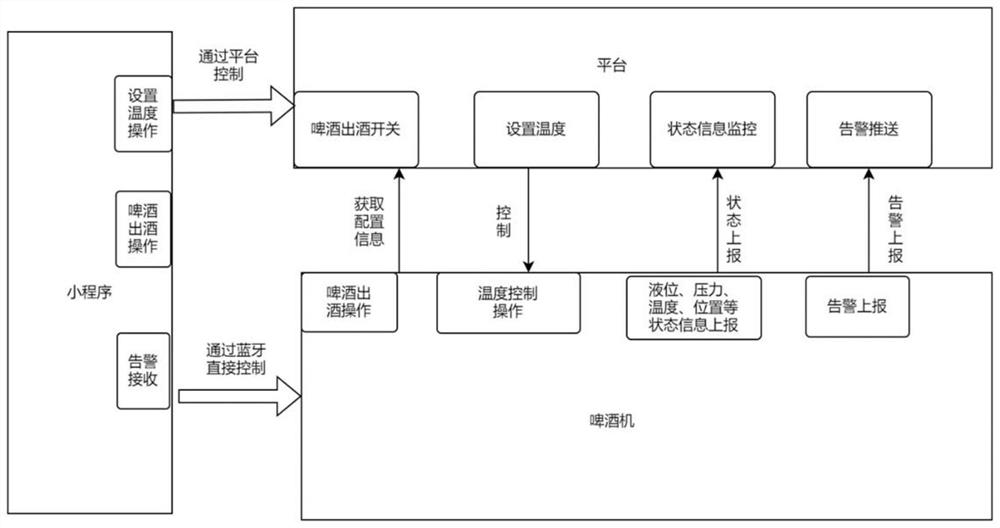

Remote control method and system of beer machine

ActiveCN114187702AExpand the function of unmanned vendingRealize direct connectionCoin-freed apparatus detailsApparatus for dispensing fluids/granular materialsEmbedded systemSoftware engineering

The invention provides a remote control method and system for a beer machine, and the method comprises the steps: building connection with an applet through Bluetooth after the beer machine detects a Bluetooth connection request sent by the applet; controlling the beer machine to carry out beer discharging operation through the applet; and the applet uploads the current beer selling information to the platform. The beer machine is connected with the applet mobile terminal through Bluetooth, Bluetooth direct connection is achieved, and the self-service selling function of the beer machine is expanded through Bluetooth direct connection.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

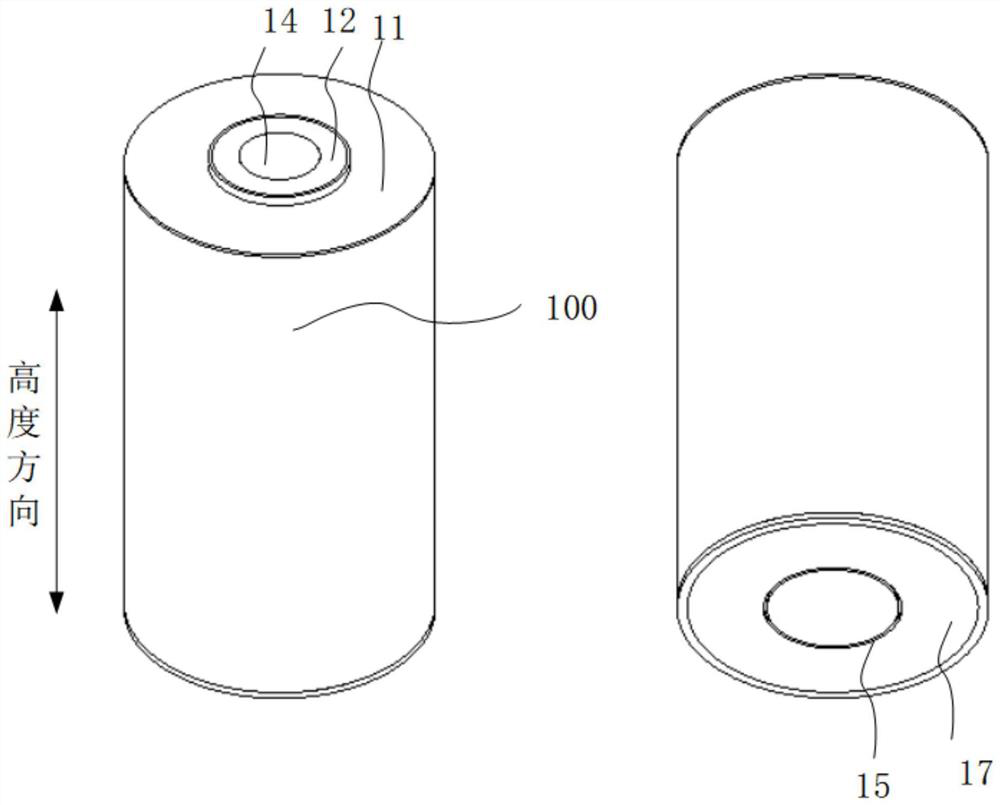

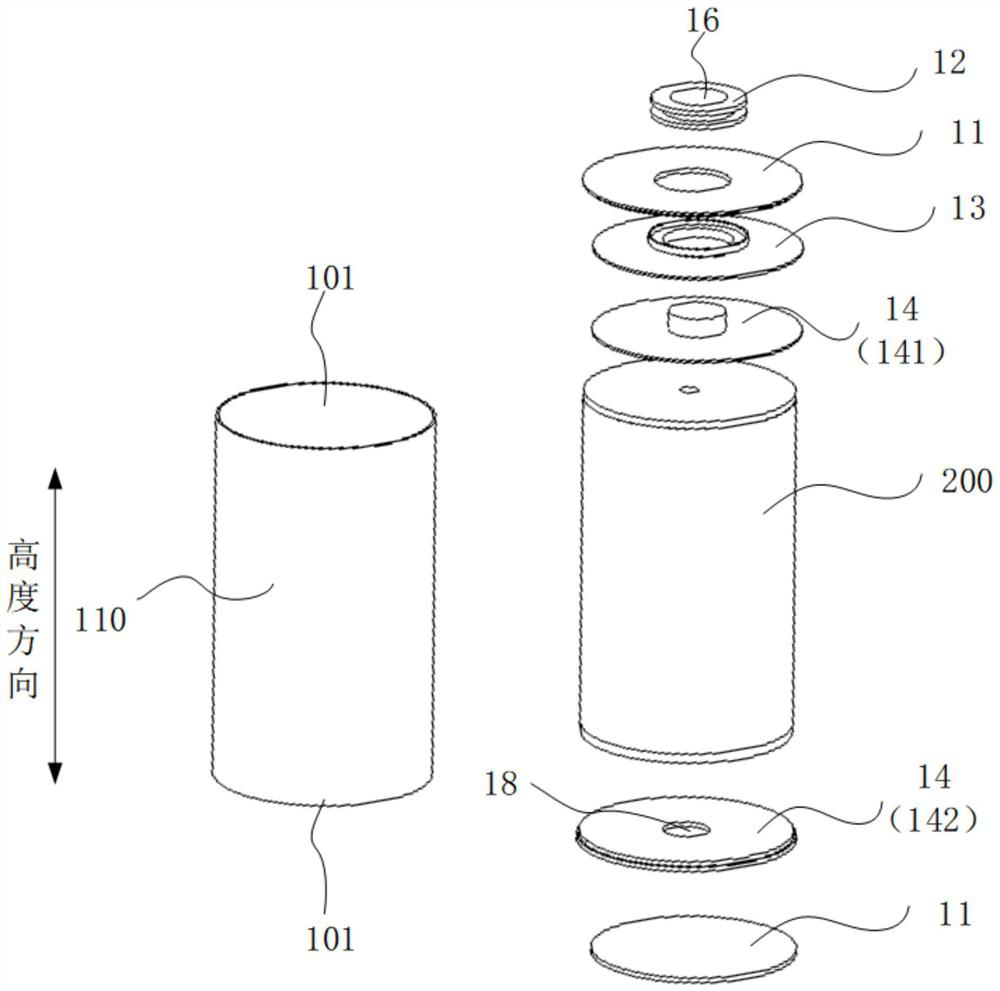

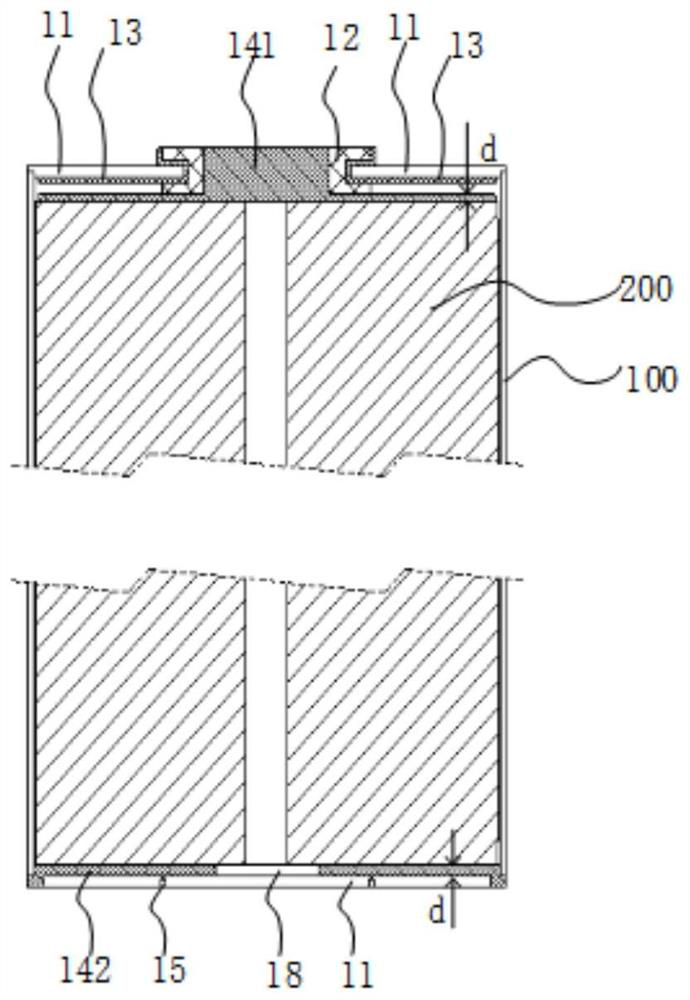

Battery

PendingCN114678662ALower internal resistanceImprove flow capacityCell component detailsInternal resistanceElectrical connection

The invention discloses a battery, relates to the technical field of batteries, and aims to solve the problems of capacity and internal resistance of the battery in related technologies. The battery comprises a shell, a battery cell and a collector plate, and the battery cell is arranged in the shell; the current collecting plate is propped against the tab of the battery cell and partially protrudes out of the shell so as to form an electric connecting electrode of the battery. As the collector plate is directly abutted against the battery cell tab, the internal space of the battery along the height direction is fully utilized, and when the height of the battery is fixed, the internal space of the shell can be fully utilized to improve the capacity of the battery cell; according to the utility model, the battery cell partially protrudes out of the shell to form an electric connecting pole of the battery, so that the direct connection between the battery cell and an external electric connecting piece can be realized, the internal resistance of the battery is further reduced, and the overcurrent capability of the battery is improved. The battery is applied to high-rate demand scenes such as electric automobiles and electric airplanes.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

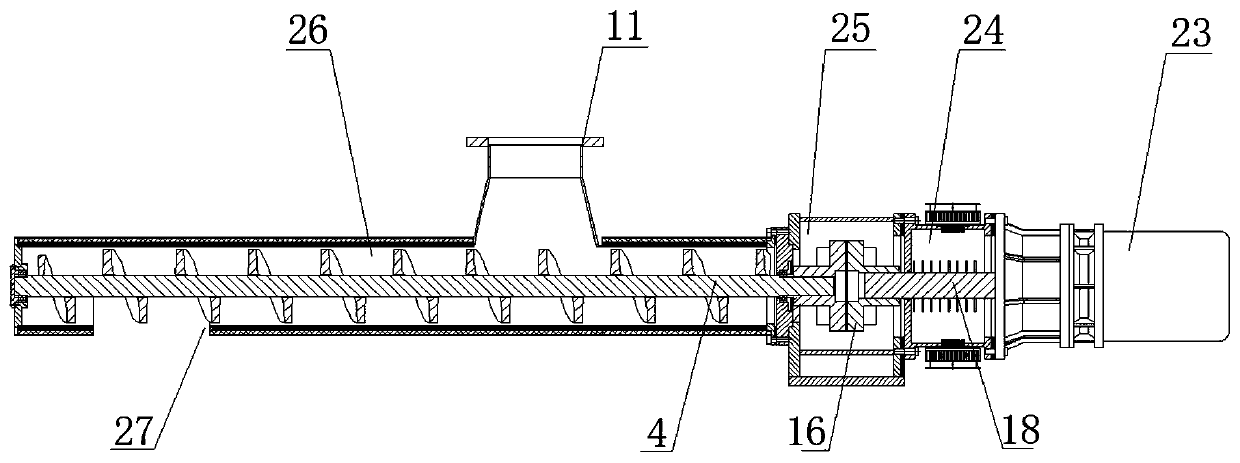

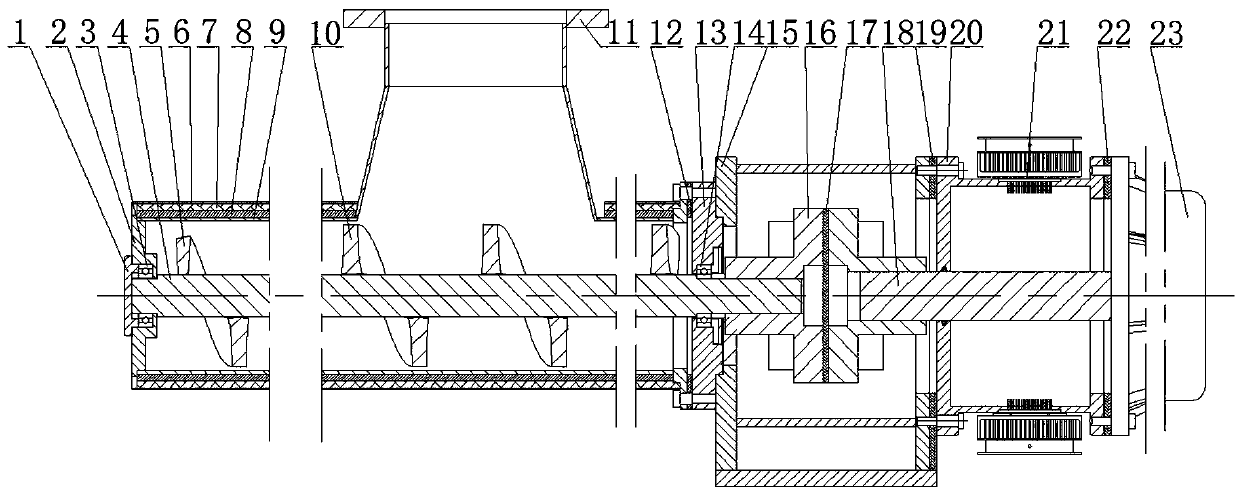

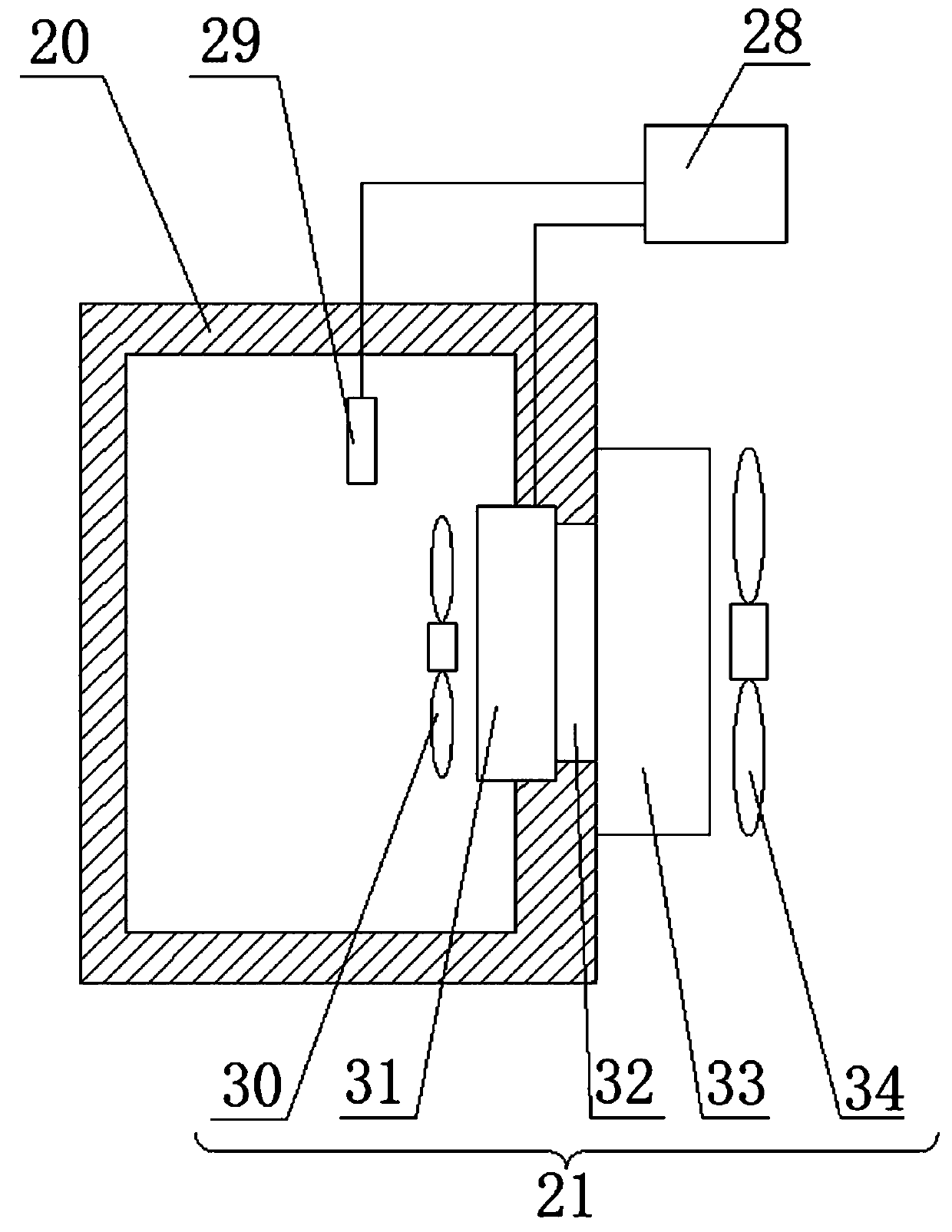

High-temperature spiral feeder

PendingCN111003428ARealize direct connectionCompact structurePackagingLoading/unloadingElectric machineEngineering

The invention relates to the field of material conveying equipment, specifically a high-temperature spiral feeder. The high-temperature spiral feeder comprises a motor reducer, a cooling section, a heat insulation section and a high temperature feeding section which are connected in sequence, wherein the output shaft of the motor reducer penetrates the cooling section and then is connected to a spiral conveyer main shaft in the high temperature feeding section through a shaft coupling in the heat insulation section; the cooling section comprises a cooling box, a temperature sensor arranged inthe inner cavity of the cooling box, a semiconductor cooler arranged on the wall of the cooling box, and a temperature controller arranged outside the cooling box; a first heat insulation gasket is clamped between the cooling box and the motor reducer; a second heat insulation gasket is clamped between the cooling box and the heat insulation section; the signal output of the temperature sensor isconnected to the temperature controller, and the signal output of the temperature controller is connected to the semiconductor cooler; and the on-off of the semiconductor cooler can be controlled by the temperature controller through the temperature signal measured by the temperature sensor. The high-temperature spiral feeder has a compact structure, does not require water cooling, and can guarantee the continuous transportation of high temperature materials.

Owner:洛阳炬星窑炉有限公司

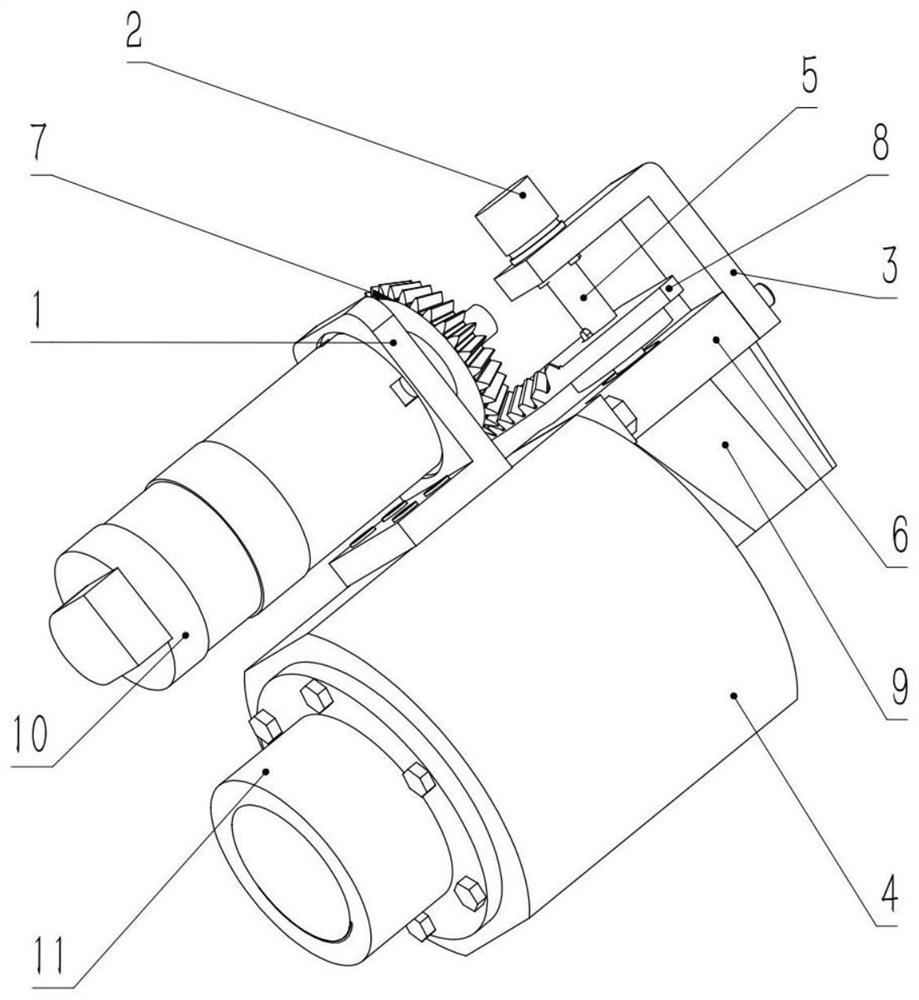

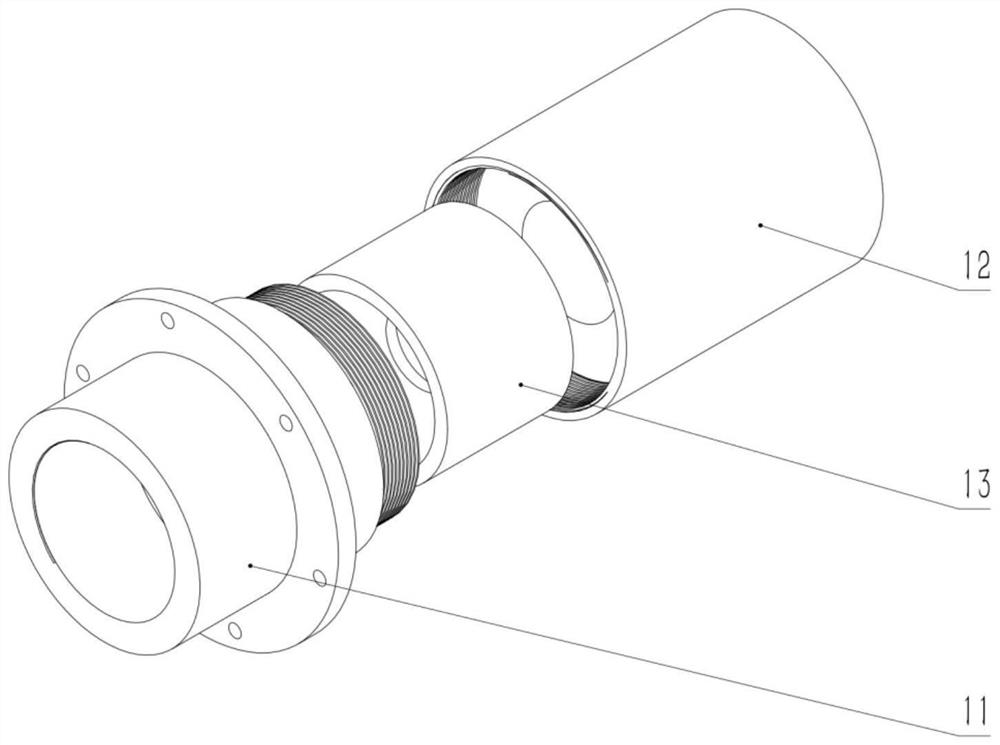

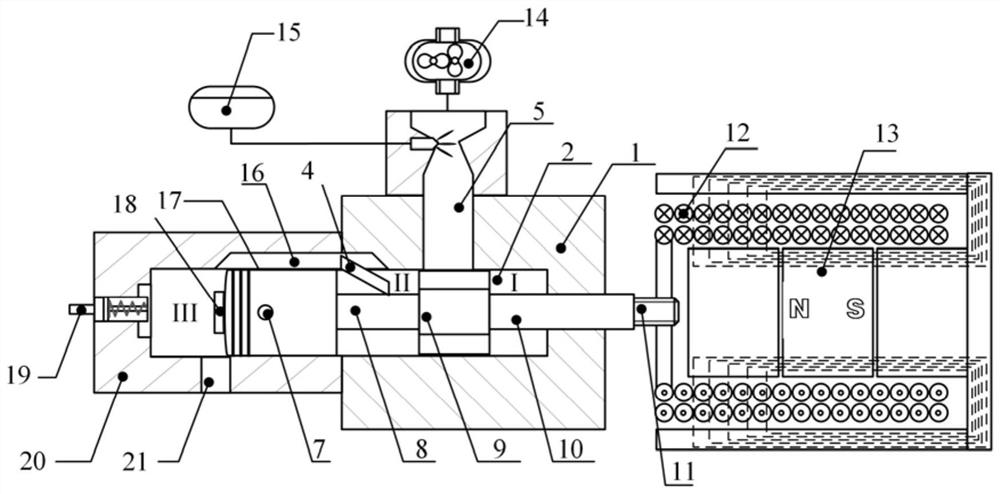

Motor-driven gas vane servo control mechanism testing device

ActiveCN113865447AOptimize structure layoutAchieve parallelismAmmunition testingWeight reductionControl engineeringElectric machinery

The invention provides a motor-driven servo control mechanism testing device. The motor-driven servo control mechanism testing device comprises an electric steering engine fixing frame, an angle sensor, a sensor bracket, a shell sleeve, a rudder shaft mounting frame and a transmission assembly, and has the following advantages that the structural layout of a steering engine is optimized, a motor shaft is parallel to a projectile body shaft, and the cross sectional area of a projectile body is effectively saved. Direct connection between the angle sensor and a rudder sheet shaft is achieved, and the deflection angle of the rudder sheet is collected more accurately and subjected to feedback control. A limiting relationship is introduced between the sensor bracket and a bevel gear plate so that the rudder sheet can only move within a preset angle. The sensor bracket and a rudder shaft containing table are designed in a split mode, and installation of the angle sensor and the bevel gear plate is facilitated. The whole testing device is simple in structure, safe, reliable and convenient for daily operation and maintenance.

Owner:NANJING UNIV OF SCI & TECH

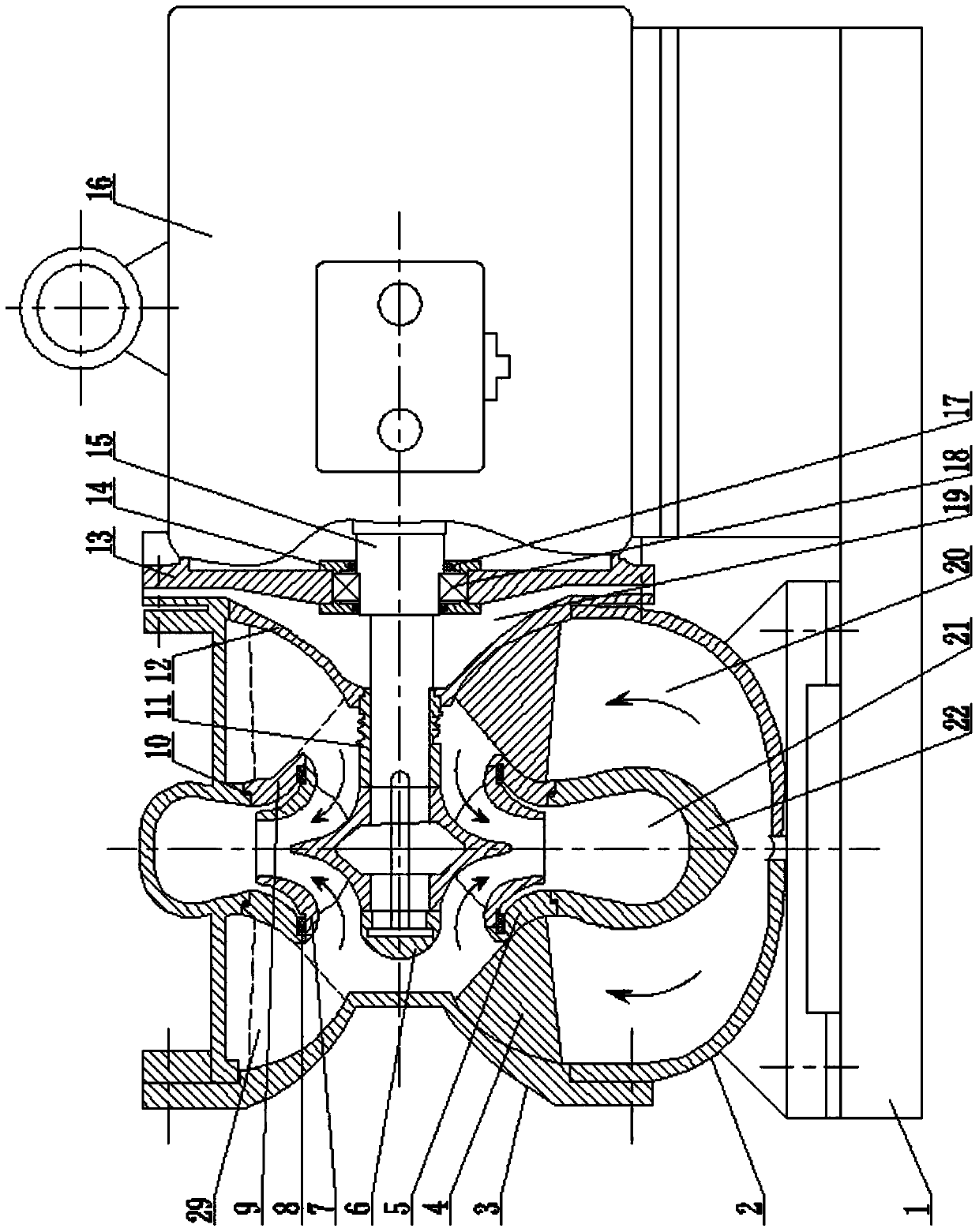

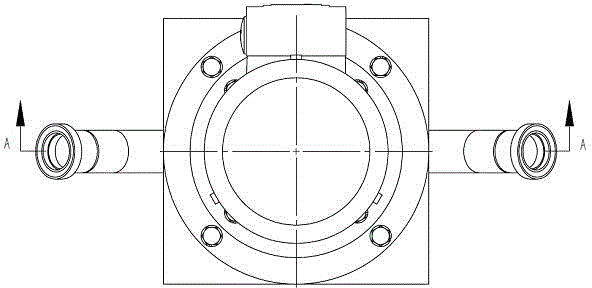

Energy-saving horizontal direct-connected single-stage double-suction centrifugal pump

InactiveCN104948501BRealize direct connectionNo transition connectionPump componentsPumpsSingle stageMaximum diameter

The invention relates to an energy-saving horizontal double-suction centrifugal pump, which includes a pump body, a pump cover, an impeller and a motor. The connection between the motor side cover and the pump cover II is fixed, and there is an open air isolation gap or a cooling water isolation cavity between the two. The motor shaft passes through the pump cover II and enters the pump body, and the impeller corresponds to the center of the vortex chamber in the middle. Installed on the motor shaft, there is a bellows type dynamic seal between the impeller and the pump cover II, the suction vortex chamber on both sides of the pump body and the discharge vortex chamber in the middle are matched with the partition wall integrated with the pump body and the partition wall by using a spigot The left and right annular partitions are separated together, the center line of the left and right annular partitions coincides with the axis of the motor, and the left and right annular partitions and the corresponding side pump cover respectively use the connecting ribs to form an integrated structure. The outer diameters of the left and right annular partition plates are greater than the maximum diameter of the impeller. It is energy-saving and high-efficiency, and at the same time, it is convenient for repair and maintenance, and significantly improves work efficiency.

Owner:姚庆义

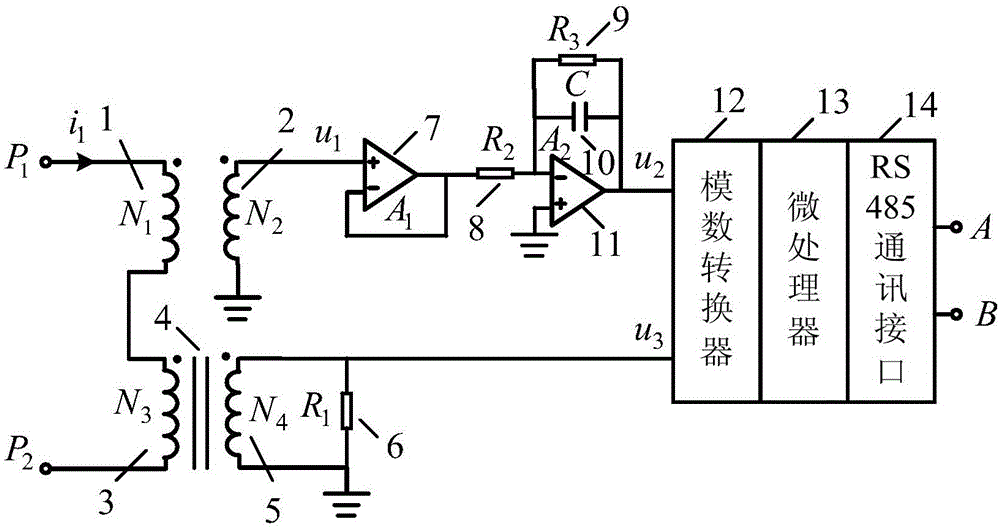

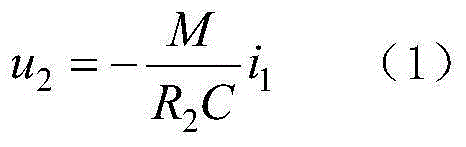

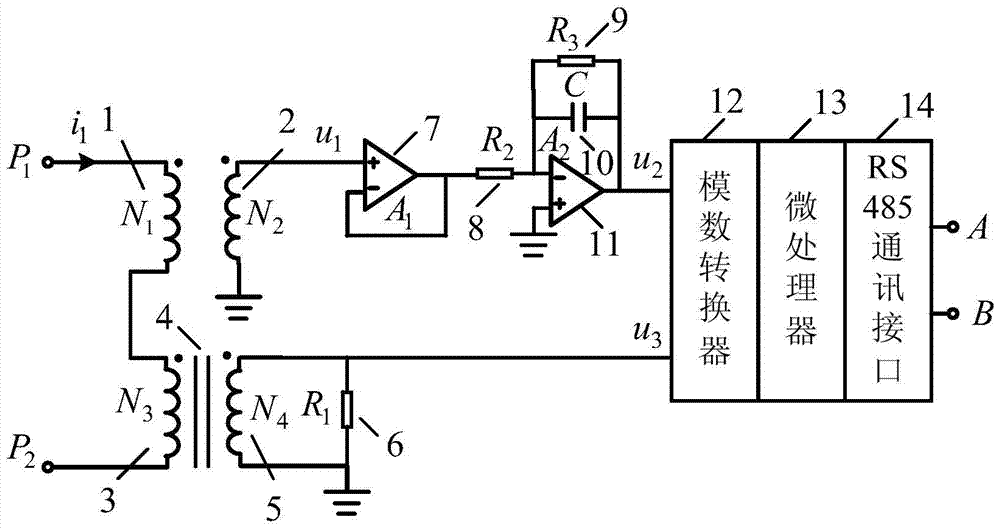

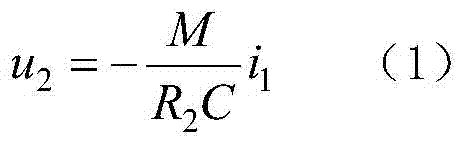

Online distortion current correction sensing device for distributed photovoltaic grid-connected power generation

ActiveCN105158717AMeasurement stabilityWith unsaturatedElectrical measurementsCapacitanceCurrent sensor

The invention discloses an online distortion current correction sensing device for distributed photovoltaic grid-connected power generation. Due to saturation, magnetic hysteresis and other characteristics of an iron core material, the existing current transformer is low in accuracy when harmonic current is measured. During a long-time use process, a Rogowski coil has problems of cold and thermal expansion, temperature drift of an integral reduction circuit component and the like, and thus accuracy is low and not stable. The device of the invention comprises a first coil, a second coil, a third coil, the iron core, a fourth coil, a first resistor, a first operational amplifier, a second resistor, a third resistor, a capacitor, a second operational amplifier, an analog-to-digital converter, a microprocessor and an RS485 communication interface; the homonymous end of the first coil and the non-homonymous end of the third coil form an input port of the sensing device, and the RS485 communication interface is an output port of the sensing device. Two primary current sensors: the Rogowski coil and the current transformer are provided, operation state monitoring can be carried out mutually, and reliability of the sensing device is improved.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO MARKETING SERVICE CENT +2

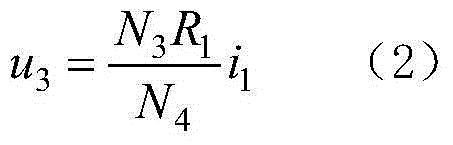

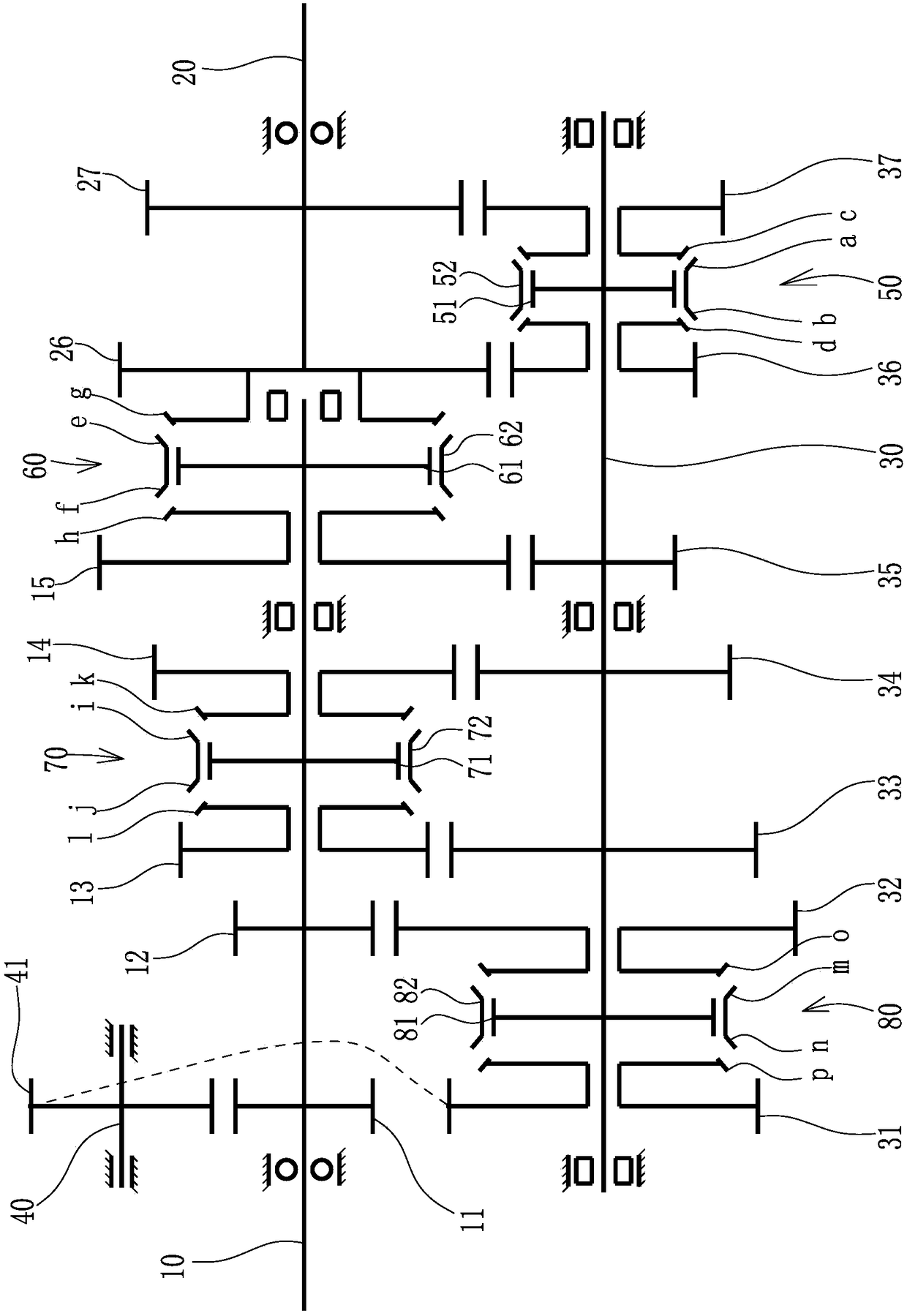

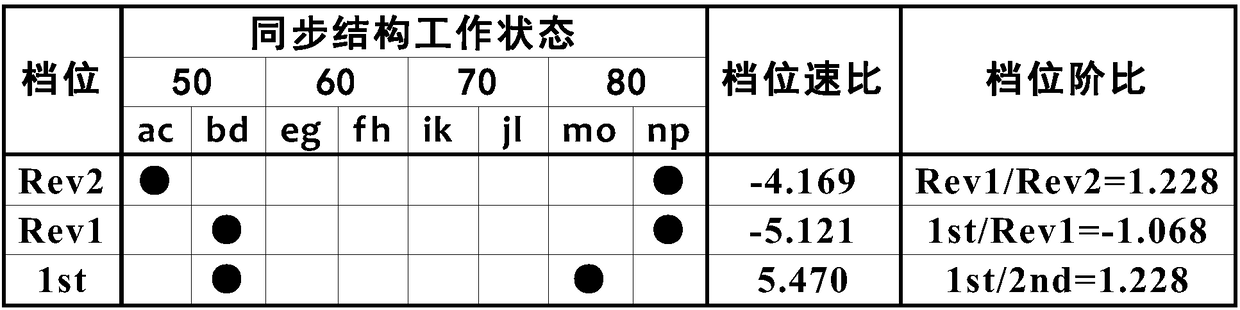

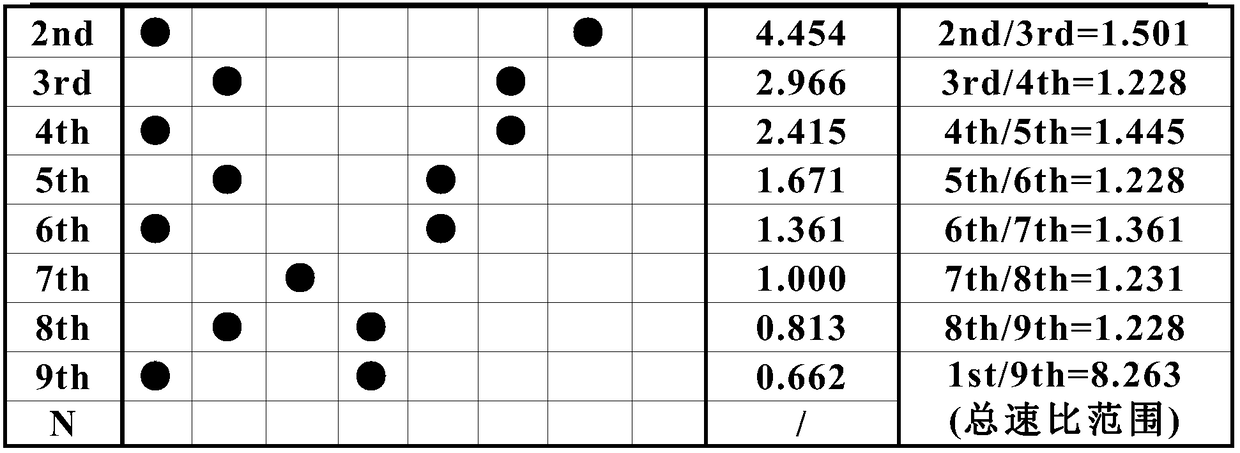

Novel multi-gear transmission

PendingCN108343715ARealize direct connectionImprove reusabilityToothed gearingsEngineeringGear transmission

The invention provides a novel multi-gear transmission and belongs to the technical field of transmissions. The novel multi-gear transmission solves the problems that an existing multi-gear transmission is complicated in structure and large in manufacturing difficulty. The novel multi-gear transmission comprises an input shaft, a middle shaft and output shaft, wherein the middle shaft is parallelto the input shaft, the output shaft and the input shaft are coaxially arranged, a reverse gear structure, a first first-grade speed reduction structure, a second first-grade speed reduction structure, a third first-grade speed reduction structure, a fourth first-grade speed reduction structure are sequentially arranged between the input shaft and the middle shaft, a first second-grade speed reduction structure and a second second-grade speed reduction structure are arranged between the middle shaft and the output shaft, a first synchronous structure is arranged between the first second-gradespeed reduction structure and the second second-grade speed reduction structure, a second synchronous structure is arranged between the fourth first-grade speed reduction structure and the first second-grade speed reduction structure, a third synchronous structure is arranged between the second first-grade speed reduction structure and the third first-grade speed reduction structure, and a fourthsynchronous structure is arranged between the reverse gear structure and the first first-grade speed reduction structure. The novel multi-gear transmission has the advantages of being simple and compact in structure, low in cost and the like.

Owner:ZHEJIANG ZOMAX TRANSMISSION CO LTD

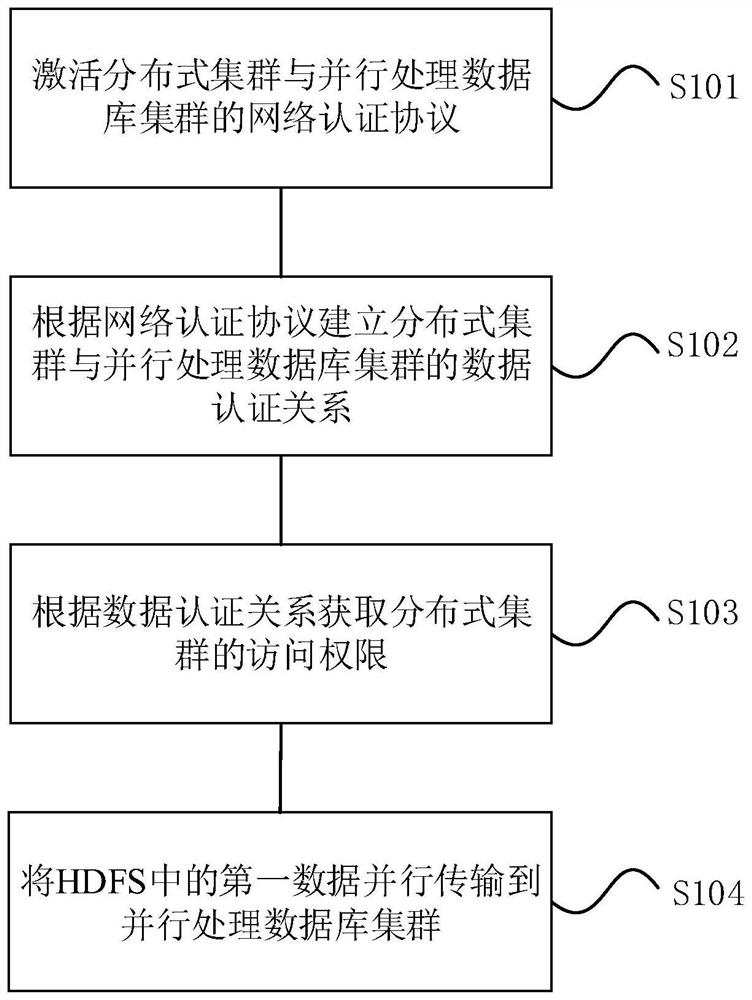

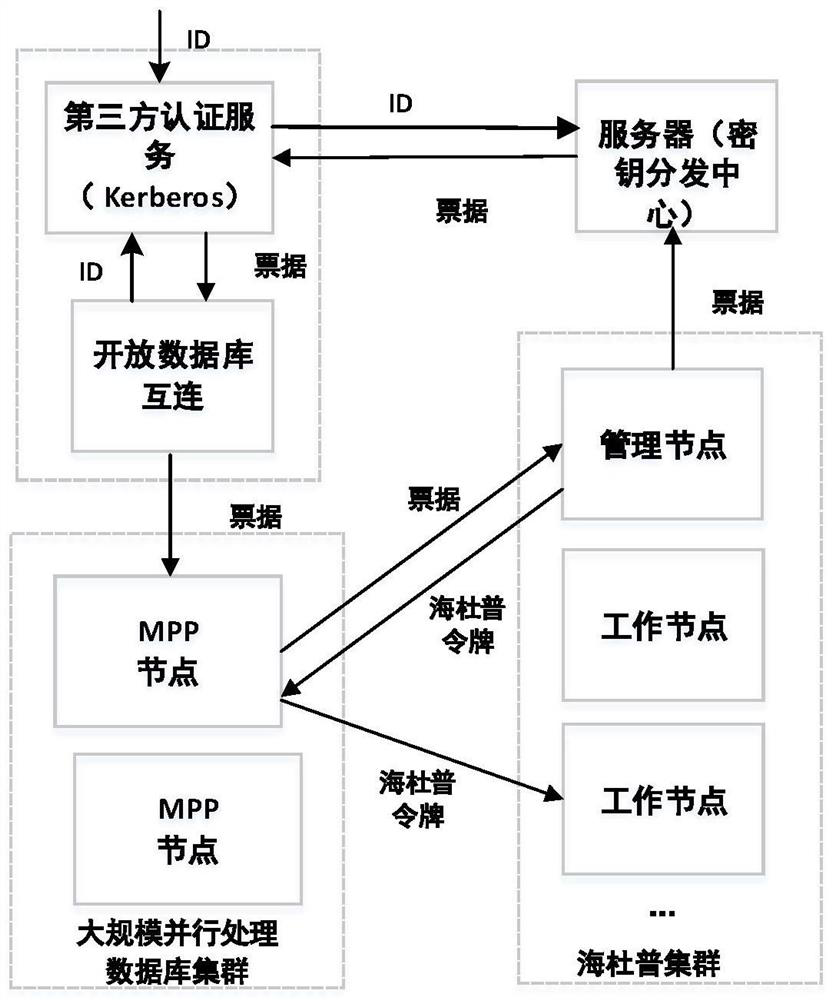

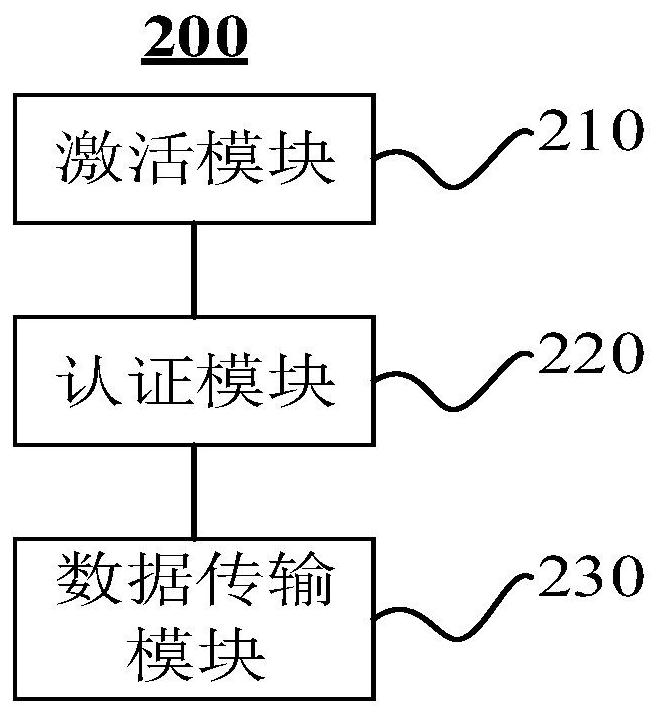

Mass heterogeneous data parallel transmission method and device, equipment and storage medium

ActiveCN113630365AImprove transmission efficiencySimplify the transfer processKey distribution for secure communicationUser identity/authority verificationWeb authenticationProtocol for Carrying Authentication for Network Access

The embodiment of the invention provides a mass heterogeneous data parallel transmission method and device, equipment and a storage medium. The method comprises the following steps: activating a network authentication protocol of a distributed cluster and a parallel processing database cluster; establishing a data authentication relationship between the distributed cluster and the parallel processing database cluster according to a network authentication protocol; obtaining the access authority of the distributed cluster according to the data authentication relationship; and transmitting the first data in the HDFS to the parallel processing database cluster in parallel according to the access permission. According to the method, the data in the HDFS can be directly imported into the parallel processing database cluster, secondary data format conversion is not needed, and the transmission efficiency of mass heterogeneous data is improved.

Owner:中移动信息技术有限公司 +1

On-line Calibration Distortion Current Sensing Device for Distributed Photovoltaic Grid-connected Power Generation

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO MARKETING SERVICE CENT +2

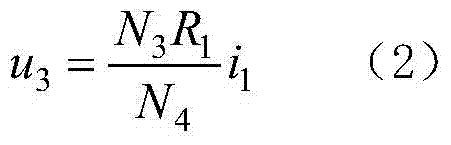

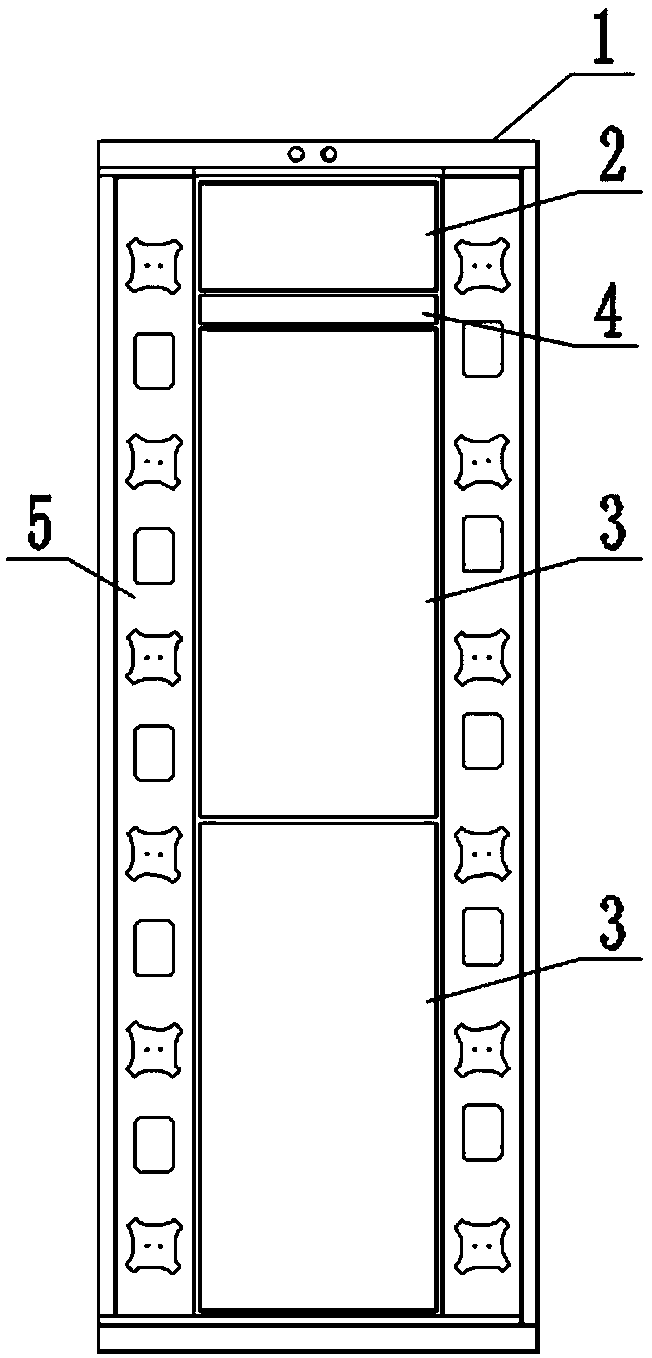

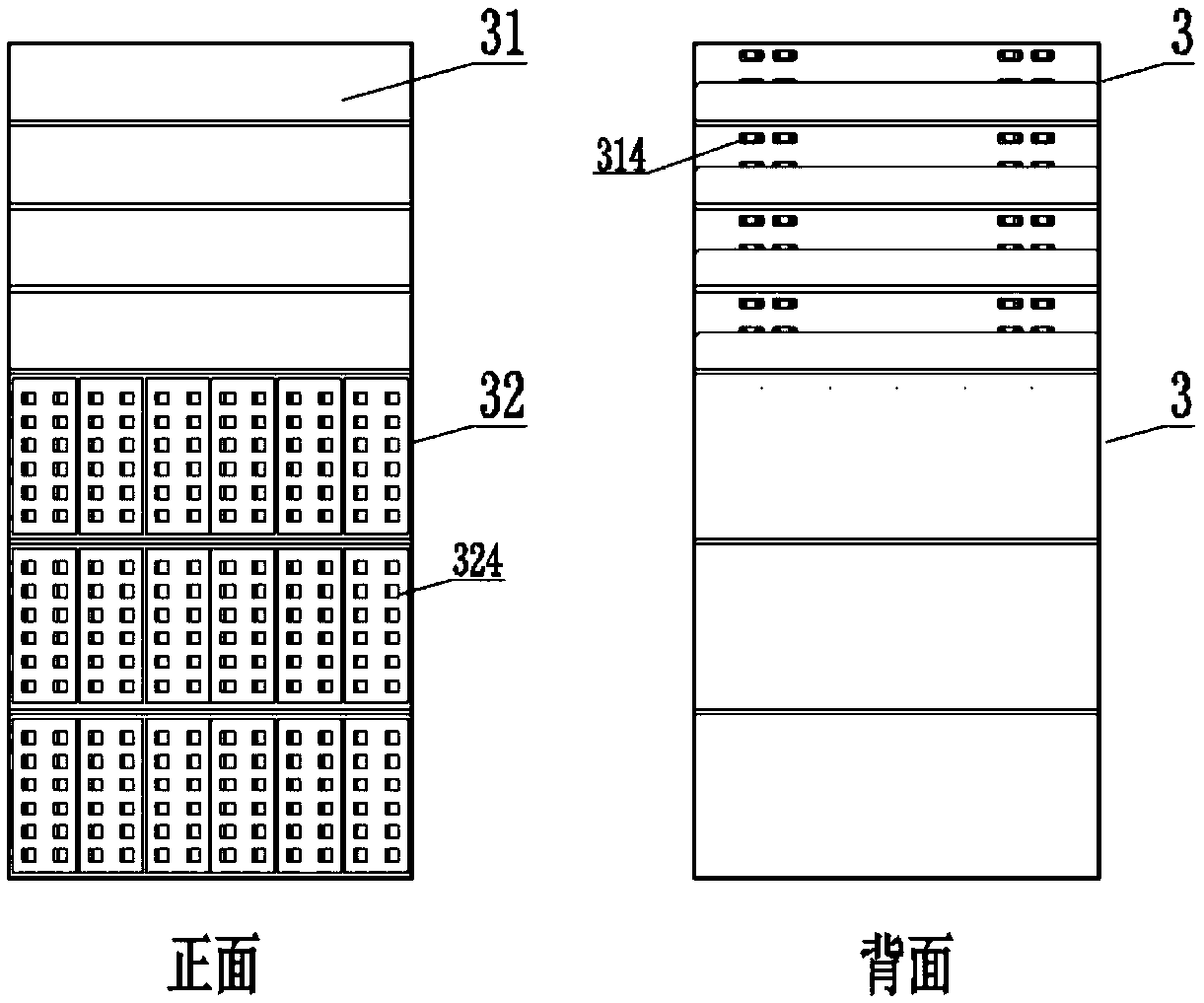

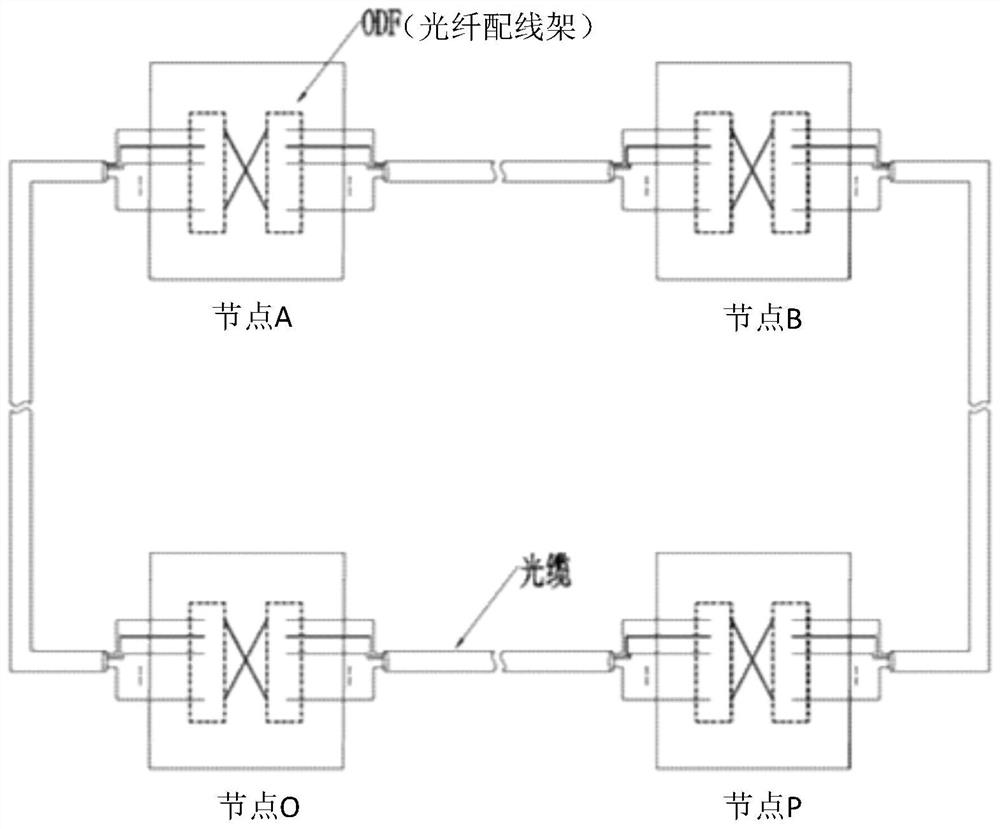

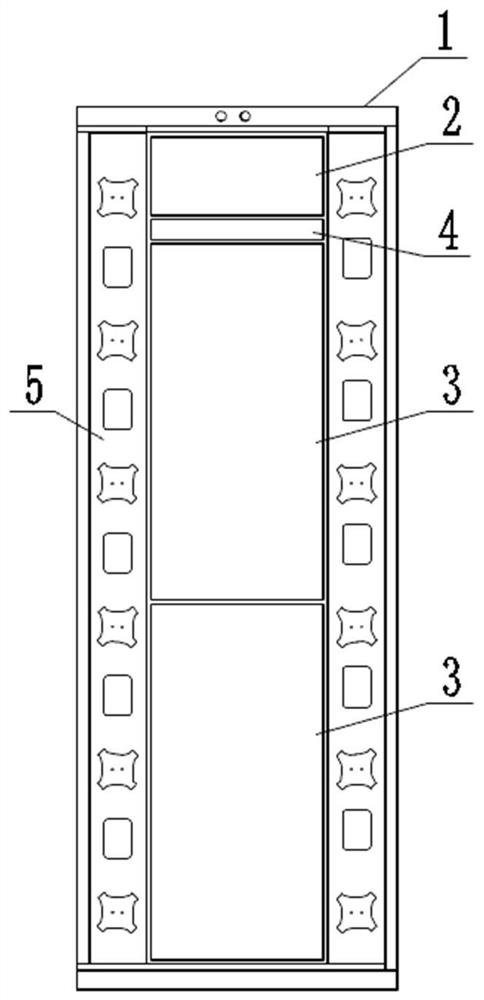

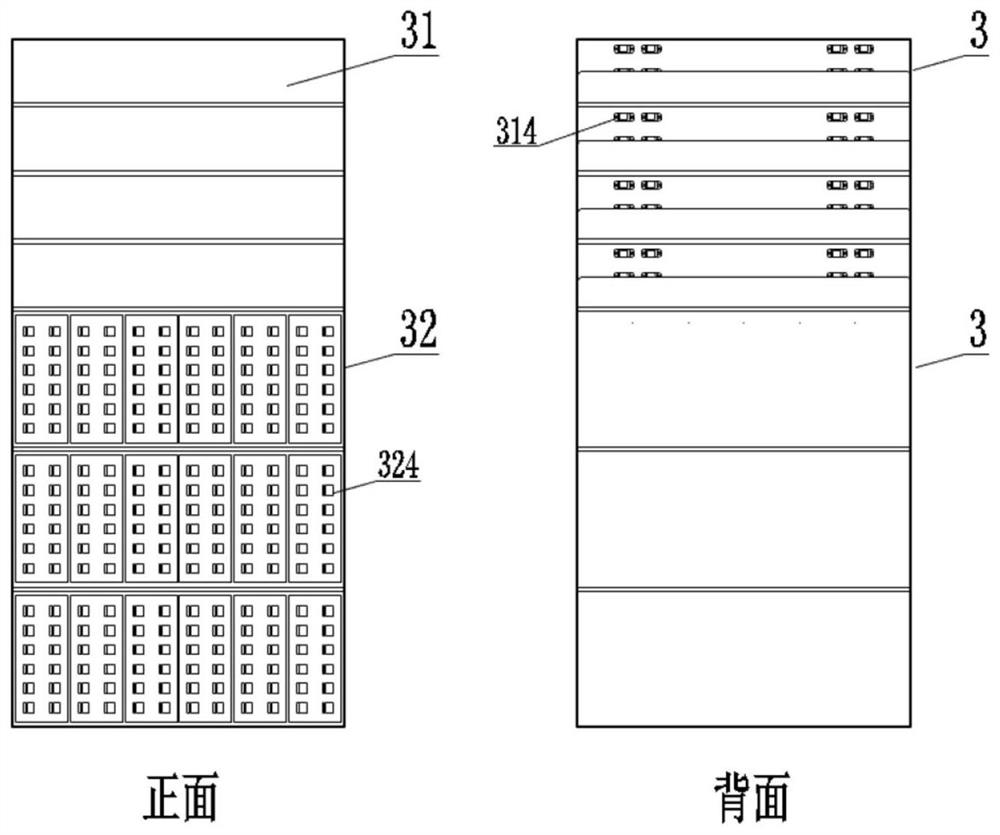

Optical cross connection equipment for metro backbone transport network

ActiveCN111239914ARealize direct connectionLarge capacityCoupling light guidesCross connectionTelecommunications

The invention discloses optical cross connection equipment for a metro backbone transport network. The optical cross connection equipment comprises frame bodies, optical cable fixing devices, a plurality of optical cross connection sub-frames, an intelligent fiber core management unit and a jumper fiber storage unit, wherein the frame body provides an installation space for equipment, and each frame body is internally provided with an optical cable fixing device, a plurality of optical cross connection sub-frames, the intelligent fiber core management unit and the jumper fiber storage unit; the optical cable fixing device is used for fixing external optical cables; a multi-core movable connector assembly is arranged in the optical cross connection sub-frame, so that each optical fiber in the external optical cable is formed at a port of the multi-core movable connector assembly and has cross capability; the intelligent fiber core management unit is used for identifying the electronic tags at the two ends of the jumper fiber so as to realize intelligent management of the use condition of the fiber core; and the jumper fiber storage unit is used for storing the excess length of the jumper fiber. The problems that an existing ODF device is small in device capacity, the number of jumper fibers in the device is large, the cross connection capacity of the device is poor, and effective management of an ODF port is lacked can be solved.

Owner:CHINA MOBILE GROUP DESIGN INST +1

Optical cross-connect device for metro backbone transport network

Owner:CHINA MOBILE GROUP DESIGN INST +1

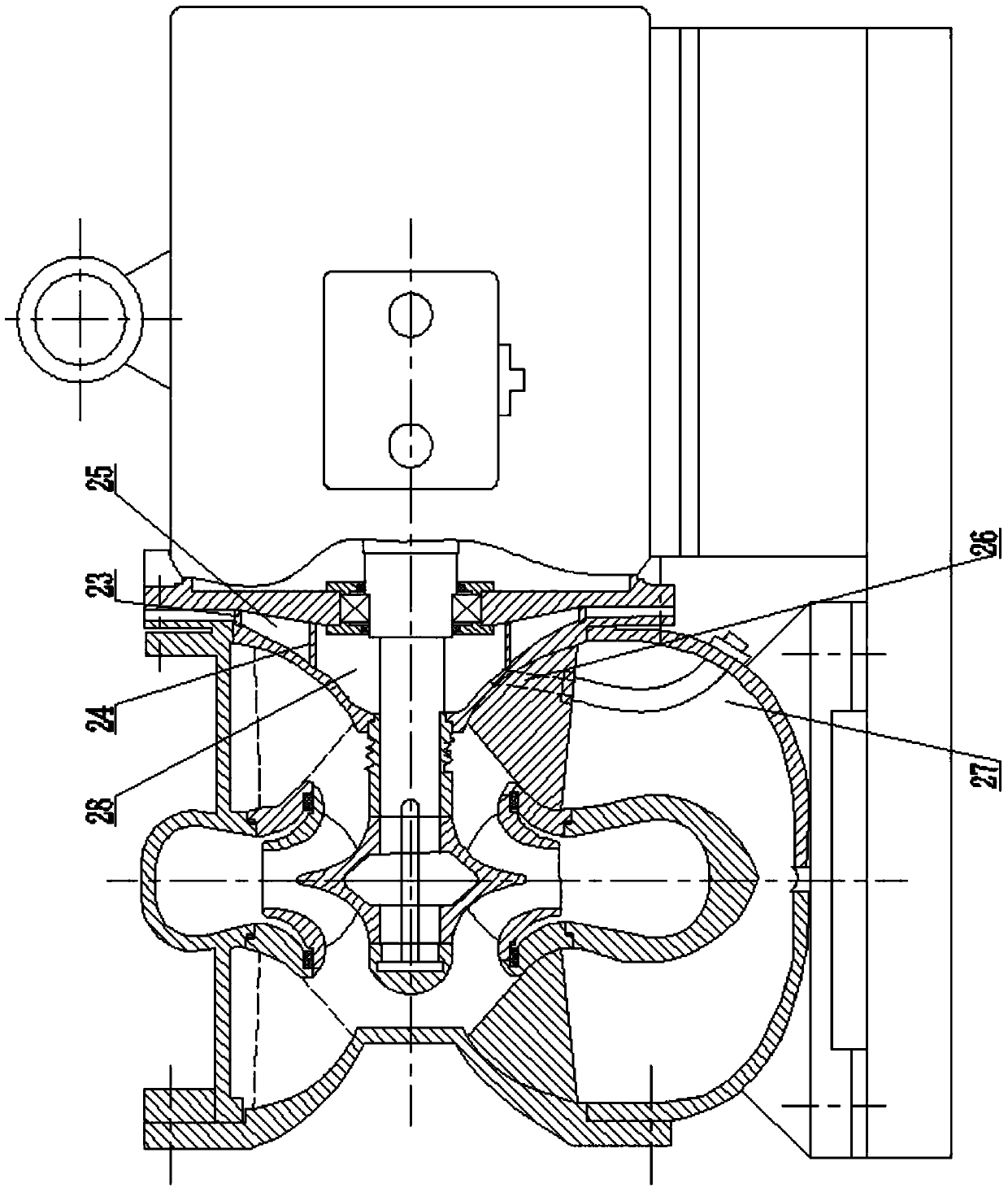

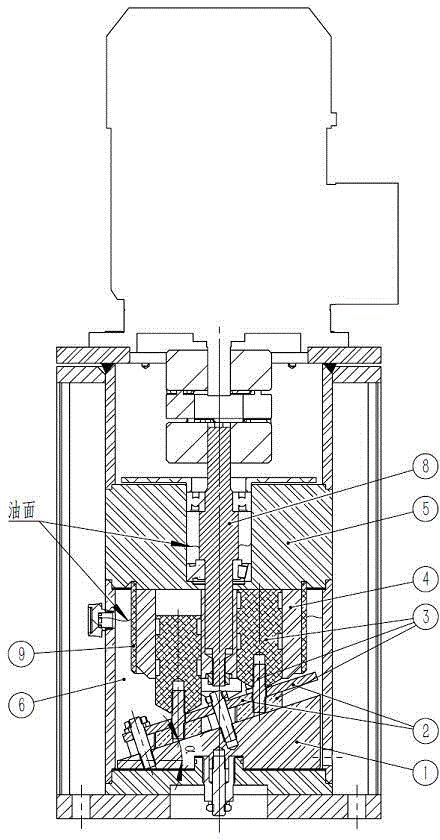

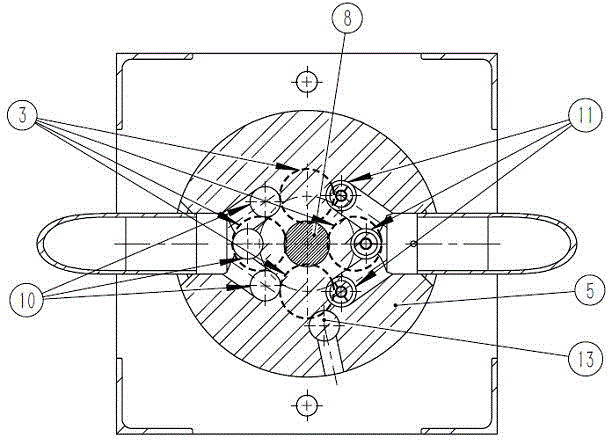

High-efficiency rotary reciprocating plunger vacuum pump

InactiveCN104481836AIncrease limit speedOptimize volumePositive displacement pump componentsMulti-stage pumpsExhaust valveReciprocating motion

The invention provides a high-efficiency rotary reciprocating plunger vacuum pump. The vacuum pump comprises a tilting disk, a plunger limiting device, a plunger component, a cylinder body, an air distribution disk, vacuum pump oil, an exhaust valve, an air inlet and an exhaust hole, wherein the cylinder body rotates; the plunger component rotates along the circumferential direction of the cylinder body under the combined action of the tilting disk, the plunger limiting device and the cylinder body and reciprocally moves along the axial direction of the cylinder body; air is sucked from the air inlet through the air distribution disk under the sealing effect of the vacuum pump oil and is discharged from the exhaust hole through an exhaust valve. The reciprocating vacuum pump has the advantages of small clearance volume, high pumping efficiency, low ultimate pressure, capabilities of realizing higher pump limit speed and realizing direct connection with a motor, small size and light weight.

Owner:付家全

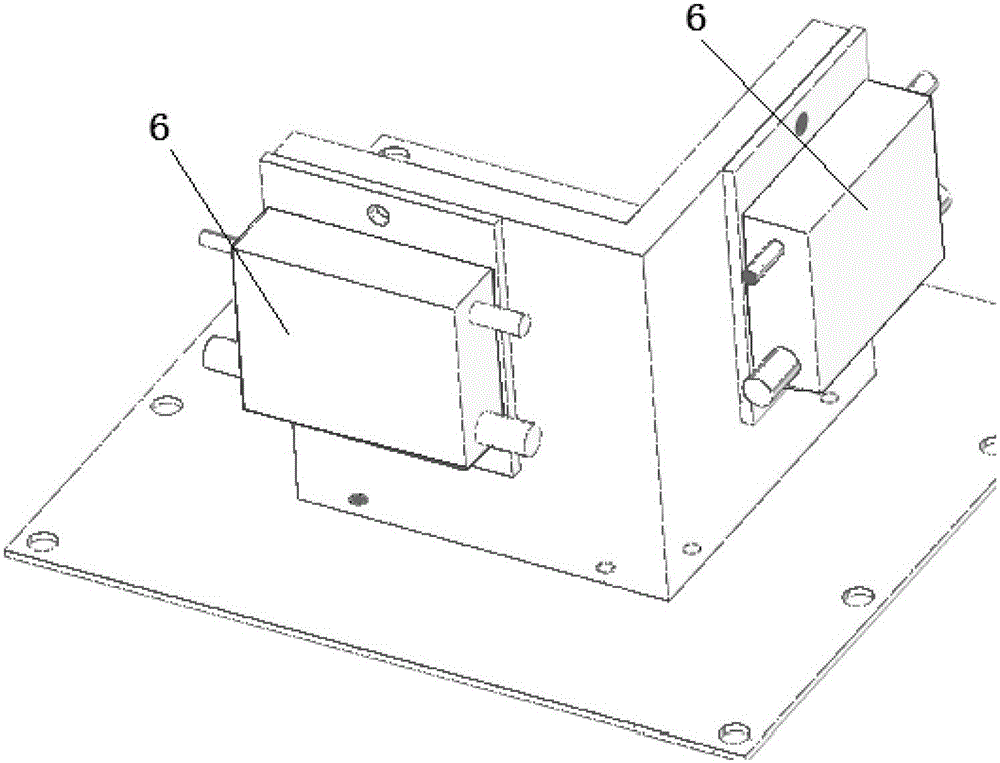

Optical Fiber Angle Sensor with Temperature Compensation for Tower Horizontal Angle Measurement

ActiveCN103245304BSolve technical problems that are difficult to maintain in the later periodHigh measurement accuracyUsing optical meansFiberGrating

The invention discloses an angle sensor provided with temperature compensation fibers and used for measuring a level angle of a pole tower. The angle sensor comprises a sensor packaging casing, a base plate, a platy swing arm, a swing hammer, a first jackscrew and a second jackscrew, wherein the base plate is fixedly connected to the top of the sensor packaging casing; one end of the platy swing arm is fixed on the base plate; the swing hammer is fixed at the other end of the platy swing arm; the first jackscrew is arranged on the left side of the sensor packaging casing and corresponds to one end of the swing hammer; the second jackscrew is arranged on the right side of the sensor packaging casing and corresponds to the other end of the swing hammer; strain detection optical fiber Bragg gratings are attached in the length direction of the platy swing arm; and environment temperature detection optical fiber Bragg gratings are in series connection with the strain detection optical fiber Bragg gratings. According to the angle sensor, high-precision level angle measurement of the pole tower can be realized and is not affected by an electric field or the environment temperature.

Owner:STATE GRID CORP OF CHINA +2

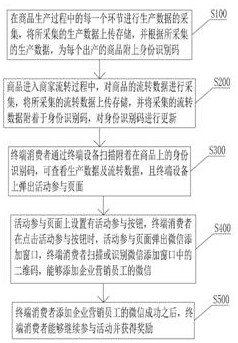

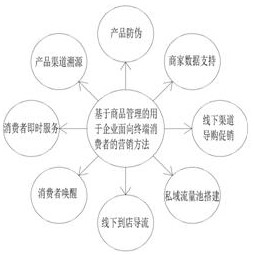

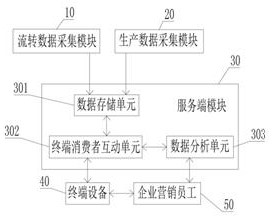

A terminal consumer-oriented marketing method and system for an enterprise based on commodity management

PendingCN114092114AEfficient acquisitionAccurate and effective marketing servicesCo-operative working arrangementsBuying/selling/leasing transactionsBusiness enterpriseIdentity recognition

The invention belongs to the technical field of commodity marketing, and particularly relates to a terminal consumer-oriented marketing method and system for an enterprise based on commodity management. According to the terminal consumer-oriented marketing method and system for an enterprise based on commodity management, commodity information tracing can be carried out; the terminal consumer is motivated to know the authenticity of the commodity and the data of the commodity production and transfer process, so that the terminal consumer is willing to scan the identity identification code on the commodity to further participate in the activity initiated by the enterprise; in this way, the information of the terminal consumer can be effectively obtained, and the obtained information of the terminal consumer is more effective; according to the invention, data support can be provided for later marketing; the enterprise is effectively helped to solve the problems of product anti-counterfeiting, channel traceability, merchant data support, consumer instant service, offline channel shopping guide and promotion, terminal consumer wakeup, offline store flow guidance, merchant private domain flow pool construction and the like; and accurate and effective marketing services are provided for enterprises.

Owner:头号网络科技(沈阳)有限公司

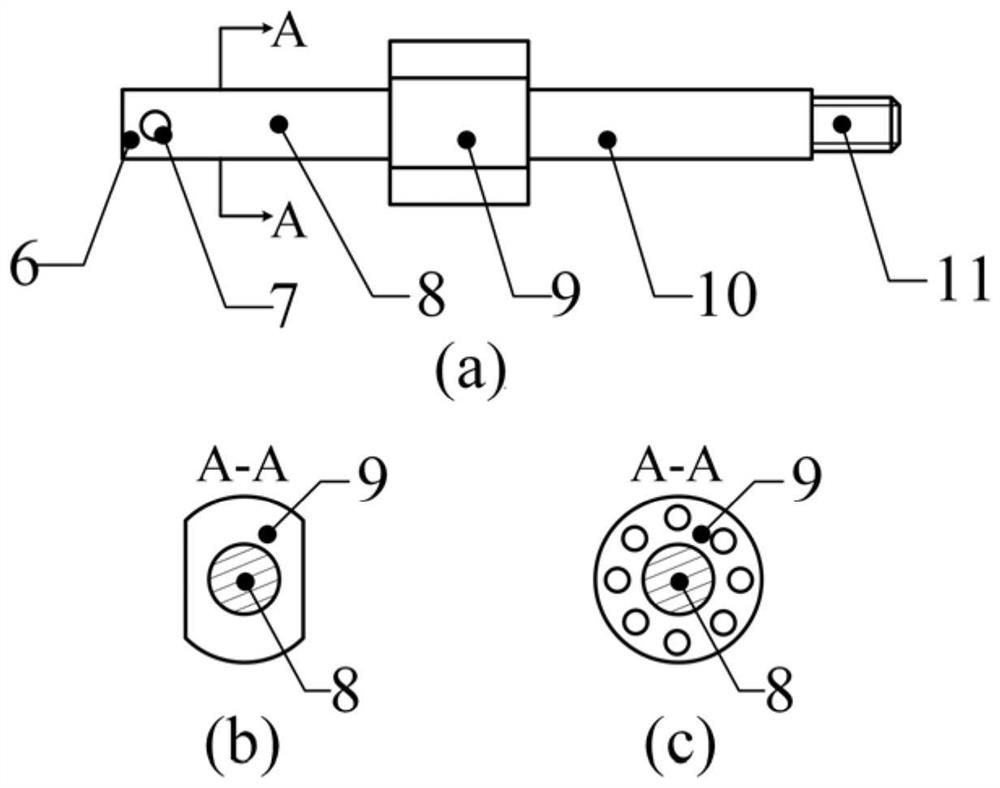

Micro-miniature linear scavenging device

ActiveCN113685265ASimple structureImprove reliabilityInternal combustion piston enginesCylinder headsMechanical engineeringGas mixing

The invention discloses a micro-miniature linear scavenging device which comprises a linear scavenging box body and a piston air distribution valve element assembly, a linear scavenging box cavity is formed in the left end of the linear scavenging box body, a rod piece matching hole communicating with the linear scavenging box cavity is formed in the right end of the linear scavenging box body, and an oil-gas mixing channel is formed in the top of the linear scavenging box body and communicates with the linear scavenging box cavity; one or more scavenging channels are arranged at the end, away from the rod piece matching hole, of the linear scavenging box cavity, and each scavenging channel penetrates through the linear scavenging box cavity to the end face matched with an external engine air cylinder; the engine air cylinder is connected to the end, wherein the one or more scavenging channels are arranged, of the linear scavenging box cavity, and each scavenging channel inclines relative to the axis of the linear scavenging box cavity and communicates with a corresponding scavenging channel in the engine air cylinder; and the piston air distribution valve element assembly is installed in the linear scavenging box cavity, one end of the piston air distribution valve element assembly extends into the rod piece matching hole, the other end of the piston air distribution valve element assembly is matched with the engine air cylinder, and an air cylinder scavenging port and an air cylinder exhaust port are formed in set positions of a power chamber of the engine air cylinder.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

A virtual router and a method for realizing the interconnection between an SDN network and a traditional IP network

ActiveCN110430114BRealize direct connectionRealize seamless interoperabilityNetworks interconnectionRouting tableEngineering

The invention discloses a virtual router, which is characterized in that: it includes an SDN controller, a kernel module, and a protocol module; The text data is encapsulated by the OF protocol through the SDN controller module, and forwarded to the corresponding interface for processing; a standard southbound interface is provided to the lower side; the kernel module: shielding the bottom layer provides a standard IP layer and interface for the operation of the upper layer protocol; and Complete the communication adaptation between the IP core message and the SDN controller; the protocol module: for processing the traditional standard router protocol, forming a corresponding routing table and forwarding table, and notifying the SDN controller through the routing engine module, The SDN controller generates flow entries according to the routing table and forwarding table, and delivers them. The invention can realize the interconnection and communication between the SDN network and the traditional network.

Owner:CHINA ELECTRONICS TECH GRP NO 7 RES INST

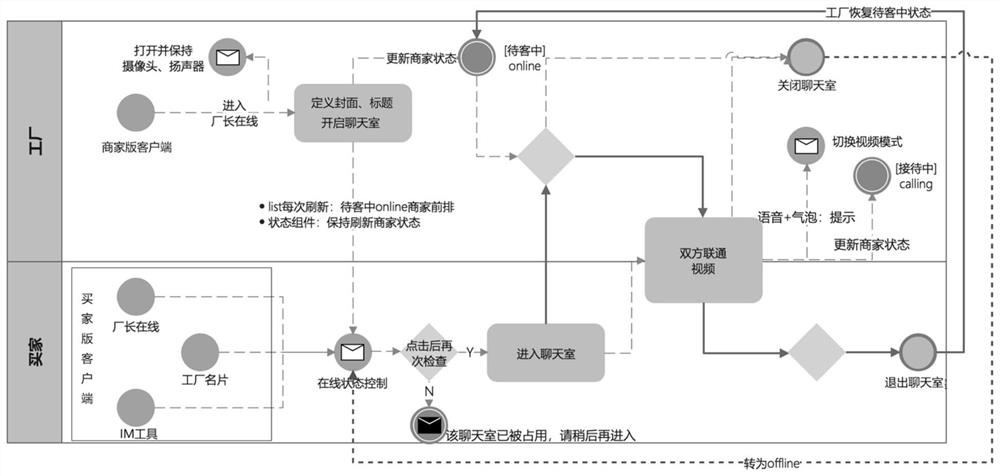

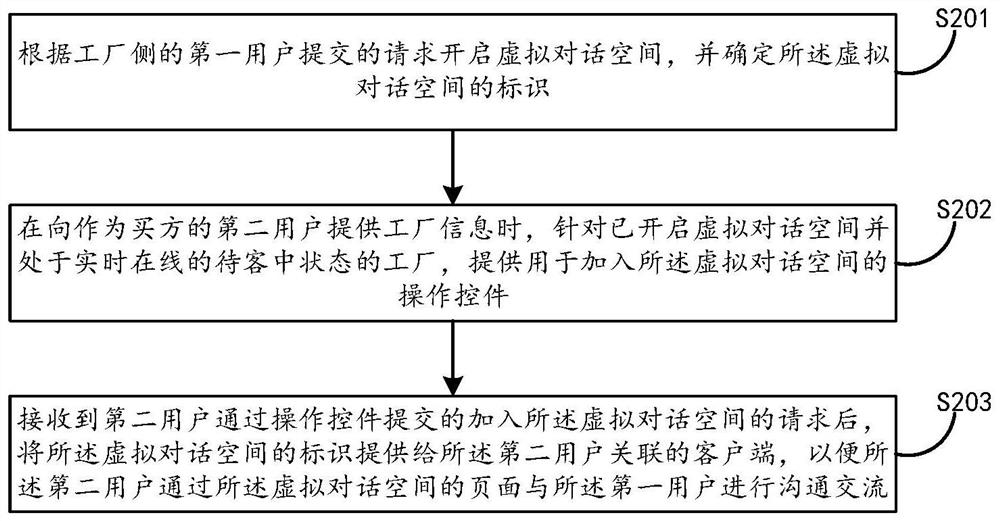

Method and device for realizing communication between users and electronic equipment

PendingCN114493740ARealize instant communicationRealize direct connectionBuying/selling/leasing transactionsTransmissionHuman–computer interactionElectronic equipment

The embodiment of the invention discloses a method and device for achieving communication between users and electronic equipment, and the method comprises the steps: opening a virtual dialogue space according to a request submitted by a first user at a factory side, and determining an identifier of the virtual dialogue space; when factory information is provided for a second user serving as a buyer, an operation control used for joining in a virtual dialogue space is provided for a factory which has opened the virtual dialogue space and is in a real-time online guest service state; and after a request for joining the virtual dialogue space submitted by a second user through an operation control is received, providing an identifier of the virtual dialogue space for a client associated with the second user, so that the second user communicates with the first user through a page of the virtual dialogue space. According to the embodiment of the invention, the communication requirements of the supplier and the demander in the B2B mode can be better met.

Owner:ALIBABA (CHINA) CO LTD

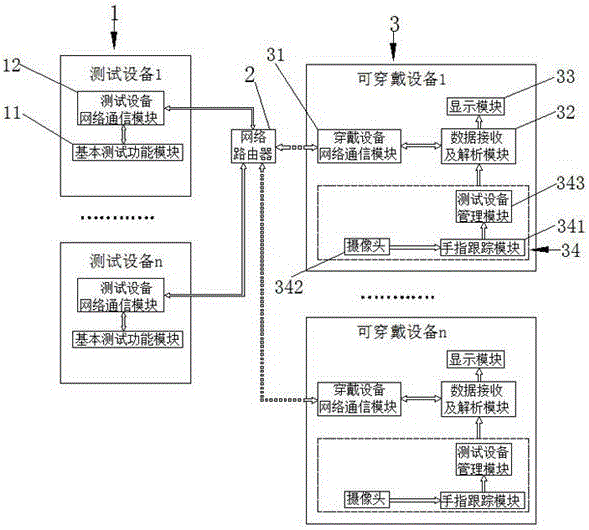

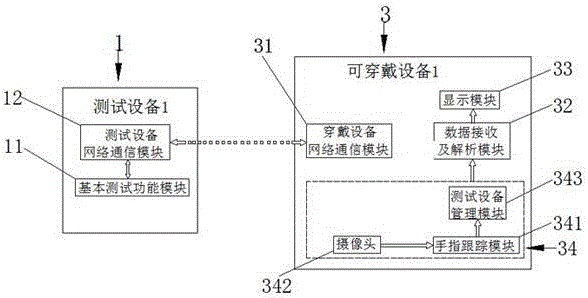

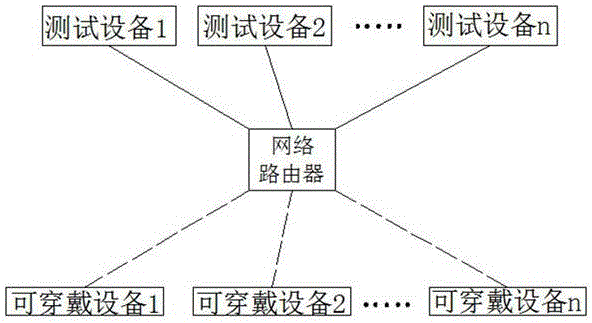

Testing system integrated with wearable devices and operation method thereof

ActiveCN105890647AImprove test efficiencyImprove maintenance efficiencyInput/output for user-computer interactionMeasurement devicesComputer moduleNetwork communication

The invention relates to a testing system integrated with wearable devices and an operation method thereof. The system comprises at least one testing device, a network router and at least one wearable device which are in communication connection sequentially, wherein the testing device comprises a basic testing function module and a testing device network communication module; the basic testing function module extracts information of a device identifier, a measurement item, measurement data and a device state, and the information is transmitted to the network router via the testing device network communication module; and the wearable device comprises a wearable device network communication module, a data receiving and analyzing module, a display module and an operation information input module. Various measurement data of the multiple testing devices can be displayed on the wearable device worn by the operator, the operator can call and switch specific measurement data according to finger actions at any time and at any place, and the operation condition of each device can be monitored.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method, device and system for web game interaction

ActiveCN104065692BRealize direct connectionImplement resourcesVideo gamesTransmissionData AppliedInteraction method

Methods, apparatus, and systems for webgame interactions are provided. A first terminal sends a request for establishing a P2P channel to a second browser, when the first browser logs in to a webgame application on the first terminal. The P2P channel is established between the first browser and the second browser, after the first browser receives an accepting response to the request for establishing the P2P channel from the second browser. The first browser uses the P2P channel to transmit webgame application data between the first browser and the second browser. An exemplary browser can include a requesting module, an establishing module, and a processing module. Another exemplary browser can include a receiving module, an obtaining module, a responding module, an establishing module, and a processing module.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com