Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Precise control of processing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

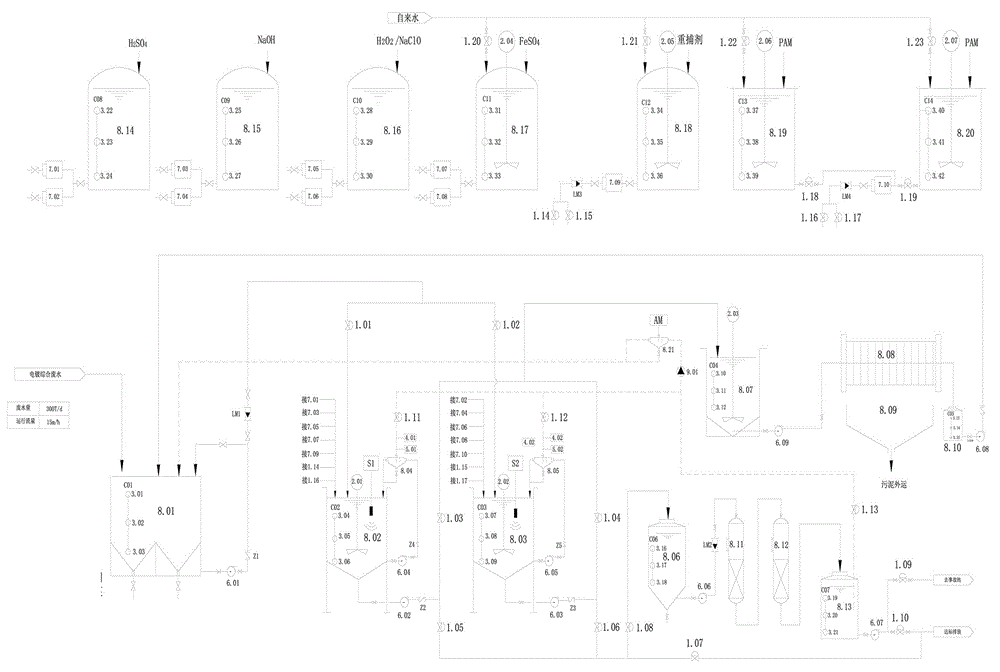

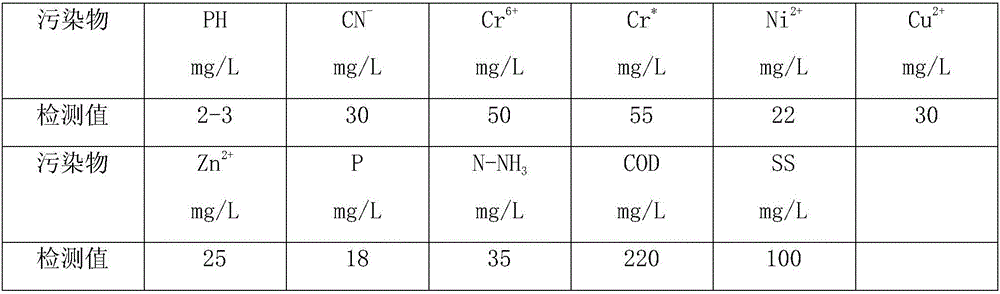

Intelligent treatment device for electroplating synthetical wastewater and control method thereof

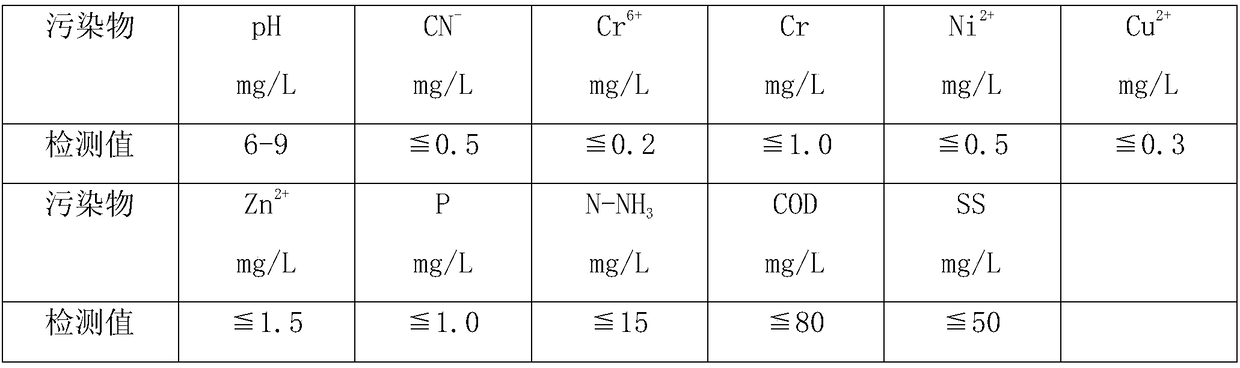

ActiveCN106277427AEnter in time automaticallyShorten water intake timeWater treatment parameter controlWater contaminantsTreatment effectPh regulation

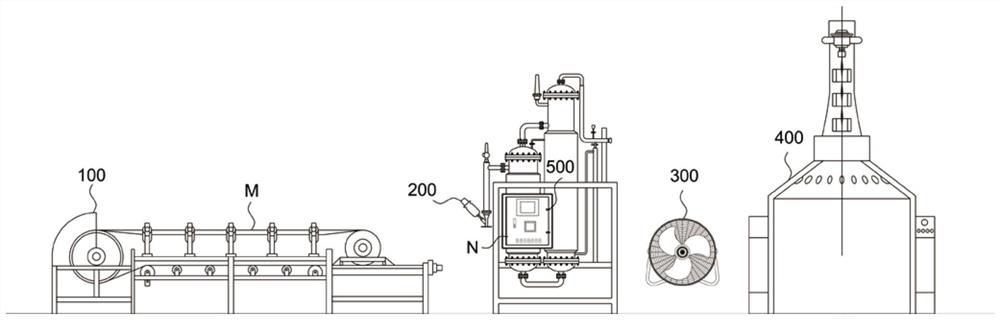

The invention relates to an intelligent control technology for electroplating synthetical wastewater, wherein through the steps of pH regulation of wastewater, oxidation, reduction, Cr<6+> filtering, heavy metal capture, settling of suspended solids, ion exchange and sludge treatment, the intelligent synthetical treatment of electroplating wastewater is realized, and the technology has the characteristics of high automation degree and good treatment effect. In the invention, the treatment process is finished by a sequencing bath method in a reactor, two or more reactors alternate to realize timely accurate dosing in the wastewater treatment process as well as real-time detection and control before discharge, the stability, reliability and economy of the wastewater treatment quality are guaranteed, and the wastewater treatment stably meets the requirements of the Discharge Standard for Electroplating Pollutants (GB21900-2008); furthermore, the intelligent unmanned operation can accurately control the wastewater treatment time, the drug adding amount and the wastewater treatment quality, so that the volume of the wastewater treatment equipment is reduced, and the treatment cost is lowered.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

Water glass waste sand regeneration treatment method used for casting

InactiveCN106040968AHigh removal rateResidue reductionMould handling/dressing devicesLiquid wasteNitrogen

The invention relates to a water glass waste sand regeneration treatment method used for casting. The water glass waste sand regeneration treatment method comprises the following steps that (1) waste sand is pretreated; (2) the pretreated sand in the step (1) is put into a high-temperature furnace and treated for 10-15 min at the temperature of 523 DEG C-525 DEG C, the mixed gas of nitrogen and oxygen is introduced into the high-temperature furnace in the treatment process, the introducing speed of the mixed gas is 0.85-0.9 m<3> / min, and secondary treatment sand is obtained; and (3) the secondary treatment sand is subjected to magnetic separation through a magnetic separator, the secondary treatment sand subjected to magnetic separation treatment is crushed, passes a 60-mesh screen and is then washed, and the washed secondary treatment sand is dried at the temperature of 55 DEG C, so that regenerated sand is obtained. The residual quantity of Na2O treated through the water glass waste sand regeneration treatment method is reduced to about 0.05%, the treated waste sand can be again used as new sand, and waste liquid treated through the method can be recycled, so that the treatment cost is reduced.

Owner:HEFEI CITY TENVER PRECISION CASTING

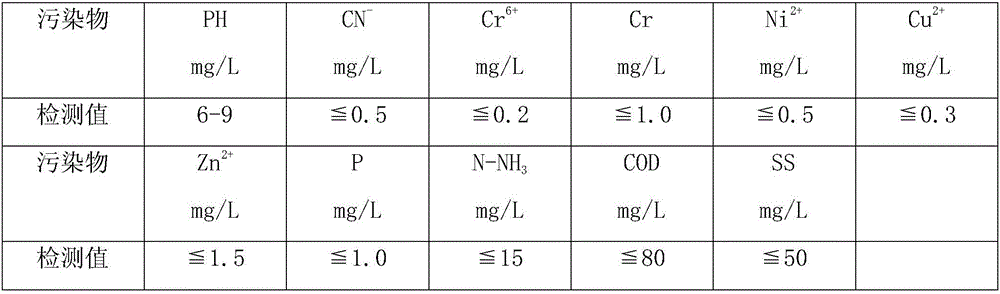

Ozone concentration intelligent measurement and control apparatus for fruit and vegetable cold storage and environment space

ActiveCN105468041AGuaranteed qualityAutomatic and precise control of concentrationControlling ratio of multiple fluid flowsOzone generatorEngineering

The invention provides an ozone concentration intelligent measurement and control apparatus for a fruit and vegetable cold storage and an environment space. The apparatus comprises three main parts, namely a two-wire system ozone transmitter; a system control box consists of an intelligent measurement and control instrument, a micro computer time control switch, a solid state relay and a 24V DC source; and an ozone generator. The two-wire system ozone transmitter is installed in the fruit and vegetable cold storage and the environment space; the ozone concentration change inside the cold storage is converted to 4-20 milliampere current change and is output to the intelligent measurement and control instrument by exchanging the ozone sensor on the two-wire system ozone transmitter with the gas inside the fruit and vegetable cold storage, and then compared with a parameter set on the intelligent measurement and control instrument to emit a relay on-off signal; the micro computer time control switch can set different processing times and intervals based on requirement to connect the intelligent measurement and control instrument relay and the micro computer time control switch relay in series, so that the intelligent measurement and control instrument relay and the micro computer time control switch relay can control the on-off of the solid state relay together, and the purpose of automatically controlling the on-off of the ozone generator is realized.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

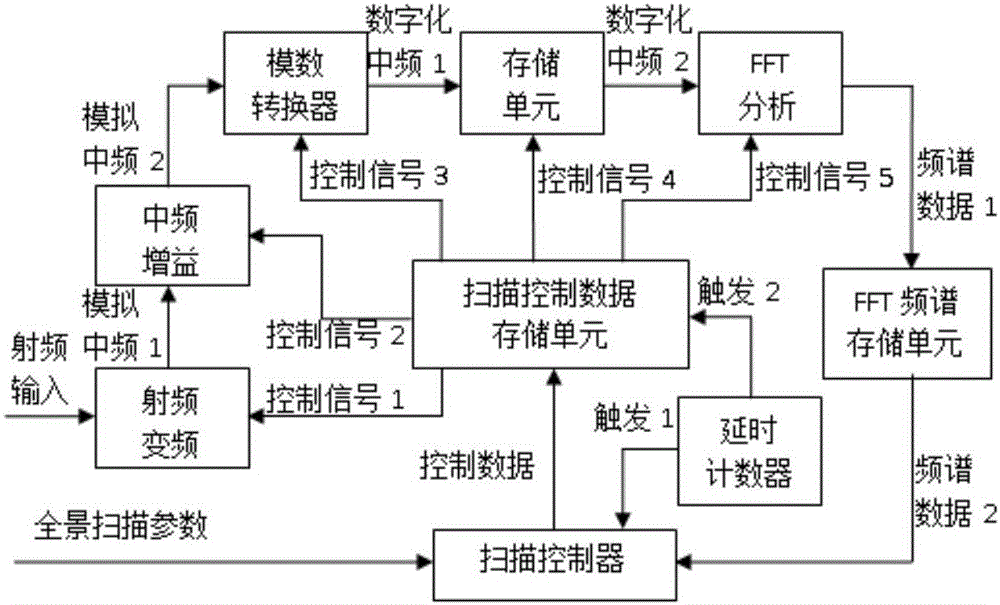

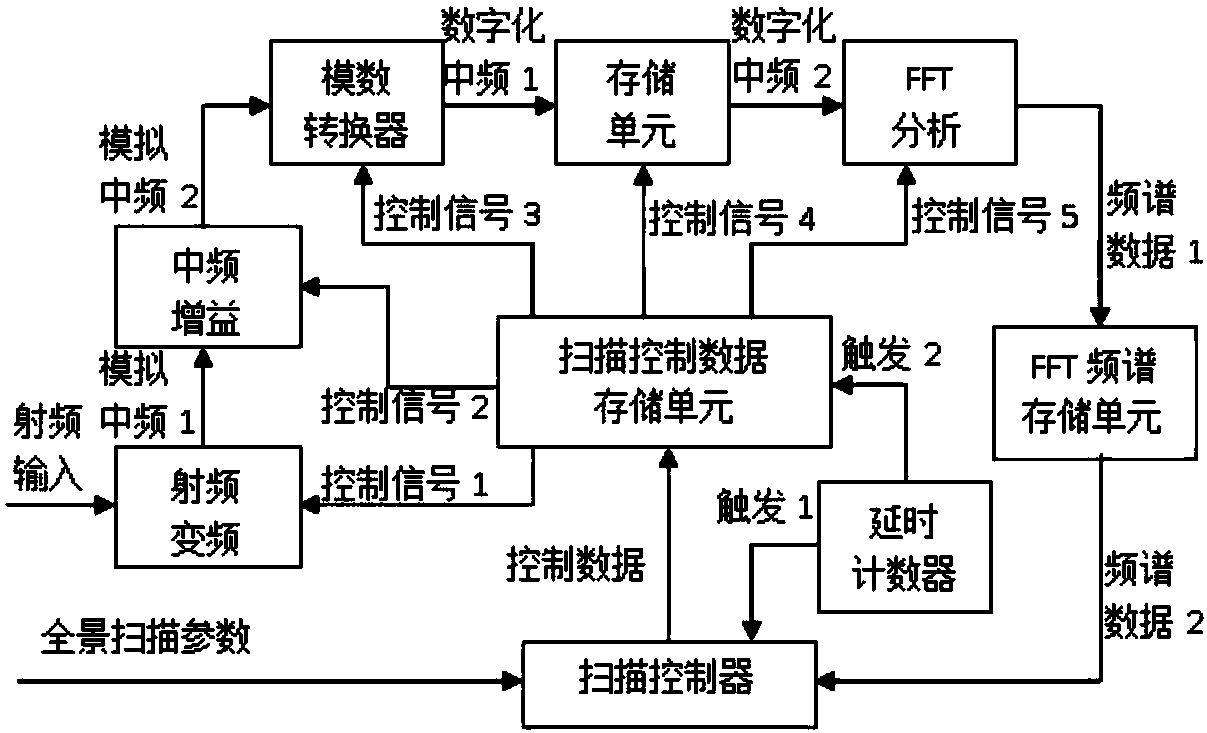

Radio frequency panoramic scanning circuit of receiver

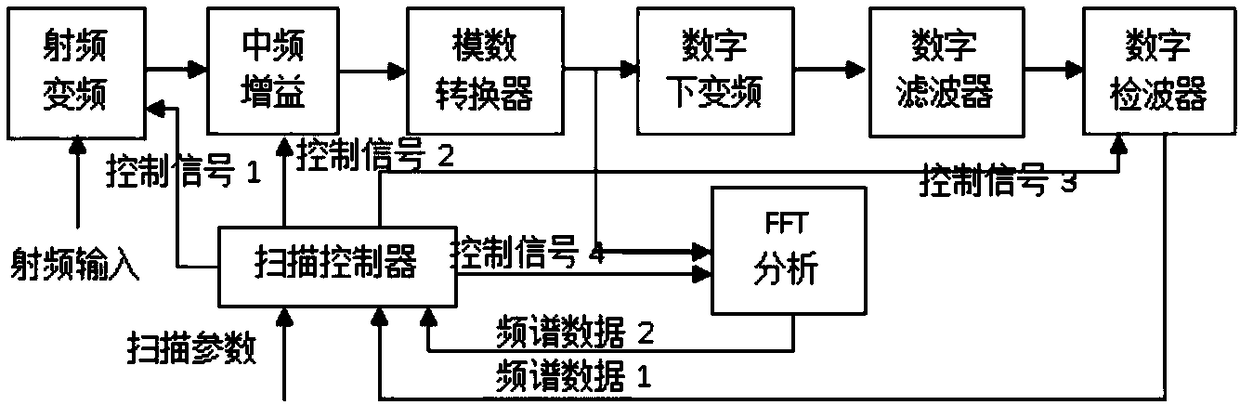

InactiveCN106374946AReduce switching timesFast scanningTransmissionFrequency spectrumImage resolution

The invention discloses a radio frequency panoramic scanning circuit of a receiver, specifically relates to the technical field of radio frequency panoramic scanning of the receiver and solves the defect that the radio frequency panoramic scanning in the prior art cannot give consideration to the scanning speed, scanning width and resolution bandwidth at the same time. The radio frequency panoramic scanning circuit of the receiver comprises a radio frequency conversion unit, an intermediate frequency gain unit, an analog to digital converter, a storage unit, an FFT analysis unit, an FFT frequency spectrum storage unit, a scanning controller, a scanning control data storage unit and a delay counter. The radio frequency conversion unit, the intermediate frequency gain unit, the analog to digital converter, the storage unit, the FFT analysis unit, the FFT frequency spectrum storage unit and the scanning controller are connected in sequence. The scanning control data storage unit is respectively connected with the radio frequency conversion unit, the intermediate frequency gain unit, the analog to digital converter, the storage unit and the FFT analysis unit. The scanning controller is connected with the scanning control data storage unit. The delay counter is connected with the scanning control data storage unit and the scanning controller.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

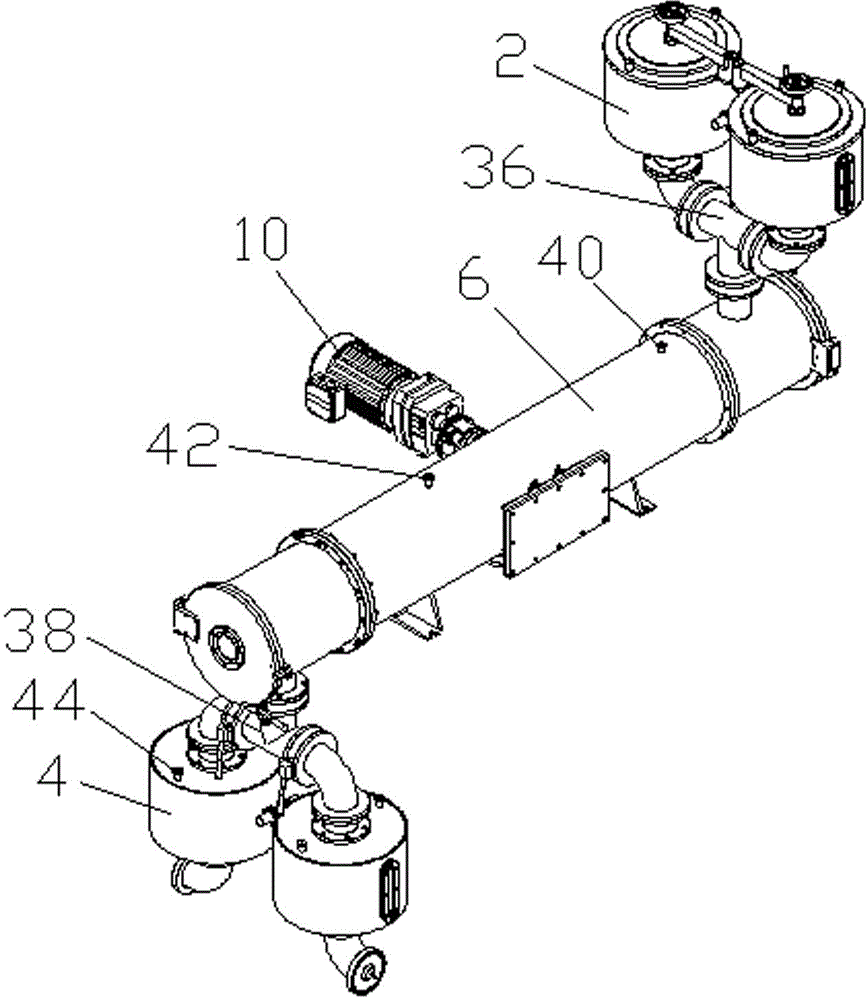

Equipment for performing modified treatment on medium and large particle seeds by using cold plasma

InactiveCN104584728AClean workspaceGuaranteed cleanlinessGerminating apparatusPhysicsRadio frequency

The invention relates to equipment for performing modified treatment on medium and large particle seeds by using cold plasma. The equipment comprises a charging barrel, a discharging barrel, and a vacuum cavity connected with the charging barrel and the discharging barrel, wherein an air exhaust is formed in the vacuum cavity and is connected with a mechanical pump; a discharge treatment device and a transfer device are arranged in the vacuum cavity; the discharge treatment device comprises two polar plates arranged in parallel and a discharge treatment radio-frequency power supply connected with the two polar plates; the distance between the two polar plates is 30-40mm; a preionization device is arranged in the vacuum cavity and comprises an electrode and a preionization radio-frequency power supply connected with the electrode; and the vacuum cavity is connected with an earth phase. According to the equipment disclosed by the invention, the preionization device is arranged in the vacuum cavity, so that the working power supply can instantaneously build up luminance, and the time needed by processing is accurately controlled; with the adoption of ionization dust removal, the working space is clean; and moreover, large-scale treatment of medium and large particle seeds with the particle size of more than 15mm can be realized under the condition that the mature process parameters are guaranteed.

Owner:虞建明 +3

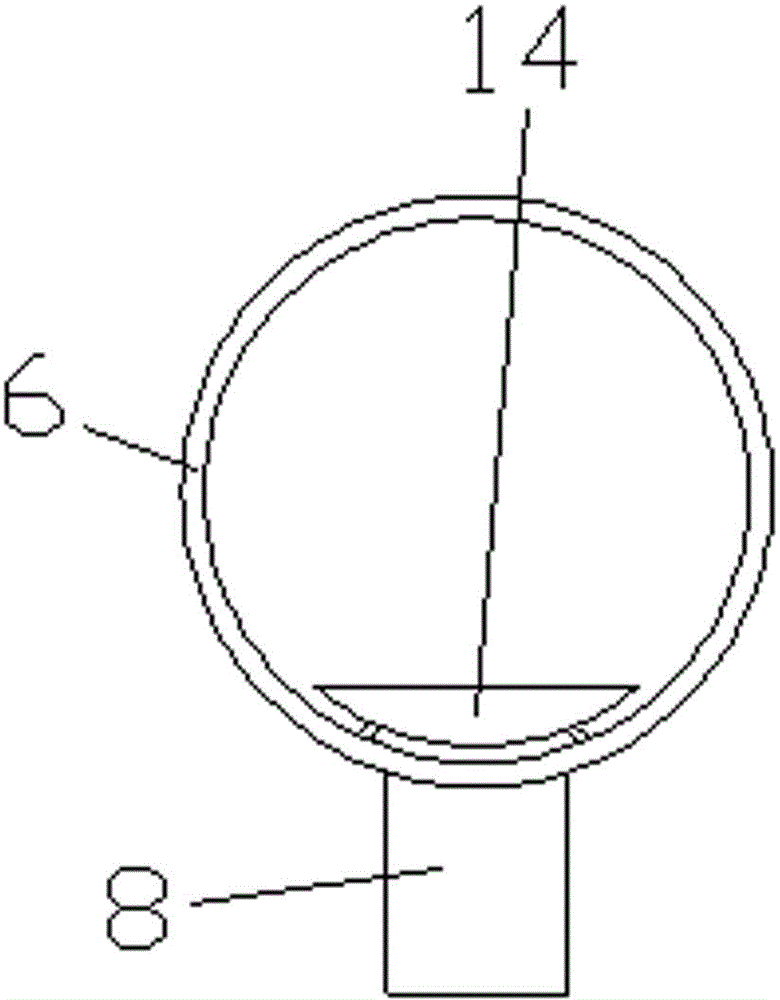

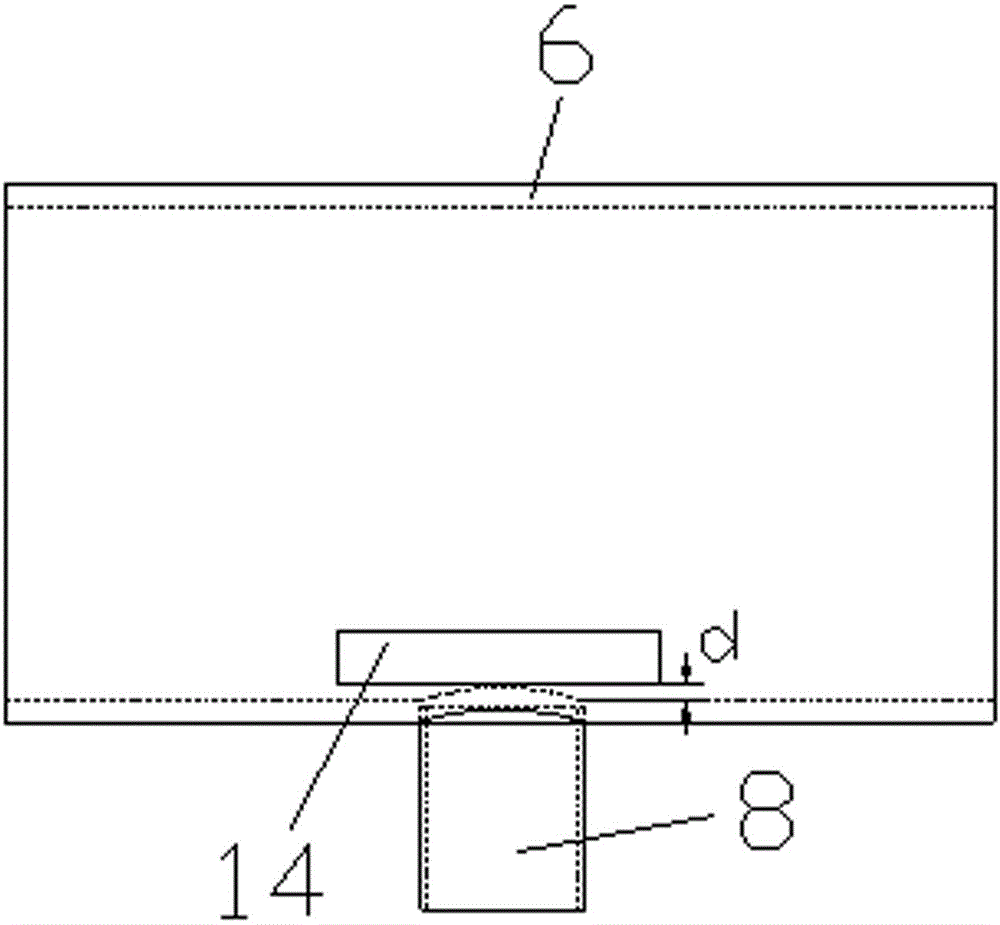

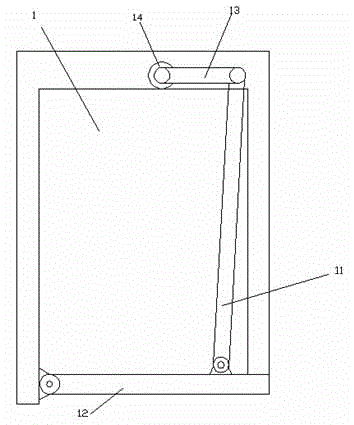

Method for carrying out heat treatment on workpiece by utilizing manually opened windows and high-temperature-resistant ceramic material

InactiveCN103642997APrecise control of processing timeAutomatically achieve automatic outputQuenching devicesTemperingElectric machinery

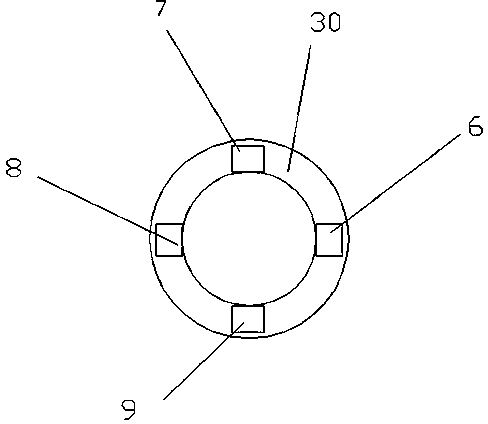

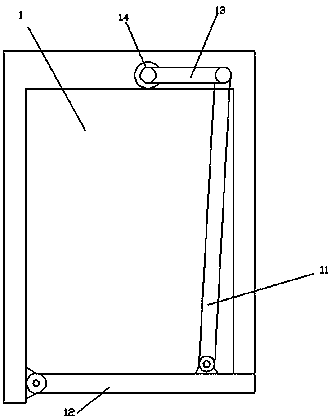

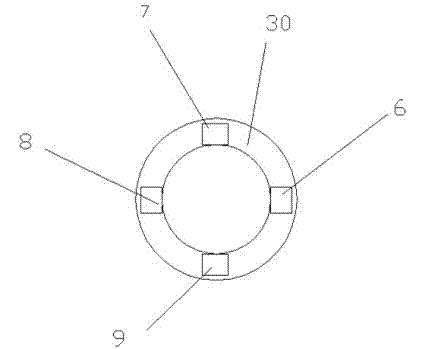

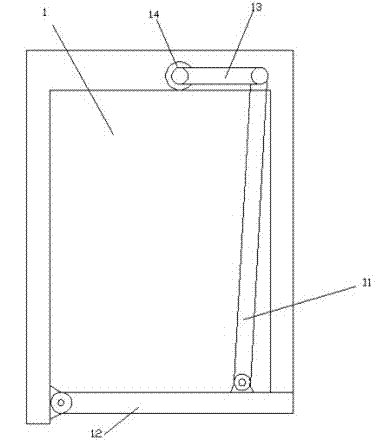

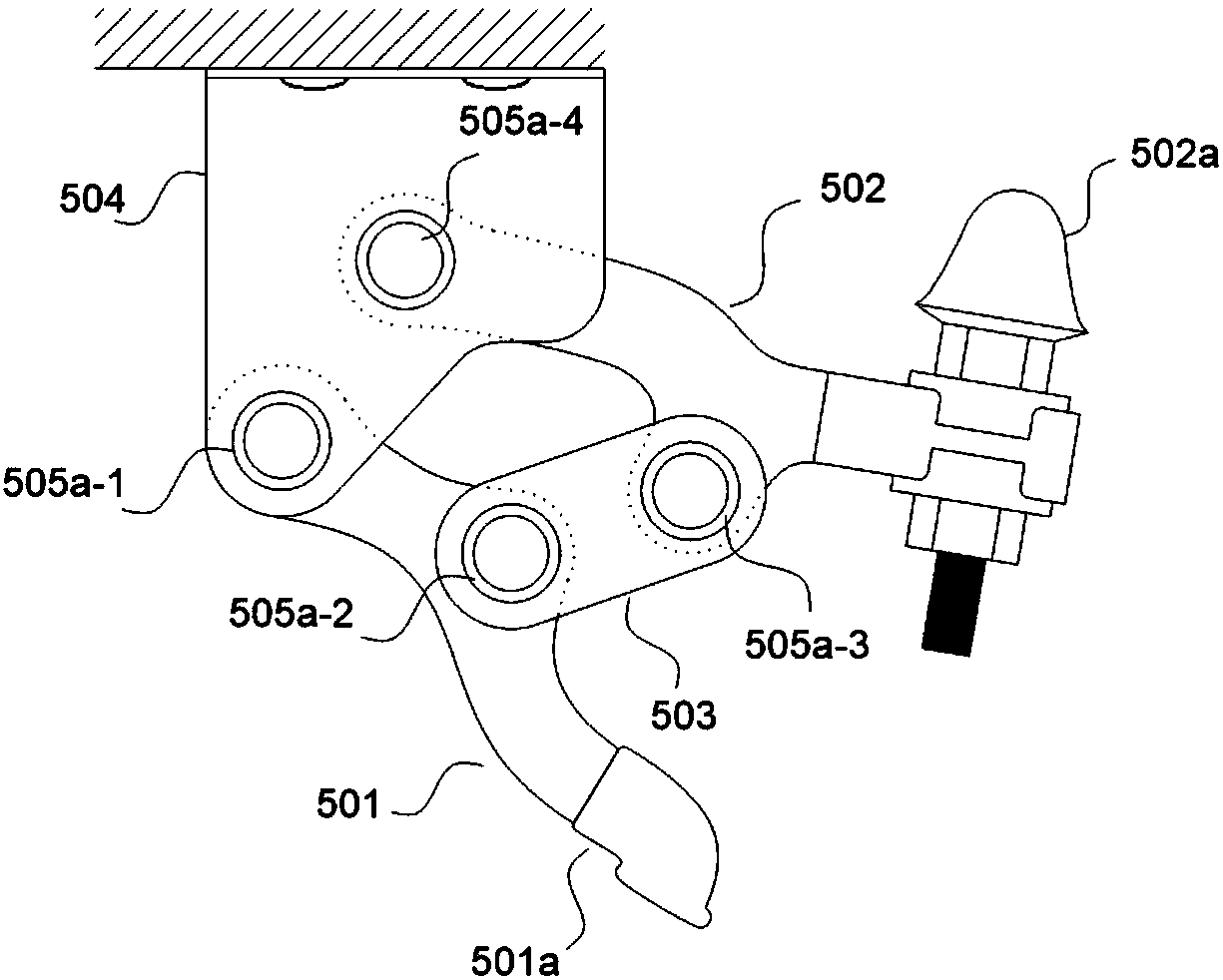

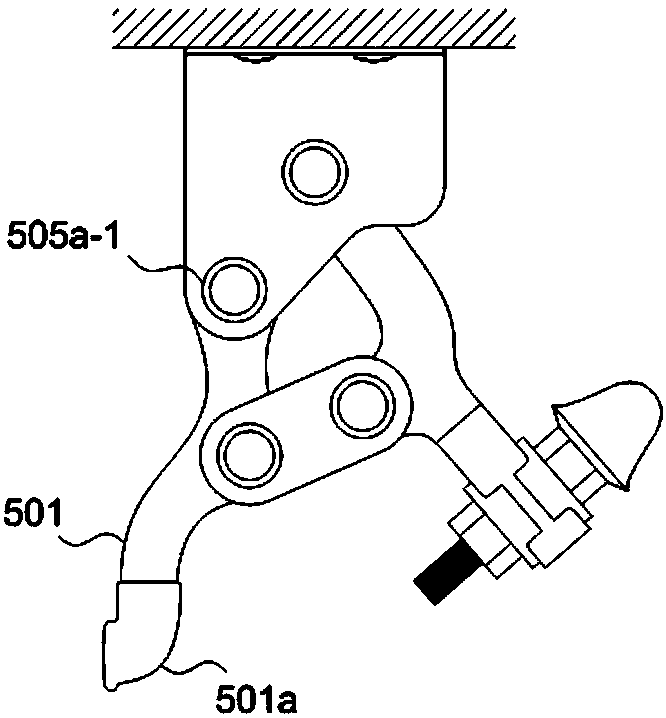

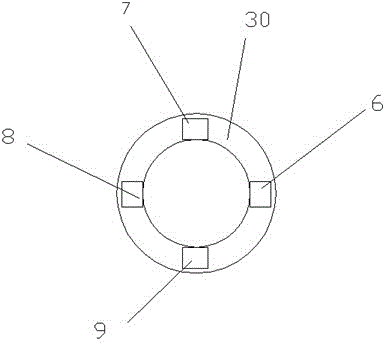

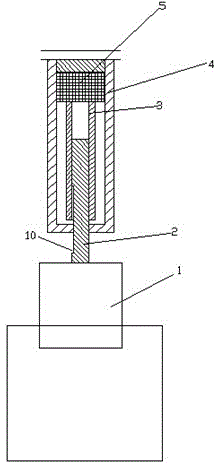

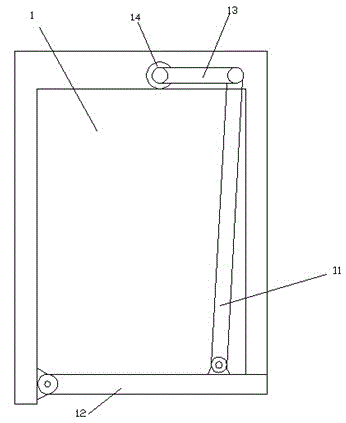

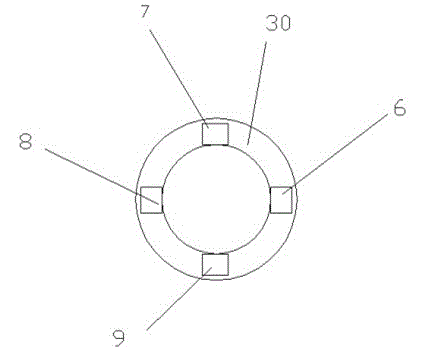

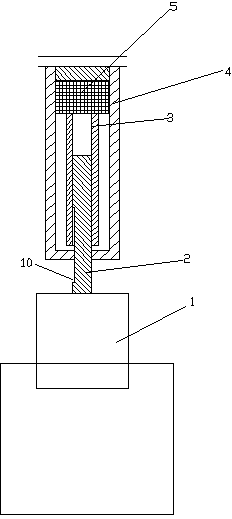

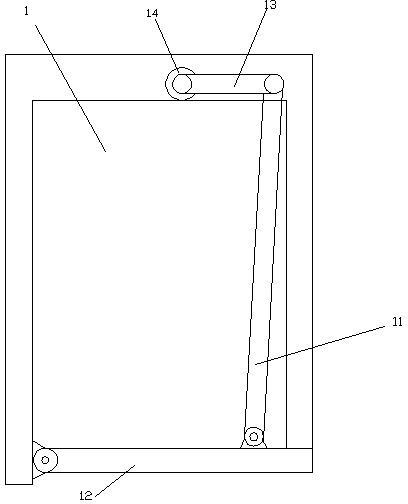

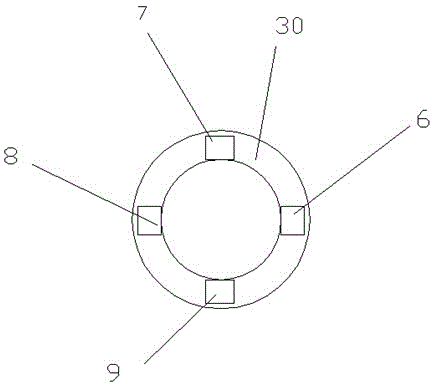

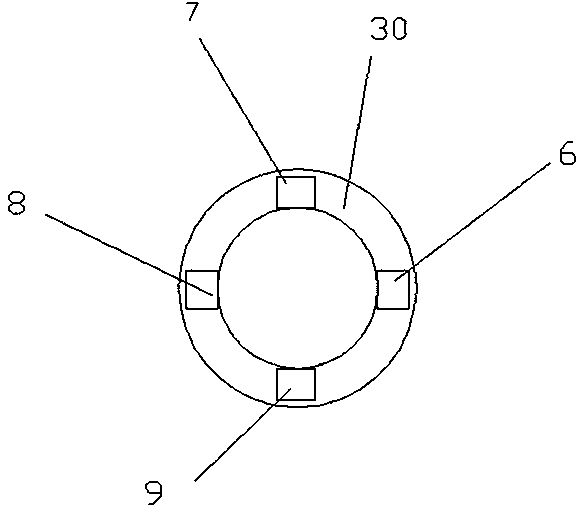

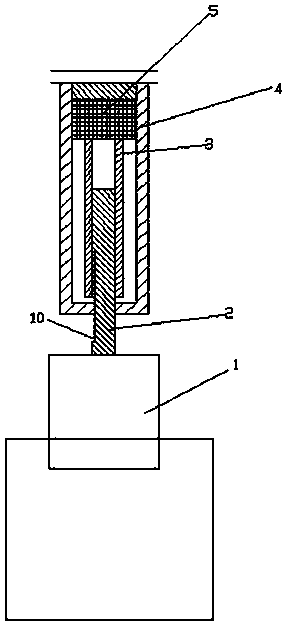

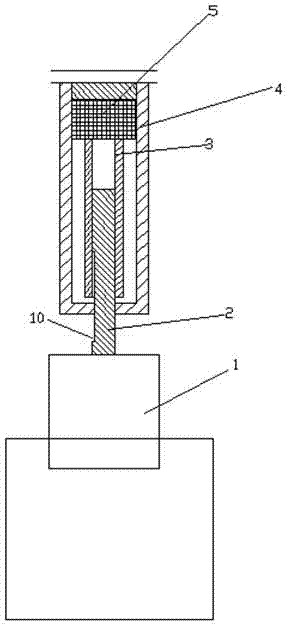

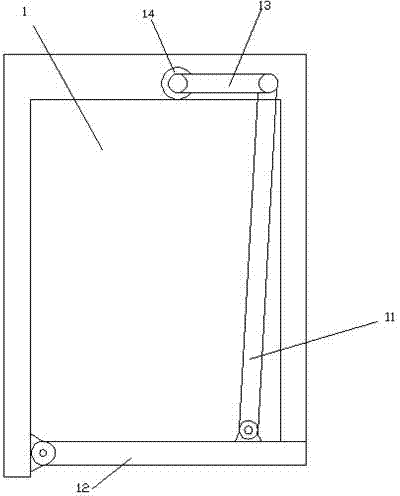

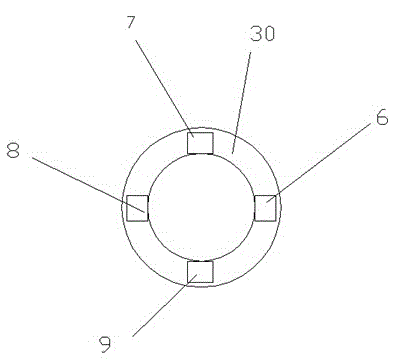

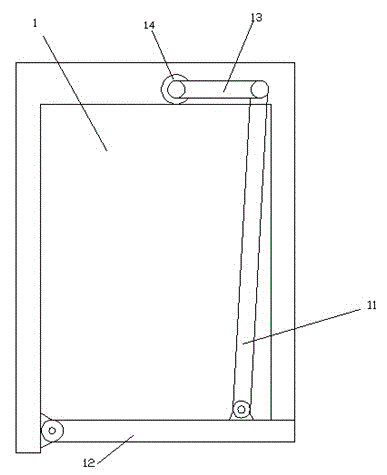

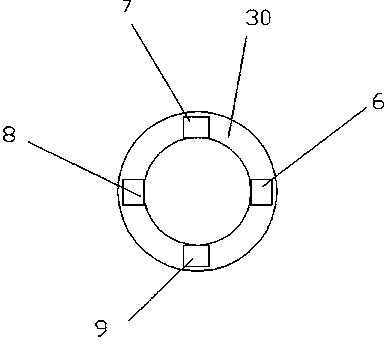

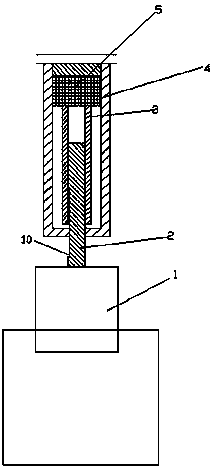

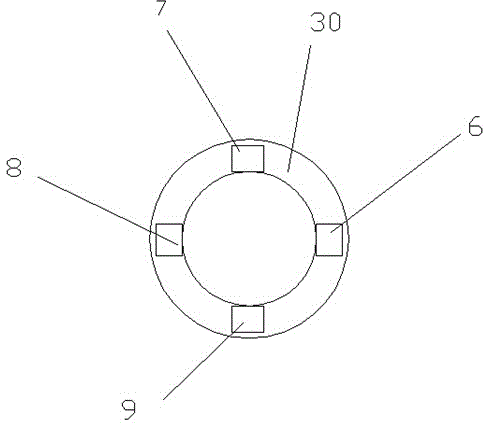

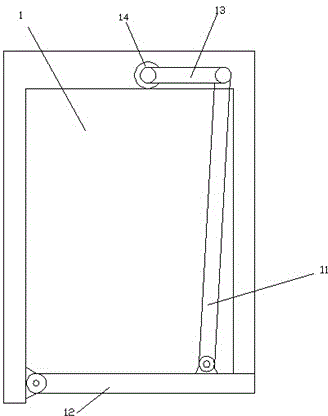

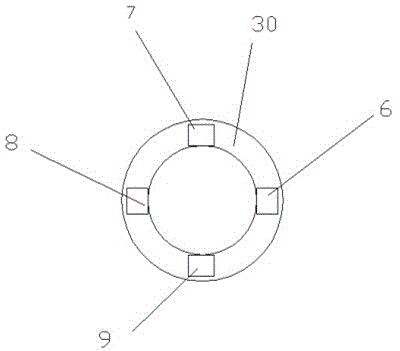

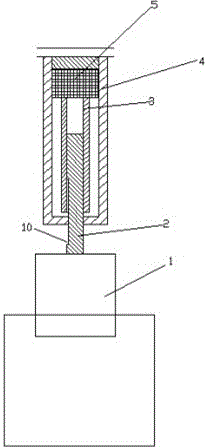

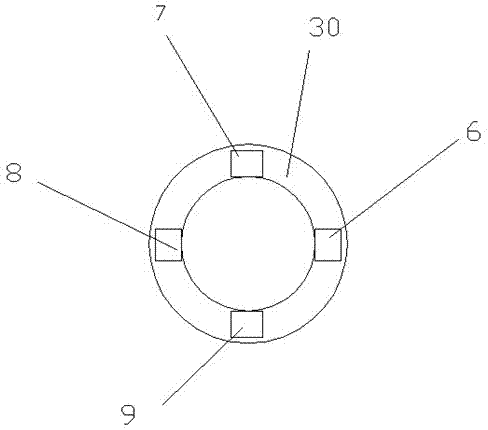

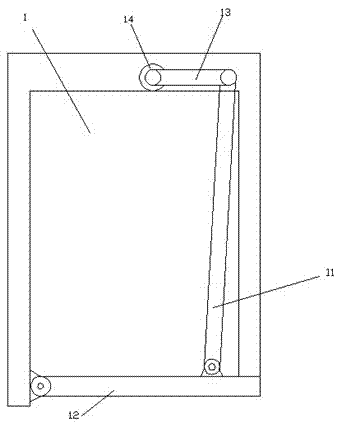

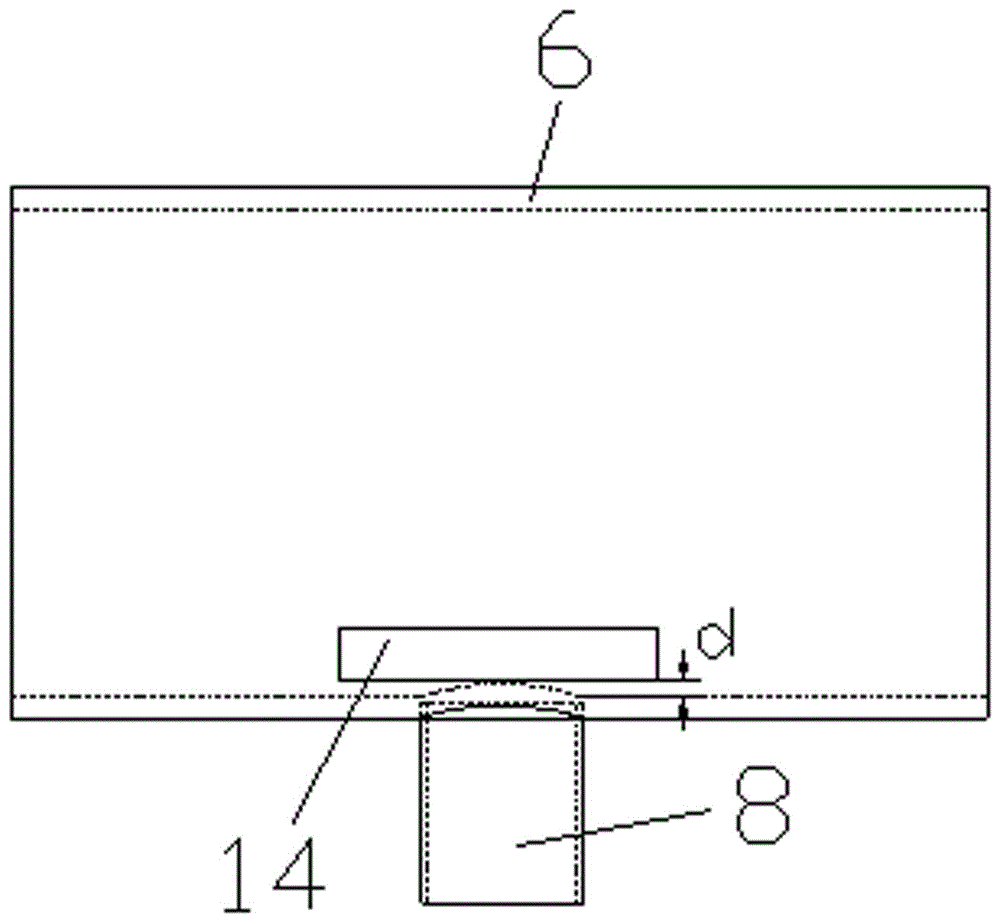

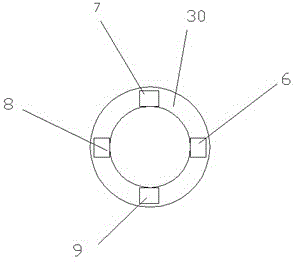

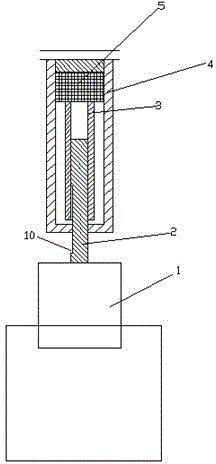

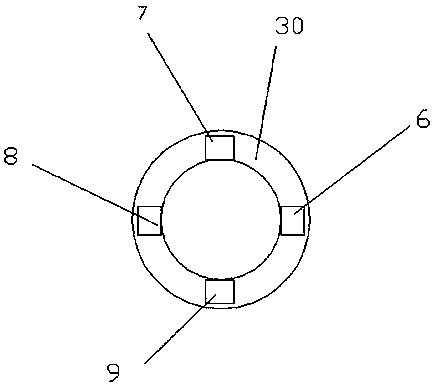

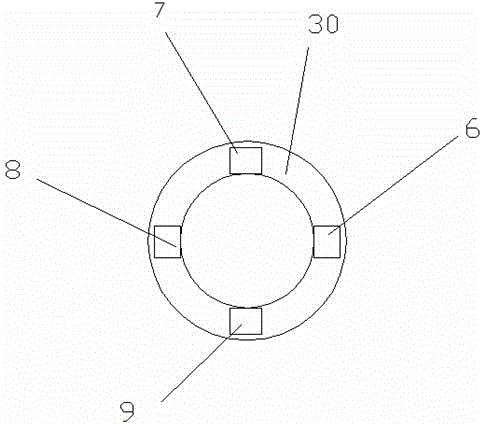

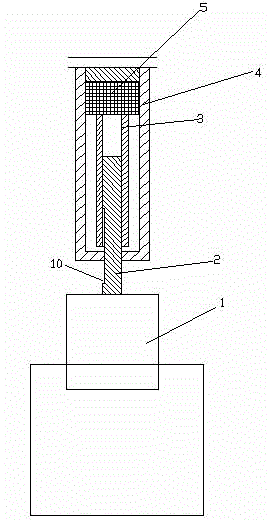

The invention provides a method for carrying out heat treatment on a workpiece by utilizing manually opened windows and a high-temperature-resistant ceramic material. In the method, a heat treatment device is used. The device comprises four container assemblies, a ring support (30), a heat treatment assembly and four lifting assemblies, wherein the heat treatment assembly comprises a heating device (6), an oil-quenching device (7), a tempering heating device (8) and a cooling loading and unloading device (9), which are uniformly arranged on the bottom of the ring support (30) along the peripheral direction of the ring support (30); each lifting assembly comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container assembly comprises a container (1) and a driving assembly, and the containers (1) are used for containing the workpiece.

Owner:安徽宇测线缆质检技术有限公司

Workpiece heat treating method

ActiveCN103667621APrecise control of processing timeAutomatically achieve automatic outputMechanical engineeringHeat treating

The invention provides a workpiece heat treating method utilizing a position signal reading device and a manually opening window. In the method, a heat treating device is used, the heat treating device comprises four container components, a ring-shaped support (30), a heat treating component and four lifting component, wherein the heat treating component comprises a heating device (6), an oil-quenching device (7), a temper heating device (8) and a cooling and demounting device (9), and all the devices are evenly arranged at the bottom of the ring-shaped support (30) in the peripheral direction of the ring-shaped support (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component, and the container (1) is used for accommodating workpieces.

Owner:安徽宇测线缆质检技术有限公司

Method for degrading aflatoxin of peanuts

ActiveCN107625028AAvoid over processingPrecise control of processing timeFood scienceAflatoxin degradationBiology

The invention discloses a method for degrading aflatoxin of peanuts. The method comprises the following steps of cleaning peanut granules, and regulating the moisture content of the peanut granules and the temperature of the peanut granules; regulating the piling thickness of peanut granule materials to be treated, and coprocessing the peanut granule materials through ultraviolet rays and electronbeams. According to the method disclosed by the invention, the ultraviolet rays and the electron beams are in synergy, and inside and outside detoxification is performed at the same time, so that thedegradation rate of the aflatoxin is obviously increased, the equipment is convenient to operate, and the method is suitable for processing reality of enterprises.

Owner:JIANGNAN UNIV

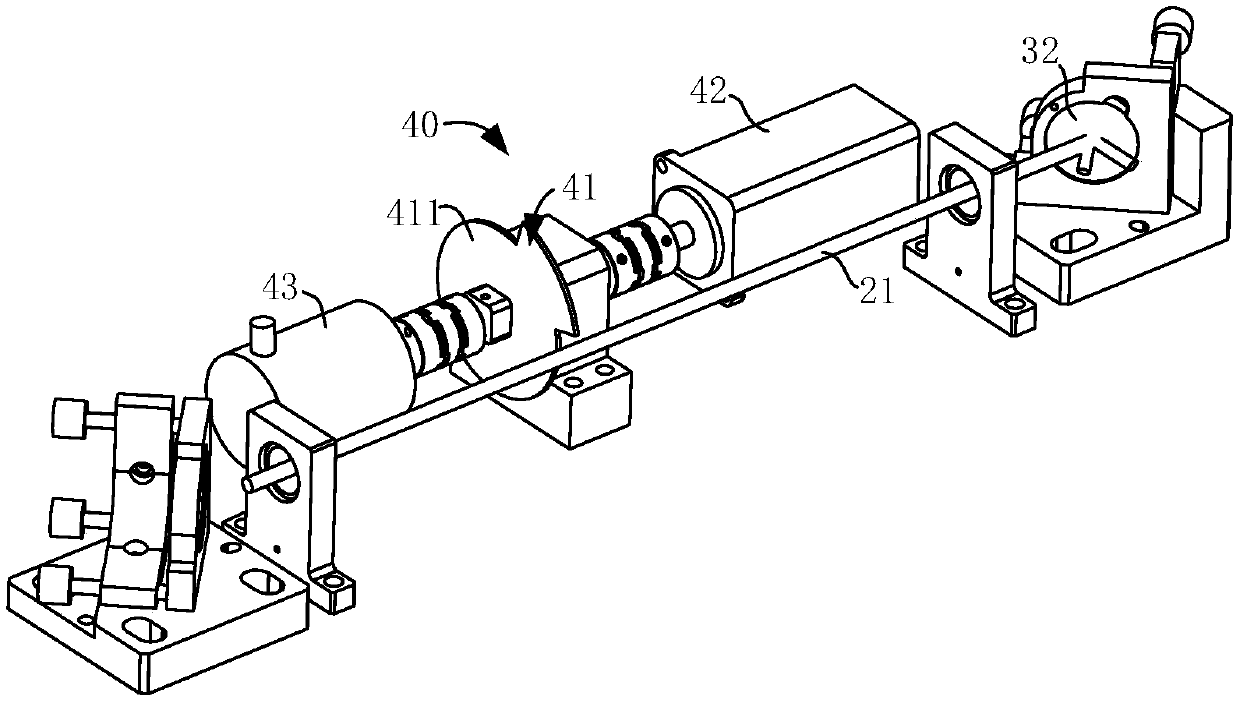

Laser processing system and laser processing method

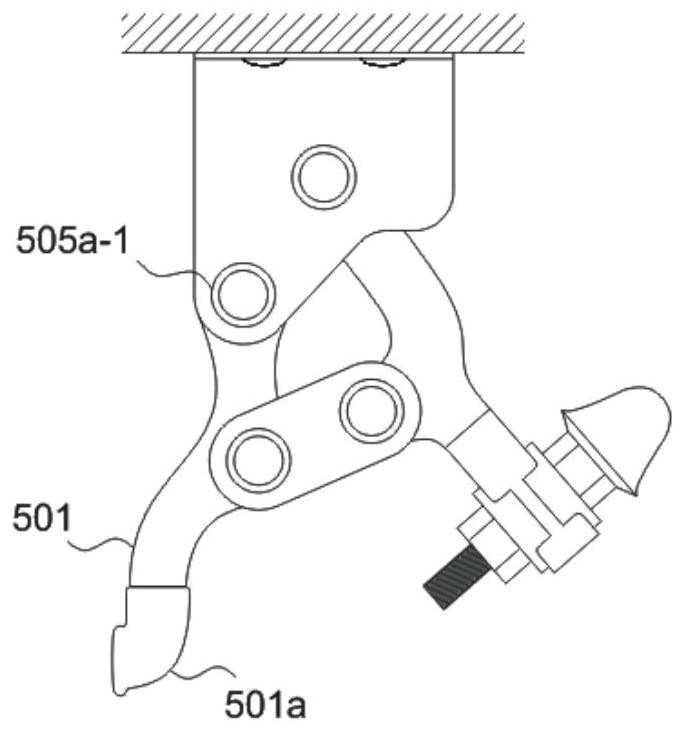

InactiveCN110919168AFlexible adjustmentFlexible processing areaLaser beam welding apparatusErbium lasersEngineering

The invention discloses a laser processing system. The laser processing system comprises a laser, an optical shutter assembly and a controller, wherein the laser is used for emitting a laser beam, andthe laser beam acts on a workpiece to be processed so as to carry out laser processing; the optical shutter assembly is arranged on the light path of the laser beam and comprises a light blocking part, and the light blocking part is rotatably arranged and used for allowing the laser beam to pass through or blocking the laser beam; and the controller controls the light blocking part to rotate so as to control the passing or blocking time of the laser beams, so that the laser beams act on the processed workpiece at intervals. The light blocking part in the optical shutter assembly is rotationally arranged and used for allowing the laser beams emitted by the laser device to pass through or be blocked, the laser beams can selectively conduct laser processing, and the processing efficiency isimproved. The time for the light blocking part to pass through or block the laser beam is achieved by controlling the light blocking part to rotate through the controller, and automation and precisionof laser processing are achieved. Meanwhile, the invention further discloses a laser processing method.

Owner:深圳市大族半导体装备科技有限公司

A workpiece heat treatment method using a circular rotating disk and three axial grooves

InactiveCN103695629BPrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlTemperingElectric machine

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Workpiece heat treating method

ActiveCN103667621BPrecise control of processing timeAutomatically achieve automatic outputElectric machineryHeat treating

Owner:安徽宇测线缆质检技术有限公司

Method for thermal treatment of workpiece by round rotating disc and contact sensor

ActiveCN103695630APrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlTemperingElectric machinery

The invention provides a method for the thermal treatment of a workpiece by a round rotating disc and a contact sensor. A thermal treatment device is used in the method. The device comprises four container assemblies, an annular bracket (30), a thermal treatment assembly and four lifting assemblies, wherein the thermal treatment assembly comprises a heating device (6), an oil quenching device (7), a tempering heating device (8) and a cooling loading-unloading device (9) which are uniformly arranged at the bottom of the annular bracket (30) in the peripheral direction of the annular bracket (30); each lifting assembly comprises a motor (5), an inner sleeve (3), a screw (2) and an outer sleeve (4); each container assembly comprises a container (1) and a driving assembly, and the container (1) is used for accommodating the workpiece.

Owner:STATE GRID ZHEJIANG YUYAO POWER SUPPLY +2

Method for carrying out heat treatment on workpiece by utilizing position signal reading device and contact sensor

ActiveCN103643006BPrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlQuenching devicesElectric machineryContact sensor

The invention provides a method for carrying out heat treatment on a workpiece by utilizing a position signal reading device and a contact sensor. In the method, a heat treatment device is used. The device comprises four container assemblies, a ring support (30), a heat treatment assembly and four lifting assemblies, wherein the heat treatment assembly comprises a heating device (6), an oil-quenching device (7), a tempering heating device (8) and a cooling loading and unloading device (9), which are uniformly arranged on the bottom of the ring support (30) along the peripheral direction of the ring support (30); each lifting assembly comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container assembly comprises a container (1) and a driving assembly, and the containers (1) are used for containing the workpiece.

Owner:南通市乐悦实业有限公司

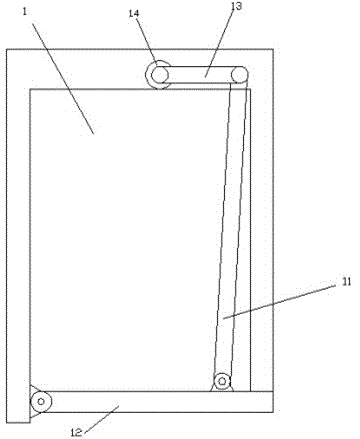

Cooker deburring turning device and method

InactiveCN112589582AEasy to fixImprove deburring efficiencyEdge grinding machinesGrinding carriagesElectric machineDrive shaft

The invention belongs to the field of cooker deburring, particularly relates to a cooker deburring turning device and method. Aiming at solving the problems that an existing cooker deburring turning device is inconvenient to fix a cooker, low in cooker deburring efficiency and incapable of removing dust generated in the deburring process and reduces the air quality, the invention provides a schemeas follows: the cooker deburring turning device comprises two first supporting plates, wherein the tops of the two first supporting plates are fixedly connected with the same base, two sides of the top of the base are fixedly connected with second supporting plates, the tops of the two second supporting plates are fixedly connected with the same top base, the top of the top base is fixedly connected with a water tank, the bottom of the base is fixedly connected with a driving motor, and an output shaft of the driving motor is fixedly connected with a driving shaft. According to the invention,the cooker can be fixed conveniently, the deburring efficiency of the cooker is high, and meanwhile, dust generated in the deburring process can be removed.

Owner:伍春燕

A method for degrading peanut aflatoxin

ActiveCN107625028BAvoid over processingPrecise control of processing timeFood scienceAflatoxin degradationElectron bunches

The invention discloses a method for degrading aflatoxin of peanuts. The method comprises the following steps of cleaning peanut granules, and regulating the moisture content of the peanut granules and the temperature of the peanut granules; regulating the piling thickness of peanut granule materials to be treated, and coprocessing the peanut granule materials through ultraviolet rays and electronbeams. According to the method disclosed by the invention, the ultraviolet rays and the electron beams are in synergy, and inside and outside detoxification is performed at the same time, so that thedegradation rate of the aflatoxin is obviously increased, the equipment is convenient to operate, and the method is suitable for processing reality of enterprises.

Owner:JIANGNAN UNIV

Workpiece thermal treatment method using three axial grooves and high-temperature-resistant ceramic material

ActiveCN103695613AImprove processing speed and processing efficiencyIncrease the level of automationQuenching devicesElectric machineryThermal treatment

The invention provides a workpiece thermal treatment method using three axial grooves and a high-temperature-resistant ceramic material. A thermal treatment device is used in the workpiece thermal treatment method and comprises four container components, an annular bracket (30), a thermal treatment component and four lifting components, wherein the thermal treatment component comprises a heating device (6), an oil quenching device (7), a tempering heating device (8) and a cooling loading and unloading device (9) which are uniformly arranged at the bottom of the annular bracket (30) along the circumferential direction of the annular bracket (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component; the containers (1) are used for containing workpieces.

Owner:启东市天汾电动工具技术创新中心

Workpiece heat treatment method

InactiveCN108149005APrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlQuenching devicesEngineeringMechanical engineering

The invention provides a workpiece heat treatment method utilizing a position signal reading device and a manual opening window. A heat treatment device is used. The heat treatment device comprises four container assemblies, an annular support, a heat treatment assembly and four lifting assemblies, wherein the heat treatment assembly comprises a heating device, an oil quenching device, a temperingheating device and a cooling loading and unloading device, and the heating device, the oil quenching device, the tempering heating device and the cooling loading and unloading device are uniformly arranged at the bottom of the annular support in the circumferential direction of the annular support; each lifting assembly comprises a motor, an inner sleeve, a screw rod and an outer sleeve; each container assembly comprises a container and a driving assembly; and the containers are used for containing workpieces.

Owner:QINGDAO XIAOMIXING ELECTRONICS TECH CO LTD

Electroplating comprehensive wastewater intelligent treatment device and its control method

ActiveCN106277427BRealize intelligenceRealize information controlWater treatment parameter controlWater contaminantsIon exchangeTherapeutic effect

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

Workpiece thermal treatment method using three axial grooves and high-temperature-resistant ceramic material

ActiveCN103695613BPrecise control of processing timeAutomatically achieve automatic outputQuenching devicesTemperingElectric machinery

Owner:启东市天汾电动工具技术创新中心

Workpiece heat treatment method using circular rotation plate and position signal reading device

ActiveCN103642999BPrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlElectric machineryEngineering

The invention provides a workpiece heat treatment method using a circular rotation plate and a position signal reading device, wherein a heat treatment device is used; the device comprises four container components, an annular frame (30), a heat treatment component and four lifting components; the heat treatment component comprises a heating device (6), an oil quenching device (7), a tempering and heating device (8) and a cooling, assembling and disassembling device (9) which are evenly arranged at the bottom of the annular frame (30) along a peripheral direction of the annular frame (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component; and a container (1) is used for holding workpieces.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Workpiece heat treatment method using circular rotation plate and position signal reading device

ActiveCN103642999APrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlElectric machineryEngineering

The invention provides a workpiece heat treatment method using a circular rotation plate and a position signal reading device, wherein a heat treatment device is used; the device comprises four container components, an annular frame (30), a heat treatment component and four lifting components; the heat treatment component comprises a heating device (6), an oil quenching device (7), a tempering and heating device (8) and a cooling, assembling and disassembling device (9) which are evenly arranged at the bottom of the annular frame (30) along a peripheral direction of the annular frame (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component; and a container (1) is used for holding workpieces.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Method for carrying out heat treatment on workpiece by utilizing manually opened windows and high-temperature-resistant ceramic material

InactiveCN103642997BPrecise control of processing timeAutomatically achieve automatic outputQuenching devicesTemperingElectric machinery

The invention provides a method for carrying out heat treatment on a workpiece by utilizing manually opened windows and a high-temperature-resistant ceramic material. In the method, a heat treatment device is used. The device comprises four container assemblies, a ring support (30), a heat treatment assembly and four lifting assemblies, wherein the heat treatment assembly comprises a heating device (6), an oil-quenching device (7), a tempering heating device (8) and a cooling loading and unloading device (9), which are uniformly arranged on the bottom of the ring support (30) along the peripheral direction of the ring support (30); each lifting assembly comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container assembly comprises a container (1) and a driving assembly, and the containers (1) are used for containing the workpiece.

Owner:安徽宇测线缆质检技术有限公司

A receiver radio frequency panoramic scanning circuit

InactiveCN106374946BReduce switching timesFast scanningTransmissionFrequency spectrumImage resolution

The invention discloses a receiver radio frequency panorama scanning circuit, and in particular relates to the technical field of receiver radio frequency panorama scan. It solves the problems of radio frequency panorama scanning in the prior art, which cannot balance the scan speed, scan bandwidth and resolution bandwidth. The receiver radio frequency panoramic scanning circuit includes radio frequency conversion, intermediate frequency gain, analog-to-digital converter, storage unit, FFT analysis, FFT spectrum storage unit, scanning controller, scanning control data storage unit and delay counter, radio frequency conversion, intermediate frequency gain , analog-to-digital converter, storage unit, FFT analysis, FFT spectrum storage unit and scan controller are connected sequentially, and the scan control data storage unit is respectively connected with radio frequency conversion, intermediate frequency gain, analog-to-digital converter, storage unit and FFT analysis, scan control The controller is connected with the scan control data storage unit, and the delay counter is connected with the scan control data storage unit and the scan controller respectively.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Workpiece thermal treatment method using three axial grooves and contact sensor

ActiveCN103695614APrecise control of processing timeAutomatically achieve automatic outputQuenching devicesTemperingElectric machinery

The invention provides a workpiece thermal treatment method using three axial grooves and a contact sensor. A thermal treatment device is used in the workpiece thermal treatment method and comprises four container components, an annular bracket (30), a thermal treatment component and four lifting components, wherein the thermal treatment component comprises a heating device (6), an oil quenching device (7), a tempering heating device (8) and a cooling loading and unloading device (9) which are uniformly arranged at the bottom of the annular bracket (30) along the circumferential direction of the annular bracket (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component; the containers (1) are used for containing workpieces.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Workpiece heat-treatment method

ActiveCN103695615BPrecise control of processing timeAutomatically achieve automatic outputQuenching devicesTemperingElectric machinery

Owner:HAIMEN CHENGJUN GLASS

Workpiece thermal treatment method using manually operated windows and contact sensor

ActiveCN103643005BPrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlQuenching devicesTemperingElectric machinery

The invention provides a workpiece thermal treatment method using manually operated windows and a contact sensor. A thermal treatment device is used in the workpiece thermal treatment method, wherein the device comprises four container components, an annular bracket (30), a thermal treatment component and four lifting components; the thermal treatment component comprises a heating device (6), an oil quenching unit device (7), a tempering heating device (8) and a cooling handling device (9), which are uniformly arranged at the bottom of the annular bracket (30) along the circumference direction of the annular bracket (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component; the containers (1) are applied to containing the workpiece.

Owner:启东市乘龙密封有限公司

Cold plasma treatment equipment for medium and large particle seed modification

InactiveCN104584728BPrecise control of processing timeGuaranteed DensityGerminating apparatusParallel plateDust control

The invention relates to a cold plasma modification treatment device for medium and large particle seeds, which includes an upper material tank, a lower material tank and a vacuum chamber connecting the upper material tank and the lower material tank, and the vacuum chamber is provided with a suction port. The air suction port is connected with a mechanical pump, and a discharge processing device and a transmission device are installed in the vacuum chamber. The discharge processing device includes two parallel plates, and a discharge processing radio frequency power supply connected to the two plates. The distance between them is 30-40mm, and a pre-ionization device is also arranged in the vacuum chamber. The pre-ionization device includes an electrode, a pre-ionization radio frequency power supply connected to the electrode, and the vacuum chamber is connected to the ground. The present invention is equipped with a pre-ionization device in the vacuum cavity, so that the working power can be ignited in an instant, and the precise control of the time required for processing is realized; the ionization dust removal is used to make the working space cleaner; under the condition of ensuring mature process parameters, it can Realize large-scale treatment of medium and large-sized seeds with seed particles larger than 15 mm.

Owner:虞建明 +3

Workpiece thermal treatment method using three axial grooves and contact sensor

ActiveCN103695614BPrecise control of processing timeAutomatically achieve automatic outputQuenching devicesTemperingElectric machinery

The invention provides a workpiece thermal treatment method using three axial grooves and a contact sensor. A thermal treatment device is used in the workpiece thermal treatment method and comprises four container components, an annular bracket (30), a thermal treatment component and four lifting components, wherein the thermal treatment component comprises a heating device (6), an oil quenching device (7), a tempering heating device (8) and a cooling loading and unloading device (9) which are uniformly arranged at the bottom of the annular bracket (30) along the circumferential direction of the annular bracket (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component; the containers (1) are used for containing workpieces.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Method for carrying out heat treatment on workpiece by utilizing position signal reading device and contact sensor

ActiveCN103643006APrecise control of processing timeAutomatically achieve automatic outputHeat treatment process controlQuenching devicesElectric machineryEngineering

The invention provides a method for carrying out heat treatment on a workpiece by utilizing a position signal reading device and a contact sensor. In the method, a heat treatment device is used. The device comprises four container assemblies, a ring support (30), a heat treatment assembly and four lifting assemblies, wherein the heat treatment assembly comprises a heating device (6), an oil-quenching device (7), a tempering heating device (8) and a cooling loading and unloading device (9), which are uniformly arranged on the bottom of the ring support (30) along the peripheral direction of the ring support (30); each lifting assembly comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container assembly comprises a container (1) and a driving assembly, and the containers (1) are used for containing the workpiece.

Owner:南通市乐悦实业有限公司

Workpiece heat treatment method using circular rotation plate and high-temperature resistant ceramic material

InactiveCN103643008BPrecise control of processing timeAutomatically achieve automatic outputFurnace typesHeat treatment furnacesTemperingElectric machinery

The invention provides a workpiece heat treatment method using a circular rotation plate and a high-temperature resistant ceramic material, wherein a heat treatment device is used; the device comprises four container components, an annular frame (30), a heat treatment component and four lifting components; the heat treatment component comprises a heating device (6), an oil quenching device (7), a tempering and heating device (8) and a cooling, assembling and disassembling device (9) which are evenly arranged at the bottom of the annular frame (30) along a peripheral direction of the annular frame (30); each lifting component comprises a motor (5), an inner sleeve (3), a screw rod (2) and an outer sleeve (4); each container component comprises a container (1) and a driving component; and a container (1) is used for holding workpieces.

Owner:FUJIAN LONGJI MECHANICAL EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com