A workpiece heat treatment method using a circular rotating disk and three axial grooves

An axial groove and rotating disk technology, applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as low work efficiency, large labor costs, and affect the accuracy of workpiece processing, and achieve higher automation levels. Effects of processing speed and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

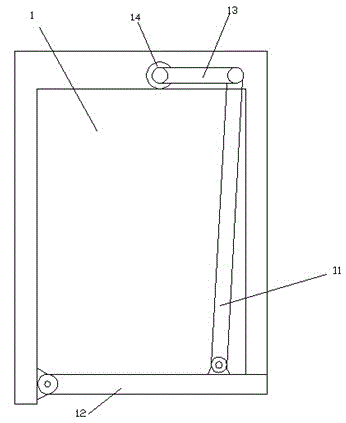

[0021] A workpiece heat treatment method utilizing a circular rotating disk and three axial grooves, which uses a heat treatment device, which includes four container components, four lifting components, a rotary positioning device, an annular support 30, a heat treatment components and racks.

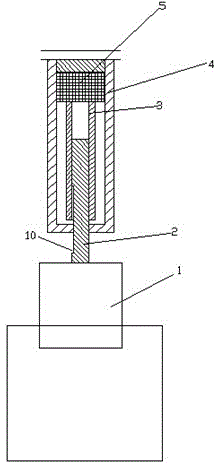

[0022] The rotary positioning device has a circular rotating disk 21, and the center of the circular rotating disk is fixedly connected with one end of a drive shaft 22, and the drive shaft 22 is rotatably arranged on the frame 20 through a bearing assembly 24. The other end of the drive shaft 22 is connected to a rotary drive motor 23 .

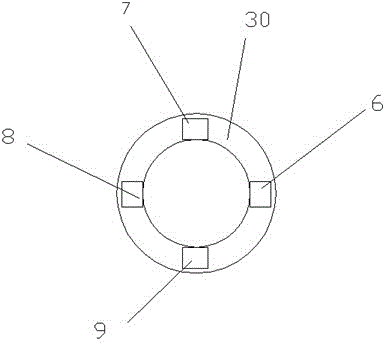

[0023] The heat treatment assembly includes a quenching heating device 6 , an oil quenching device 7 , a tempering heating device 8 and a cooling loading and unloading device 9 , and the above four devices are uniformly arranged along the circumferential direction of the annular support 30 .

[0024] The four lifting assemblies are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com