Electroplating comprehensive wastewater intelligent treatment device and its control method

A technology of electroplating synthesis and treatment equipment, which is applied in the direction of water treatment parameter control, metallurgical wastewater treatment, multi-stage water treatment, etc., can solve the problems of easy fouling and clogging of membranes, complex components of comprehensive wastewater, and difficulty in popularization, etc., and achieve shortening of influent the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example provides a treatment method for generating 150 cubic meters of comprehensive electroplating wastewater every day. 1. The composition of wastewater is as follows:

[0046] Table 1

[0047]

[0048] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

[0049] 2. Flow / velocity

[0050] Peak flow Q P =15m 3 / h time T P = 4h

[0051] Average flow Q 0 =7.5m 3 / h time T 0 =20h

[0052] 3. Discharge standard after wastewater treatment:

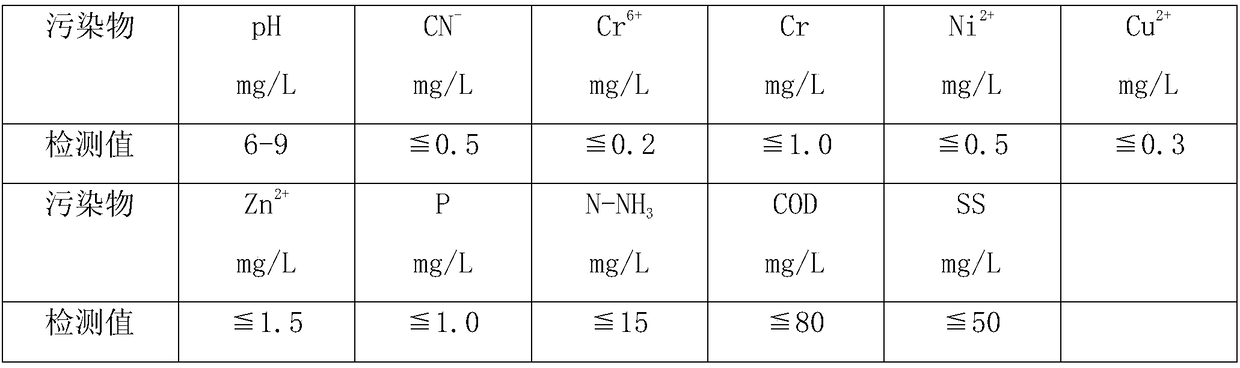

[0053] Table 2

[0054]

[0055] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

[0056] The system equipment is composed as follows: figure 1 shown

[0057] 1. Waste water collection system: composed of 8.01 tank, ultrasonic level gauge C01, PP centrifugal pump 6.01, electromagnetic flowmeter LM1 and UPVC pipe valve.

[0058] Q P =10m 3 / h T p =4h batch processing time=4h batch processing volume=15×2m 3 (2 reactors, each effective volume = 15m 3 ) = 30m 3 Q t =30÷4=7.5m 3 / h

[0059] Effective...

Embodiment 2

[0094] The comprehensive electroplating wastewater treatment method that produces 300 cubic meters of electroplating every day provided by this embodiment.

[0095] 1. The composition of wastewater is as follows:

[0096] Table 1

[0097]

[0098] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

[0099] 2. Flow / velocity

[0100] Peak flow Q P =25m 3 / h time T P =6h

[0101] Average flow Q 0 =15m 3 / h time T 0 =20h

[0102] 3. Discharge standard after wastewater treatment:

[0103] Table 2

[0104]

[0105] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

[0106] The system equipment is composed as follows:

[0107] 1. Waste water collection system: composed of 8.01 tank, ultrasonic level gauge C01, PP centrifugal pump 6.01, electromagnetic flowmeter LM1 and UPVC pipe valve.

[0108] Q P =25m 3 / h T p =6h Reaction tank batch processing time=4h Batch processing capacity=30×2m 3 (2 reactors, each effective volume = 30m 3 ) = 60m 3 Q t =60÷4=1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com