Intelligent treatment device for electroplating synthetical wastewater and control method thereof

A technology of electroplating synthesis and treatment device, which is applied in water treatment parameter control, metallurgical wastewater treatment, multi-stage water treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This example provides a treatment method for generating 150 cubic meters of comprehensive electroplating wastewater every day.

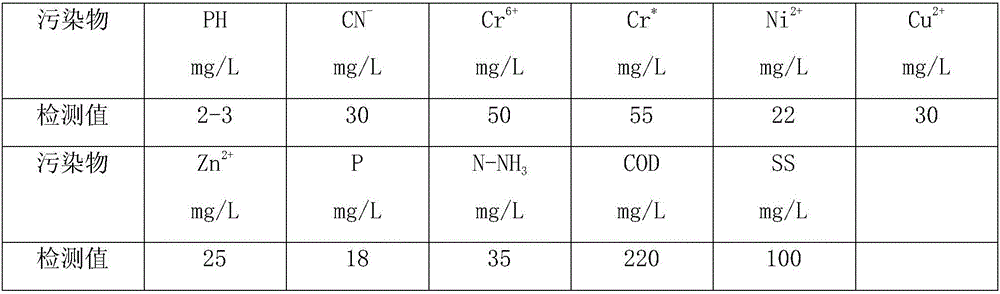

[0046] 1. The composition of wastewater is as follows:

[0047] Table 1

[0048]

[0049] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

[0050] 2. Flow / velocity

[0051] Peak flow Q P =15m 3 / h time T P = 4h

[0052] Average flow Q 0 =7.5m 3 / h time T 0 =20h

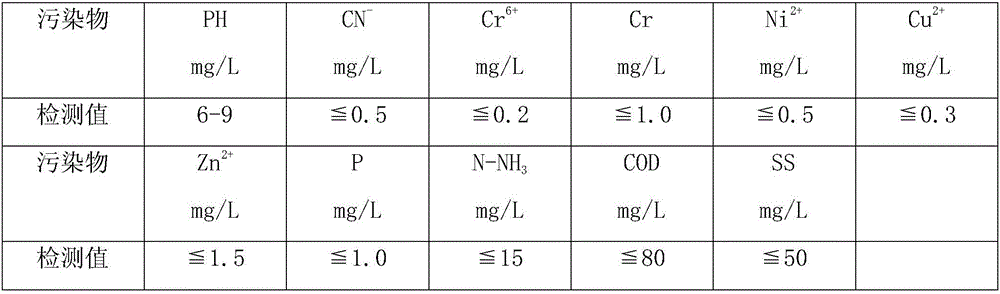

[0053] 3. Discharge standard after wastewater treatment:

[0054] Table 2

[0055]

[0056] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

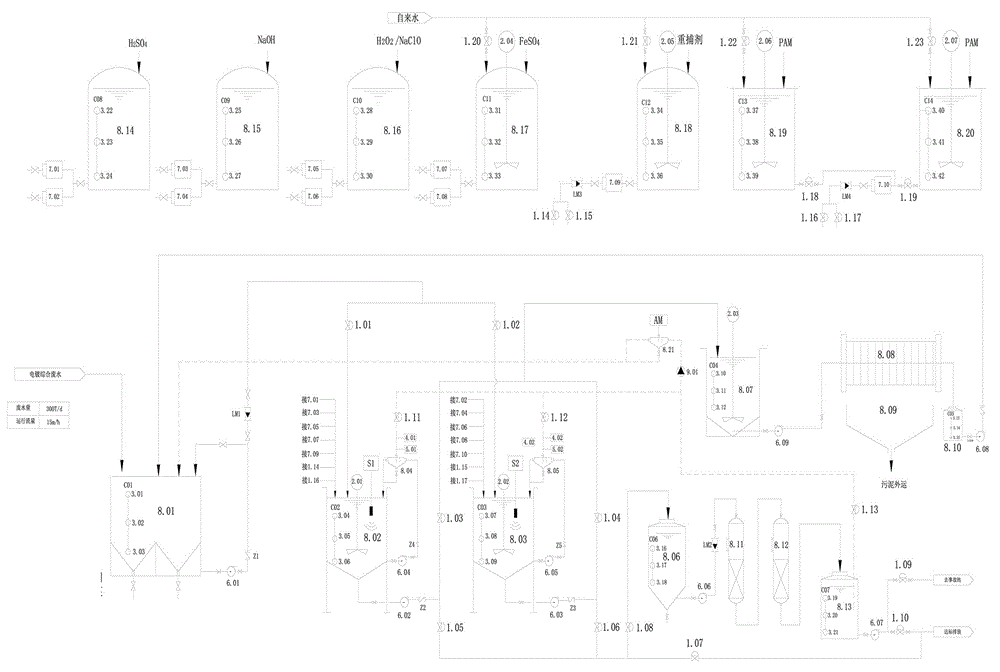

[0057] The system equipment is composed as follows: figure 1 shown

[0058] 1. Waste water collection system: composed of 8.01 tank, ultrasonic level gauge C01, PP centrifugal pump 6.01, electromagnetic flowmeter LM1 and UPVC pipe valve.

[0059] Q P =10m 3 / h T p = 4h batch processing time = 4h batch processing volume = 15×2m 3 (2 reactors, each effective volume = 15m 3 ) = 30m 3 Q t =30÷4=7.5m 3 / h

[00...

Embodiment 2

[0094] The comprehensive electroplating wastewater treatment method that produces 300 cubic meters of electroplating every day provided by this embodiment.

[0095] 1. The composition of wastewater is as follows:

[0096] Table 1

[0097]

[0098] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

[0099] 2. Flow / velocity

[0100] Peak flow Q P =25m 3 / h time T P =6h

[0101] Average flow Q 0 =15m 3 / h time T 0 =20h

[0102] 3. Discharge standard after wastewater treatment:

[0103] Table 2

[0104]

[0105] Note*: Cr is total chromium--Cr 6+ with Cr 3+ Sum.

[0106] The system equipment is composed as follows:

[0107] 1. Waste water collection system: composed of 8.01 tank, ultrasonic level gauge C01, PP centrifugal pump 6.01, electromagnetic flowmeter LM1 and UPVC pipe valve.

[0108] Q P =25m 3 / h T p = 6h reaction tank batch time = 4h batch capacity = 30×2m 3 (2 reactors, each effective volume = 30m 3 ) = 60m 3 Q t =60÷4=15m 3 / h

[0109]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com