Washing machine and control method thereof

A washing machine and washing tub technology, applied in the field of washing machines, can solve problems such as the failure to effectively monitor the status, the inability to fully soften the tap water, and the prolonged water intake time of the tap water, so as to shorten the water intake time, improve operational reliability, and facilitate control and operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

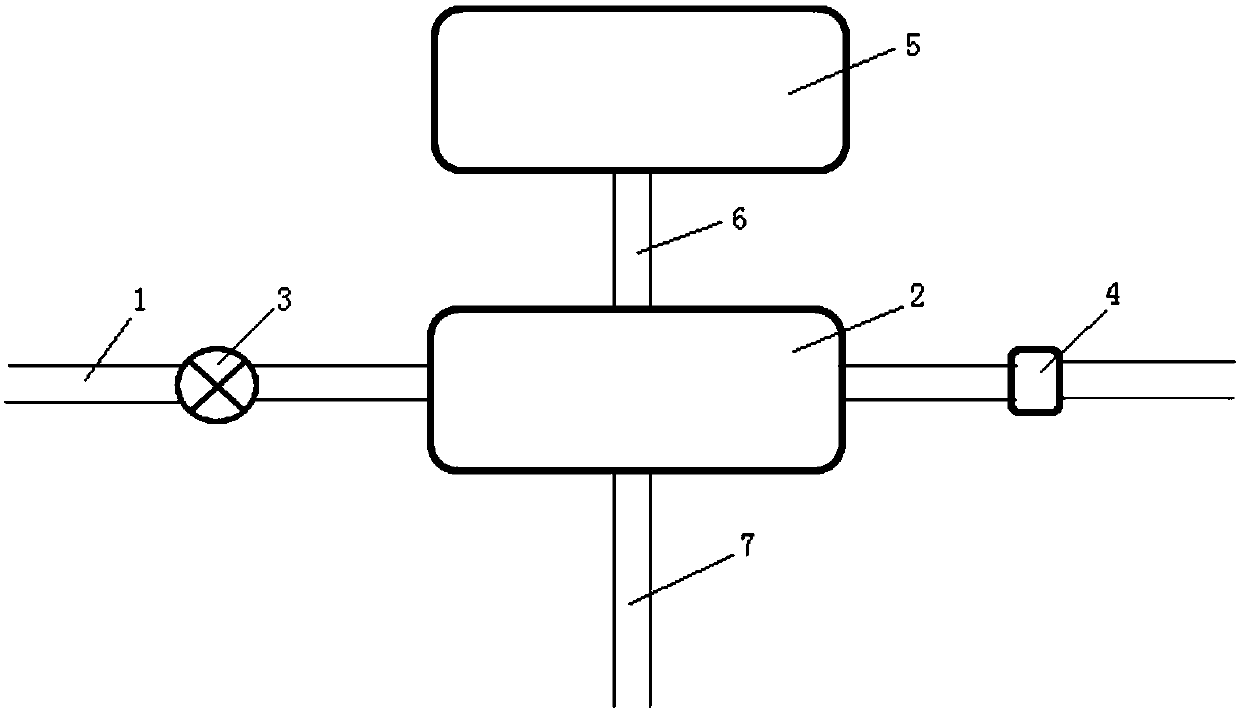

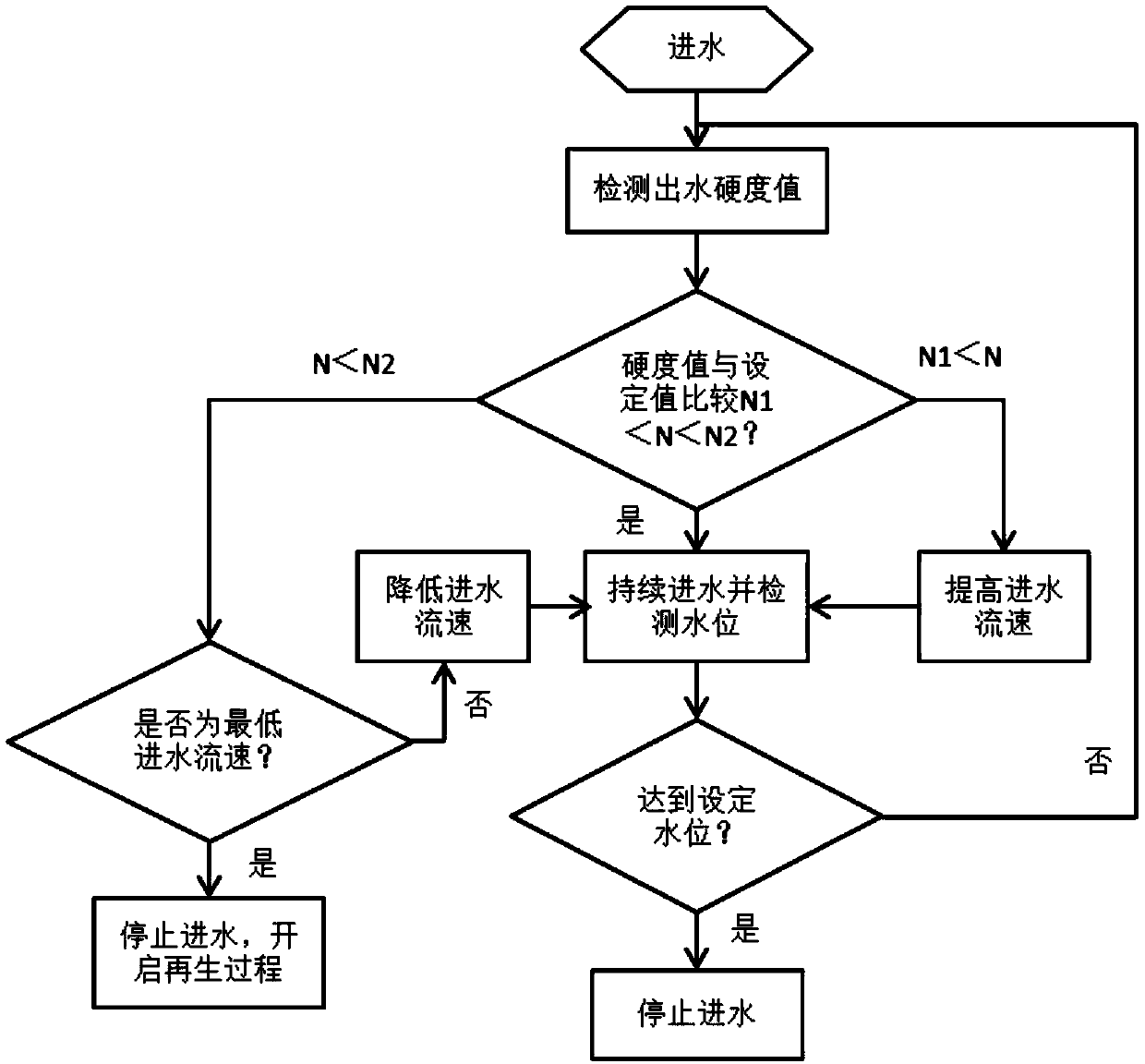

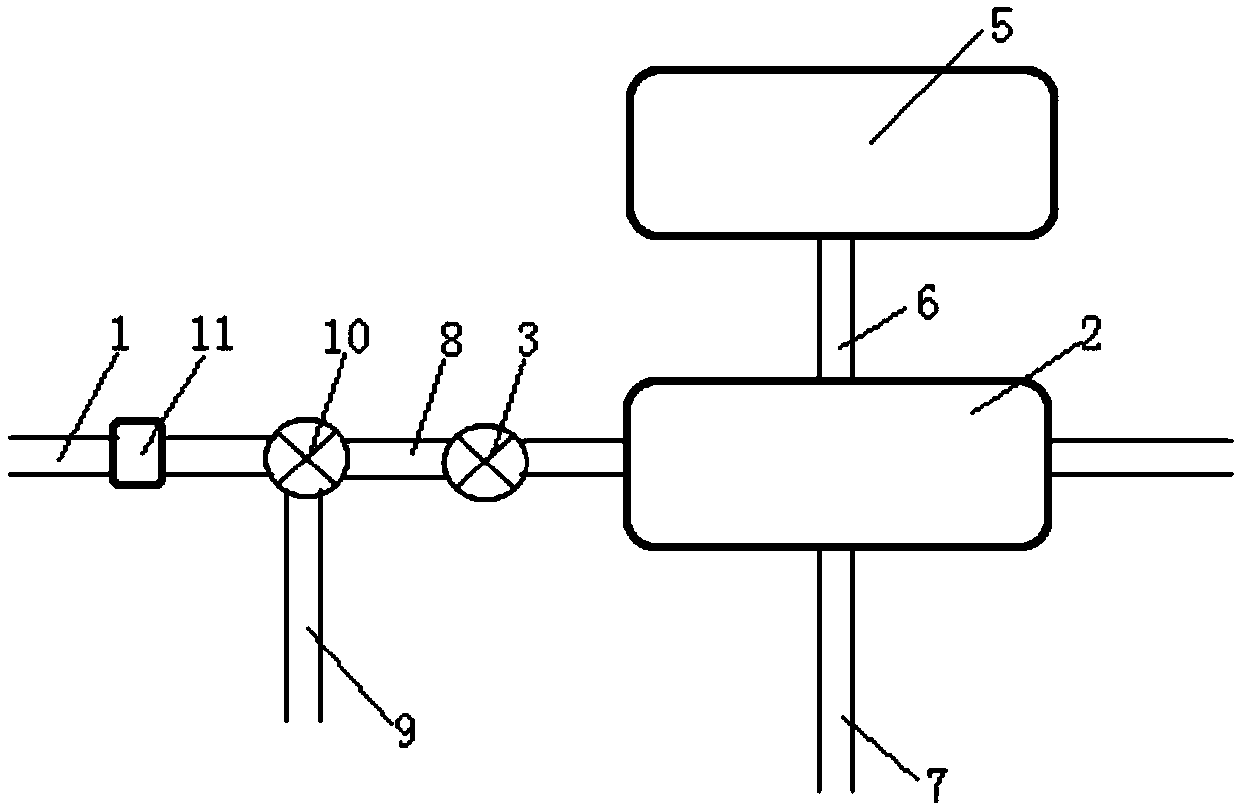

[0042] Such as figure 1 As shown, this embodiment introduces a washing machine, which includes an inlet waterway 1 connecting the external water supply pipeline of the washing machine and the washing tub. A flow rate control device 3 for controlling the flow rate of the influent water flow and a second water quality detection device 4 for detecting the water quality of the influent water flow located upstream of the optimization device 2 are arranged on the top, the second water quality detection device 4 is connected to the flow rate control device 3 connected so that the flow velocity control device 3 controls the flow velocity of the water inlet channel 1 according to the detection information of the second water quality detection device 4 .

[0043]In the present invention, the flow rate control device 3 is arranged upstream of the optimization device 2 to realize the control of the flow rate of the water flowing into the optimization device 2. The residence time of the w...

Embodiment 2

[0057] Such as figure 1 As shown, the difference between this embodiment and Embodiment 1 is that the second water quality detection device 4 is arranged downstream of the optimization device 2 to detect the water quality of the influent water flow downstream of the optimization device 2, so that the flow rate control device 3 according to the downstream of the optimization device 2 Influent water quality control optimization device 2 upstream flow rate of influent water. In a corresponding washing machine control method, the detected inflow is the inflow after water quality optimization treatment.

[0058] In the present invention, the second water quality detection device 4 is arranged downstream of the optimization device 2 to detect the water quality of the water flowing out of the optimization device 2, so that the control of the flow rate is based on the water quality of the water flow out of the optimization device 2, so that the outflow The water quality of the optimi...

Embodiment 3

[0062] Such as figure 1 As shown, the difference between this embodiment and Embodiments 1 and 2 is that the optimization device 2 includes an optimization cavity, and an optimization material with water quality optimization capability is arranged inside the optimization cavity, and the water inlet channel 1 passes through the optimization cavity and communicates with the optimization cavity . Optimizing substances are used to improve water quality parameters.

[0063] The water quality optimization capability of the optimization substance at least includes reducing the hardness of the influent water flow. The optimized substance can be ion exchange resin, or other substances that can reduce the hardness of influent water flow. In a corresponding washing machine control method, the water quality optimization treatment at least includes reducing the hardness of the incoming water flow.

[0064] The washing machine also includes a regeneration device 5. The regeneration devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com