Workpiece heat treating method

A workpiece and process technology, applied in the field of workpiece heat treatment technology, can solve the problems of low work efficiency, large labor cost, consumption, etc., and achieve the effect of improving processing speed and processing efficiency, and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

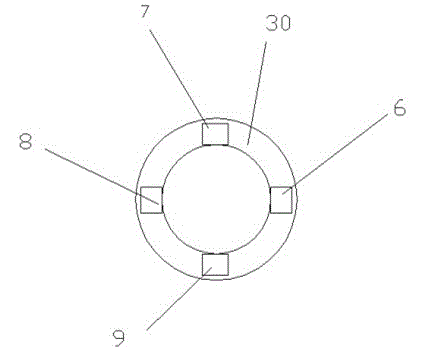

[0019] A workpiece heat treatment method using a position signal reading device and manually opening a window, which uses a heat treatment device, which includes four container assemblies, four lifting assemblies, a rotary positioning device, a ring support 30, and a heat treatment assembly and racks.

[0020] The heat treatment assembly includes a quenching heating device 6, an oil quenching device 7, a tempering heating device 8 and a cooling loading and unloading device 9, and the above four devices are uniformly arranged along the circumferential direction of the annular support 30; wherein, the annular The support 30 is respectively provided with four peripheral position signal sending devices corresponding to the four devices, and a peripheral position signal reading device is arranged on the rotary positioning device. When the rotary positioning device rotates, the The peripheral position signal reading device can read the position signals sent by the four periphera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com