Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Not prone to bending deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

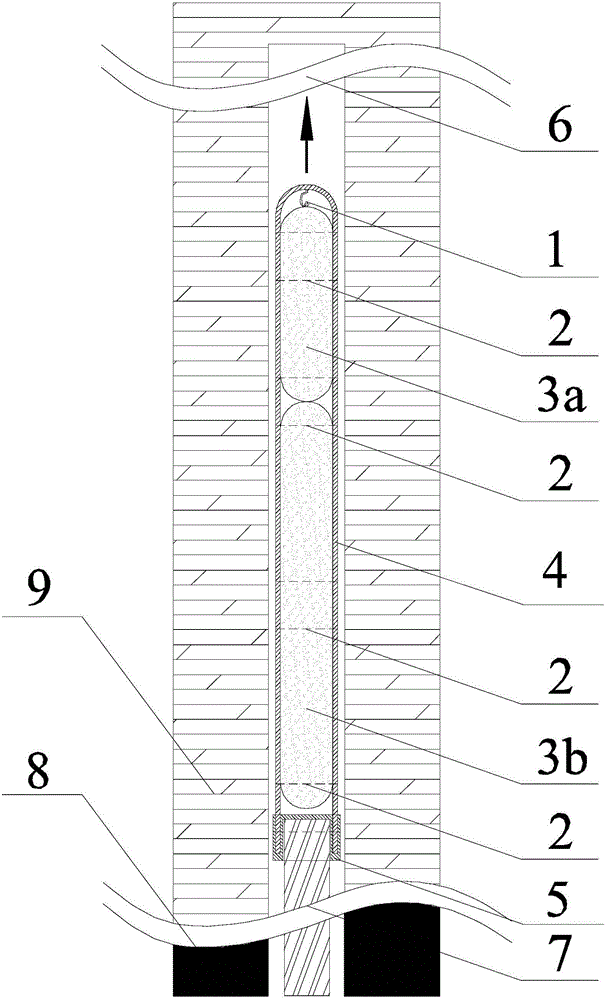

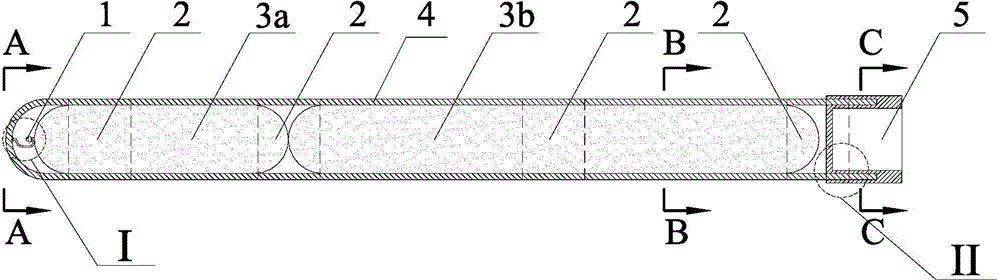

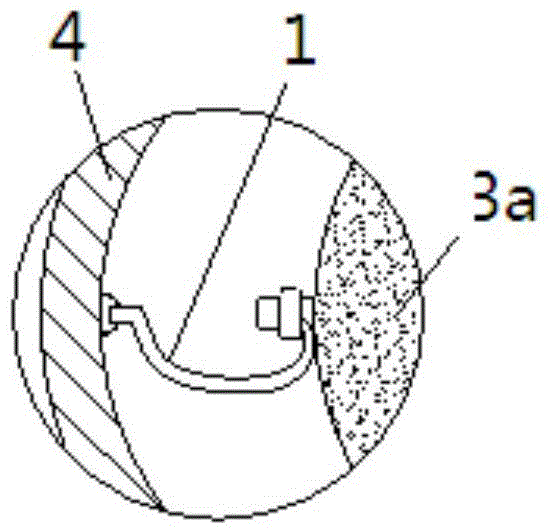

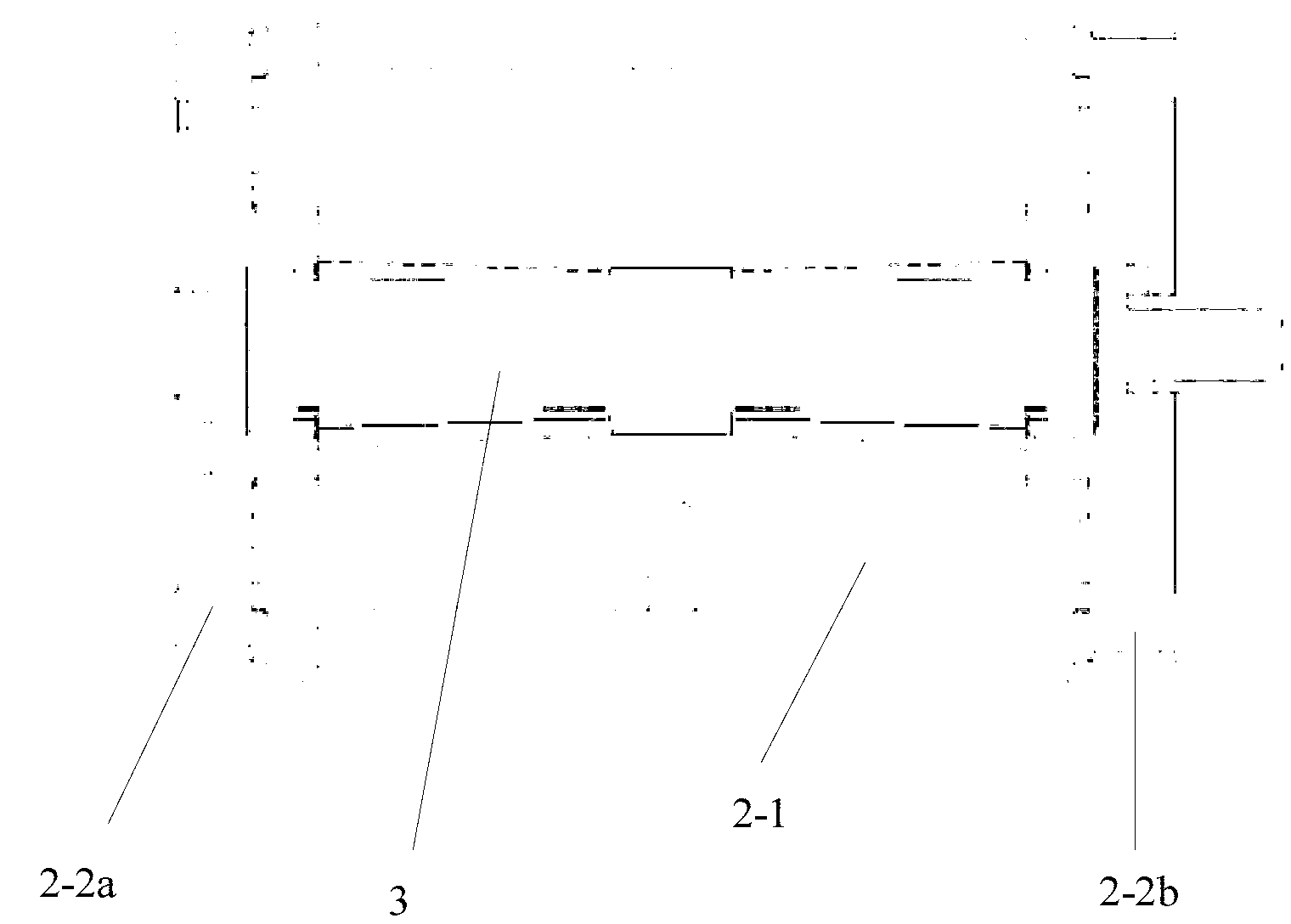

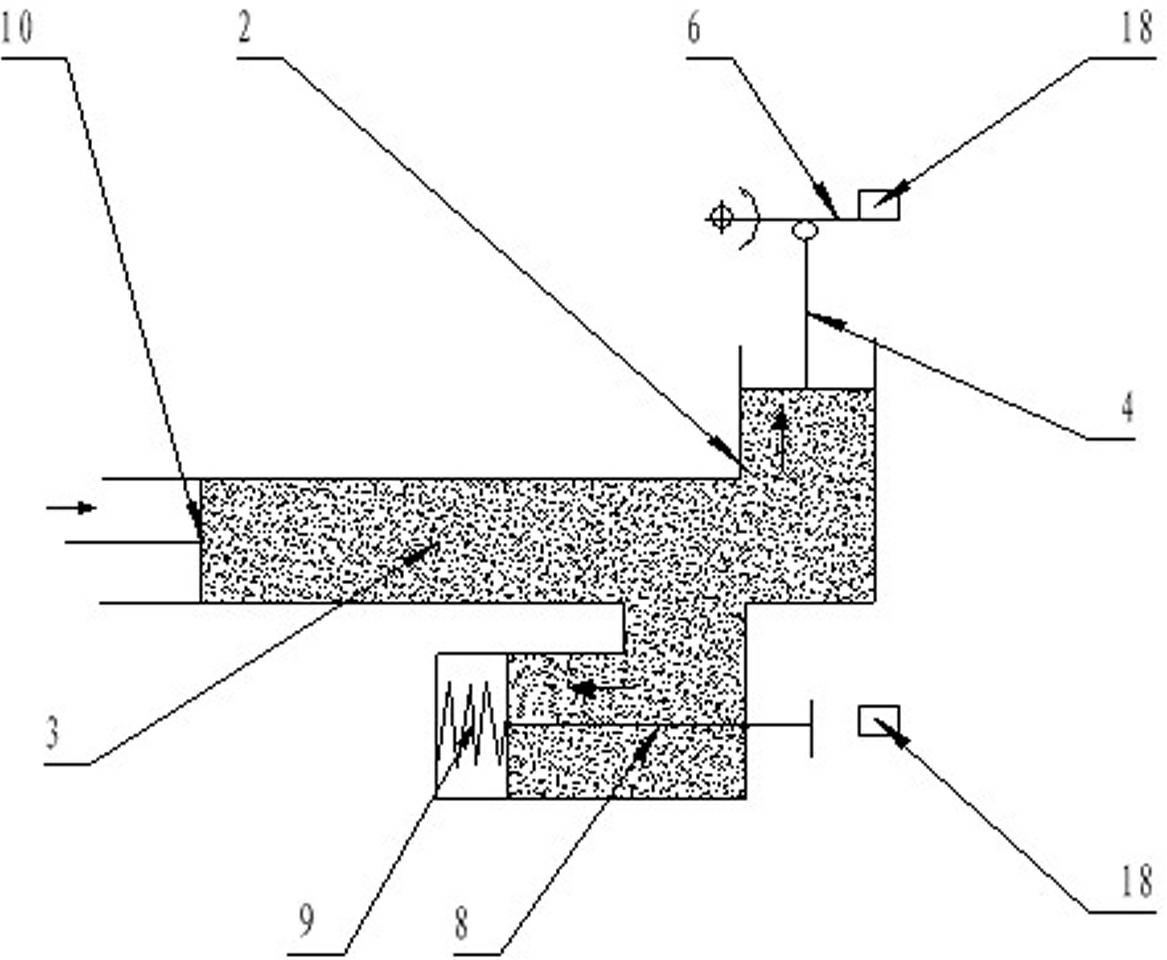

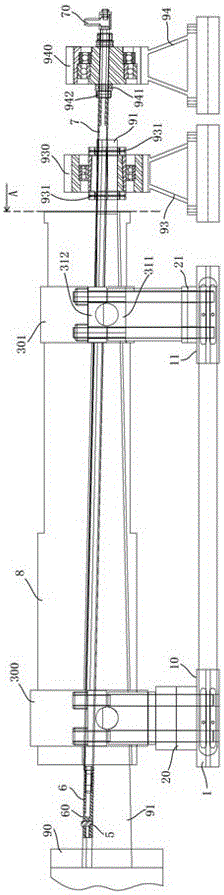

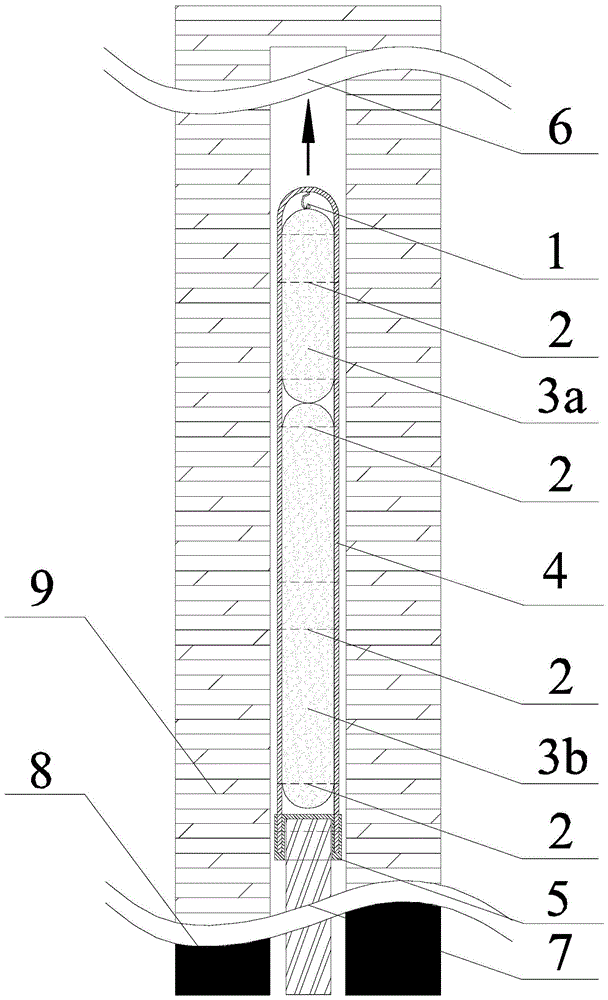

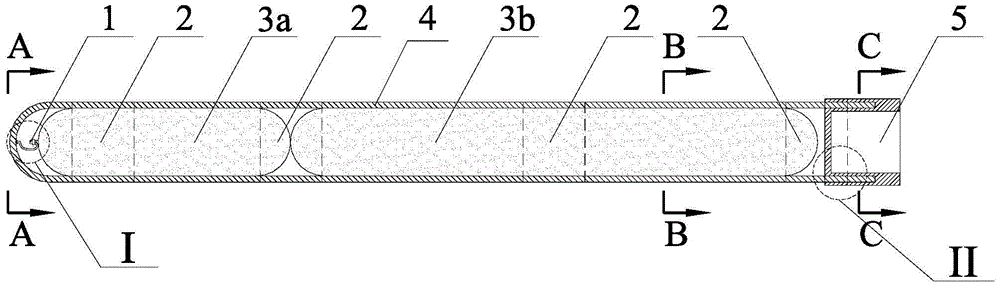

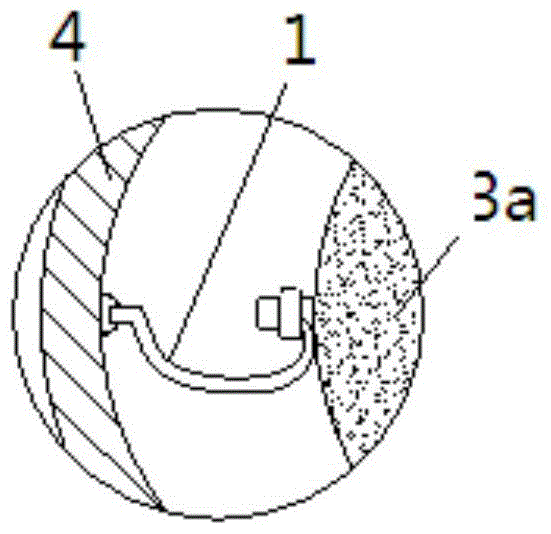

Integral push-lead type device and method for installation of tunnel anchor cable anchoring agent

ActiveCN104695990AAvoid multiple pushesReduce labor intensityAnchoring boltsHigh probabilityUltimate tensile strength

The invention discloses an integral push-lead type method for the installation of a tunnel anchor cable anchoring agent. The method comprises the following steps: connecting multiple anchoring agent cartridges filled with the anchoring agent integrally; installing the integrally connected anchoring agent cartridges in a push-lead mechanism; propping an anchor cable against a base plate at the rear end of the push-lead mechanism, and then inserting the push-lead mechanism equipped with the anchoring agent cartridges into a drilled hole formed in rock or coal; pushing the anchor cable toward a drilling direction, so that the push-lead mechanism reaches the top of the drilled hole, using a roof bolter for continuing to push and stir the anchor cable correspondingly, so that the multiple anchoring agent cartridges in the push-lead mechanism are broken, and the anchor cable is anchored in the stable rock or coal by using the anchoring agent. In addition, the invention further provides a device for the method; the device has the advantages of simple structure and good stability, and can effectively solve the problems of multiple-time installation of the anchoring agent cartridges, high probability of blockage of drilled holes, complicated installation process, long support time, high labor intensity of workers and other difficulties restricting the development of the tunnel support technology in the installation process of the existing anchoring agent cartridges.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

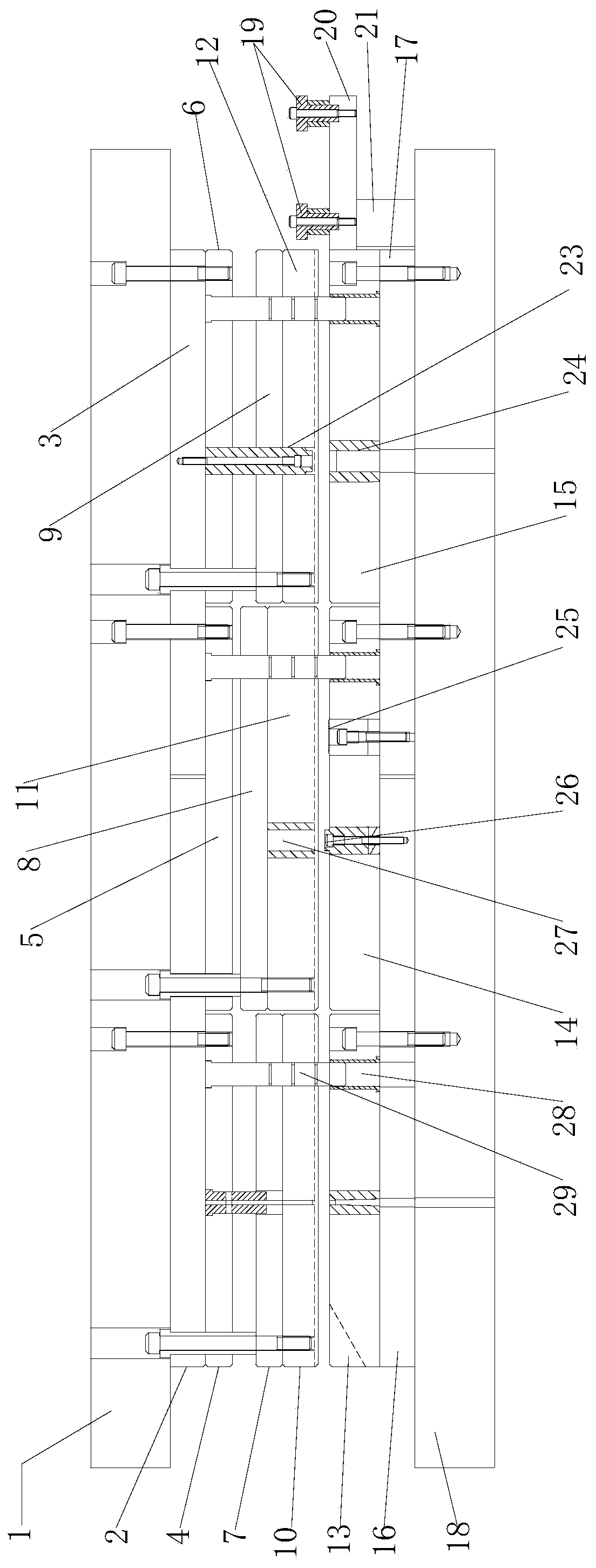

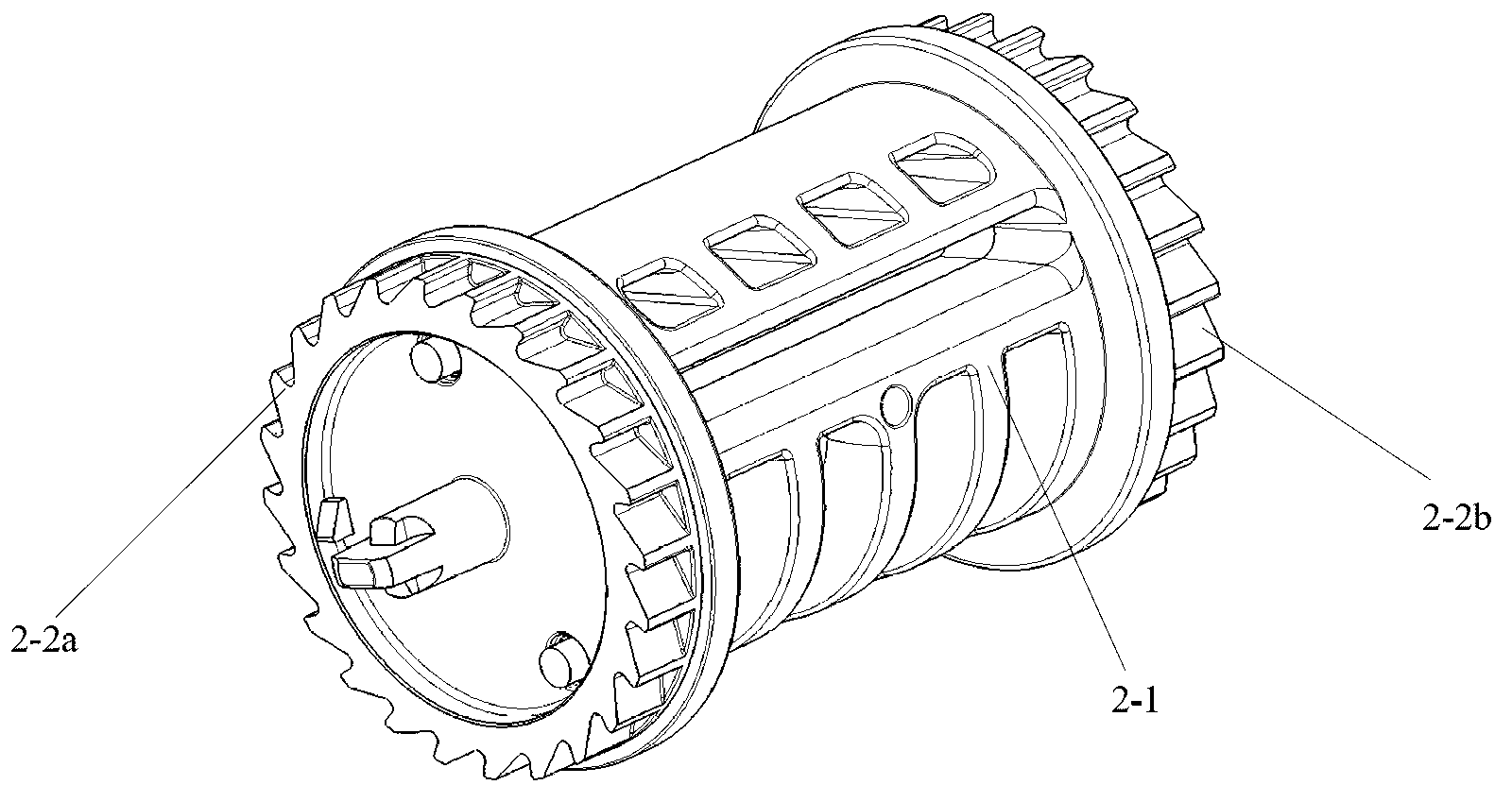

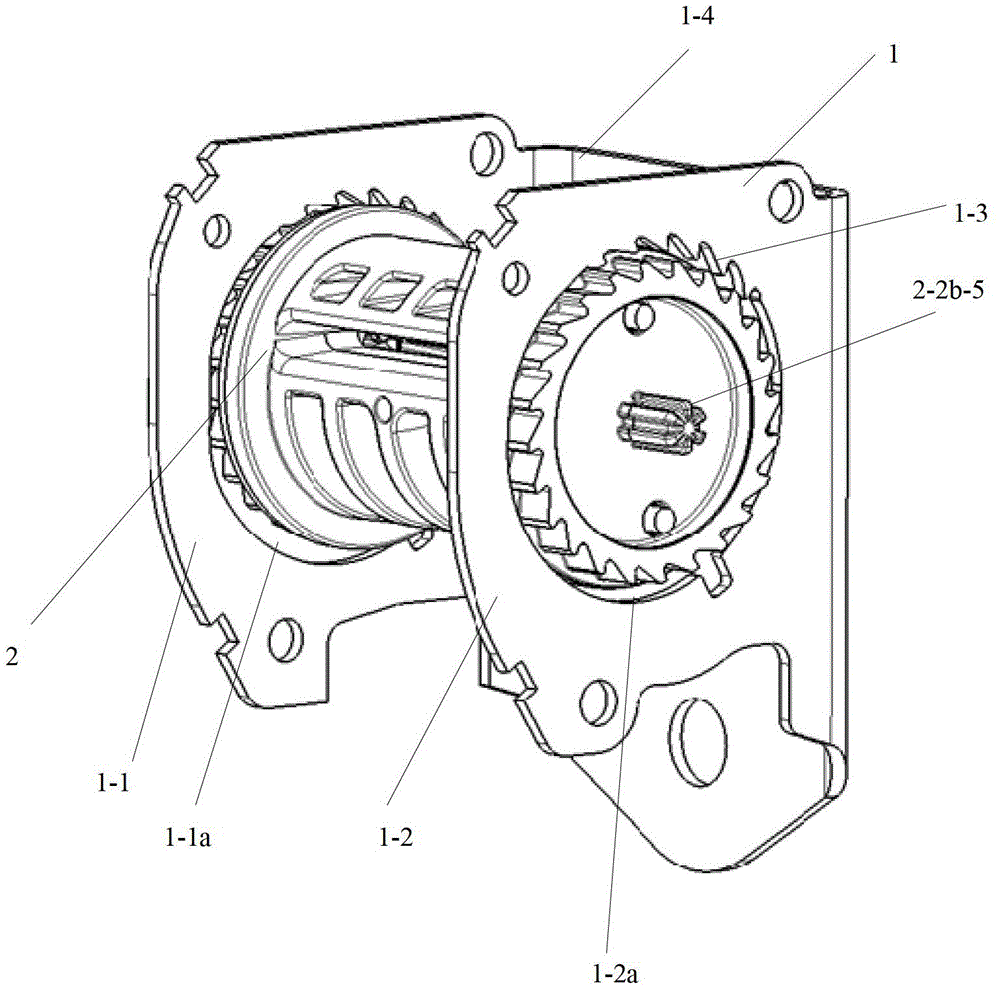

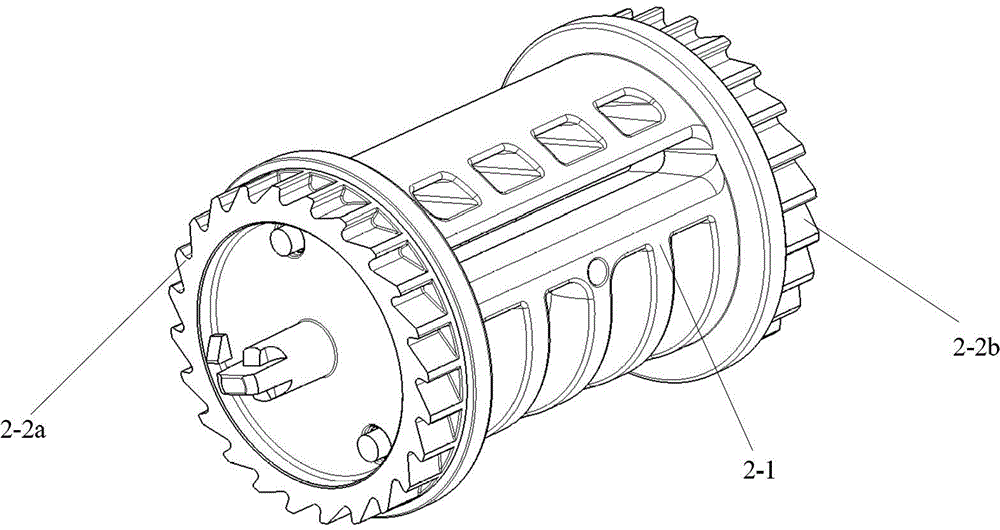

Retractor for safety belt and safety belt assembly

ActiveCN102837664AOvercoming the problem of unfixed locking positionImprove accuracyBelt retractorsEngineeringBelt safety

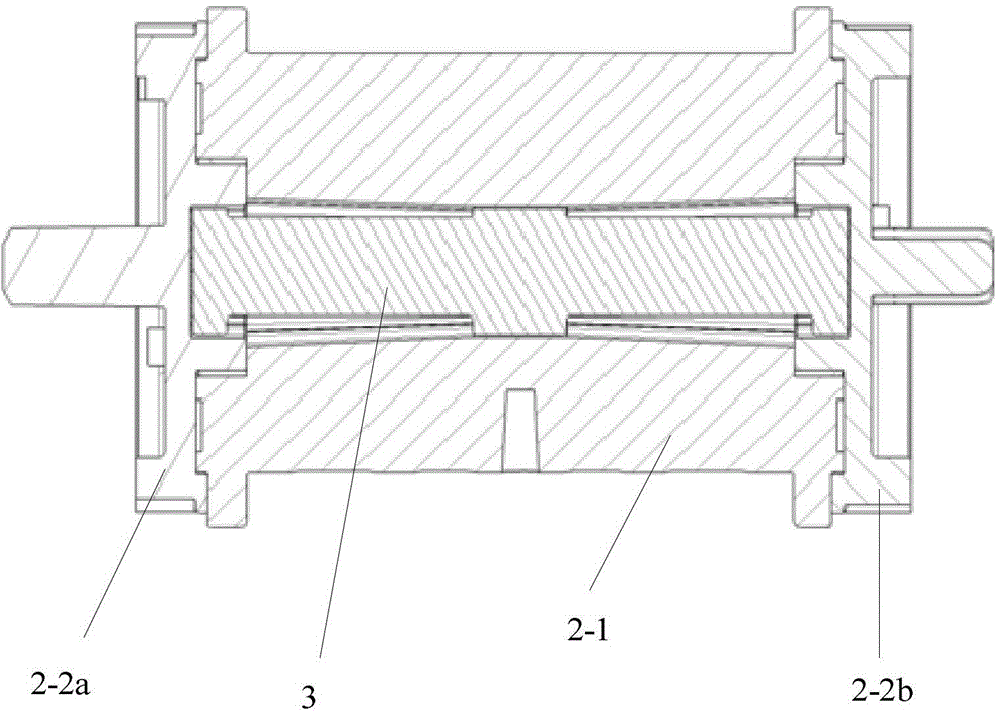

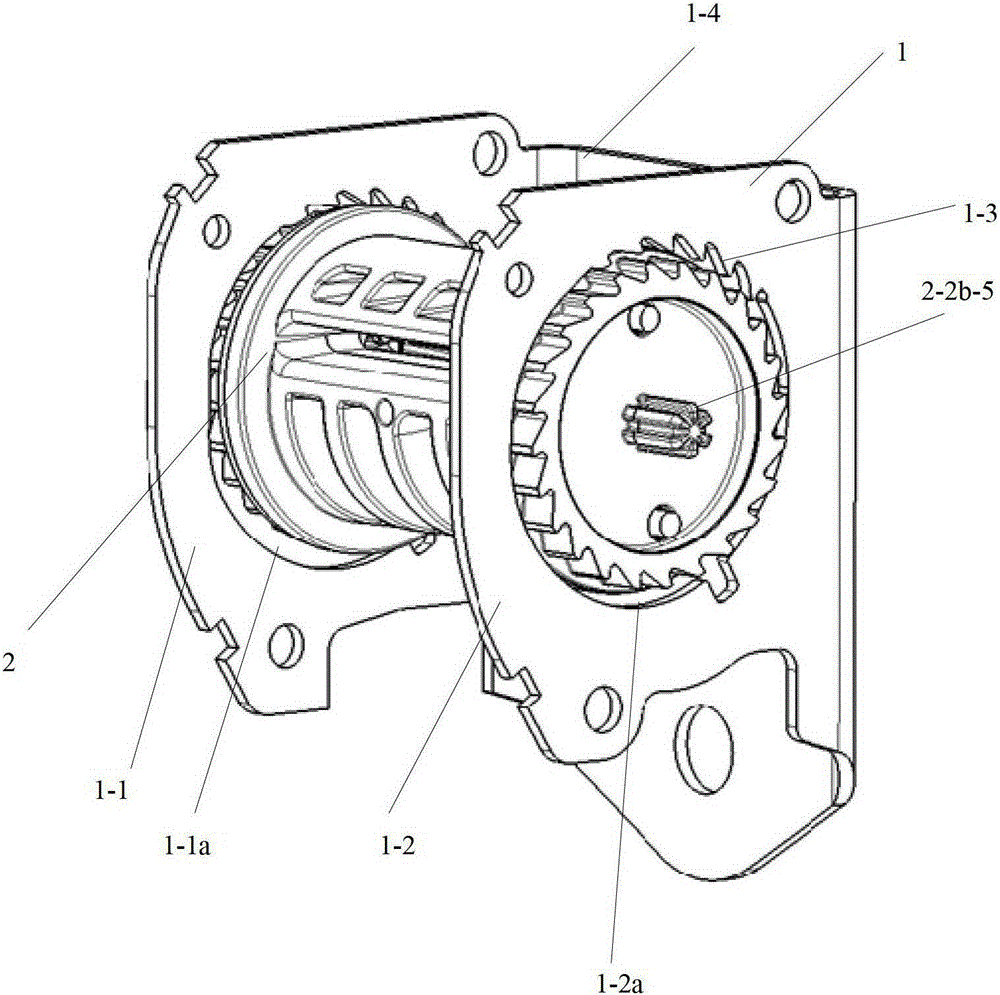

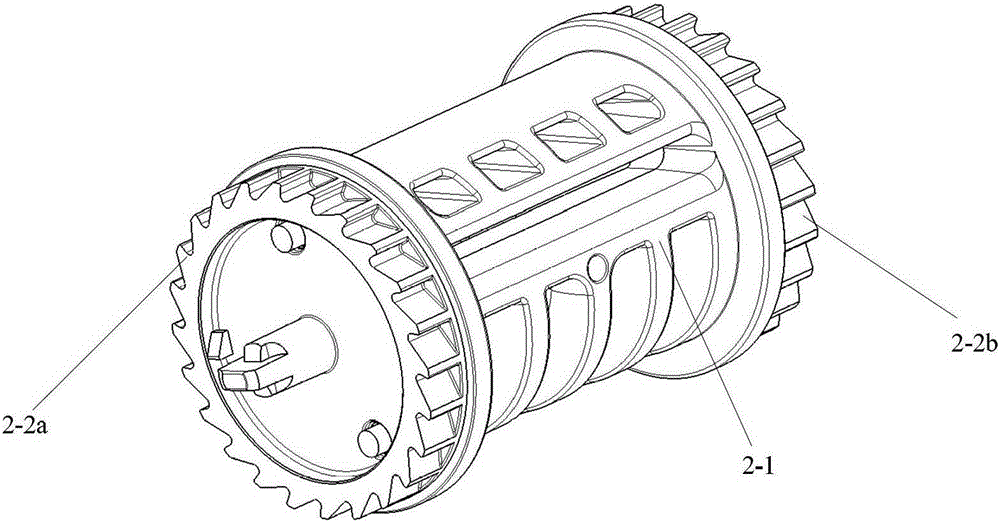

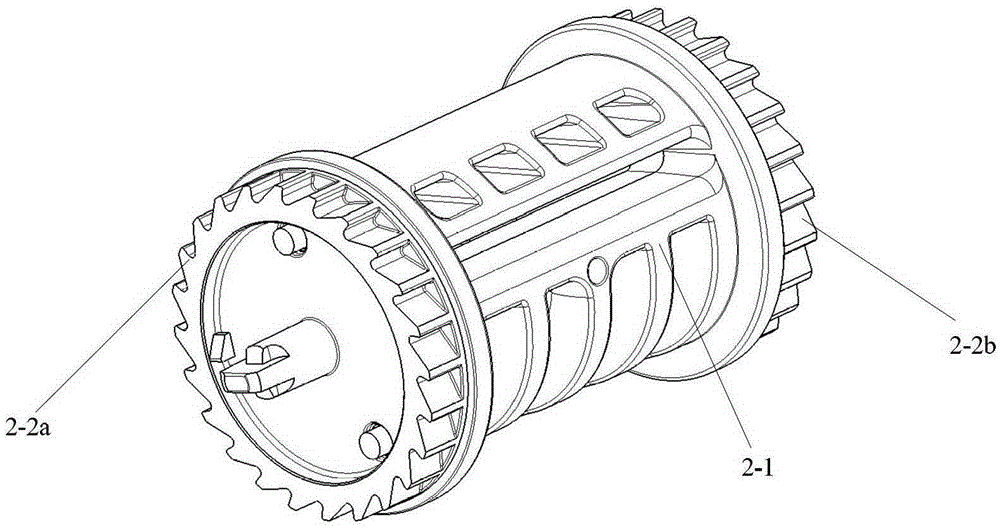

The invention provides a retractor for a safety belt. A retractor frame comprises two opposite side walls, and corresponding positions of the two opposite side walls are provided with round holes with inner tooth sections. The tooth sections are arranged at a position corresponding to the outward traction direction of a braided belt. A retraction shaft comprises a core shaft which is provided with a though hole along the central axis and is used for winding the braided belt, and two separating end covers which are respectively installed at two ends of the core shaft. The periphery of each end cover is provided with outer teeth matched with inner teeth on the frame. A torsion bar is bar-shaped, the axial middle of the torsion bar is provided with a middle section of outer teeth, and the inner teeth matched with the outer teeth are installed in the though hole of the core shaft. Connection between the torsion bar and the two separating end covers at two ends is achieved at a crossing position between the torsion bar and the two separating end covers through a gear installed at the crossing position and gears correspondingly installed at the end covers. The retractor for the safety belt overcomes the shortcoming that the position of the locking of a retractor is unfixed, and improvement of control accuracy of the retractor is benefited. The invention further provides a safety belt assembly.

Owner:和励科技有限公司

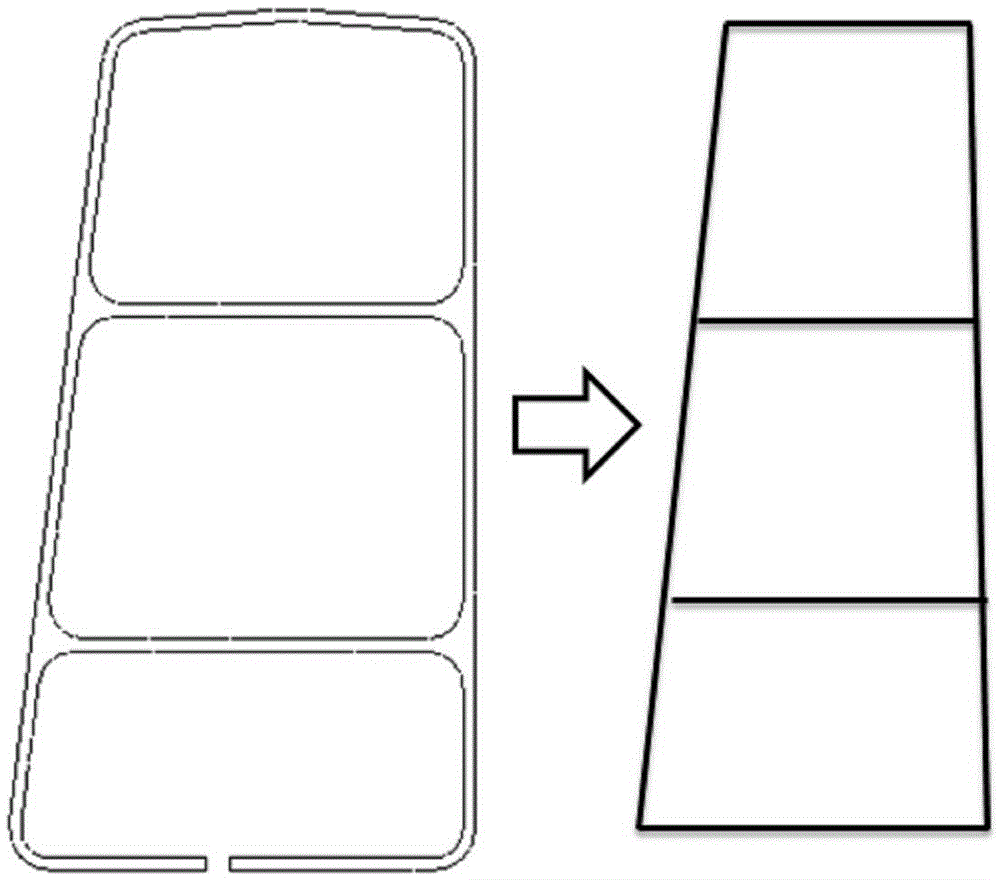

Automobile body front longitudinal beam structure and automoible

The invention discloses an automobile body front longitudinal beam structure and an automobile provided with the automobile body longitudinal beam structure. The automobile body front longitudinal beam structure comprises a front longitudinal beam main body which comprises a front section part made from a cast aluminum material and a rear section part made from an ultrahigh-strength steel material. The front section part comprises an energy absorption box section, a connecting piece section, a straight beam section and a bent section which are connected in sequence. The front section part is connected with the rear section part through the bent section. By adoption of the front longitudinal beam structure made from steel and aluminum, the weight of an automobile body can be remarkably lowered, and advantages in fuel economy performance and the like are achieved; and through the structure different from that of a traditional sheet metal component, collision energy distribution is optimized, the energy absorption efficiency is improved, and accordingly the collision performance of the whole automobile is improved.

Owner:SAIC GENERAL MOTORS +1

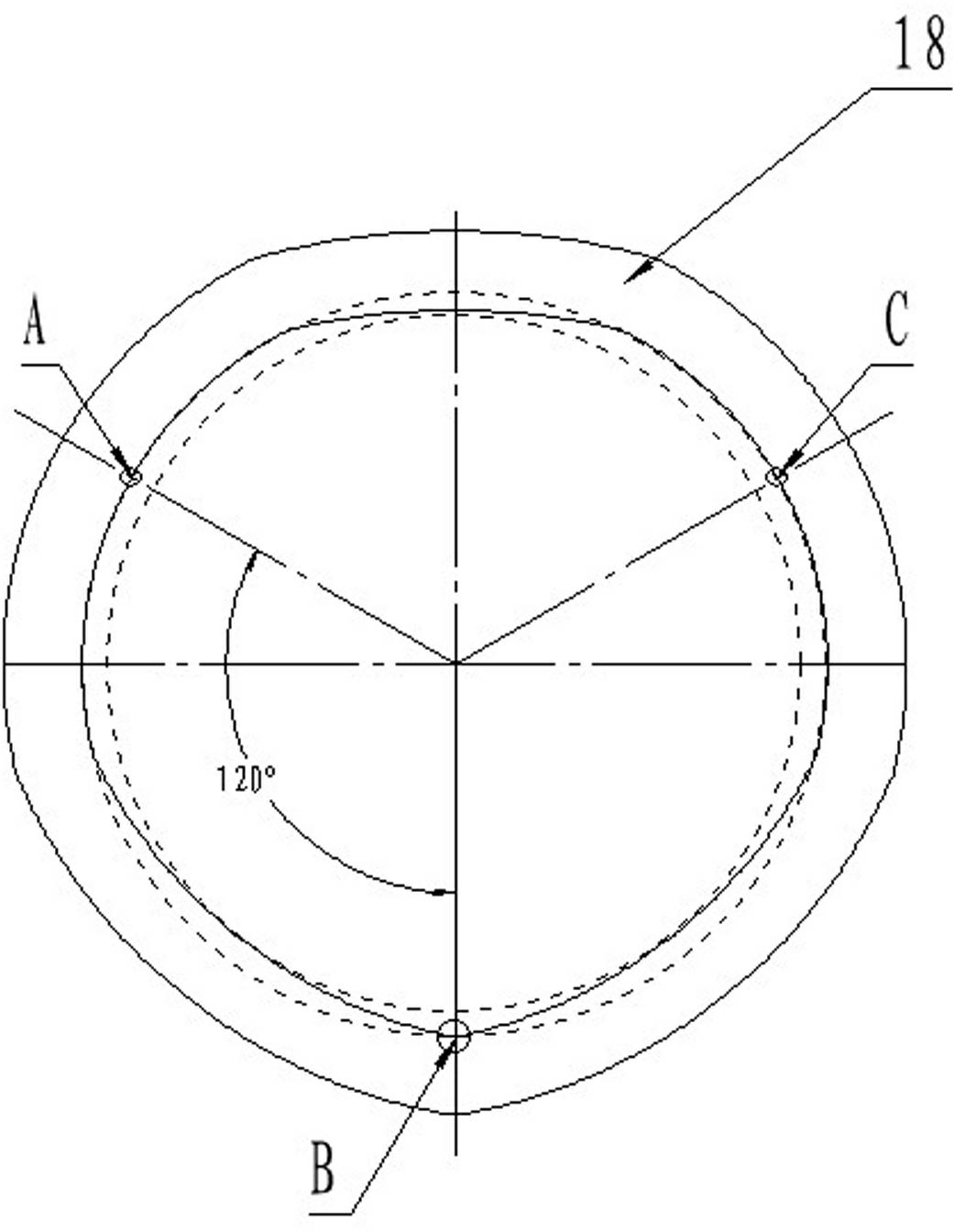

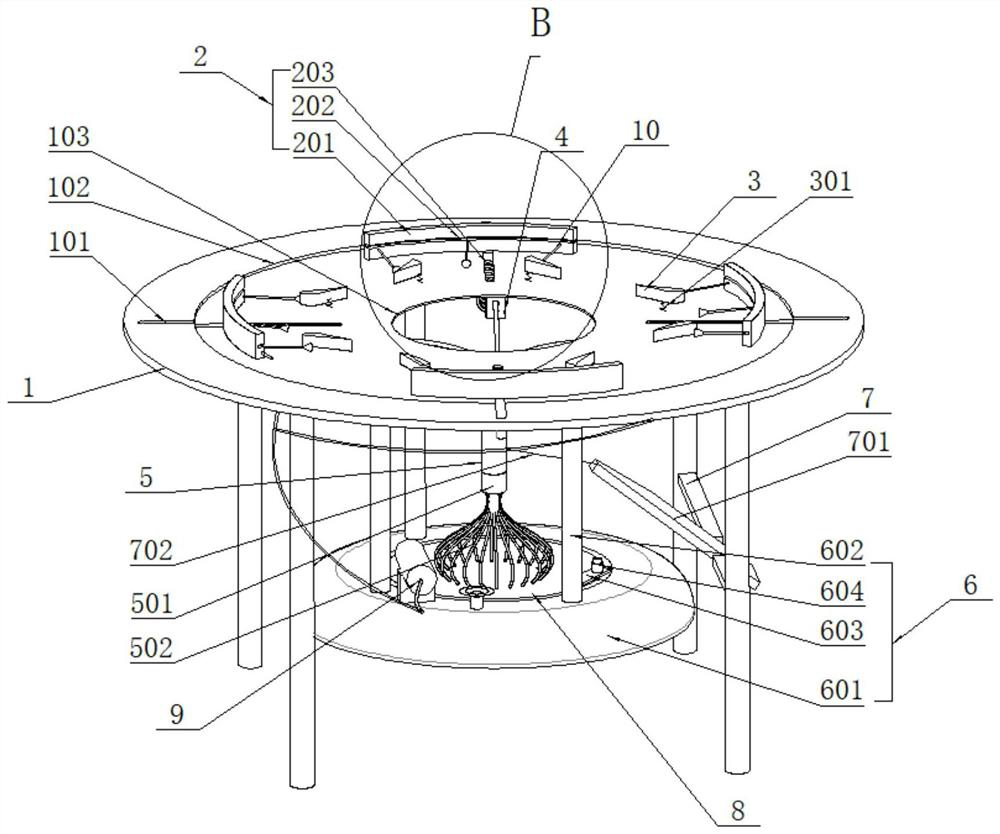

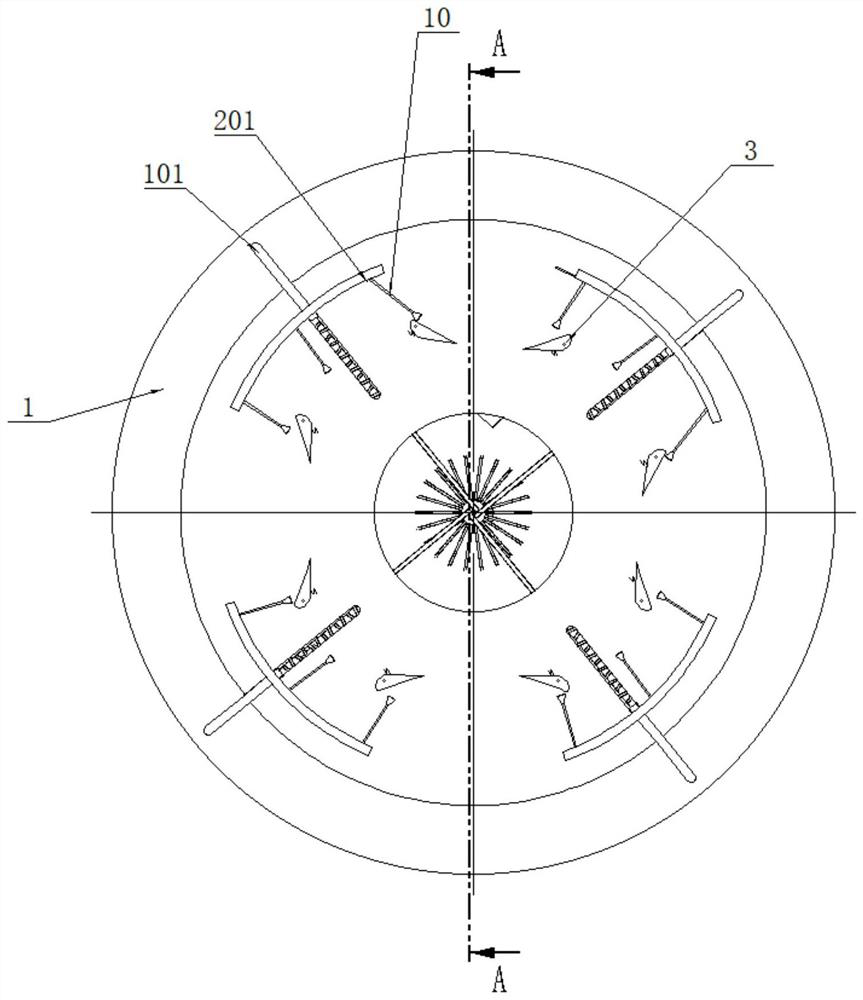

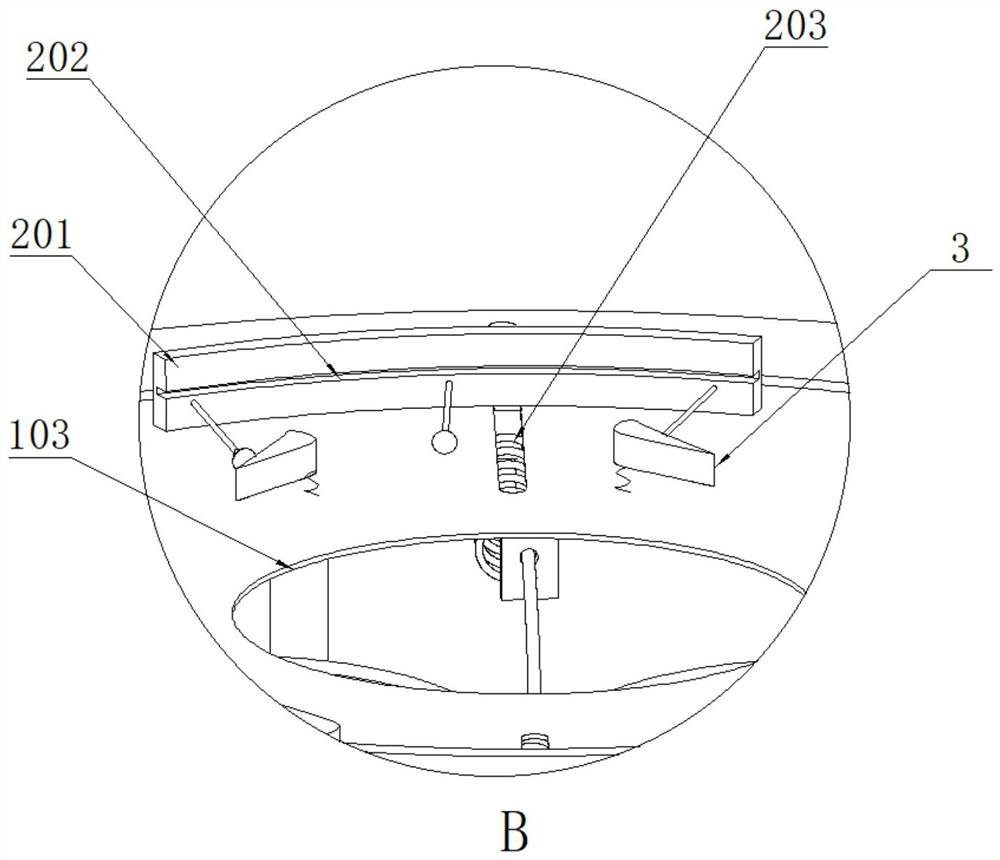

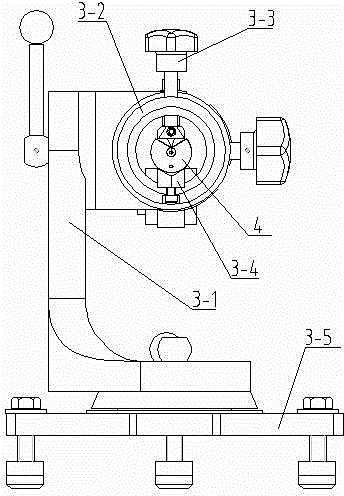

Automatic multi-claw hydraulic returning and clamping chuck and use method thereof

The invention relates to a machine tool accessory and particularly provides an automatic multi-claw hydraulic returning and clamping chuck. According to the automatic multi-claw hydraulic returning and clamping chuck, the technical problems that automatic stable clamping and automatic blanking cannot be realized by workpieces are solved. The automatic multi-claw hydraulic returning and clamping chuck comprises a rotary oil cylinder and a clamp body, wherein a communicator oil cavity is arranged in an inner cavity of the clamp body; a plurality of clamping plungers are arranged on the clamp body in the radial direction of the clamp body; the clamp body is also provided with rocker arm type claws matched with the clamping plungers through a plurality of pin rolls respectively; claw springs are arranged between the rocker arm type claws and the clamp body respectively; a plurality of jacking pistons are arranged on the clamp body in the axial direction of the clamp body; and the automatic multi-claw hydraulic returning and clamping chuck further comprises a driving piston communicated with the tail end of the communicator oil cavity and is connected with the rotary oil cylinder through a jacking rod. The invention also provides a method for processing operation by using the automatic multi-claw hydraulic returning and clamping chuck.

Owner:吴松祥

Continuous die structure for square washers

InactiveCN103611798AEasy to uninstallReduce the difficulty of unloadingShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention relates to the technical field of dies and discloses a continuous die structure for square washers. The continuous die structure is characterized in that an upper die plate is sequentially connected with upper backing plates, fixed plates, stripping pads and stripping plates through guide posts. The fixed plates and the stripping pads are spaced. A middle hole stamping die, a pressure corner stamping die and a nail stamping die are sequentially disposed between the upper die plate and a lower die plate. The middle hole stamping die is used for stamping a middle hole of a square washer. The pressure corner stamping die is used for stamping two face pressure corners of the middle hole of the square washer. The nail stamping die is used for stamping a stamp nail of the square washer. The middle hole stamping die comprises a middle hole finish stamping male die disposed at the lower end of the upper die plate and a middle hole finish stamping female die which is disposed on a cavity plate and which corresponds to the middle hole finish stamping male die. The pressure corner stamping die is disposed on the cavity plate and provided with tilt angles. The nail stamping die comprises a nail stamping female die disposed at the lower ends of the stripping plates and a nail stamping male die which is disposed on the cavity plate and which corresponds to the nail stamping female die. The continuous die structure for square washers has the advantages that stripping is easier, blanks are convenient to remove, and bending deformation occurs rarely.

Owner:广州市腾歌音响设备有限公司

Torsion bar for safety belt coiling device as well as safety belt coiling device and safety belt assembly

InactiveCN102837663AShorten the lengthNot easy to bend and deformBelt retractorsEngineeringLimit value

The invention provides a torsion bar for a safety belt coiling device. The torsion bar is in a bar shape and the axial length of the torsion bar is not more than the axial length of a coiling shaft; peripheral outer teeth are arranged at two end parts and the middle part of the torsion bar and the outer teeth at the two end parts of the torsion bar are matched with inner teeth of central concave holes of end faces of the two end faces on the coiling device; the peripheral outer teeth at the middle part are matched with inner teeth arranged at the middle section of a through hole at a central axis position of a core shaft; the torsion bar is divided from the middle part of the axial direction to form a two-section type structure; and the peripheral outer teeth at the middle part are located at abutted end parts of two sections. Compared with the prior art, the torsion bar disclosed by the invention does not pass through an end cover and is shorter in length, so that the torsion bar is not easy to bend and deform and the use process is safer and more stable. The torsion bar is divided into the two sections, so that different safety belt force limiting value requirements can be met through the combination of different diameters or materials. The invention further provides the safety belt coiling device using the torsion bar and a safety belt assembly.

Owner:和励科技有限公司

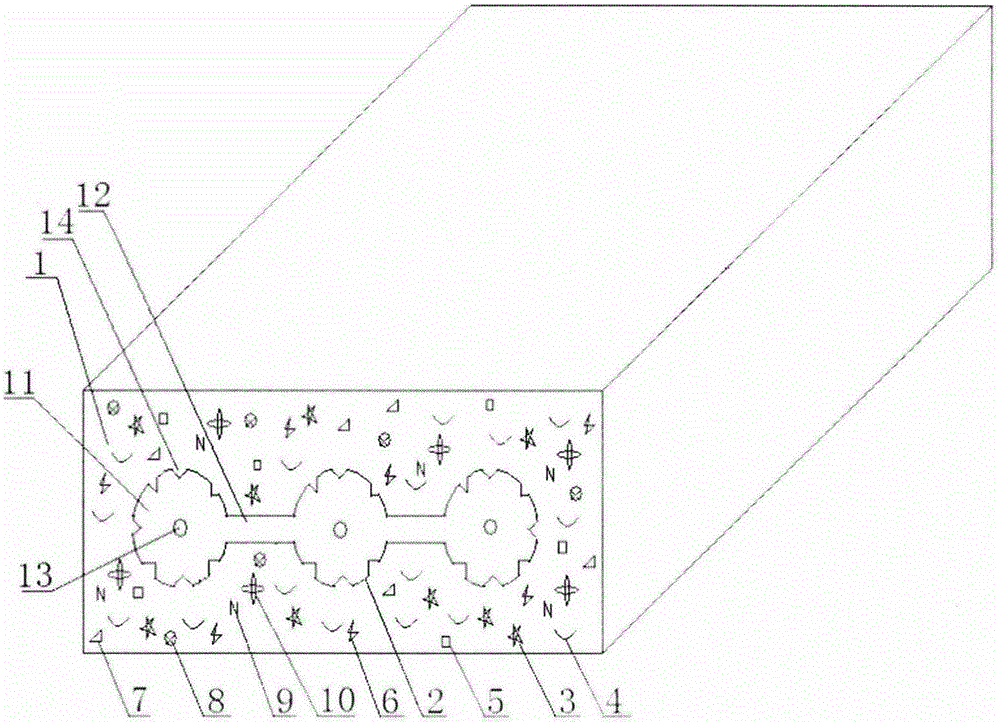

Internally-enhanced lightweight composite plate and production method thereof

The invention relates to an internally-enhanced lightweight composite plate and a production method thereof; the internally-enhanced lightweight composite plate is composed of a micro-foamed plastic-wood composite layer and a hollow fiber-reinforced plastic internal enhancement layer; the micro-foamed plastic-wood layer is made by mixing modified plastic particles, wood powder, chitosan, chlorinated polyethylene, stearic acid, azodicarbonamide, baking soda and citric acid, and calendering. The hollow fiber-reinforced plastic internal enhancement layer is formed of hollow pillar tubes and connection plates arranged among the hollow pillar tubes, and the hollow pillar tubes are provided with a hollow tube in the center and V-shaped grooves in the outer surface. The internally-enhanced lightweight composite plate is reasonable in design, simple in structure, unique in shape, and convenient to produce and manufacture, and can be produced and processed just by using traditional fiber-reinforced plastic hand lay-up and plastic mixing as well as die pressing process, the production process is highly mechanized, less labor is reduced, and the internally-enhanced lightweight composite plate is low in production cost, good in strength, high in modulus, high in rigidity and creep-resistant, rarely deforms and bends during usage, and is higher in bearing capacity; the internally-enhanced lightweight composite plate is suitable for the manufacture of products, such as trays, packaging boxes, floor plates, shelving boards, car sheds, roofs, and building forms.

Owner:NANJING FORESTRY UNIV

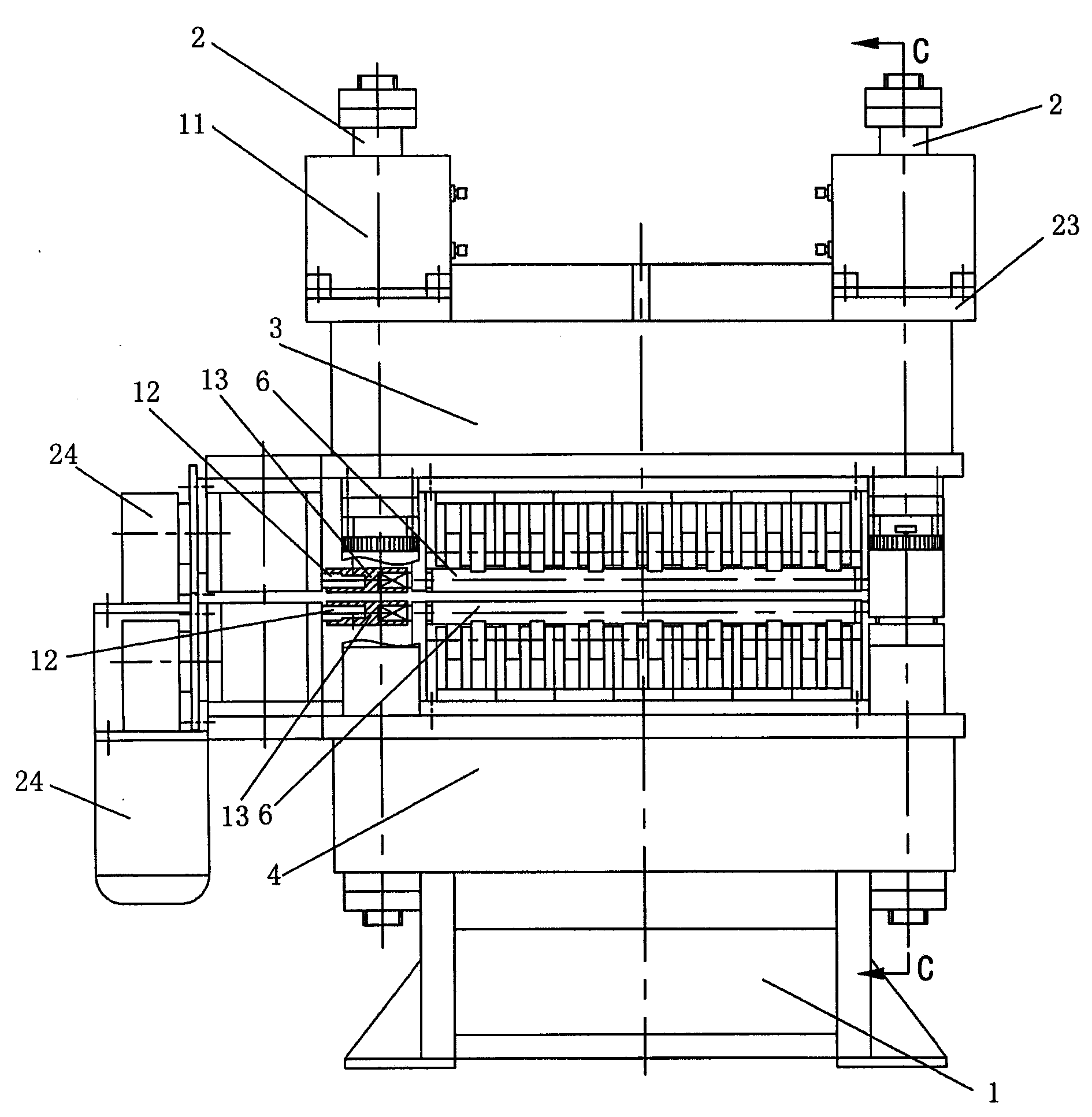

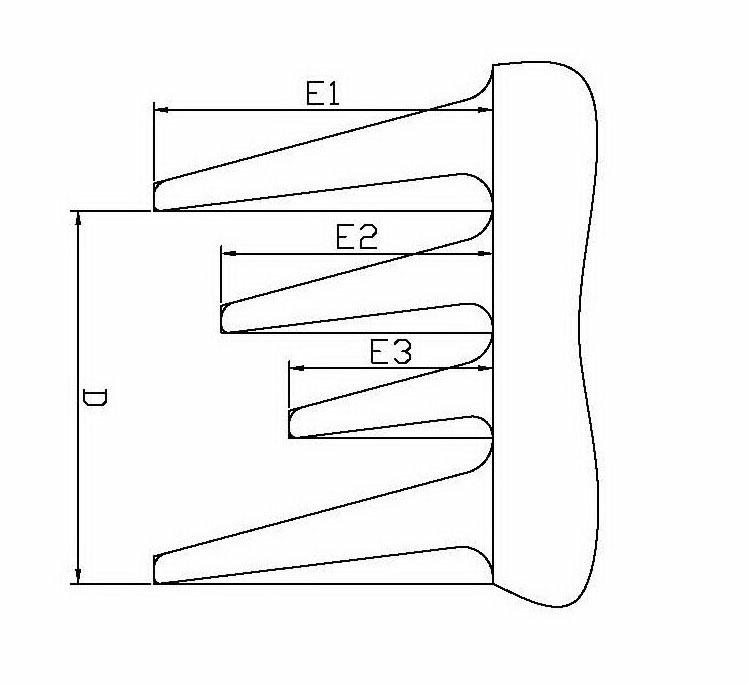

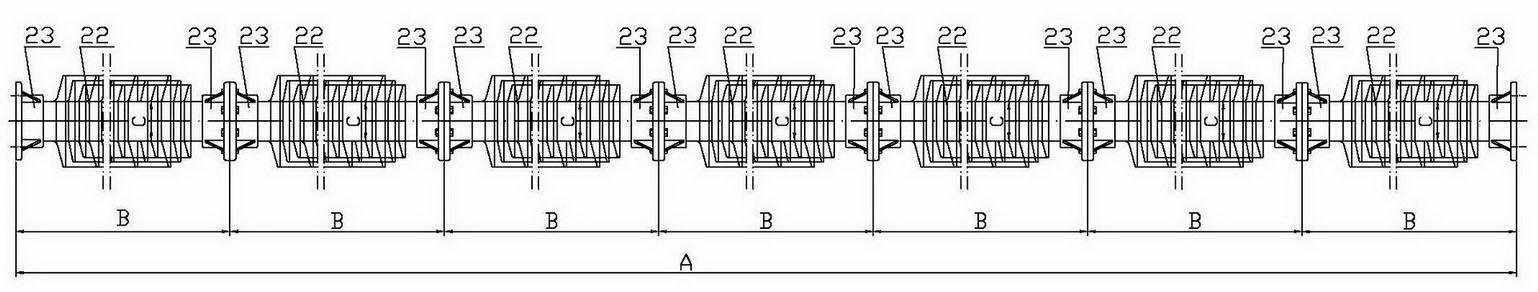

Hydraulic precision leveling machine

The invention discloses a hydraulic precision leveling machine which comprises an upper roller group, a lower roller group, a load bearing beam, a machine base and four upright posts, wherein the upper roller group and the lower roller group are respectively and fixedly provided with power decelerating devices, the load bearing beam is composed of an upper beam and a lower beam which is fixedly arranged on the machine base, the upper roller group is fixedly connected with the upper beam, the lower roller group is fixedly connected with the lower beam, the four upright posts are respectively and fixedly sheathed on four corners of the lower beam, and the upper beam can be movably sheathed on the four upright posts. Both the upper roller group and the lower roller group comprise a plurality of leveling rollers, wall plates, a plurality of support brackets, a plurality of fixing shafts and a plurality of support jockey pulleys, wherein the leveling rollers are arranged side by side and can be rotatablely supported on the wall plates on both sides, the fixing shafts are supported on the support brackets, and the support jockey pulleys can be rotatablely sheathed on the corresponding fixing shaft. The hydraulic precision leveling machine has the advantages of high leveling precision, simple structure and low manufacturing cost, and leveling requirements for plates with different thicknesses can be satisfied.

Owner:常州市中安机械制造有限公司

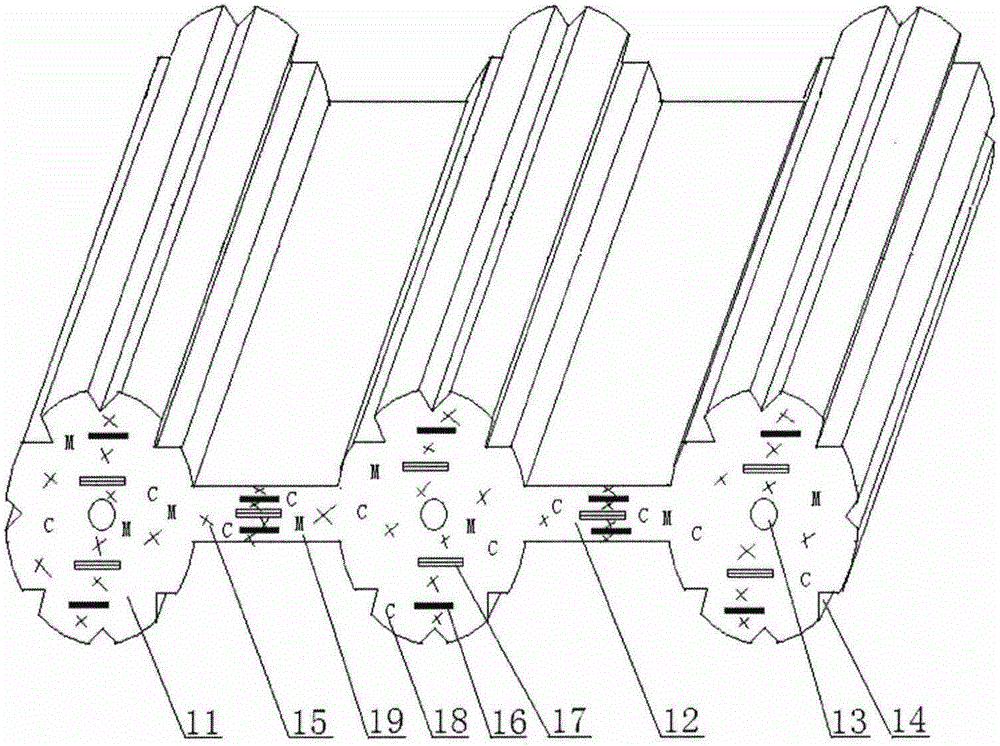

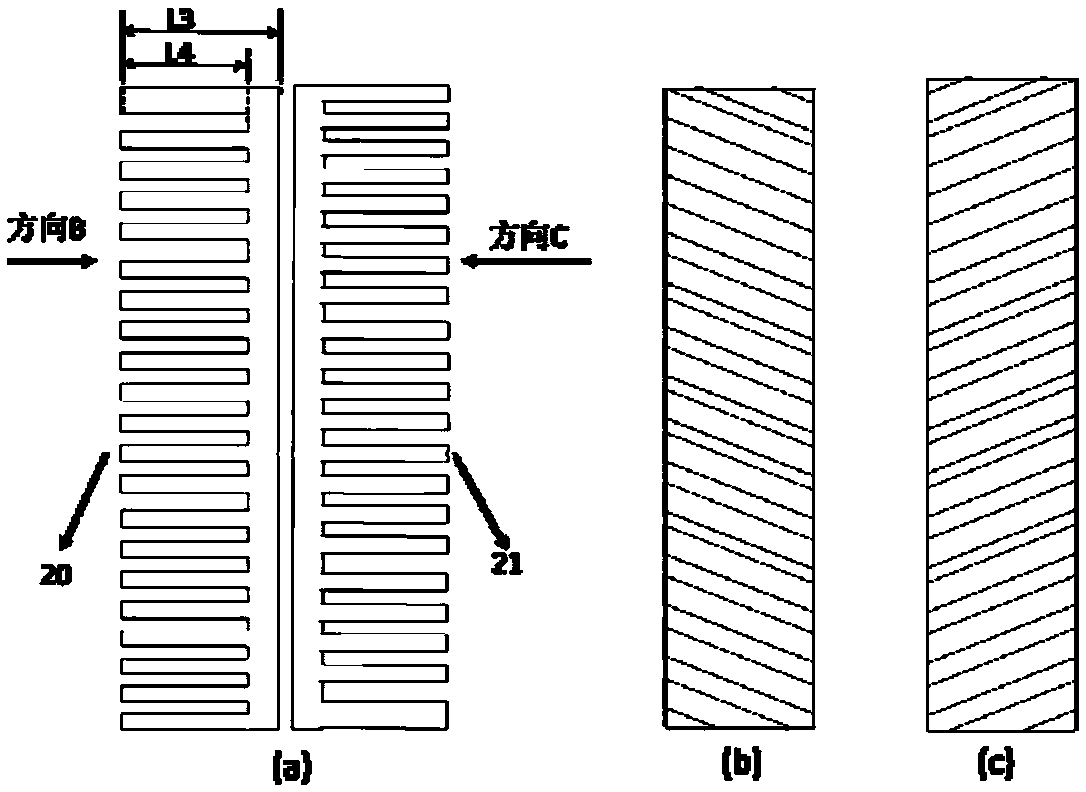

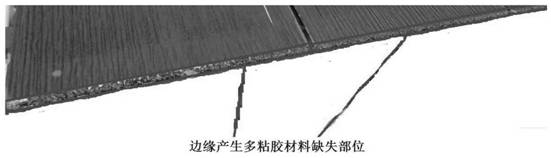

Plate core of artificial structural plate and manufacturing method thereof

InactiveCN110405867AImprove fastnessIncrease contactLaminationLamination apparatusEnvironmental resistanceAdhesive

The invention provides a plate core of an artificial structural plate. The plate core of the artificial structural plate comprises a plurality of core strip units, the core strip units are provided with multi-layer structures in the length direction of the plate core, each core strip unit at least comprises a double-transverse pressure-bearing body which extends in the length direction of the plate core and an inclined pulling structure which is obliquely arranged relative to the double-transverse pressure-bearing body, each core strip unit sequentially comprises the double-transverse pressurebearing body and the inclined pulling structure in the length direction of the plate core, and is formed by stacking and bonding the double-transverse pressure bearing body and the inclined pulling structure, and the core plate is formed by repeatedly stacking the core strip units in the length direction of the plate core. According to the plate core of the artificial structural plate, the strength of the artificial plate can be effectively improved, the bearing capacity of the artificial plate is improved, the using amount of an adhesive is reduced, and the effects of being green and environment-friendly are achieved. On the basis, the invention further provides a manufacturing method of the plate core. The method can be used for mechanical operation, and is simple in process and high inproduction efficiency.

Owner:ZHENJIANG SUNSIER DENDRO TECH CO LTD

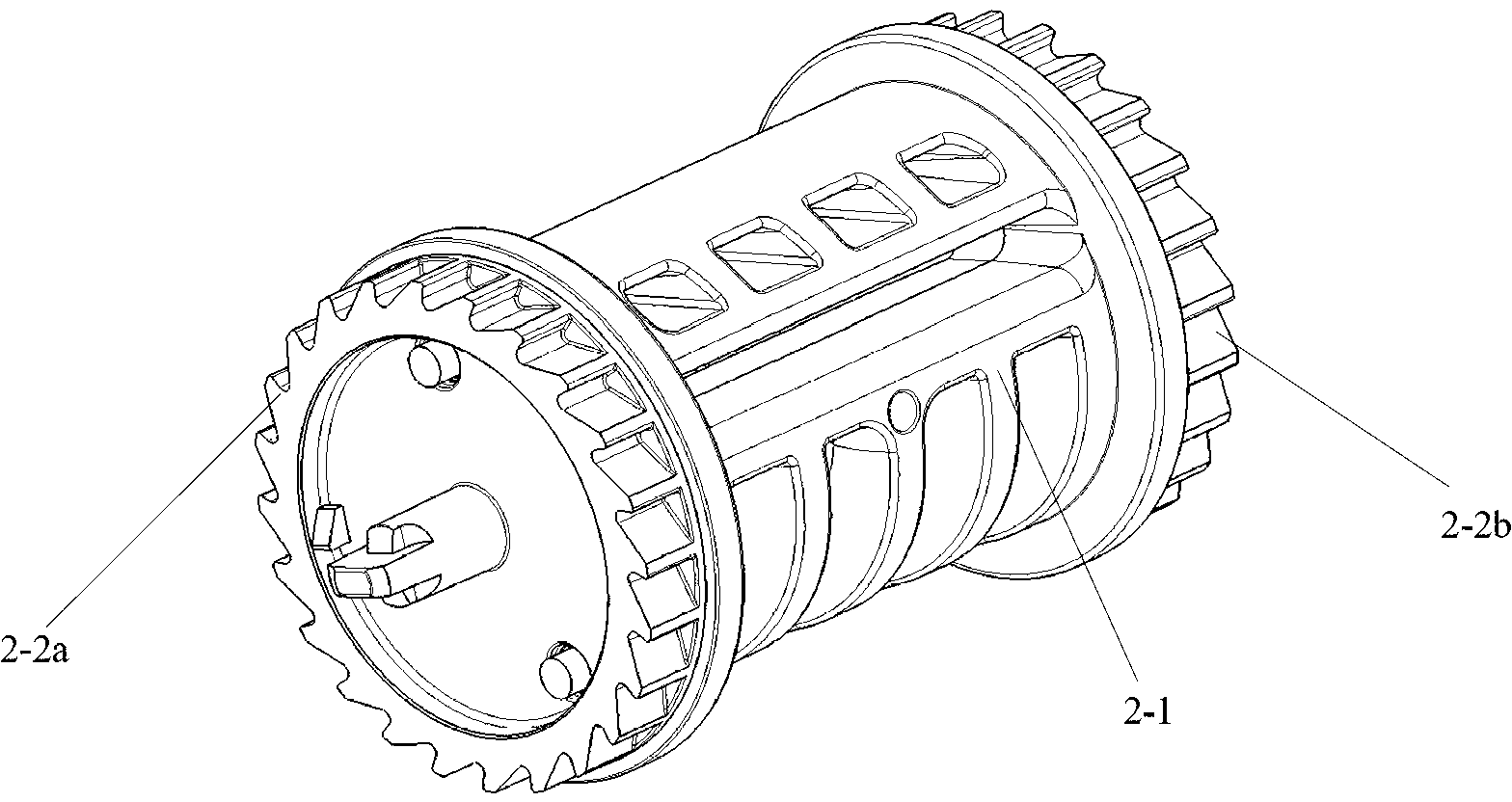

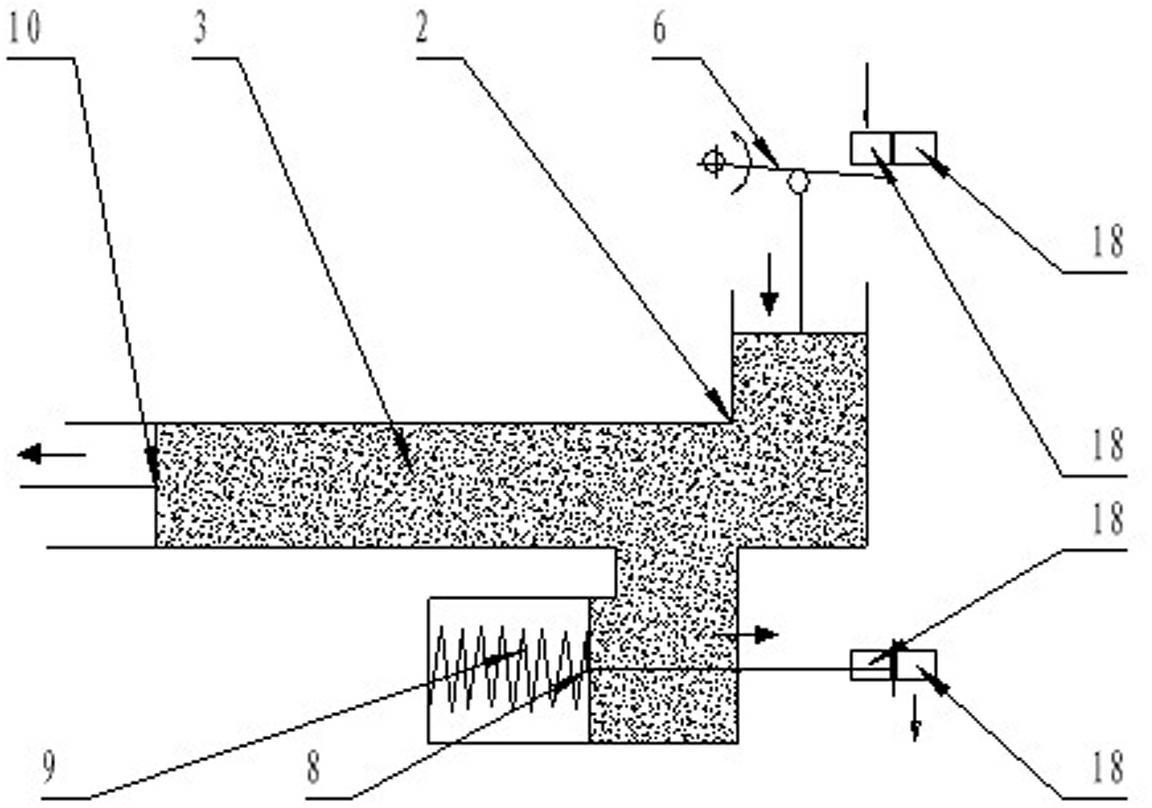

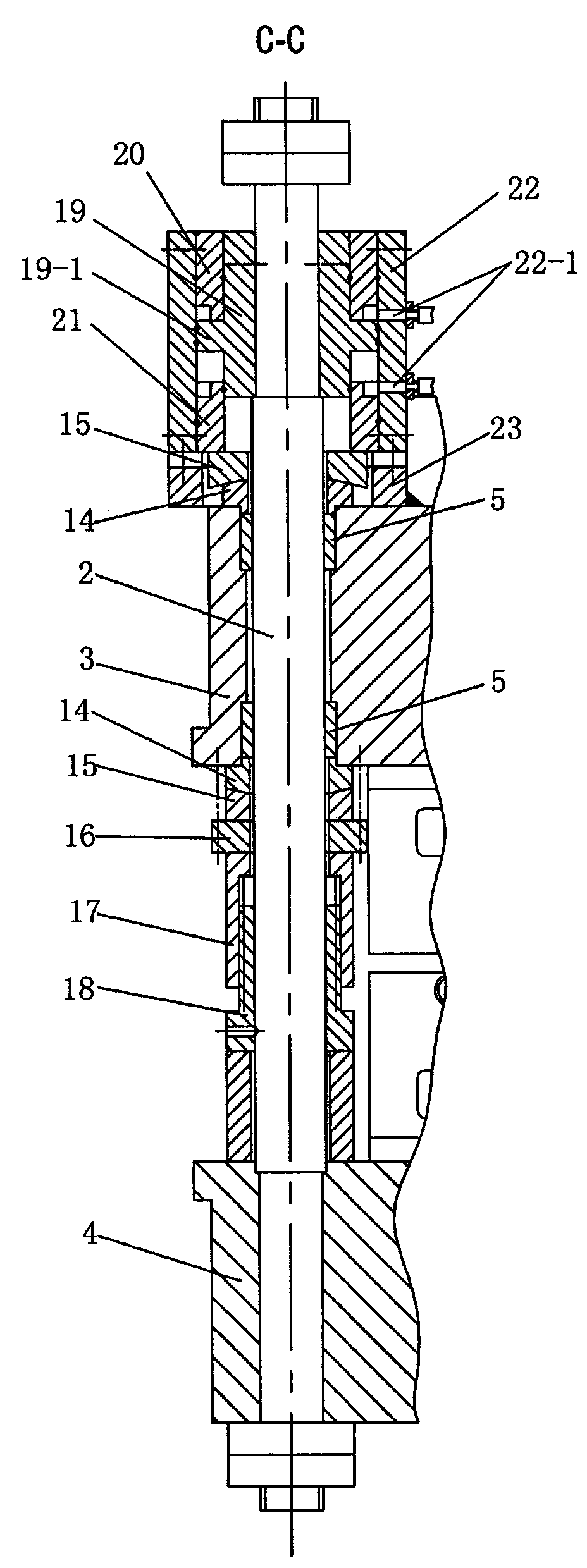

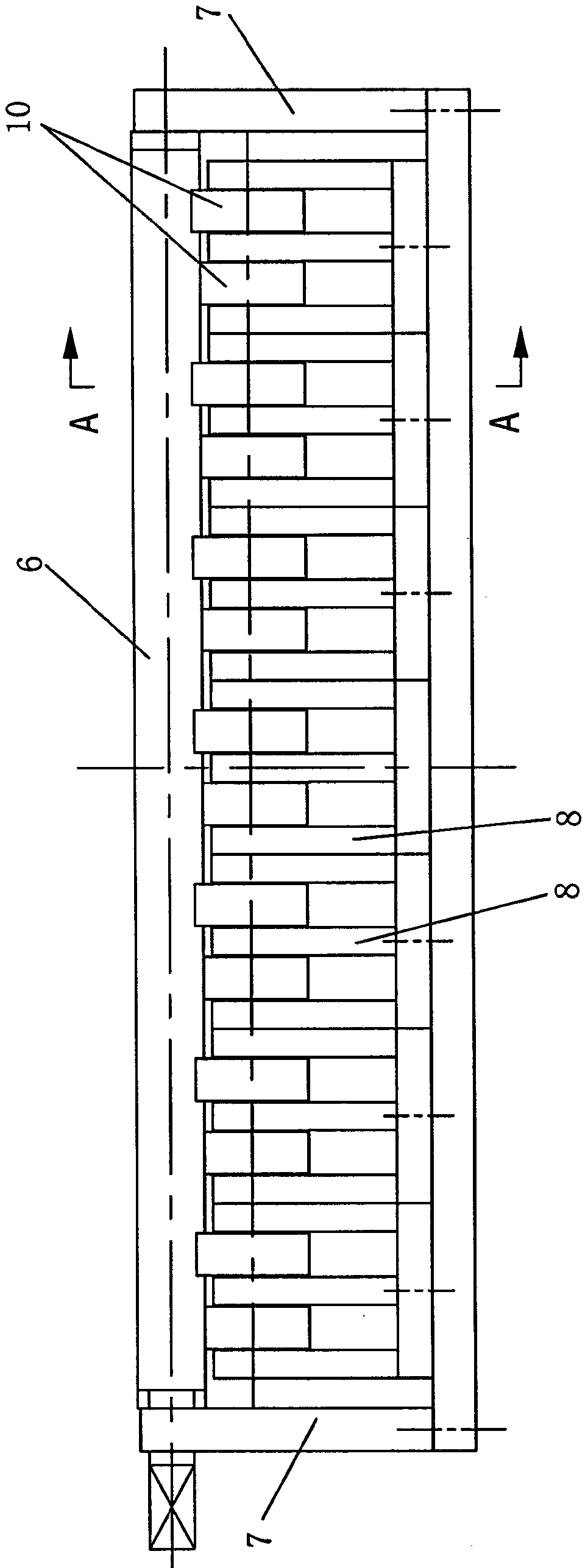

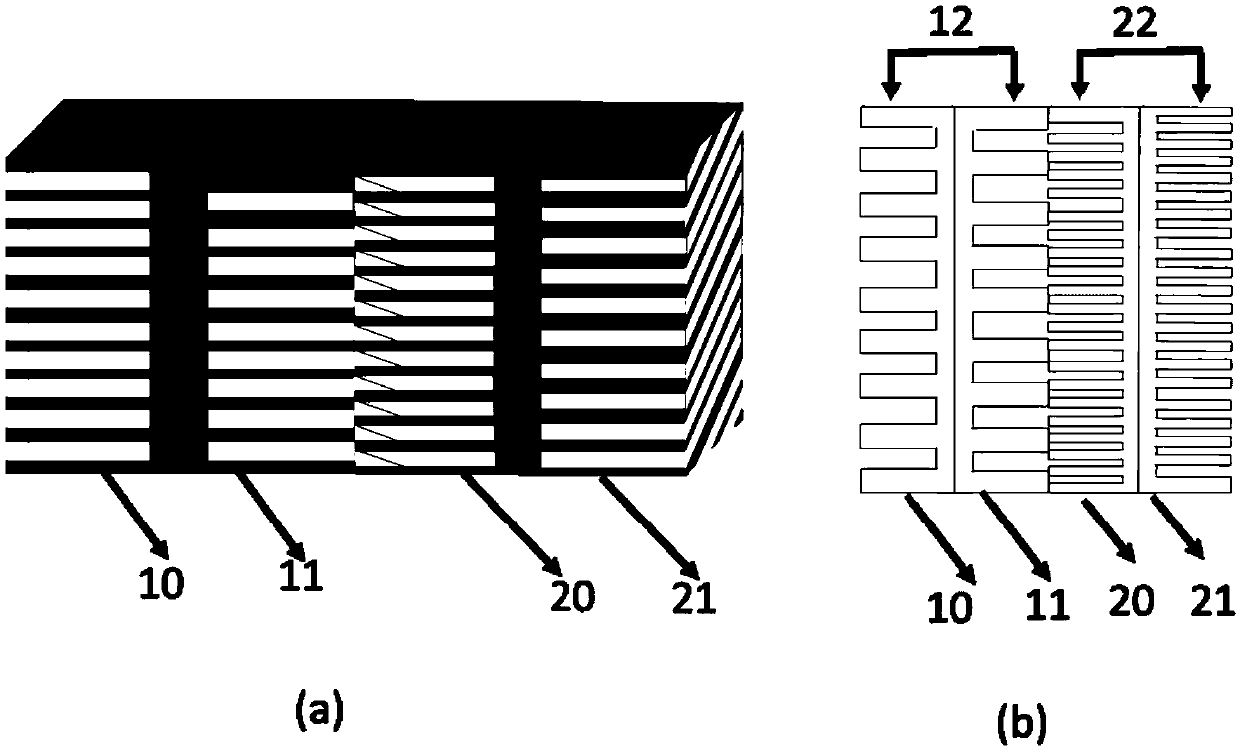

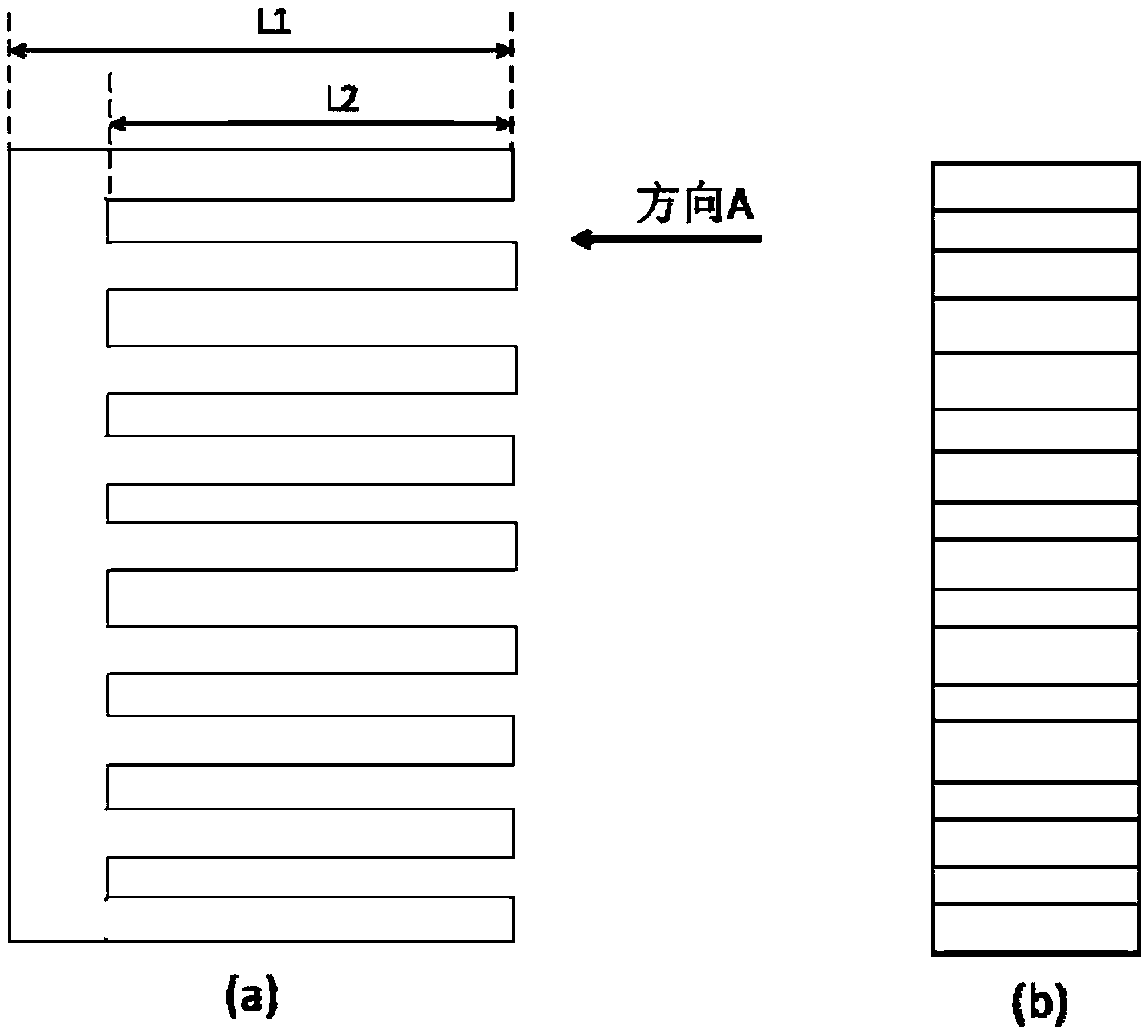

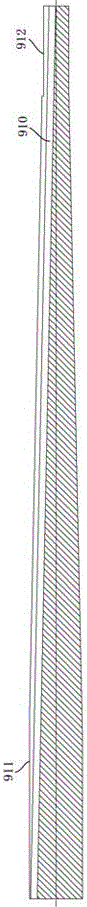

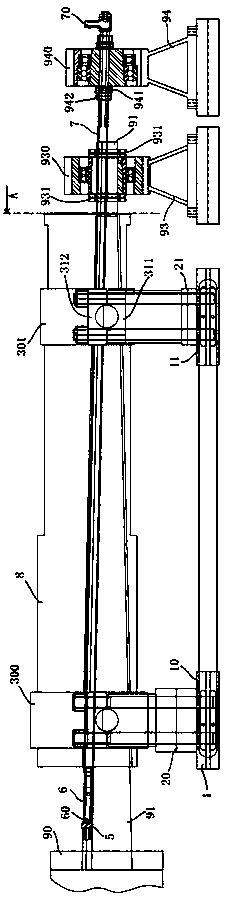

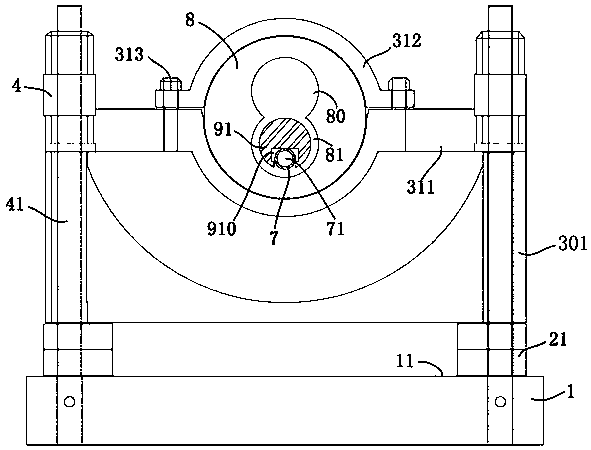

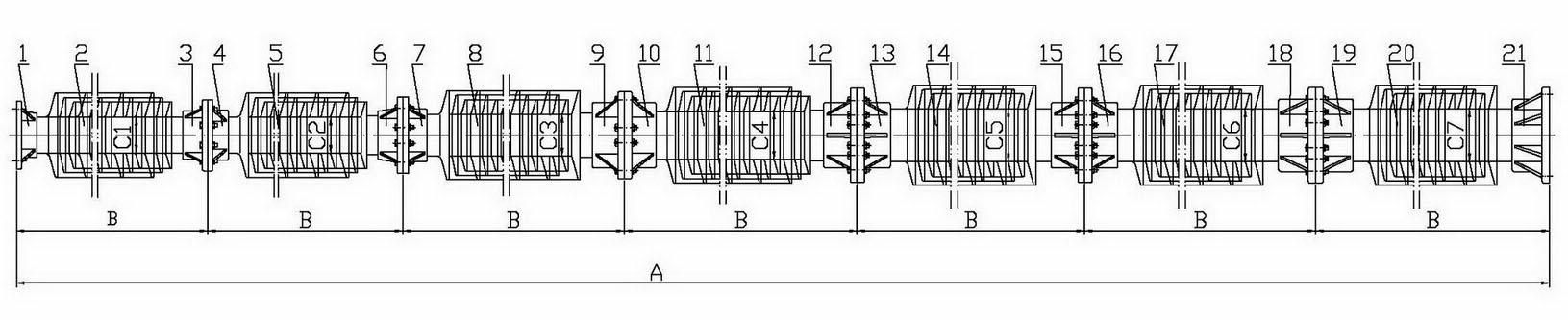

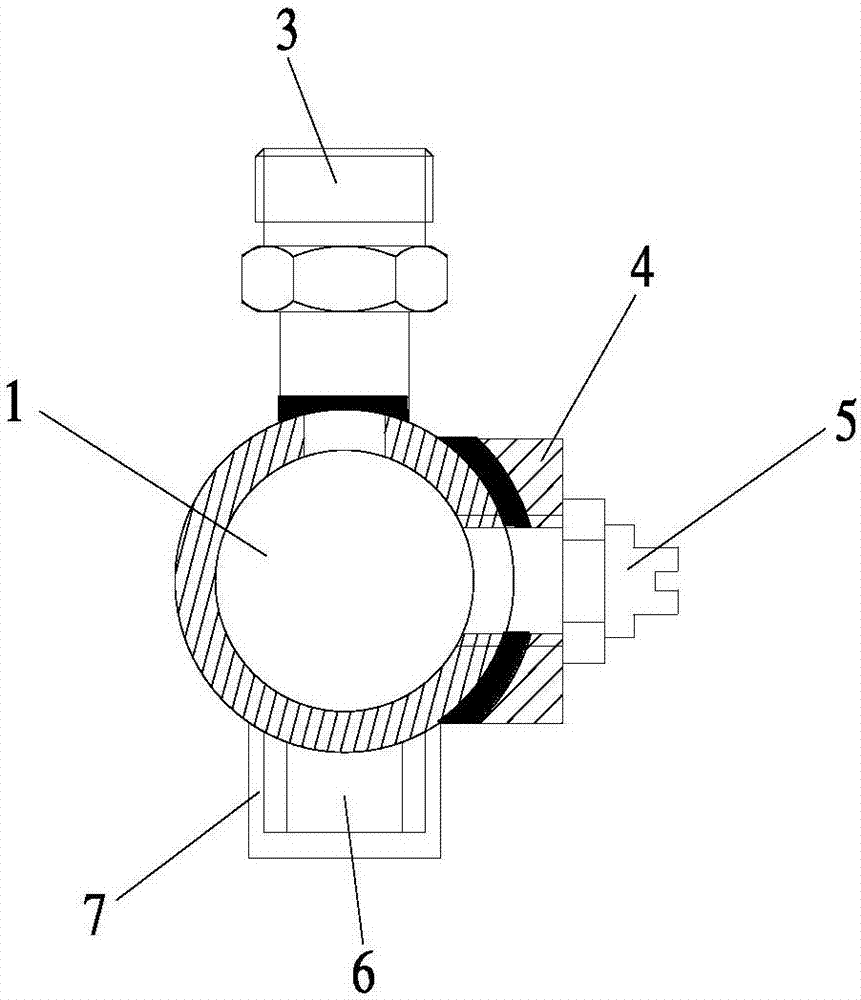

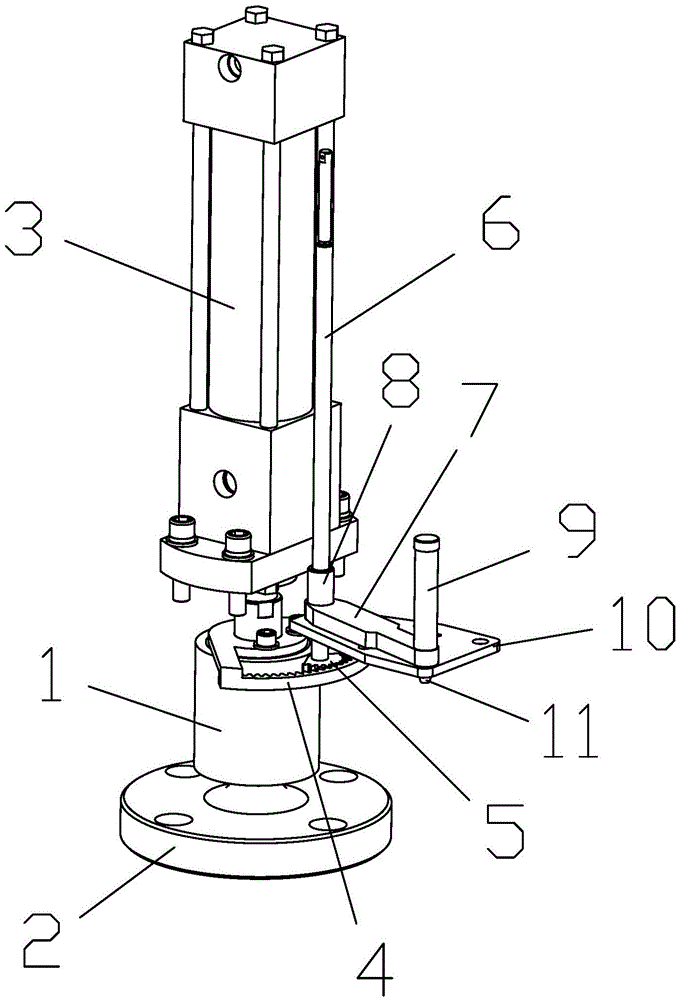

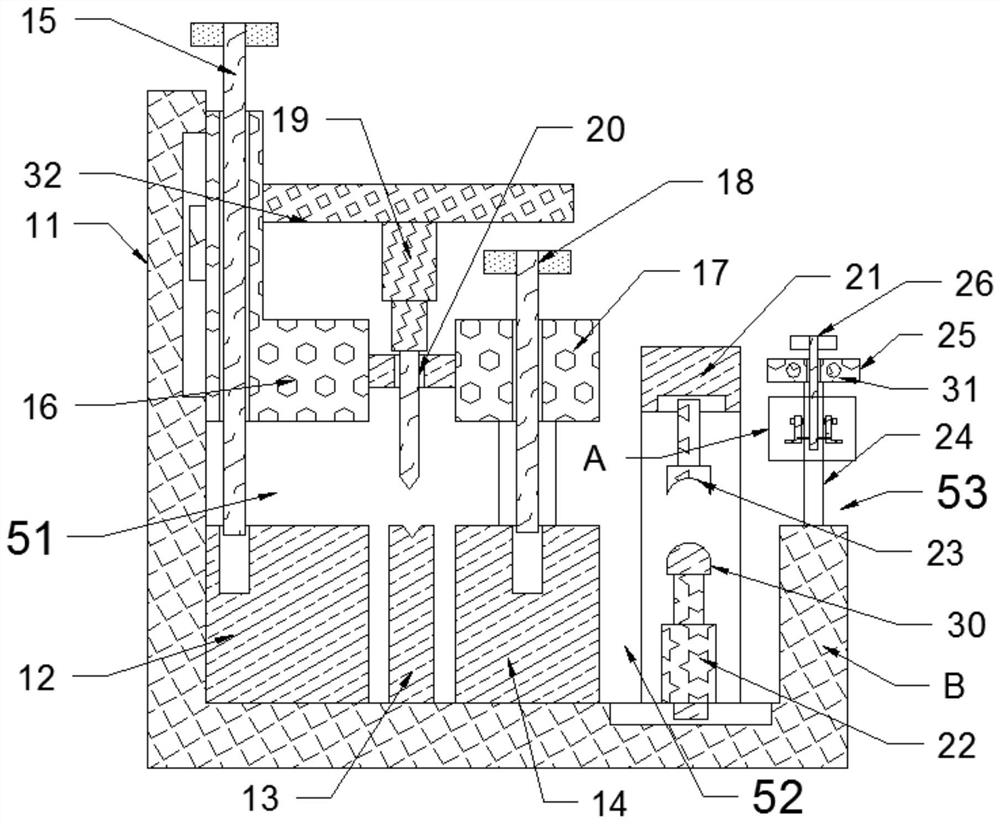

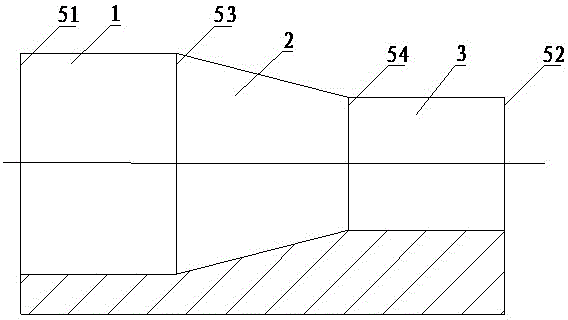

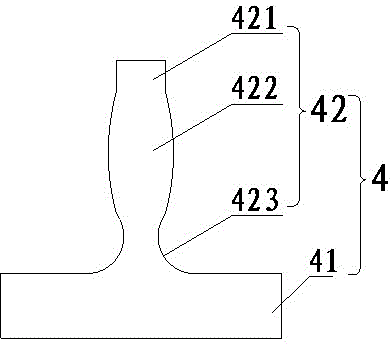

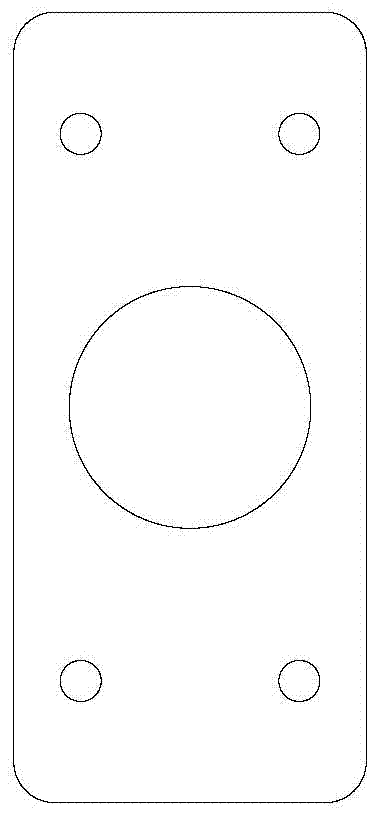

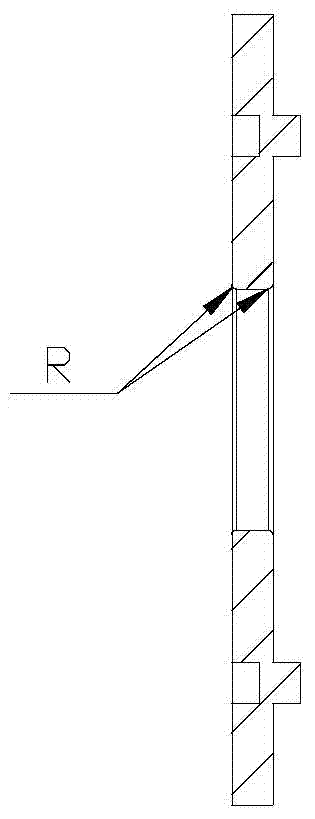

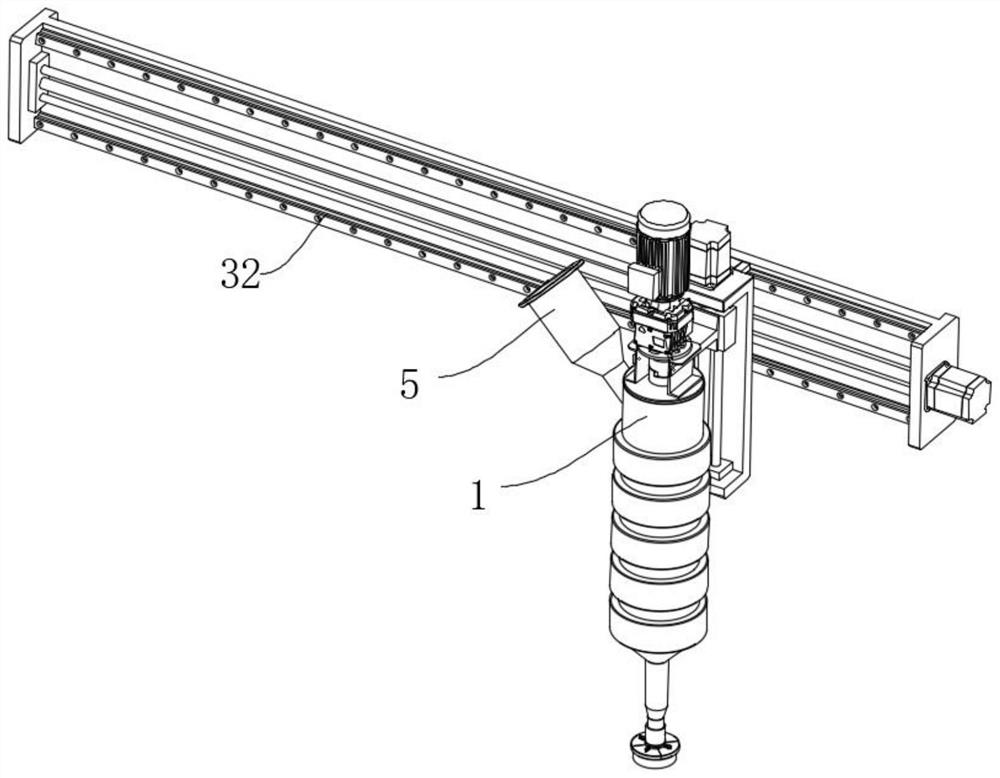

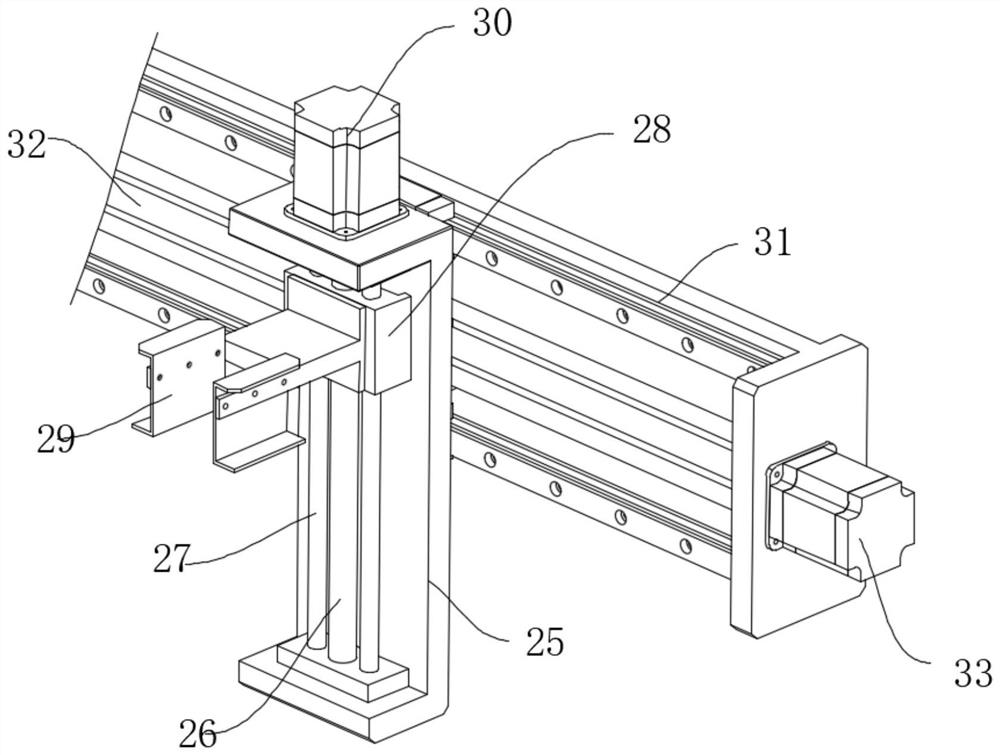

Boring cutter installing shaft, boring assembly and boring mill

InactiveCN105772793AImprove stabilityNot prone to bending deformationTurning toolsTool holdersMechanical engineering

The invention provides a boring cutter installing shaft, a boring assembly and a boring mill. The boring mill comprises a rack and the boring assembly. The boring assembly comprises a boring cutter rotating relative to a workpiece, and the boring cutter installing shaft. The boring cutter installing shaft comprises a shaft body, the shaft body is used for stretching into a to-be-machined hole of the workpiece during using, and the two ends of the shaft body extend out of the two ends of the to-be-machined hole to form two supporting ends. A guiding structure used for guiding moving assembly of the boring cutter so as to enable the boring cutter to machine the to-be-machined hole into a needed forming hole is arranged on the shaft body in the length direction in an extending manner. The boring mill further comprises a driving mechanism used for driving the boring cutter to move along the guiding structure in a guiding manner. When the boring assembly is used for conducting boring, due to the fact that the two ends of the shaft body are the supporting ends and are stably supported, the whole boring cutter installing shaft is good in stability and not prone to bending or deforming, the boring cutter moves along the shaft body in the guiding manner and rotates relative to the workpiece, the boring cutter is stable and reliable when boring the inner circumferential face of the to-be-machined hole, vibration cannot happen, the inner hole machining precision is greatly improved, and the machining quality is guaranteed.

Owner:赵圣和

a boring machine

InactiveCN105772793BImprove stabilityNot prone to bending deformationTurning toolsTool holdersEngineeringMechanical engineering

The invention provides a boring cutter installing shaft, a boring assembly and a boring mill. The boring mill comprises a rack and the boring assembly. The boring assembly comprises a boring cutter rotating relative to a workpiece, and the boring cutter installing shaft. The boring cutter installing shaft comprises a shaft body, the shaft body is used for stretching into a to-be-machined hole of the workpiece during using, and the two ends of the shaft body extend out of the two ends of the to-be-machined hole to form two supporting ends. A guiding structure used for guiding moving assembly of the boring cutter so as to enable the boring cutter to machine the to-be-machined hole into a needed forming hole is arranged on the shaft body in the length direction in an extending manner. The boring mill further comprises a driving mechanism used for driving the boring cutter to move along the guiding structure in a guiding manner. When the boring assembly is used for conducting boring, due to the fact that the two ends of the shaft body are the supporting ends and are stably supported, the whole boring cutter installing shaft is good in stability and not prone to bending or deforming, the boring cutter moves along the shaft body in the guiding manner and rotates relative to the workpiece, the boring cutter is stable and reliable when boring the inner circumferential face of the to-be-machined hole, vibration cannot happen, the inner hole machining precision is greatly improved, and the machining quality is guaranteed.

Owner:赵圣和

±1120kv DC Rod Porcelain Insulator

InactiveCN102290160AOptimal Design StructureUnique craftsmanshipSuspension/strain insulatorsAdhesiveMetallurgy

The invention discloses a ±1120kV DC rod-shaped porcelain insulator, which is composed of 7 equal-height porcelain components. The connections are fastened by flanges. It is mainly used to support the isolating switch in the converter station of the ±1120kV UHV DC transmission project of the State Grid Corporation of China, and it plays the role of insulation and mechanical support for the isolating switch equipment. The DC rod-shaped porcelain insulator product of the present invention has good design structure, unique process performance, excellent antifouling ability, short production cycle, good product performance, beautiful appearance, the total height of the insulator is reduced to 14700mm, and the bending strength can reach 8kN and above.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

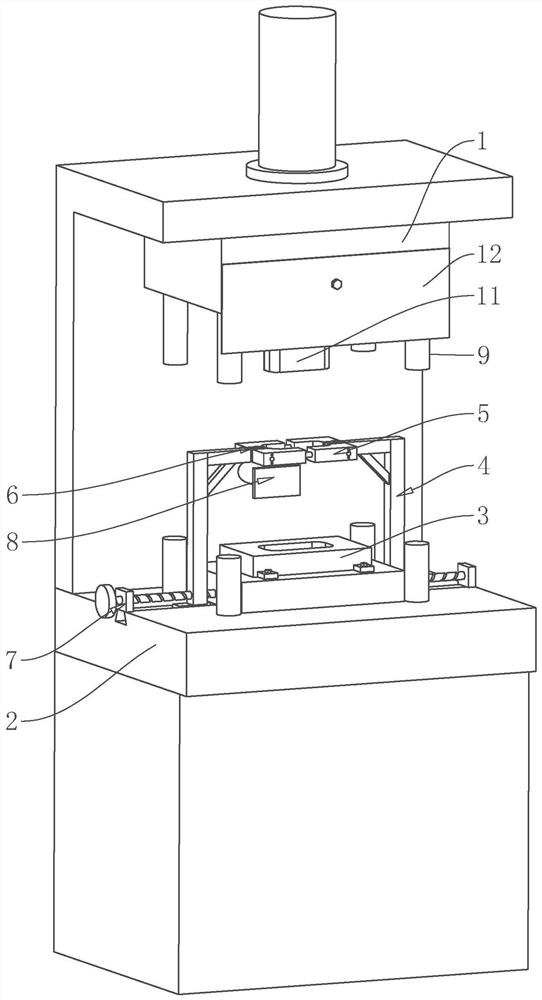

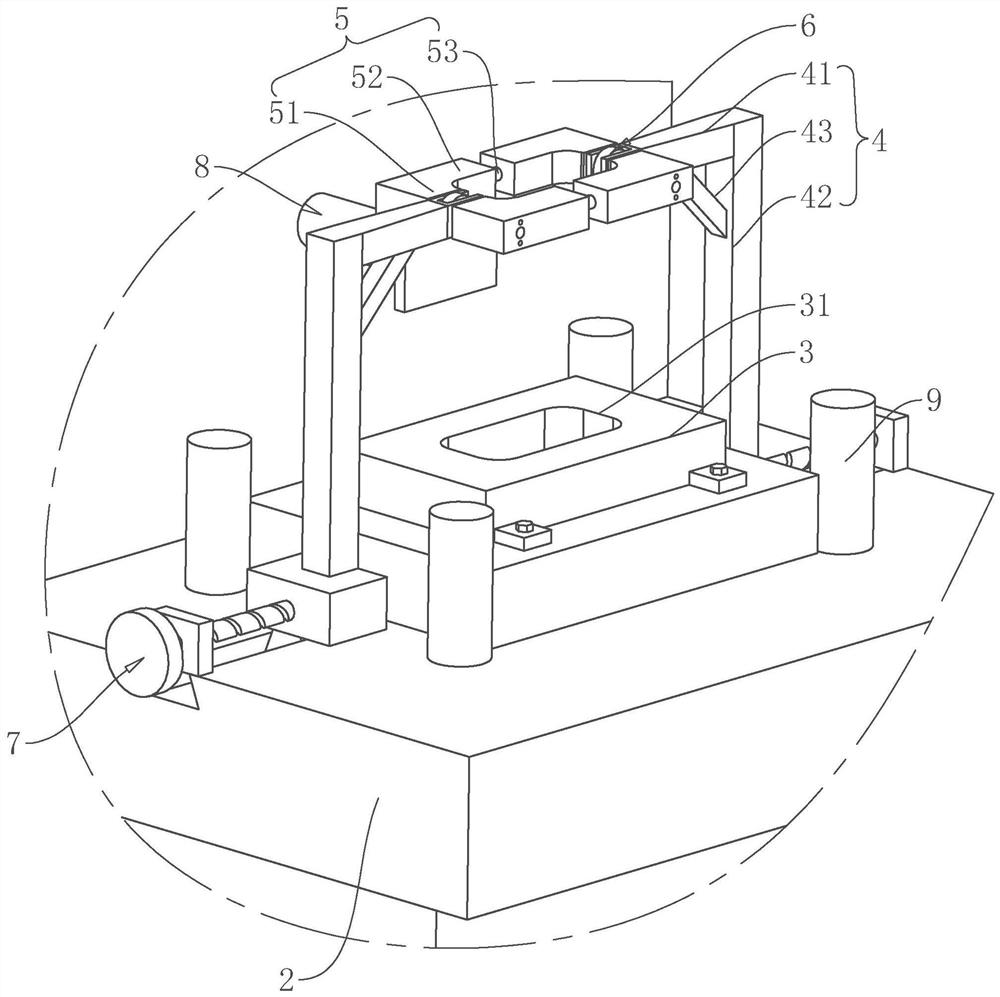

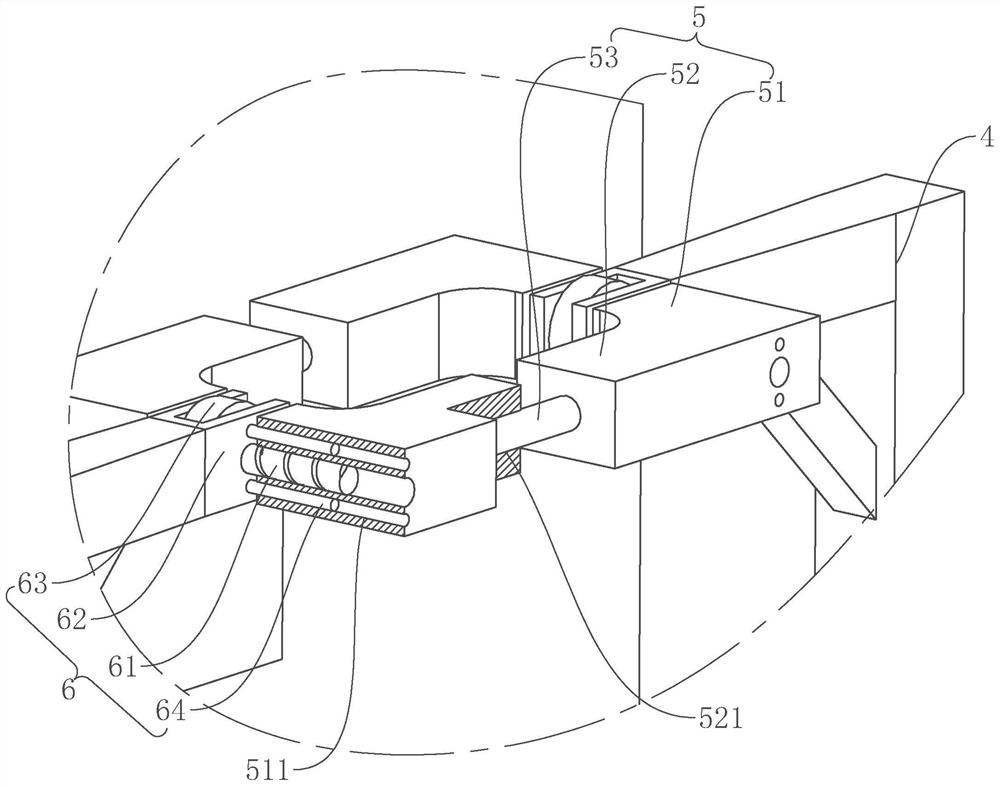

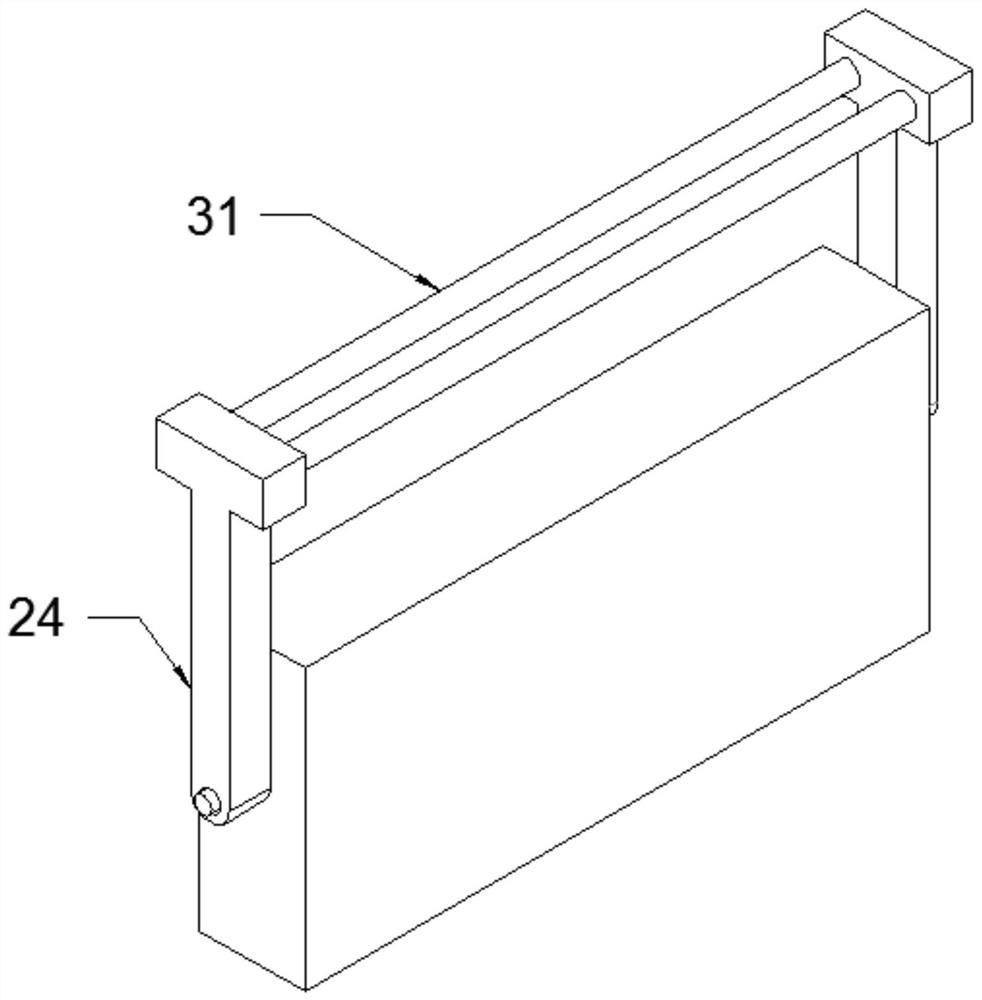

Shell manufacturing mold demolding device for mobile power supply production

PendingCN113732177AImprove operational convenience and precisionIncrease connection areaShaping toolsEjection devicesManufacturing engineeringMold removal

The invention relates to a shell manufacturing mold demolding device for mobile power supply production and relates to the field of mobile power supply production. The mold demolding device comprises stamping equipment, a mold arranged below the stamping equipment, a rack arranged below the mold at an interval, a filler box detachably connected to the upper side of the rack, two supporting frames slidably connected to the upper side of the rack and a demolding adjusting frame arranged between the two supporting frames. The demolding adjusting frame comprises two longitudinal rod groups and two transverse rod groups, each longitudinal rod group comprises two longitudinal adjusting rods, and each transverse rod group comprises two transverse adjusting rods; a longitudinal adjusting mechanism used for adjusting a distance between the two longitudinal adjusting rods is arranged in each longitudinal rod group, and a transverse adjusting mechanism used for adjusting a distance between the two transverse adjusting rods in each transverse rod group is arranged between the two supporting frames and the rack. The shell manufacturing mold demolding device has the effects that the size of a demolding device is convenient to adjust, and shells of different sizes are convenient to machine.

Owner:SHENZHEN HUAMEI XINGTAI TECH CO LTD

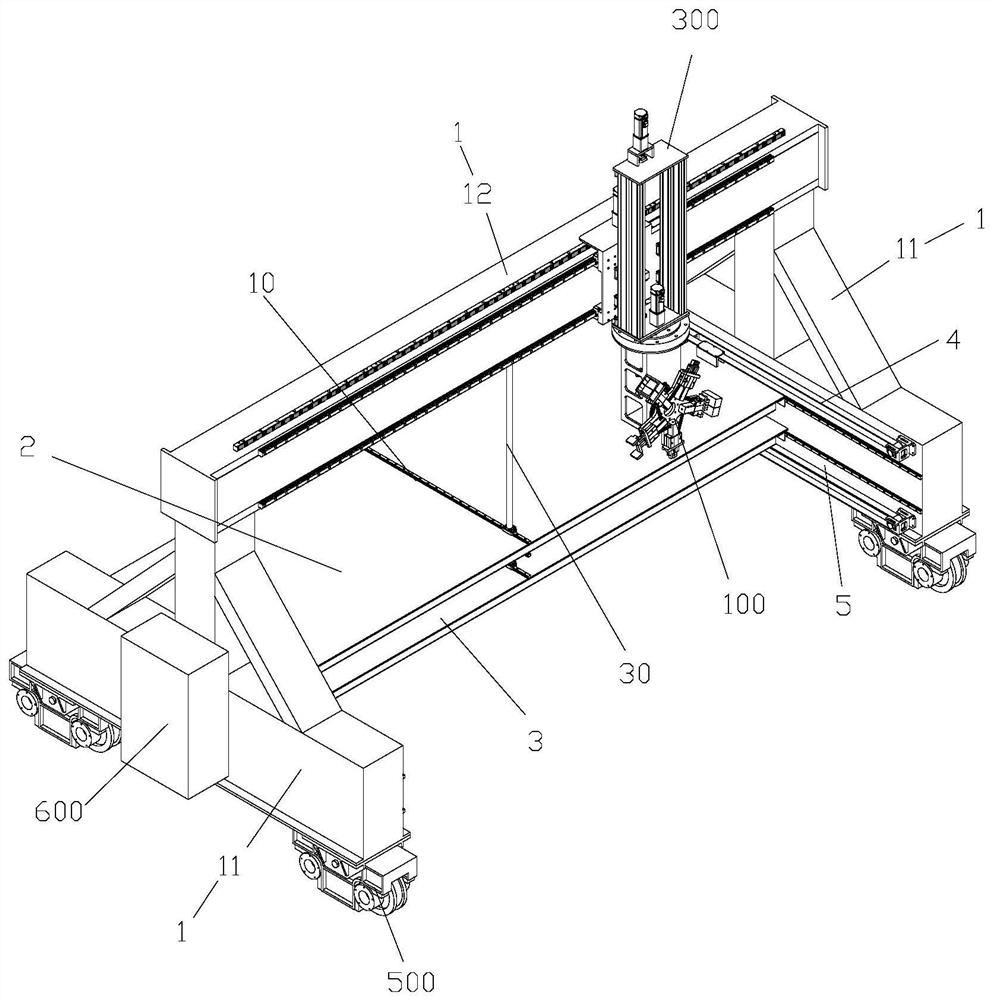

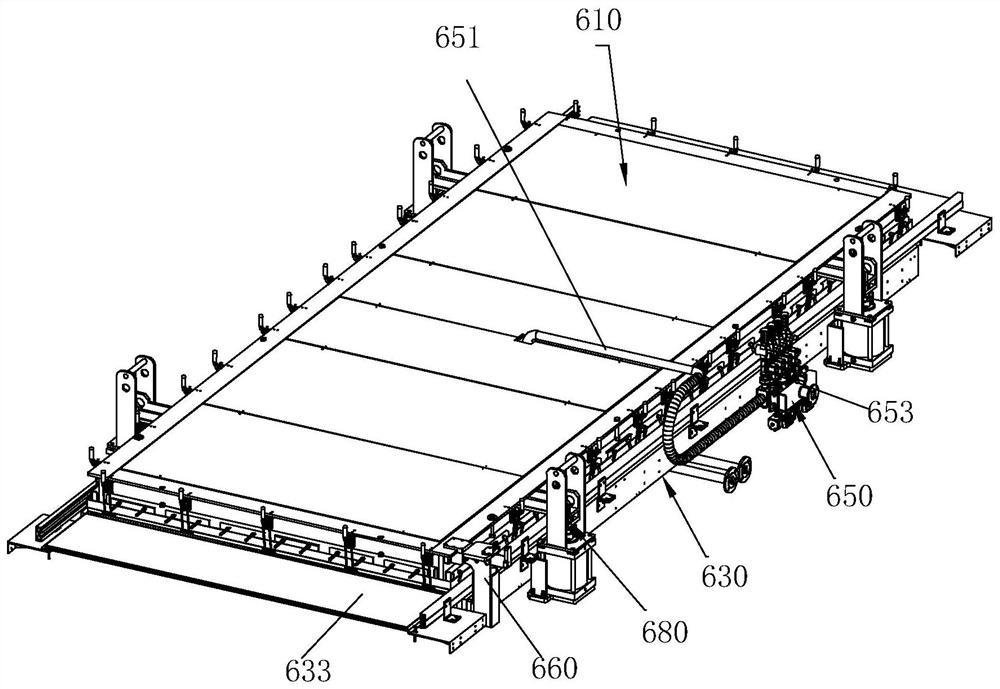

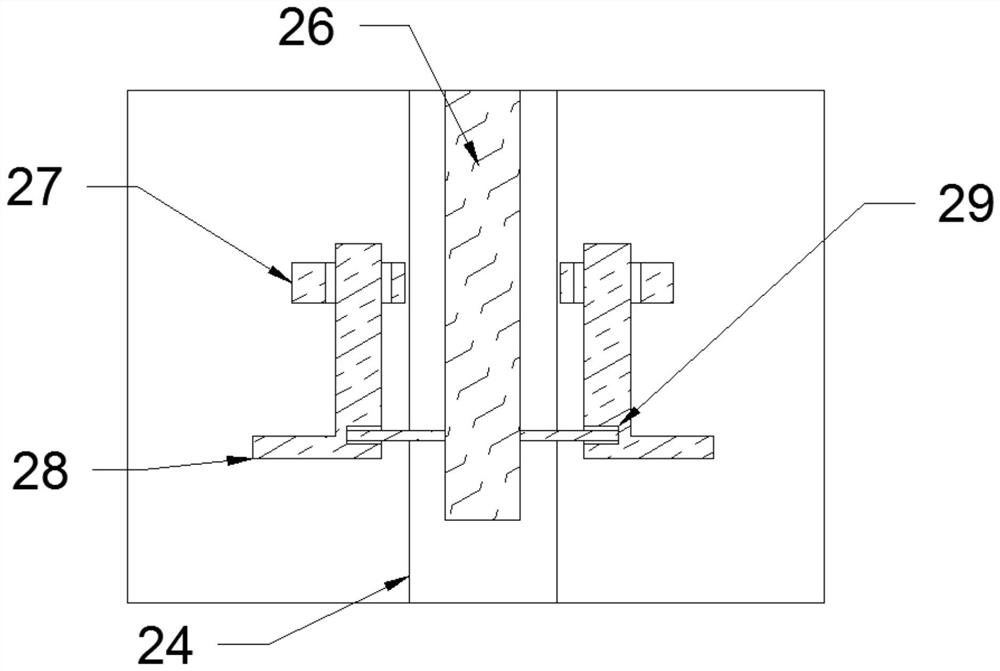

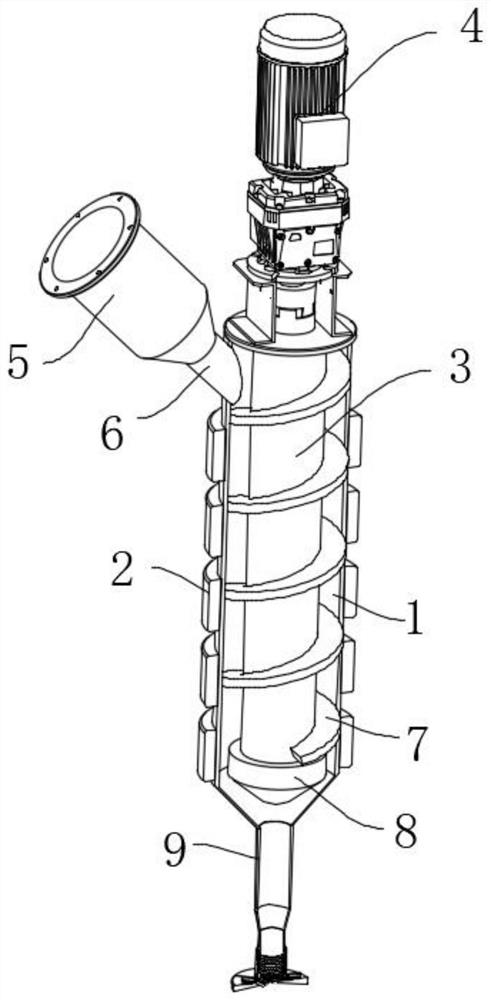

Workpiece storage mechanism and workpiece picking and placing equipment

InactiveCN111960099APlay the role of reinforcementNot prone to bending deformationConveyorsControl devices for conveyorsEngineeringMechanical engineering

The invention provides a workpiece storage mechanism and workpiece picking and placing equipment. The workpiece storage mechanism comprises a rack, a first tray and a first reinforcing structure, wherein the first tray is used for bearing a workpiece, and the first end and the second end, which are oppositely arranged in a first preset direction, of the first tray, are in sliding fit with the rack, so that the first tray is slidably arranged on the rack in the second preset direction; the second preset direction is perpendicular to the first preset direction; the first reinforcing structure isin sliding fit with the first tray, so that when the first tray slides relative to the rack, the first reinforcing structure exerts upward force on the first tray; and the position between the firstreinforcing structure and the first tray is located between the first end and the second end of the first tray. The workpiece storage mechanism solves the problem of poor bearing capacity of the traystructure in the prior art.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

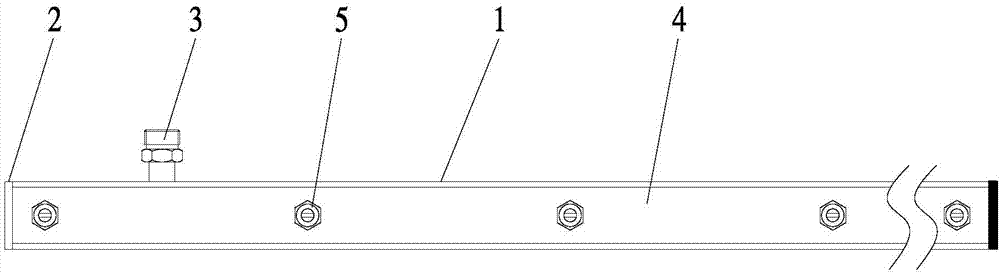

Deformation-resistant anti-freezing sprayer nozzle component for sanitation cleaning trolley

InactiveCN107088481AImprove cleaning efficiencyEliminate Welding ErrorsSpray nozzlesSprayerStructural engineering

The invention discloses a deformation-resistant anti-freezing sprayer nozzle component for a sanitation cleaning trolley. The deformation-resistant anti-freezing sprayer nozzle component comprises a sprayer nozzle, wherein a plug is fixed at each of the two ends of the sprayer nozzle; and a water supply connector is arranged on the side wall of the sprayer nozzle. The deformation-resistant anti-freezing sprayer nozzle component further comprises a connecting plate, wherein one side of the connecting plate is integrally welded with the outer wall of the sprayer nozzle; the other side of the connecting plate is a flat and straight face; a plurality of threaded holes leading to the interior of the sprayer nozzle are formed in the flat and straight face at intervals along the axis of the sprayer nozzle; the axes of the threaded holes are within the same plane; each threaded hole is in threaded connection with a nozzle; and a heating device is arranged on the outer wall of the sprayer nozzle, extends in the axial direction of the sprayer nozzle and is used for heating the sprayer nozzle. According to the deformation-resistant anti-freezing sprayer nozzle component, a linear water curtain is formed during operation of the plurality of nozzles, so that the cleaning efficiency is improved, and the sprayer nozzle and the nozzles can be prevented from blockage and even frost crack due to freezing.

Owner:FUJIAN LONGMA ENVIRONMENTAL SANITATION EQUIP

An integral push-and-pull method for installation of roadway anchor cable anchoring agent

ActiveCN104695990BAvoid multiple pushesReduce labor intensityAnchoring boltsHigh probabilityUltimate tensile strength

The invention discloses an integral push-lead type method for the installation of a tunnel anchor cable anchoring agent. The method comprises the following steps: connecting multiple anchoring agent cartridges filled with the anchoring agent integrally; installing the integrally connected anchoring agent cartridges in a push-lead mechanism; propping an anchor cable against a base plate at the rear end of the push-lead mechanism, and then inserting the push-lead mechanism equipped with the anchoring agent cartridges into a drilled hole formed in rock or coal; pushing the anchor cable toward a drilling direction, so that the push-lead mechanism reaches the top of the drilled hole, using a roof bolter for continuing to push and stir the anchor cable correspondingly, so that the multiple anchoring agent cartridges in the push-lead mechanism are broken, and the anchor cable is anchored in the stable rock or coal by using the anchoring agent. In addition, the invention further provides a device for the method; the device has the advantages of simple structure and good stability, and can effectively solve the problems of multiple-time installation of the anchoring agent cartridges, high probability of blockage of drilled holes, complicated installation process, long support time, high labor intensity of workers and other difficulties restricting the development of the tunnel support technology in the installation process of the existing anchoring agent cartridges.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

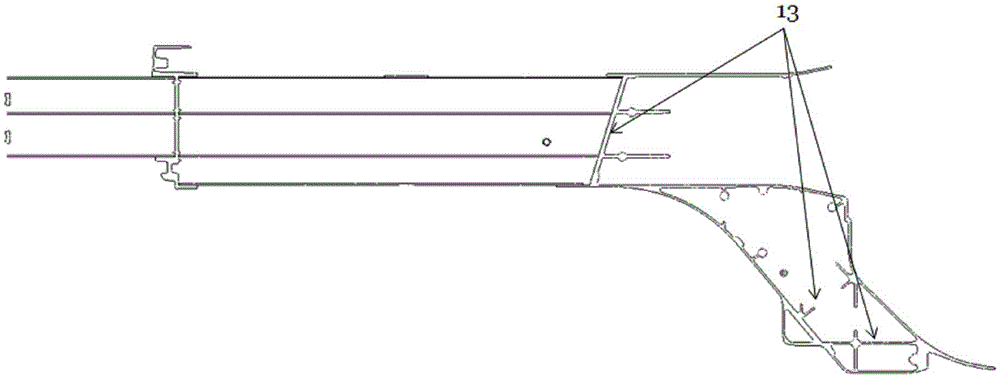

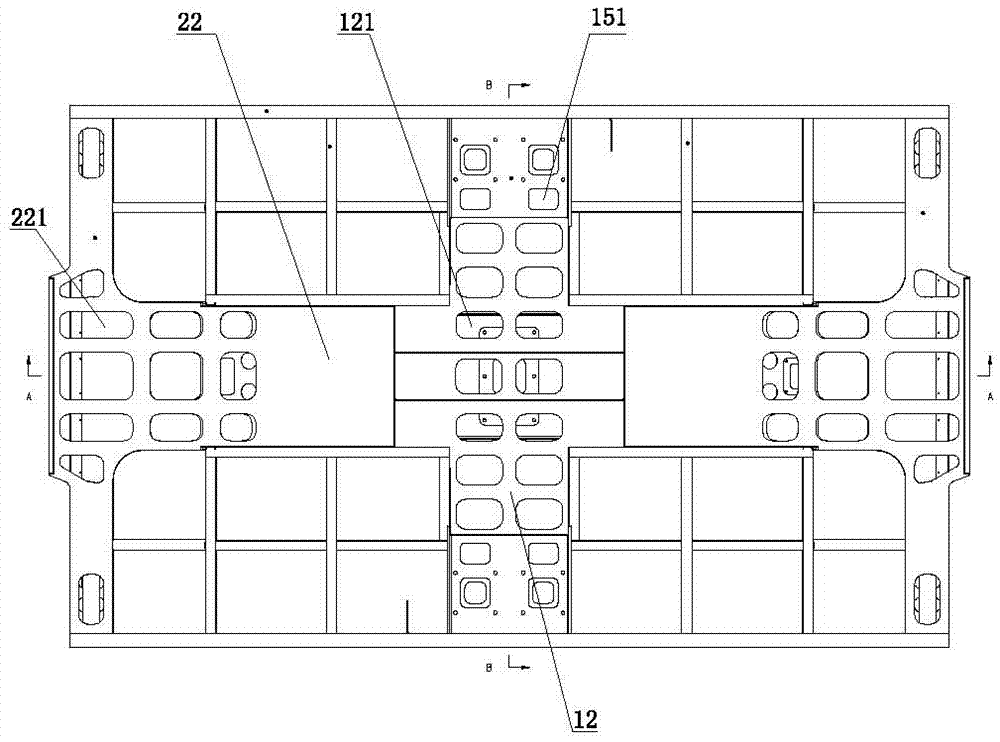

A method of driving a trailer bogie based on a low-floor trailer body

The invention discloses a method for driving a trailer bogie based on the body of a low-floor trailer. Specifically, the driving force is first transmitted to the hinged seat, and the driving force on the hinged seat is along the longitudinal beam lower cover plate, longitudinal beam upper cover plate, The side plates of the longitudinal beam and the ribs of the longitudinal beam are continuously transmitted to the traction connecting seat, and the traction connecting seat transmits the driving force to the frame through the traction device, and transmits the driving force to the wheel set through the primary suspension and the axle box; the longitudinal beam When transmitting the driving force, a vertical component force F will be generated on the part extending obliquely 1 . This method makes the transmission performance of the traction force better, and makes the stability and safety performance of the low-floor trailer good during operation.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

Metal plate machining workbench

The invention relates to a metal plate machining workbench. The metal plate machining workbench comprises a pedestal; four clamping mechanisms and a rubber base are further arranged on the periphery and in the middle of the pedestal respectively; four pull ropes are arranged on the rubber base; the other ends of the pull ropes are connected to the clamping mechanisms; a cross beam is further arranged between two supporting rods at the bottom of the pedestal; a rotating shaft is arranged in the middle of the cross beam; a pedal is installed on the rotating shaft; the pedal is connected with therubber base through a steel chain arranged on the pedal, so that when the pedal is pressed downwards, the four clamping mechanisms are driven by the ropes to clamp a metal plate through the pull-downaction; the four clamping mechanisms are sequentially connected with the pedal in a pull rope connection mode; and in the actual use process, an operator only needs to step on the pedal to enable theround metal plate to be clamped in four directions; stress is concentrated after clamping; the metal plate clamped in the four directions is not prone to bending deformation when punched by punchingequipment; and therefore the metal plate machining workbench is suitable for clamping the round metal plate and is more reasonable in clamping structure.

Owner:WENLING ZHIYING ELECTRONICS TECH CO LTD

Mold locking mechanism of dual-mold vulcanizing machine

The invention discloses a mold locking mechanism of a dual-mold vulcanizing machine. The mold locking mechanism comprises a sector-shaped inner gear, a sector-shaped outer gear, a guiding shaft and a poking rod, wherein the sector-shaped inner gear is fixed on a cross recess base; the sector-shaped outer gear is meshed with the sector-shaped inner gear; the lower end of the guiding shaft is fixedly connected with the sector-shaped outer gear; one end of the poking rod is provided with a sleeve; the guiding shaft is arranged in the sleeve; the other end of the poking rod is provided with a handle; the guiding shaft can slide up and down in the sleeve and is connected with the sleeve by a guiding flat key; the upper surface and the lower surface of the sector-shaped inner gear are respectively provided with a limiting plate; and the sector-shaped outer gear is clamped by the two limiting plates which are in sliding contact with the surface of the sector-shaped outer gear. The mold locking mechanism disclosed by the invention has the advantages that the structure is simple, and the installation and the debugging are easy; all part supports do rotating and lifting movement, no translation is caused, and the wear among parts is small, so that the service life is long and the movement accuracy can be maintained at a relatively high level all the time; and the locking is in place, so that the probability of falling of molds is reduced.

Owner:青岛维特智能装备有限公司

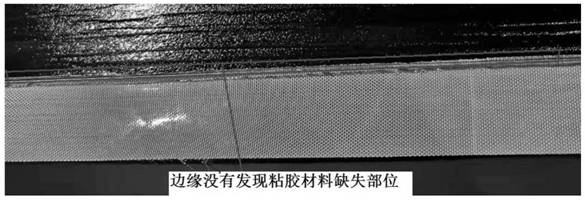

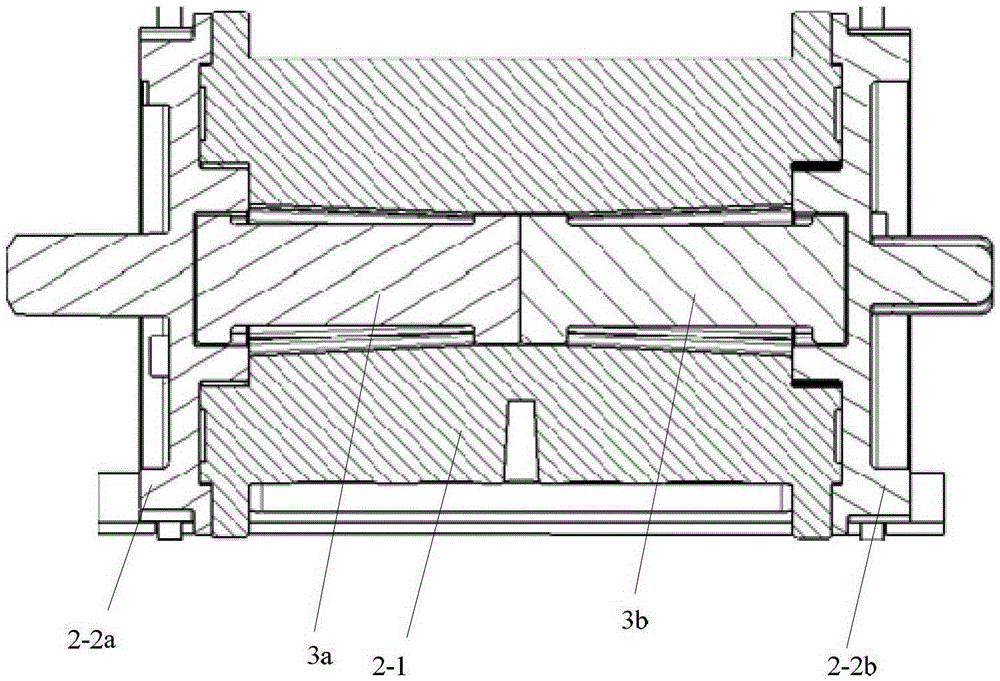

Photovoltaic module hot pressing curing method and pressing equipment used for hot pressing curing

ActiveCN110676335BNot easy to dischargeNot easy to flow outLaminationLamination apparatusAdhesiveEngineering

The purpose of the present invention is to solve the problem that the prior art photovoltaic module packaging method and packaging equipment are easy to produce cavities at the corners of the battery module when the viscosity of the adhesive is high when the photovoltaic module is packaged, so that the performance of the battery module is affected. Provide a The press equipment used for hot-press curing of photovoltaic modules and the hot-press curing method of photovoltaic modules adopt the following hot-press curing method of photovoltaic modules, the layered parts that have completed the vacuum heating and pressing step are transferred to the second lower chamber, and the curing chamber is closed Finally, fill compressed gas into the upper chamber 2, press the flexible pressure member against the upper surface of the photovoltaic module to heat and press the photovoltaic module to cure, adopt the method and equipment of the present invention to heat and pressurize the photovoltaic module to cure, in a non-vacuum state The lower chamber is filled with compressed gas, and the compressed gas exerts positive pressure on the flexible pressure member from above the flexible pressure member. When the photovoltaic module is under pressure, the adhesive moves slowly, which can reduce the side cavity and reduce the generation of holes. .

Owner:秦皇岛博硕光电设备股份有限公司

Torsion bar for seat belt retractor and seat belt retractor, seat belt assembly

InactiveCN102923091BShorten the lengthNot easy to bend and deformBelt retractorsStress conditionsEngineering

The invention provides a torsion bar for a safety belt retractor. The torsion bar is rod-like, peripheral outer teeth are arranged at two ends and in the middle of the torsion bar, the outer teeth at the two ends of the torsion bar are matched with inner teeth of central concave holes in the end faces of two end covers on the retractor, and the peripheral outer teeth in the middle of the torsion bar are matched with inner teeth on the middle section of a through hole in the middle axis of a core shaft; and the axial length of the torsion bar is not greater than that of a scroll. The torsion bar is shortened, so that bending deformation of the torsion bar is avoided, the torsion bar is not subjected to other restraint outside the end covers on the two sides, the overall stress condition of the torsion bar is simplified, and the torsion bar is safe and stable in use. The invention simultaneously provides the safety belt retractor using the torsion bar and a safety belt assembly.

Owner:和励科技有限公司

Retractor and seat belt assembly for seat belt

InactiveCN102837664BOvercoming the problem of unfixed locking positionImprove accuracyBelt retractorsSeat beltEngineering

The invention provides a retractor for a safety belt. A retractor frame comprises two opposite side walls, and corresponding positions of the two opposite side walls are provided with round holes with inner tooth sections. The tooth sections are arranged at a position corresponding to the outward traction direction of a braided belt. A retraction shaft comprises a core shaft which is provided with a though hole along the central axis and is used for winding the braided belt, and two separating end covers which are respectively installed at two ends of the core shaft. The periphery of each end cover is provided with outer teeth matched with inner teeth on the frame. A torsion bar is bar-shaped, the axial middle of the torsion bar is provided with a middle section of outer teeth, and the inner teeth matched with the outer teeth are installed in the though hole of the core shaft. Connection between the torsion bar and the two separating end covers at two ends is achieved at a crossing position between the torsion bar and the two separating end covers through a gear installed at the crossing position and gears correspondingly installed at the end covers. The retractor for the safety belt overcomes the shortcoming that the position of the locking of a retractor is unfixed, and improvement of control accuracy of the retractor is benefited. The invention further provides a safety belt assembly.

Owner:和励科技有限公司

Torsion bar for seat belt retractor and seat belt retractor, seat belt assembly

InactiveCN102837663BShorten the lengthNot easy to bend and deformBelt retractorsSeat beltLimit value

The invention provides a torsion bar for a safety belt coiling device. The torsion bar is in a bar shape and the axial length of the torsion bar is not more than the axial length of a coiling shaft; peripheral outer teeth are arranged at two end parts and the middle part of the torsion bar and the outer teeth at the two end parts of the torsion bar are matched with inner teeth of central concave holes of end faces of the two end faces on the coiling device; the peripheral outer teeth at the middle part are matched with inner teeth arranged at the middle section of a through hole at a central axis position of a core shaft; the torsion bar is divided from the middle part of the axial direction to form a two-section type structure; and the peripheral outer teeth at the middle part are located at abutted end parts of two sections. Compared with the prior art, the torsion bar disclosed by the invention does not pass through an end cover and is shorter in length, so that the torsion bar is not easy to bend and deform and the use process is safer and more stable. The torsion bar is divided into the two sections, so that different safety belt force limiting value requirements can be met through the combination of different diameters or materials. The invention further provides the safety belt coiling device using the torsion bar and a safety belt assembly.

Owner:和励科技有限公司

Metal plate panel bending tool and bending method

InactiveCN113828660ANot easy to bend and deformImprove utilizationMetal-working feeding devicesPositioning devicesManufacturing engineeringWire rope

The invention discloses a metal plate panel bending tool and a bending method. The metal plate panel bending tool comprises a wire pressing mechanism, a clamping mechanism is arranged on one side of the wire pressing mechanism, the clamping mechanism comprises a straight rod, two sliding shafts are fixedly arranged on one side of the straight rod, three hanging blocks are arranged on the sliding shafts in a sliding mode, one side of each hanging block is provided with a clamping screw rod through threads in a meshing mode, one side of the clamping screw rod is fixedly connected with three steel wire ropes, and the other side of each steel wire rope is fixedly connected to clamping jaws. According to the metal plate panel bending tool, the wire pressing device is used for carrying out wire pressing operation on a workpiece to be treated in advance, the clamping jaws penetrate through holes of the workpiece and shrinks the workpiece, and therefore fixing is conveniently carried out on the workpiece during bending; and meanwhile, tensioning and fixing are carried out on the three clamping jaws by utilizing the steel wire ropes, it is guaranteed that the holes of the workpiece have certain structural stability in the bending process, the workpiece is not prone to bending deformation in the bending process, the utilization rate of the workpiece is improved, and efficiency is further improved.

Owner:黎磊

A T-shaped copper material extrusion die

The invention discloses a T-shaped copper material extrusion die which comprises a forming die, a transition die, a shaping die and an extrusion punch, wherein the transition die is fixedly connected between the forming die and the shaping die, the forming die comprises a first die core, the shaping die comprises a second die core, a third die core and a fourth die core are respectively arranged at two ends of the transition die, the structure size of the first die core is greater than that of the second die core, the structure size of the third die core is identical with that of the first die core, the structure size of the fourth die core is identical with that of the second die core, the third die core and the fourth die core are in smooth transition, and the appearance structure size of the extrusion punch is identical with that of the second die core. Through the mode, the T-shaped copper material extrusion die is simple in structure, produced T-shaped steel is uniform in size, high in bearing capacity, difficult to bend and deform, good in deformation resistance performance, and stable in product performance.

Owner:佛山市顺德区晋天机械有限公司

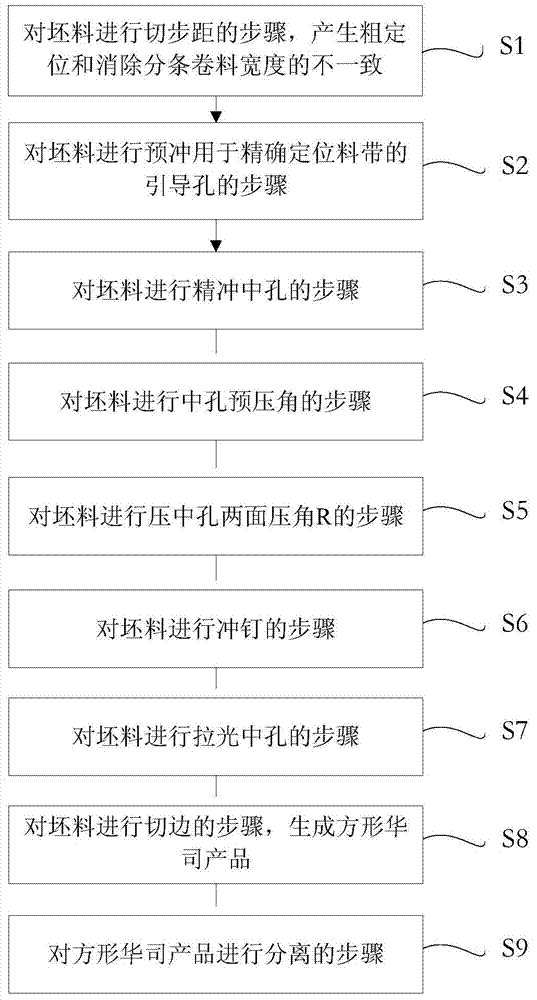

A production process of square washer continuous mold

InactiveCN103611795BEasy to uninstallReduce the difficulty of unloadingShaping toolsEngineeringMechanical engineering

The invention relates to the technical field of dies and discloses a manufacturing process of a continuous die for square washers. The manufacturing process of the continuous die includes the steps of S1, cutting steps for a blank; S2, pre-stamping the blank for precisely positioning a guide hole for a strip; S3, finish-stamping a middle hole in the blank; S4, pre-pressing corners of the middle hole in the blank; S5, pressing the two face pressure corners R of the middle hole in the blank; S6, stamping a nail for the blank; S7, scraping the middle hole of the blank; S8, cutting edges of the blank to obtain a finished square washer; S9, separating the finished square washer. In the step S5, a pressure corner male die for pressing the two face pressure corners R of the middle hole is provided with a single-face tilt angle; in the step S6, a nail stamping female die is fixed on a stripping plate, moves with one strip, and stamps a nail when the bottom of the die is ejected. The manufacturing process of the continuous die for square washers has the advantages that stripping is easier and bending deformation occurs rarely.

Owner:广州顺辰金属制品有限公司

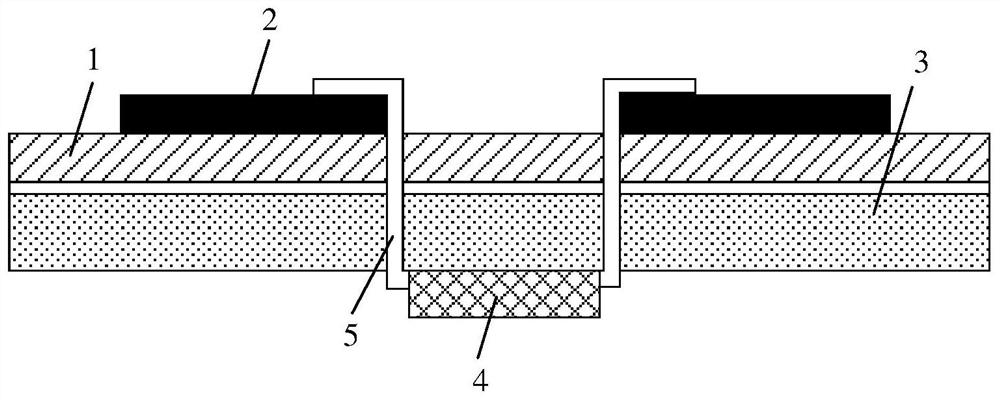

Manufacturing method of circuit board

InactiveCN112118681AAvoid failureImprove structural stabilityPrinted circuit assemblingCircuit bendability/stretchabilityMechanical engineeringDirect printing

The invention provides a manufacturing method of a circuit board, and relates to the technical field of electronic circuits. The manufacturing method of the circuit board provided by the invention comprises the following steps: S1, forming a first conductive circuit on a first surface of a flexible first substrate in a direct printing manner; and S2, forming a second substrate on the second surface of the first substrate, wherein the second substrate is used for improving the hardness of the circuit board. According to the technical scheme, the manufacturing process of the circuit board can besimplified, and the structural stability of the circuit board is improved.

Owner:BEIJING DREAM INK TECH CO LTD

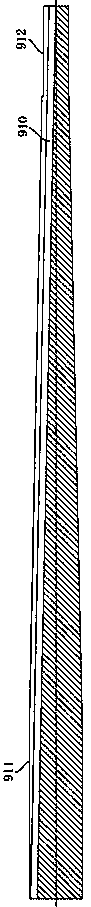

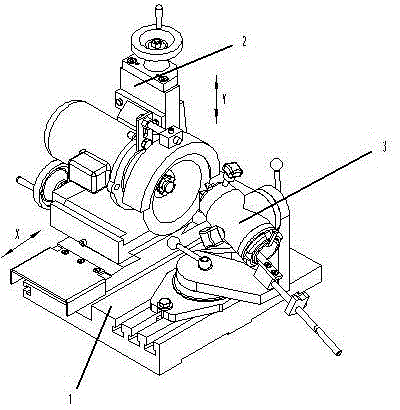

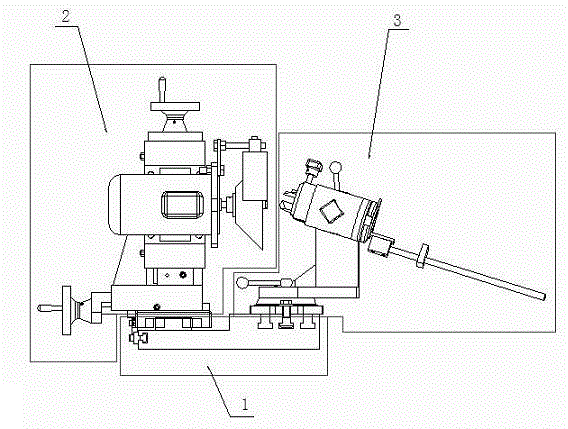

A sharpening fixture for single-edged gun drill

Owner:SHANGHAI NINGYUAN PRECISION MACHINERY

Ultrathin heat sublimation transfer paper and preparation method thereof

The invention discloses an ultrathin heat sublimation transfer paper. The ultrathin heat sublimation transfer paper comprises a base material, a binding agent and a coating coated on the surface of the base material, wherein the coating comprises carboxymethyl cellulose, sucrose, glycerol, starch, polyvinyl chloride resin, polyethylene glycol fatty acid ester, fumed silica, aluminum oxide, calciumcarbonate, a bactericide, a polysaccharide derivative, kaolin, titanium dioxide, sodium polyacrylate, bentonite powder and a dispersing agent. The invention further discloses a preparation method ofthe ultrathin heat sublimation transfer paper, the preparation method is that the materials of all the components is carried out dissolving, mixing, heating, uniformly stirring, and discharging by steps. According to the method, the polysaccharide derivative and glycerol are added, so that the paper surface is smooth, the phenomenon of bending deformation is not easy to occur, and the heat sublimation printing quality is improved, so that the application of the ultrathin heat sublimation transfer paper is realized, and the transfer rate of the produced paper is improved, and the application ofthe ultrathin paper in the field of thermal sublimation is improved.

Owner:SUZHOU JIGU NEW MATERIAL CO LTD

Industrial robot for injection molding production

The invention relates to the field of industrial robots, in particular to an industrial robot for injection molding production, which comprises a cylinder body, a pushing part is arranged on the inner side of the cylinder body, a feeding part is arranged on the side surface of the cylinder body close to the upper end, and a communicated injection molding pipe is arranged at the lower end of the cylinder body. The mold comprises an injection molding pipe, the position, close to the lower end, of the outer surface of the injection molding pipe is slidably sleeved with a sleeve through an elastic mechanism, the lower end face of the sleeve is provided with a plurality of sealing plates which are in sliding fit with the sleeve, the sealing plates are arranged in an annular array, and the lower end of the sleeve is jointly sealed by the sealing plates. The step of reverse pressure relief after screw propulsion is omitted, the self-plugging function is achieved, meanwhile, molding particles at the end of an injection molding material can be removed during injection molding, the possibility of plugging is effectively reduced, meanwhile, the self-plugging device can be applied to the environment with long adjacent injection molding intervals, the universality is better, and the injection molding stability is improved.

Owner:深圳宗汉曙光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com