Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "No deviation will occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

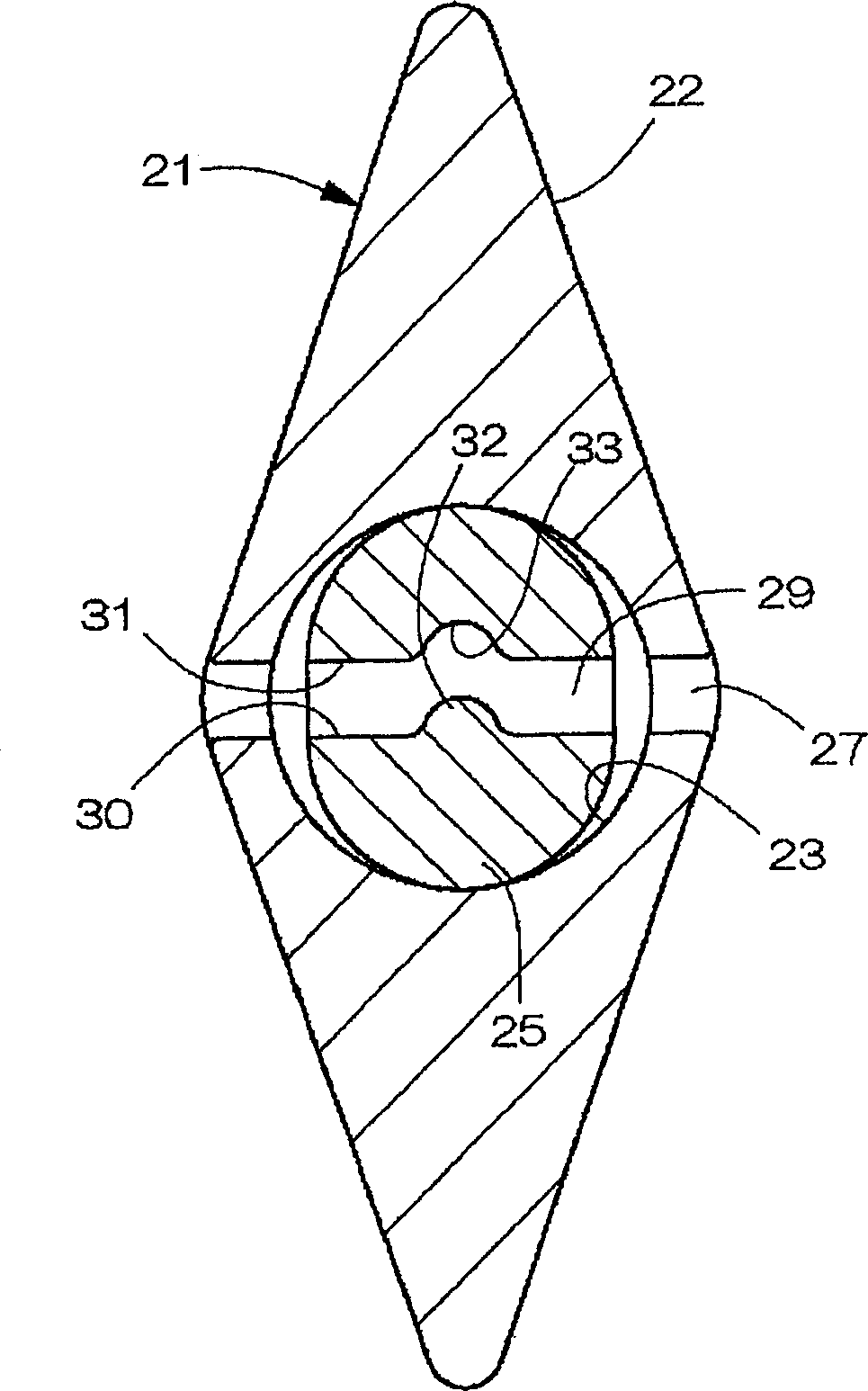

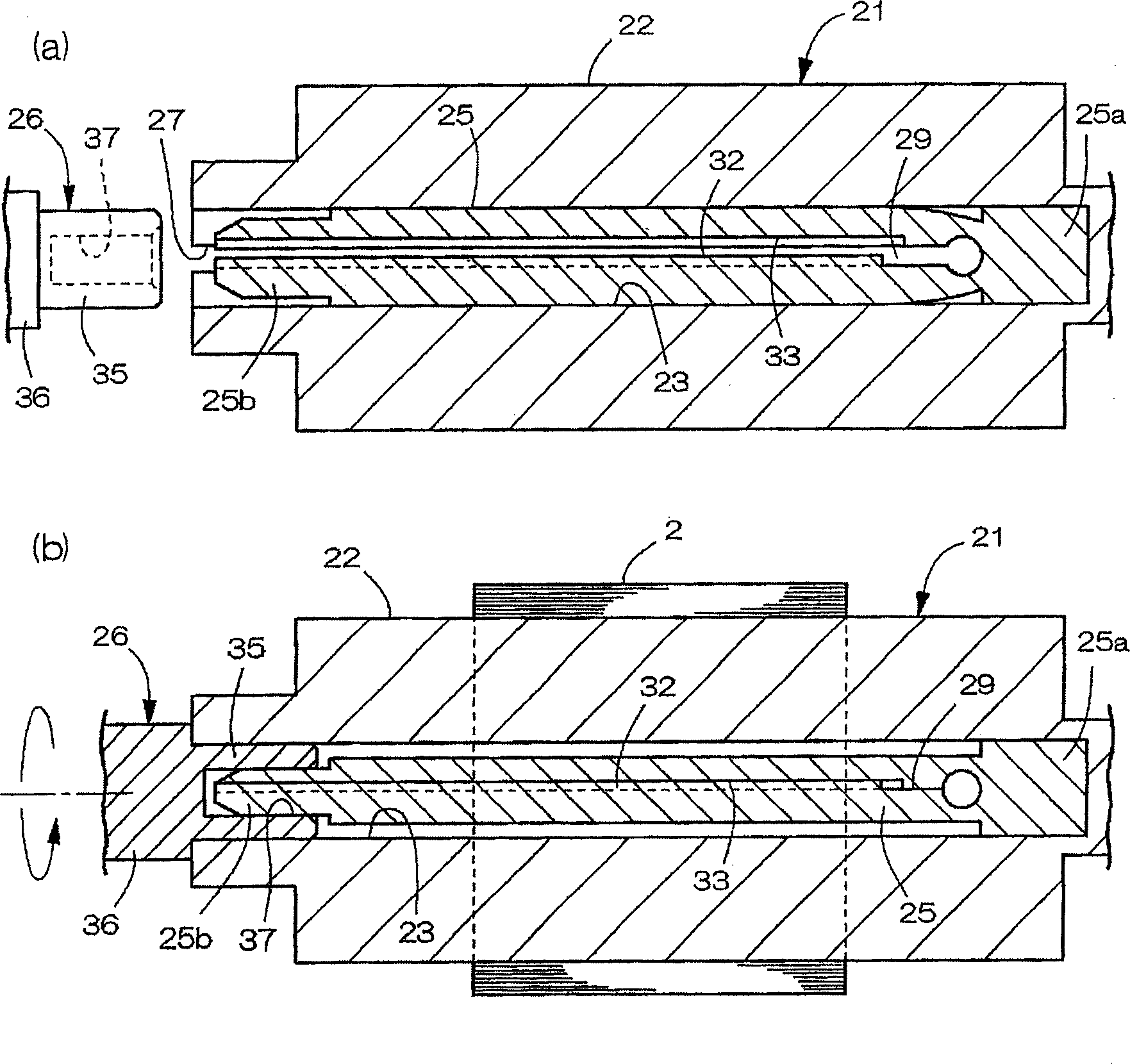

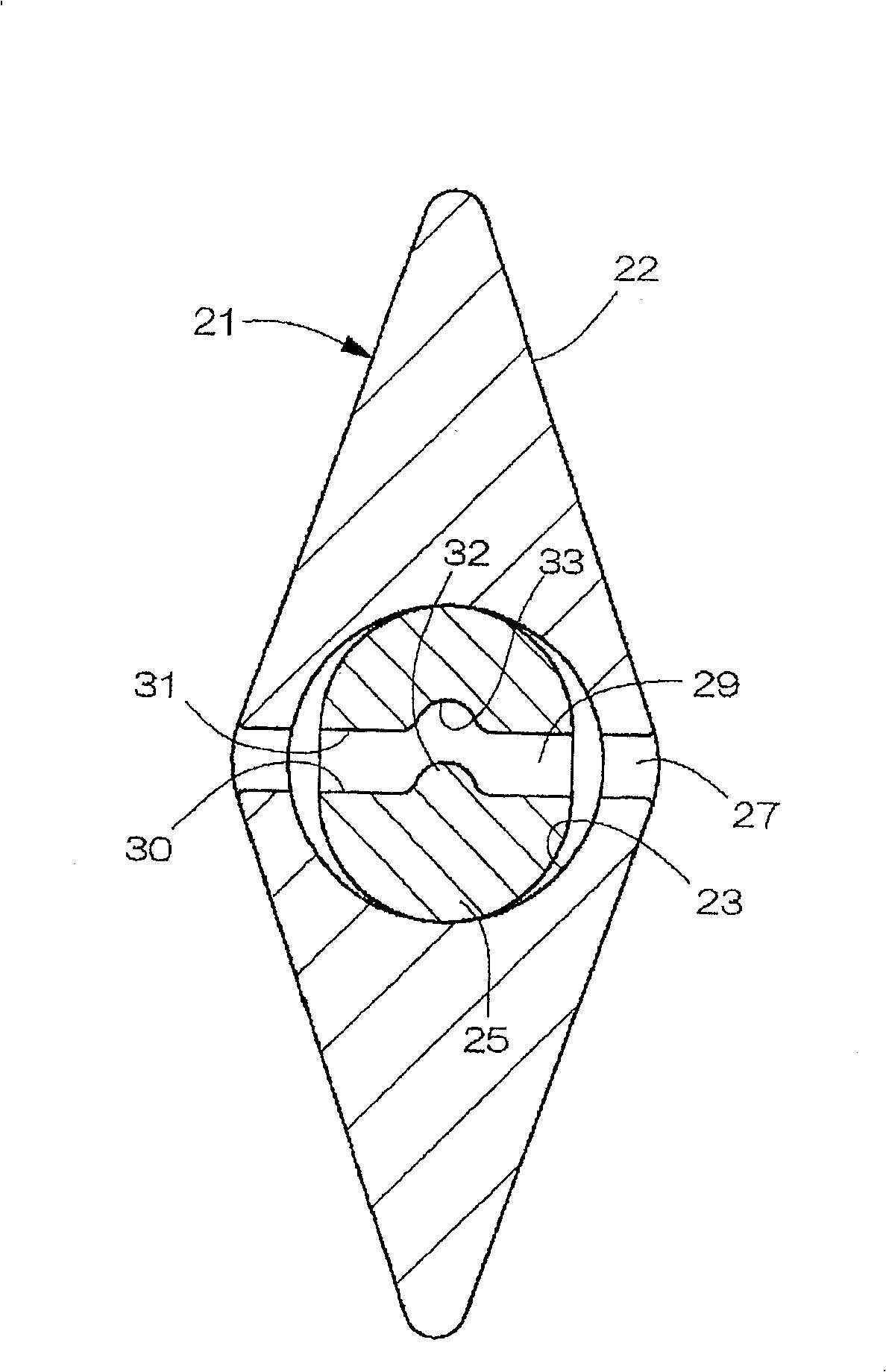

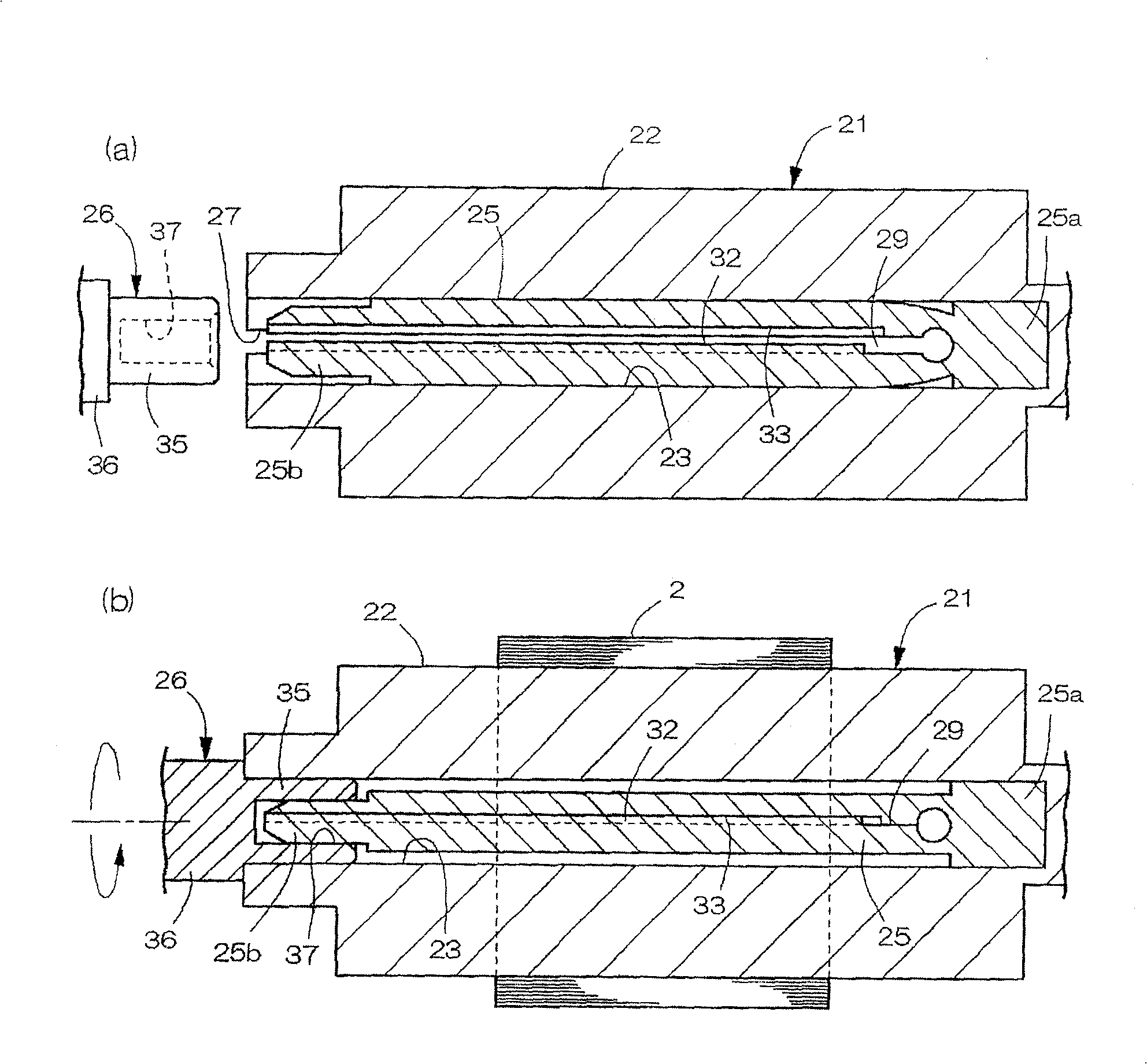

Roll core and electrode body manufacturing method using same

ActiveCN1848509ANo deviation will occurNo peeling etc.Assembling battery machinesCell electrodesEngineeringElectrode

The invention provides a winding core with simple structure and capable of clamping and fixing the diaphragm. The winding core (21) includes: the outer shaft (22) for winding the positive electrode (6) and the negative electrode (7) and the diaphragm (9); the central shaft (25) for fixing the diaphragm (9); the outer shaft (25) of the embedded part (35) A receiving shaft (26) embedded in the front end portion (25b) of the central shaft (25). The outer shaft (22) has a space (23) open at one end thereof, and the central shaft (25) is arranged in the space (23). The center shaft (25) has a center shaft slit (29) open at one end thereof. The outer shaft (22) has an outer shaft slot (27) opposite the central shaft slot (29). Insert the two overlapping diaphragms (9, 9) into the central shaft slit (29) through the outer shaft slit (27), and externally fit the embedded part (35) of the receiving shaft (26) into the central shaft (25) When on the front end portion (25b) of the front end (25b), the diaphragm (9) is clamped and fixed by the closed central axis slit (29).

Owner:MAXELL HLDG LTD

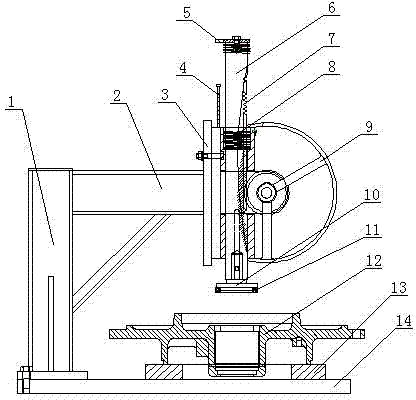

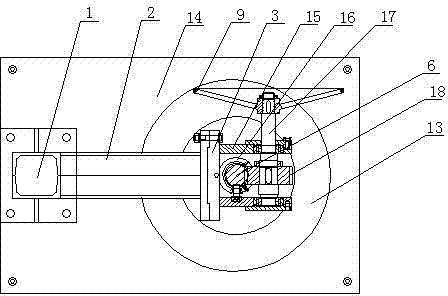

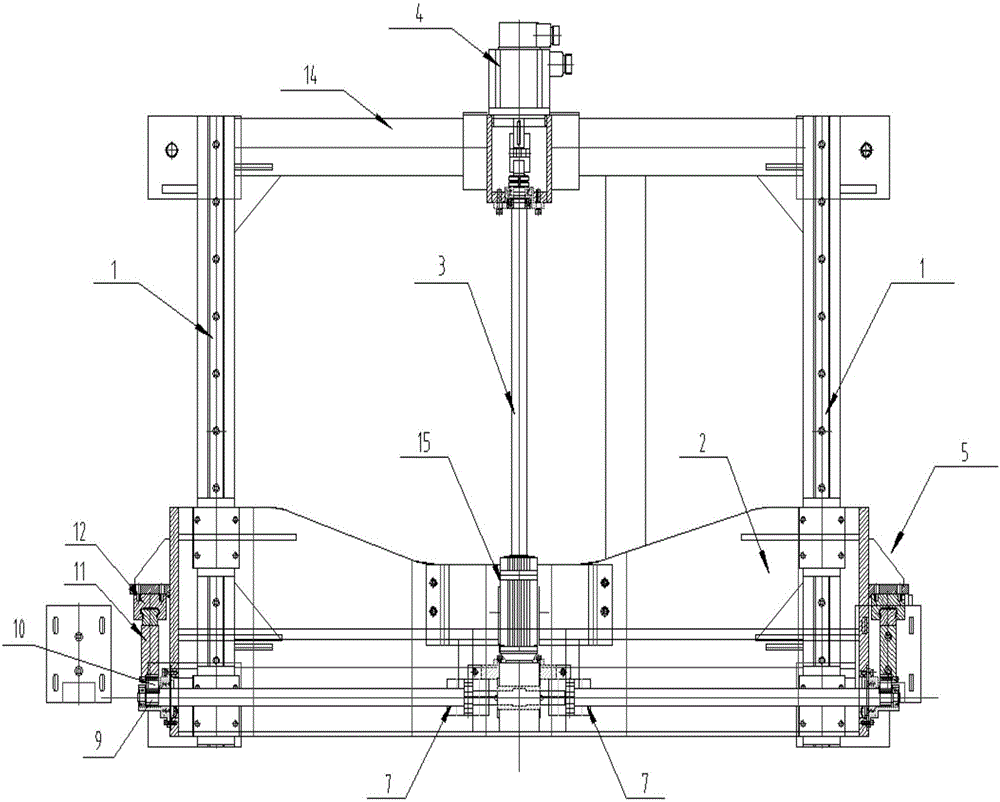

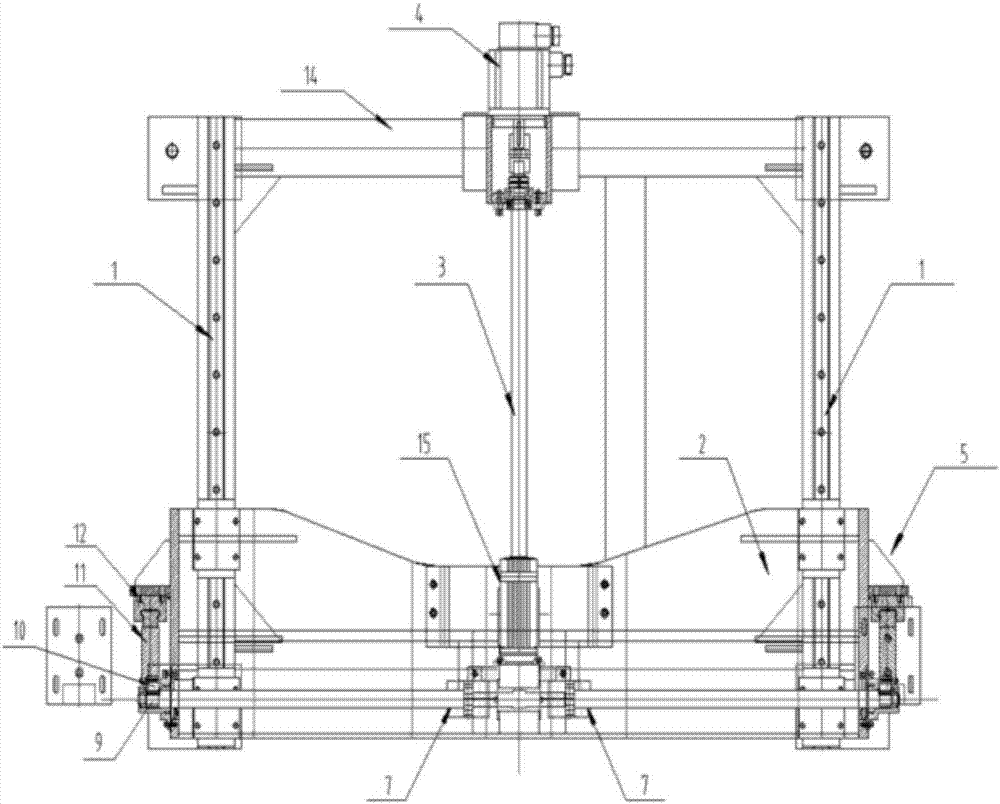

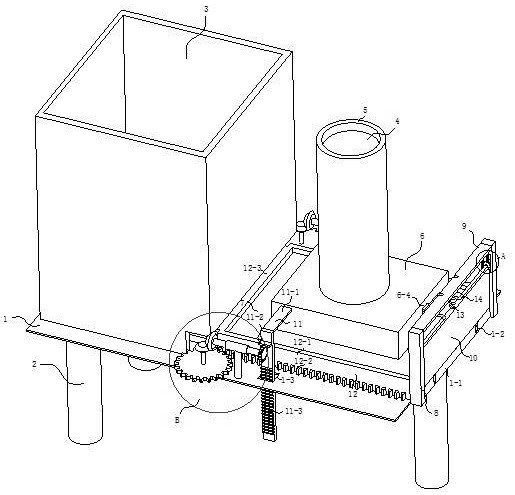

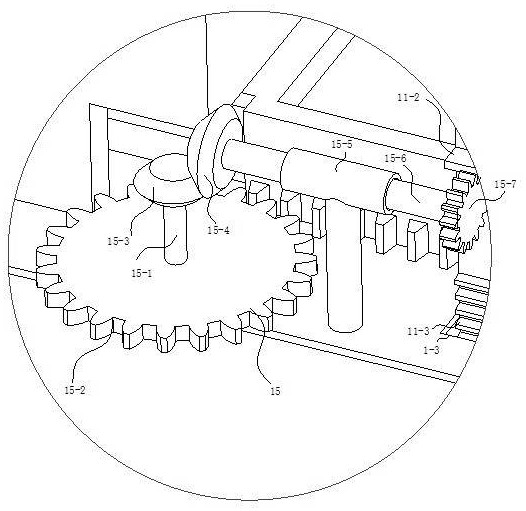

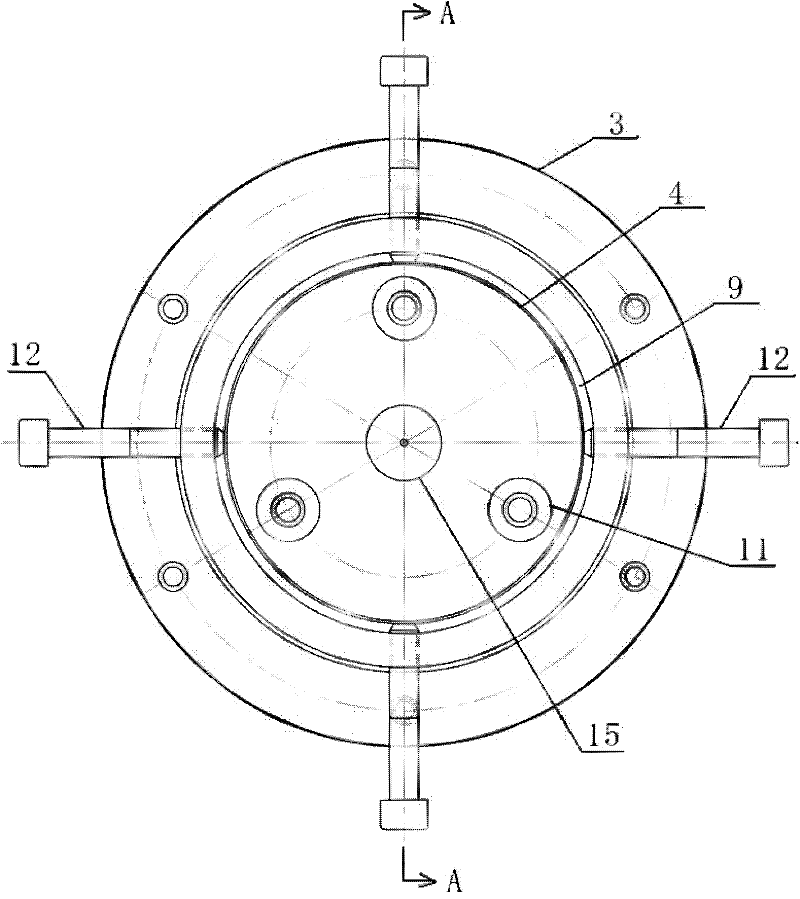

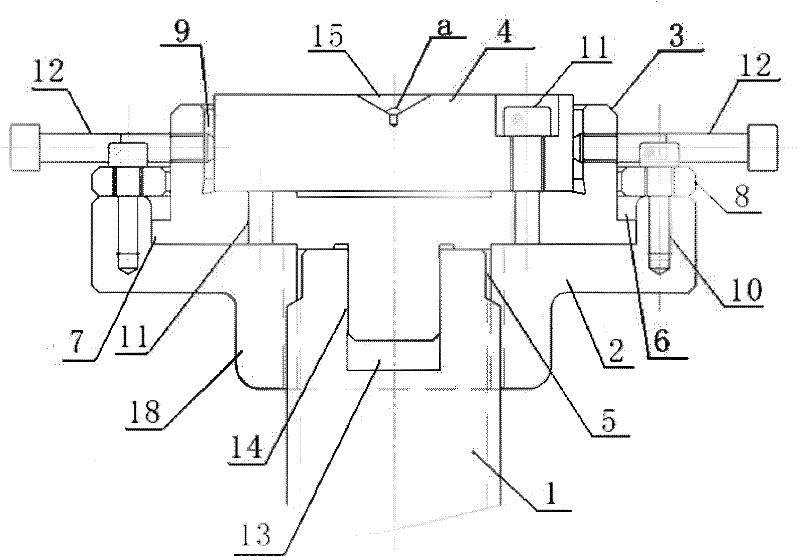

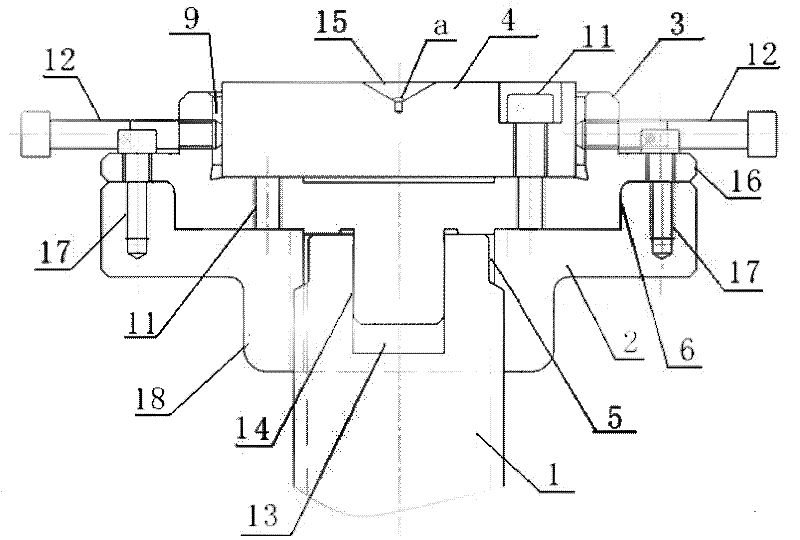

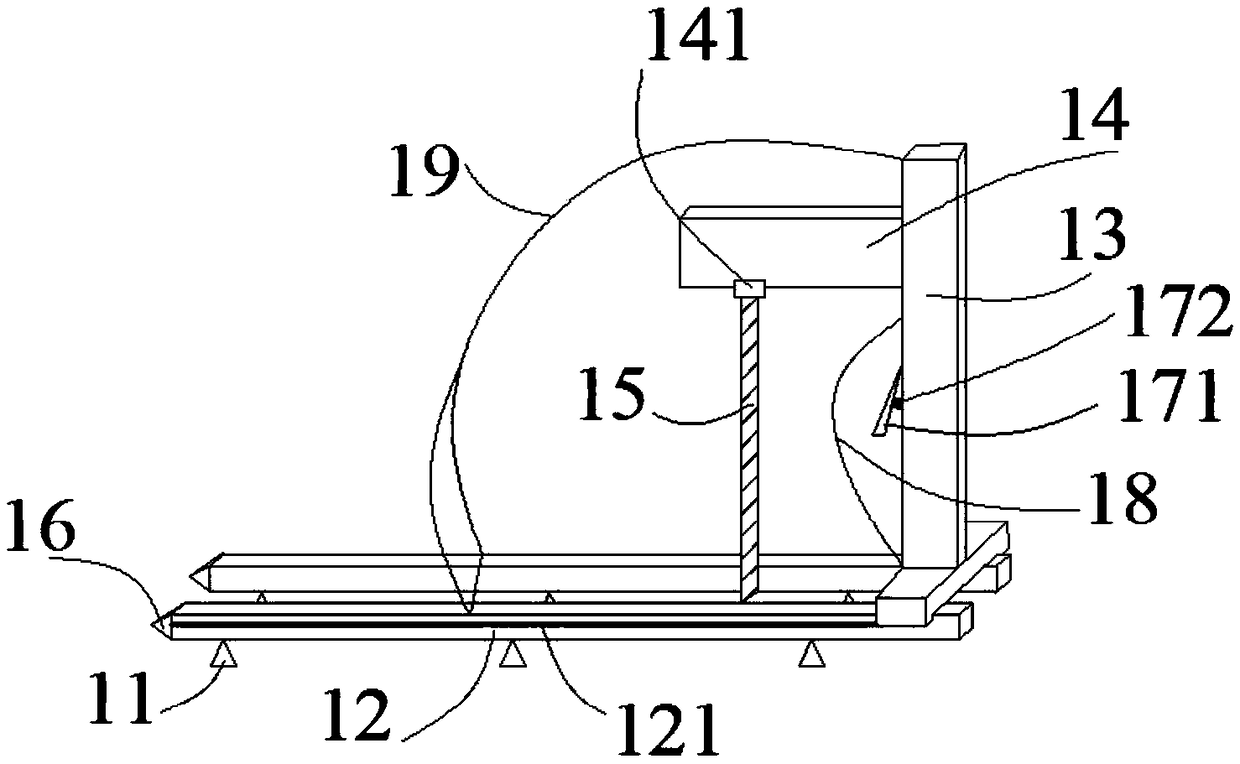

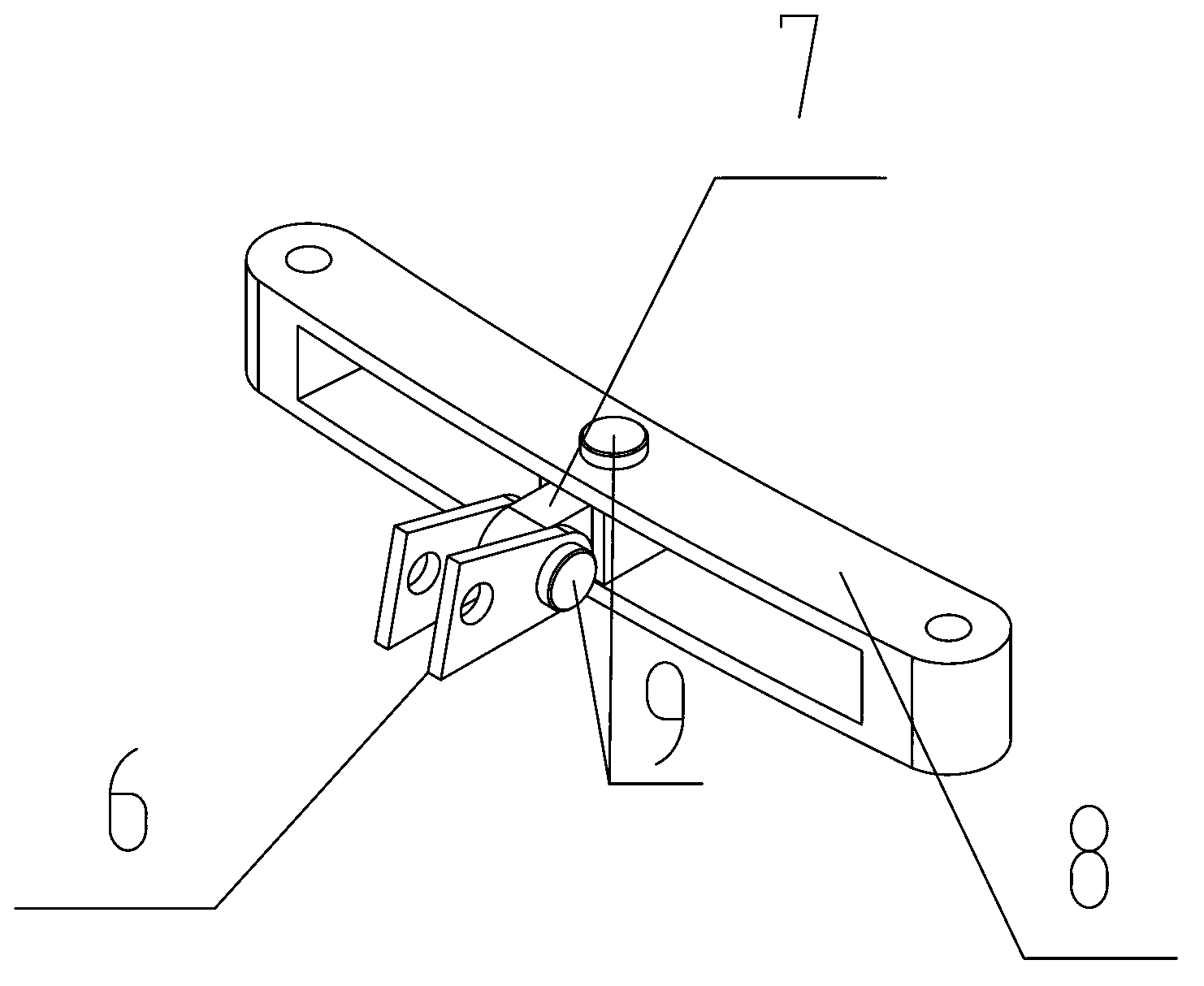

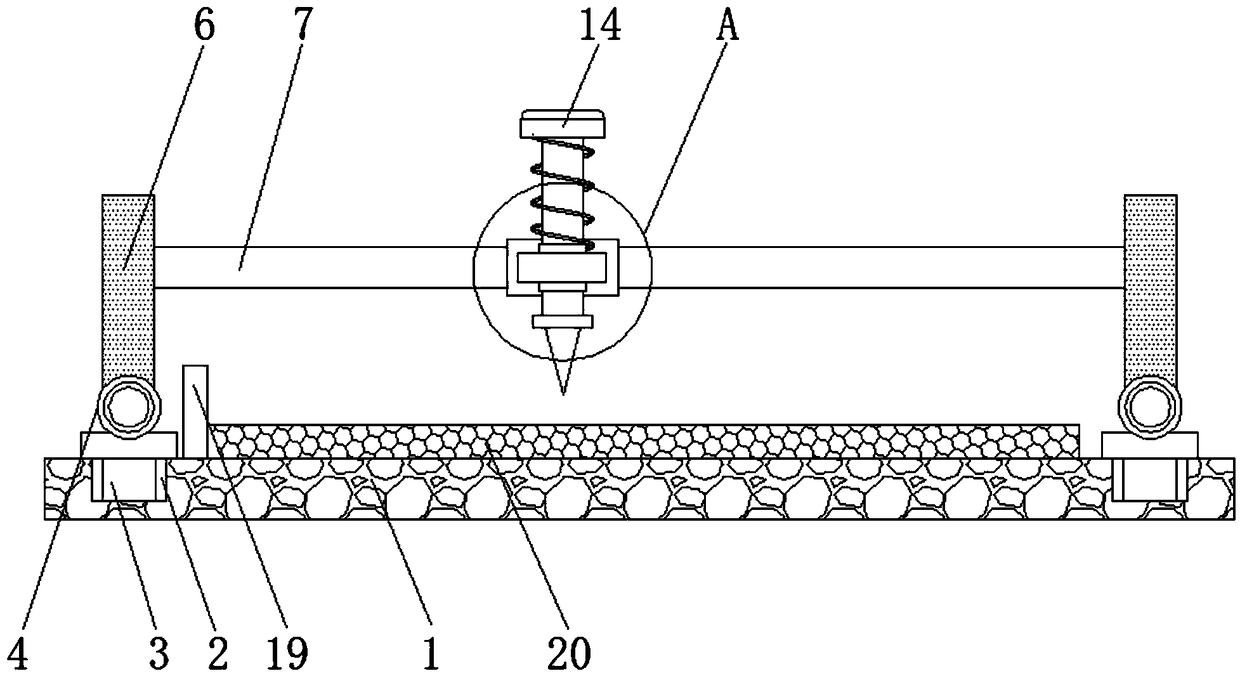

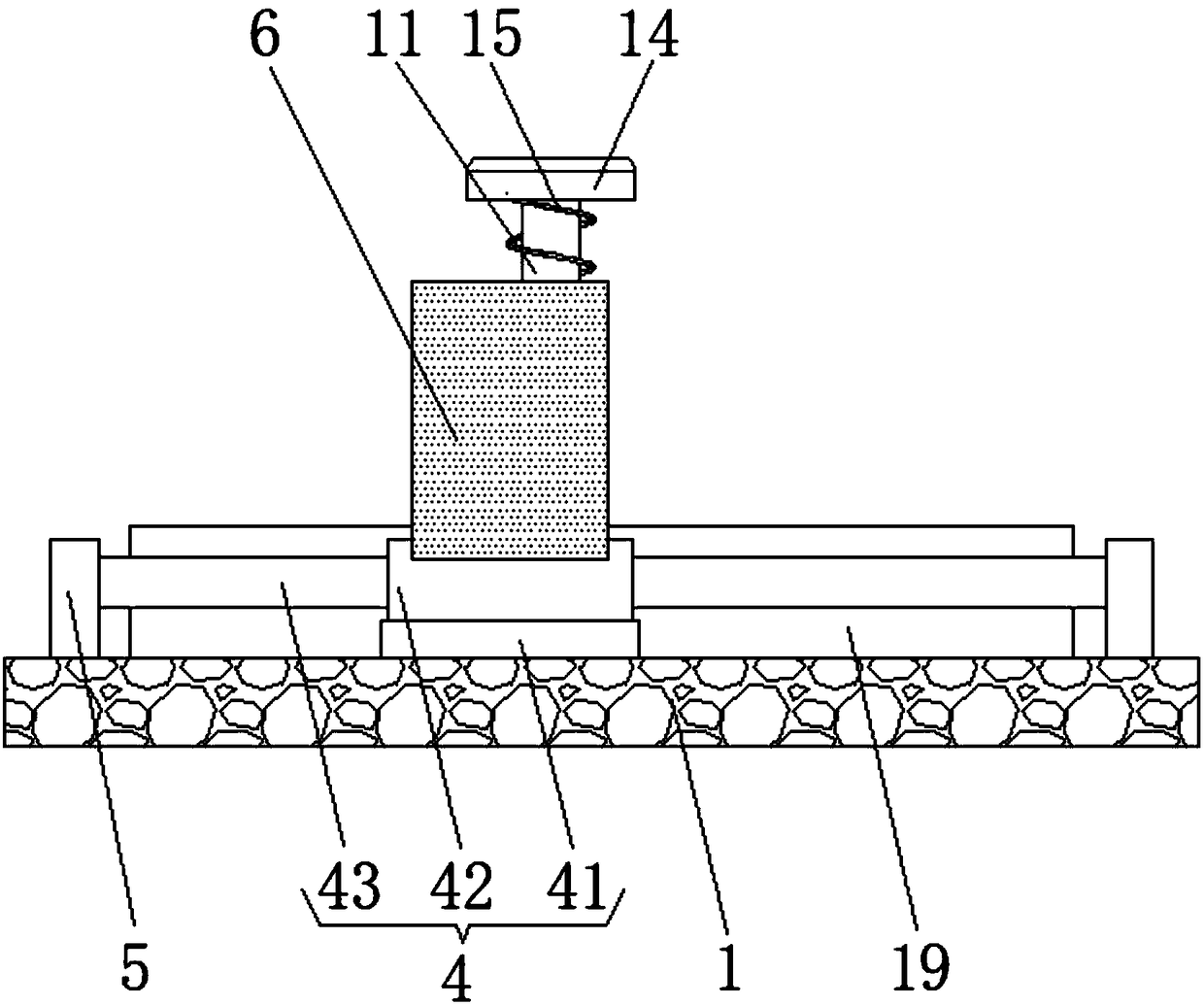

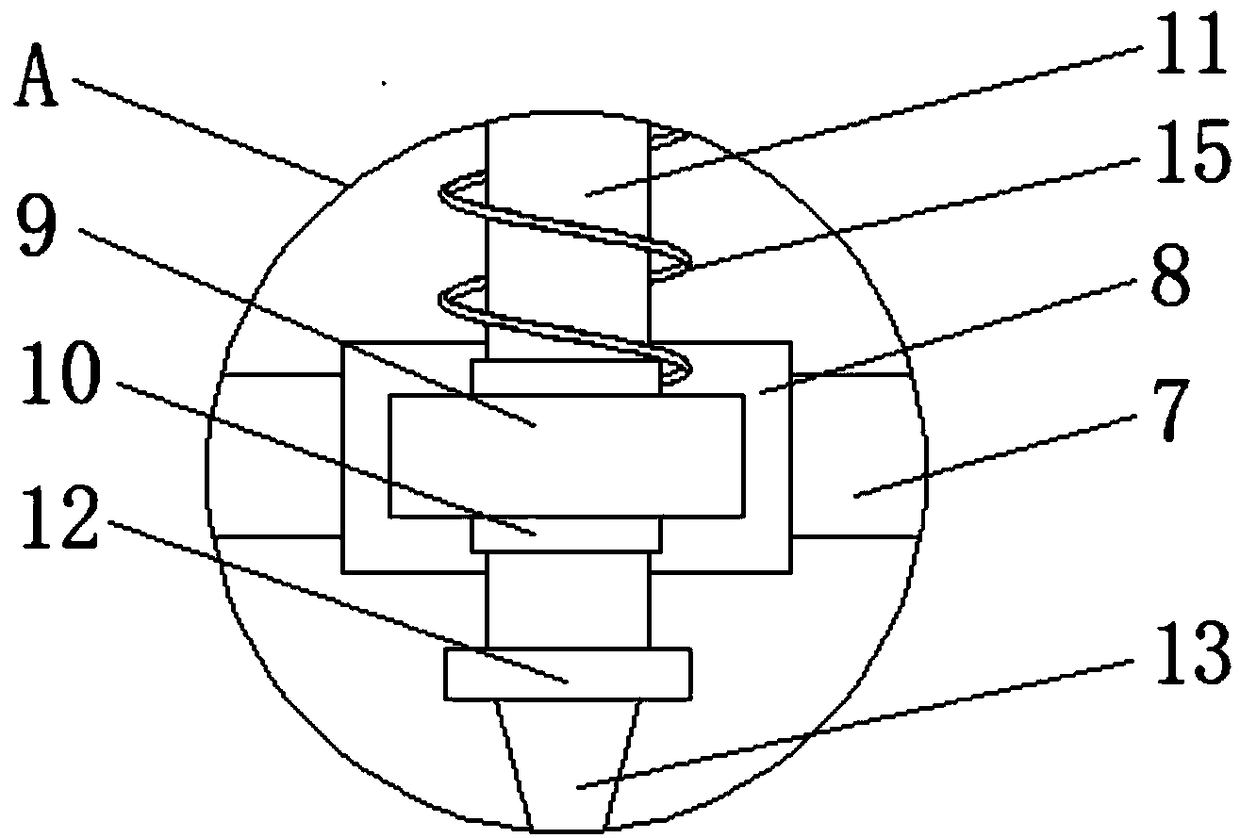

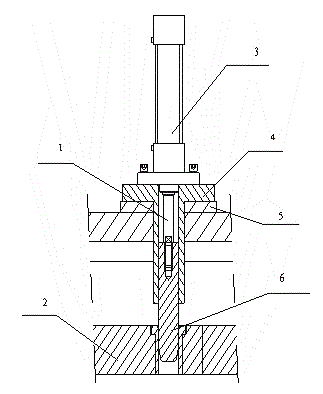

Working table for installing mechanical seal of water pump

InactiveCN103878561ANo deviation will occurReduce adverse effectsMetal working apparatusMetal-working hand toolsEngineeringCanis lupus familiaris

The invention provides a working table for installing a mechanical seal of a water pump and relates to the technical field of water pump machining tools. The working table comprises a working table body, a supporting frame, a supporting arm, a mounting base, a sliding sleeve, a slide bar, a support, a hand wheel shaft, a hand wheel, an assembly port, a lifting rack, a gear, a baffle and a reset spring. The working table is characterized in that an annular pump cover base is arranged at the position, opposite to the slide bar, of the working table body, the lower end of the slide bar is provided with a sealing ring pressing plate, a buffer pressure pad is arranged on the sealing ring pressing plate, a vertical threaded rod is formed in the upper portion of the mounting base, a stroke adjusting bolt is arranged in the threaded hole, and the upper end of the slide bar is provided with a limiting stop dog matched with the stroke adjusting bolt. In the using process, a pump cover is placed on the pump cover base, a static ring of the mechanical seal is placed into a mounting groove of the pump cover, the stroke of the sealing ring pressing plate is adjusted, and then the hand wheel is rotated to drive the sealing ring pressing plate to press the static ring of the mechanical seal into the mounting groove of the pump cover. The working table has the advantages of being simple in structure, convenient to use, high in assembling accuracy, assembling speed and assembling quality, good in sealing performance and long in service life.

Owner:SHANDONG SHUANGLUN EMMECOM PUMPS

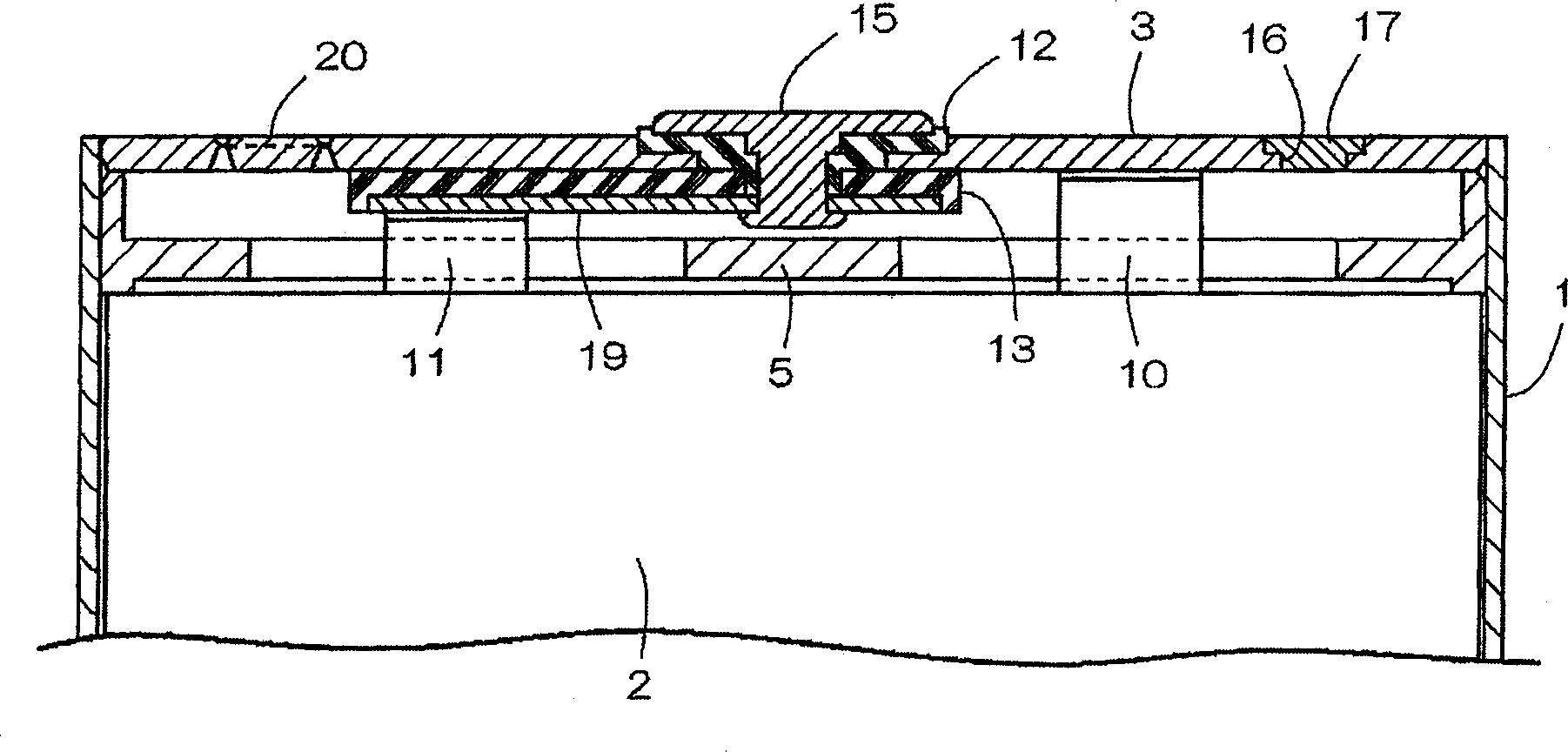

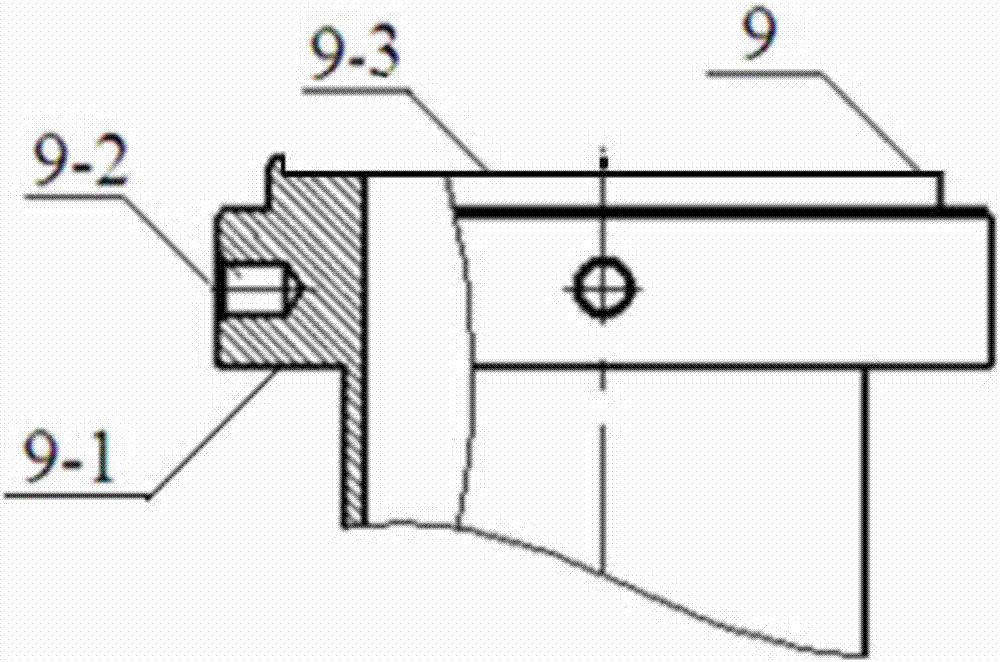

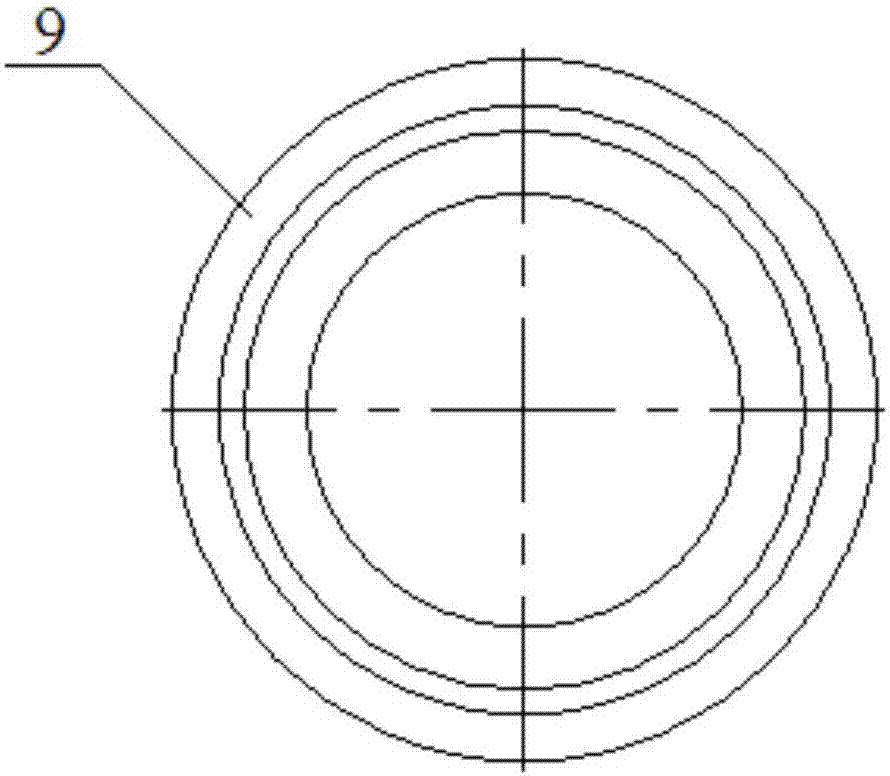

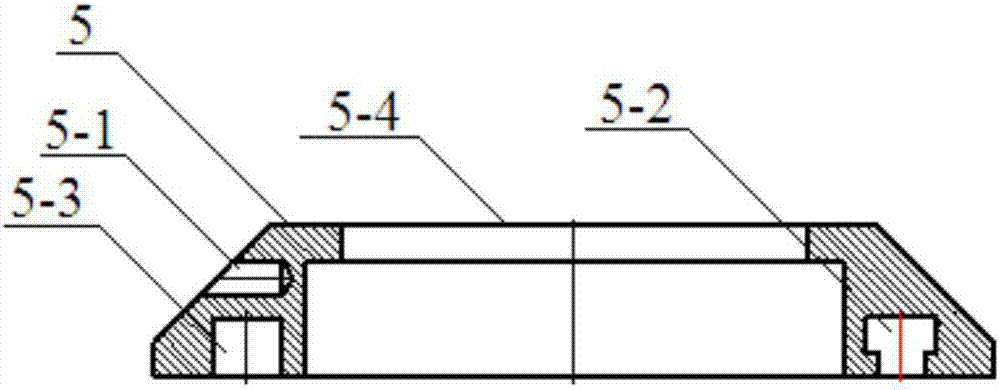

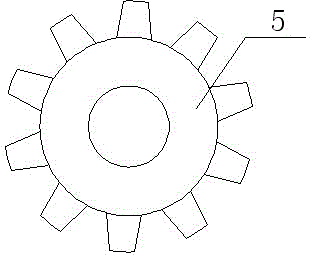

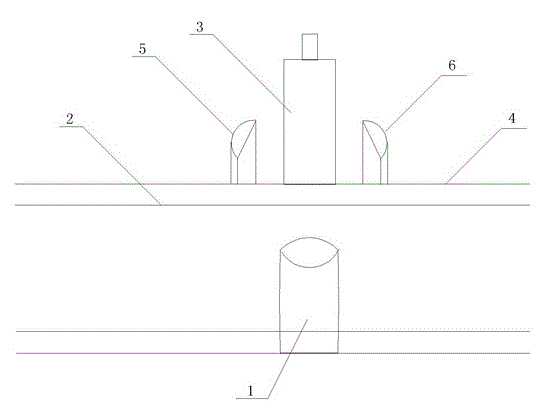

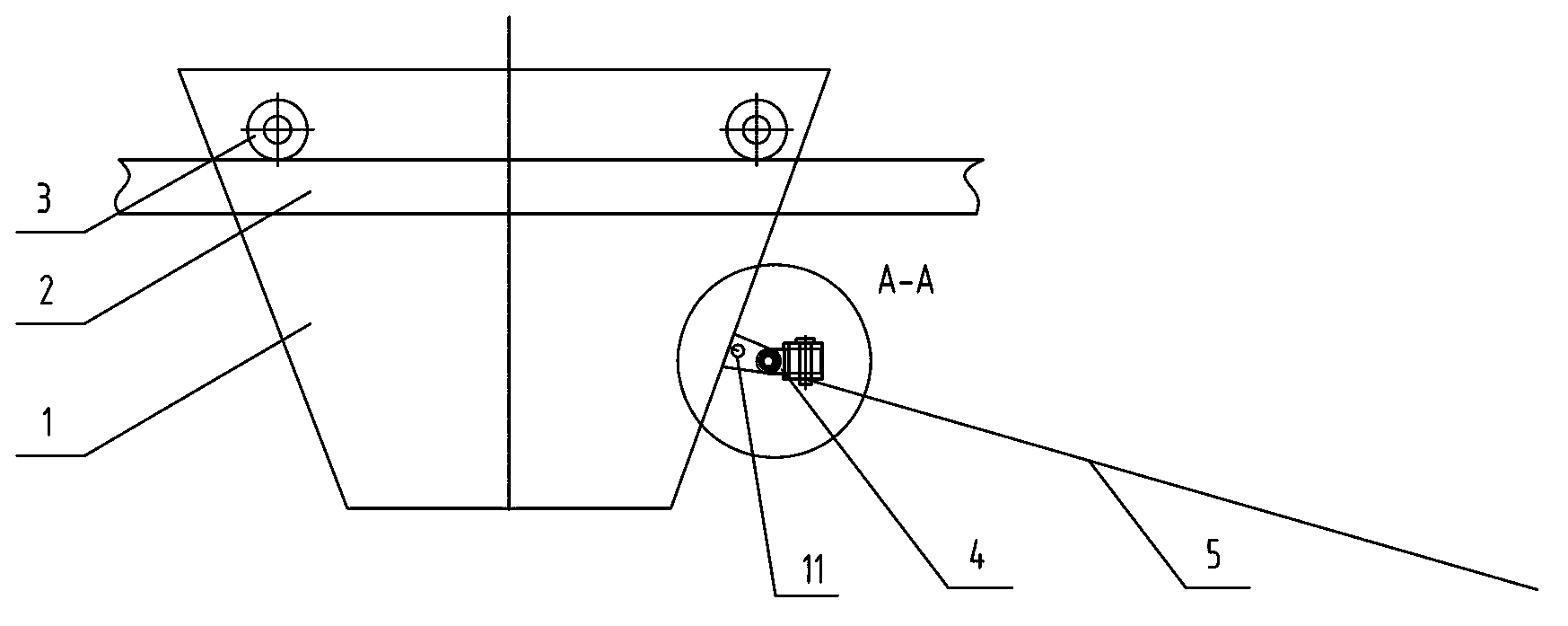

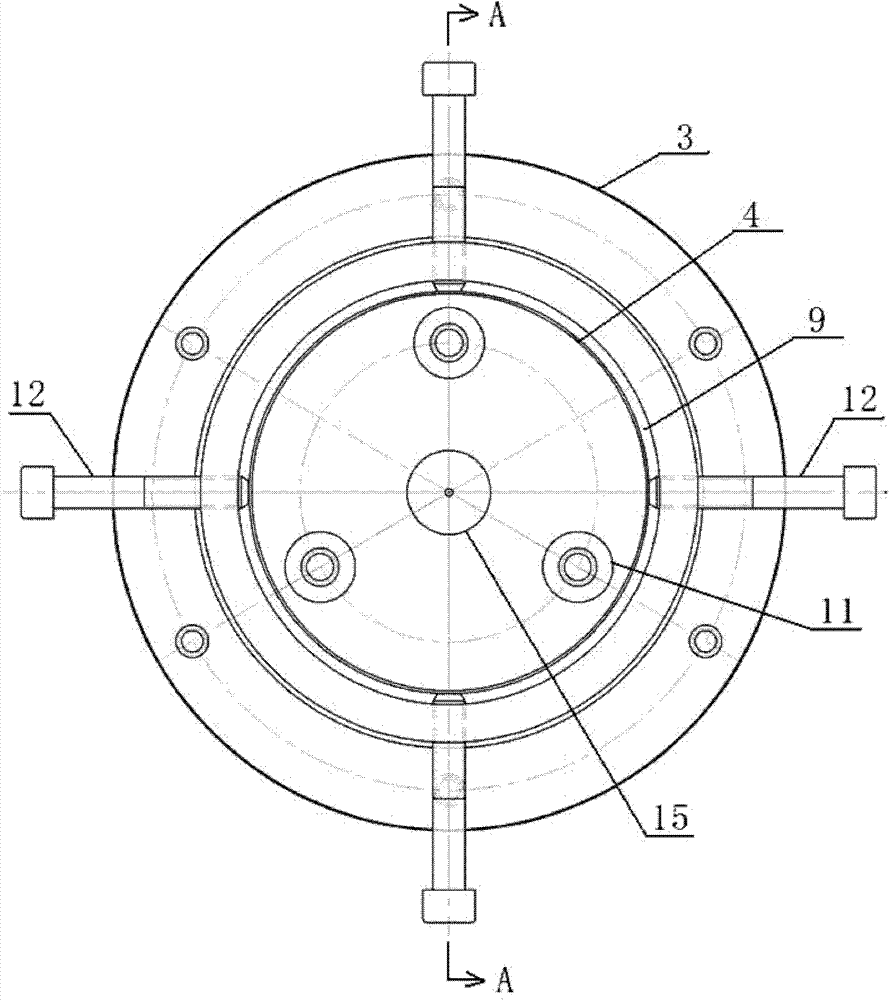

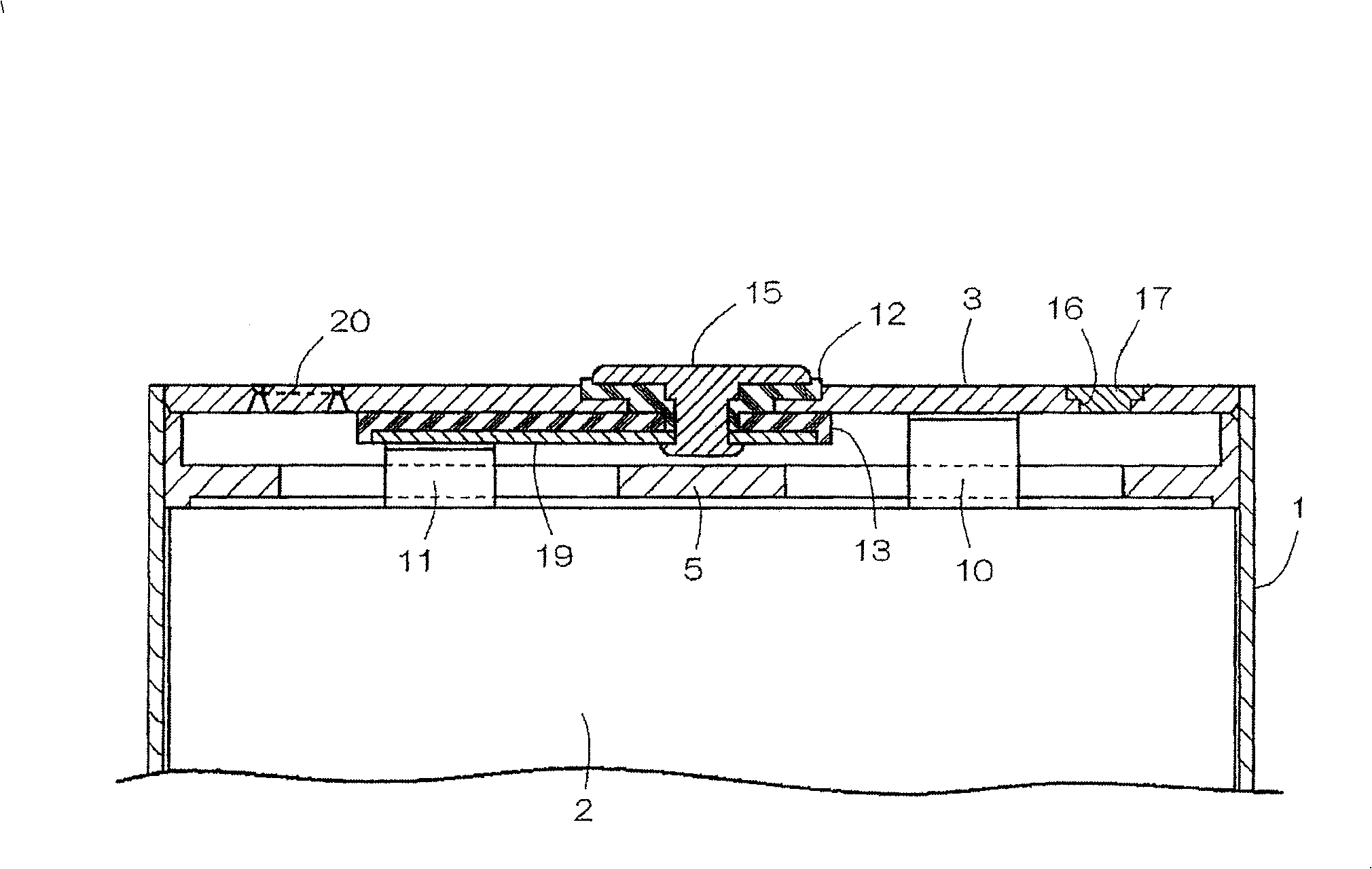

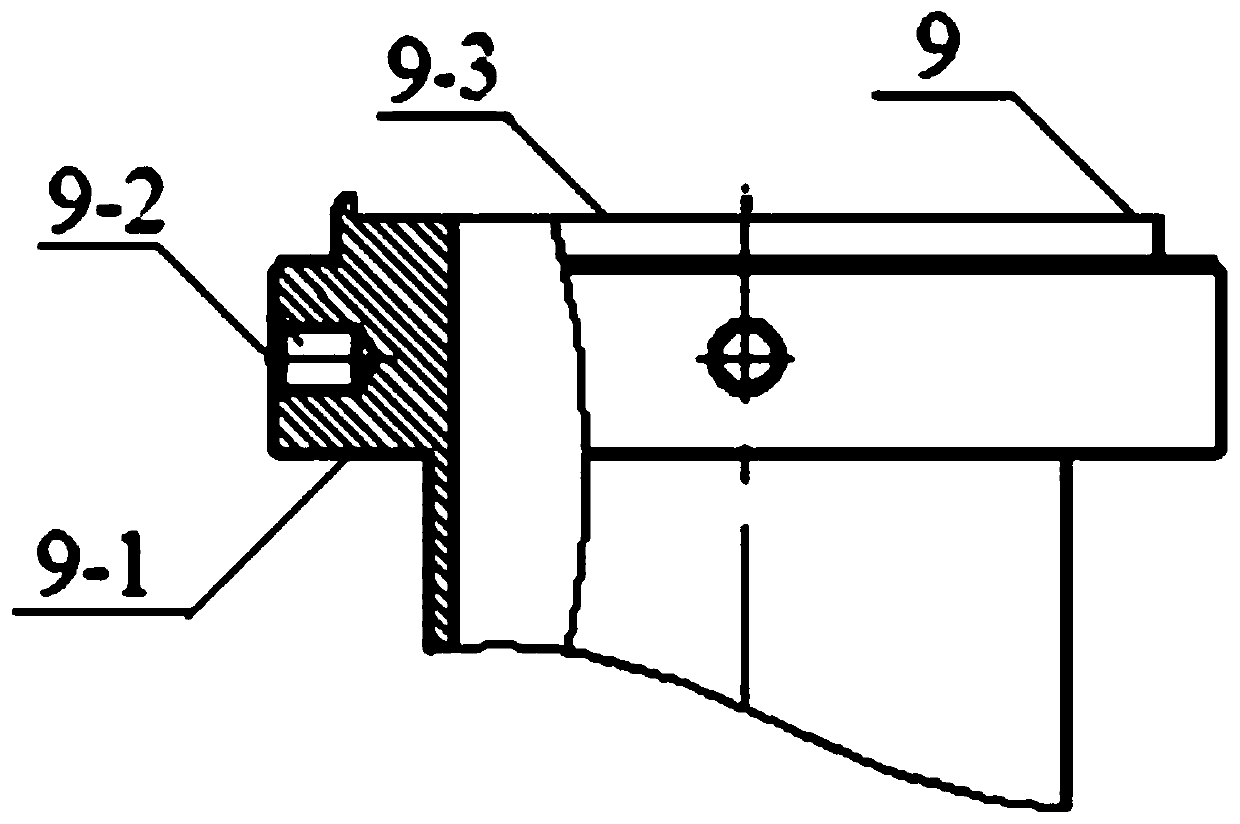

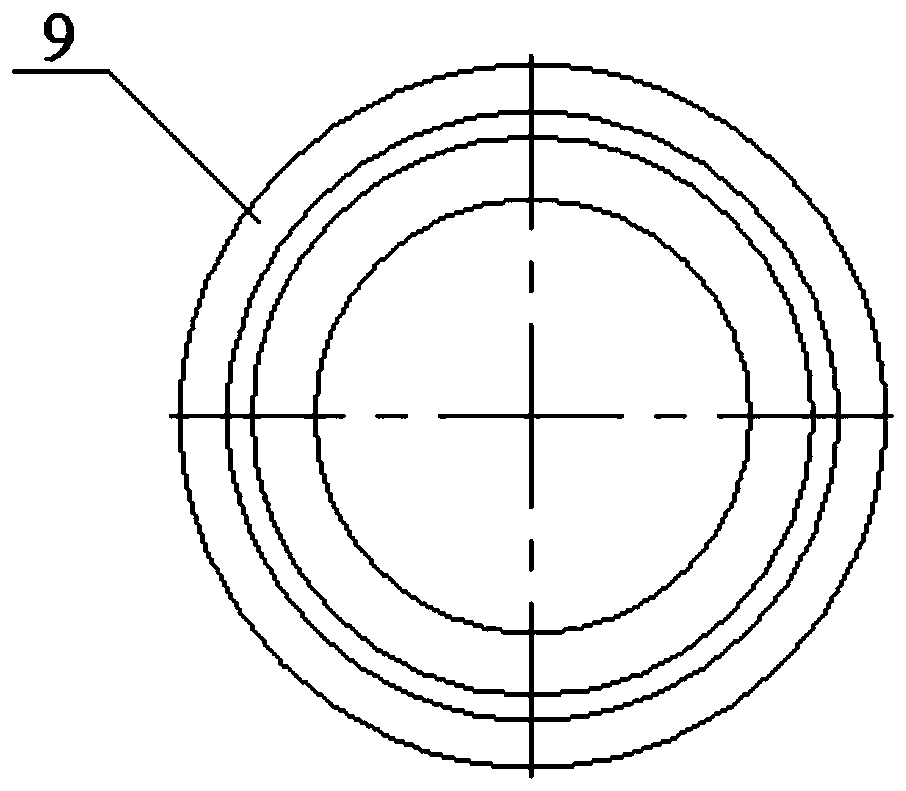

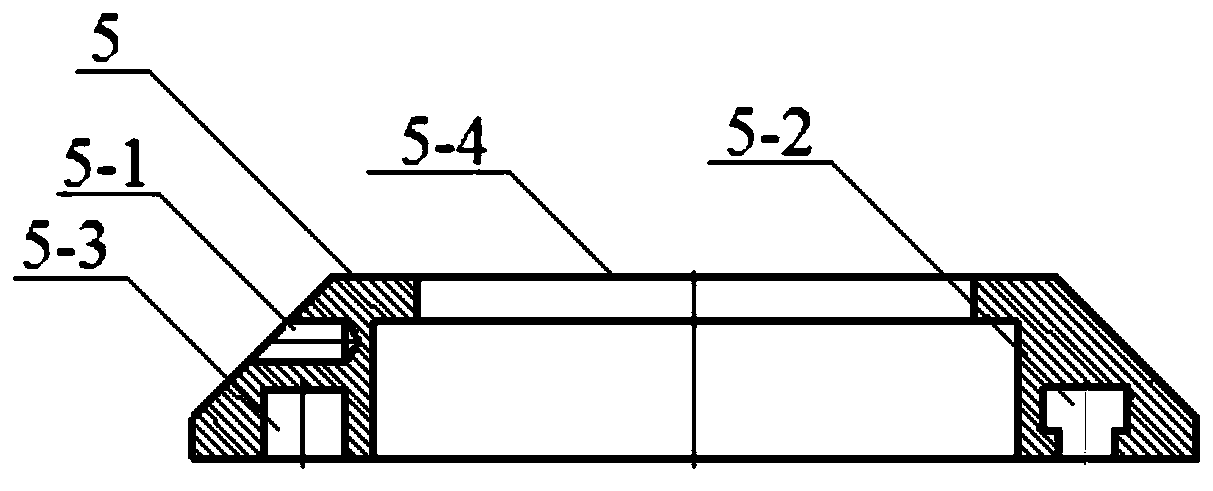

Counter-gravity casting riser tube positioning mechanism

ActiveCN107096903ANo deviation will occurMolten metal conveying equipmentsCasting moldMaterials science

The invention relates to a counter-gravity casting riser tube positioning mechanism, and aims to solve the technical problems that deviation of a riser tube and a sealing gasket (ring) is easily caused by an existing method, and then failing of pouring is caused. A casting mold 1, a cavity 2, a sprue gate 3, a riser tube upper sealing gasket 4, a positioning ring 5, a middle partition 6, a positioning bolt 7, a riser tube lower sealing gasket 8 and a riser tube 9 are successively arranged on the counter-gravity casting riser tube positioning mechanism from top to bottom, the riser tube 9 is fixed on the middle partition 6 through the positioning ring 5 and the positioning bolt 7, a flange 9-1 is arranged at the upper end of the riser tube 9, a hoisting opening 9-2 is formed in a side surface of the flange 9-1, the upper section of the positioning ring 5 is a conical table, the lower section of the positioning ring 5 is a cylindrical table, and a hoisting hole 5-1 is formed in a side surface of the conical table. According to the counter-gravity casting riser tube positioning mechanism, positioning is implemented by the positioning ring and the middle partition, therefore, the riser tube and the sealing gasket (ring) cannot deviate, and pouring can be successful. The invention belongs to the field of riser tube positioning mechanisms.

Owner:HARBIN INST OF TECH

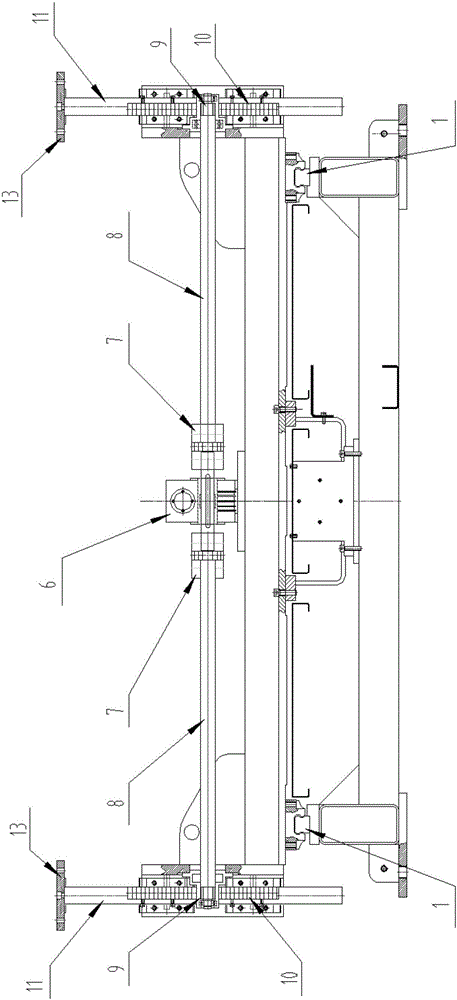

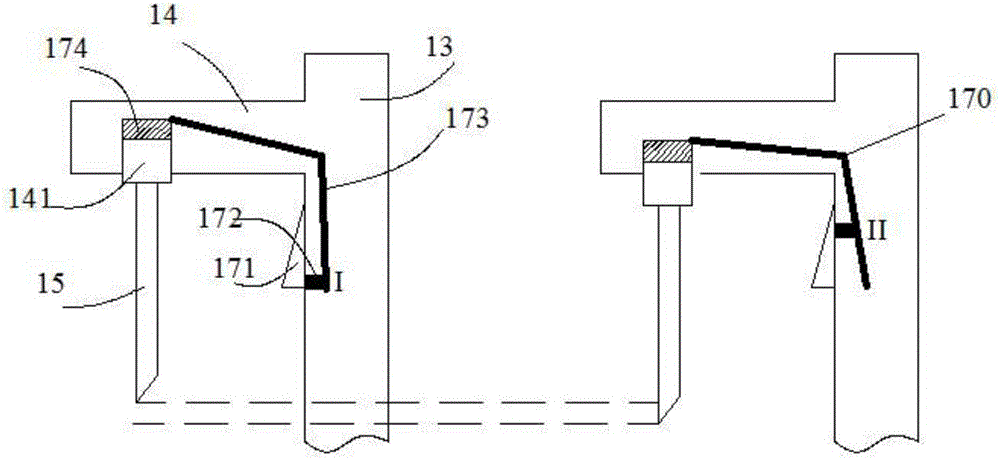

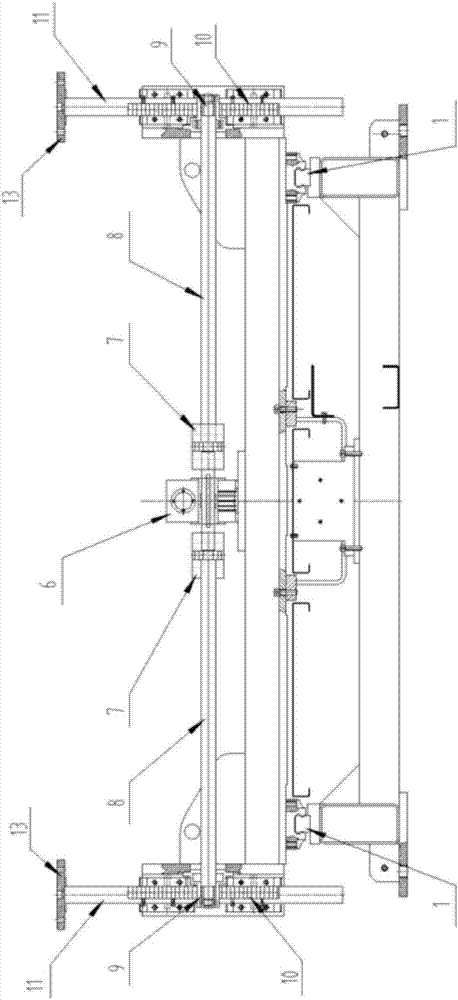

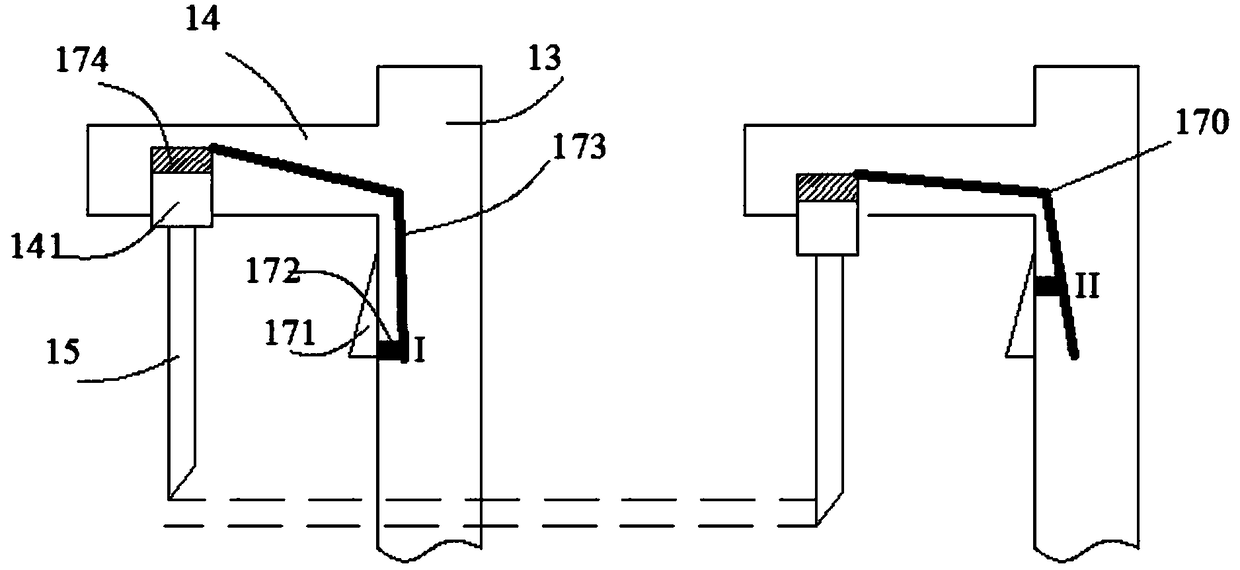

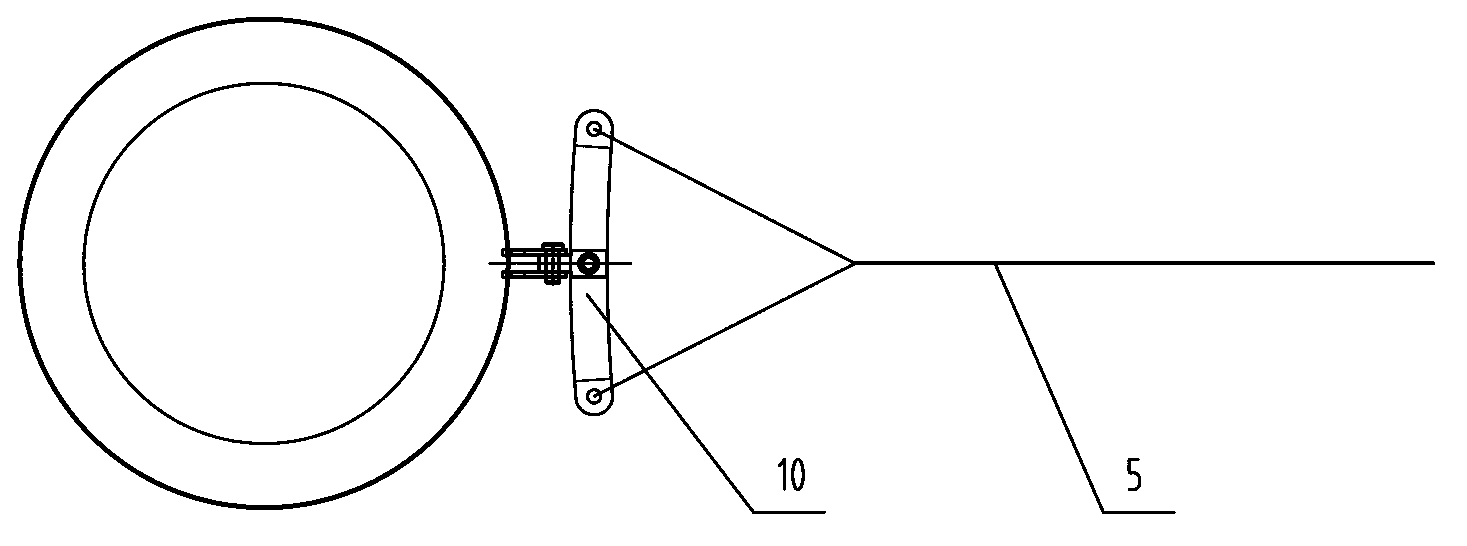

Rear material blocking mechanism for bending machines, and bending machine

InactiveCN105057485AAccurate locationNo deviation will occurMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a rear material blocking mechanism for bending machines, and a bending machine. The rear material blocking mechanism for bending machines comprises two linear guide rails arranged in parallel, wherein a dragging plate is arranged on the two linear guide rails and can move on the linear guide rails, and the dragging plate is connected with a screw rod; the screw rod is connected with a forward-backward movable servo motor; two lifting devices are arranged on the dragging plate. The rear material blocking mechanism disclosed by the invention adopts a frame type integrated structure, and the two linear guide rails are parallel to each other; the integrated structure guarantees that the positions of the guide rails are accurate and cannot deviate, so that the material blocking accuracy is realized.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

Glass cutting device

ActiveCN105753305AImprove cutting yieldNo deviation will occurGlass severing apparatusGlass knifeEngineering

The invention provides a glass cutting device which comprises suckers, a guide track, a fixing rack and a glass cutter, wherein the suckers are arranged below the guide track; the suckers are used for sucking glass to be cut; the extending track of the guide track is identical to the cutting track of the glass to be cut; the fixing rack is connected with the guide track in a sliding manner; the fixing rack and the suckers are respectively arranged on two sides of the guide track; the fixing rack is provided with a cutter holder; the glass cutter is fixed on the cutter holder; the glass cutter faces to a plane where the guide track is placed. As the glass cutter is fixed on the fixing rack, the fixing rack is connected with the guide track in a sliding manner, the glass to be cut is fixed on the guide track through the suckers in a sucking manner, the glass cutter points to the glass to be cut, and the movement track of the glass cutter on the surface of the glass is limited through the guide track, the glass cutter is not deflected in the cutting process, and the cutting pass percent of the glass is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

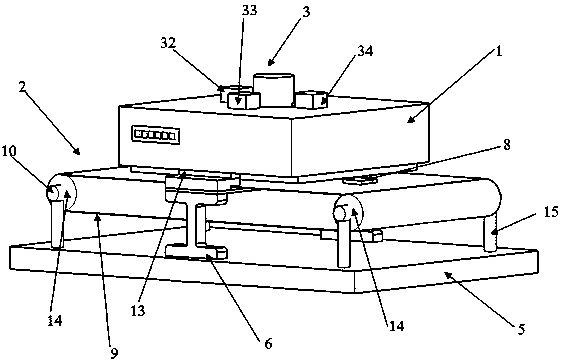

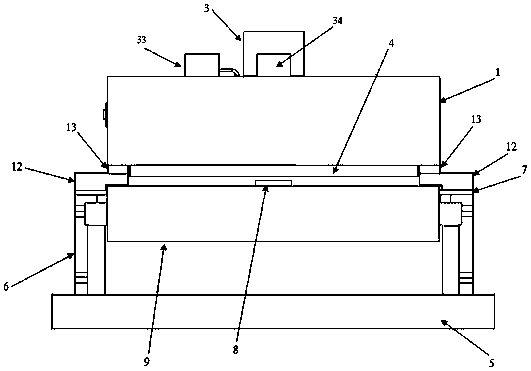

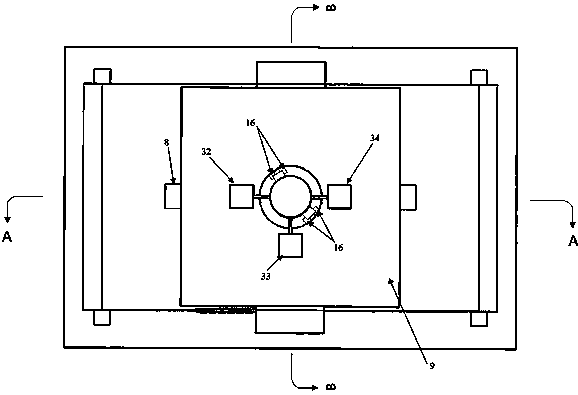

Glass panel polishing machine tool and polishing method

ActiveCN109227257AAvoid damageRealize automatic operationGrinding feedersPlane surface grinding machinesProduction lineEngineering

The invention discloses a glass panel polishing machine tool. The glass panel polishing machine tool comprises a cylindrical through hole formed in the center of a cover body, a polishing device penetrates through the through hole and makes the polishing device ascend and descend through a lifting mechanism, and the cover body is arranged above a conveying mechanism; the conveying mechanism comprises a support, two transmission rollers arranged at the left end and the right end of the support, a transmission motor and a conveying belt; the conveying belt sleeves the two transmission rollers atthe left end and the right end. The glass panel polishing machine tool is provided with a damping supporting device, so that the machine tool is particularly suitable for processing mobile phone panels and other glass panels with relatively high optical performance requirements; furthermore, an almost insulating environment is kept in the polishing operation process, and the interference of static electricity to the polishing process is reduced; furthermore, the machine tool is also suitable for being directly added into a production line to realize automatic operation in a processing environment.

Owner:SHANDONG CHUANGHUI TECH CO LTD

Back gauge for bending machine and bending machine

InactiveCN106862406AAccurate locationNo deviation will occurMetal-working feeding devicesPositioning devicesElectric machineryPress brake

The invention discloses a back gauge for a bending machine and the bending machine. The back gauge for the bending machine comprises two linear guide rails parallel to each other; the two linear guide rails are provided with a carriage; the carriage can move on the two linear guide rails and is connected with a screw rod; the screw rod is connected with a servo motor capable of moving front and back; and the carriage is provided with two lifting devices. According to the back gauge for the bending machine and the bending machine, a frame-type integrated structure is adopted, the two linear guide rails are parallel, the effect that the guide rails are accurate in position and cannot deviate is ensured through the integrated structure, and accordingly, the accuracy of the back gauge is achieved.

Owner:郭敏青

Novel straw conveying device

InactiveCN105621058AAvoid no-load phenomenonThe no-load phenomenon hasConveyorsControl devices for conveyorsEngineeringMechanical field

The invention discloses a novel straw conveying device and relates to the field of industrial machinery. The novel straw conveying device comprises a conveying belt and a motor, wherein a pressure sensor is arranged on the conveying belt; the pressure sensor is connected with an intelligent transmission; the intelligent transmission is connected with the motor; a driving gear is arranged on the motor; and the drive gear is connected with the conveying belt. The novel straw conveying device has the advantages of saving energy, protecting environment, changing speed intelligently, preventing the conveying belt from a deviation phenomenon and the like.

Owner:TIANJIN QUANYUZHENG PLASTIC PROD

Steel plate straightening and stamping integrated equipment for rolled steel

InactiveCN111790809AEasy to unloadPrecise positioningMetal-working feeding devicesPositioning devicesSteel platesStamping

The invention discloses steel plate straightening and stamping integrated equipment for rolled steel, and relates to the field of rolled steel stamping. The equipment comprises a lower die plate, supporting columns, a stamping die column, a straightening pressing plate and a connecting sleeve; the lower die plate is fixedly connected with the ground through the supporting columns, the straightening pressing plate is connected with the stamping die column through the connecting sleeve, and the stamping die column and the straightening pressing plate are externally connected with a driving piece; and a feeding device, a material returning device, a reversing structure and a sealing plate are fixedly arranged on the lower die plate, the reversing structure is connected with a straightening pressing plate through a transmission plate, a lifting structure is arranged on the sealing plate, and a telescopic traction structure is arranged on the straightening pressing plate. The steel plate straightening and stamping integrated equipment for the rolled steel solves the technical problems that a traditional device is discontinuous in stamping and low in precision.

Owner:北京康乾白祥商贸有限公司

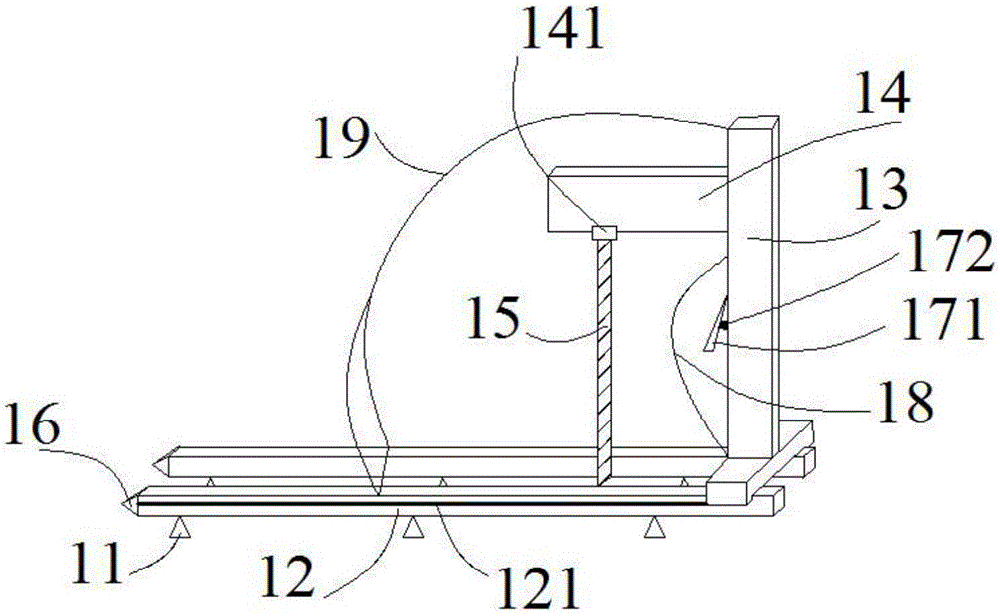

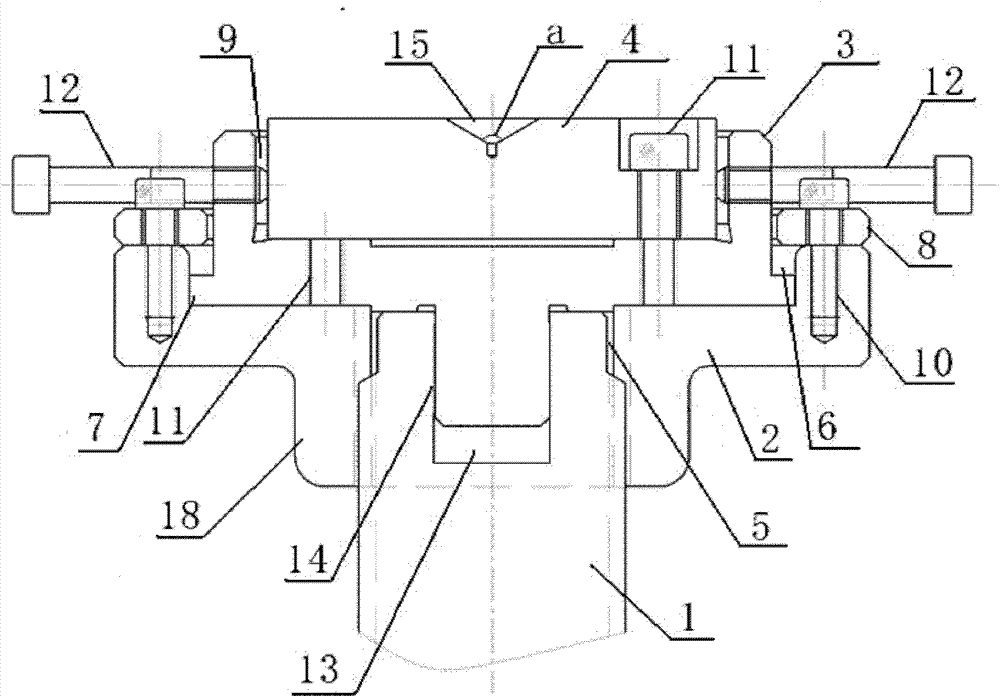

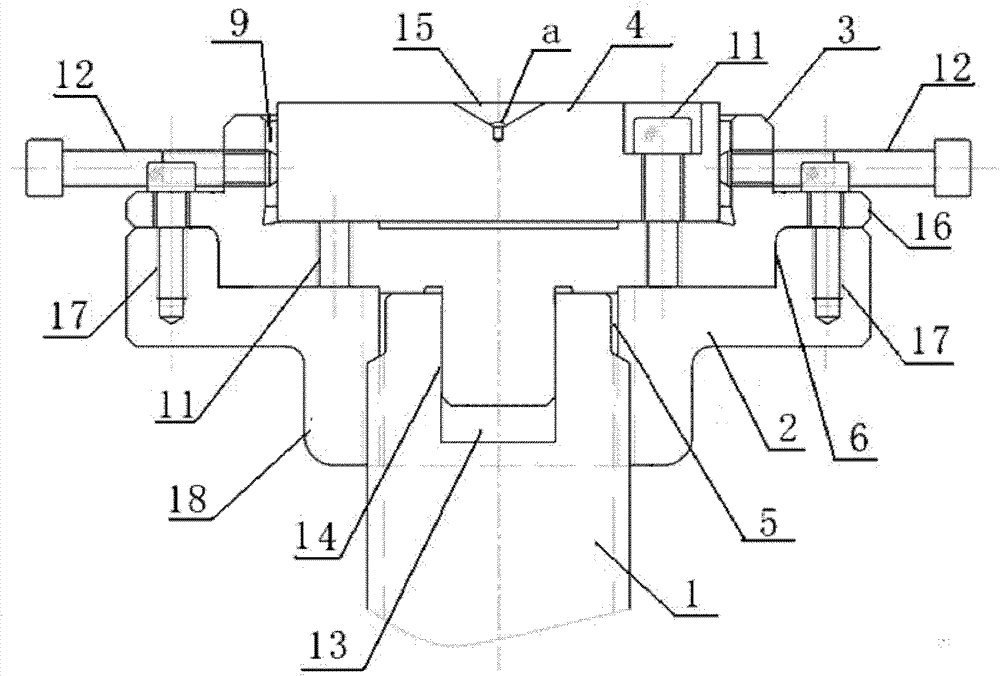

Special clamp for Rockwell hardometer measuring tool

ActiveCN102252905AGuarantee authenticityNo deviation will occurInvestigating material hardnessSclerometerHardness

The invention discloses a special clamp for a Rockwell hardometer measuring tool. The clamp comprises an installation pedestal, a platform fixing pedestal and a cylindrical workpiece measuring platform, wherein, the installation pedestal is connected with a lifting bar, the middle of the installation pedestal is provided with a first groove in which the platform fixing pedestal is arranged, the middle of the platform fixing pedestal is provided with a second groove in which the cylindrical workpiece measuring platform is fixed, and the whole clamp is positioned and fixed through jack-up of the platform fixing pedestal resulting from close cooperation of the installation pedestal and the lifting bar. Compared to the prior art, the invention has the following advantages: since a measuring platform is adjusted and fixed in one shot, it is not needed to calibrate center points for each measuring, thereby enabling simple operation, convenience and efficiency; no deviation of objects to be measured is guaranteed in measuring and a measuring probe and the center of the objects to be measured are kept consistent, thereby ensuring authenticity and accuracy of measured data of hardness and avoiding damage of equipment like hardometer probes, internal levers, etc.

Owner:TSUBAKI HOOVER TAICANG

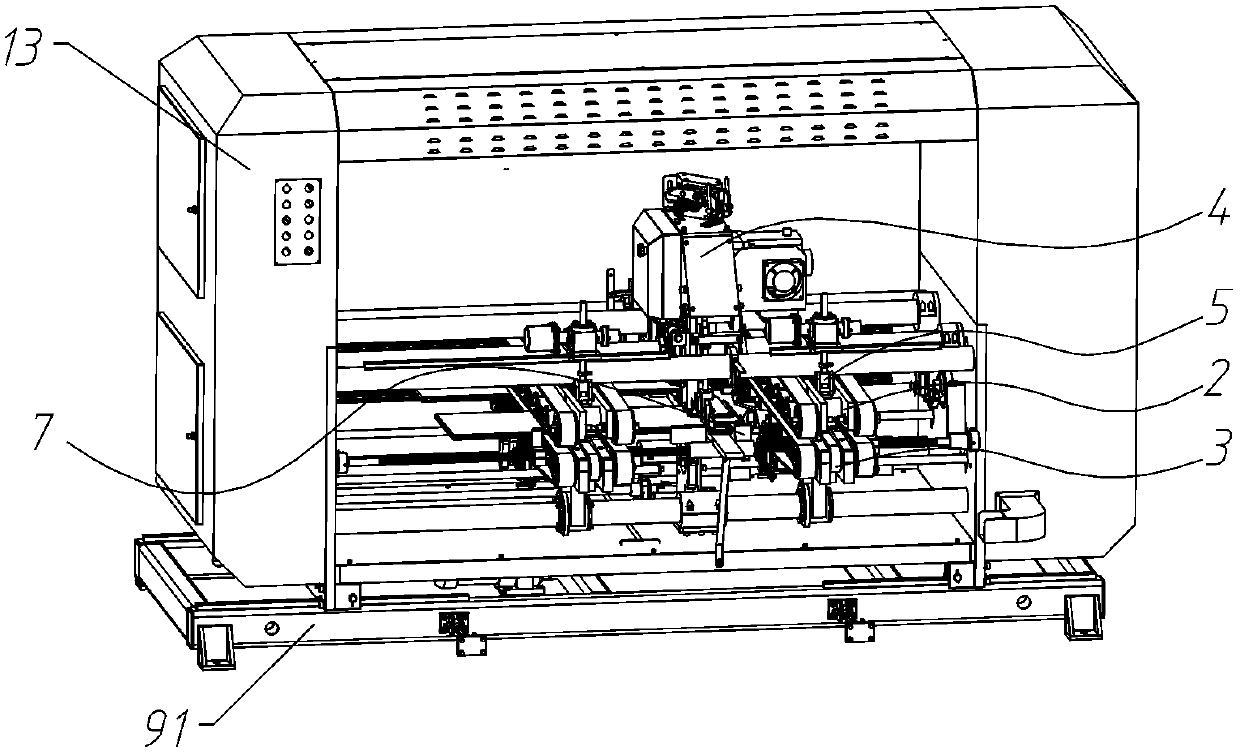

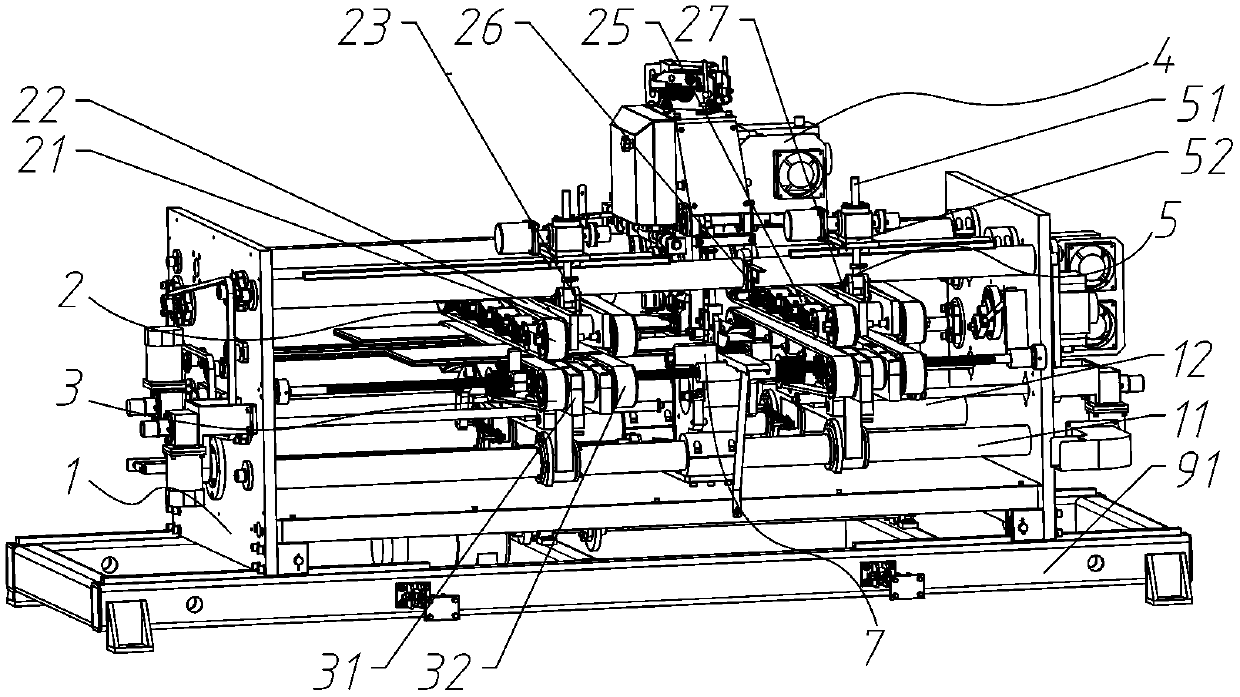

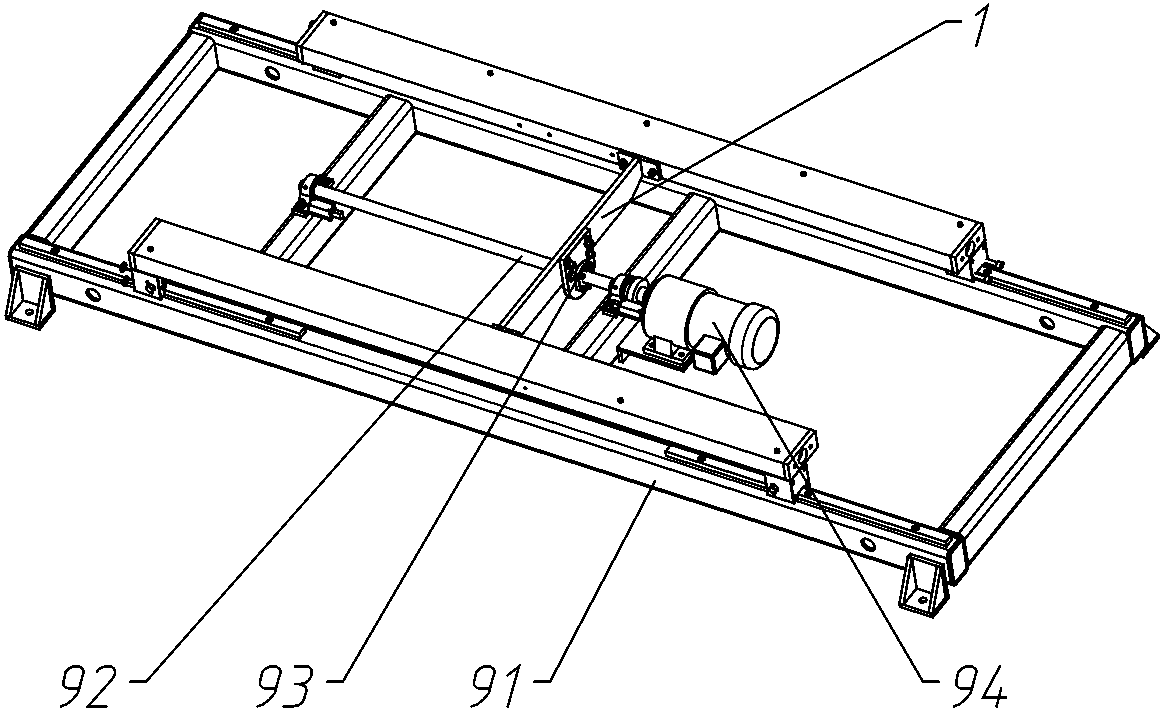

Carton stapler with paper board clamping positions being changeable

The invention belongs to the technical field of carton binding, and provides a carton stapler with paper board clamping positions being changeable. The carton stapler comprises a rack, an upper conveying mechanism, a lower conveying mechanism and a paper stapling device. The upper conveying mechanism comprises a first connecting plate and first conveying belts. The first connecting plate is arranged on the rack in a transverse sliding manner. The number of the first conveying belts is two, the two first conveying belts are arranged on the two sides of the first connecting plate correspondingly, and the first conveying belts are used for conveying paper boards in the longitudinal direction. The lower conveying mechanism comprises a second connecting plate and second conveying belts. The second connecting plate is arranged on the rack in a transverse sliding manner. The number of the second conveying belts is two, the two second conveying belts are arranged on the two sides of the secondconnecting plate correspondingly, and the second conveying belts are used for conveying the paper boards in the longitudinal direction. The paper stapling device is arranged on the rack and is used for stapling the paper boards. By means of the technical scheme, the problem that carton staplers are not suitable for binding of paper boards small in transverse size in the prior art is solved.

Owner:TANGSHAN JIAJIE PACKAGE MACHINERY MFG

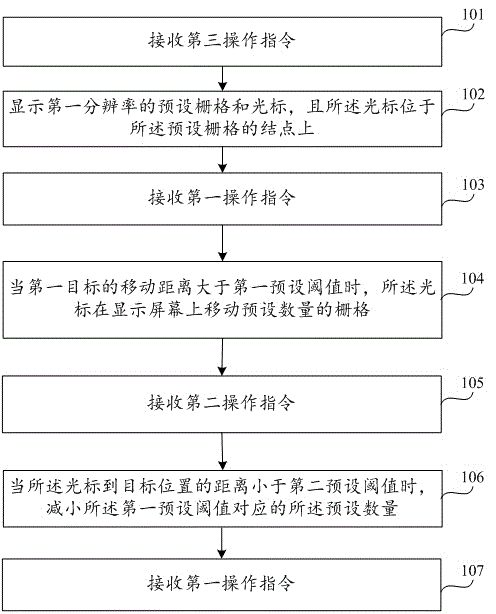

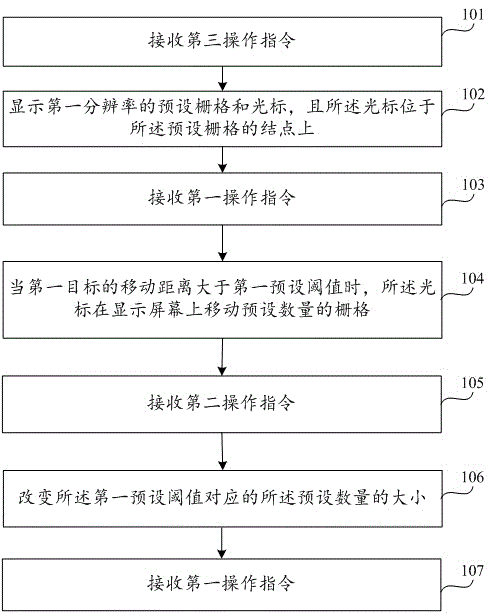

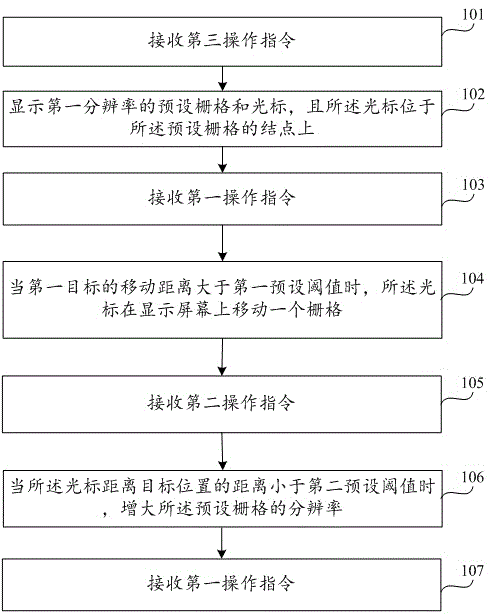

Cursor movement method and device for medical display and medical equipment

ActiveCN106325507AImprove accuracyRestricted degrees of freedomInput/output for user-computer interactionGraph readingMedical equipmentOperability

The invention discloses a cursor movement method and device for medical display and medical equipment and belongs to the field of medical display. The method comprises: when receiving a first operation instruction and a movement distance of a first target being greater than a first pre-set threshold value, moving a cursor on a display screen for grids with a pre-set quantity, namely the movement distance of the first target corresponding to the quantity of the movement grids of the cursor on the display screen; when receiving a second operation instruction, changing the size of the pre-set quantity corresponding to the first pre-set threshold value, so as to change a movement distance of the cursor, corresponding to the movement distance of the first target, on the display screen under the condition that the size of the pre-set quantity of the grids is not changed, namely adjusting the size of the movement distance of the cursor, corresponding to the movement distance of the first target, on the display screen by a user according to distances between the cursor and a target position. The cursor gets close to the target position limitlessly, and the accuracy of cursor movement and the operability of the user are improved.

Owner:QINGDAO HISENSE MEDICAL EQUIP

Glass cutting device

ActiveCN105753305BImprove cutting yieldNo deviation will occurGlass severing apparatusCutting glassGlass cutter

The invention provides a glass cutting device which comprises suckers, a guide track, a fixing rack and a glass cutter, wherein the suckers are arranged below the guide track; the suckers are used for sucking glass to be cut; the extending track of the guide track is identical to the cutting track of the glass to be cut; the fixing rack is connected with the guide track in a sliding manner; the fixing rack and the suckers are respectively arranged on two sides of the guide track; the fixing rack is provided with a cutter holder; the glass cutter is fixed on the cutter holder; the glass cutter faces to a plane where the guide track is placed. As the glass cutter is fixed on the fixing rack, the fixing rack is connected with the guide track in a sliding manner, the glass to be cut is fixed on the guide track through the suckers in a sucking manner, the glass cutter points to the glass to be cut, and the movement track of the glass cutter on the surface of the glass is limited through the guide track, the glass cutter is not deflected in the cutting process, and the cutting pass percent of the glass is increased.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Positioning mechanism for planar full-automatic labeling machine

InactiveCN104670604ANo deviation will occurAchieve attachmentLabelling machinesLabelling short rigid containersMechanical engineeringPulsed power

The invention discloses a positioning mechanism for a planar full-automatic labeling machine. The positioning mechanism comprises a push part connected with a pulsed power source, wherein the push part is positioned on one side of a transfer guide rail; a rotating part opposite to the push part is arranged on the other side of the transfer guide rail; the transfer guide rail is arranged on a rack; a first positioning part and a second positioning part are arranged on the rack part at which the rotating part is positioned; and a label is positioned in any positioning part. According to the positioning mechanism provided by the technical scheme, accurate pushing, rotating and positioning operations in the labeling process can be guaranteed.

Owner:DONGGUAN JINBIAO AUTOMATION EQUIP

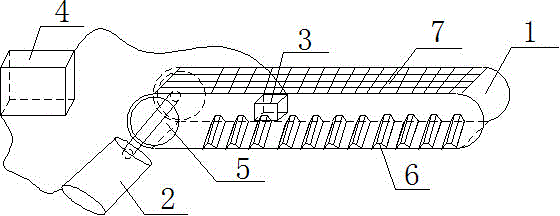

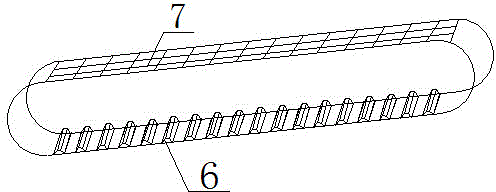

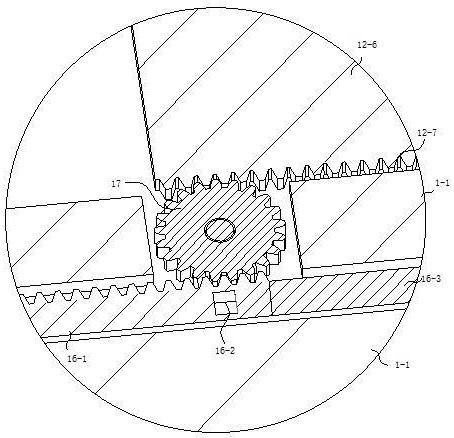

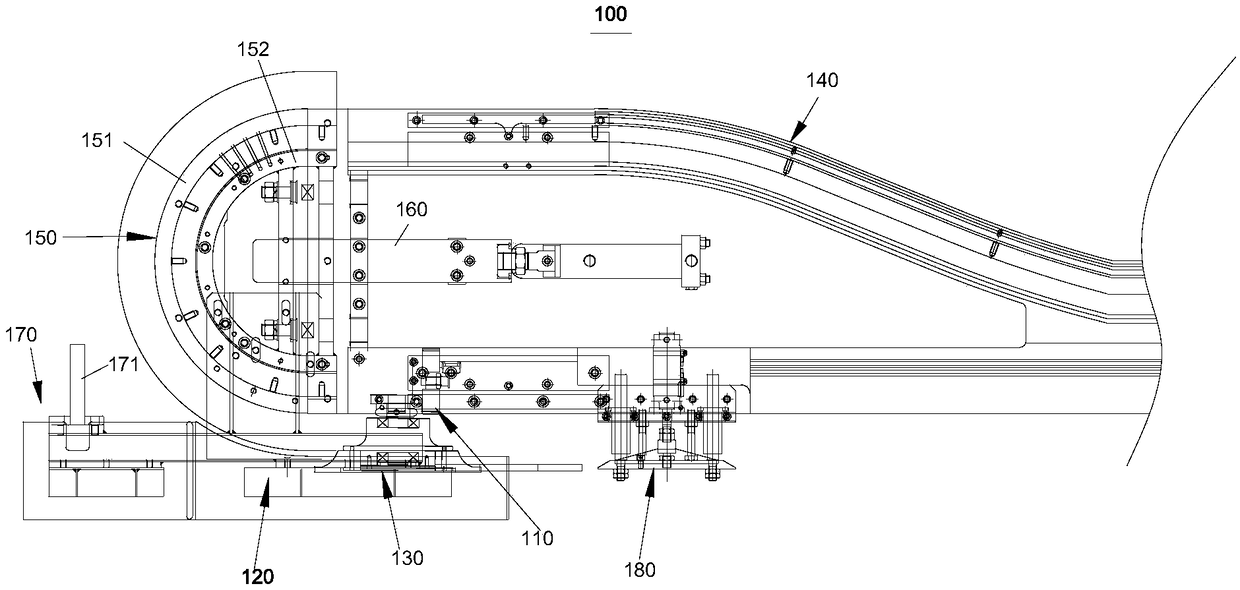

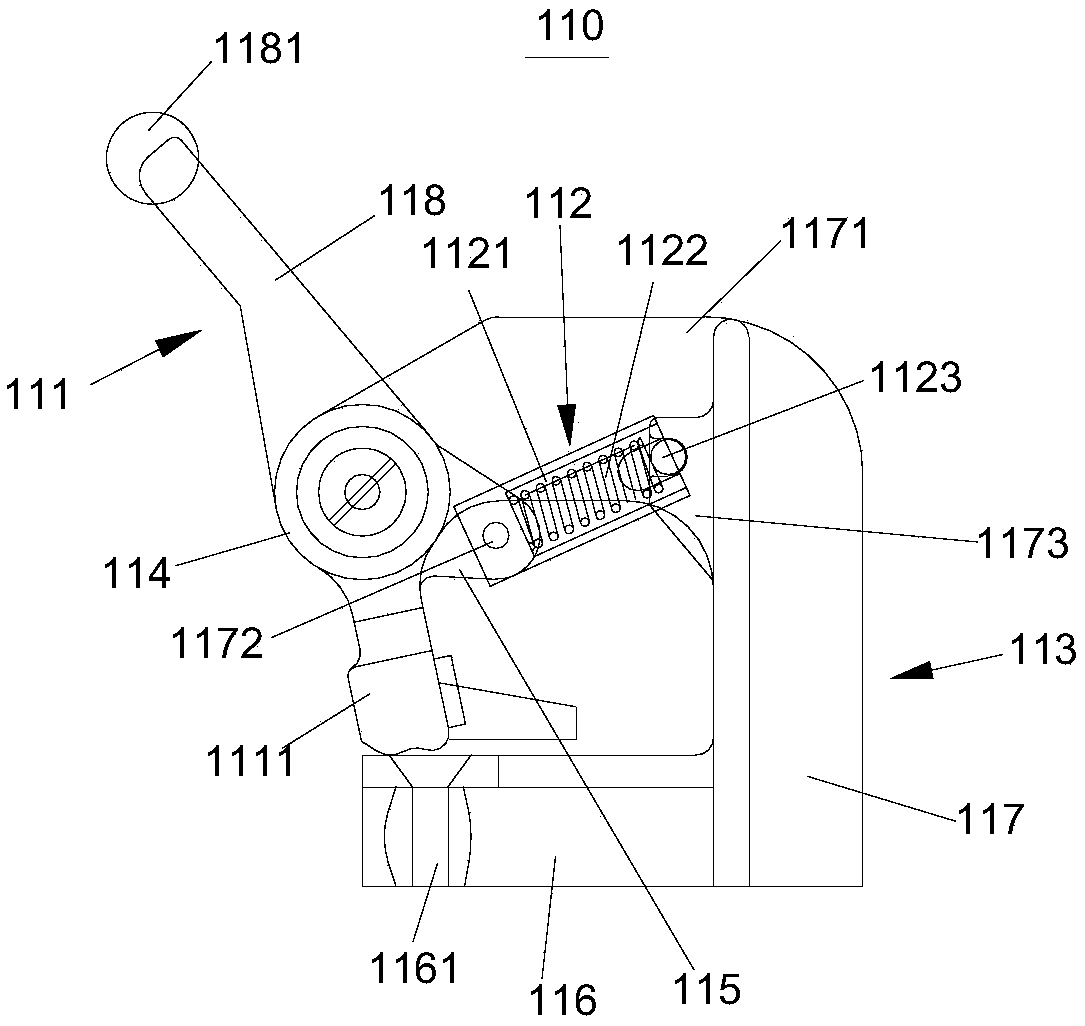

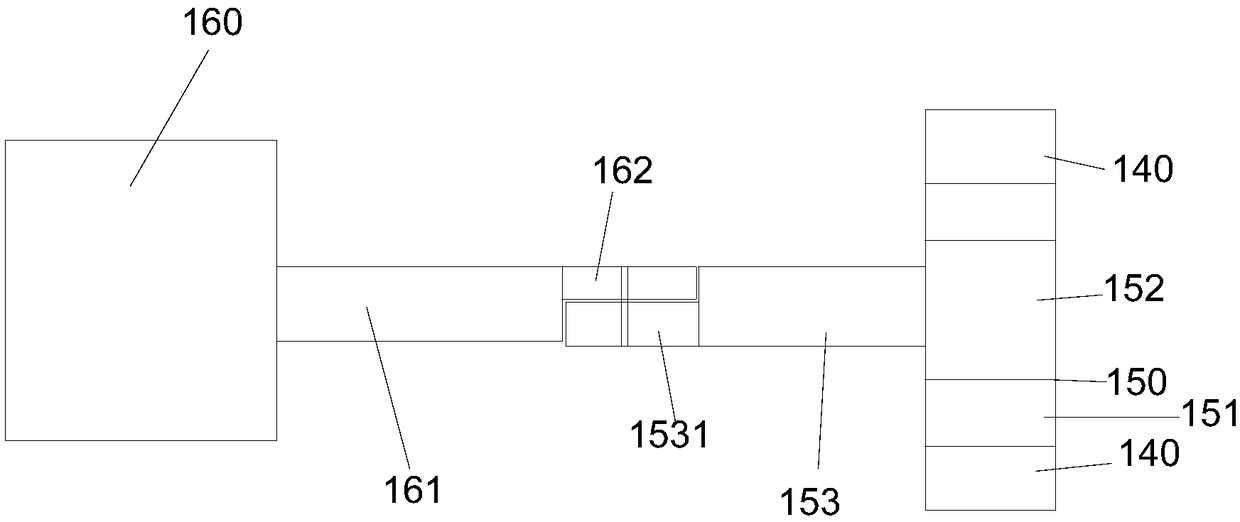

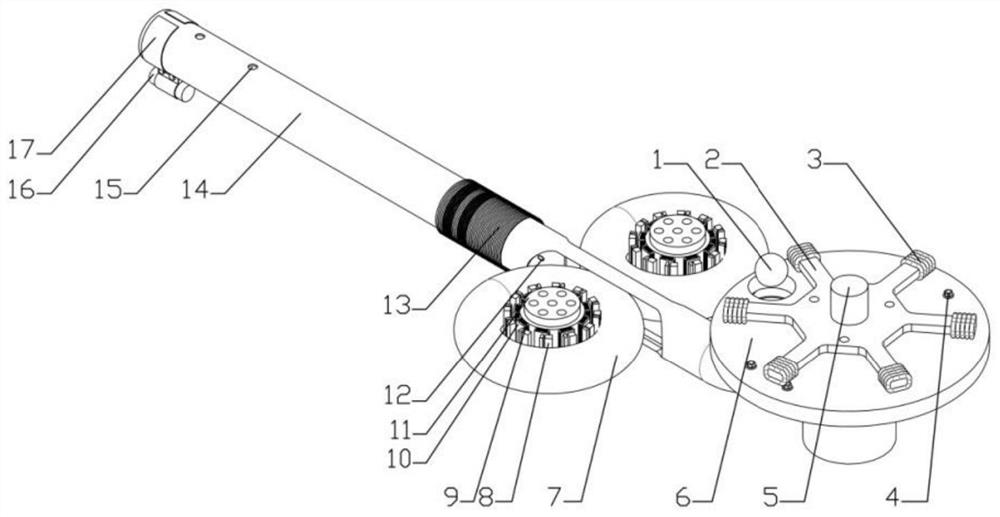

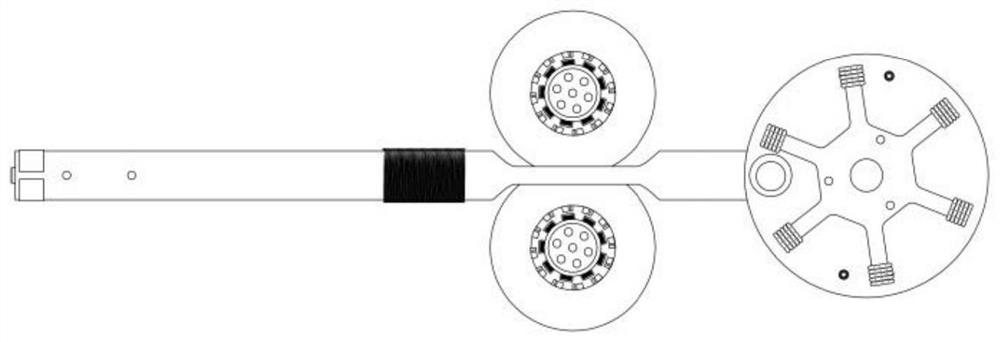

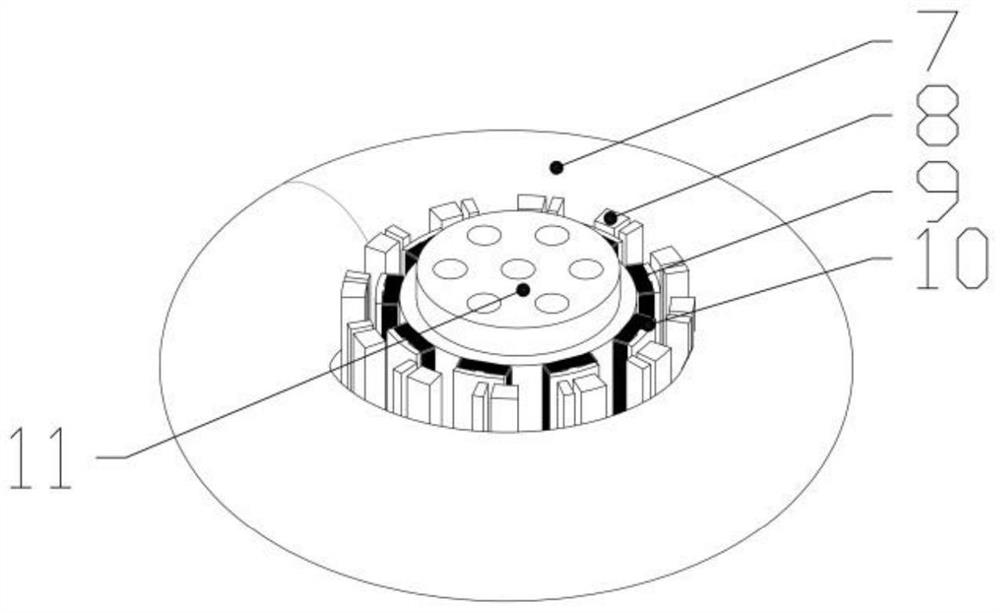

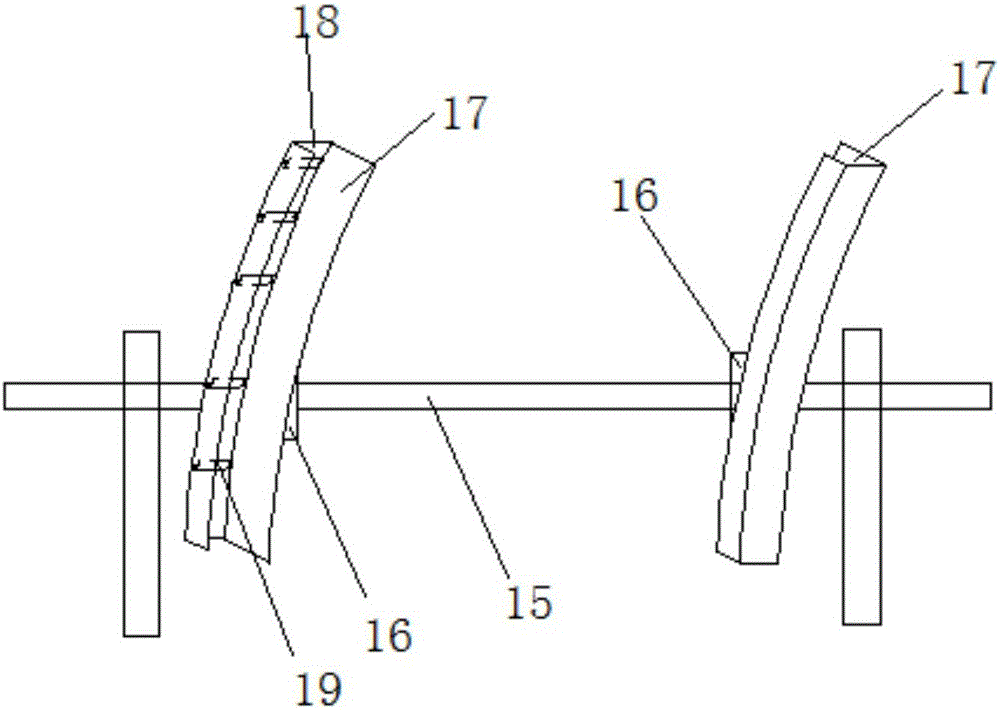

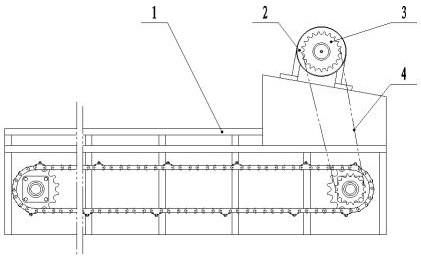

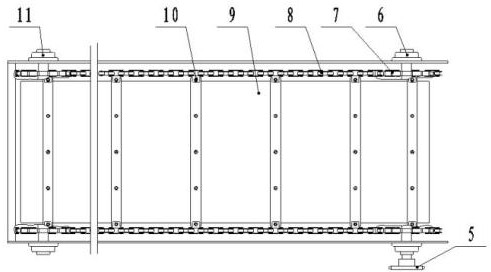

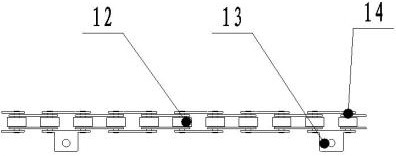

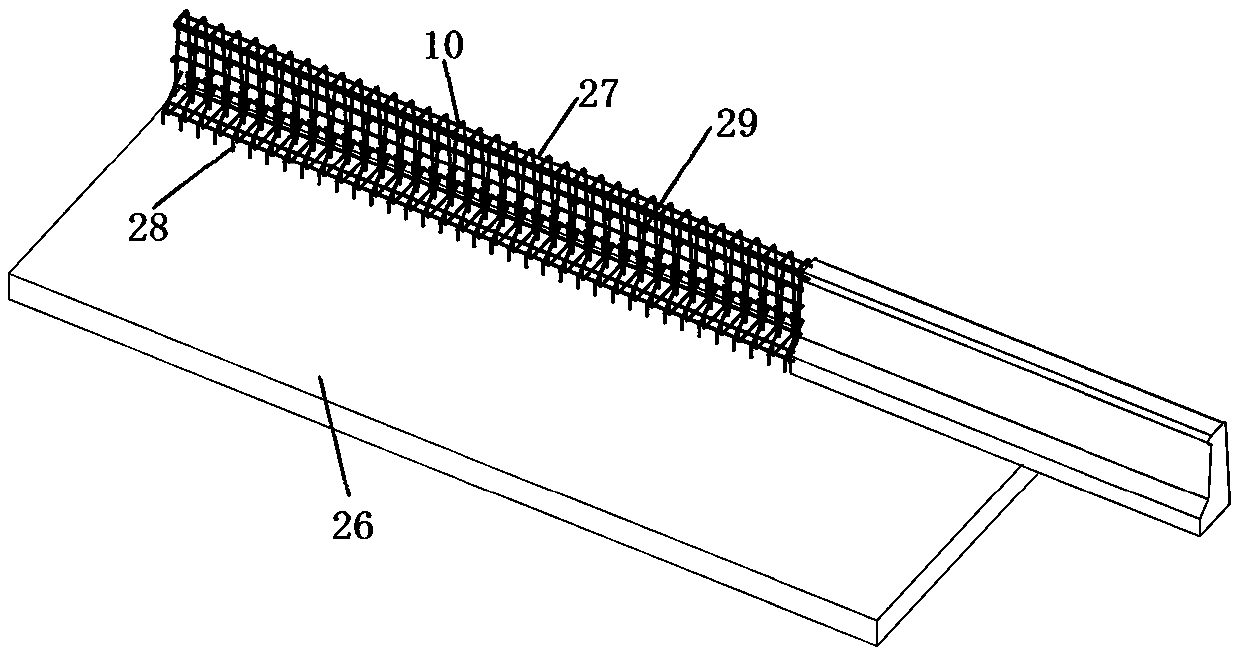

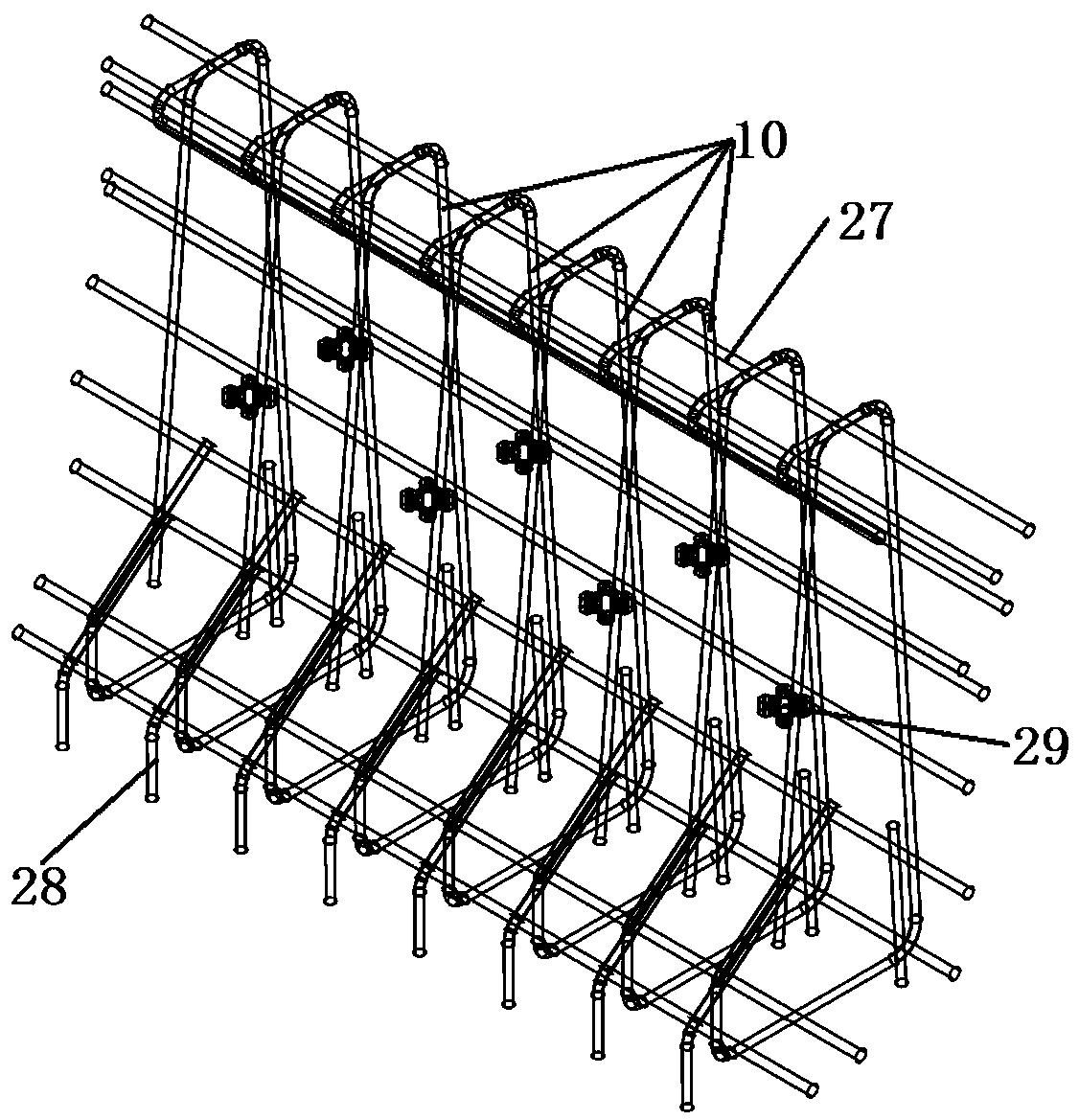

A chain clamp type transmission mechanism and a chain clamp type transmission device for wet separation membrane extraction of a lithium ion battery

PendingCN109192908ANo deviation will occurSimple structureFinal product manufactureCell component detailsForeign matterNew energy

The invention provides a chain clamp type transmission mechanism and a chain clamp type transmission device for wet separation membrane extraction of a lithium ion battery, belonging to the field of new energy equipment and mechanical design. The chain clamp type transmission mechanism of the lithium ion battery wet method diaphragm extraction obtained by the design has the advantages of simple overall structure, easy adjustment and installation, convenient manufacture and low cost. As that two side of the diaphragm are clamped by the chain clamp through the chain clamp type transmission, thediaphragm is in a suspended state in the extraction tank, the surface of the diaphragm is not scratch, and the diaphragm is not in contact with other objects, thereby reducing the possibility that thediaphragm is contaminated by foreign matter in the extraction tank; When the diaphragm is conveyed by the chain clamp, the two sides of the diaphragm are clamped and can only travel along the track of the chain clamp, so the running deviation phenomenon of the diaphragm does not occur. The speed of the whole chain-clamp transmission mechanism can be greatly improved.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

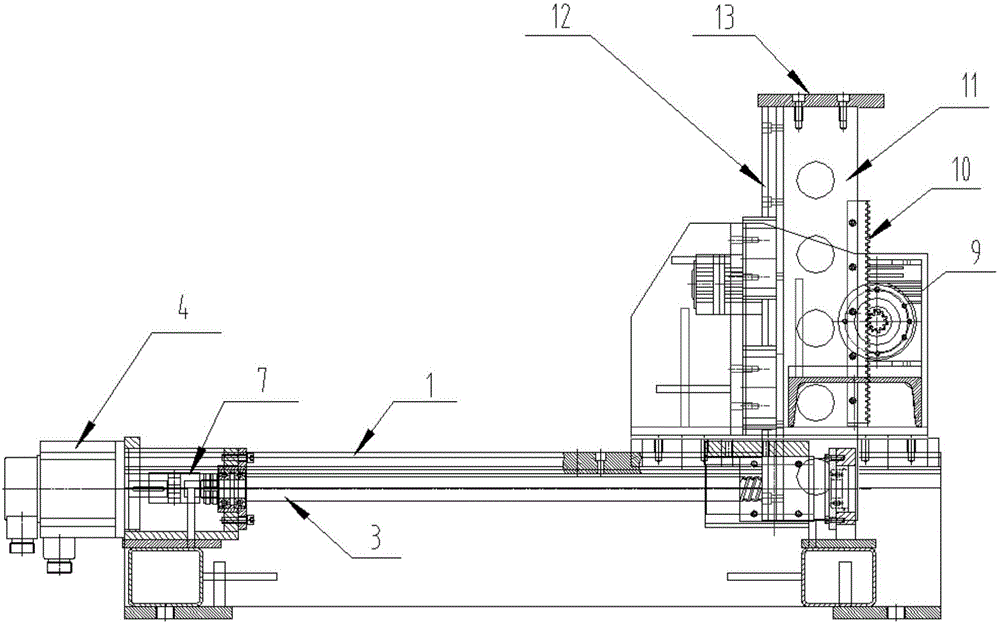

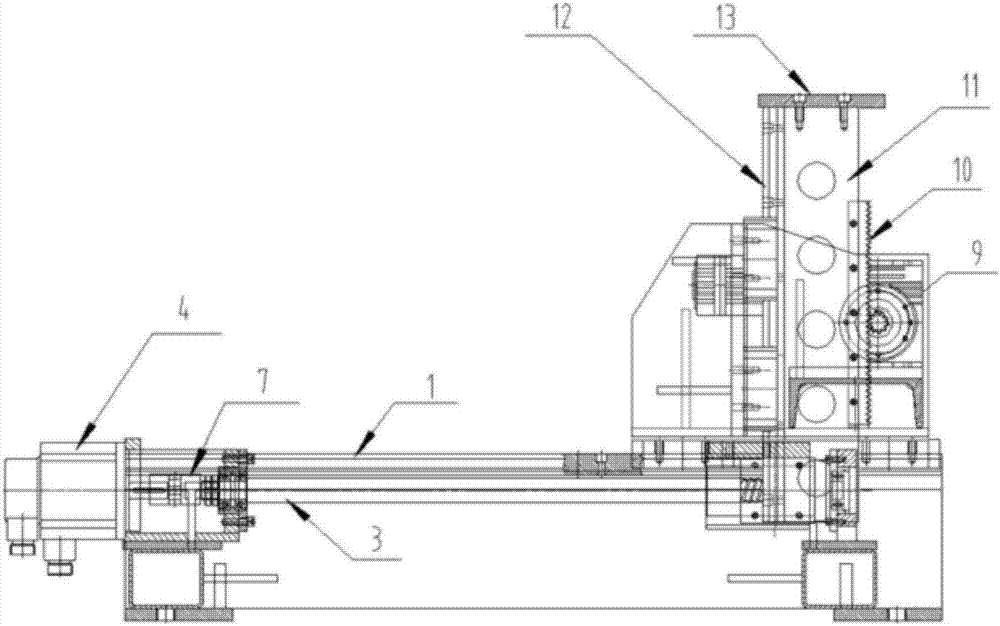

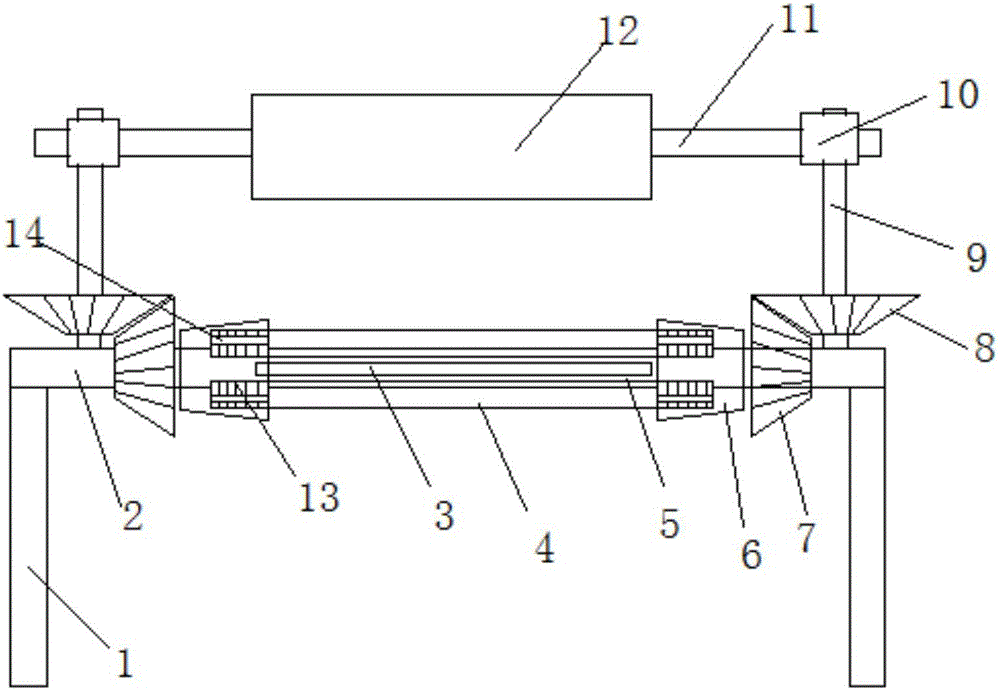

Multi-shot continuous launching test platform

PendingCN112268790ASolve problems that require a certain initial velocityNo deviation will occurStrength propertiesEngineeringTest platform

The invention provides a multi-shot continuous launching test platform, belongs to the field of shot peening strengthening, and overcomes the defects that laboratory shot peening equipment cannot meetthe strengthening requirement of small materials and the shot peening speed cannot be adjusted. The multi-shot continuous launching test platform comprises a shot filling device, a shot driving device and a shot launching device. The shots are continuously provided by an open magazine, the shot drives a friction wheel to provide initial velocity, an electromagnetic acceleration coil is powered onwhen the shot touches a pressure sensor, and the shot hits a sample after being accelerated by forward thrust due to an instantly generated magnetic field. The initial speed of the shot can be calculated through a related formula according to the rotating speed of the driving friction wheel. The speed of the shot out of a launching tube can be measured by a laser speed measuring device. The effect of different projectile launching directions is achieved by controlling the angle of the sample. The test platform can be used for a shot peening test in a laboratory, and has the advantages of simple installation, convenient operation, good reliability and the like.

Owner:ANHUI UNIV OF SCI & TECH

Automatic steel plate alignment winding and unwinding device

The invention discloses an automatic steel plate alignment winding and unwinding device which comprises a winding shaft, wherein two ends of the winding shaft are respectively mounted through brackets; an axial opening is formed in a section of distance of the winding shaft; a winding clamping cover is arranged outside the winding shaft in a sleeving manner; an opening is formed in one side of the winding clamping cover; conical locking sleeves are respectively arranged at two ends of the winding clamping cover in a sleeving manner; driving bevel gears are respectively arranged at two ends of the winding shaft and respectively meshed with driven bevel gears above the driving bevel gears; the driven bevel gears are respectively arranged on lead screws on corresponding sides; the bottoms of the lead screws are rotationally arranged on the brackets through bearings; sliding sleeves are respectively screwed on the lead screws; a connecting rod is arranged between the sliding sleeves; a compression roller is arranged on the connecting rod in a sleeving manner. The automatic steel plate alignment winding and unwinding device disclosed by the invention is high in stability, time / manual labor-saving and high in winding efficiency, and the winding quality can be guaranteed, so that the hidden danger caused by unsafe factors in the operation is avoided under double protection of an arc-shaped conveying rack before winding and a synchronous extrusion compression roller during winding.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Traction balance mechanism for traveling car on track

InactiveCN102795238AReduce prone to deviationReduce the disadvantages of getting stuck and breaking the traction ropeRailway coupling accessoriesMechanical equipmentEngineering

The invention mainly relates to a balance device applied to material conveying mechanisms in road construction machinery industry and mechanical equipment manufacturing industry, in particular to a traction balance mechanism for a traveling car on a track, which belongs to the technical field of mechanical structures. The traction balance mechanism comprises a material conveying car, wherein a plurality of traveling wheels are arranged beside the material conveying car, a track is arranged at the lower ends of the wheels, a connecting plate is arranged at the front end of the car, the connecting plate is connected with a material conveying balance mechanism through a shaft pin, a steel wire rope is arranged on the material conveying balance mechanism, and the car is pulled to advance on the track through the steel wire rope. The traction balance mechanism has the advantages of simple assembly and reasonable structure, and can conveniently ensure the safety in operation of equipment by regulating the angle during the operation of the equipment.

Owner:无锡佳能工程机械有限公司

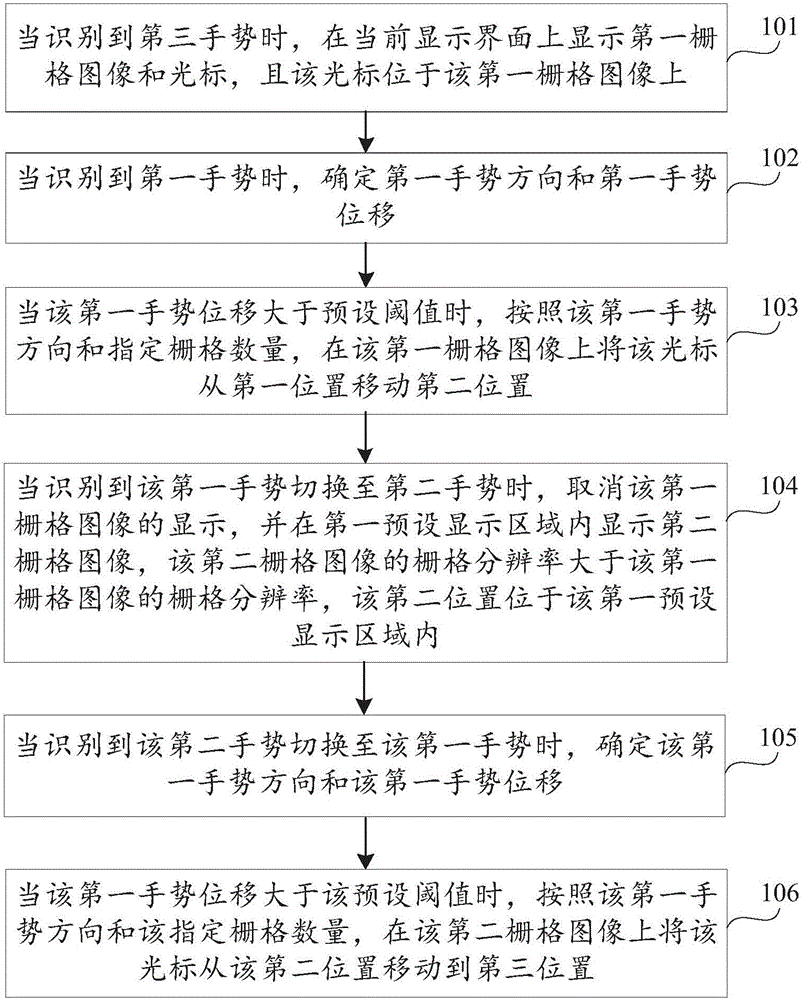

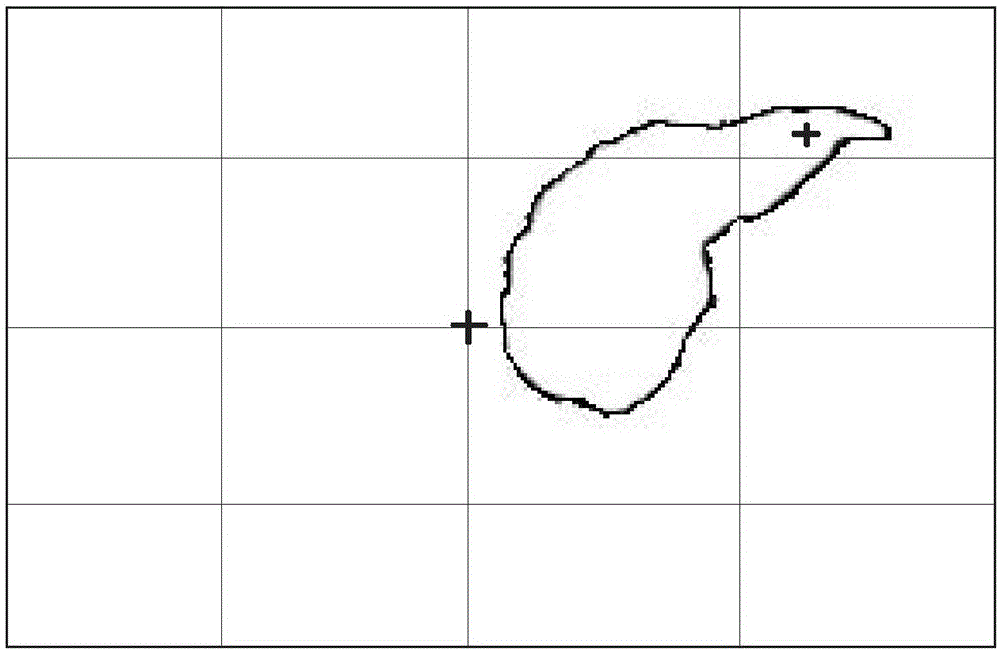

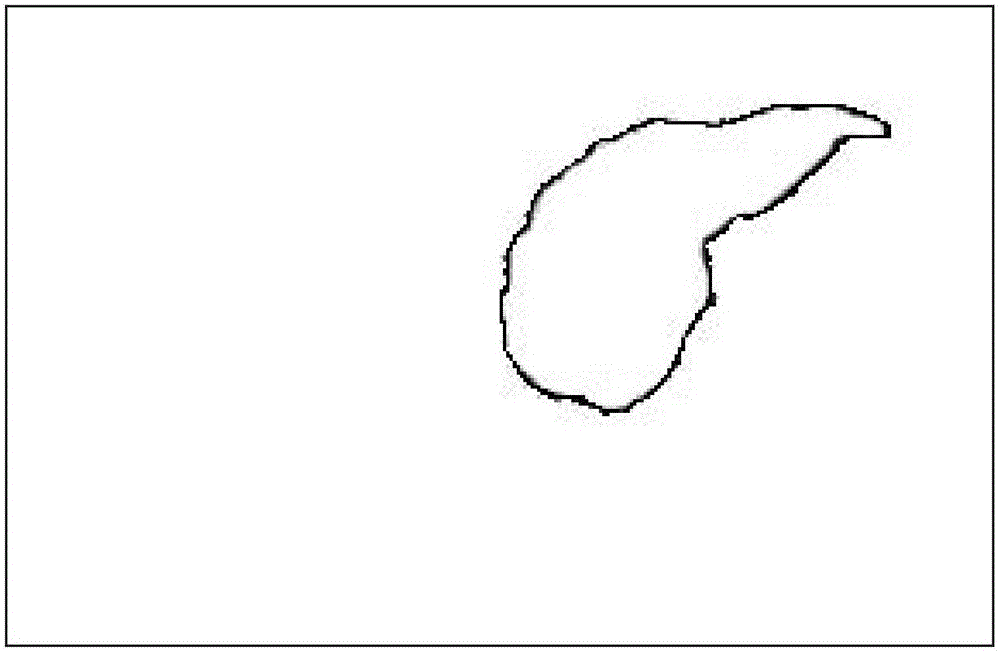

Gesture-based cursor moving method and device for medical display

ActiveCN106293098AReduce grid sizeImprove accuracyInput/output for user-computer interactionGraph readingImage resolutionOperability

The invention discloses a gesture-based cursor moving method and device for medical display and belongs to the field of gesture recognition. The method comprises: upon recognition of a first gesture, determining a first gesture direction and a first gesture displacement; when the first gesture displacement is greater than a preset threshold, moving a cursor on a first raster image from a first position to a second position according to the first gesture direction and a specified raster quantity; when it is recognized that the first gesture is switched to a second gesture, canceling display of the first raster image, and displaying in a second raster display area, a second raster image having a raster resolution greater than that of the first raster image, with the second position positioned in the second raster display area. By constructing the second raster image with higher resolution in the first display area included a position of the cursor, it is possible for the cursor to infinitely approach a target position, cursor movement accuracy is improved, and operability for a user is improved.

Owner:QINGDAO HISENSE MEDICAL EQUIP

Cursor movement method and device for medical display and medical device

ActiveCN106250711AReduce movement accuracyImprove accuracySpecial data processing applicationsSpecific program execution arrangementsOperabilityComputer vision

The invention discloses a cursor movement method and device for medical display and a medical device and belongs to the field of medical display. The method comprises the steps of moving a cursor on a display screen for grids of preset quantity when a first operation instruction is received and the movement distance of a first target is greater than a first preset threshold value, wherein the movement distance of the first target corresponds to the movement grid quantity of the cursor on the display screen; changing the magnitude of the preset quantity corresponding to the first preset threshold value when a second operation instruction is received; and changing the movement distance of the cursor on the display screen corresponding to the movement distance of the first target under the condition that the sizes of the preset grids are not changed, wherein a user can adjust the magnitude of the movement distance of the cursor on the display screen according to the distance from the cursor to a target location, wherein the movement distance of the first target corresponds to the movement distance of the cursor. The cursor can be close to the target location limitlessly, and the movement accuracy of the cursor and the operability of the user can be improved.

Owner:QINGDAO HISENSE MEDICAL EQUIP

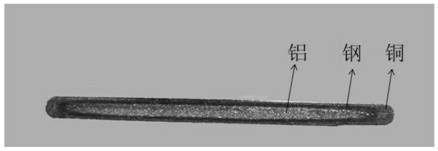

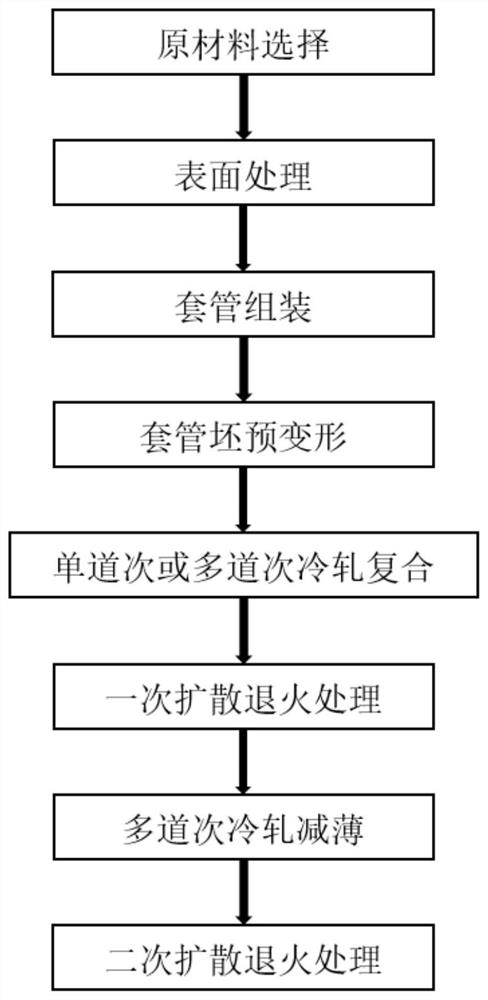

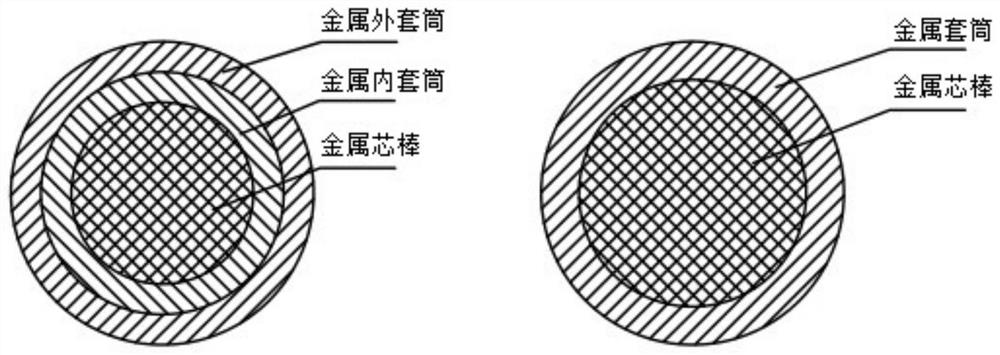

Preparation process of multilayer metal composite belt

PendingCN113477712AImprove composite effectImprove compound rateMetal rolling arrangementsManufactured materialComposite plate

The invention discloses a preparation process of a multilayer metal composite belt, and relates to the technical field of preparation of multilayer metal composite belts. The preparation process comprises the following process steps: (S1) selecting raw materials for low-temperature annealing; (S2) polishing and cleaning the selected raw materials; (S3) nesting and assembling the treated raw materials; (S4) forging and pre-deforming the assembled sleeve blank to form a sleeve blank with a sharp wedge-shaped front end; (S5) cold-rolling and compounding the pre-deformed sleeve blank; (S6) diffusing and annealing the cold-rolled and compounded metal composite belt; (S7) carrying out multi-pass cold rolling and thinning on the heat-treated metal composite belt; and (S8) secondarily diffusing and annealing the cold-rolled and thinned multilayer metal composite belt. The obtained multilayer metal composite belt is flat and smooth in surface and high in binding force; and compared with the prior art, the preparation process is low in requirements on production equipment, high in raw material combination freedom degree, flexible in product specification, simple in preparation process, low in production cost and suitable for large-scale industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Tailoring device used for PV piece

PendingCN109465870AGuaranteed cropping effectNo deviation will occurMetal working apparatusEngineeringMachining

The invention discloses a tailoring device used for a PV piece, and relates to the technical field of plastic machining. The device comprises a bottom plate, two sliding grooves are formed in the upper surface of the bottom plate, the two sliding grooves are formed in the left side and the right side of the upper surface of the bottom plate correspondingly, sliding blocks are in sliding connectioninto the sliding grooves, a sliding device is fcixedly connected to the upper surfaces of the sliding blocks, one end of the front face of the sliding device and one end of the back face of the sliding device are fixedly connected with baffles, and the lower surfaces of the two baffles are fixedly connected to the upper surface of the bottom plate. According to the tailoring device used for the PV piece, the sliding device, a second sliding rod, a second sliding sleeve, a nut, a screw, a third sliding rod, a third sliding sleeve and a blade are arranged, the blade can tailors the PV piece directly, compared with manual tailoring, the straight-line tailoring standard is mastered, the condition that the tailoring path deviates is avoided, the tailoring effect of the PV piece is ensured, andconvenience is brought to tailoring of PV piece.

Owner:重庆迈瑞新材料有限公司

Rubber hose cutting-off device for preventing cutting knife from being deviated

InactiveCN105082240ASmooth cutNo deviation will occurMetal working apparatusAgricultural engineering

The invention discloses a rubber hose cutting-off device for preventing a cutting knife from being deviated, which relates to the field of rubber hose processing, and is applied to cutting off of rubber hoses. The rubber hose cutting-off device comprises a cutting knife, a hydraulic device, a connecting rod, a fixed backing plate, a fixed deviation resisting frame and a rack, wherein the fixed backing plate is fixedly arranged at the upper end of the rack; the fixed deviation resisting frame is arranged on the fixed backing plate; the hydraulic device is arranged on the fixed deviation resisting frame; the hydraulic device is connected with the cutting knife through the connecting rod; the cutting knife is positioned at the central position of the rack. The rubber hose cutting-off device disclosed by the invention has the beneficial effects that by additionally mounting the fixed deviation resisting frame, the cutting knife moves in a direction perpendicular to the rack of the cutting-off device, the deviation phenomenon is avoided, and further a rubber hose notch becomes neat.

Owner:TIANJIN BINHAI ZHONGGUAN RUBBER HOSE

Special clamp for Rockwell hardometer measuring tool

ActiveCN102252905BGuarantee authenticityNo deviation will occurInvestigating material hardnessSclerometerHardness

The invention discloses a special clamp for a Rockwell hardometer measuring tool. The clamp comprises an installation pedestal, a platform fixing pedestal and a cylindrical workpiece measuring platform, wherein, the installation pedestal is connected with a lifting bar, the middle of the installation pedestal is provided with a first groove in which the platform fixing pedestal is arranged, the middle of the platform fixing pedestal is provided with a second groove in which the cylindrical workpiece measuring platform is fixed, and the whole clamp is positioned and fixed through jack-up of the platform fixing pedestal resulting from close cooperation of the installation pedestal and the lifting bar. Compared to the prior art, the invention has the following advantages: since a measuring platform is adjusted and fixed in one shot, it is not needed to calibrate center points for each measuring, thereby enabling simple operation, convenience and efficiency; no deviation of objects to be measured is guaranteed in measuring and a measuring probe and the center of the objects to be measured are kept consistent, thereby ensuring authenticity and accuracy of measured data of hardness and avoiding damage of equipment like hardometer probes, internal levers, etc.

Owner:TSUBAKI HOOVER TAICANG

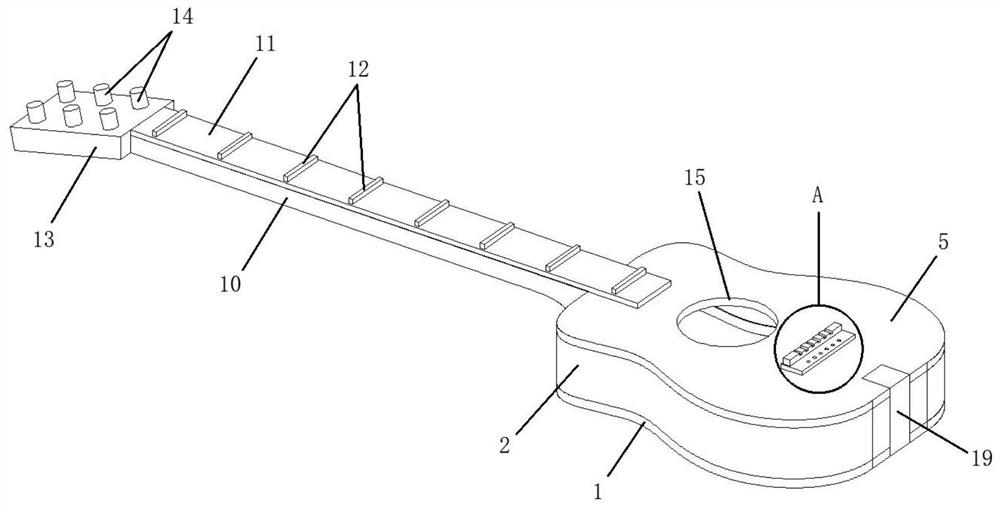

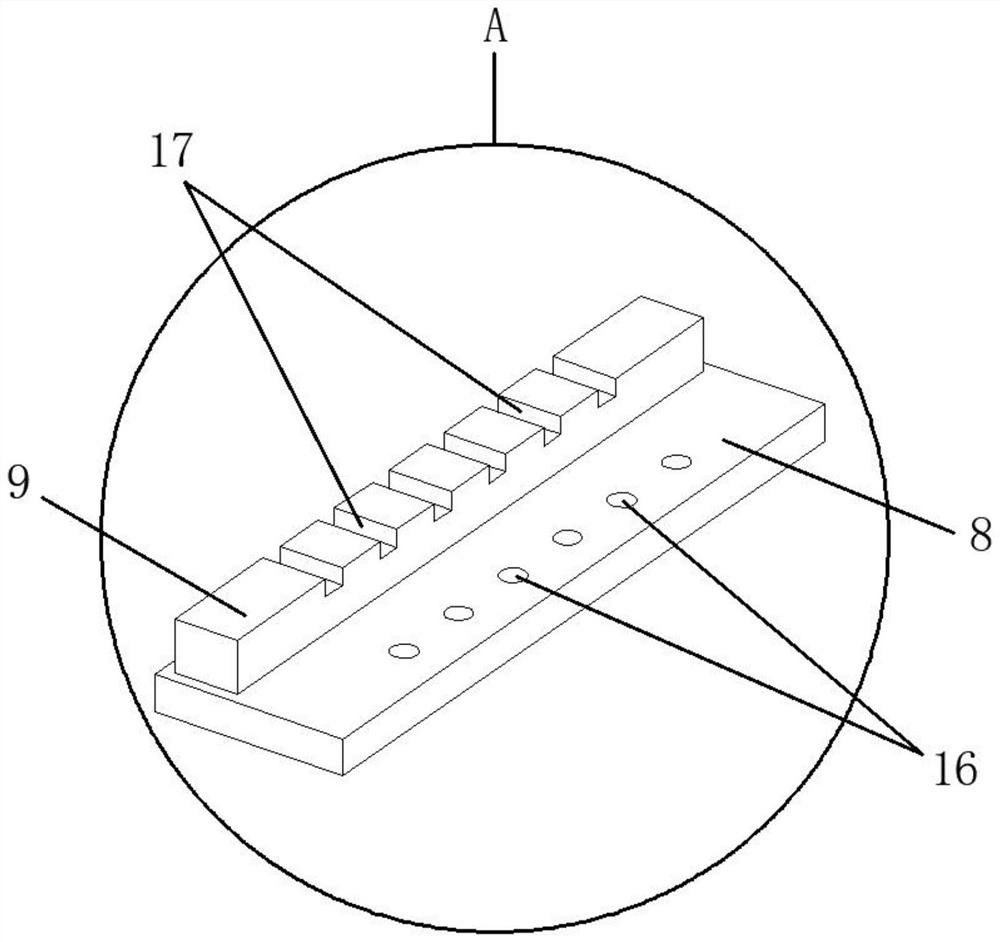

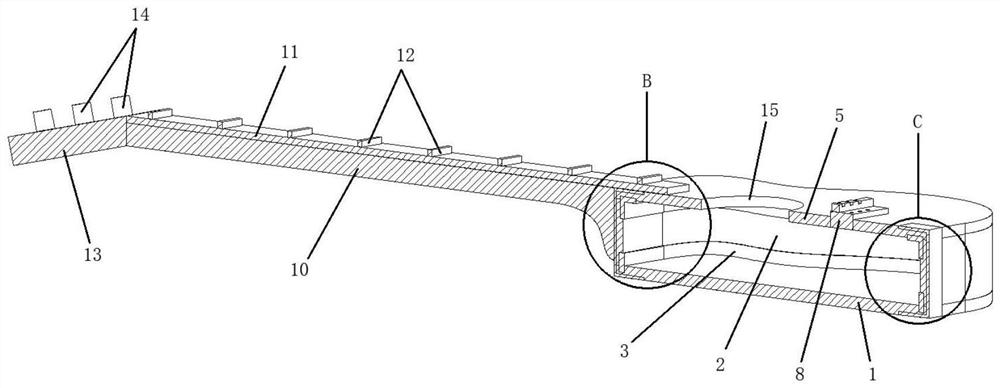

Guitar, guitar body and preparation method thereof

PendingCN111968609AImprove connection strengthHigh connection strong connection strengthGuitarsStructural engineeringSound quality

The invention relates to the technical field of guitars. The invention relates to a guitar, in particular to a guitar, a guitar body and a preparation method thereof. The guitar comprises a bottom plate, and a side frame is fixedly arranged on one side of the bottom plate; a mounting groove A is formed in one side of the bottom plate; a reinforced positioning frame is fixedly arranged on the innerside of the mounting groove A; a connecting groove A is formed in the inner side of the side frame, the reinforcing positioning frame is fixedly connected to the inner side of the connecting groove A, a panel is fixedly arranged on one side of the side frame, a mounting groove B is formed in one side of the panel, an L-shaped connecting frame is fixedly arranged on the inner side of the mountinggroove B, and a connecting groove B is formed in the inner side of the side frame and fixedly connected to the inner side of the connecting groove B. When in use, by arranging the bottom plate, the side frame, the reinforced positioning frame, the connecting groove A, the panel, the L-shaped connecting frame, the connecting groove B, an anti-opening groove, a U-shaped anti-glue-failure buckle andthe L-shaped groove, the guitar has the functions of relatively high connecting strength, good sound quality, relatively long service life, glue failure prevention, convenience in mounting and manufacturing and the like.

Owner:惠州市赛雅乐器有限公司

Cursor movement method for medical display, cursor movement device and medical equipment

ActiveCN106095118AReduce sizeImprove accuracyInput/output for user-computer interactionGraph readingMedical equipmentSimulation

The invention discloses a cursor movement method for medical display, a cursor movement device and medical equipment. The method includes: when a first operation instruction is received and a movement distance of a first target is larger than a first preset threshold, moving a cursor on a display screen by a grid, namely the movement distance of the first target is in correspondence to grid number of the cursor moving on the display screen; when a second operation instruction is received and a distance between the cursor and a target position is smaller than a second preset threshold, increasing resolution of preset grids on the display screen, namely reducing size of the preset grids, and then reducing a movement distance of the cursor on the display screen corresponding to the movement distance of the first target, namely when the cursor approaches to the target position, a user shortens the movement distance, corresponding to the movement distance of the first target, of the cursor on the display screen to realize infinite approaching of the cursor to the target position, and cursor movement accuracy and operability are improved.

Owner:QINGDAO HISENSE MEDICAL EQUIP

Roll core and electrode body manufacturing method using same

ActiveCN100477368CNo deviation will occurNo peeling etc.Assembling battery machinesFinal product manufactureEngineeringElectrode

Owner:MAXELL HLDG LTD

Anti-gravity casting riser positioning mechanism

The invention relates to a counter-gravity casting riser tube positioning mechanism, and aims to solve the technical problems that deviation of a riser tube and a sealing gasket (ring) is easily caused by an existing method, and then failing of pouring is caused. A casting mold 1, a cavity 2, a sprue gate 3, a riser tube upper sealing gasket 4, a positioning ring 5, a middle partition 6, a positioning bolt 7, a riser tube lower sealing gasket 8 and a riser tube 9 are successively arranged on the counter-gravity casting riser tube positioning mechanism from top to bottom, the riser tube 9 is fixed on the middle partition 6 through the positioning ring 5 and the positioning bolt 7, a flange 9-1 is arranged at the upper end of the riser tube 9, a hoisting opening 9-2 is formed in a side surface of the flange 9-1, the upper section of the positioning ring 5 is a conical table, the lower section of the positioning ring 5 is a cylindrical table, and a hoisting hole 5-1 is formed in a side surface of the conical table. According to the counter-gravity casting riser tube positioning mechanism, positioning is implemented by the positioning ring and the middle partition, therefore, the riser tube and the sealing gasket (ring) cannot deviate, and pouring can be successful. The invention belongs to the field of riser tube positioning mechanisms.

Owner:HARBIN INST OF TECH

Combined conveying device

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

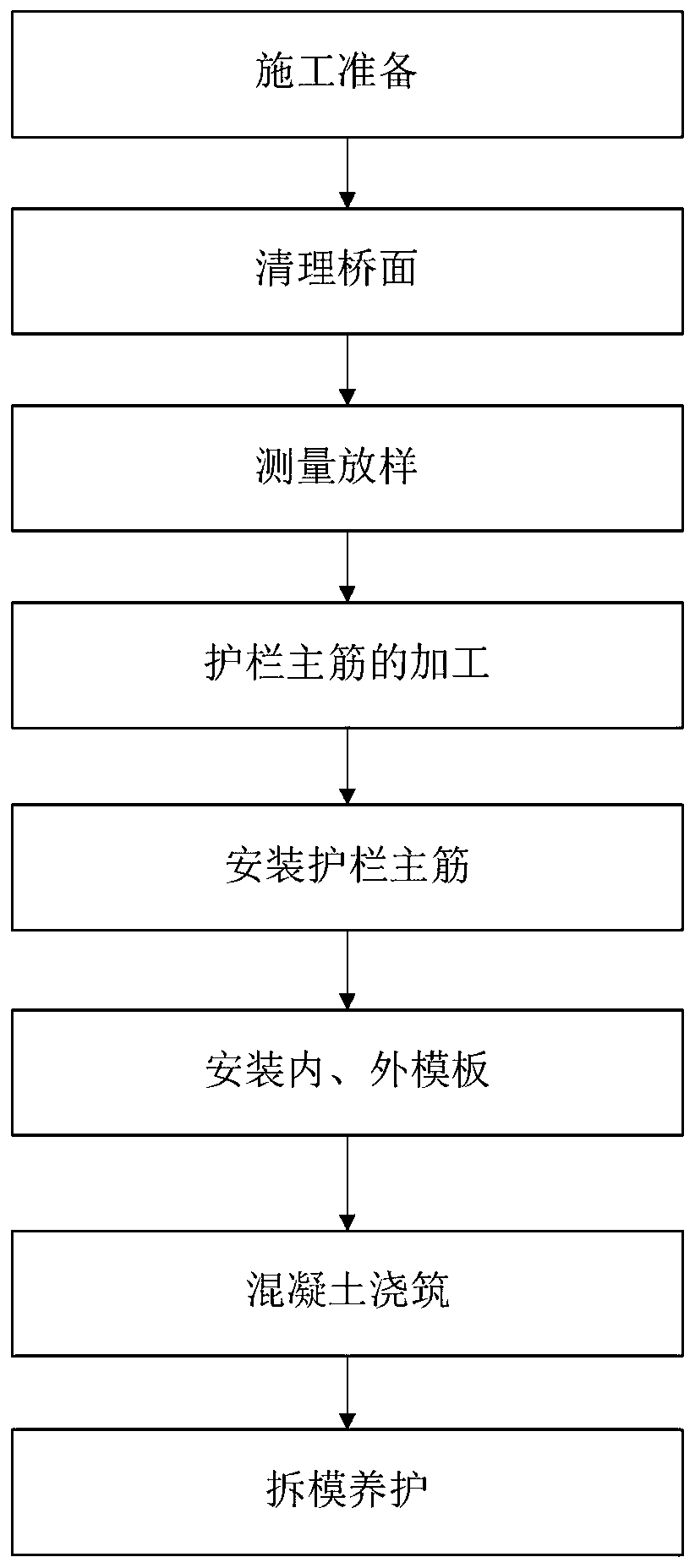

Construction method of bridge concrete anti-collision guardrail

PendingCN110258337AMeet construction requirementsRealize processing and shapingBridge structural detailsBridge erection/assemblySurface cleaningTotal station

The invention relates to a construction method of a bridge concrete anti-collision guardrail. The construction method comprises the following steps that construction preparation is carried out, wherein a beam plate of a bridge is erected according to the designed paying-off position, and a plurality of guardrail pre-buried ribs are pre-buried on the side beams on the two sides; bridge surface cleaning is carried out, wherein an air compressor is used for carrying out scabbling and blowing-washing on the bottom of the guardrail to be installed, and the distance between the adjacent guardrail pre-buried ribs is adjusted to be l; measuring and placing the guardrail; measuring and lofting are carried out, wherein a control point on the inner side of the guardrail by using a total station, and a design side line on the inner side of the guardrail is obtained through the control point; machining of a guardrail main bar is carried out, wherein machining and shaping are carried out on steel bars entering a construction site through a machining mold frame to obtain the guardrail main bar conforming to the design size; the guardrail main bar is mounted; an inner formwork and an outer formwork are mounted, wherein the inner formwork and the outer formwork are arranged on the two sides of the mounted guardrail main bar correspondingly, and connecting pieces are arranged at the tops of the inner formwork and the outer formwork; concrete pouring is carried out; and formwork disassembly and curing are carried out. According to the construction method, a positioning jig frame and a machining formwork are adopted to complete the standardized construction of the guardrail in a cooperative mode, so that the working efficiency is improved.

Owner:HENAN HIGHWAY ENG GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com