Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Maintain internal and external pressure balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

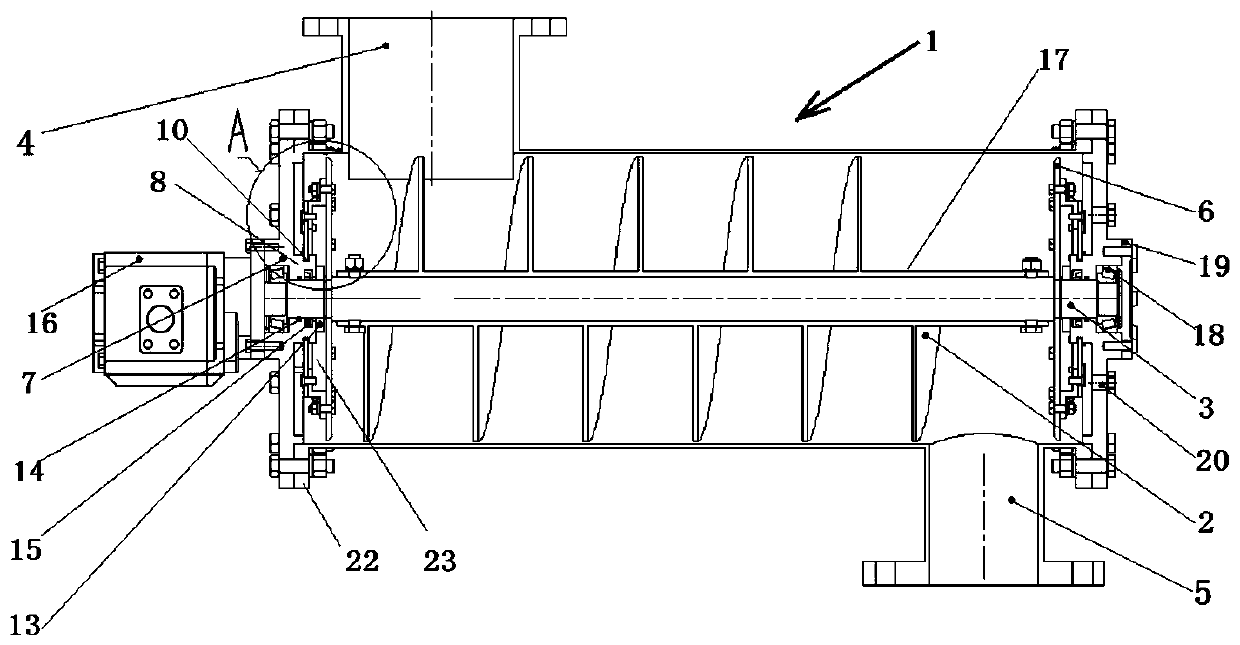

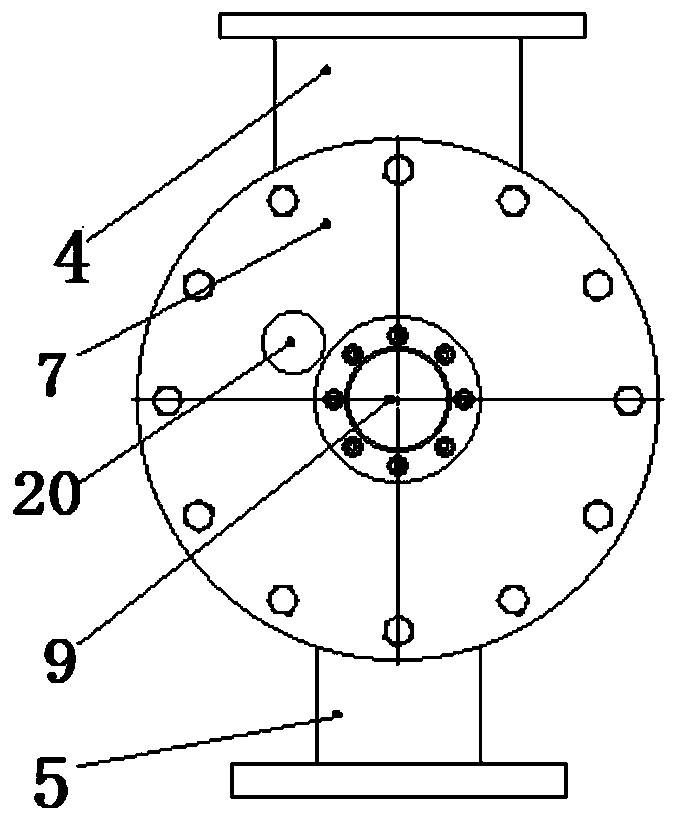

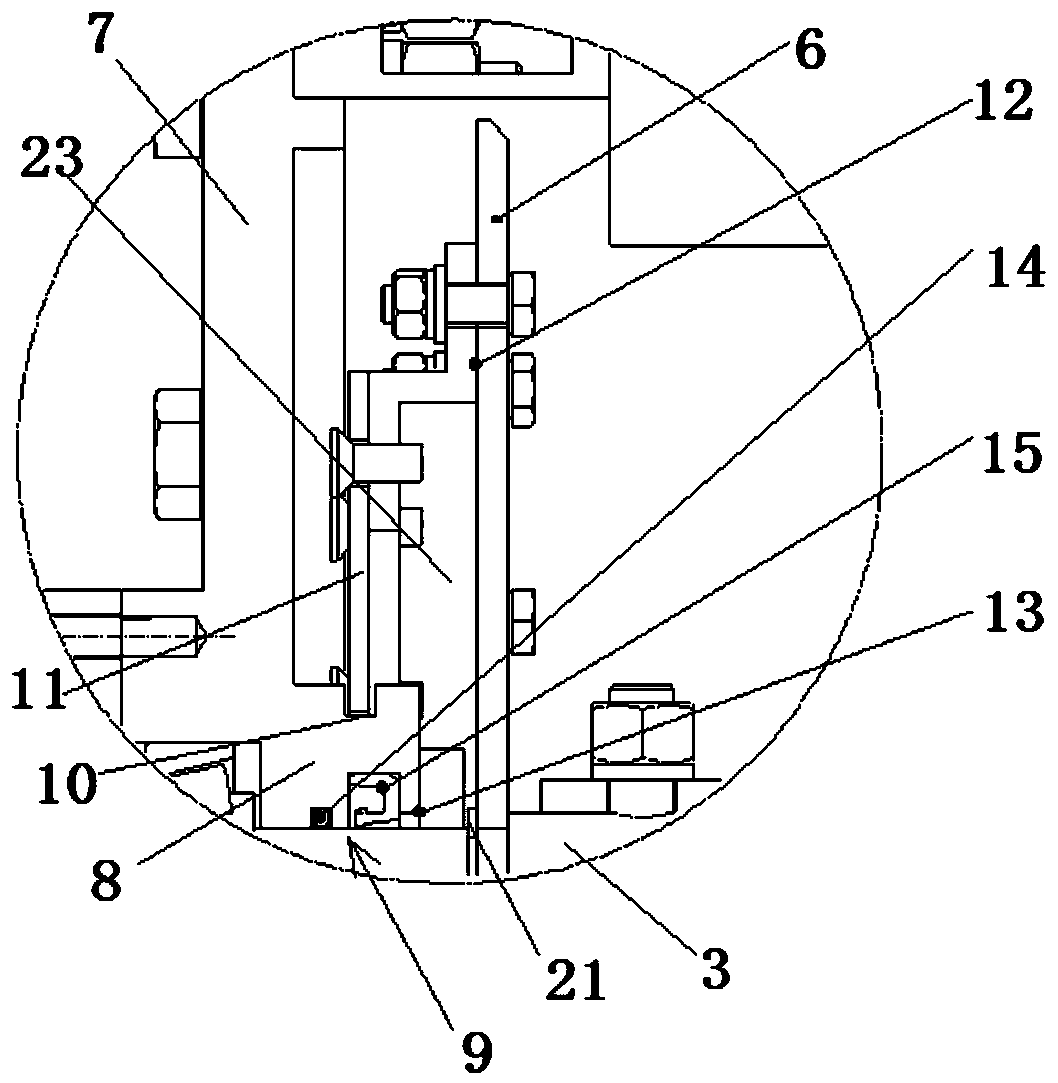

Screw feeder for underwater coarse mineral particles

The invention discloses a screw feeder for underwater coarse mineral particles. The screw feeder for the underwater coarse mineral particles comprises a cylinder and a rotary shaft. The rotary shaft is arranged in the cylinder and provided with screw blades. The two ends of the rotary shaft are pivoted to the cylinder. A feed port and a discharge port are formed in the outer walls of the two endsof the cylinder. The ends, close to the feed port and the discharge port, of the rotary shaft are each sleeved with an annular partition plate. The edges of the annular partition plates extend to positions near the inner wall of the cylinder. According to the screw feeder for the underwater coarse mineral particles, the internal pressure and the external pressure of the screw feeder can be kept balanced, so that uniform conveying of materials is achieved; meanwhile, the service life of the whole screw feeder is prolonged through the multiple sealing technique; and in addition, the adaptabilityof the feeder is improved through the replaceable screw blades.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

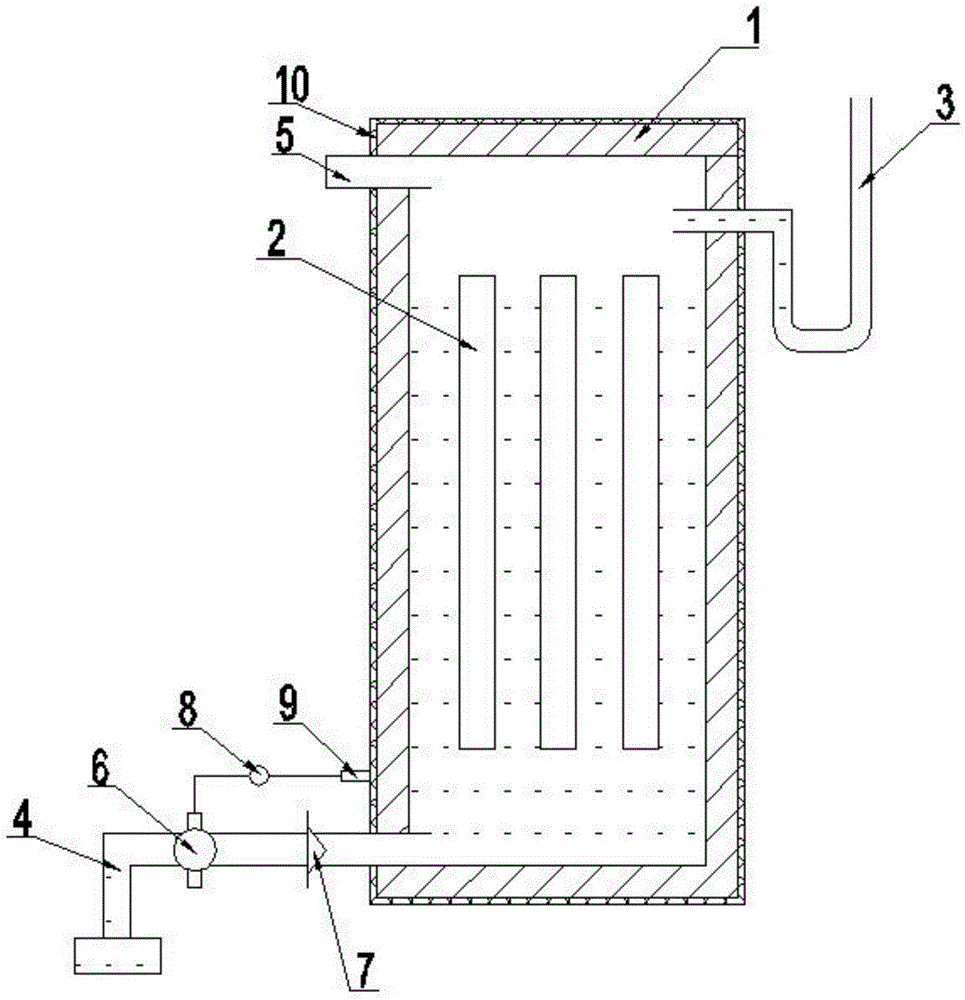

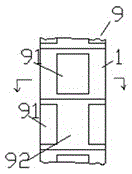

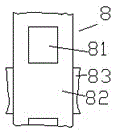

Thermal-insulation fireproof steel structure

InactiveCN105369907AAvoid continuous workImprove fire performanceHeat proofingFire proofingWater sourceThermal insulation

The invention discloses a thermal-insulation fireproof steel structure. A steel structure body (1) is a square steel tube or a round steel tube, multiple hollow tubes (2) with two closed ends are arranged inside the steel structure body (1), and the upper portion of an inner cavity of the steel structure body (1) is connected with an exhaust pipe (3); the lower end of the inner cavity of the steel structure body (1) is connected with a water inlet pipe (4), the upper end of the same side is connected with a water outlet tube (5), a water source sequentially passes through a water pump (6) and a one-way valve (7) to enter the inner cavity of the steel structure body, a starting switch of the water pump (6) is connected with an electromagnetic valve (8), and the other end of the electromagnetic valve (8) is connected with a temperature sensor (9). The interior of a steel structure building can be kept at constant temperature for a long time, and meanwhile fireproofness can be achieved effectively at a low cost.

Owner:JIANGSU HUAHAI STEEL STRUCTURE CO LTD

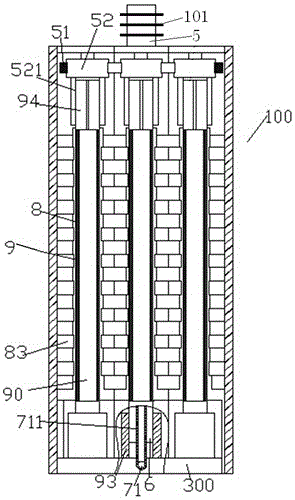

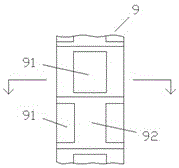

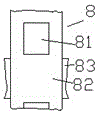

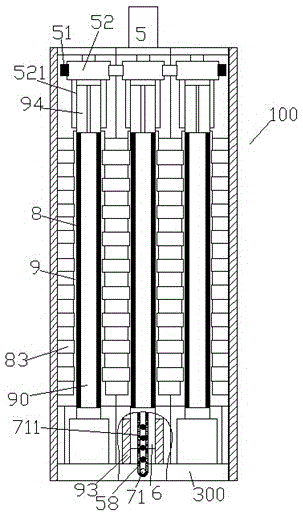

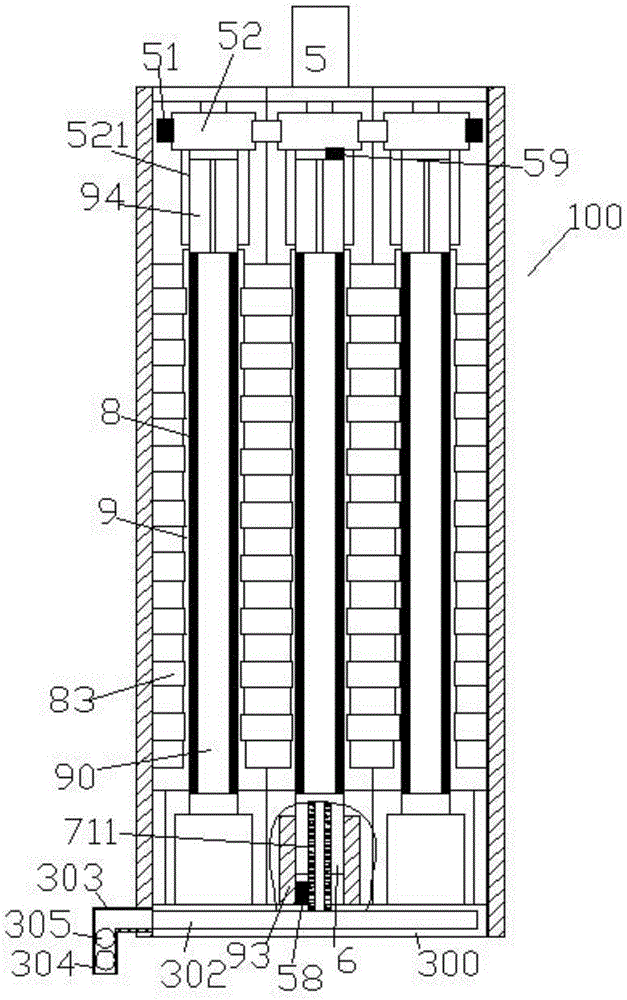

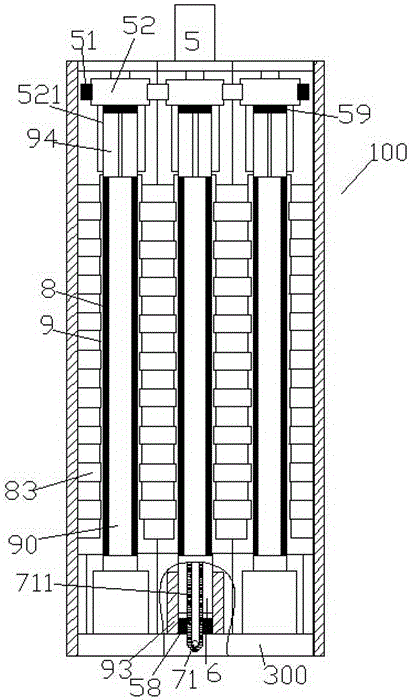

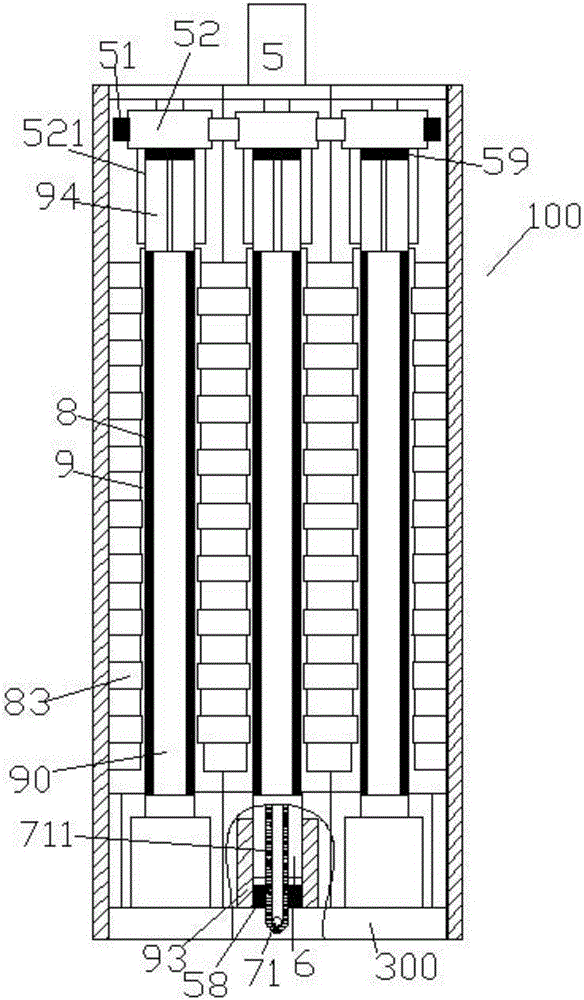

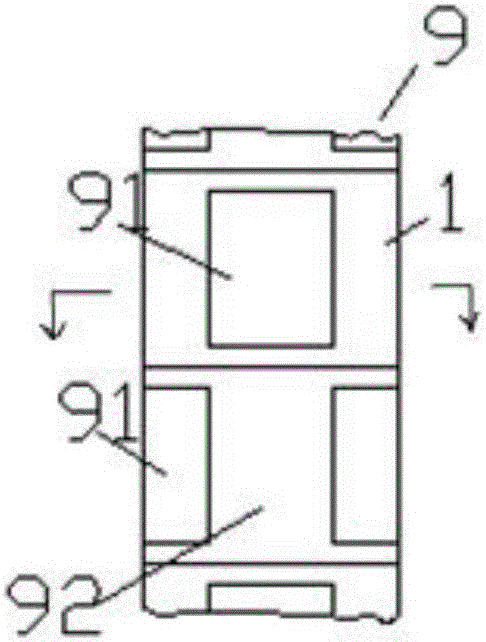

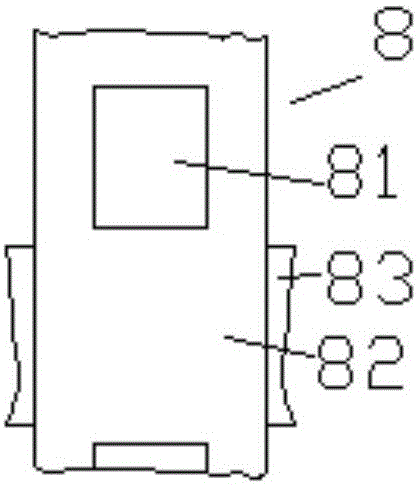

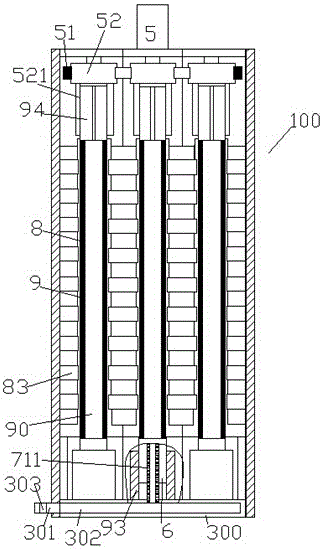

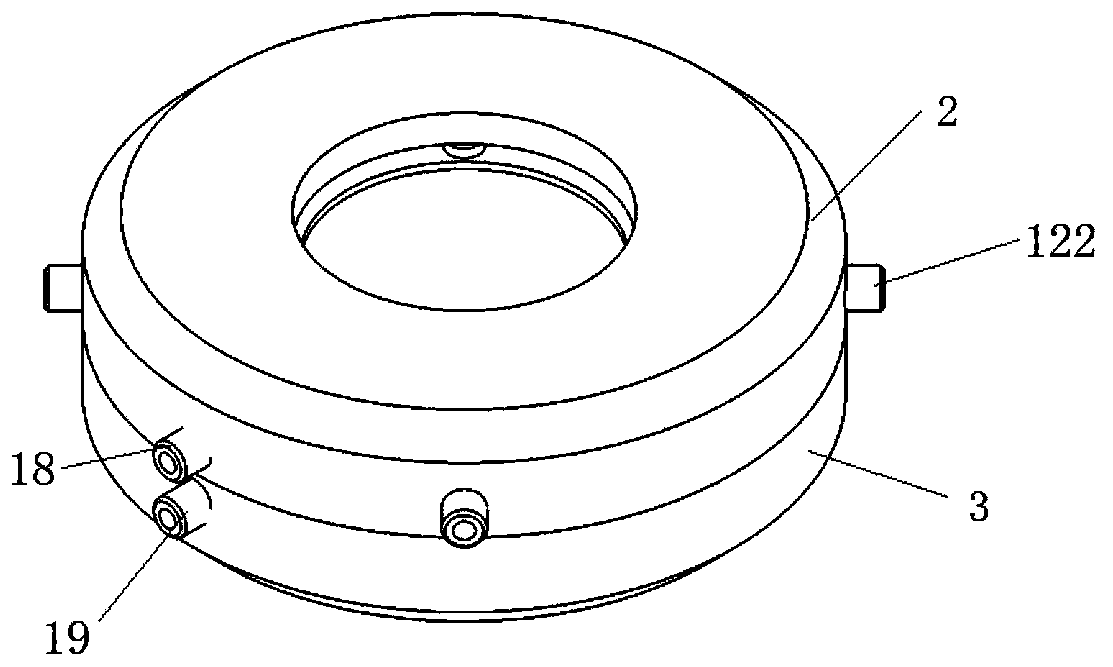

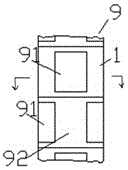

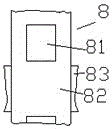

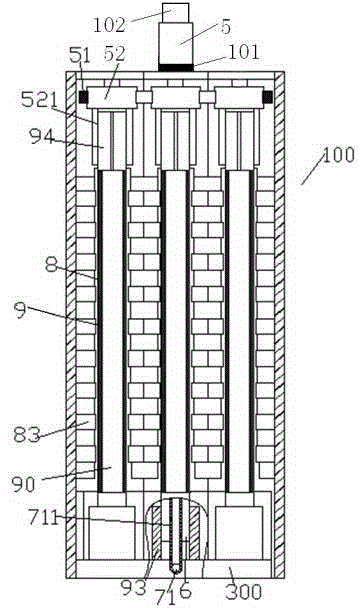

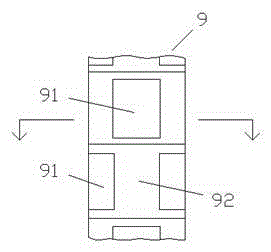

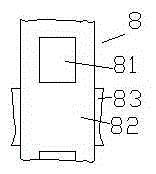

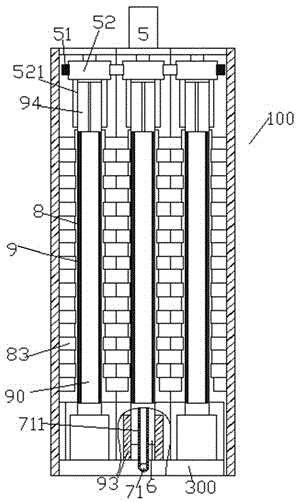

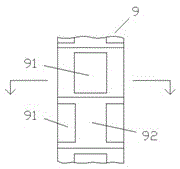

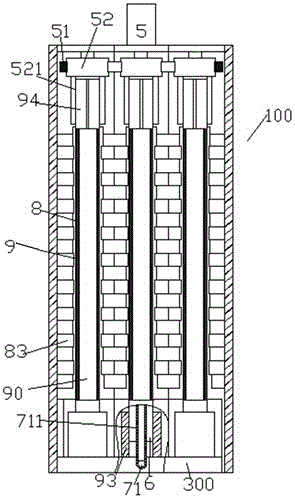

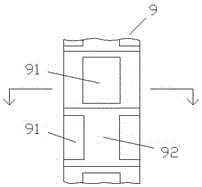

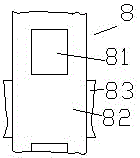

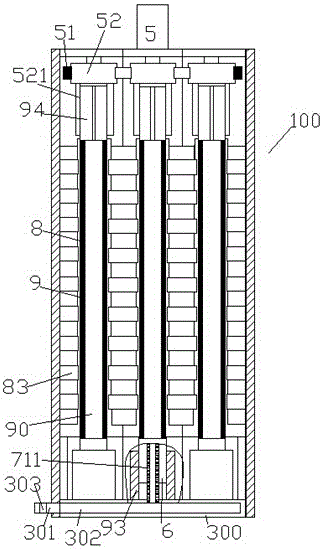

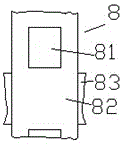

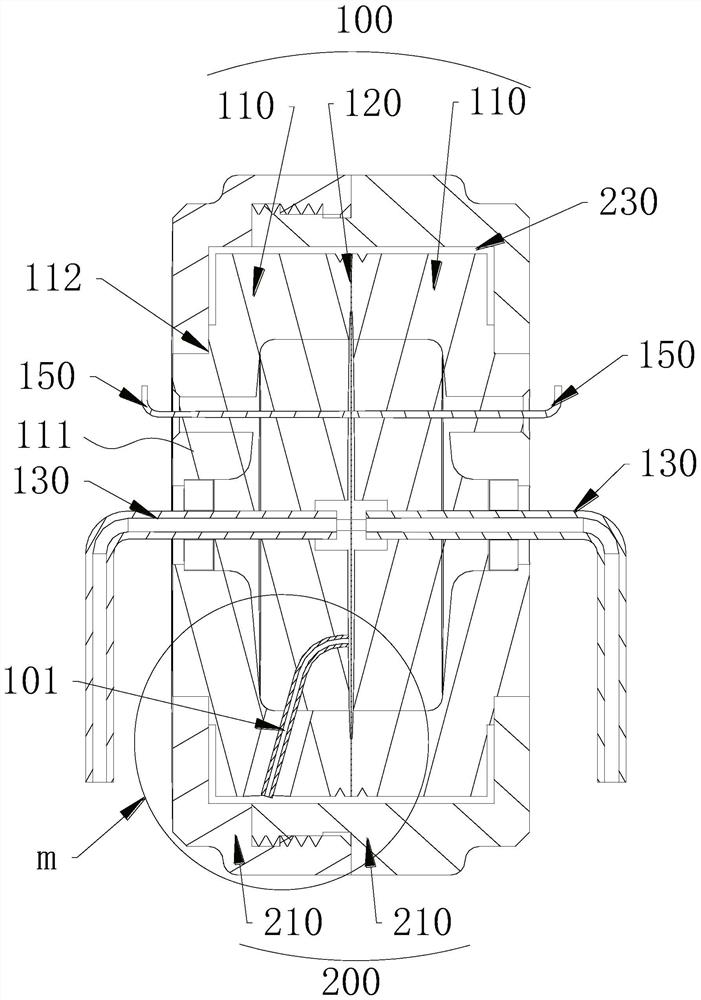

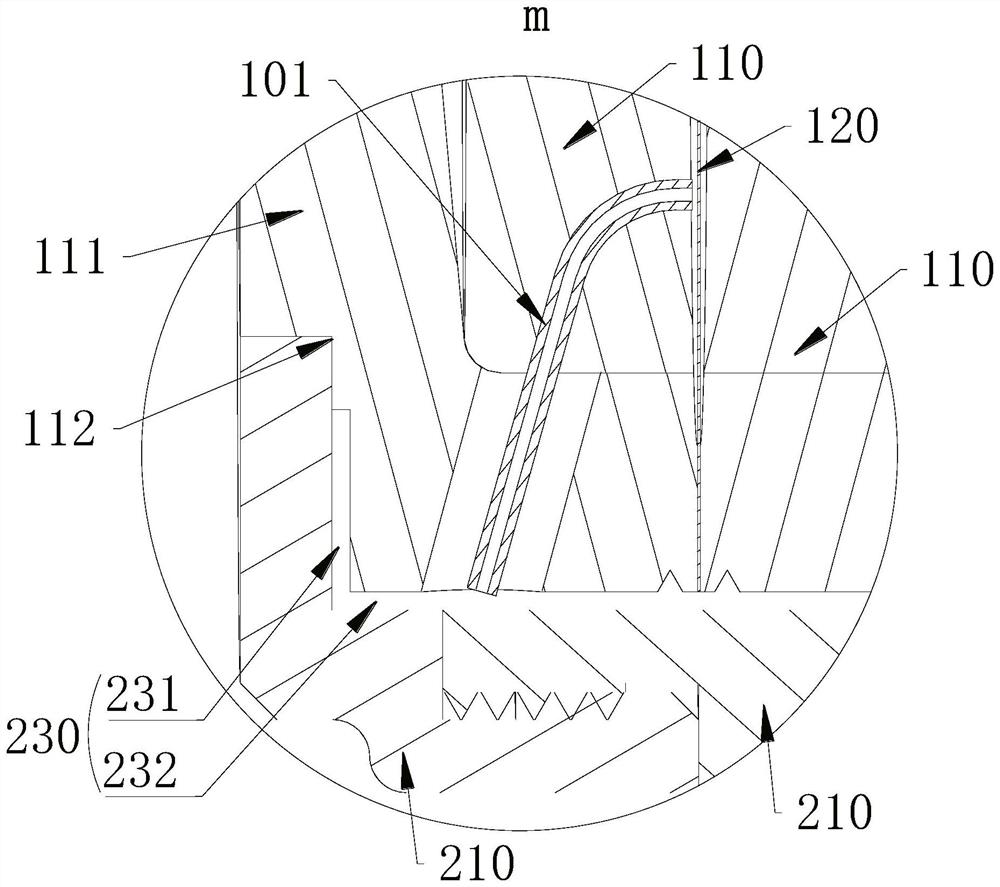

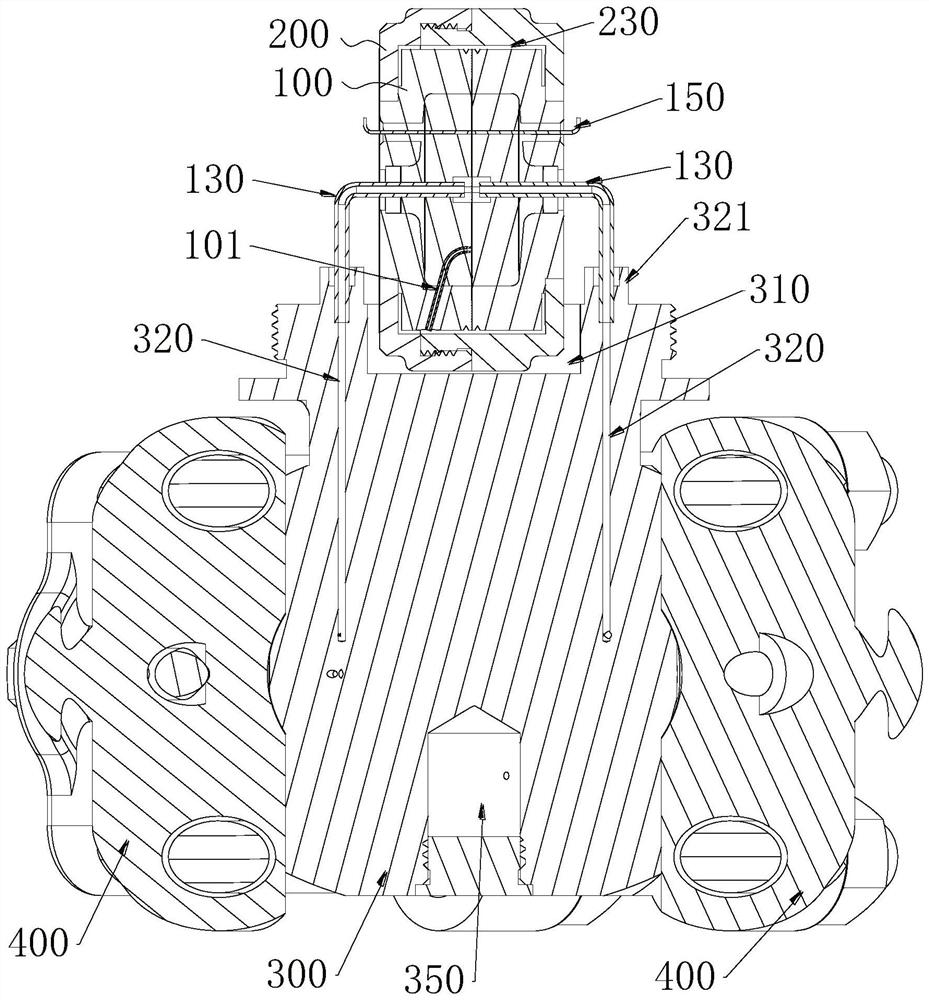

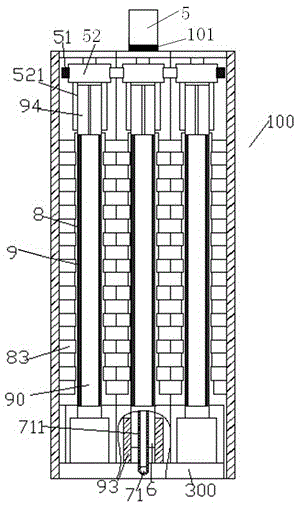

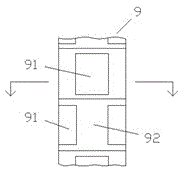

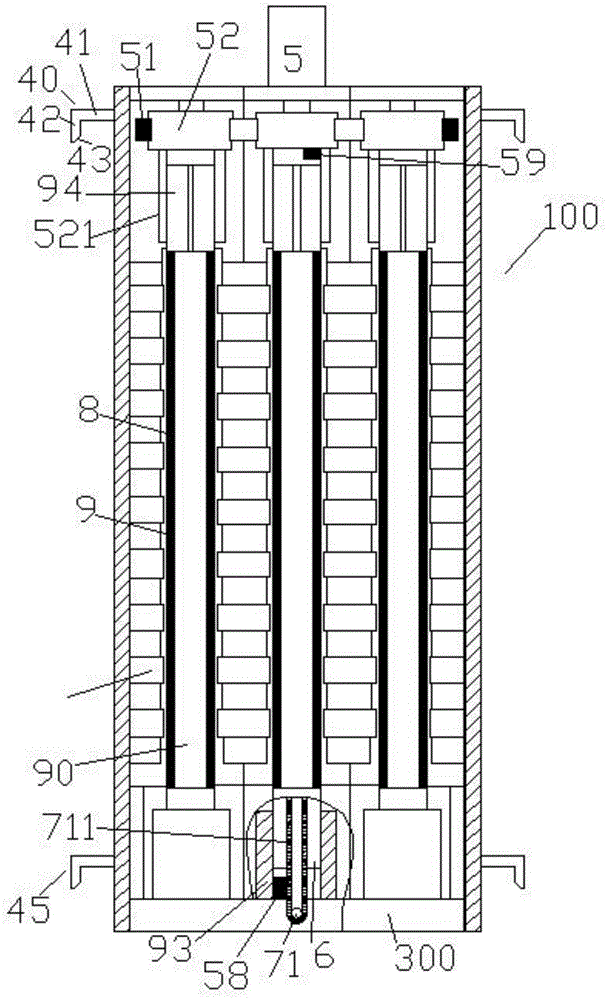

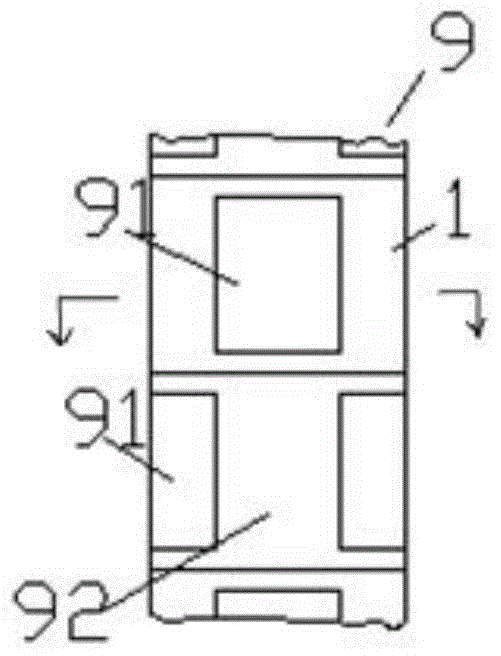

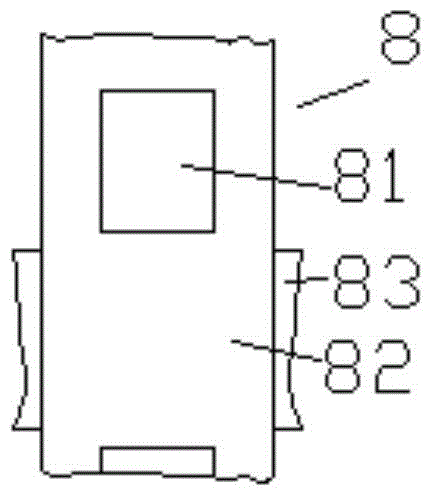

Waste gas processing device with prolonged service life

ActiveCN105126467AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentWaste management

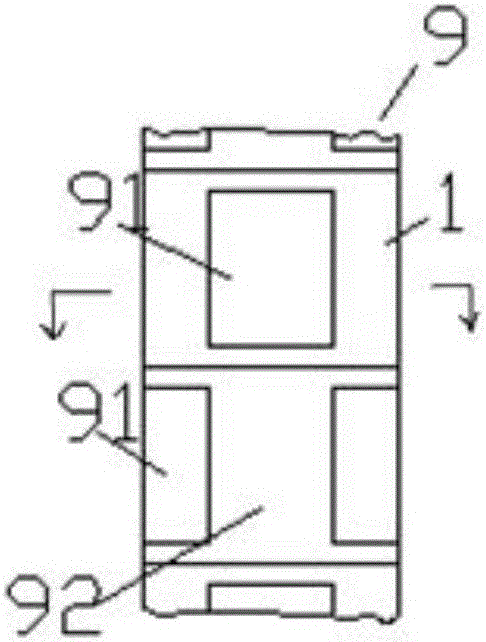

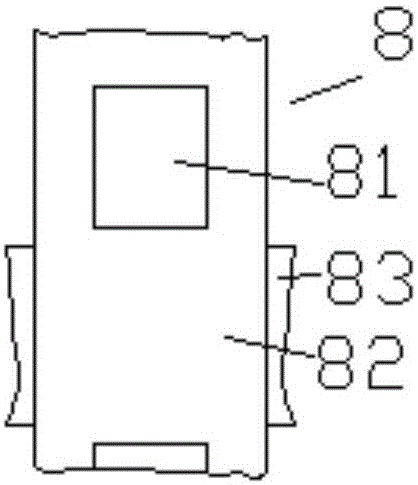

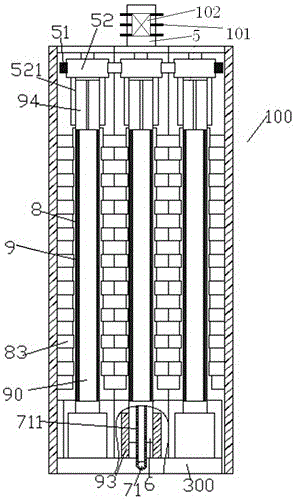

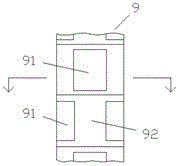

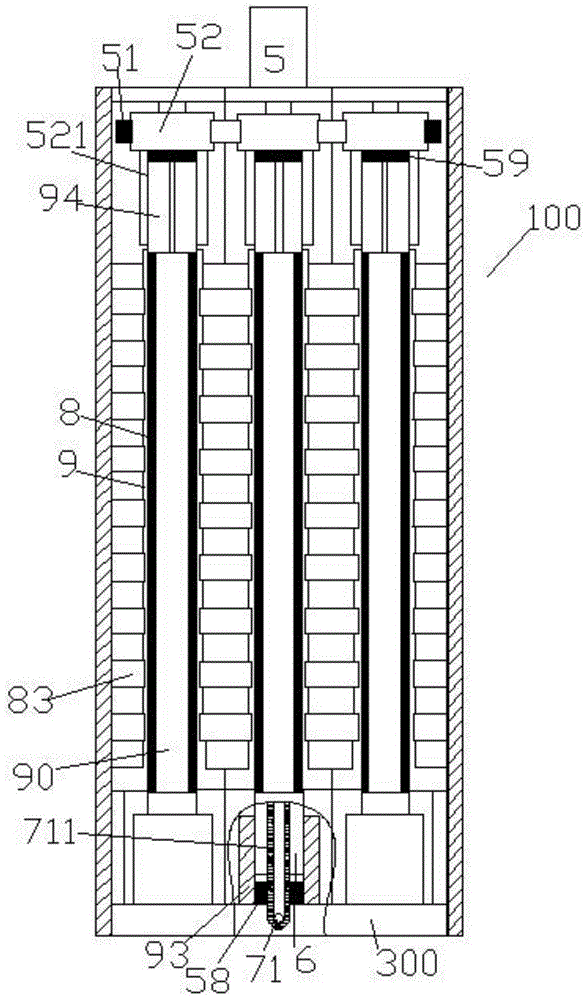

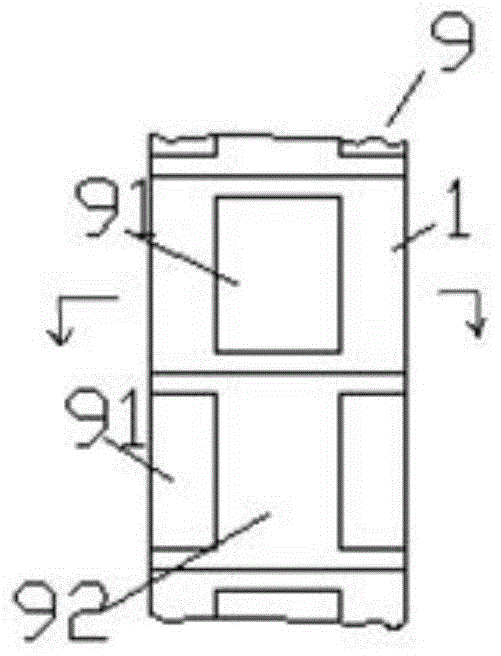

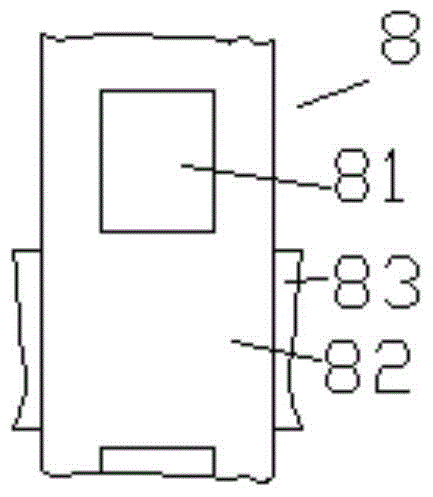

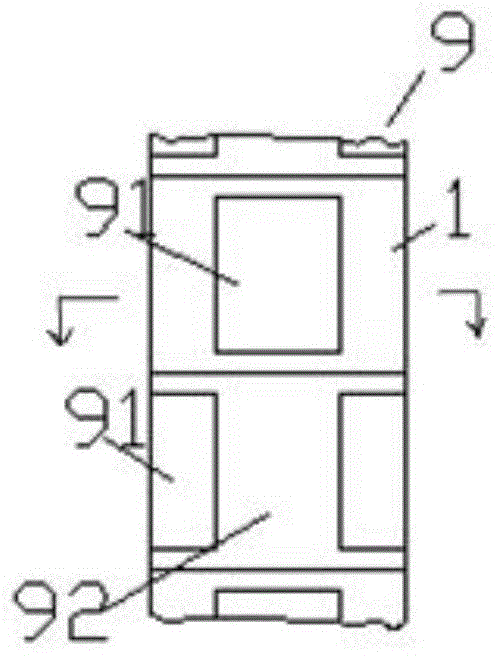

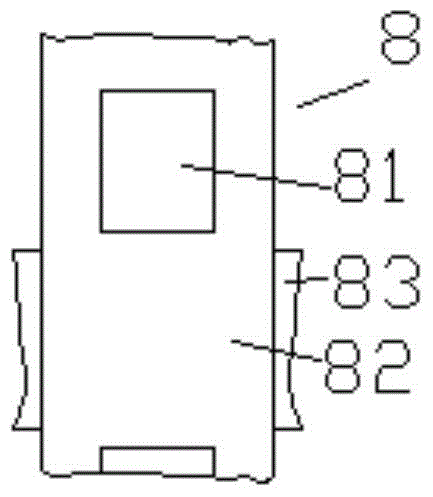

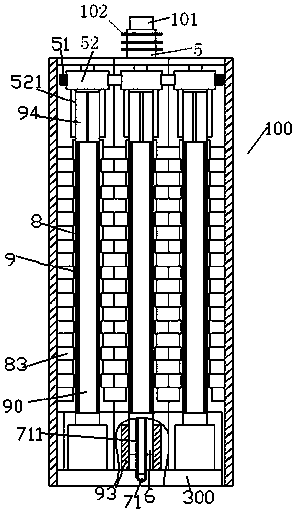

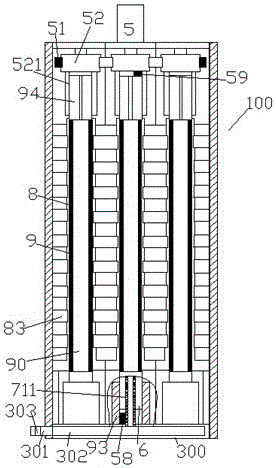

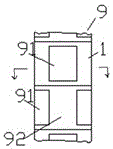

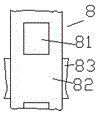

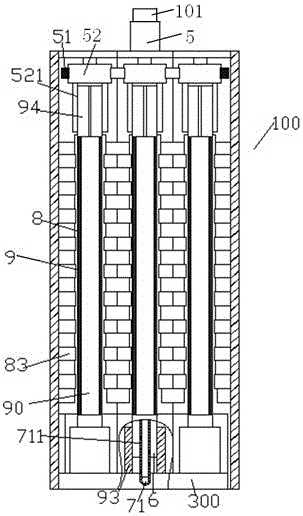

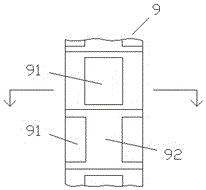

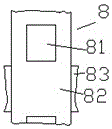

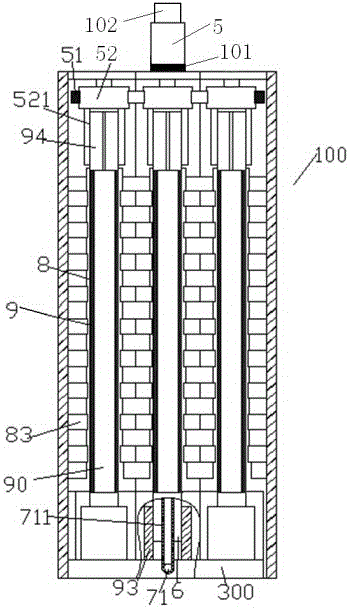

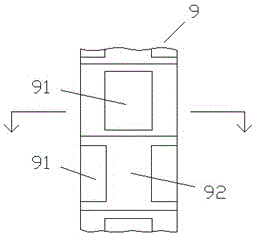

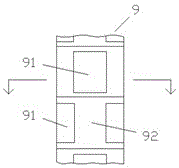

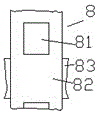

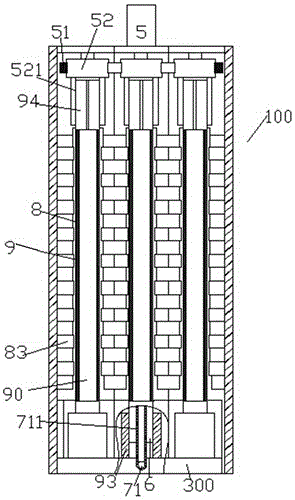

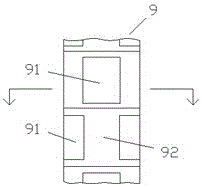

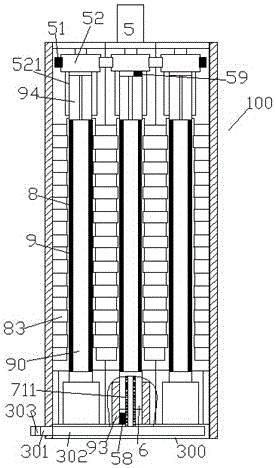

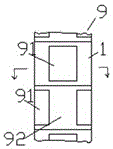

A waste gas processing device (100) with a prolonged service life is used to process waste gas in processing equipment (200) provided with a plurality of inner work stations (201). The processing equipment (200) comprises six inner work stations (201), which are evenly arranged in the circumferential direction; each inner work station (201) is communicated with the waste gas process device (100), which is positioned on the center of the processing equipment (200), through a connection pipe (202); so the generated processing waste gas in each inner work station (201) can be pumped into the waste gas processing device, and the waste gas processing device filters the waste gas. The waste gas processing device (100) comprises a support frame, six waste gas filtering column units, which are arranged in the support frame, and a bottom circular plate (300), which is arranged on the bottom of the support frame and is provided with a waste gas inlet pipeline (71), which is used to connect each waste gas filtering column unit with the connection pipe (202).

Owner:NINGBO HONGJING ENVIRONMENTAL PROTECTION TECH

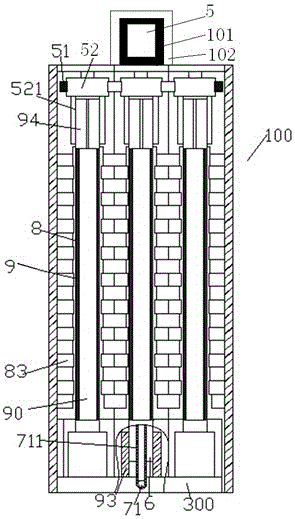

Industrial waste gas treatment device

ActiveCN105080240AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentToxic industrial waste

An industrial waste gas treatment device is used for treating waste gas of processing equipment (200) with a plurality of internal work stations (201). The processing equipment (200) comprises the six internal work stations (201) evenly distributed in the circumferential direction, each internal work station (201) is communicated with a waste gas treating device (100) located in the center of the processing equipment (200) through a connecting pipe (202), and therefore processing waste gas generated in the internal work stations (201) is pressed into the waste gas treating device (100) to be filtered. The waste gas treating device (100) comprises a supporting frame, six waste gas filtering column units arranged in the supporting frame, and a bottom annular plate (300), wherein the bottom annular plate (300) is arranged at the bottom of the supporting frame and provided with waste gas inlet pipelines (71) for connecting the waste gas filtering column units with the connecting pipes (202).

Owner:河北晴空环保科技有限公司

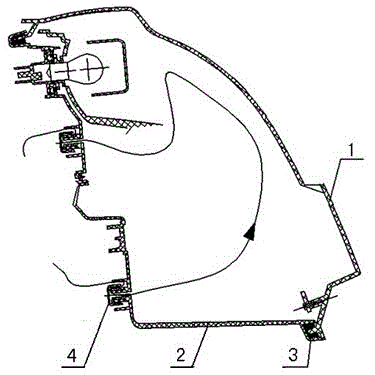

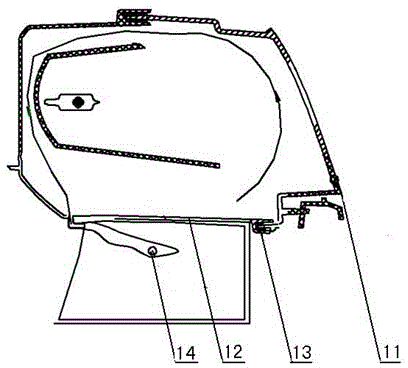

Full-sealed structure of automobile headlamp

InactiveCN104964226AIncrease air humidityMaintain internal and external pressure balanceGas-tight/water-tight arrangementsOptical signallingIlluminanceStructural engineering

The invention relates to a full-sealed structure of an automobile headlamp. The full-sealed structure comprises a lens and a lamp housing. The edge of the lens is matched with a glue groove of the lamp housing and sealed by PUR glue. The full-sealed structure is characterized in that the lower portion of the lamp housing is provided with a self-balancing valve; and a self-balancing balloon is connected with the self-balancing valve in a matching mode and communicated with an inner cavity of a lamp body. The full-sealed structure of the automobile headlamp has following beneficial effects: reliable sealing performance is obtained; the headlamp is prevented against water ingress due to fogging; the headlamp can be used in harsh weather; and illuminance of ground of the headlamp is ensured in favor of driving safety.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

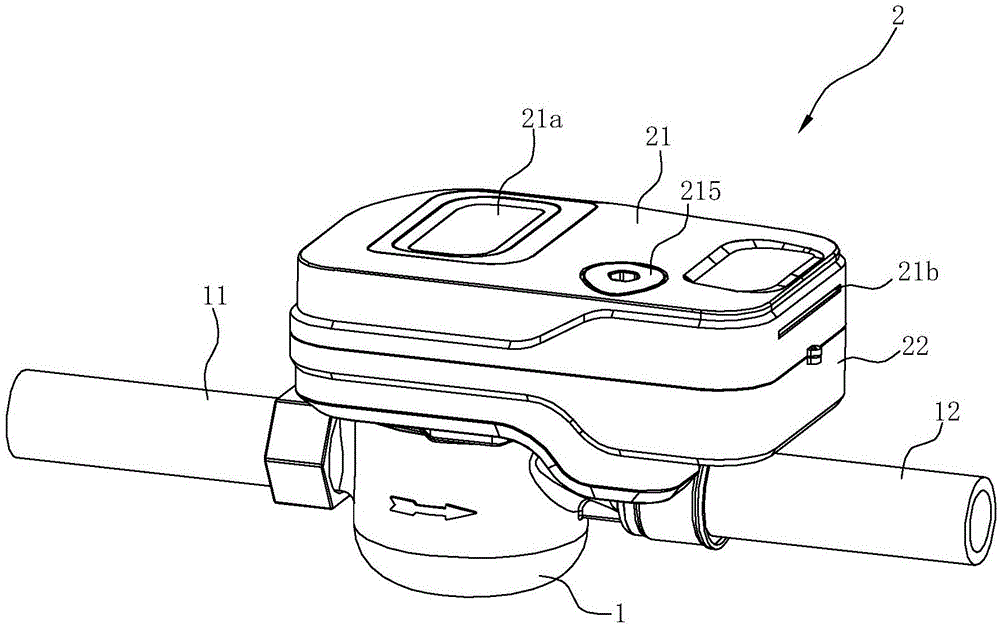

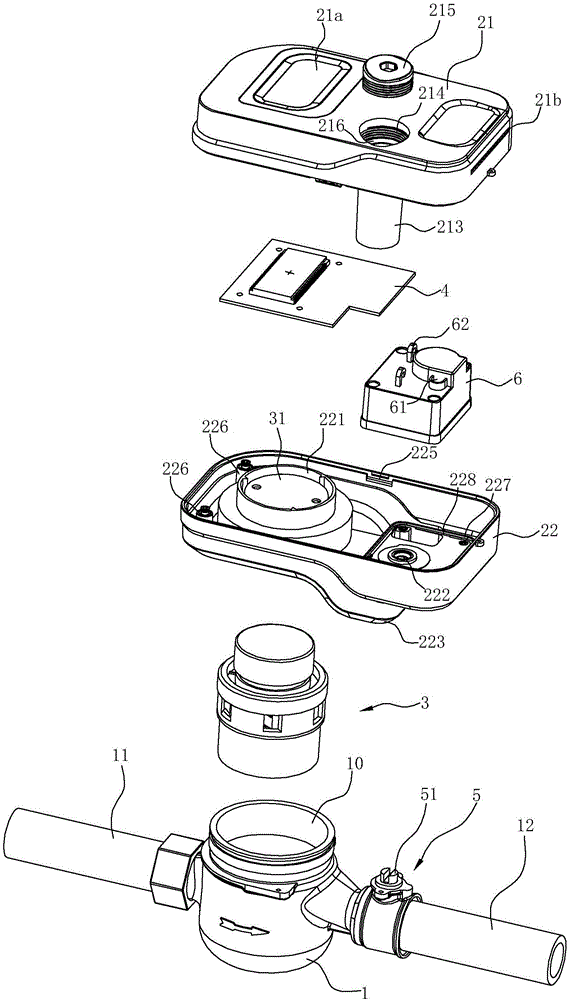

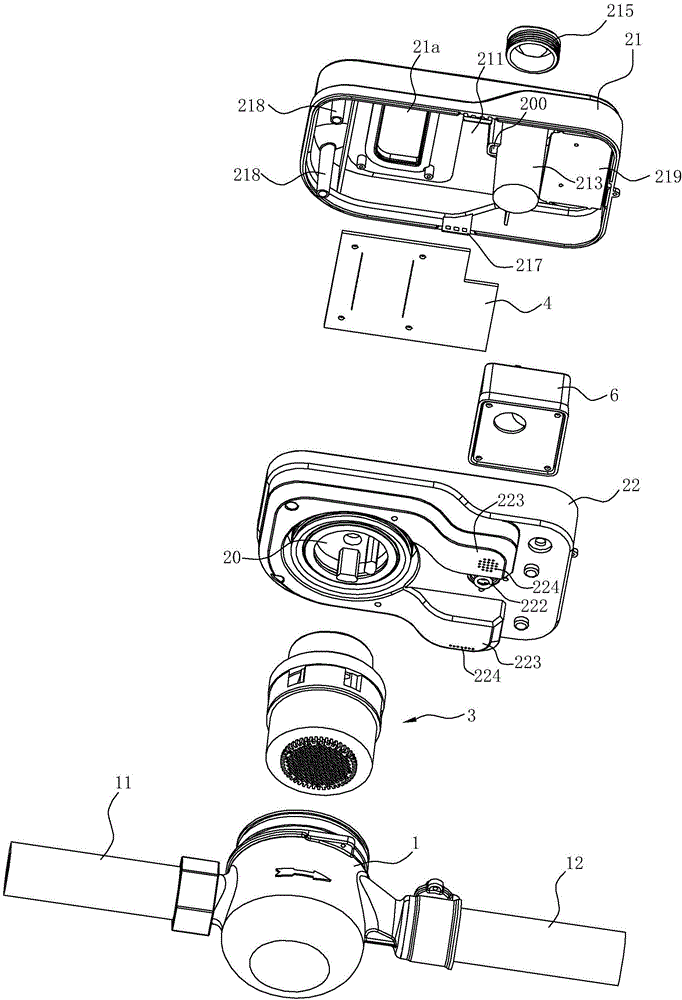

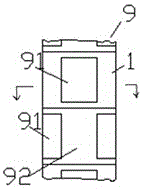

Electronic water meter with three-proofing function

The invention relates to an electronic water meter with a three-proofing function. The electronic water meter comprises a base, a shell, a water flow metering component, a spherical valve component and a main circuit board, an installation groove used for installing the main circuit board and an installation cavity used for installing a control circuit board of the water flow metering component are formed in the inner side of the shell, the installation groove and the installation cavity are both filled with organic silicon gel which can cover the corresponding circuit boards, and the wire outlet terminals in the shell are each coated with a silica gel layer; the shell is provided with first through holes allowing water vapor to get in and out. According to the electronic water meter, through structure design is adopted, a seal ring does not need to be arranged on the joint of the whole shell, air tightness sealing is not needed, the water vapor can pass through freely through the first through holes, the internal and external pressure balance in the water meter shell is guaranteed, the problems that in the water meter using process, plastic deformation occurs due to the imbalance of the internal and external pressure, and the water vapor is accumulated due to the fact that for the air tightness structure, the water vapor can easily get in but not easily get out are effectively solved, the reliability of the water meter is improved, and the service life of the water meter is prolonged.

Owner:LEIMENG NINGBO LTD BY SHARE LTD

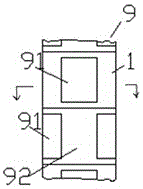

Intelligent waste gas treatment device

ActiveCN105032052AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentWaste management

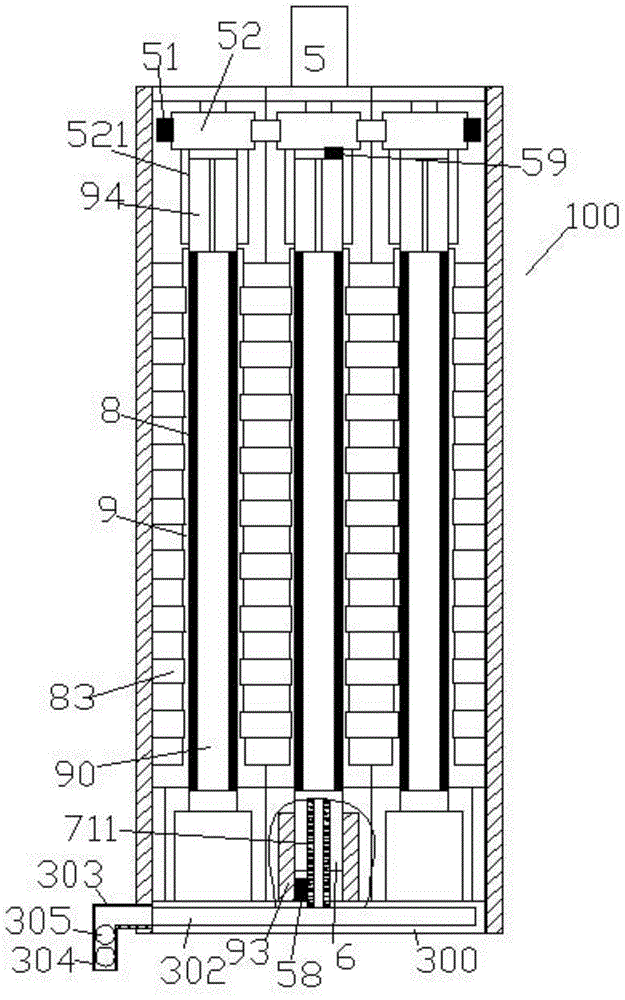

An intelligent waste gas treatment device (100) is used for treating waste gas of processing equipment (200) with six internal working stations (201). The processing equipment (200) comprises the internal working stations (201) evenly arranged in the circumferential direction, all the internal working stations (201) are communicated with an annular gas collection pipe (306) detachably installed on the processing equipment (200) through connecting pipes (202), and a detachable gas delivery pipe (301) used for being communicated with the waste gas treatment device (100) located in the center of the processing equipment (200) is arranged on the annular gas collection pipe (306); accordingly, processing waste gas generated in the internal working stations (201) is firstly delivered into the annular gas collection pipe (306) and then delivered into the waste gas treatment device (100) from the annular gas collection pipe (306) to be filtered.

Owner:淮安市绿能环境技术有限公司

Exhaust treatment device capable of being quickly cooled

ActiveCN105032051AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentFiltration

An exhaust treatment device (100) capable of being quickly cooled is used for treating exhaust of processing equipment (200) containing multiple inner workstations (201), wherein the processing equipment (200) comprises six inner workstations (201) uniformly arranged in the circumferential direction; each of the inner workstations (201) is communicated with the exhaust treatment device (100) positioned in the center of the processing equipment (200) through a connecting pipe (202); processing exhaust generated in each of the inner workstations (201) is fed into the exhaust treatment device (100) by pressure for filtration; the exhaust treatment device (100) comprises a support frame, six exhaust filtration column units arranged in the support frame and a bottom annular plate (300) of an exhaust inlet pipeline (71) which is arranged at the bottom of the support frame and used for connecting each of the exhaust filtration column units with the corresponding connecting pipe (202).

Owner:GUIPING PRODIVITY PROMOTION CENT

Exhaust gas treatment device for treating exhaust gas of processing equipment

ActiveCN105107288AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationExhaust gasExhaust fumes

An exhaust gas treatment device (100) for treating exhaust gas of processing equipment (200) comprises six internal workstations (201) which are uniformly arranged in the circumferential direction, wherein each of the six internal workstations (201) is communicated with the exhaust gas treatment device (100) at the center of the processing equipment (200) through a connecting pipe (202), so that processing exhaust gas generated in each of the six internal workstations (201) is pressed to the exhaust gas treatment device (100) to be filtered; the exhaust gas treatment device (100) comprises a supporting rack, six exhaust gas filter column units arranged in the supporting rack and a bottom circular plate (300) in the bottom of the supporting rack provided with an exhaust gas inlet pipeline (71) for connecting each of the exhaust gas filter column units with the connecting pipe (202).

Owner:YANGZHOU LVQUAN ENVIRONMENTAL ENG TECH

Waste gas treatment device for processing equipment

ActiveCN104998477AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentWorkstation

Disclosed is a waste gas treatment device (100) for processing equipment (200). The processing equipment (200) comprises six internal workstations (201) evenly arranged in the circumferential direction. Each internal workstation (201) is communicated with the waste gas treatment device (100) located in the center of the processing equipment (200) through a connecting pipe (202), and therefore processed waste gas generated inside each internal workstation (201) is pressed and conveyed into the waste gas treatment device (100) to be filtered. The waste gas treatment device (100) comprises a supporting frame, six waste gas filtering column units and an annular bottom plate (300), wherein the six waste gas filtering column units are arranged inside the supporting frame, and the annular bottom plate (300) is arranged at the bottom of the supporting frame and provided with waste gas inlet pipelines (71) connecting the waste gas filtering column units with the connecting pipes (202).

Owner:浙江划云环境技术有限公司

Easily cleaned exhaust gas treatment apparatus

ActiveCN104984614AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationFiltrationExhaust fumes

Provided is an easily cleaned exhaust gas treatment apparatus (100) that is used to treat exhaust gas of a processing device (200) that has multiple internal workstations (201). The processing device (200) comprises six internal workstations (201) that are uniformly arranged in a circumferential direction; each of the internal workstations (201) is communicated, through a connecting pipe (202), with an annular gas gathering pipe (306) that can be detachably mounted on the processing device (200); a gas delivery pipe (301) is provided on the annular gas gathering pipe (306); the gas delivery pipe (301) is used to be communicated with the exhaust gas treatment apparatus (100) that is located in the center of the processing device (200), and the gas delivery pipe is detachable; therefore, processing exhaust gas generated in each of the internal workstations (201) is firstly delivered to the annular gas gathering pipe (306), and then is delivered from the annular gas gathering pipe (306) to the exhaust gas treatment apparatus (100) for filtration.

Owner:广东联力科技有限公司

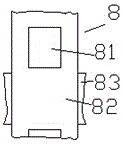

A high-temperature and high-pressure visualized microscopic oil reservoir chip holder and its use method

ActiveCN107703036BMeet high temperature requirementsMeet high pressure requirementsHydrodynamic testingWork holdersSapphireMaterials science

The invention relates to a high-temperature and high-pressure visual microscopic oil reservoir chip holder and a use method thereof, wherein the holder is characterized in that the chip holder comprises a holder main body; the holder main body comprises an annular base, an annular top cover, a sapphire lens arranged at the lower part of the base, a press plate for fixing the sapphire lens, anothersapphire lens arranged on the top of the top cover, another press plate for fixing the another sapphire lens, and a microfluidic chip arranged on the base; the base is in blot connection with the topcover, and the microfluidic chip is fixed by an extrusion force between the base and the top cover; a space enclosed by the top cover, the second sapphire lens and the microfluidic chip is an upper seal cavity body, the upper seal cavity body is connected with an upper cavity body connector, and the upper cavity body connector communicates with the outside; a space enclosed by the base, the firstsapphire lens and the microfluidic chip is a lower seal cavity body, the lower seal cavity body is connected with a lower cavity body connector, and the lower cavity body connector communicates withthe outside. The holder can be widely applied in the field of micro-scale effect research.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

An industrial waste gas treatment device

ActiveCN105080240BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentToxic industrial waste

An industrial waste gas treatment device is used for treating waste gas of processing equipment (200) with a plurality of internal work stations (201). The processing equipment (200) comprises the six internal work stations (201) evenly distributed in the circumferential direction, each internal work station (201) is communicated with a waste gas treating device (100) located in the center of the processing equipment (200) through a connecting pipe (202), and therefore processing waste gas generated in the internal work stations (201) is pressed into the waste gas treating device (100) to be filtered. The waste gas treating device (100) comprises a supporting frame, six waste gas filtering column units arranged in the supporting frame, and a bottom annular plate (300), wherein the bottom annular plate (300) is arranged at the bottom of the supporting frame and provided with waste gas inlet pipelines (71) for connecting the waste gas filtering column units with the connecting pipes (202).

Owner:河北晴空环保科技有限公司

Novel exhaust-gas treatment apparatus

InactiveCN105148639AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentGas pipeline

A novel exhaust-gas treatment apparatus is applied to treat exhaust gas of processing equipment (200) possessing multiple internal work stations (201), wherein the processing equipment (200) comprises six internal work stations (201) uniformly distributed at the circumferential direction; each internal work station (201) is communicated with an exhaust-gas treatment device (100) at the central of the processing equipment (200) via connection pipes (202), and thus processing exhaust gases generated in the internal work stations (201) are sent to the exhaust-gas treatment device (100) for filtering; and the exhaust-gas treatment device (100) comprises a support frame, six exhaust-gas filtering column units arranged on the support frame, and bottom annular plates (300) which is arranged at the bottom of the support frame and is provided with exhaust-gas inlet pipelines (71) used for connecting the exhaust-gas filtering column units with the responding connection pipes.

Owner:温州市洞头新凯实业有限公司

Exhaust gas treatment device with electric control valve

InactiveCN105107289AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentElectric control

An exhaust gas treatment device (100) with an electric control valve is used for treating exhaust gas of processing equipment (200) provided with a plurality of internal workstations (201), wherein the processing equipment (200) comprises six internal workstations (201) which are uniformly arranged in the circumferential direction; each of the internal workstations (201) is communicated with the exhaust gas treatment device (100) at the center of the processing equipment (200) through a connecting pipe (202), so that processing exhaust gas generated in each of the six internal workstations (201) is pressed to the exhaust gas treatment device (100) to be filtered; the exhaust gas treatment device (100) comprises a supporting rack, six exhaust gas filter column units arranged in the supporting rack and a bottom circular plate (300) in the bottom of the supporting rack provided with an exhaust gas inlet pipeline (71) for connecting each of the exhaust gas filter column units with the connecting pipe (202).

Owner:深圳江南环保工程设计院有限公司

Exhaust gas treatment device for processing equipment

ActiveCN104998477BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentWorkstation

Disclosed is a waste gas treatment device (100) for processing equipment (200). The processing equipment (200) comprises six internal workstations (201) evenly arranged in the circumferential direction. Each internal workstation (201) is communicated with the waste gas treatment device (100) located in the center of the processing equipment (200) through a connecting pipe (202), and therefore processed waste gas generated inside each internal workstation (201) is pressed and conveyed into the waste gas treatment device (100) to be filtered. The waste gas treatment device (100) comprises a supporting frame, six waste gas filtering column units and an annular bottom plate (300), wherein the six waste gas filtering column units are arranged inside the supporting frame, and the annular bottom plate (300) is arranged at the bottom of the supporting frame and provided with waste gas inlet pipelines (71) connecting the waste gas filtering column units with the connecting pipes (202).

Owner:浙江划云环境技术有限公司

An intelligent waste gas treatment device

ActiveCN105032052BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentWaste gas

Owner:淮安市绿能环境技术有限公司

A fast and controllable exhaust gas treatment device

ActiveCN105107309BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentWorkstation

A quick-radiating controllable exhaust gas treatment device is used for treating exhaust gas of processing equipment (200) provided with a plurality of internal workstations (201), wherein the processing equipment (200) comprises six internal workstations (201) which are uniformly arranged in the circumferential direction; each of the internal workstations (201) is communicated with the exhaust gas treatment device (100) at the center of the processing equipment (200) through a connecting pipe (202), so that processing exhaust gas generated in each of the six internal workstations (201) is pressed to the exhaust gas treatment device (100) to be filtered; the exhaust gas treatment device (100) comprises a supporting rack, six exhaust gas filter column units arranged in the supporting rack and a bottom circular plate (300) in the bottom of the supporting rack provided with an exhaust gas inlet pipeline (71) for connecting each of the exhaust gas filter column units with the connecting pipe (202).

Owner:广东联翰环境科技有限公司

A waste gas treatment device with a valve

ActiveCN105032048BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentFiltration

The invention discloses a waste gas treatment device (100) with a valve. The device is used for treating the waste gas of processing equipment (200) which includes a plurality of internal work stations (201), wherein the processing equipment (200) includes six internal work stations (201) arranged uniformly in the circumferential direction; each internal work station (201) is communicated with the waste gas treatment device (100) positioned in the center of the processing equipment (200) through a connecting pipe (202), so that the processing waste gas produced in each internal work station (201) is pressed and conveyed to the waste gas treatment device (100) for filtration; the waste gas treatment device (100) includes a support frame, six waste gas filter column units arranged in the support frame, and a bottom ring plate (300) positioned at the bottom of the support frame and provided with a waste gas inlet pipeline (71) used for connecting the waste gas filter column units with the connecting pipes (202).

Owner:JIANGSU SUYAN VALVE MASCH CO LTD

An intelligent exhaust gas treatment device that is easy to clean

ActiveCN105032049BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentEngineering

Owner:江苏博闻环保科技有限公司 +1

A speed-adjustable exhaust gas treatment device

InactiveCN105080237BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationExhaust gas

A waste gas treatment device (100) with adjustable speed is used for treating waste gas of machining equipment (200) provided with multiple internal working stations (201), the machining equipment (200) comprises the six internal working stations (201) evenly arrayed in the circumferential direction, and each internal working station (201) is communicated with the waste gas treatment device (100) located in the center of the machining equipment (200) through a connecting pipe (202), so that machining waste gas generated by all the internal working stations (201) is conveyed to the waste gas treatment device (100) in a pressure mode to be filtered. The waste gas treatment device (100) comprises a supporting frame, six waste gas filtering column units and a bottom annular plate (300), wherein the six waste gas filtering column units are arranged in the supporting frame, and the bottom annular plate (300) is arranged at the bottom of the supporting frame and provided with waste gas inlet pipelines (71) used for connecting all the waste gas filtering column units with the connecting pipes (202).

Owner:广东凯特净环保工程有限公司

A waste gas treatment device

InactiveCN105148639BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentExhaust fumes

A novel exhaust-gas treatment apparatus is applied to treat exhaust gas of processing equipment (200) possessing multiple internal work stations (201), wherein the processing equipment (200) comprises six internal work stations (201) uniformly distributed at the circumferential direction; each internal work station (201) is communicated with an exhaust-gas treatment device (100) at the central of the processing equipment (200) via connection pipes (202), and thus processing exhaust gases generated in the internal work stations (201) are sent to the exhaust-gas treatment device (100) for filtering; and the exhaust-gas treatment device (100) comprises a support frame, six exhaust-gas filtering column units arranged on the support frame, and bottom annular plates (300) which is arranged at the bottom of the support frame and is provided with exhaust-gas inlet pipelines (71) used for connecting the exhaust-gas filtering column units with the responding connection pipes.

Owner:温州市洞头新凯实业有限公司

A waste gas treatment device that is easy to clean

ActiveCN104984614BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationFiltrationWorkstation

Owner:广东联力科技有限公司

Pressure balance system

PendingCN113654713AMaintain internal and external pressure balanceHigh precisionPressure difference measurement between multiple valvesFluid pressure measurement using capacitance variationEngineeringPressure balance

The invention discloses a pressure balance system which comprises a diaphragm type pressure sensor, two pressure transmitting cavities separated from each other are arranged in the diaphragm type pressure sensor, a closed pressure stabilizing box covers the diaphragm type pressure sensor, and a closed cavity is formed between the inner wall of the pressure stabilizing box and the outer wall of the diaphragm type pressure sensor, the outer wall of the diaphragm type pressure sensor is wrapped by the cavity, the cavity forms a pressure stabilizing cavity, a balance flow channel penetrates through the shell of the diaphragm type pressure sensor, and one pressure transmitting cavity is communicated with the pressure stabilizing cavity through the balance flow channel. The diaphragm type pressure sensor has the beneficial effects that through the compact and ingenious structural design, the use of a liquid pressure transmission medium is greatly reduced while the balance of the internal and external pressure of the diaphragm type pressure sensor is ensured, meanwhile, the unbalance of the pressure in the two pressure transmission cavities of the sensor caused by temperature change is remarkably reduced, and the precision of the sensor is improved.

Owner:CHONGQING WECAN PRECISION INSTR

A noise reduction exhaust gas treatment device

ActiveCN105080239BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationNoise reductionWorkstation

Owner:JIANGSU KEHUI ENVIRONMENTAL TECH CO LTD

An exhaust gas treatment device with controllable intake air

ActiveCN105032076BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationFiltrationWaste gas

The invention discloses an air inflow controllable waste gas treatment device (100) which is used for treating the waste gas of a processing equipment (200) provided with a plurality of internal work stations (201), wherein the processing equipment (200) includes six internal work stations (201) arranged uniformly in the circumferential direction; each internal work station (201) is communicated with the waste gas treatment device (100) positioned in the center of the processing equipment (200) through a connecting pipe (202), so that the processing waste gas produced in each internal work station (201) is pressed and conveyed to the waste gas treatment device (100) for filtration; the waste gas treatment device (100) includes a support frame, six waste gas filter column units arranged in the support frame, and a bottom ring plate (300) positioned at the bottom of the support frame and provided with a waste gas inlet pipeline (71) used for connecting the waste gas filter column units and the connecting pipes (202).

Owner:徐州鑫源环保设备有限公司

Waste gas treatment device with damping function

ActiveCN104998476AMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationDamping functionEngineering

The invention provides a waste gas treatment device (100) with a damping function. The waste gas treatment device (100) is used for treating waste gas generated from a processing device (200) with six internal workstations (201). The six internal workstations (201) are evenly arranged in the circumferential direction of the processing device (200). Each internal workstation (201) is communicated with a waste gas treatment device (100) in the center of the machining device (200) through a connection pipe (202) so as to achieve the purpose that the machining waste gas generated in each internal workstation (201) is sent into the waste gas treatment device (100) in a pressed mode to be filtered. The waste gas treatment device (100) comprises supporting frames, six waste gas filtering units arranged in the corresponding supporting frames and annular bottom plates (300) of waste gas inlet pipelines (71) arranged at the bottoms of the supporting frames and used for connecting all the waste gas filtering column units and the connection pipes (202).

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

A waste gas treatment device that is easy to overhaul

ActiveCN105126489BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentExhaust gas

The invention discloses a waste gas processing device (100) convenient for maintenance. The provided waste gas processing device (100) is used to process waste gas in processing equipment (200), which is provided with a plurality of inner work stations (201). The processing equipment (200) comprises six inner work stations (201), which are evenly arranged on the circumferential direction; each inner work station (201) is communicated with the waste gas processing device (100) which is arranged on the center of the processing equipment (200) through a connection pipe (202); thus the processing waste gas generated in each inner work station (201) can be pumped to the waste gas processing device (100), the waste gas is filtered in the waste gas processing device (100); the waste gas processing device (100) comprises a support frame, six waste gas filtering cylinder units, which are arranged in the support frame, and a bottom circular plate (300), which is arranged on the bottom of the support frame and is used to connect each waste gas filtering cylinder unit to the connection pipe (202), of a waste gas inlet pipeline (71).

Owner:江苏凯威药用包装有限公司

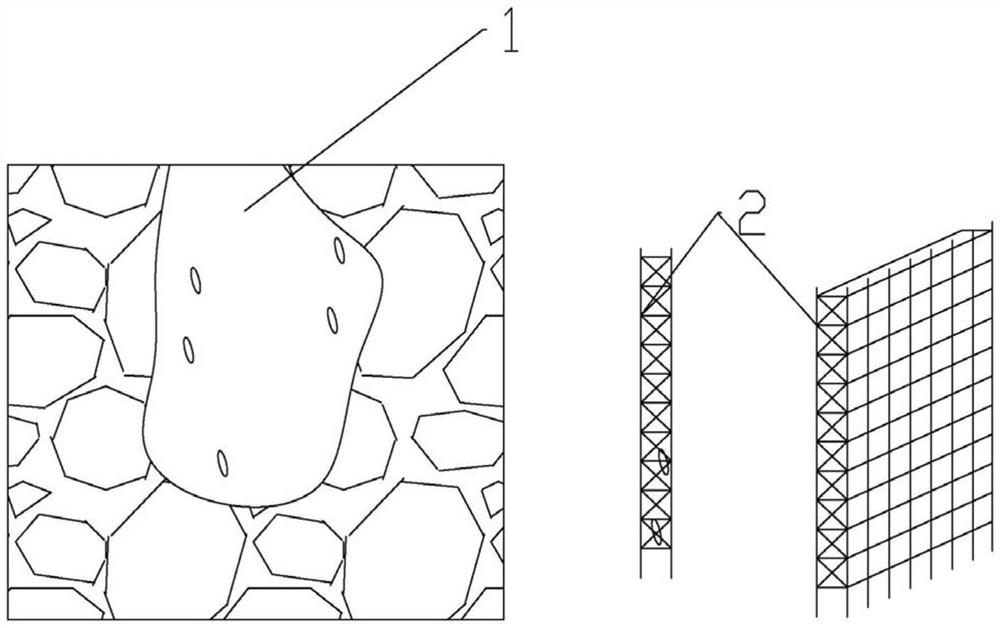

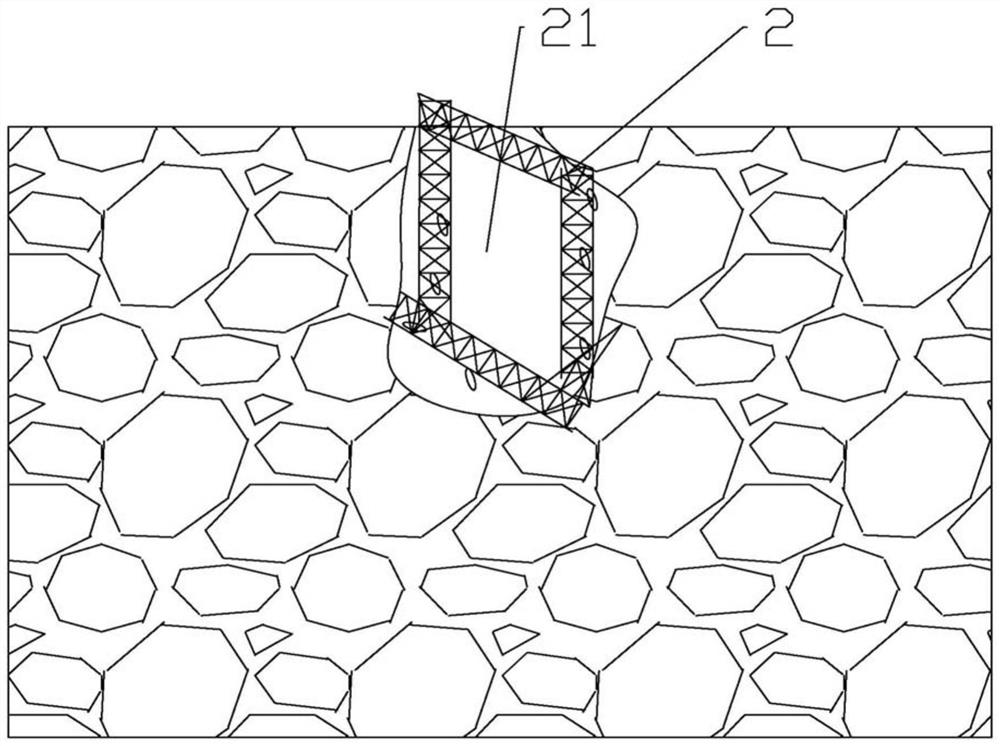

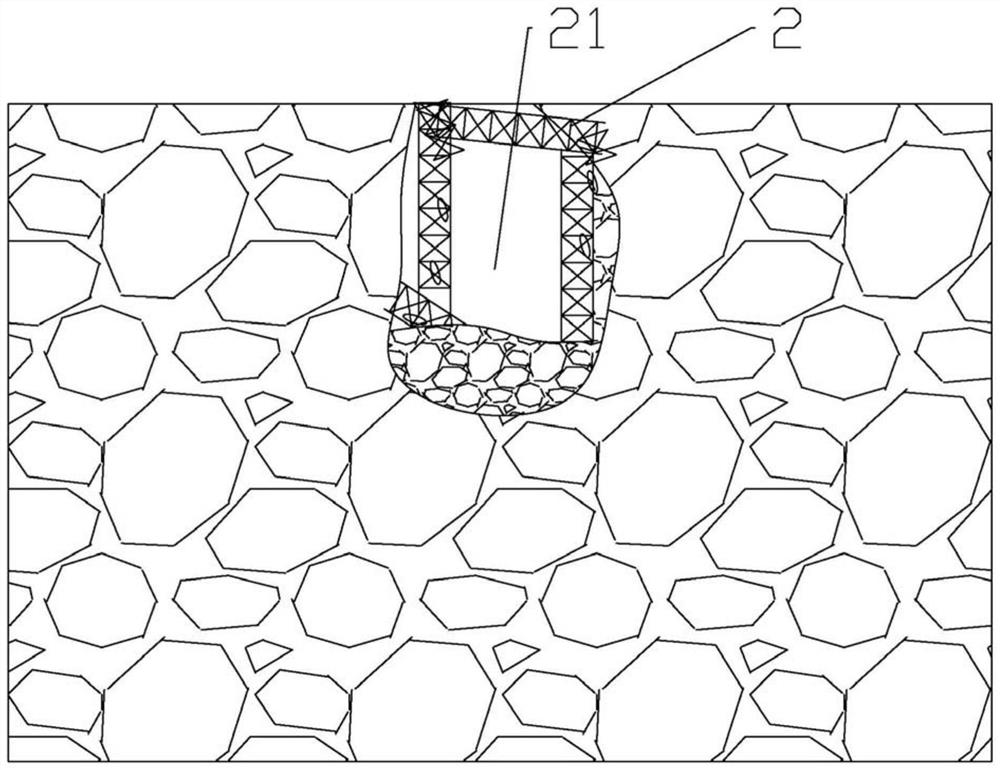

A method of repairing deep pits

InactiveCN109137699BPlay a supporting roleMaintain internal and external pressure balanceRoads maintainenceRepair materialMesh reinforcement

The invention discloses a method for repairing deep pits. The method comprises the following steps: cleaning and loosening soil; drawing an integral structure chart of pits; establishing a fixed bar-mat reinforcement cage and arranging preserved holes; casting concrete at the bottom; inflating an air bag; adding concrete for pouring solidification to form the early form of an enclosed container; exhausting the air bag to get away from the early form; carrying out plastic spraying or brush coating of cement slurry; spraying or brush coating an elastic waterproof material; installing pipelines and functional valves; and filing and discharging a supercharging medium. The enclosed cavity is formed into a pressurized enclosed cavity capable of realizing self-adjustment of inner pressure intensity and outer pressure intensity, valve switches can suffer from the change of pressure intensity so as to control the supercharging medium to come in or out of the enclosed cavity, so that the inner air pressure and the outer air pressure of the enclosed cavity are adjusted to be balanced to keep the stability to form a structure similar to a supercharging pneumatic tire, a large quantity of repair material resources are saved, and the construction is easy.

Owner:励土峰

An exhaust gas treatment device equipped with a limit sensor

InactiveCN104998487BMeet design needsMaintain internal and external pressure balanceDispersed particle filtrationProcess equipmentEngineering

A waste gas treatment device (100) equipped with limiting sensors is used for conducting treatment on waste gas of processing equipment (200) provided with multiple internal workstations (201), wherein the processing equipment (200) comprises the six internal workstations (201) which are evenly arranged in the peripheral direction, each internal workstation (201) is communicated with an annular gas collection pipe (306) installed on the processing equipment (200) through a connecting pipe (202), and a gas delivery pipe (301) used for being communicated with the waste gas treatment device (100) which is located in the center of the processing equipment (200) is arranged on the annular gas collection pipe (306), so that processing waste gas produced in each internal workstation (201) is conveyed into the annular gas collection pipe (306) firstly and then conveyed into the waste gas treatment device (100) to be filtered from the annular gas collection pipe (306).

Owner:XIAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com