A high-temperature and high-pressure visualized microscopic oil reservoir chip holder and its use method

A high-temperature, high-pressure, and gripper technology, applied in the direction of workpiece gripping devices, instruments, scientific instruments, etc., can solve the problem of high temperature and high pressure in reservoirs that are difficult to simulate, limit the application of microscopic reservoir chips, and achieve visualization and small volume of grippers. Requirements and other issues, to achieve the effect of rich oil injection scheme, wide application range and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

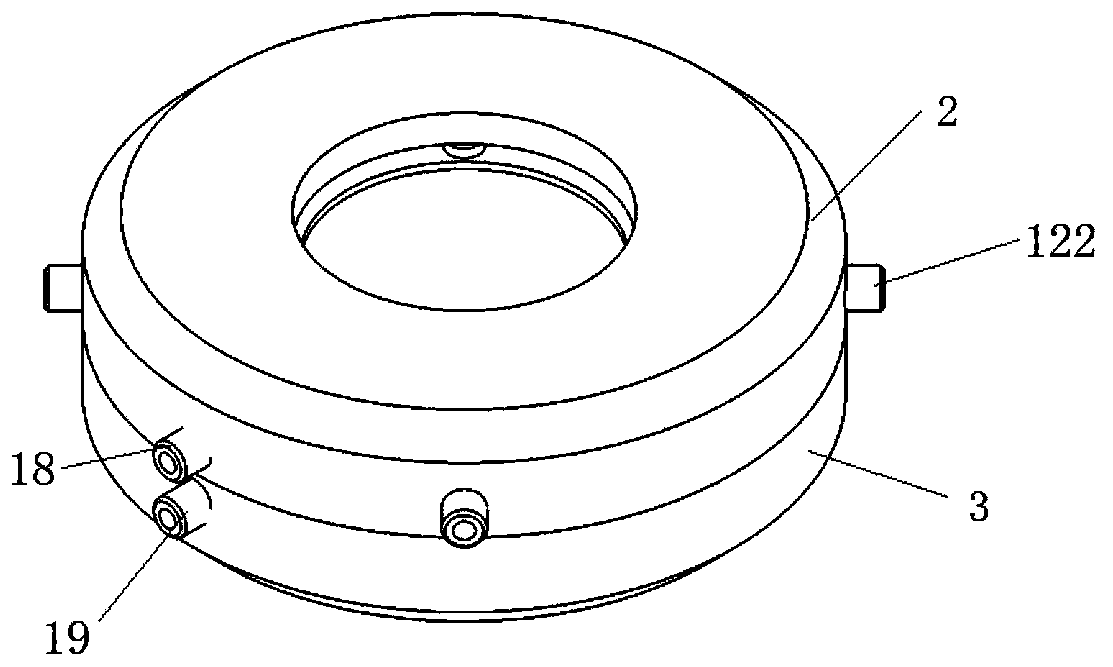

[0022] Such as Figure 1 ~ Figure 3 As shown, the present invention provides a high-temperature and high-pressure visualized microscopic oil reservoir chip holder, which includes a holder body 1 and upper and lower thermal insulation covers 2 and 3 nested outside the holder body 1 . The holder body 1 includes an annular base 11, an annular top cover 12 matching the base 11, a first sapphire lens 13 arranged at the bottom of the base 11, and a first sapphire lens 13 arranged at the bottom of the base 11 for fixing the first sapphire lens 13. The pressure plate 14 , the second sapphire lens 15 arranged on the upper part of the top cover 12 , the second pressure plate 16 arranged on the upper part of the top cover 12 for fixing the second sapphire lens 15 and the microfluidic chip 17 arranged on the upper part of the base 11 . The base 11 and the top co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com