Full-sealed structure of automobile headlamp

A fully sealed technology for automobile headlights, which is applied to vehicle parts, lighting and heating equipment, transportation and packaging, etc., can solve the problems of water vapor condensation and the decrease of the sealing performance of the shell, and achieve the balance of internal and external pressure and ensure the illumination of the ground , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and traditional semi-enclosed headlight the present invention will be further described.

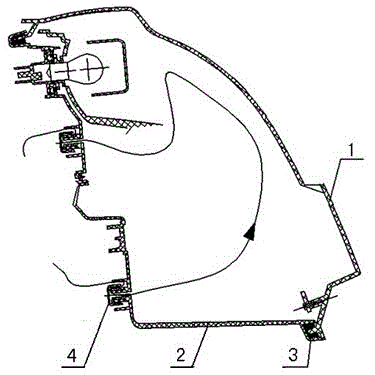

[0020] see figure 1 The traditional semi-enclosed headlight shown includes the original light distribution mirror 1, the original lamp housing 2, and the original sealant 3 (to connect and seal the light distribution mirror and the lamp housing to prevent water vapor from entering the lamp body), and the original ventilation The cap 4 is arranged at the rear of the lamp housing to circulate air and maintain the balance of internal and external air pressure, but at the same time it also brings the risk of moisture entering the lamp body. Moisture molecules in the air enter the lamp body through the breathable cap, and are easy to condense on the optical mirror, forming fogging.

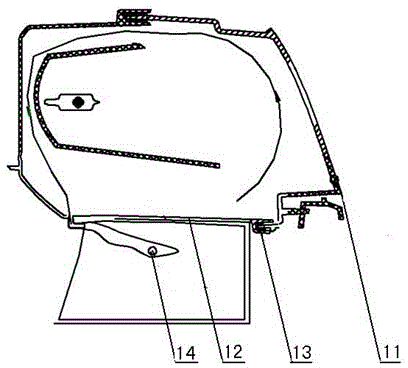

[0021] see figure 2 The fully sealed structure of a kind of automobile headlights shown includes a light distribution mirror 11 and a lamp housing 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com