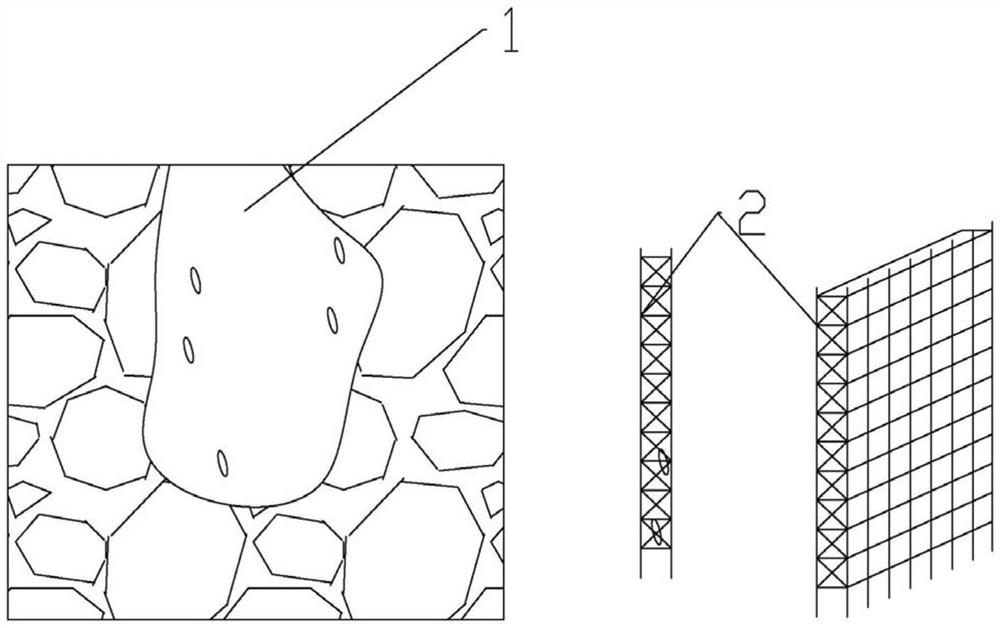

A method of repairing deep pits

A technology for deep pits and steel mesh, applied in the field of repairing deep pits, can solve the problems of complex structure, high manufacturing cost, easy damage to the plane again, and achieve the effect of saving repair material resources and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

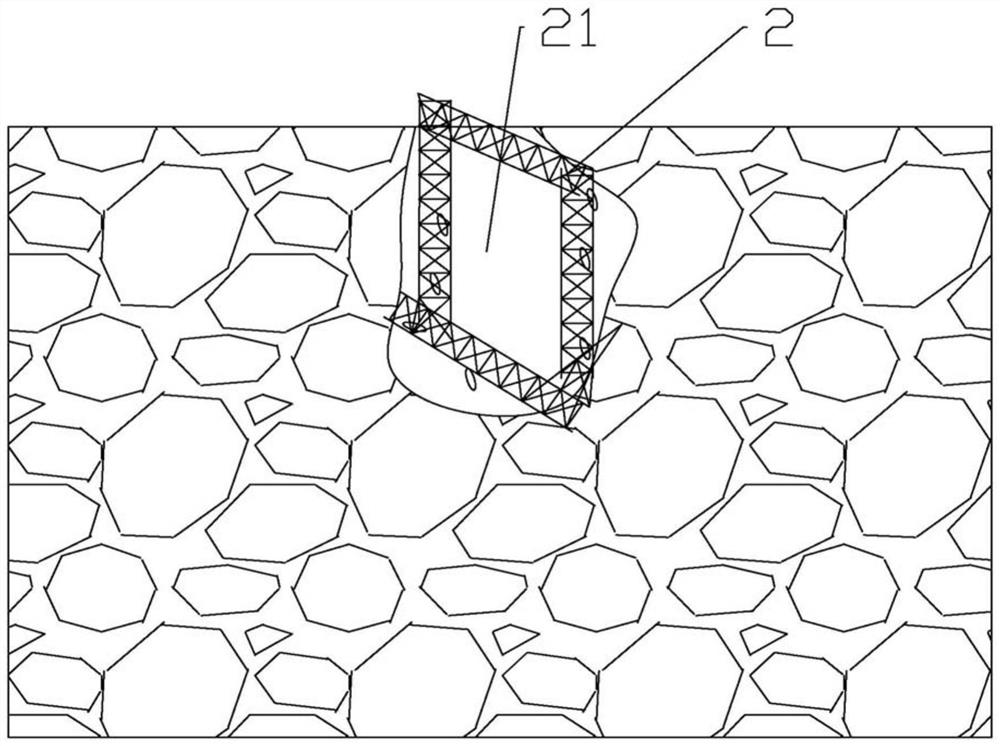

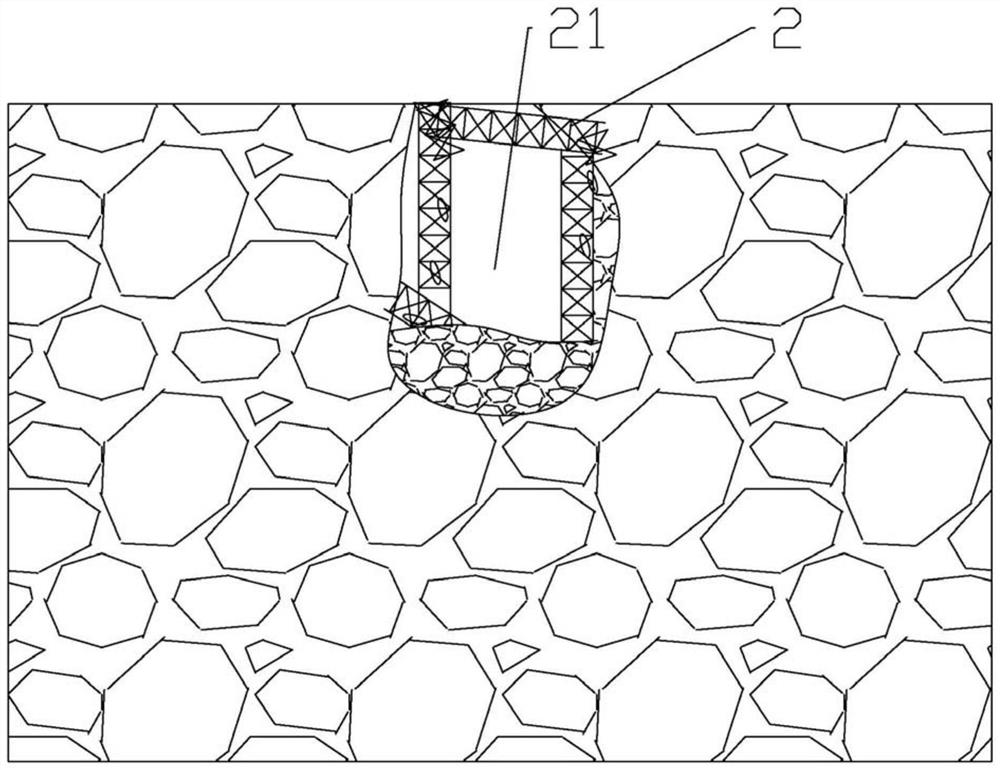

Method used

Image

Examples

Embodiment approach

[0062] As a specific embodiment, the pipeline 4 includes: a water inlet pipe 41, an air guide pipe 42 and a large flow water inlet pipe body 43; In the hole position 22, only part of the pipe body is exposed for installing valves or other devices. The position of the reserved hole position 22 is lower than the plane. Specifically, all the pipes 4 are set in a gradually concave area, forming a structure similar to a sewer. Rainwater can be recovered. When the internal pressure of the enclosed chamber 6 is discharged by the exhaust valve 421 on the air guide pipe 42 due to the high temperature, the internal pressure will be insufficient after the temperature drops, and the collected rainwater will be flushed into the water inlet pipe 41. The one-way check valve 411 and the irrigation enters the enclosure chamber 6;

[0063] Correspondingly, the step S10 also includes:

[0064] i) Fill the enclosed cavity 6 with garbage through the large-flow water inlet pipe body 43, and then i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com