An intelligent exhaust gas treatment device that is easy to clean

A waste gas treatment device, waste gas technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of waste, small distance, different adsorption effects, etc., to reduce production costs, simplify structure, maintain internal and external The effect of pressure equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

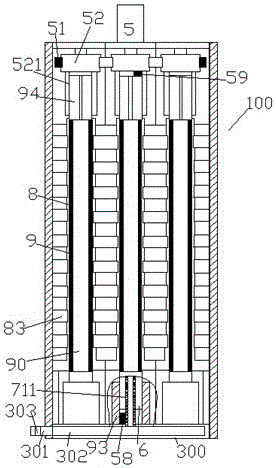

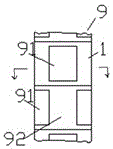

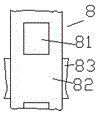

[0012] Combine below Figure 1-6 The present invention will be described in detail.

[0013] According to an embodiment, an intelligent waste gas treatment device 100 that is easy to clean is used to treat the waste gas of a processing equipment 200 with a plurality of internal workstations 201, wherein the processing equipment 200 includes six Each internal work station 201, each of the internal work stations 201 communicates with the annular gas gathering pipe 306 detachably installed in the processing equipment 200 through the connecting pipe 202, and the annular gas gathering pipe 306 is provided with a The exhaust gas treatment device 100 at the center of 200 is connected to the detachable gas delivery pipe 301, so that the processing exhaust gas generated in each of the internal workstations 201 is first transmitted to the annular gas collection pipe 306, and then from the annular gas collection pipe 306 to the exhaust gas treatment device 100 for filtering, the exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com