Sidetrack horizontal well track design method under control point constraint condition

A technology of sidetracking horizontal wells and constraints, applied in calculations, special data processing applications, instruments, etc., can solve problems such as inability to guarantee the optimal trajectory, inconvenient construction of the trajectory, and time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

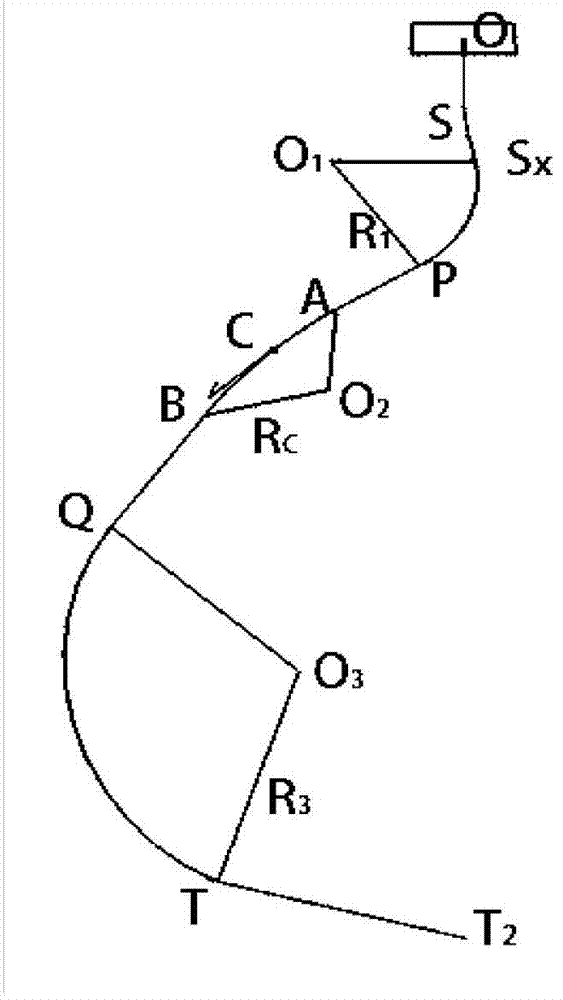

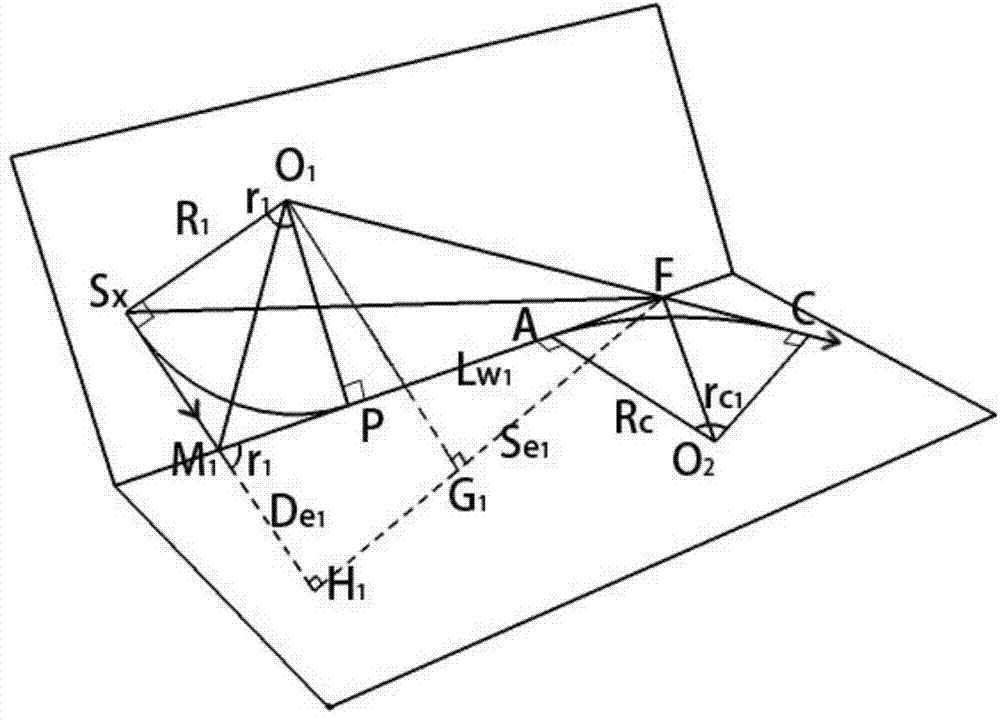

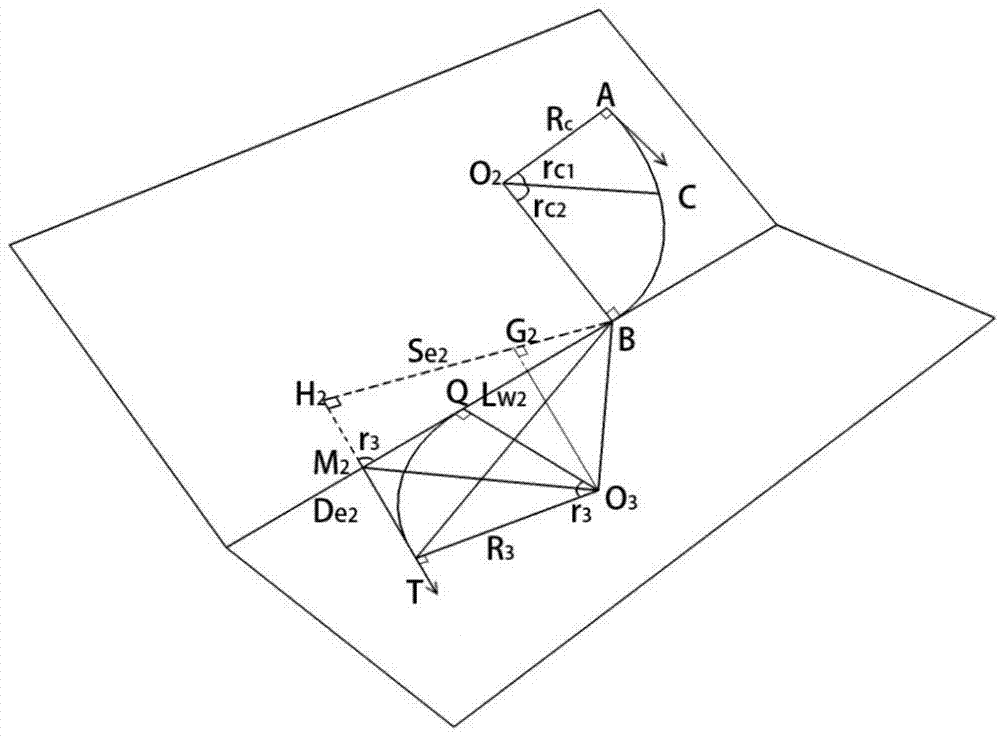

[0129] Such as figure 1 A section of the borehole track shown, S is the sidetracking point: the coordinates are (N S ,E S ,D S ), measured well depth L S ;Inclination angle α S ;Azimuth φ S . T is the first target point: coordinates (N T ,E T ,D T ); target well inclination angle α T ;target azimuth φ T . T2 is the second target point: coordinates (NT2 ,E T2 ,D T2 ); target well inclination angle α T2 ;target azimuth φ T2 . Anti-collision constraint point C: coordinates (N C ,E C ,D C ), between the sidetracking point S and the first target point T. Among them, the first target point T and the second target point T 2 There is a horizontal section in between, and the design of the drilling trajectory is relatively simple. This embodiment mainly studies the trajectory design model from the sidetracking point S to the first target point T. The target points in this embodiment all refer to the first target point.

[0130] The specific steps of the sidetracking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com