Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128results about How to "Increase the total stroke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of processing waste product into fuel

InactiveUS20050142250A1Efficient conversionControlled and adjustable resistanceMilk preparationSolid fuelsWaste streamWaste product

Fuels used may be derived from existing waste streams such as animal wastes and streams of discarded or unwanted animal byproducts generated at animal slaughterhouses. A method of processing organic waste products into fuel includes homogenizing the waste products. The waste products are heated and pressurized. Water is removed from the waste products. Selected constituent of the waste products are separated from the waste products into a waste stream. The waste stream is blended with a fuel to form a bio-fuel mixture.

Owner:STONE MICHAEL

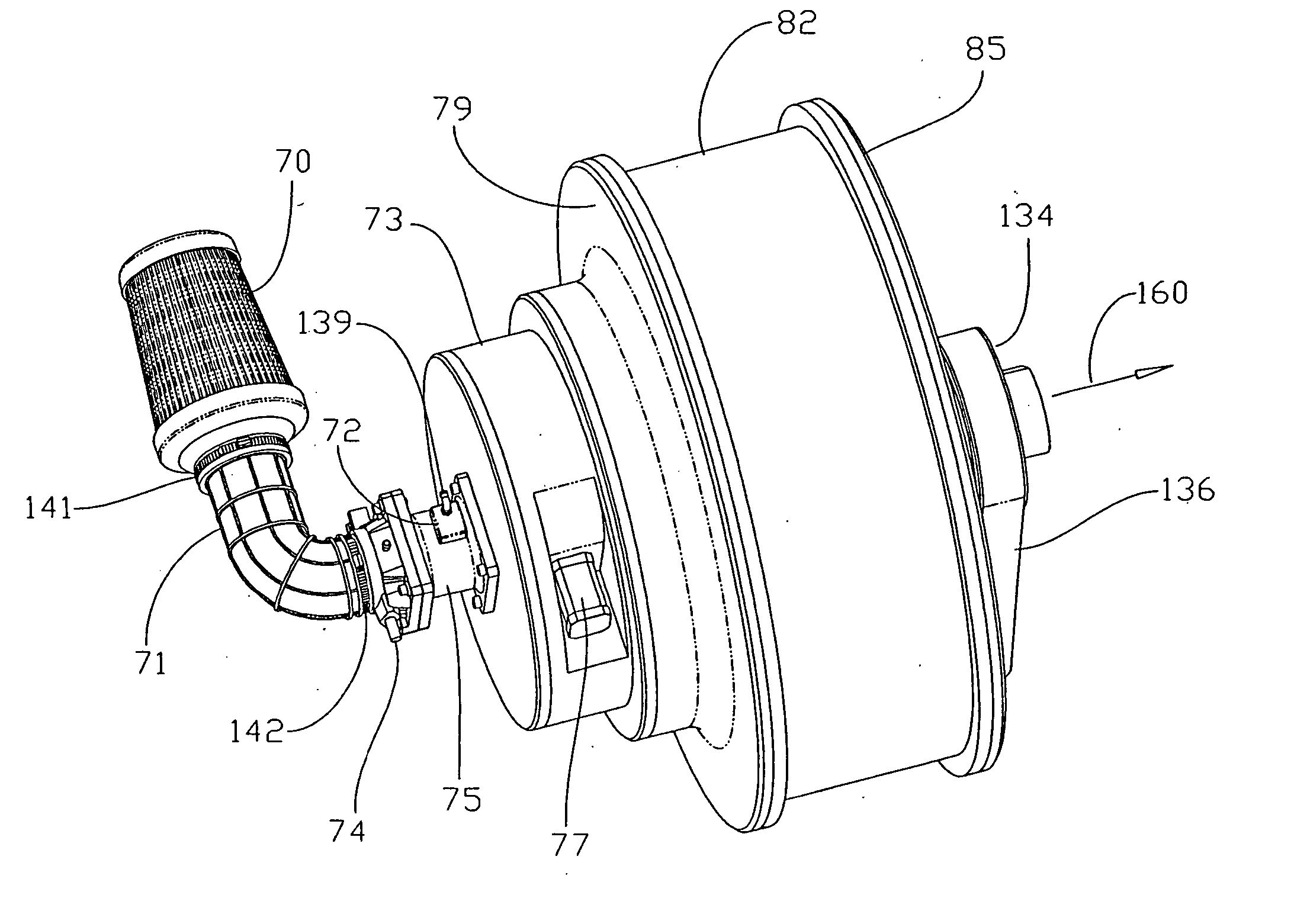

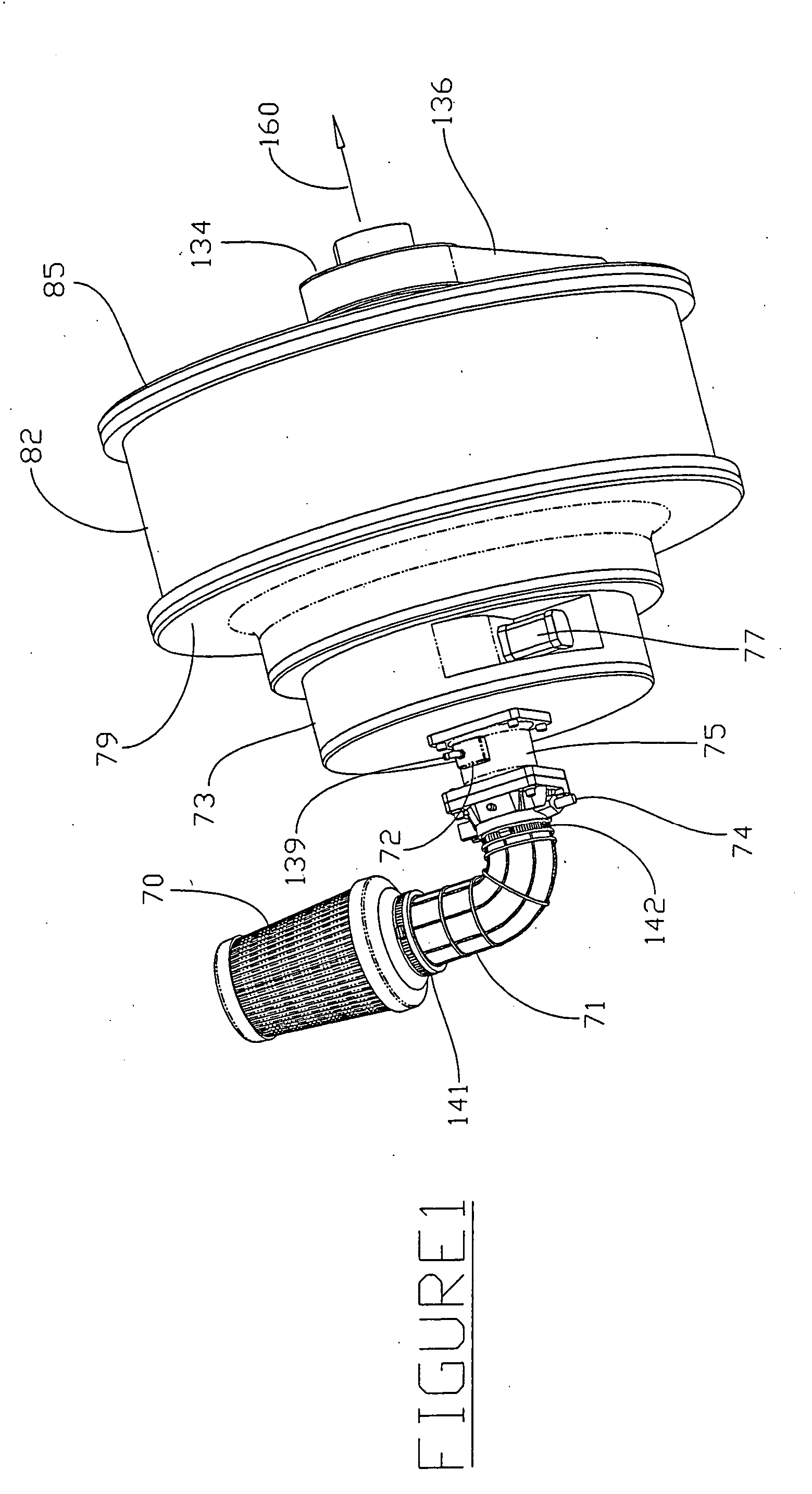

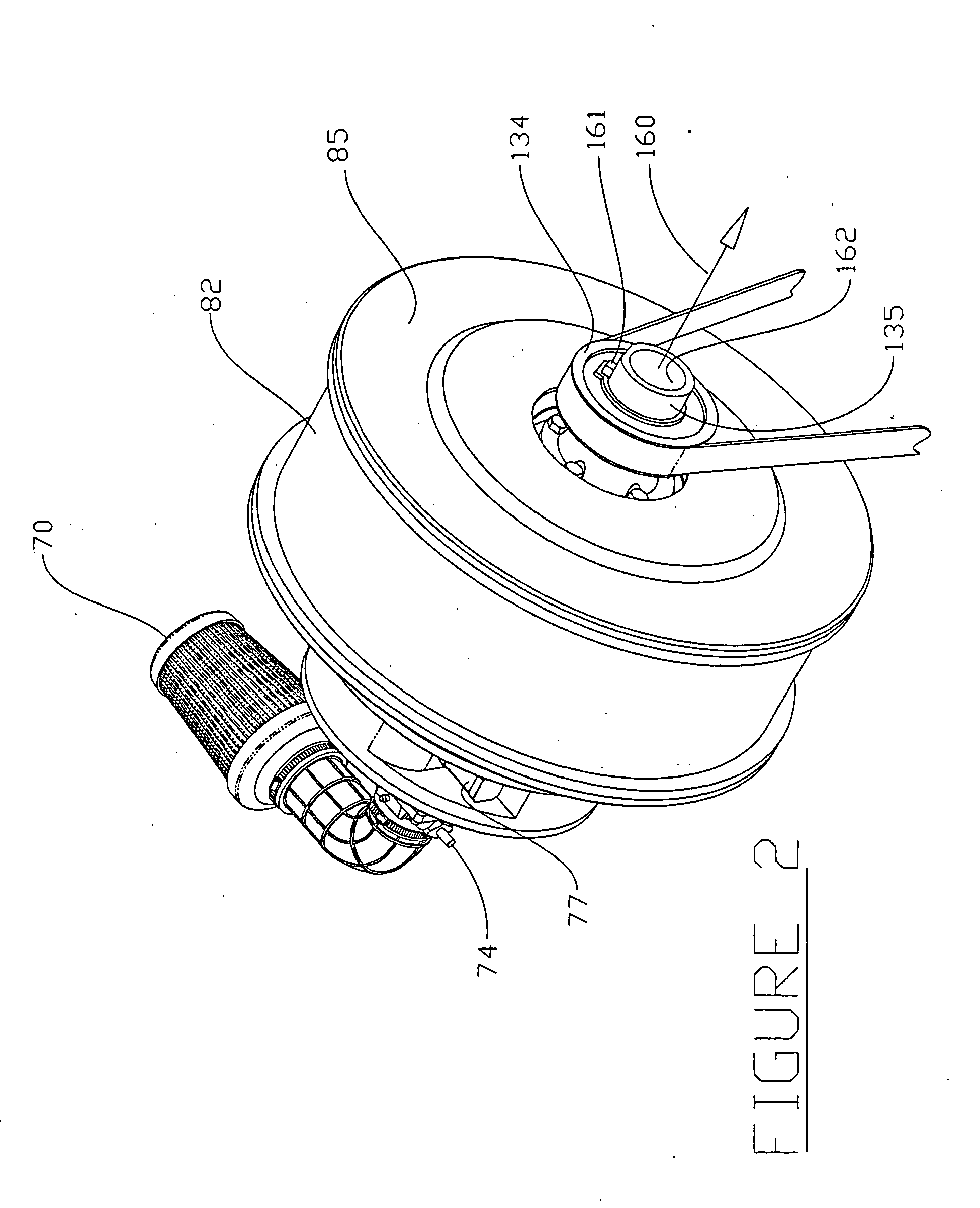

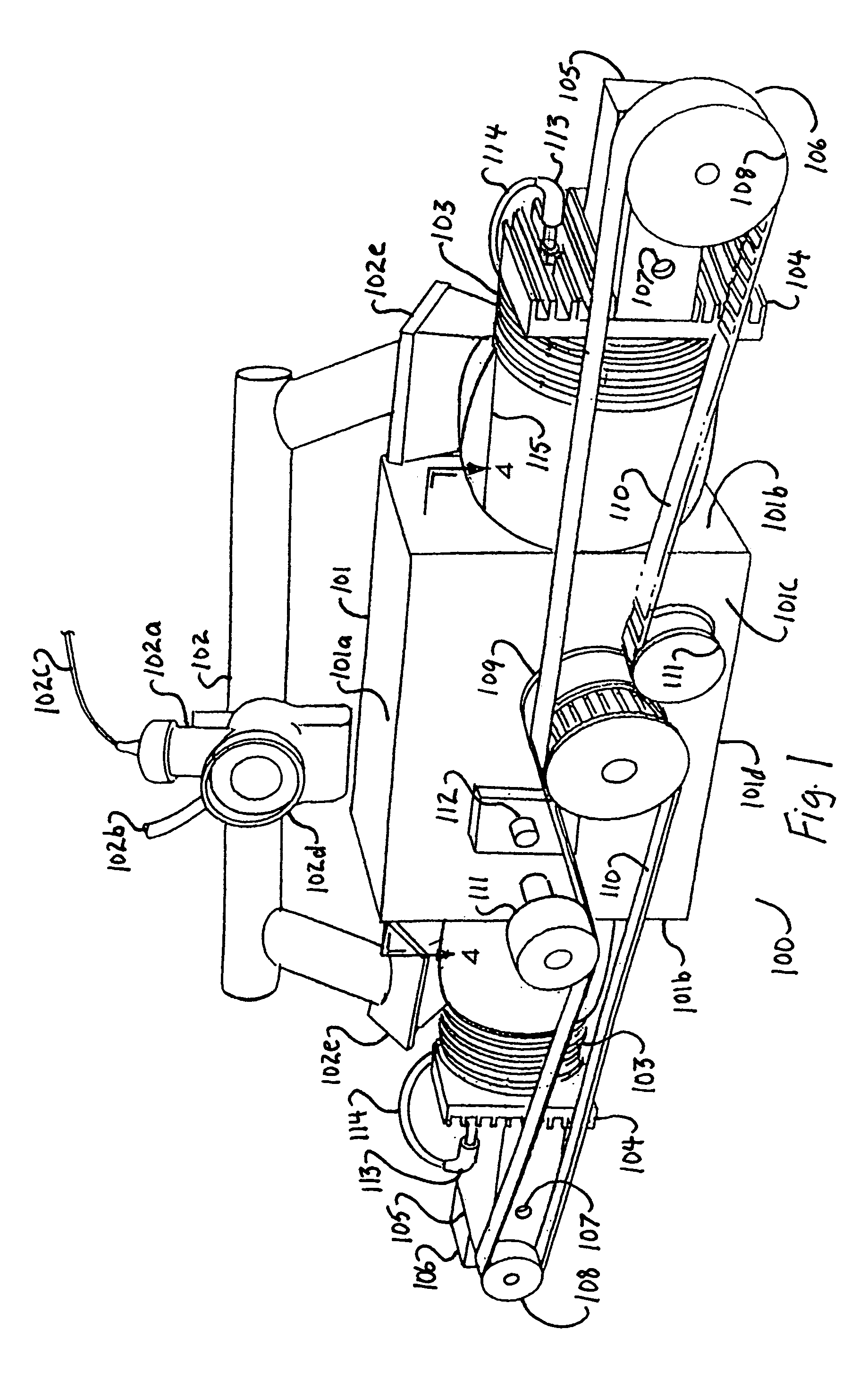

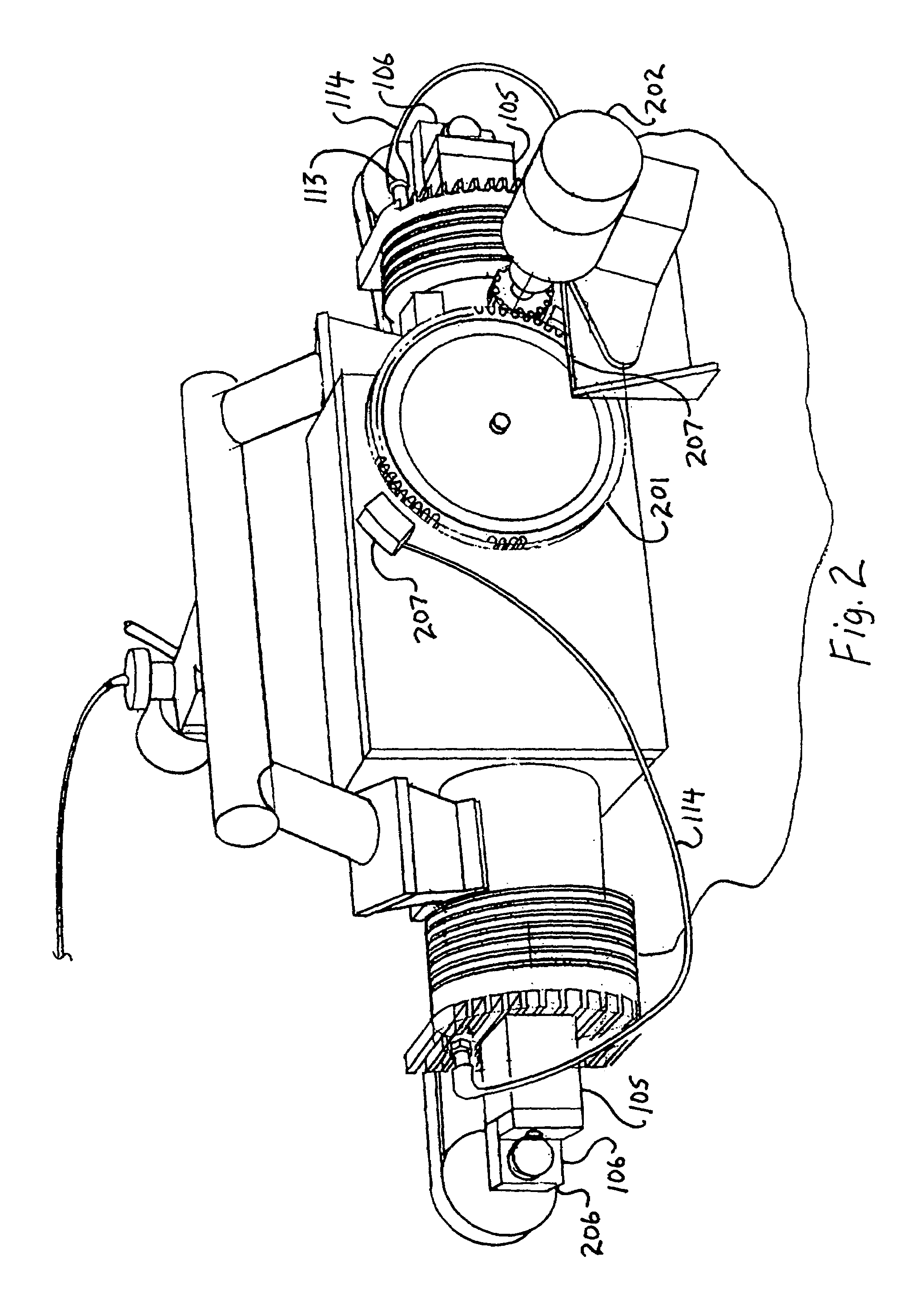

Internal combustion engine machine incorporating significant improvements in power, efficiency and emissions control

InactiveUS7104227B2Increase powerImprove efficiencyValve arrangementsLubrication of auxillariesExternal combustion engineFour-stroke engine

A two stroke cycle internal combustion engine machine that does not require lubricating oil to be mixed with its fuel, producing greater efficiency, higher power to weight ratio, cooler operating temperatures, a wider speed range, greater simplicity, and lower toxic emissions, many of the improvements also transferable to four stroke engines.

Owner:WARREN III C MADISON

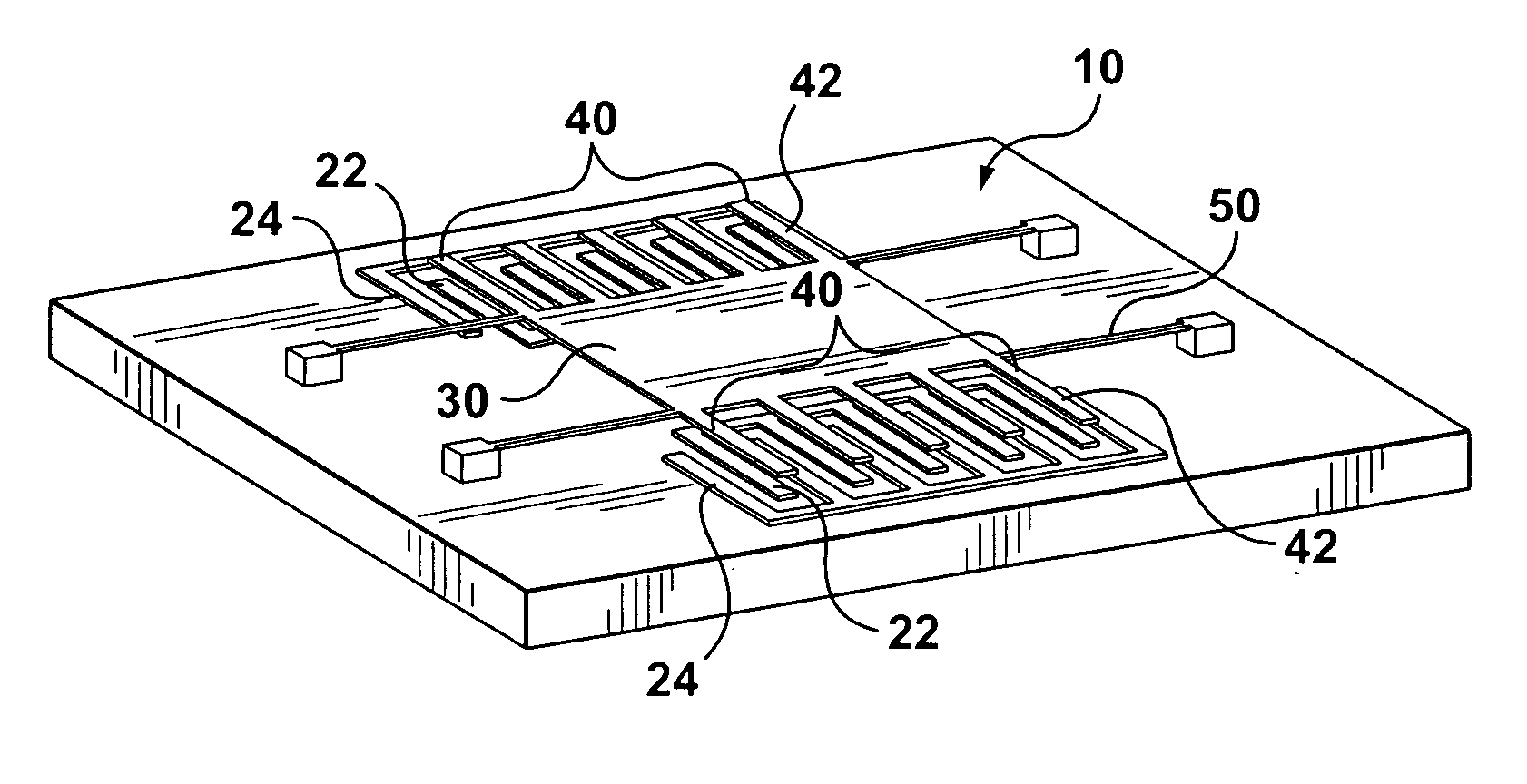

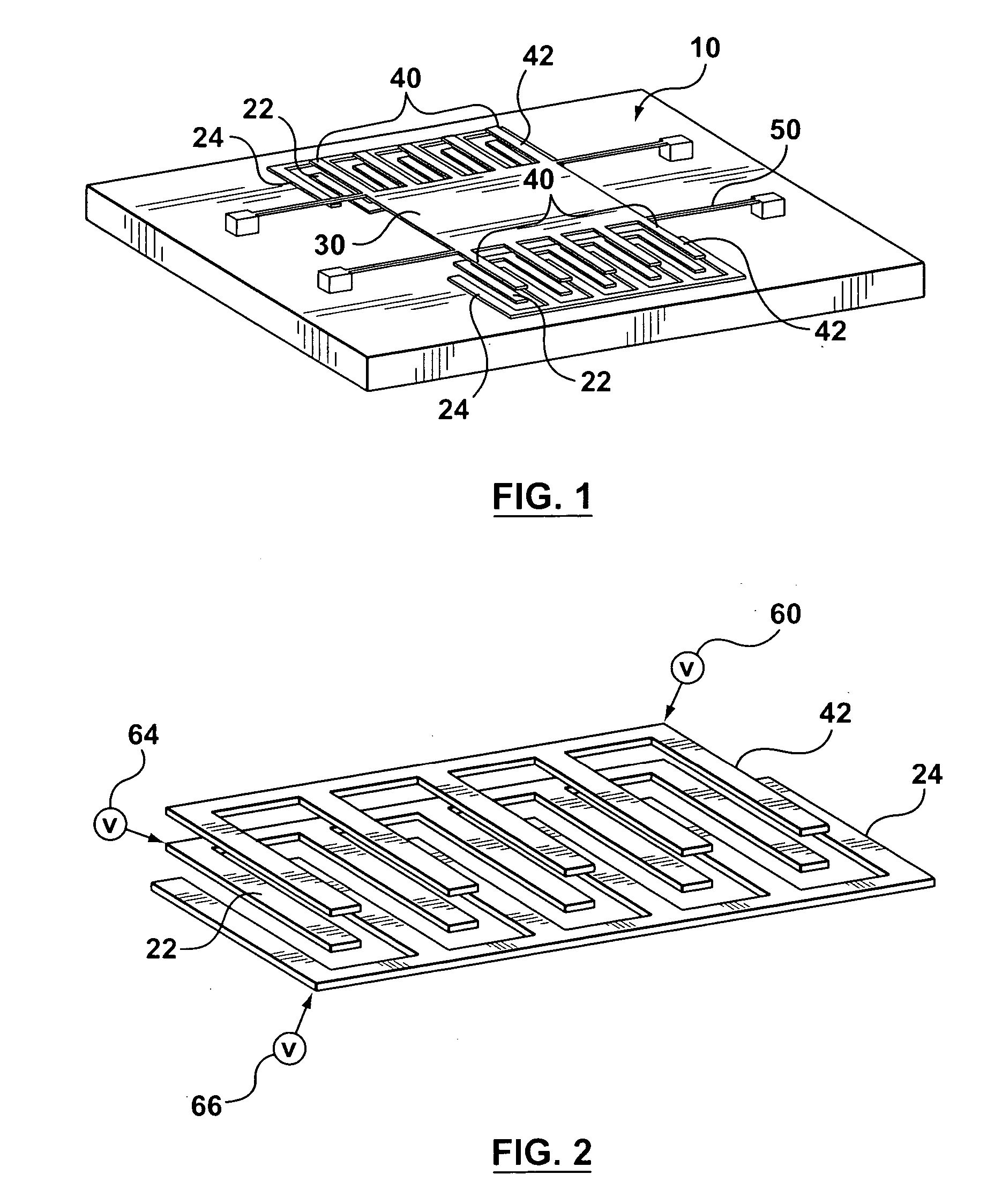

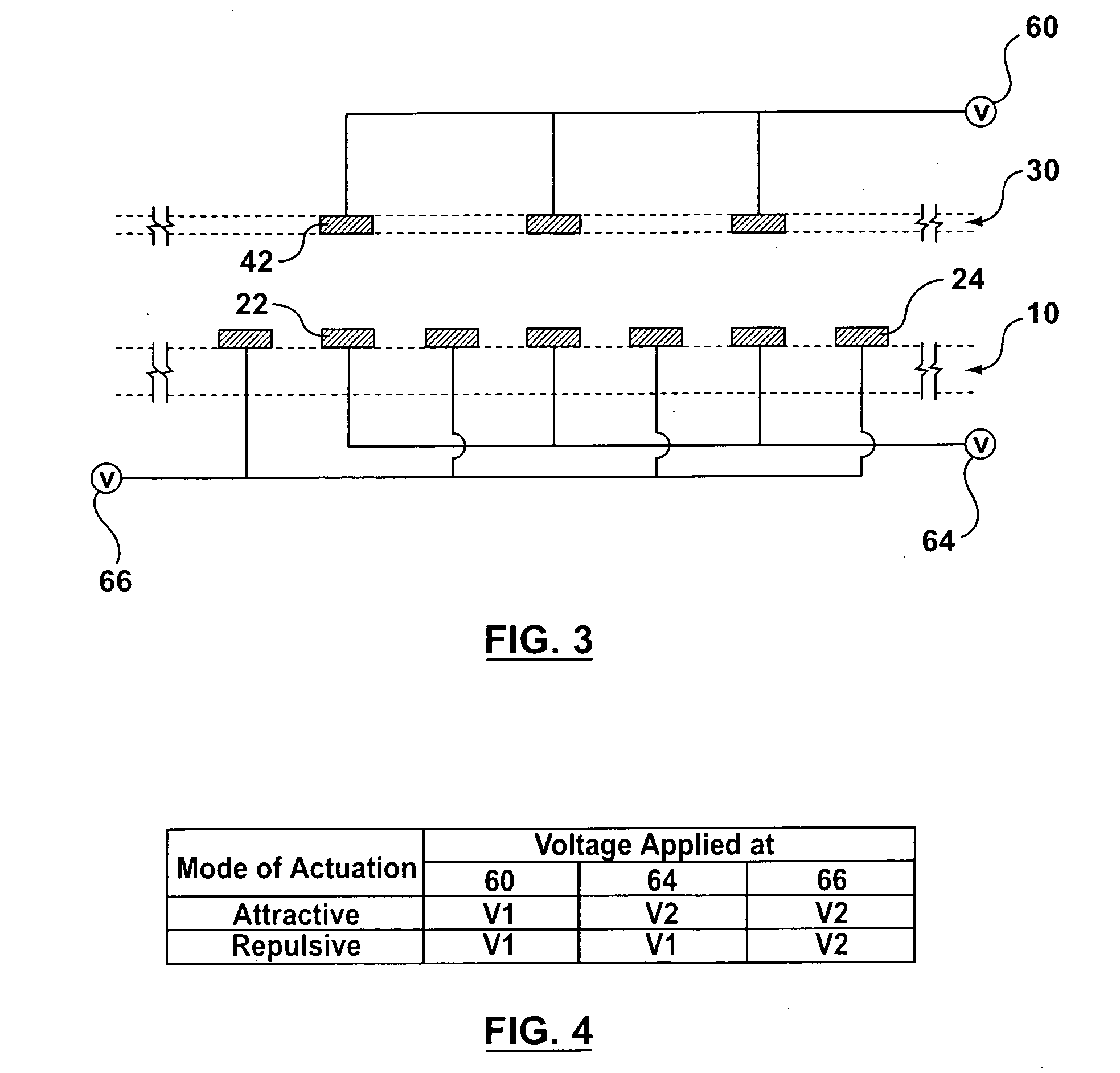

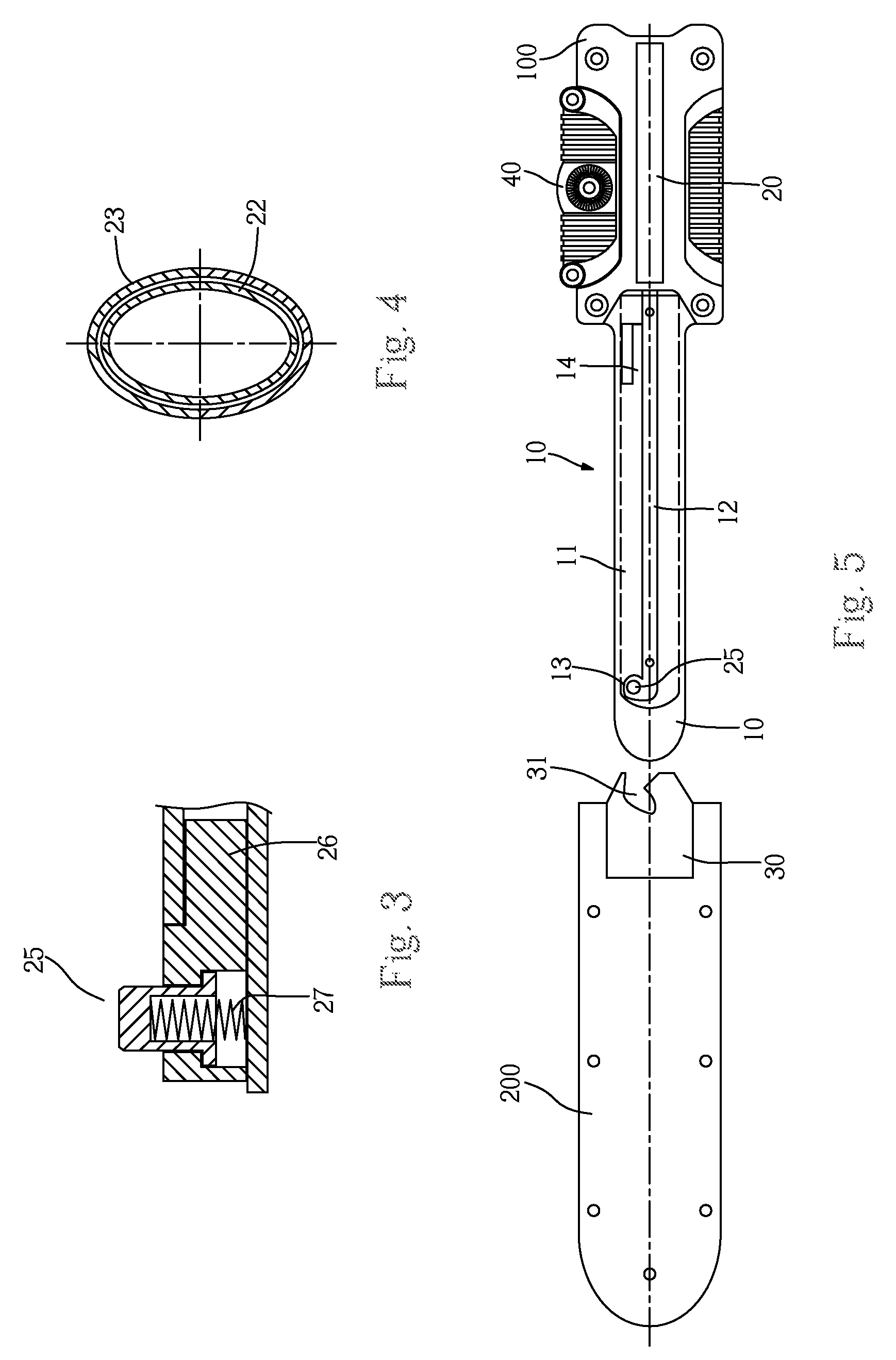

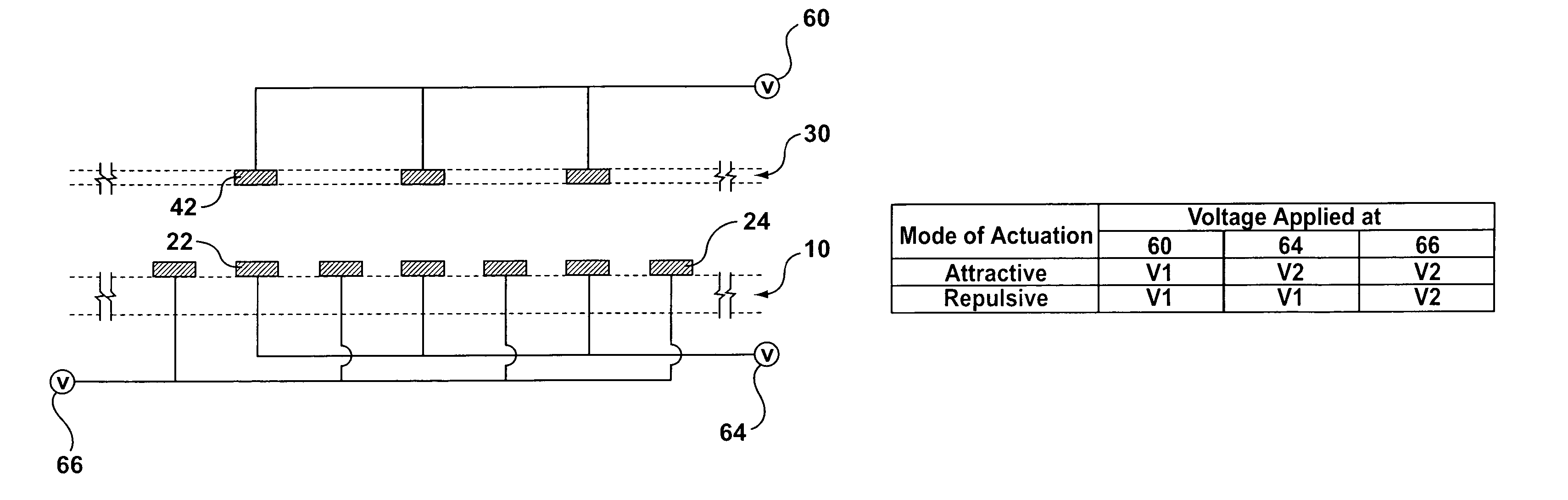

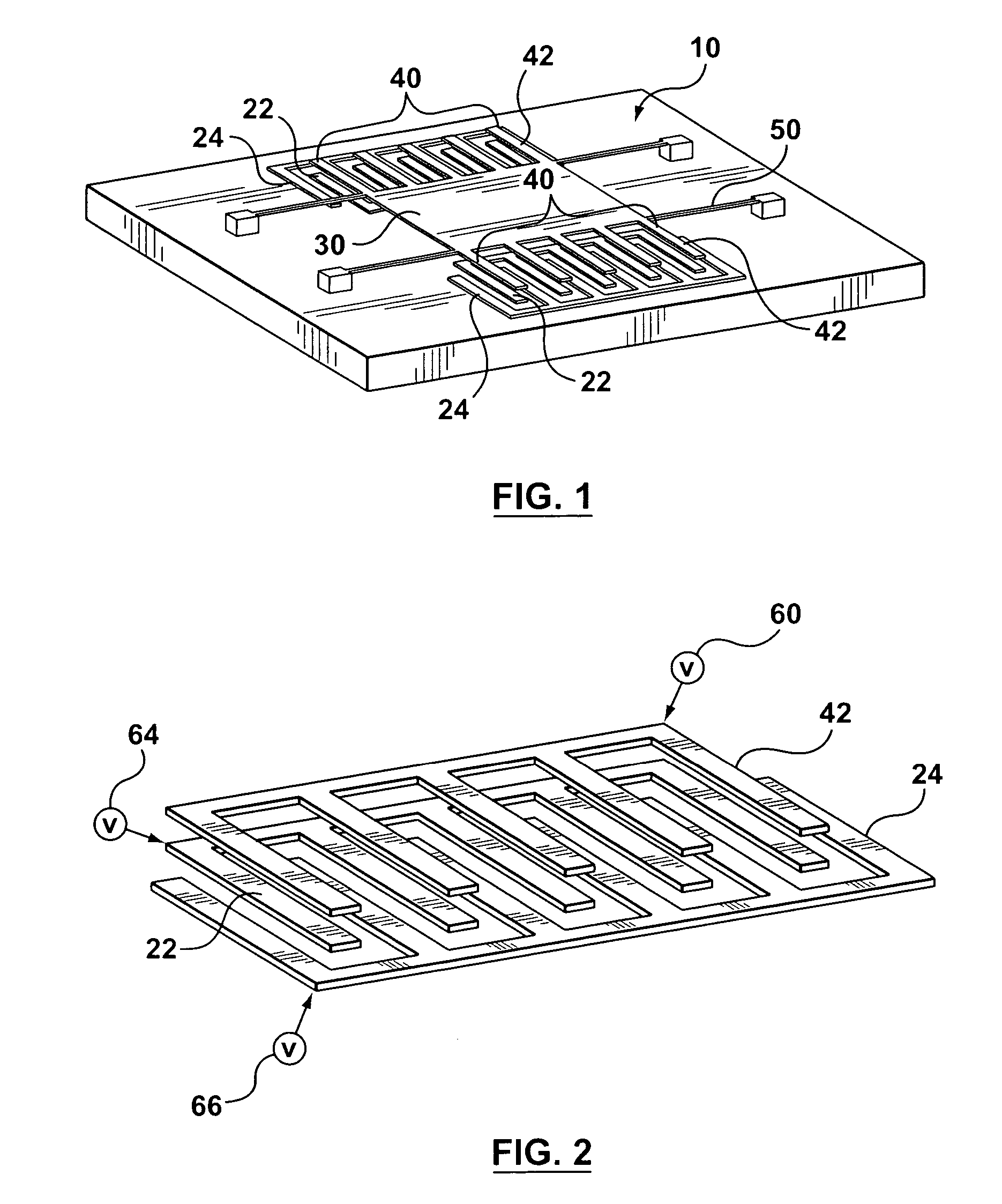

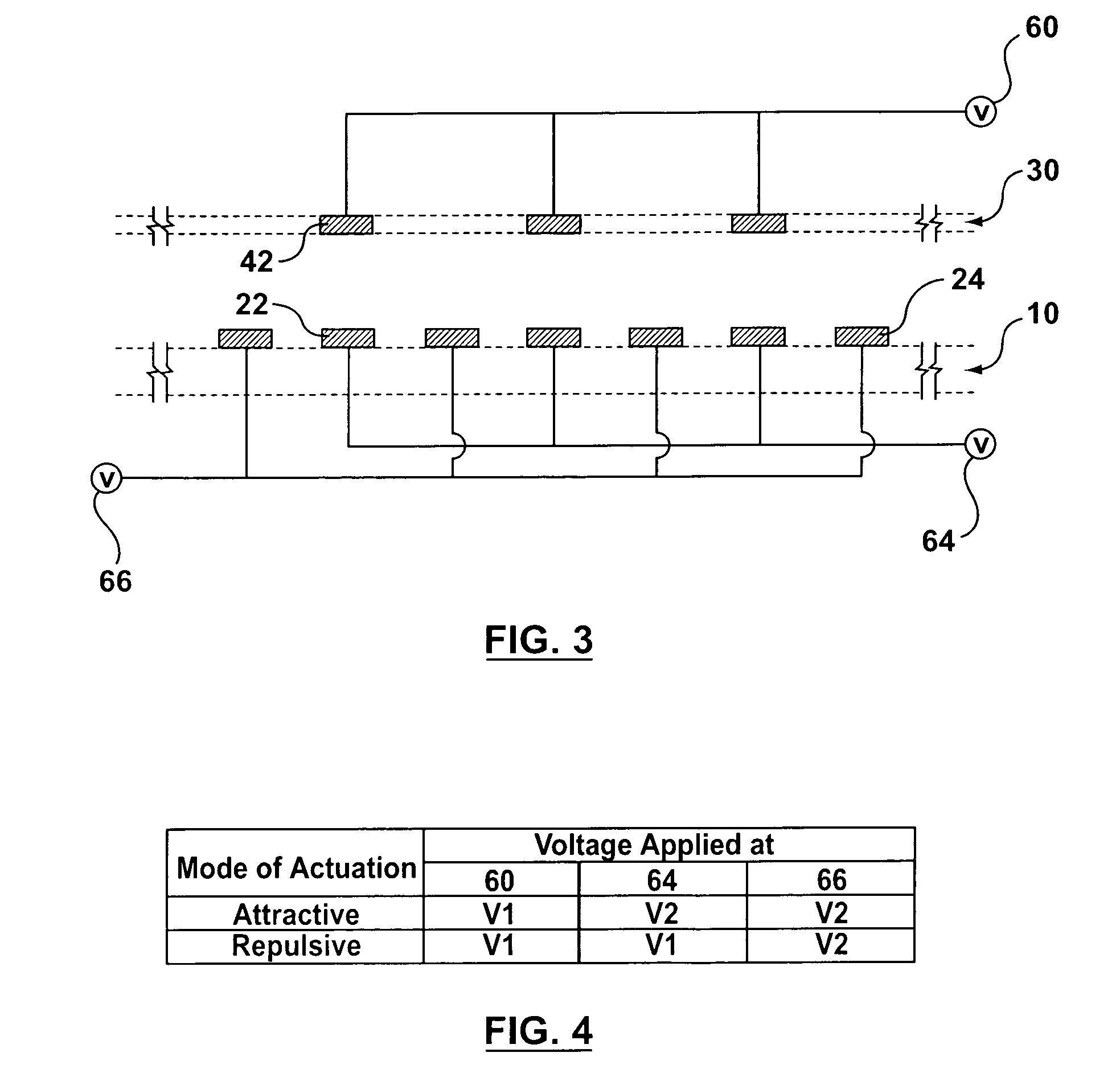

Bi-directional actuator utilizing both attractive and repulsive electrostatic forces

InactiveUS20060082251A1Easily incorporateIncrease the total strokePiezoelectric/electrostrictive device detailsElectrostatic motorsRepulsion forceElectrode array

An electrostatic actuator comprising: first and second comb arrays of electrodes arranged on a base, the electrodes of the first and second comb arrays being interleaved; a third comb array of electrodes spring mounted over the first and second comb arrays, the electrodes of the third comb array being essentially aligned with the electrodes of the second comb array; means for applying a first voltage to the third comb array and a second voltage to the first and second comb arrays to generate an attractive force acting on the third comb array to move the third comb array toward the second comb array; and, means for applying the first voltage to the second and third comb arrays and the second voltage to the first comb array to generate a repulsive force acting on the third comb array to move the third comb array away from the second comb array.

Owner:HE +1

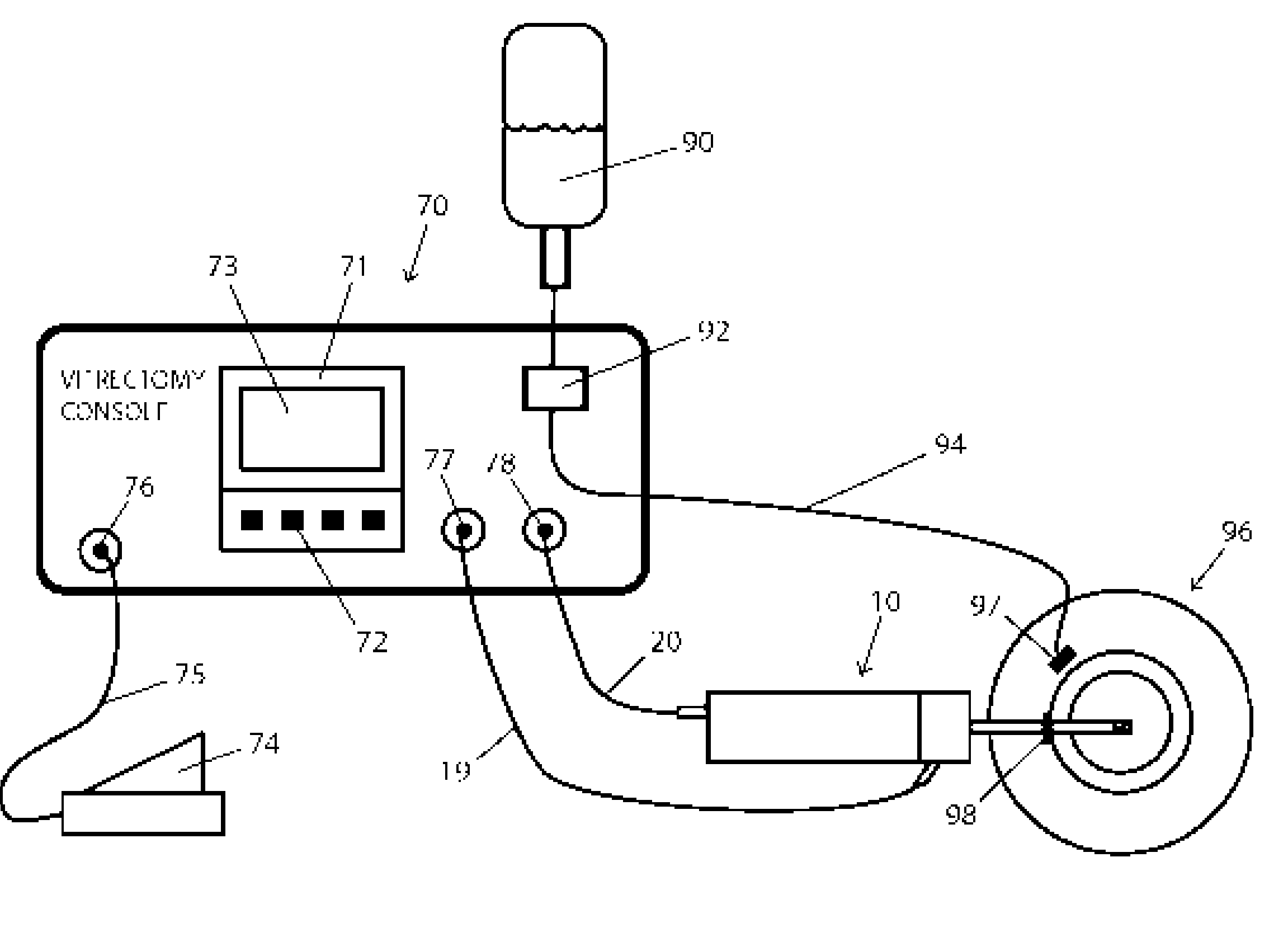

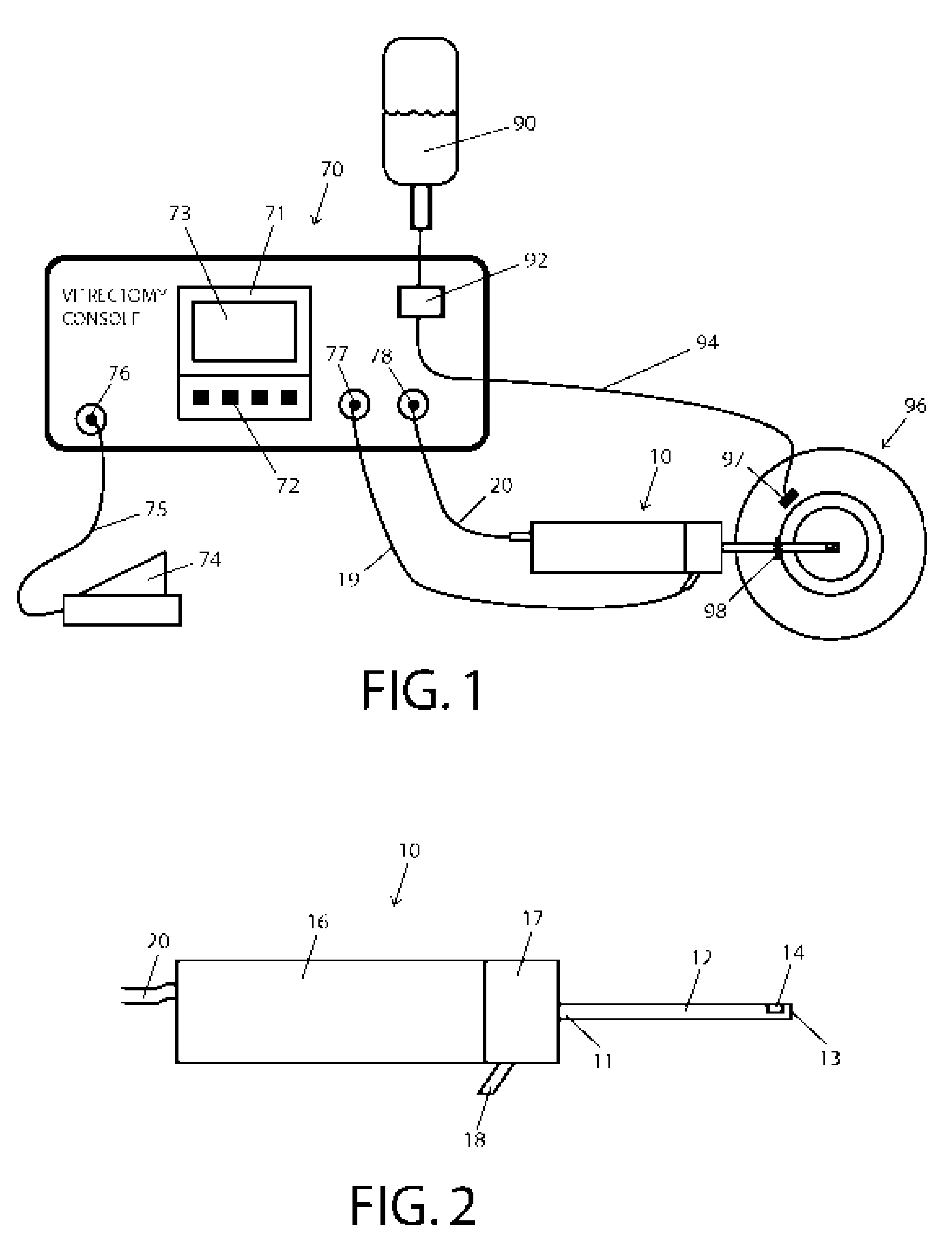

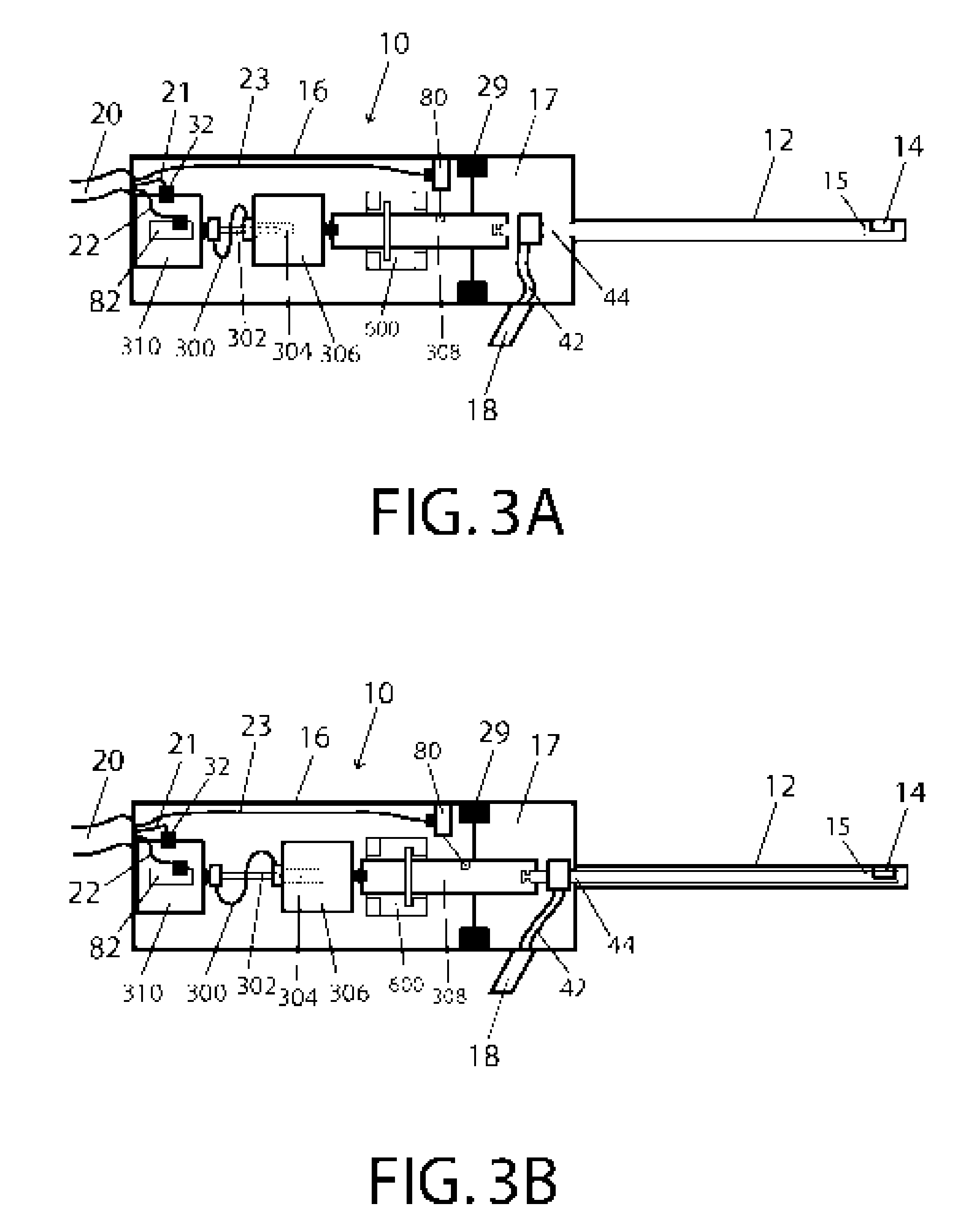

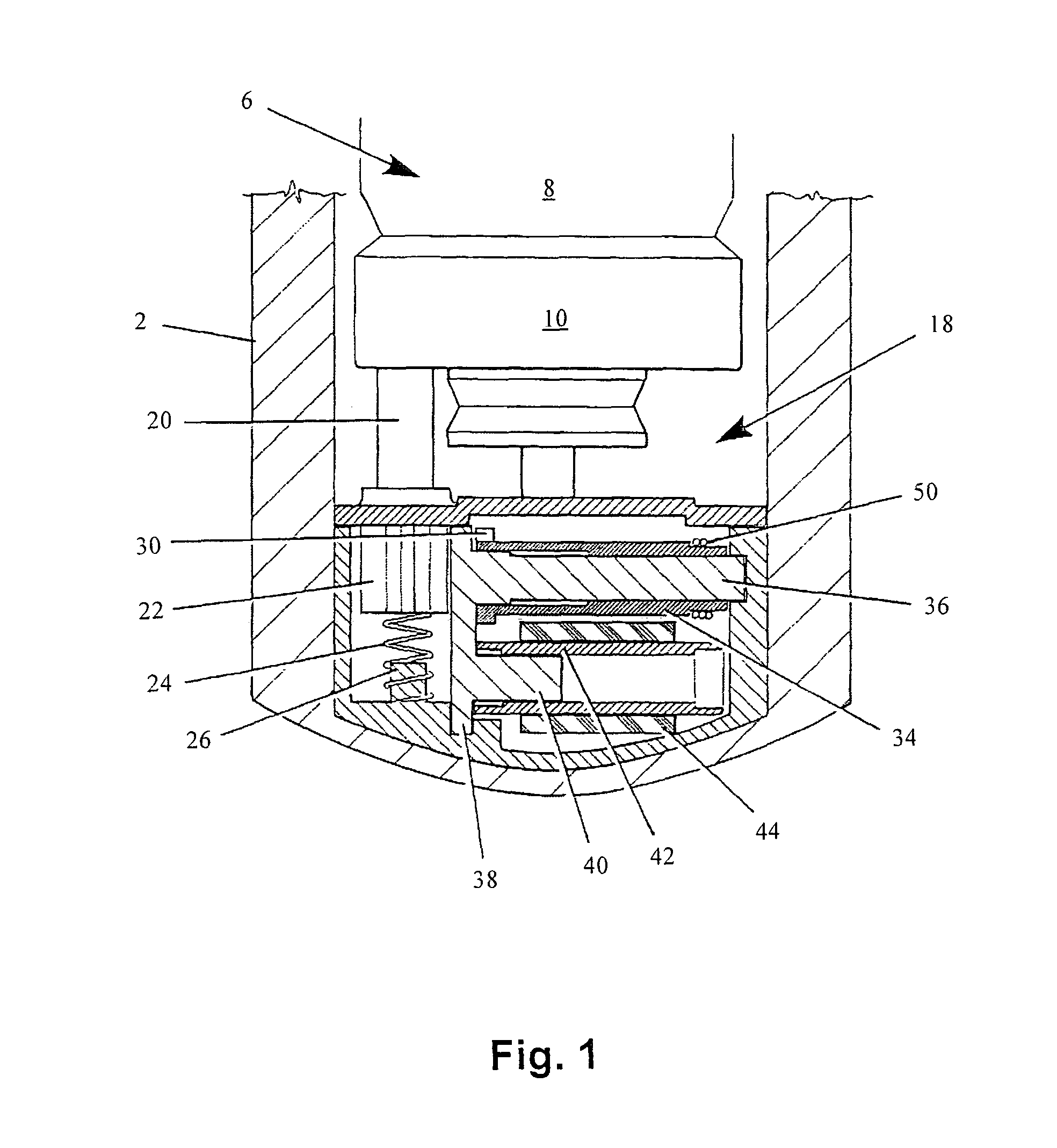

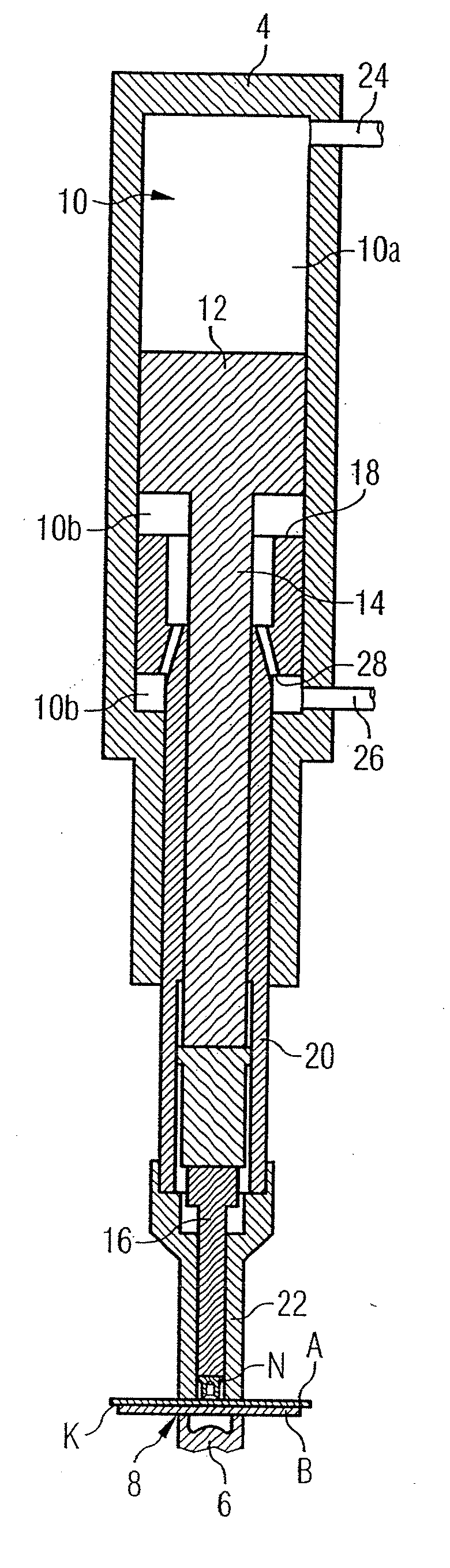

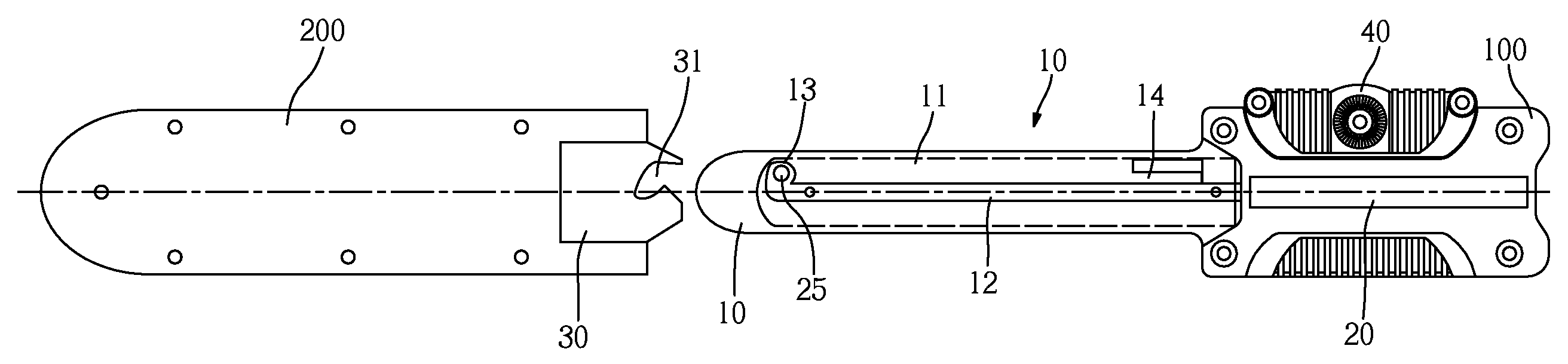

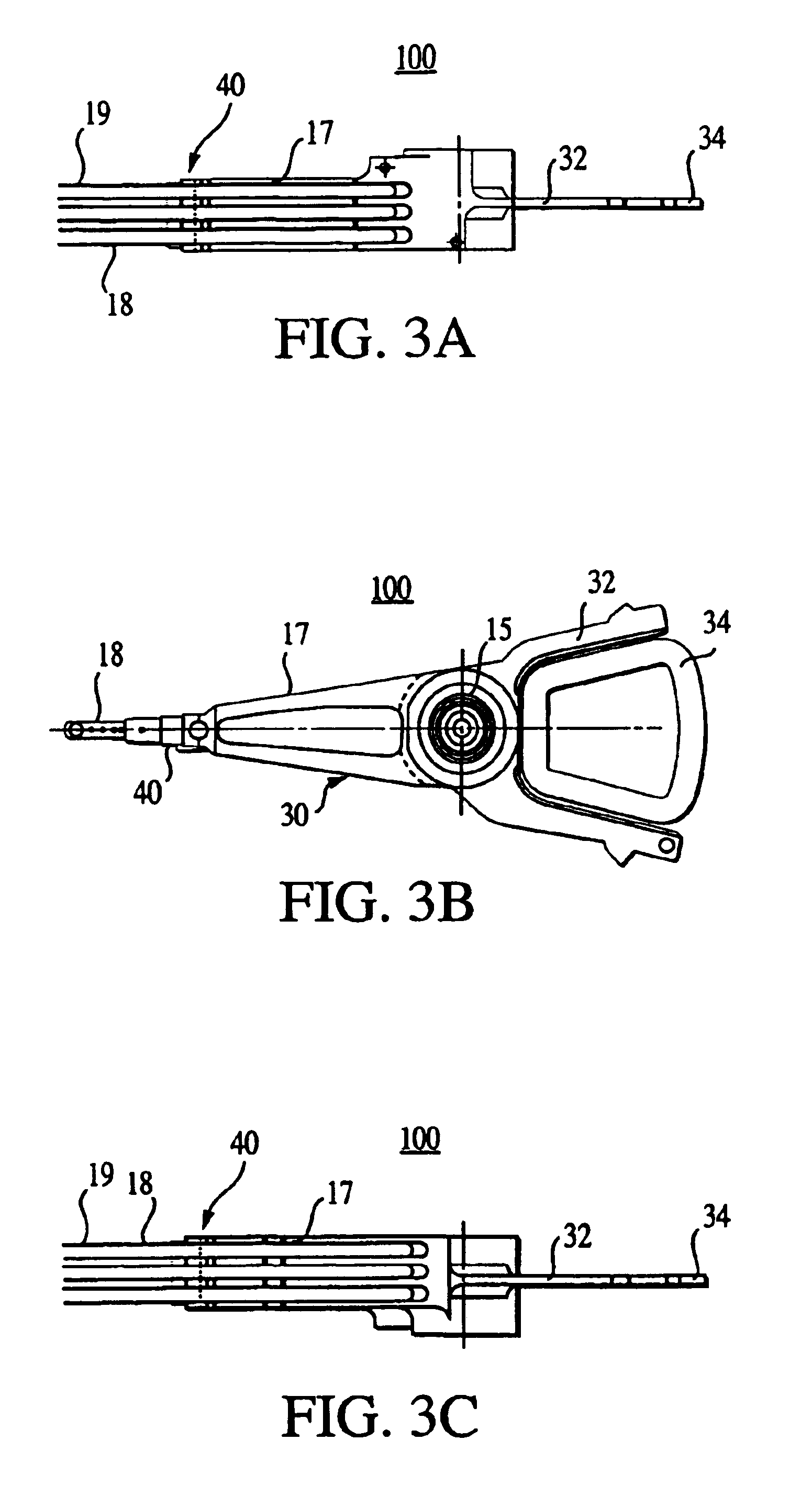

Spring-Mass Surgical System

InactiveUS20070129732A1Increase the total strokeIncrease computing speedEye surgeryExcision instrumentsElectricityPiezoelectric actuators

A high-speed surgical handpiece (10) of the kind suitable for vitreoretinal surgery having a cutter (44) and an actuator (310). The cutter (44) is a guillotine-type cutter activated by a spring-mass system excited at harmonic frequency by a piezoelectric actuator (310) that receives a driving signal from a driving controller. The controller can have control and display units with a plurality of input mechanisms receiving input from a user. The control unit produces a piezoelectric actuator output signal to excite the spring-mass system at harmonic frequency. Fast cutting rates with reduced duty cycle as well as a proportional mode of operation are available. Low degrees of vibration and noise generation are produced.

Owner:ZACHARIAS JAIME

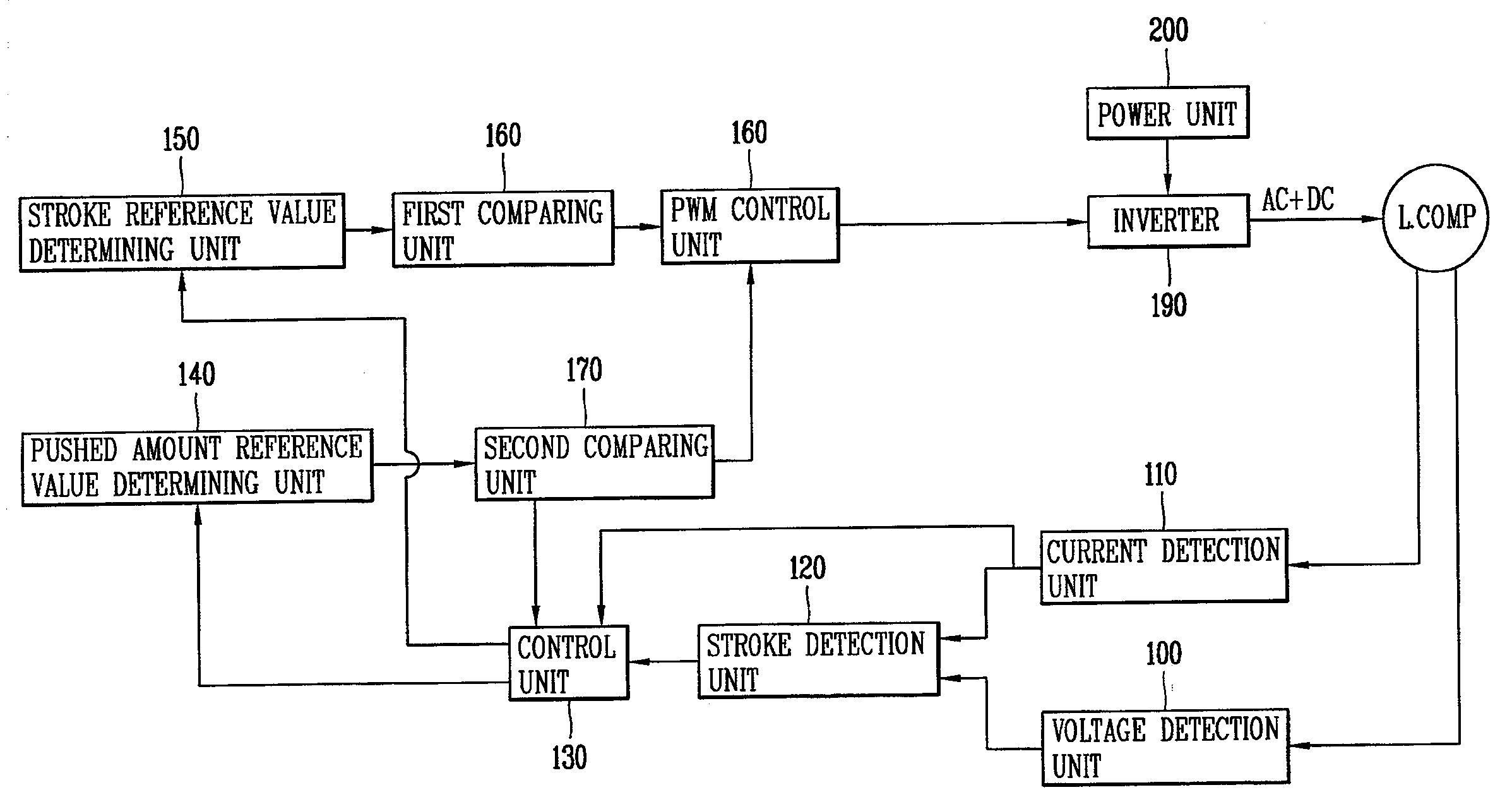

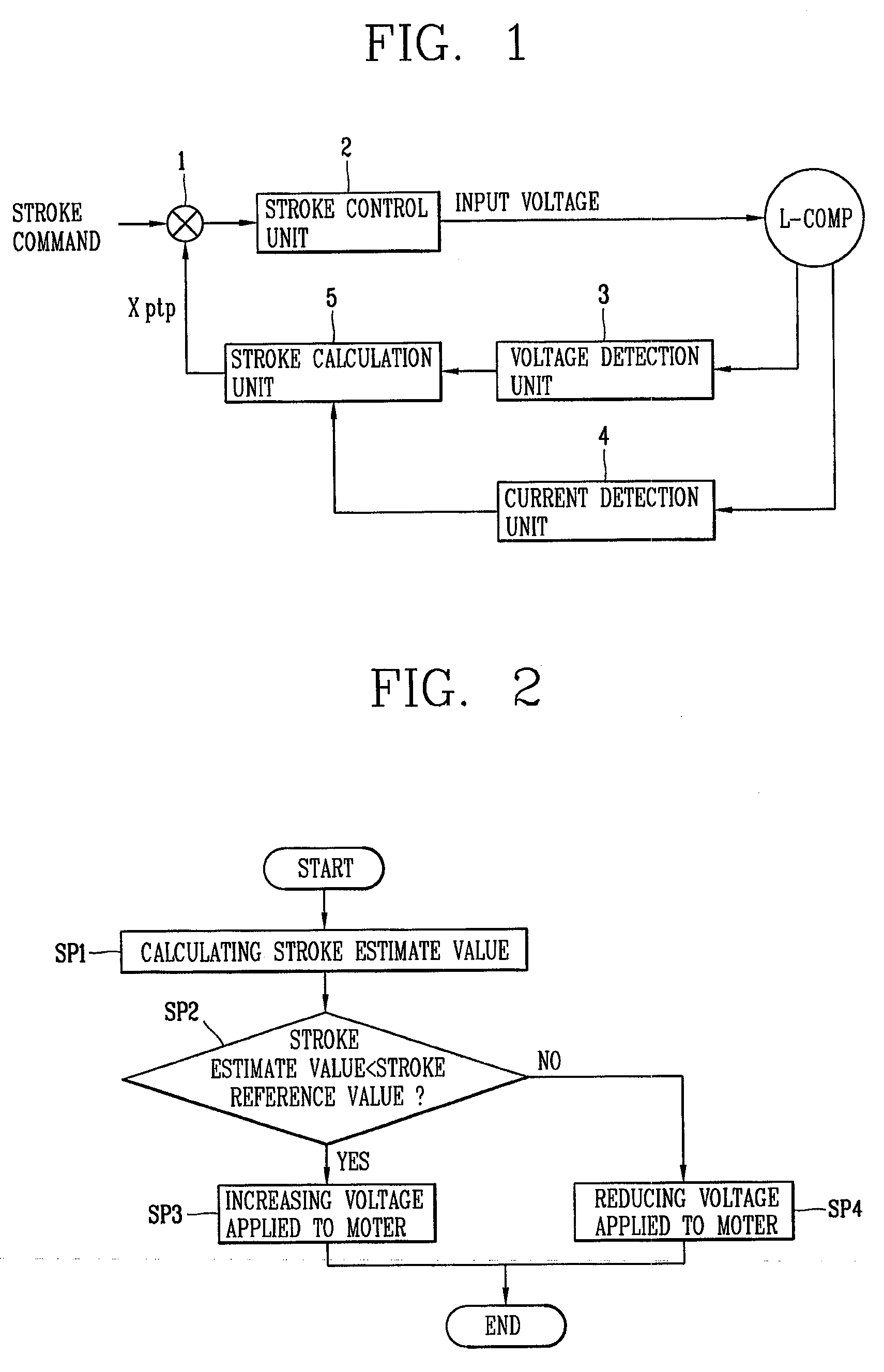

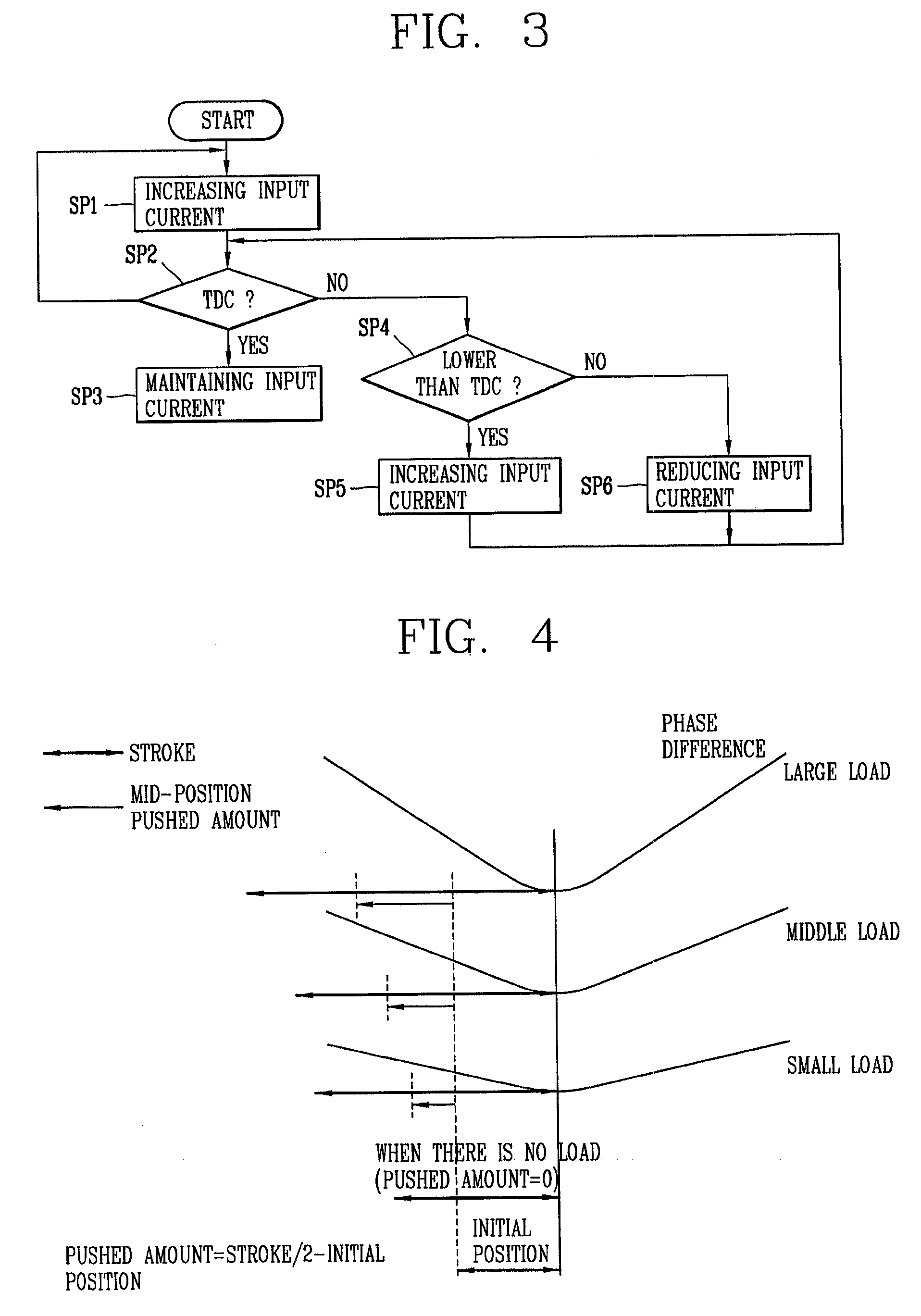

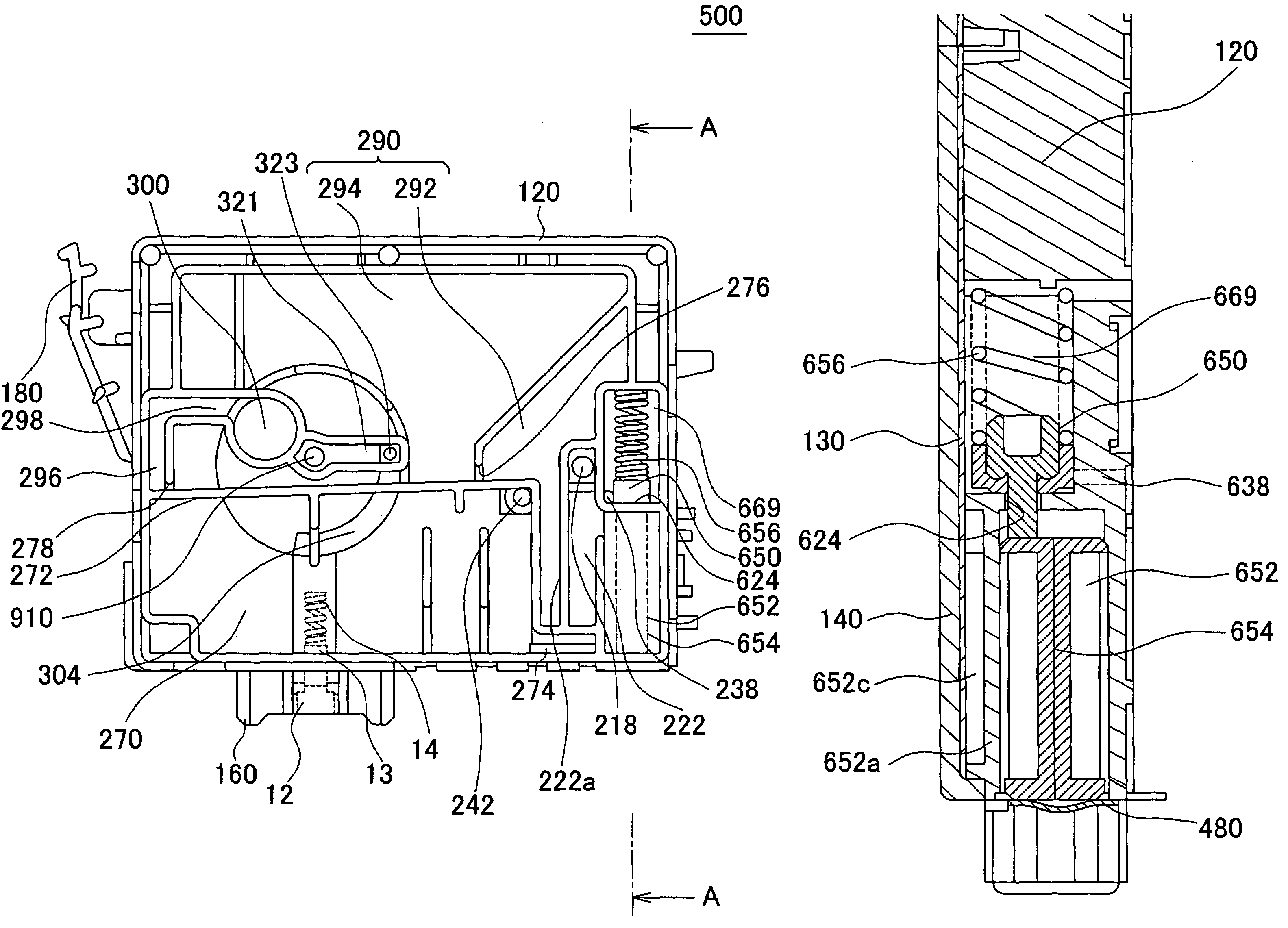

Driving control apparatus and method for linear compressor

ActiveUS20090097987A1Large volumeIncrease the total strokeElectronic commutation motor controlExternal parameterPhase differenceDc current

An apparatus for controlling an operation of a reciprocating compressor, includes: a control unit for detecting a current pushed amount of a piston when a TDC is detected as an inflection point of a phase difference between stroke and current, comparing the current pushed amount with a pushed amount reference value, and applying a DC voltage applied to a linear motor based on the comparison result. An AC voltage and a DC voltage are applied to the linear motor to increase the stroke, and when the TDC is detected, the current pushed amount is calculated and compared with the pushed amount reference value, and then, the DC voltage or a DC current applied to the linear motor is varied based on the comparison result, thereby obtaining a maximum compression volume without collision of the piston.

Owner:LG ELECTRONICS INC

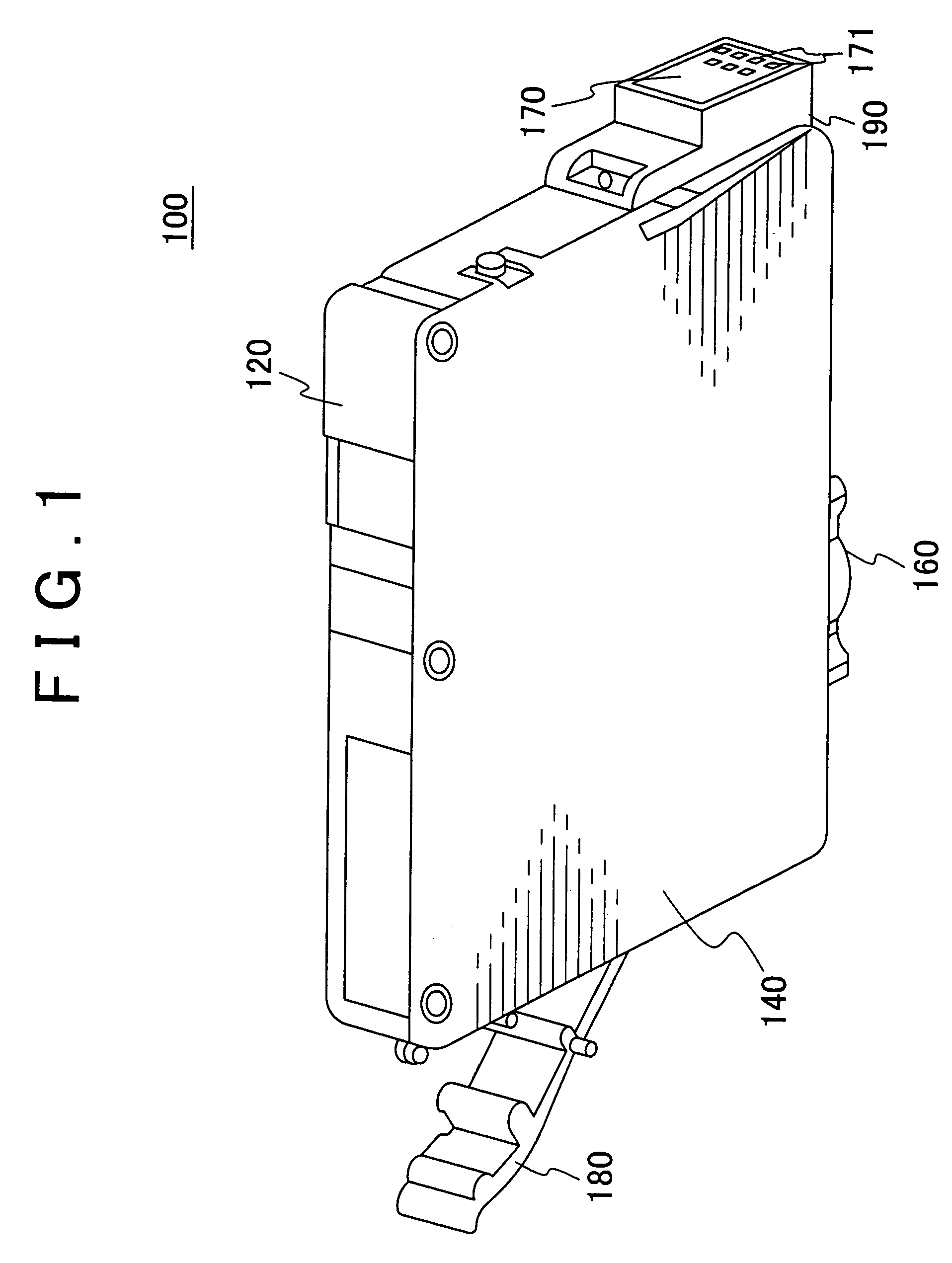

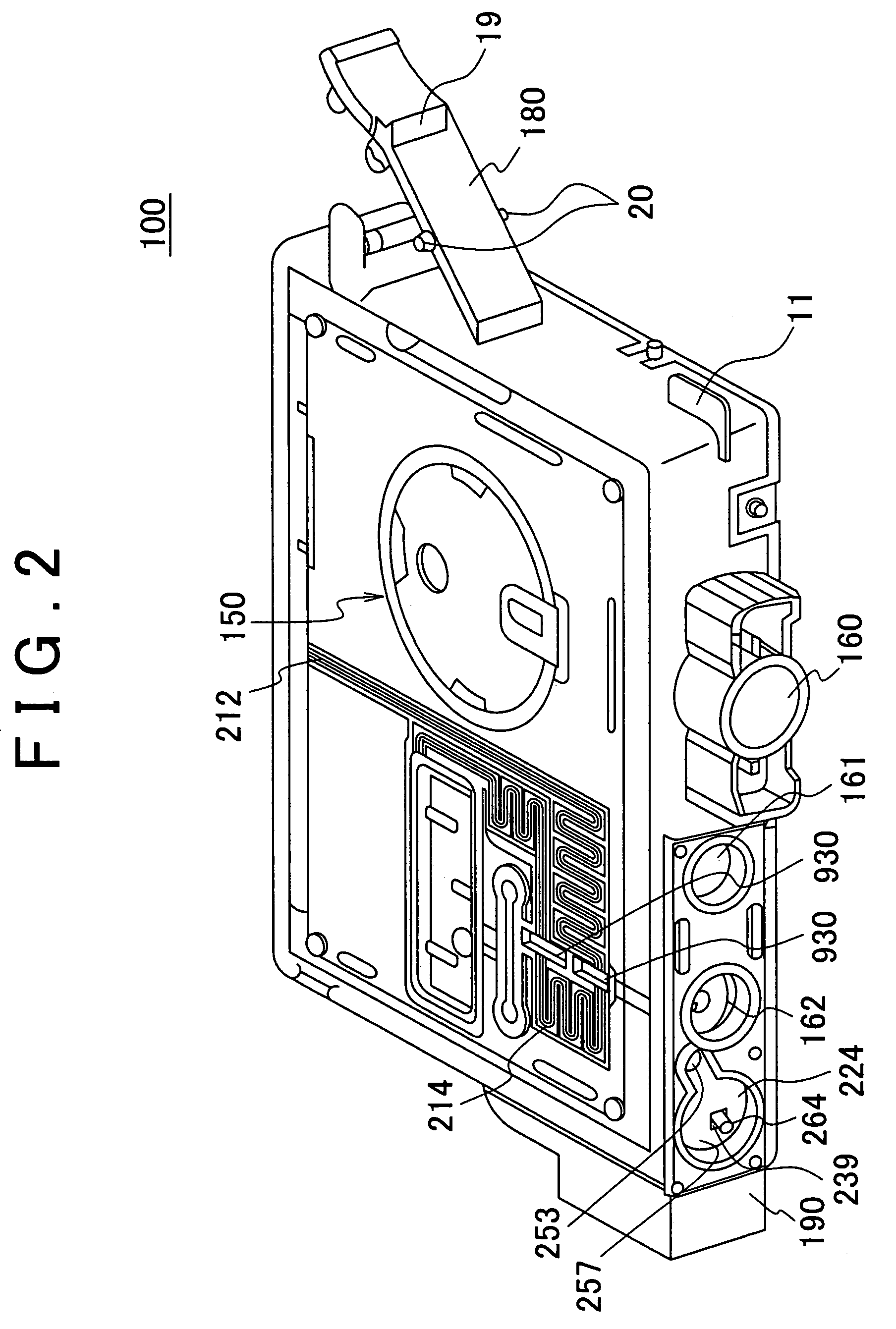

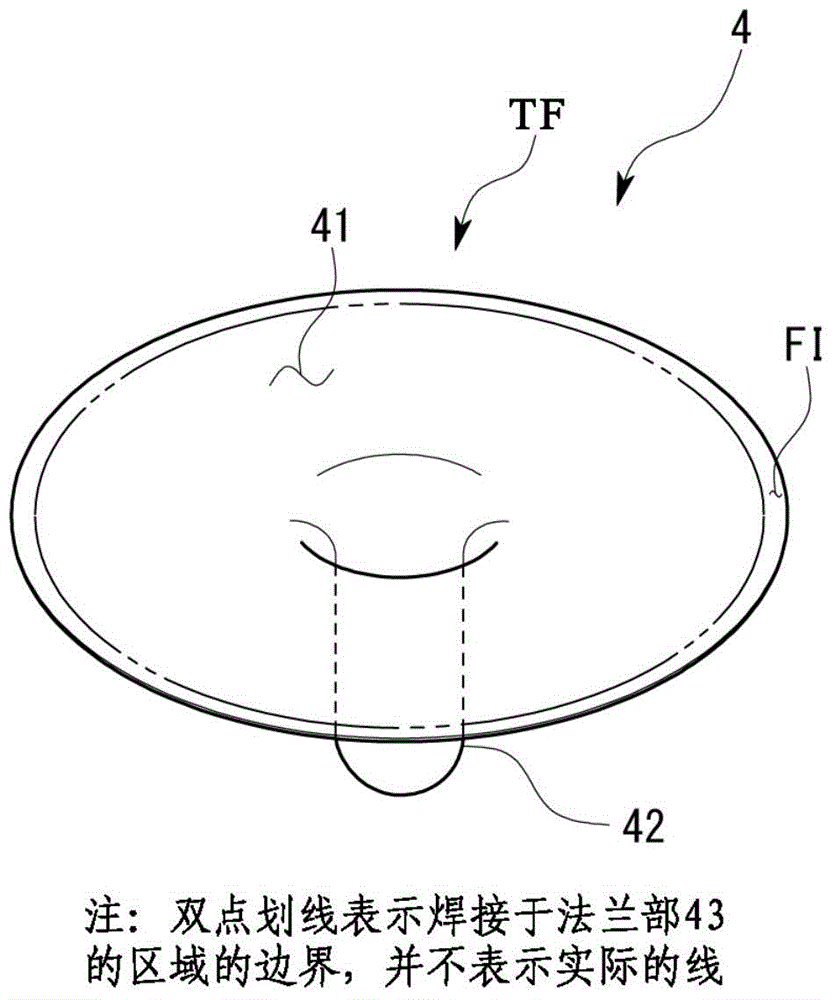

Liquid cartridge

An ink cartridge is provided with an ink accommodating section for containing ink, an ink supplying part for supplying ink contained in the ink accommodating section to an inkjet type recording apparatus by inserting an ink supplying needle provided at a lower part of the inkjet type recording apparatus, and an atmospheric valve, which seals a communicating hole in order that the ink accommodating section and the atmosphere communicate, while opening a communicating hole, which allows the ink accommodating section to communicates with the atmosphere, by moving perpendicular to a direction in which the ink cartridge is inserted into the inkjet type recording apparatus by being pushed up by a contact member.

Owner:SEIKO EPSON CORP

Method of processing waste product into fuel

InactiveUS7455704B2Efficient conversionControlled and adjustable resistanceMilk preparationSolid fuelsWaste streamWaste product

Fuels used may be derived from existing waste streams such as animal wastes and streams of discarded or unwanted animal byproducts generated at animal slaughterhouses. A method of processing organic waste products into fuel includes homogenizing the waste products. The waste products are heated and pressurized. Water is removed from the waste products. Selected constituent of the waste products are separated from the waste products into a waste stream. The waste stream is blended with a fuel to form a bio-fuel mixture.

Owner:STONE MICHAEL

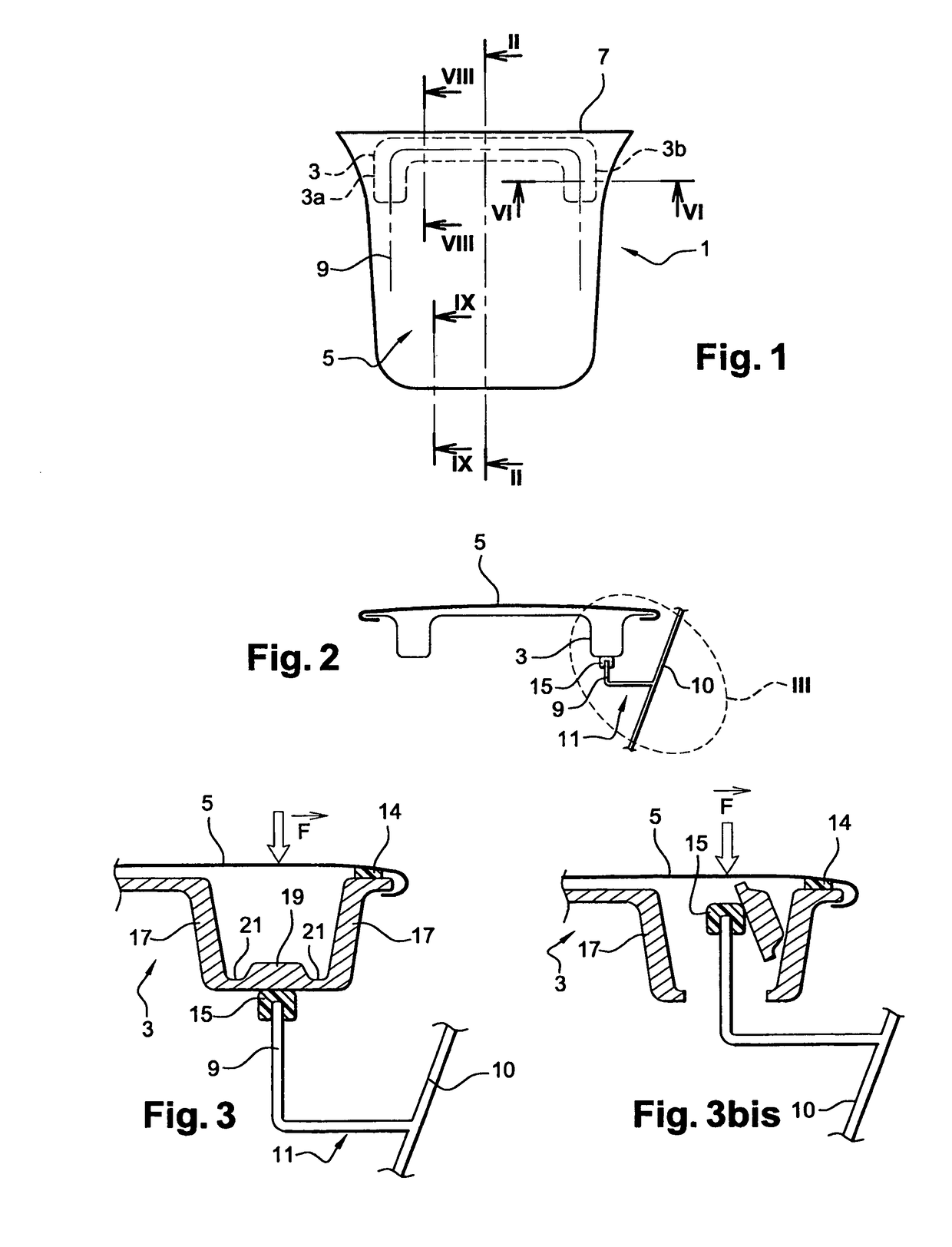

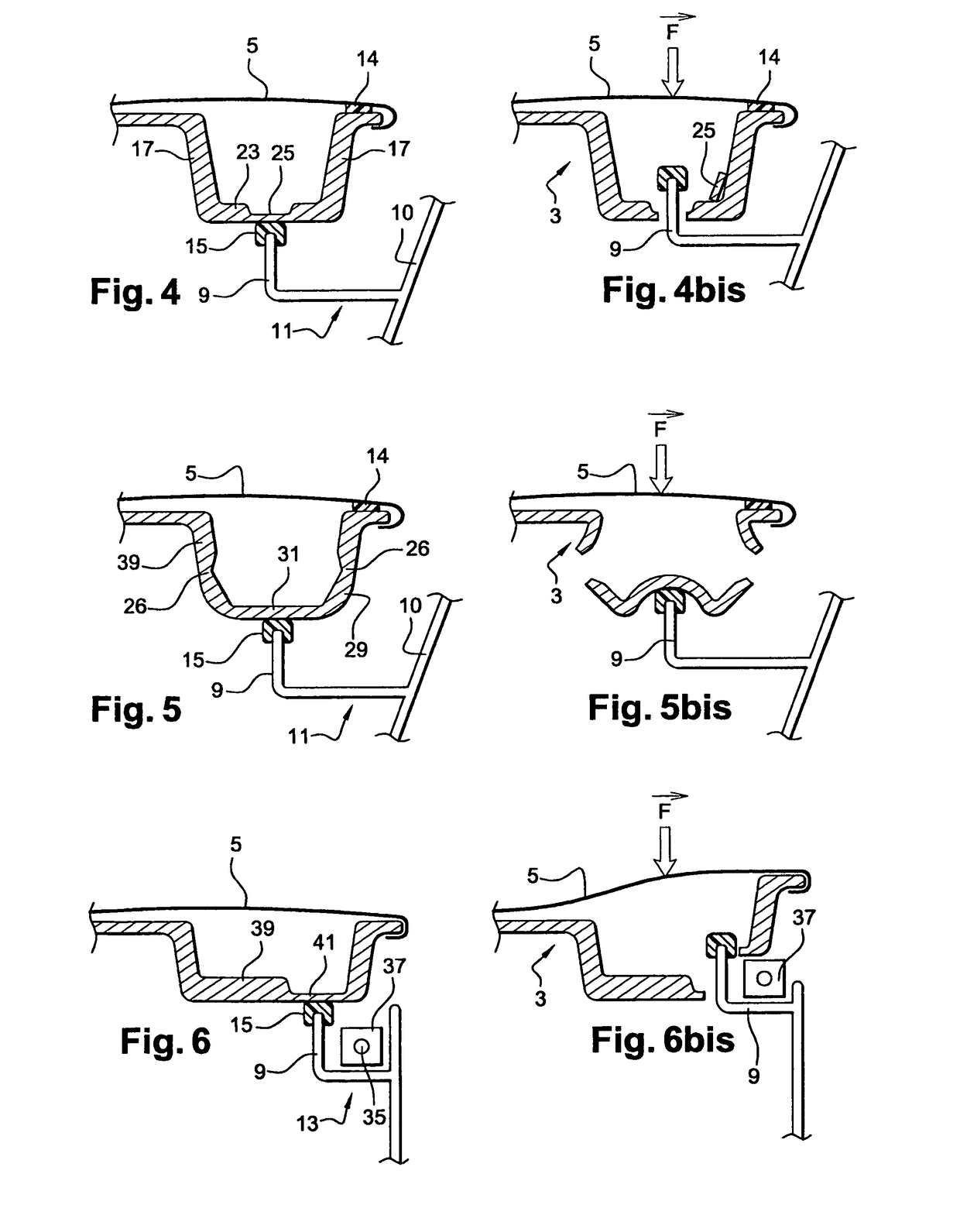

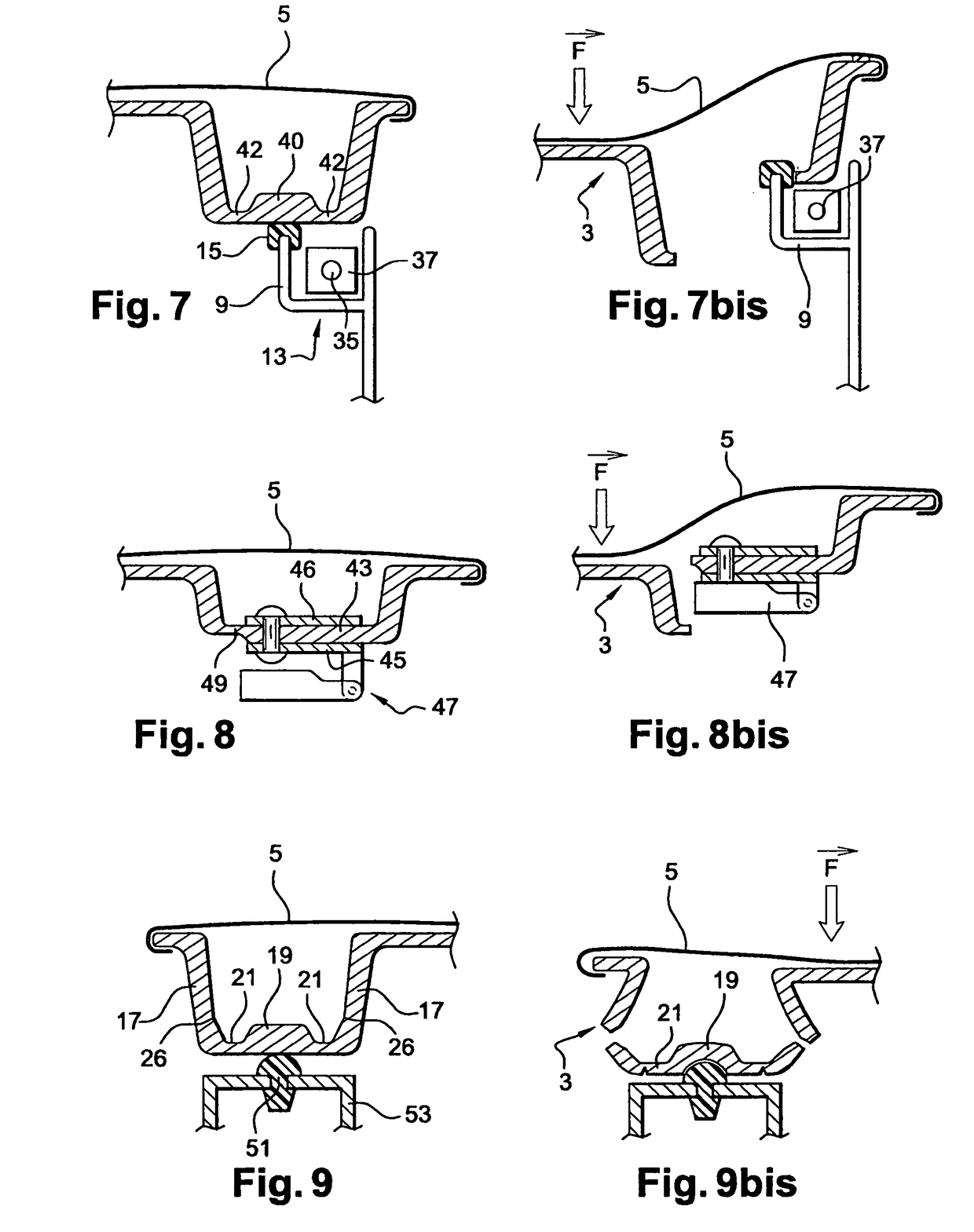

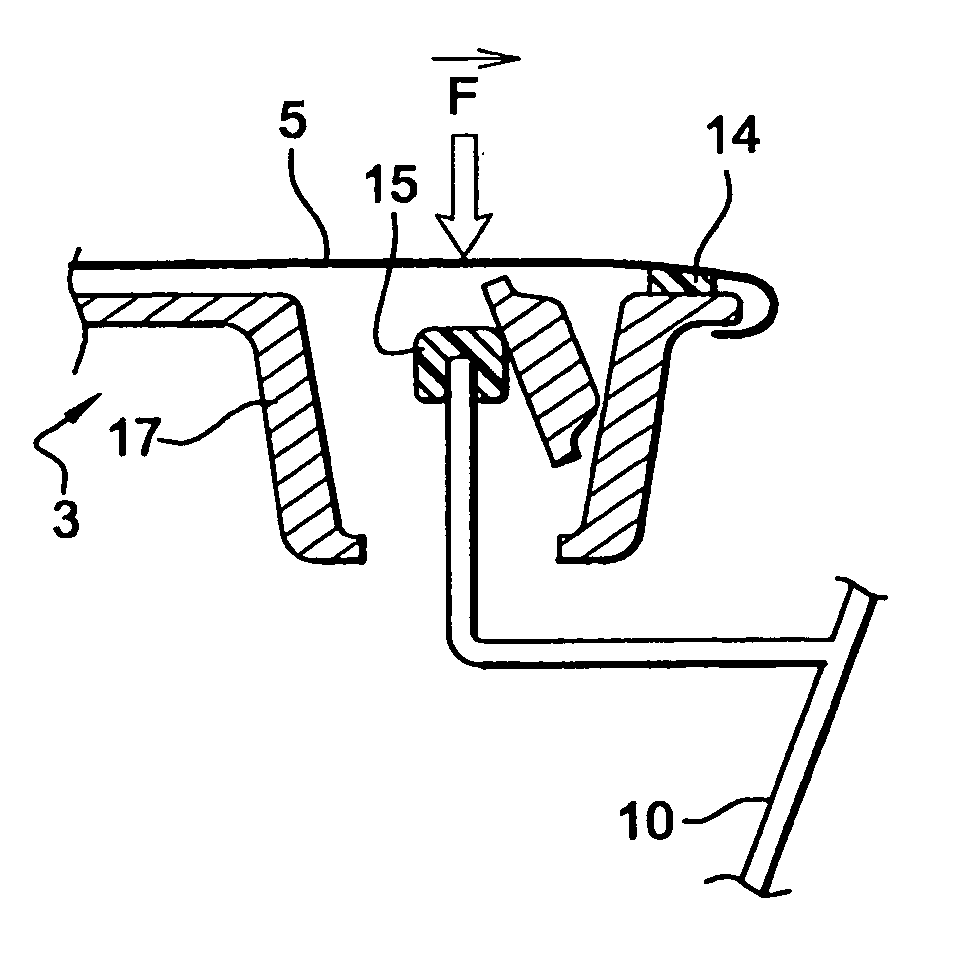

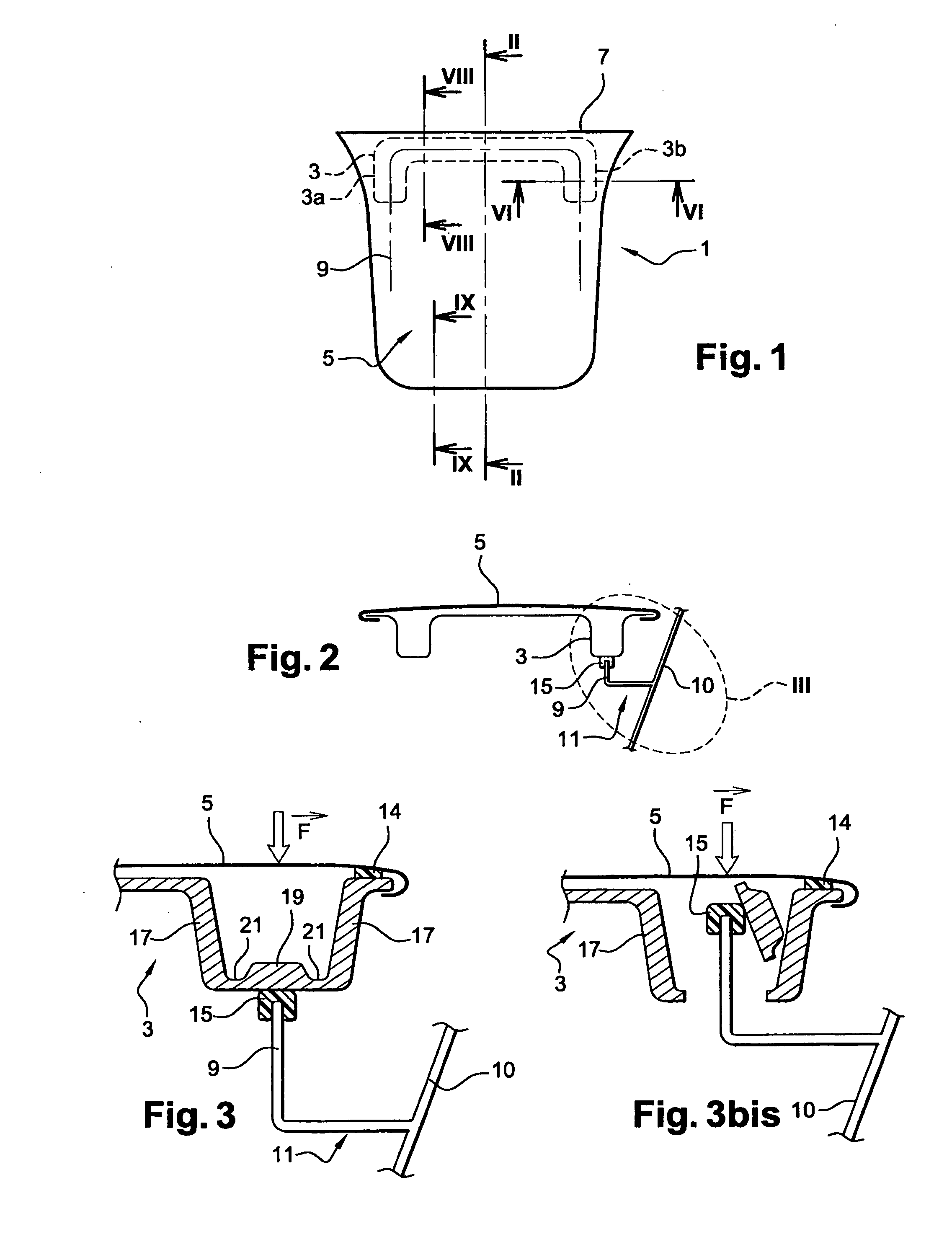

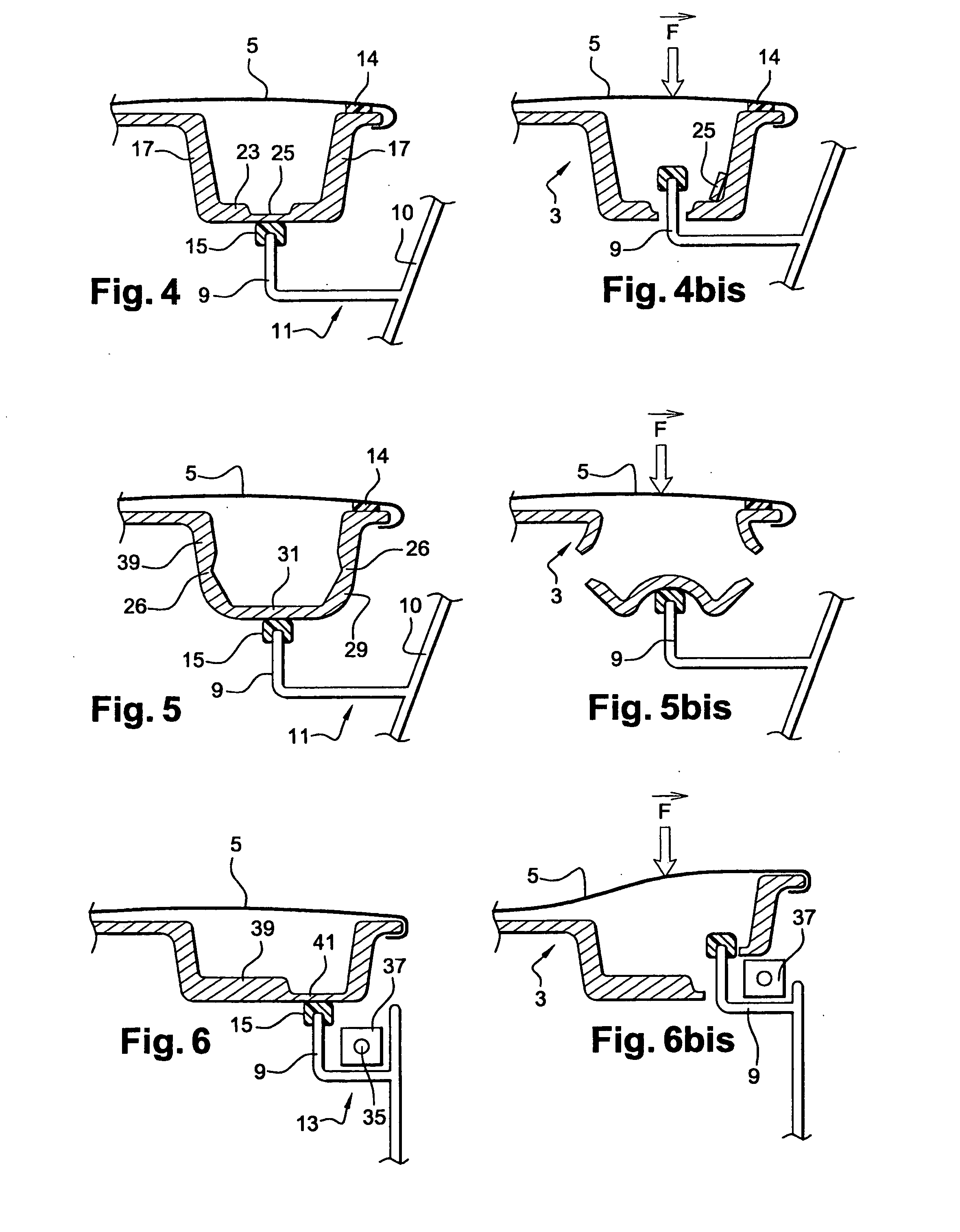

Lining for the hood of an automotive vehicle and combinations thereof with certain parts of the vehicle

InactiveUS8118352B2Handling a pedestrian impact effectivelyEasy to handleVehicle seatsPedestrian/occupant safety arrangementEngineeringWeakness

A motor vehicle hood lining for stiffening the hood in the vicinity of its periphery and co-operating therewith to form a hollow body over at least a fraction of its periphery, the lining being generally of channel section with a bottom and side walls. Said bottom or at least one of said side walls presents, at least locally, a zone of weakness that is dimensioned in such a manner that in the event of the hood impacting the head of a pedestrian, once the bottom of the hollow body has come to bear against a high hard point placed in the engine compartment, the zone of weakness breaks. The invention also relates to a combination of such a lining with various hard points in an engine compartment.

Owner:CO PLASTIC OMNIUM

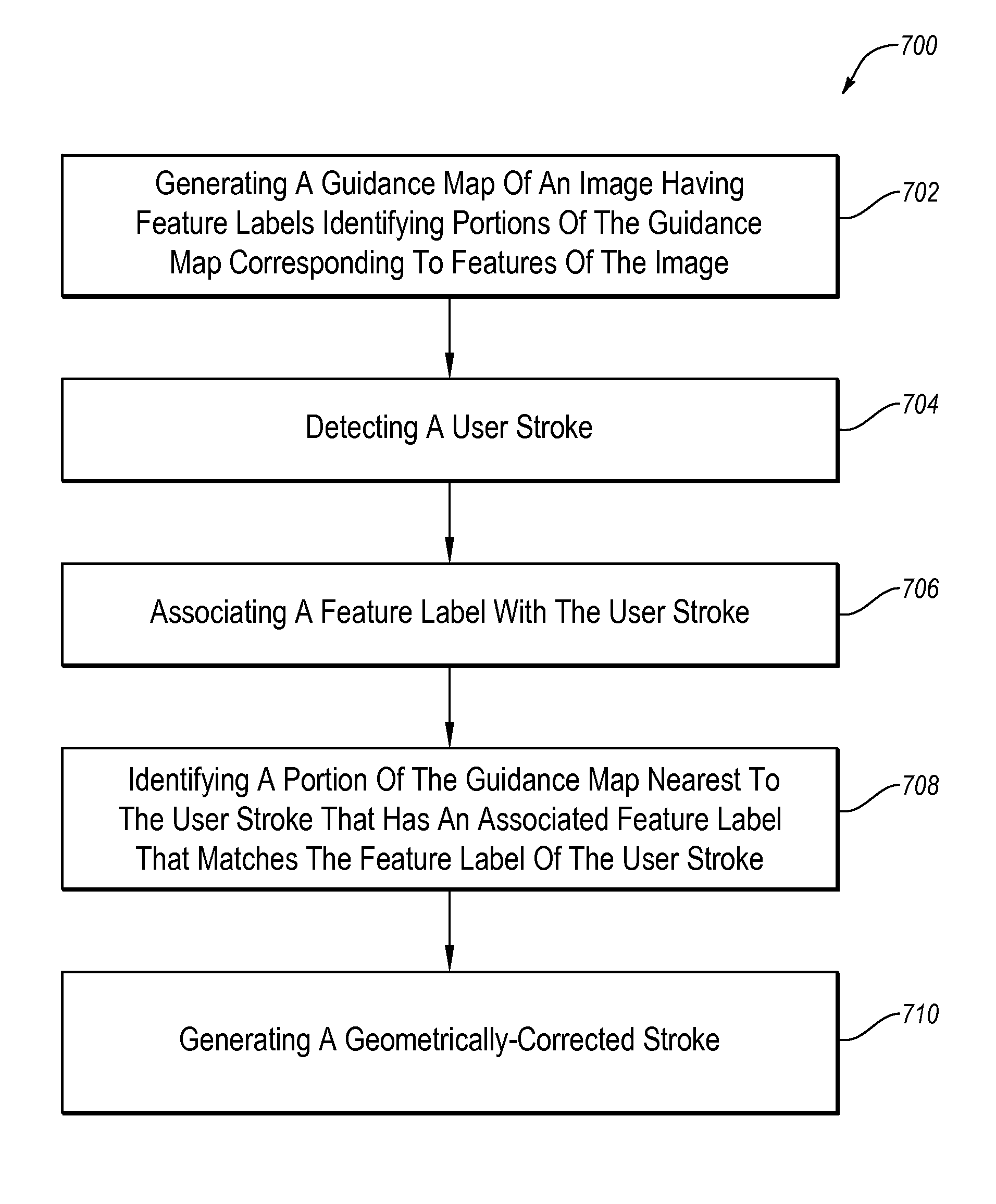

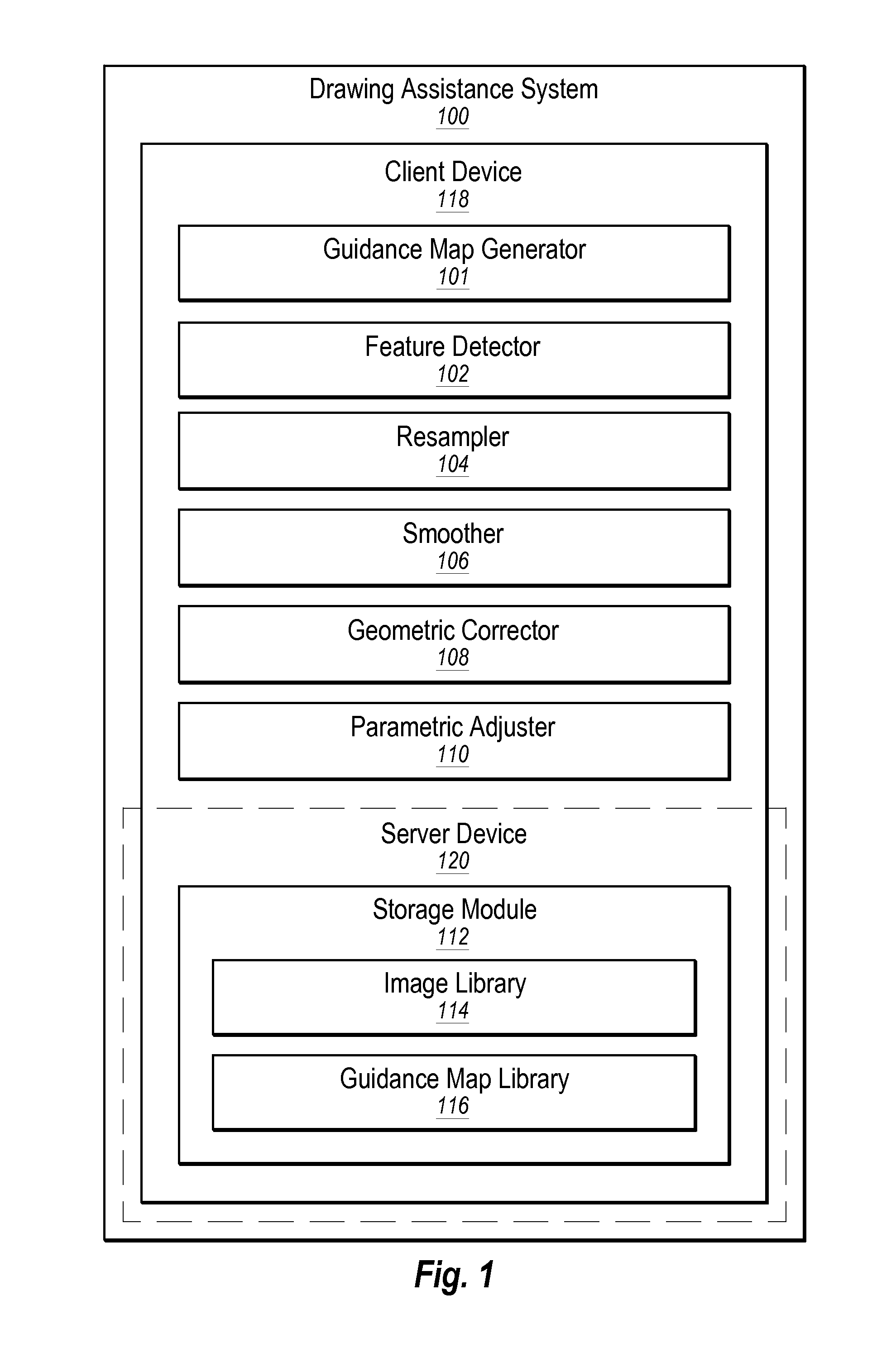

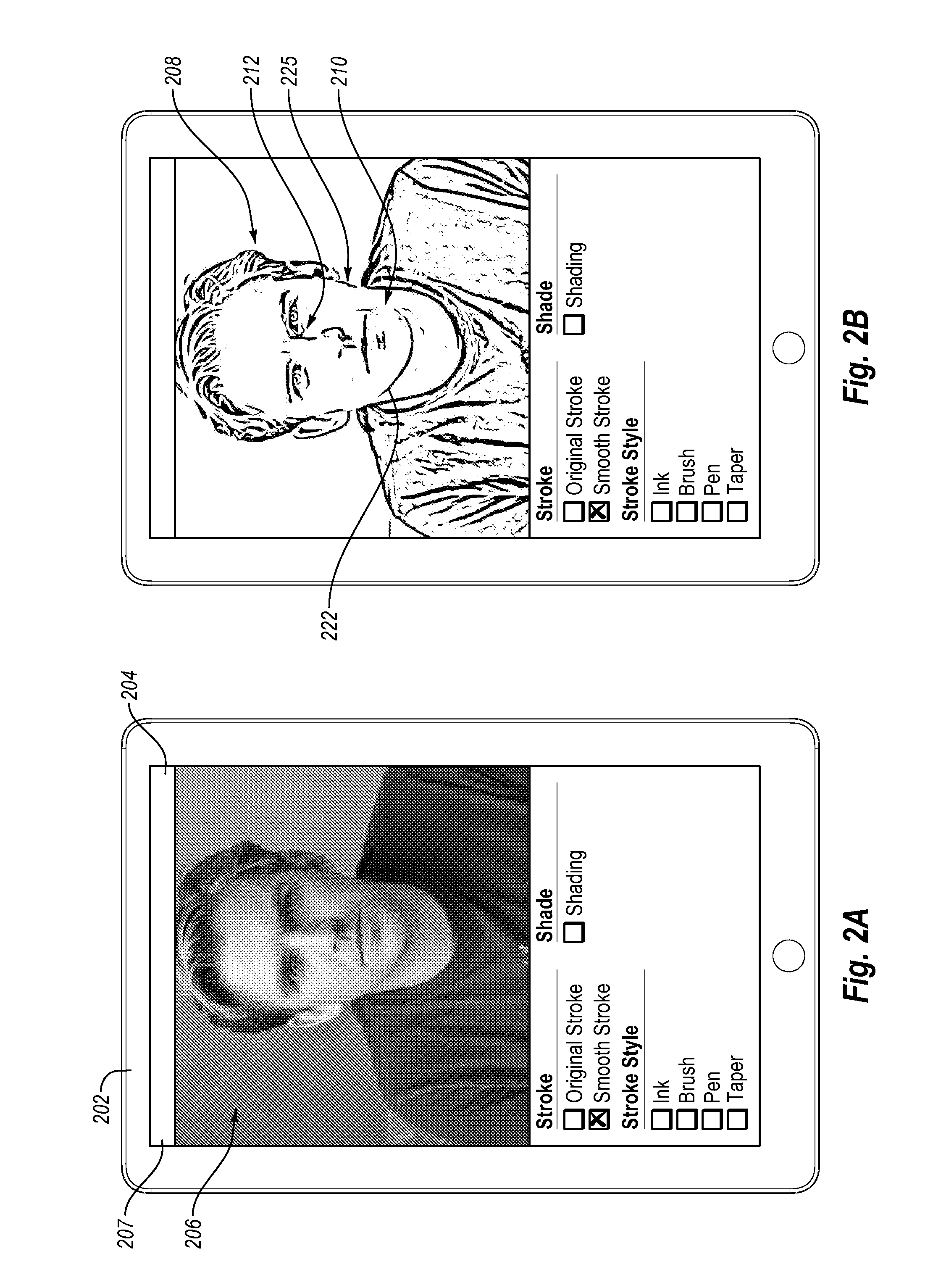

Providing drawing assistance using feature detection and semantic labeling

ActiveUS20150221070A1Increase the total strokeAccurate placementImage enhancementDrawing from basic elementsComputer scienceFeature detection

Methods for providing drawing assistance to a user sketching an image include geometrically correcting adjusting user strokes to improve their placement and appearance. In particular, one or more guidance maps indicate where the user “should” draw lines. As a user draws a stroke, the stroke is geometrically corrected by moving the stroke toward a portion of the guidance maps corresponding to the feature of the image the user is intending to draw based feature labels. To further improve the user drawn lines, parametric adjustments are optionally made to the geometrically-corrected stroke to emphasize “correctly” drawn lines and de-emphasize “incorrectly” drawn lines.

Owner:ADOBE INC

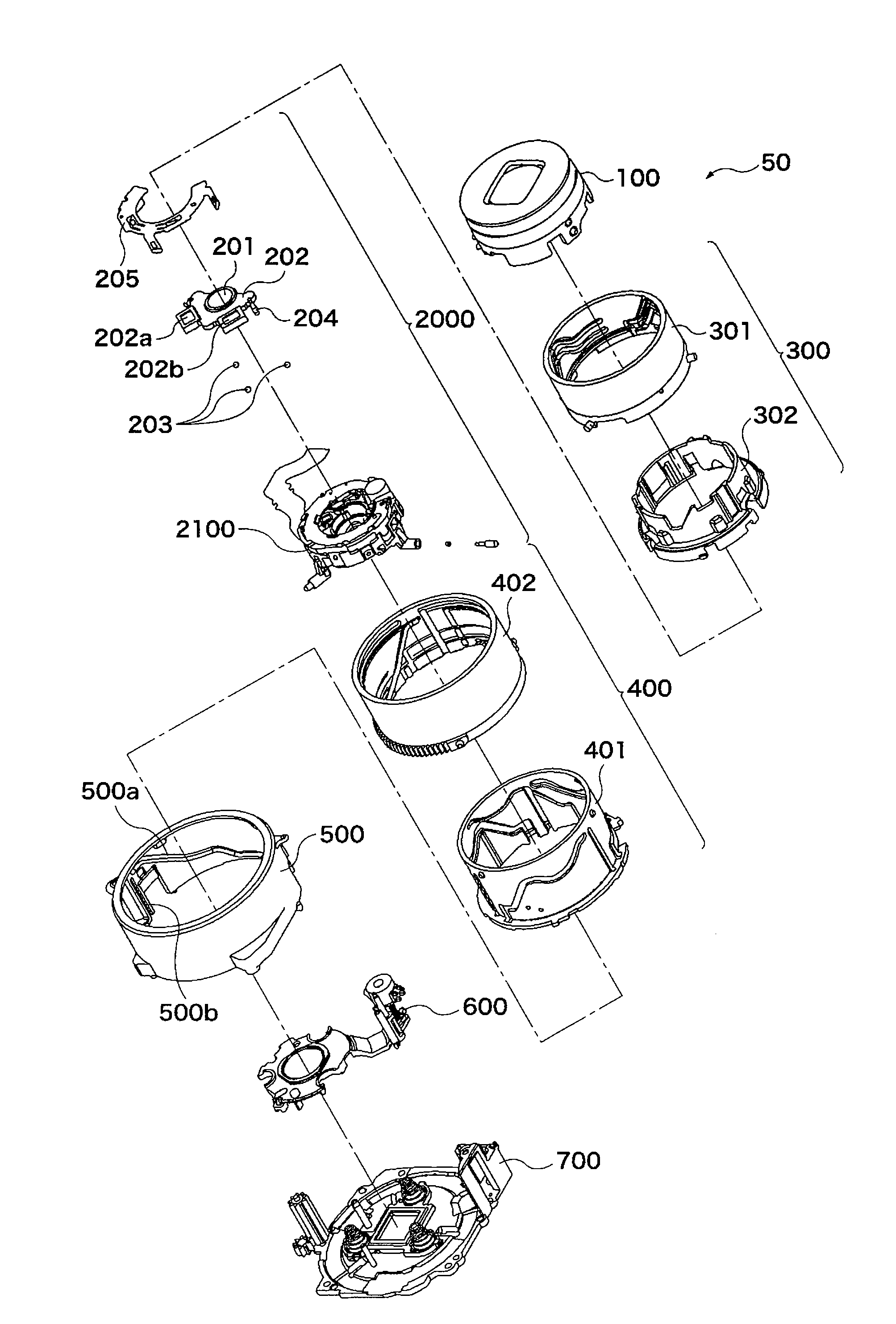

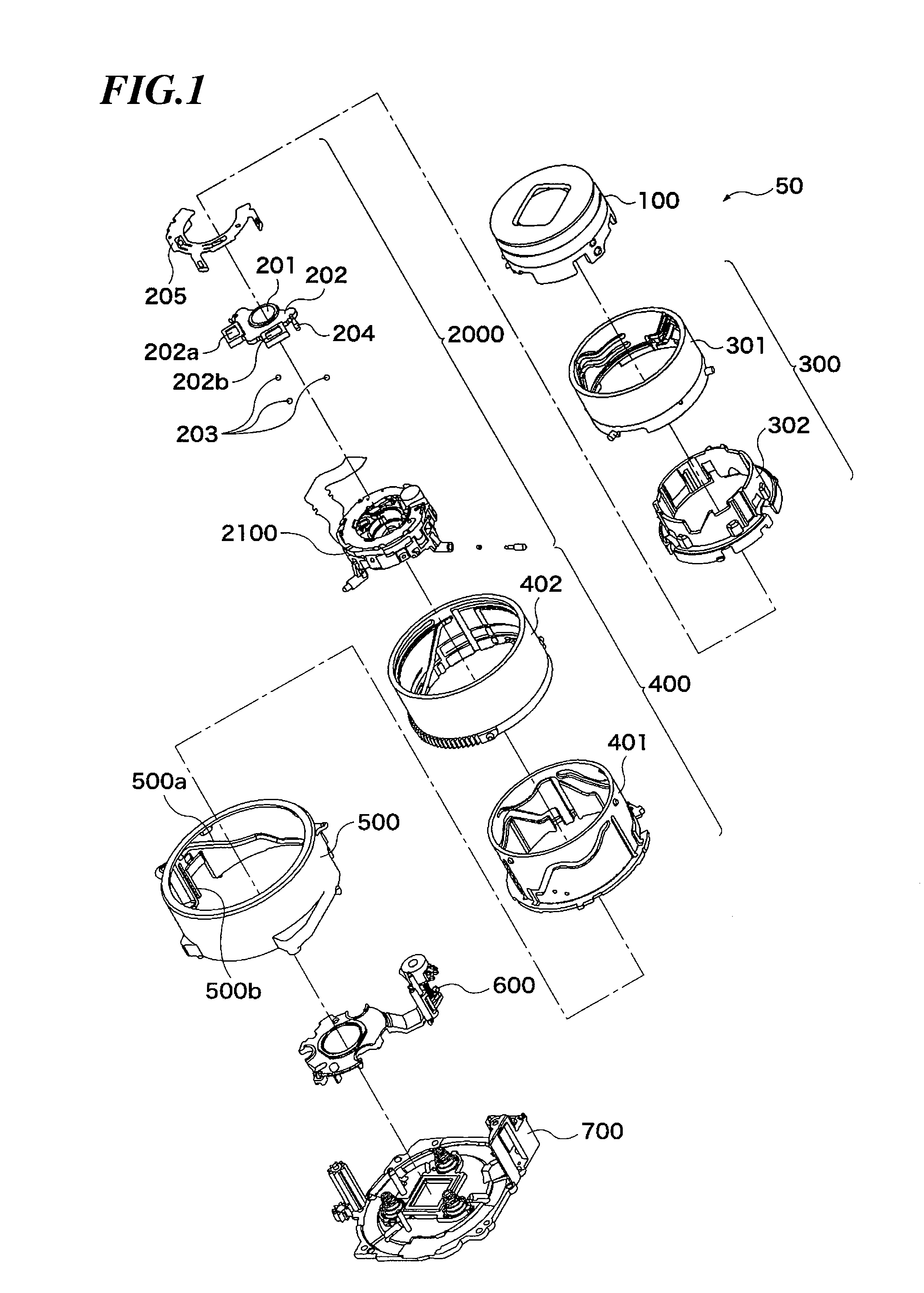

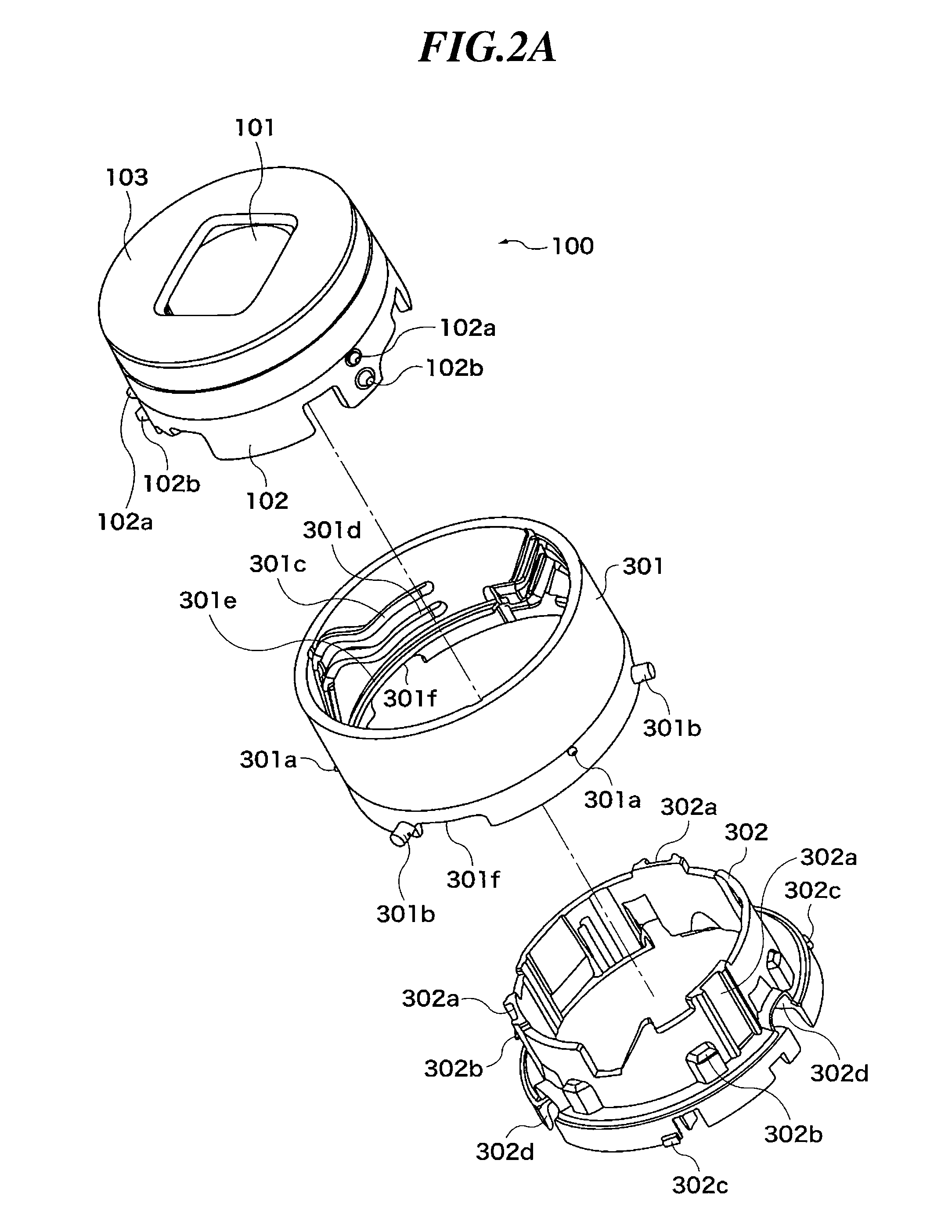

Zoom lens barrel that attains a higher photographing magnification

A zoom lens barrel capable of attaining a higher photographing magnification by reducing spacing between lens groups in a telephoto state. A first lens group barrel holds a first lens group. A second lens group holding member supported by a third cam barrel holds a second lens group. A spring member urges the holding member toward the first lens group. Cam followers are formed at an opposite end of the holding member from the first lens group. Cam grooves for engagement with the cam followers are formed on the third cam barrel. When the holding member is urged by the spring member in a non-shooting region, each cam groove is brought into contact via one cam surface with the associated cam follower. In a shooting region, the cam groove is brought into contact with the cam follower via two cam surfaces.

Owner:CANON KK

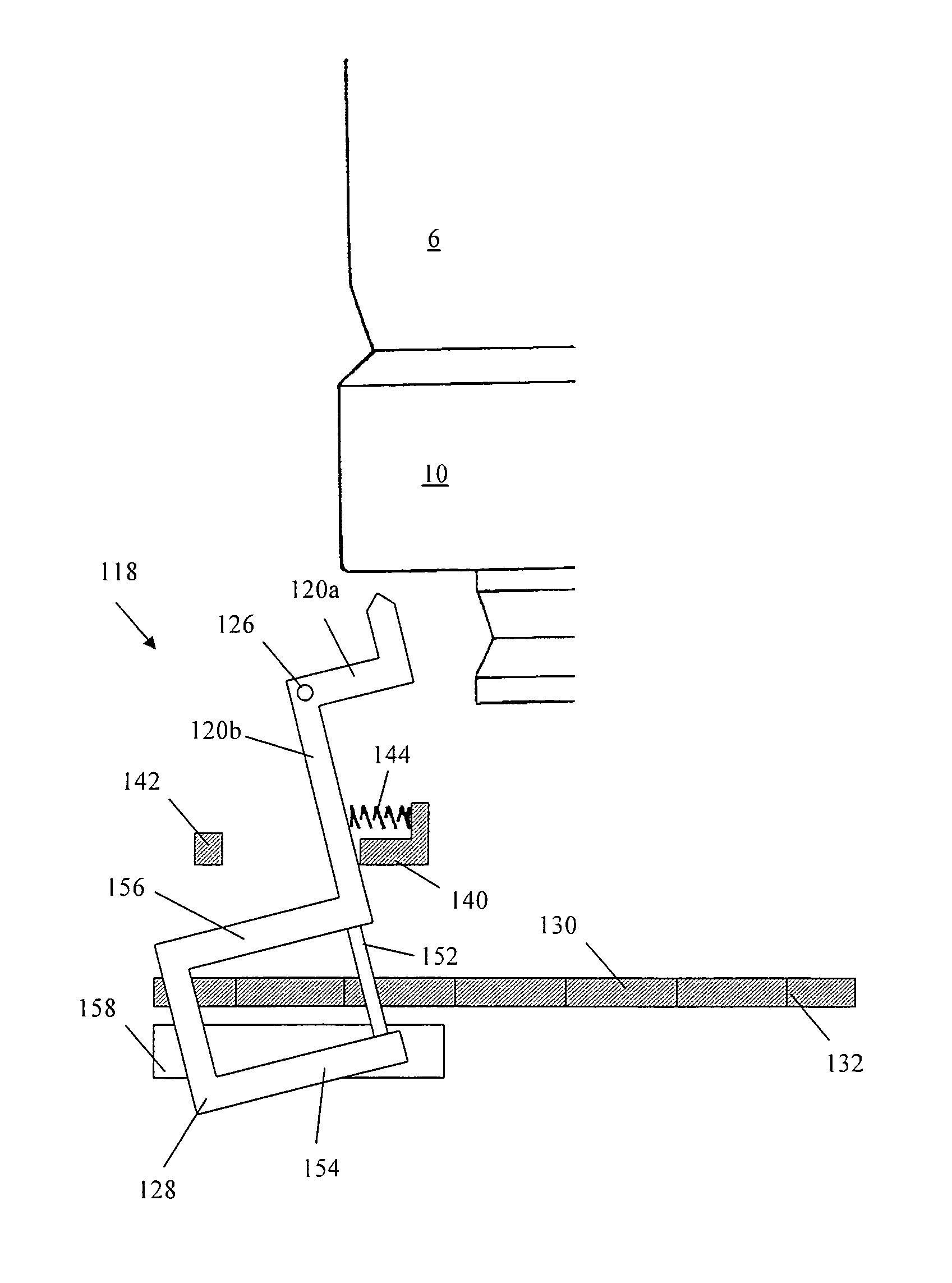

Dose counter for a metered-dose inhaler

ActiveUS8662381B2Increase the total strokeMinimising component wearRespiratorsMedical devicesGear wheelDisplay device

A dose counter for counting doses of medicament dispensed by or remaining in a metered-dose inhaler. The dose counter includes: a rotatably mounted gear wheel having a circular arrangement of ratchet teeth; a display coupled to the gear wheel, the display having a visible array of dose counting indicia indexable in response to rotary motion of the gear wheel; and an actuator mechanism having a driver for rotatably driving the gear wheel in response to the dispensation of a medicament dose, the driver being arranged to engage the ratchet teeth of the gear wheel. The actuator mechanism includes a pivotally mounted lever having an input portion. The lever is arranged to amplify a linear stroke at the input portion such that a linear stroke of the driver exceeds the linear input stroke. By amplifying the stroke, the risk of undercounting due to insufficient stroke length may be reduced.

Owner:IVAX INT BV

Lining for the hood of an automotive vehicle and combinations thereof with certain parts of the vehicle

InactiveUS20100045070A1Avoid flatteningEasy to makeVehicle seatsPedestrian/occupant safety arrangementMobile vehicleEngineering

A motor vehicle hood lining for stiffening the hood in the vicinity of its periphery and co-operating therewith to form a hollow body over at least a fraction of its periphery, the lining being generally of channel section with a bottom and side walls. Said bottom or at least one of said side walls presents, at least locally, a zone of weakness that is dimensioned in such a manner that in the event of the hood impacting the head of a pedestrian, once the bottom of the hollow body has come to bear against a high hard point placed in the engine compartment, the zone of weakness breaks. The invention also relates to a combination of such a lining with various hard points in an engine compartment.

Owner:CO PLASTIC OMNIUM

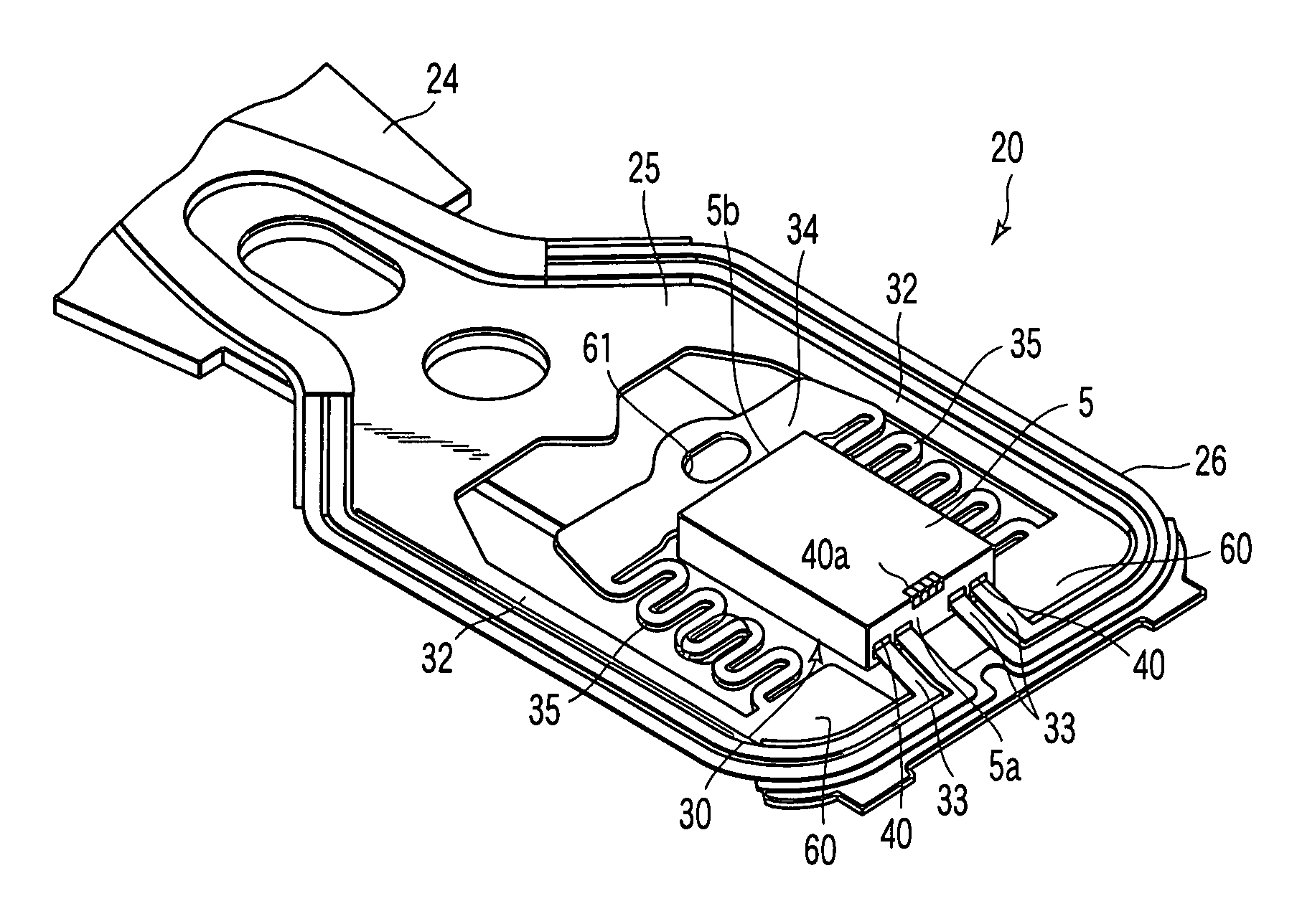

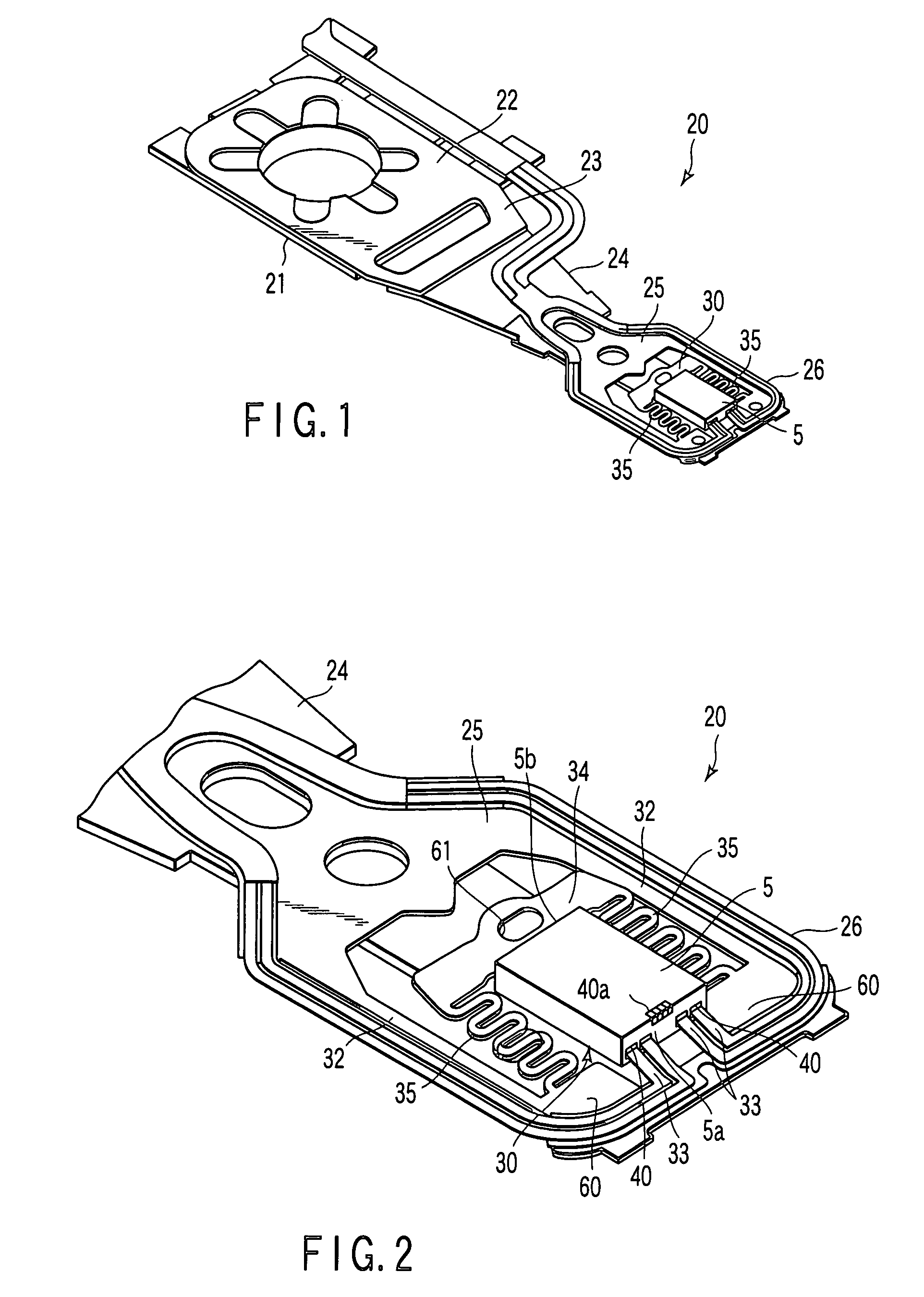

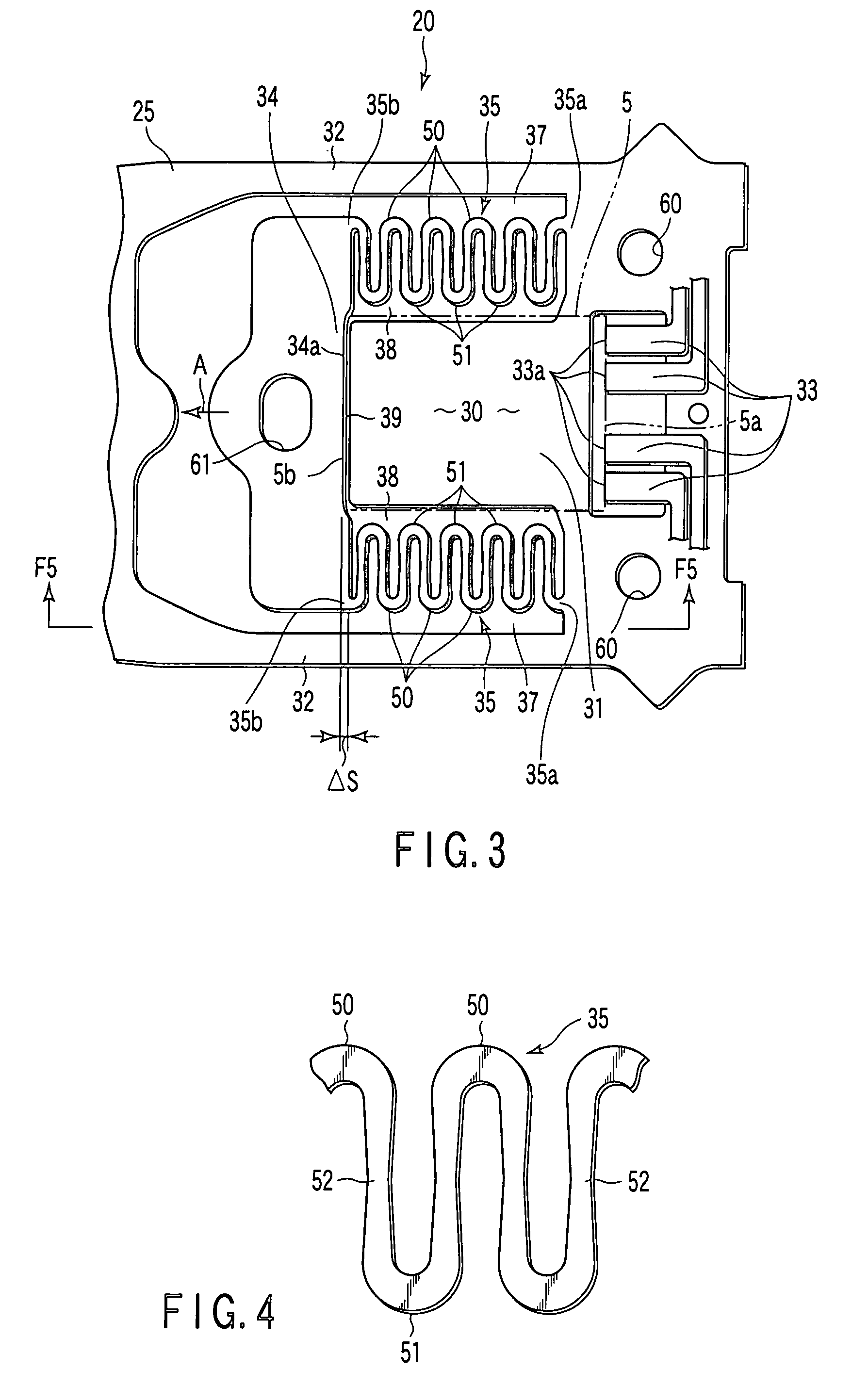

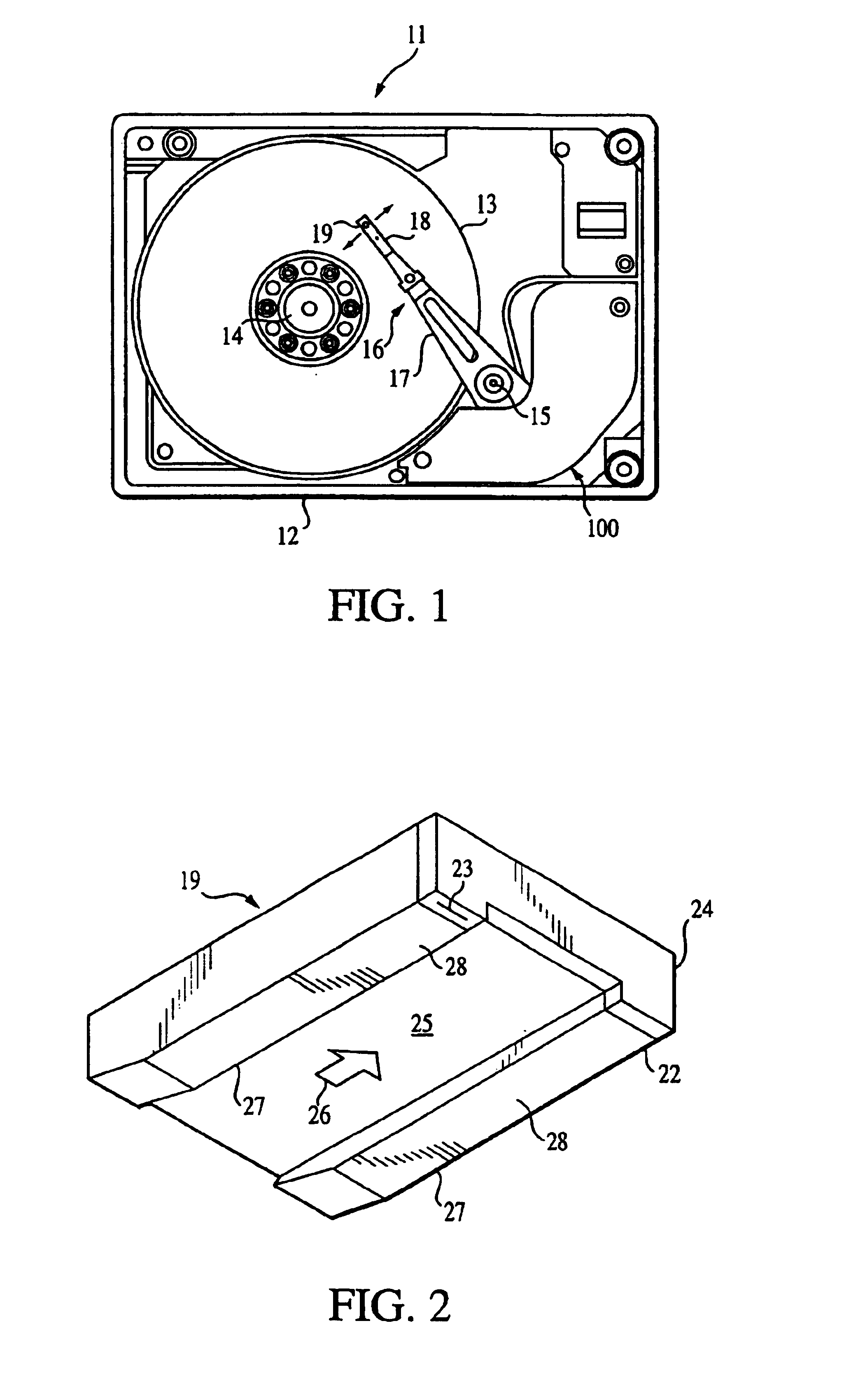

Slider supporting apparatus including a flexure having spring characteristics and manufacturing method therefor

ActiveUS7889460B2Increase the total strokeLong extension strokeRecord information storageMounting/attachment of transducer headEngineeringMechanical engineering

A slider supporting apparatus is provided with a flexure formed of a metal plate having spring characteristics. The flexure comprises a gimbals portion including a tongue, a first support portion which supports one longitudinal end of a slider, a second support portion which supports the other end of the slider, and a spring portion composed of a pair of flat springs. Convexes and concaves of each flat spring are alternately formed along a surface direction of the flexure by etching. The flat springs extend to a length which allows the slider to be inserted between the support portions when subjected to a tensile load, and contract to a length such that the slider can be held between the support portions when subjected to no tensile load.

Owner:NHK SPRING CO LTD

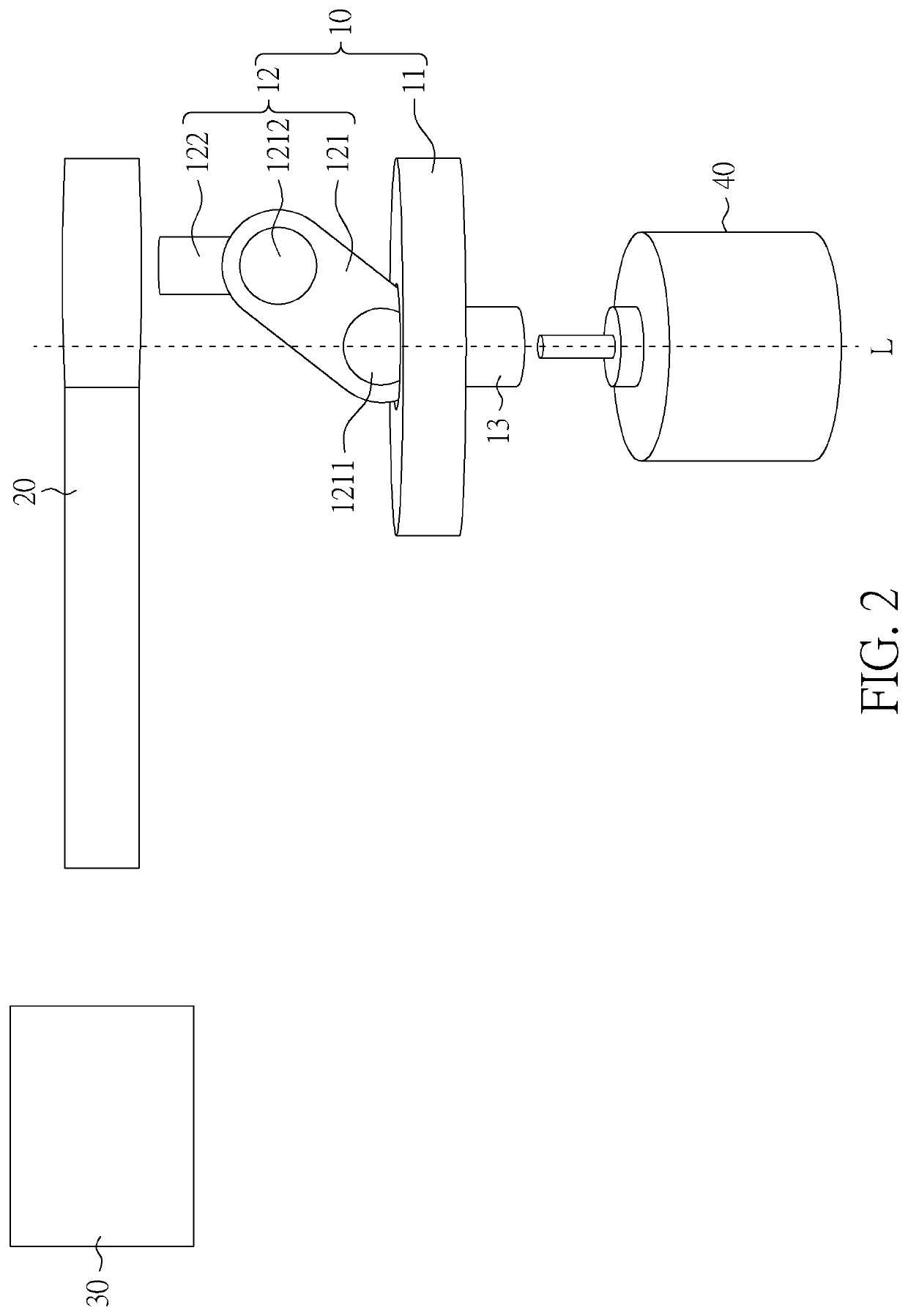

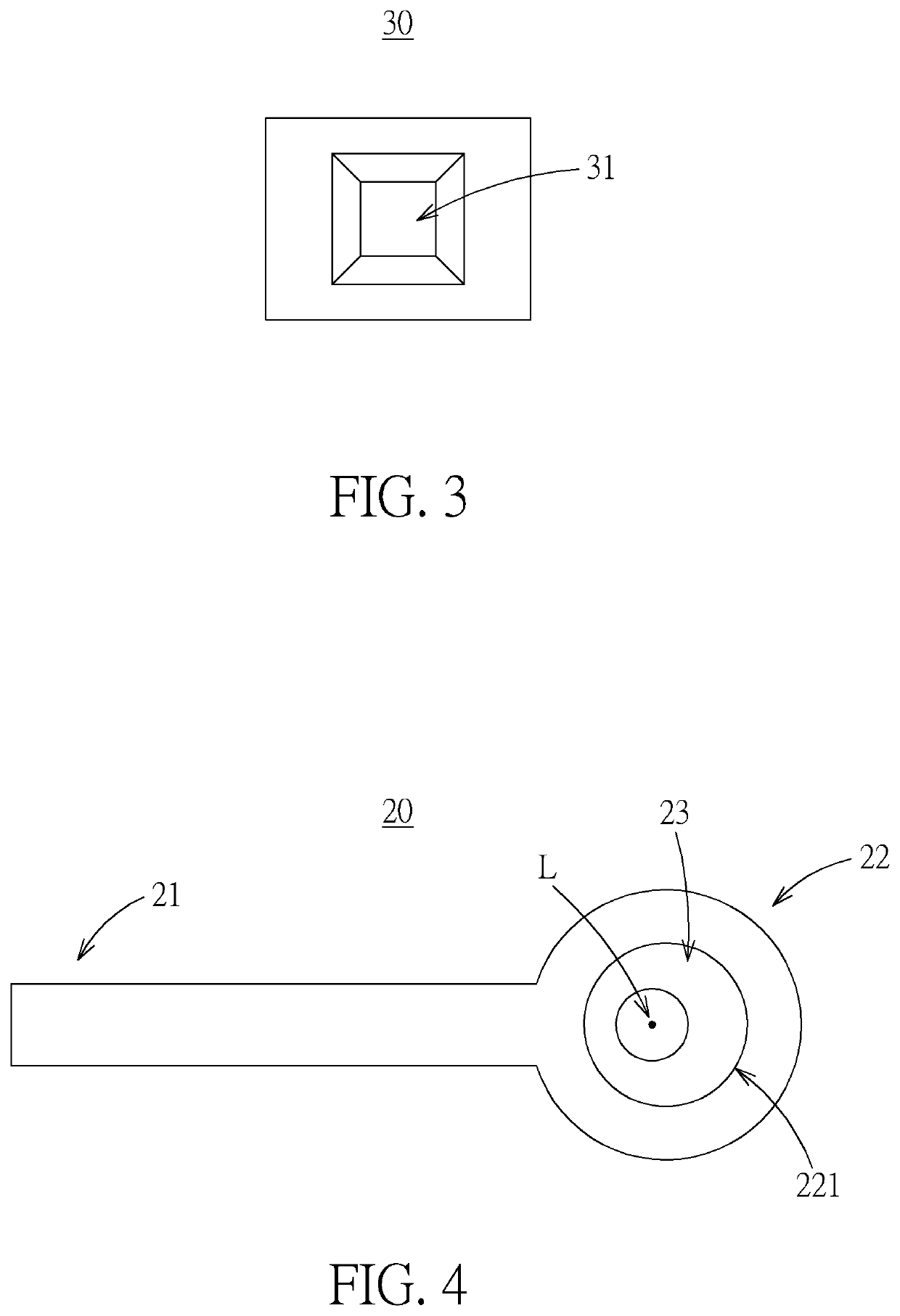

Linear driving mechanism with variable stroke varied by a slanted moving shaft

InactiveUS20200393026A1Simple structureReduce distanceMetal sawing devicesGearingDrive by wireControl theory

The linear driving mechanism includes a main body, a linear moving component, a guiding component and a driving component. The main body includes a seat and a moving shaft. The driving component is connected to a rotating shaft of the seat. The moving shaft passes through a driving slot formed on the linear moving component. The guiding component is for guiding a linear movement of the linear moving component. A stroke of the linear moving component of the linear driving mechanism can be changed by approaching or distancing the linear moving component and the seat of the main body to increase or decrease the displacement of the moving shaft located inside the driving slot. Therefore, the linear driving mechanism has not only simple structure but also flexibility in use.

Owner:CHOK DEE TRADING CO LTD

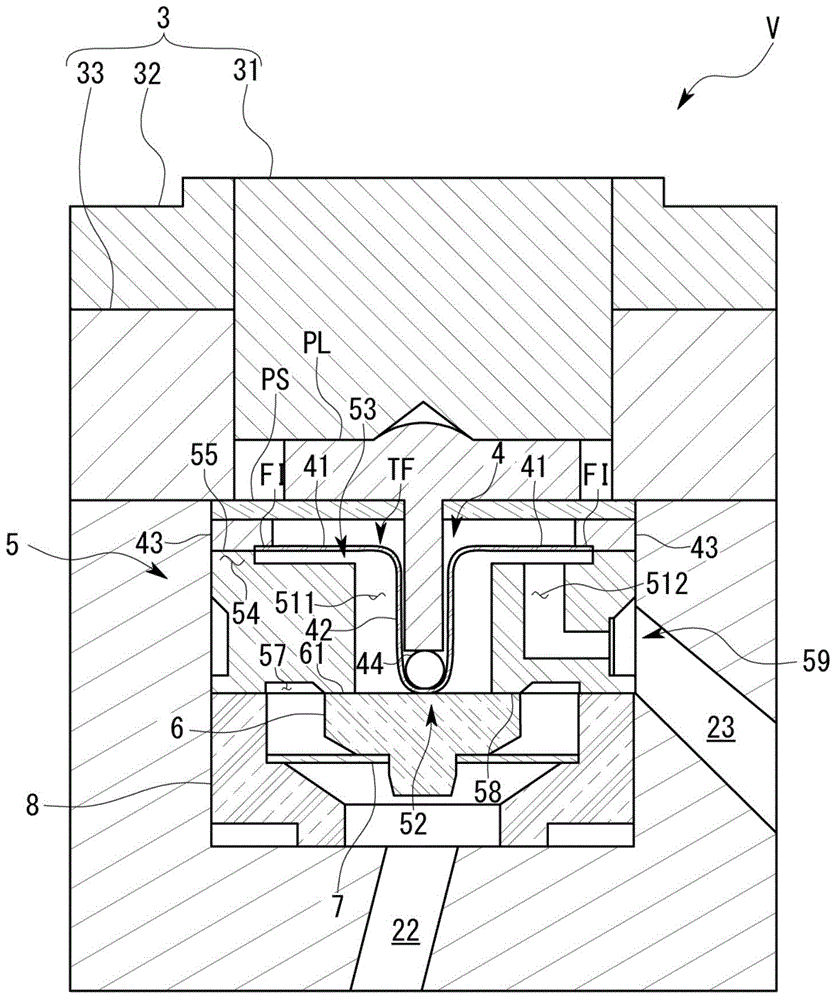

Fluid control valve

ActiveCN104075006AIncrease the total strokeSpindle sealingsDiaphragm valvesFluid controlDiaphragm structure

In order to make it possible to increase a diameter and output thereof, a diaphragm structure is provided that has low repulsiveness, can be largely deformed to increase a stroke even without being applied with a large force from an actuator, and is unlikely to give rise to a defect or fault even when formed thin, and a fluid control valve is provided with the diaphragm structure and the actuator that presses the diaphragm structure, wherein the diaphragm structure is provided with: a protruding part that is formed in a tubular shape and pressed by the actuator; a brim part that spreads from a base end of the protruding part outward with respect to the protruding part; and a support part that is formed on an outer circumference of the brim part and attached to another member, and the brim part is formed in a film shape.

Owner:HORIBA STEC CO LTD

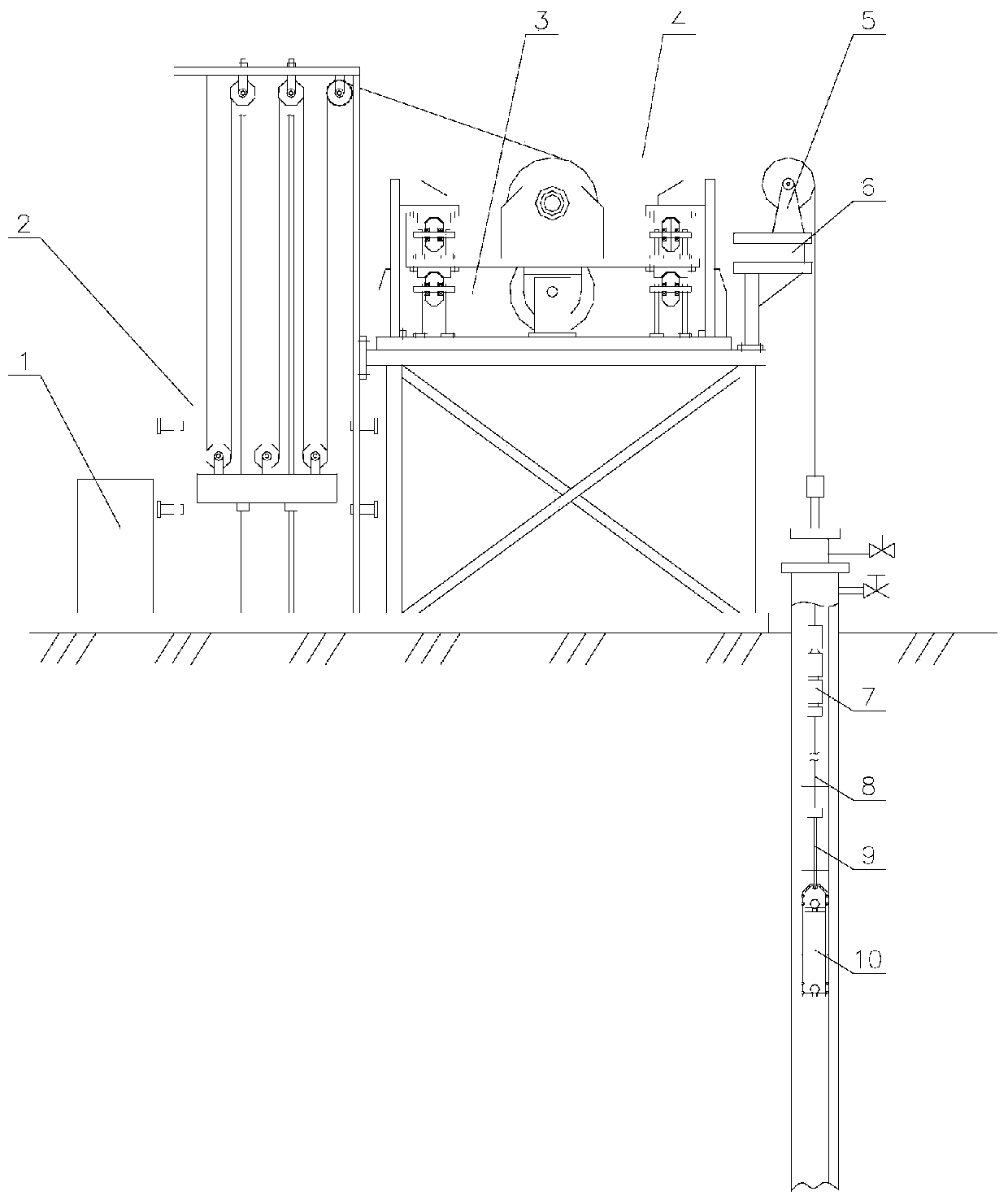

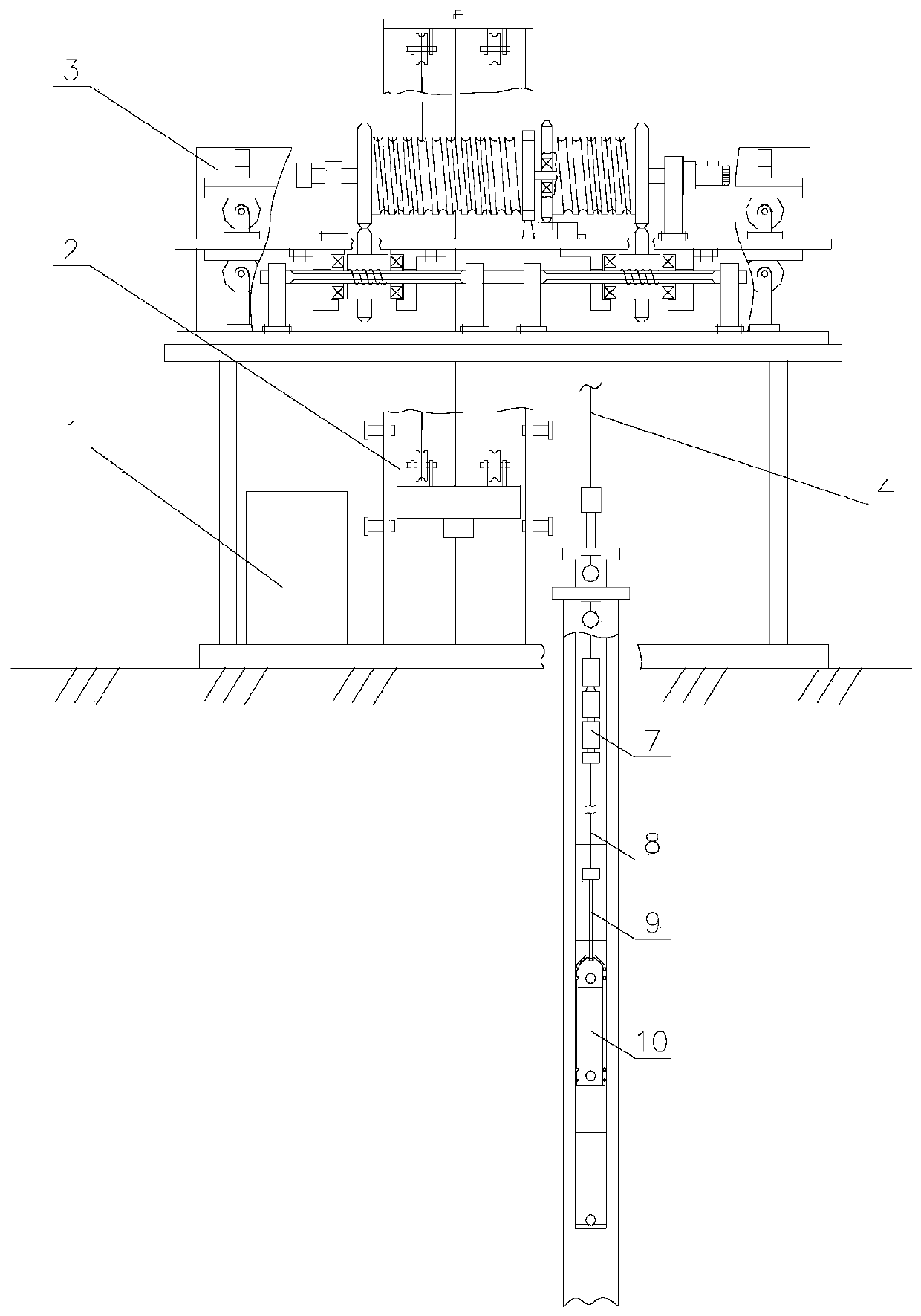

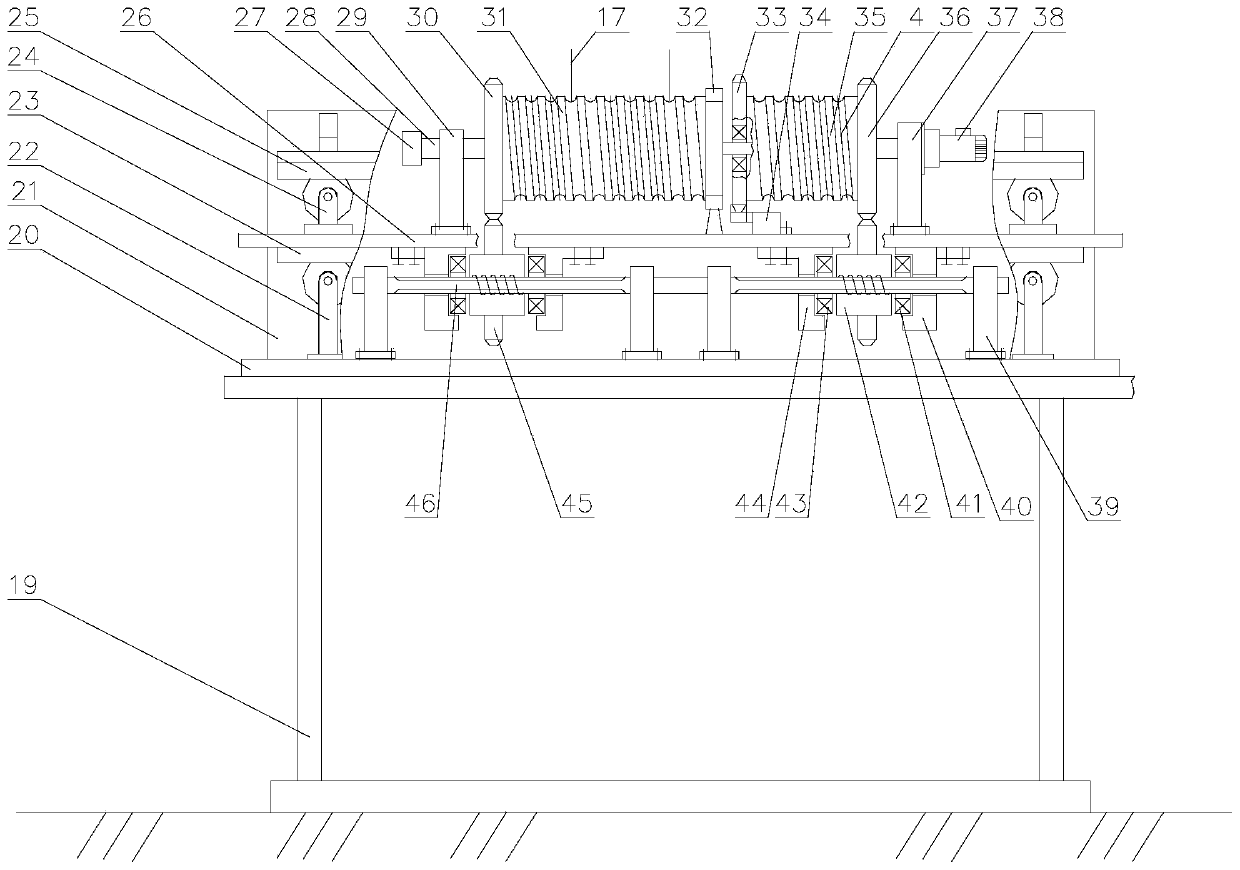

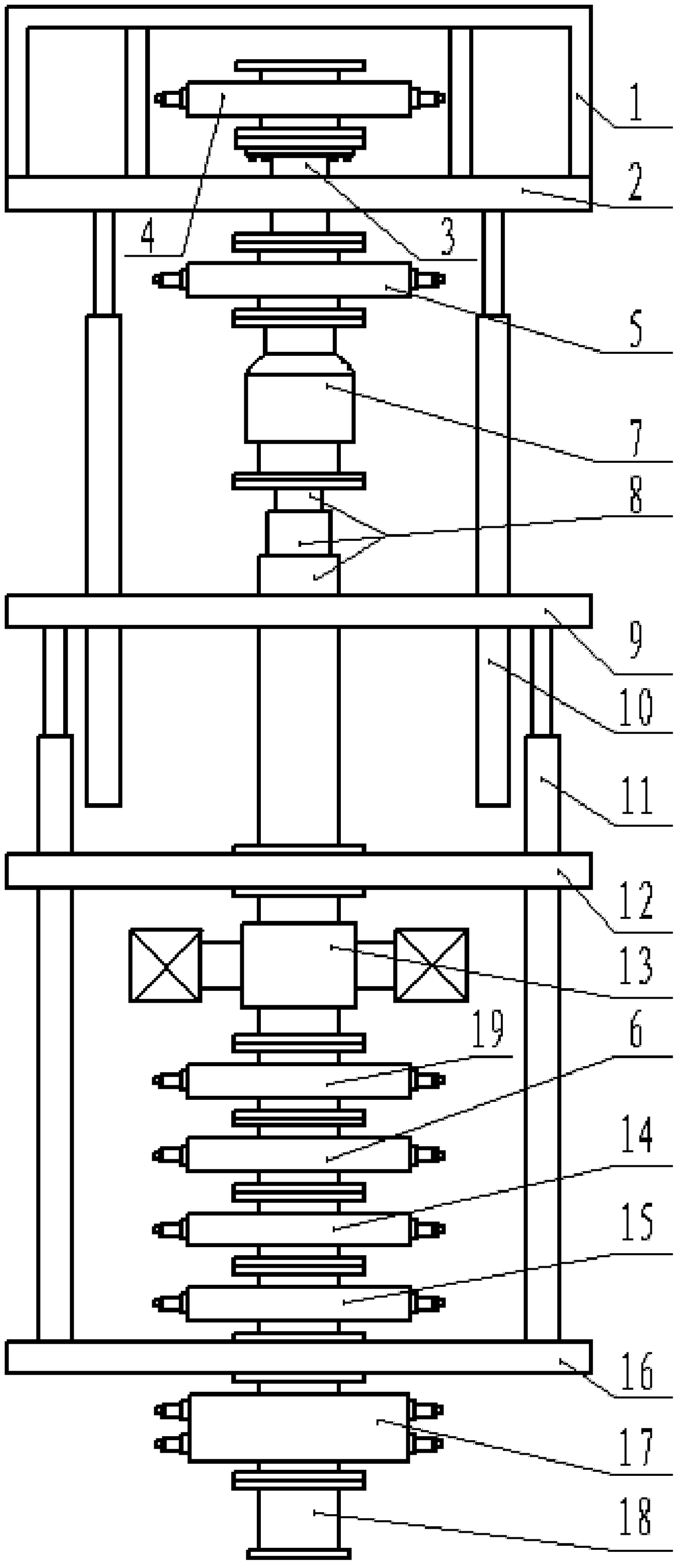

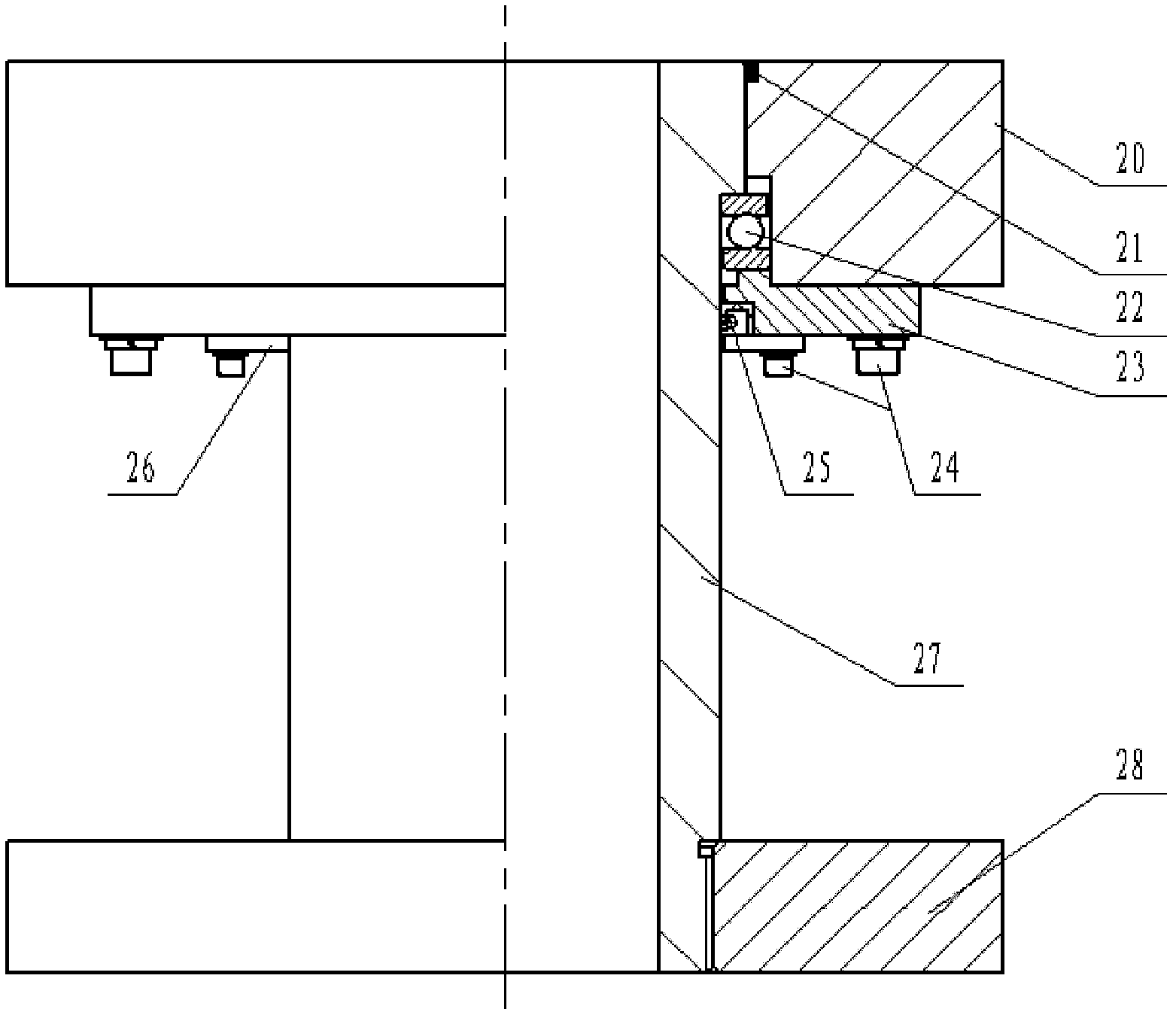

Intelligent super-long stroke pumping unit

The invention relates to an intelligent super-long stroke pumping unit which comprises an electric control cabinet, a driving system, a flexible polish rod winding the driving system and a counterweight system connected to the driving system. The output end of the flexible polish rod winds a supporting wheel and is successively connected to a rotary pup joint, a sucker rod, a weighted lever and asuper-long stroke pump. A regional central control room is connected to the electric control cabinet through a remote data wireless bridge, and the electric control cabinet is connected to the drivingsystem through a cable. The intelligent super-long stroke pumping unit is used for improving the stroke of the pumping unit, eliminating the included angle between the flexible polish rod and a hoisting sheave and prolongs the service life of the polish rod, so that a balance weight of the super-long stroke pumping unit is realized. The super-long stroke pumping unit is further energy-saving. Thepump efficiency, yield, annular liquid level position of an oil jacket can be reflected instantaneously by the electric control cabinet. The oil sucking speed or intermittent oil pumping is adjustedautomatically according to liquid supply data to achieve efficient operation, so that purposes of long stroke, low time of strokes, large displacement, intelligent control, optimized oil extraction, extension of periods of replacing a tube rod and examining the pump and remote digitalized control management are achieved.

Owner:沃森埃里克

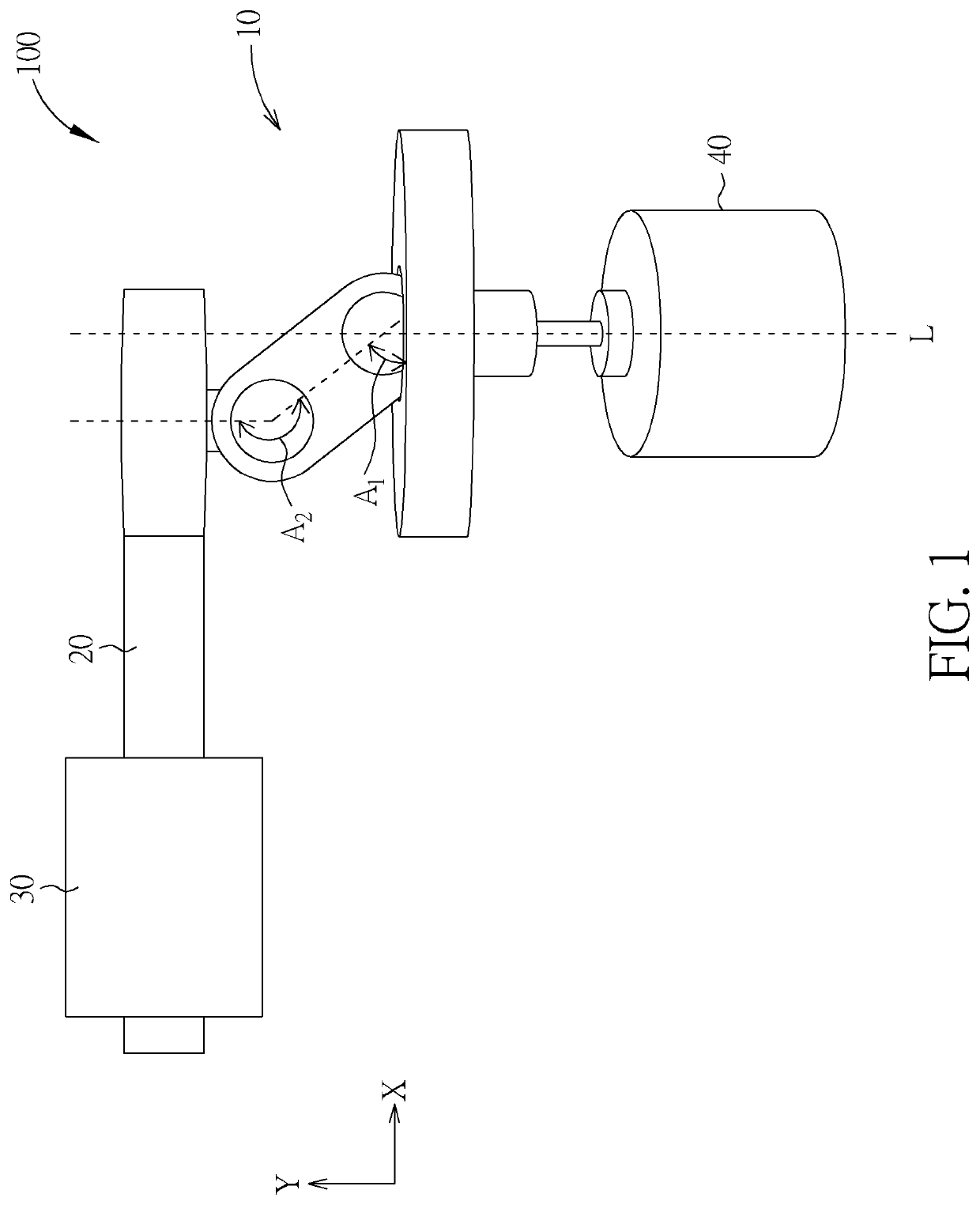

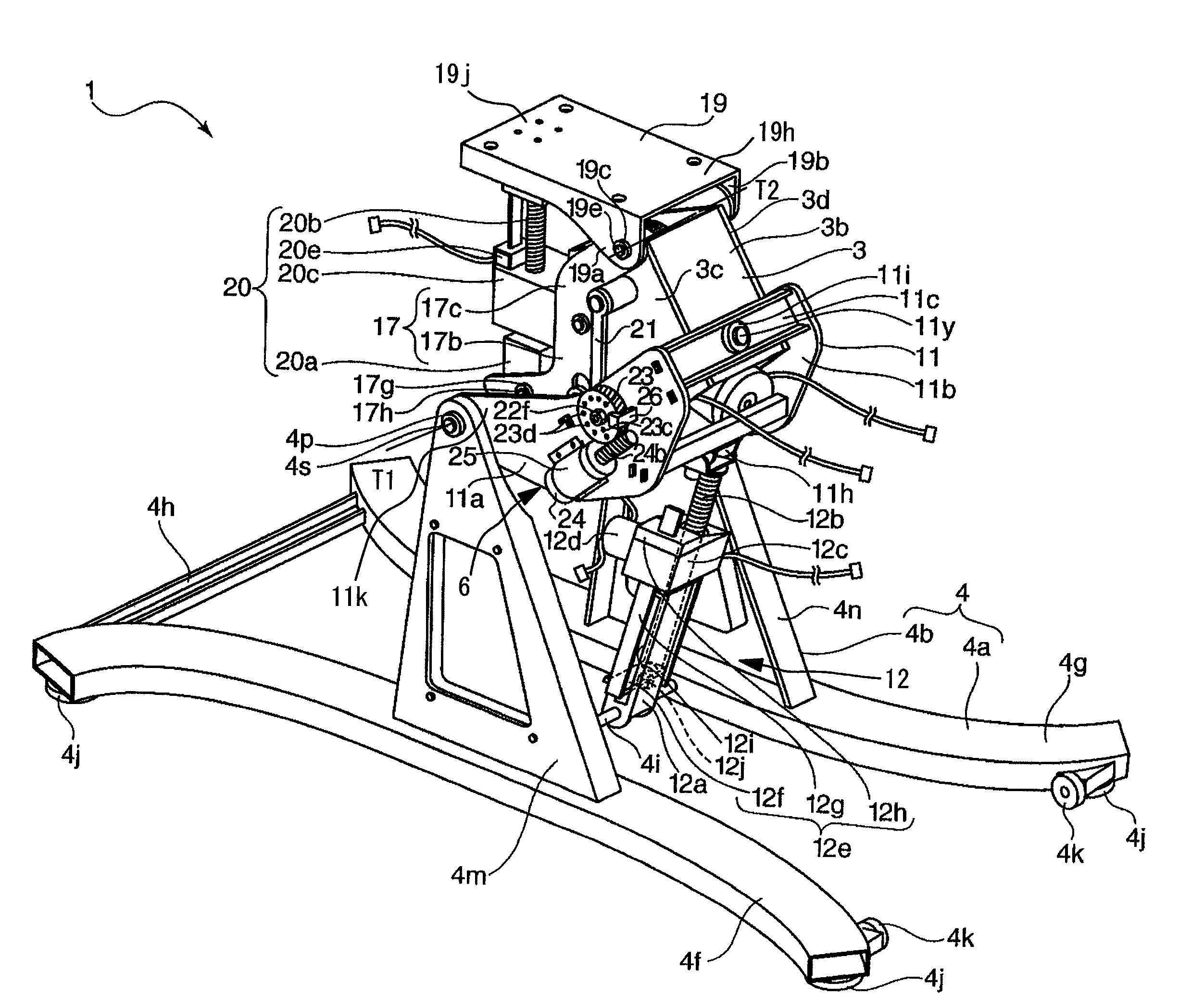

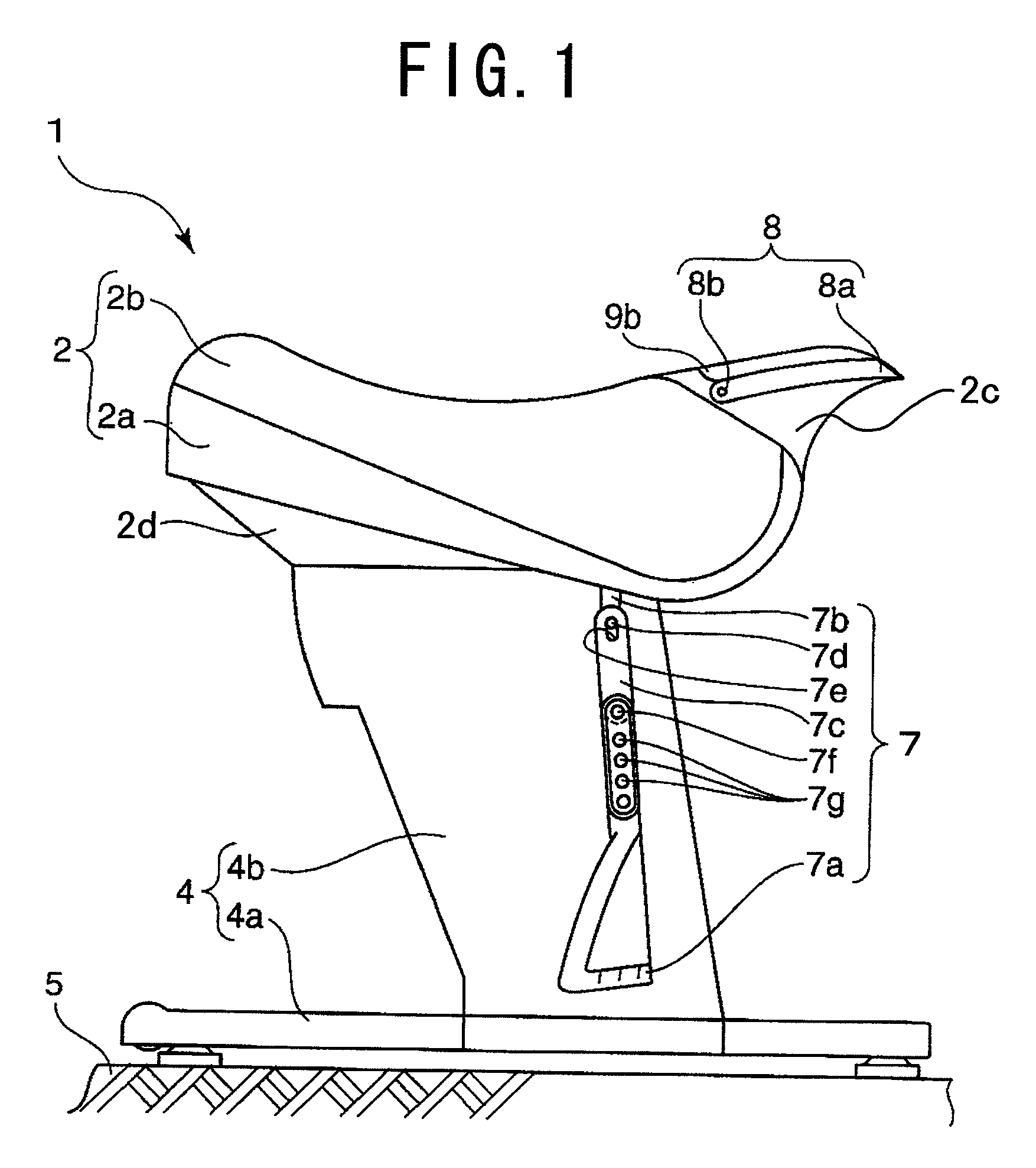

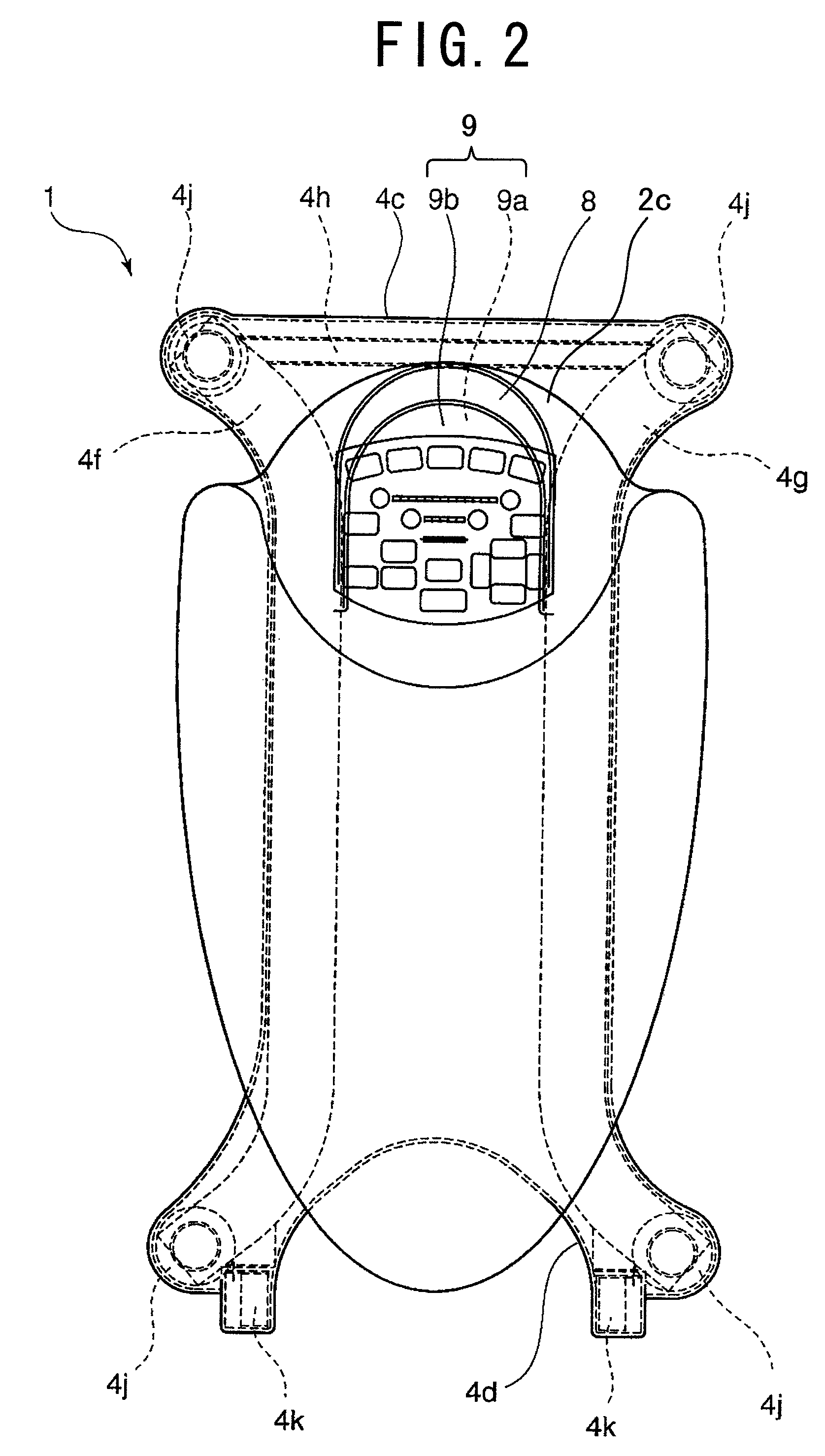

Balance exercise machine

InactiveUS7775939B2Improved patterningIncrease the total strokeBowling gamesCosmonautic condition simulationsEngineeringExercise machine

In a balance exercise machine (1), a swing mechanism (3) that swings a seat (2) in both of an anteroposterior direction (direction X) and a widthwise direction (direction Y) is rotatably supported on a supporting unit (119 around a predetermined rotation axis (T0). A first inclination mechanism (12) that stands up or down the rotation axis (T0) is provided between the supporting unit (11) and a pedestal (4). A second inclination mechanism (20) that can compensate the posture of the seat (2) is provided between the seat (2) and the swing mechanism (3). By driving the swing mechanism (3), the first inclination mechanism (12) and the second inclination mechanism (20) independently with each other, a stroke of swing motion of the seat can be expanded or contracted. Alternatively, by driving the swing mechanism (3), the first inclination mechanism (12) and the second inclination mechanism (20) in conjunction with each other, the trace of the motion of the seat (2) can be varied.

Owner:MATSUSHITA ELECTRIC WORKS LTD

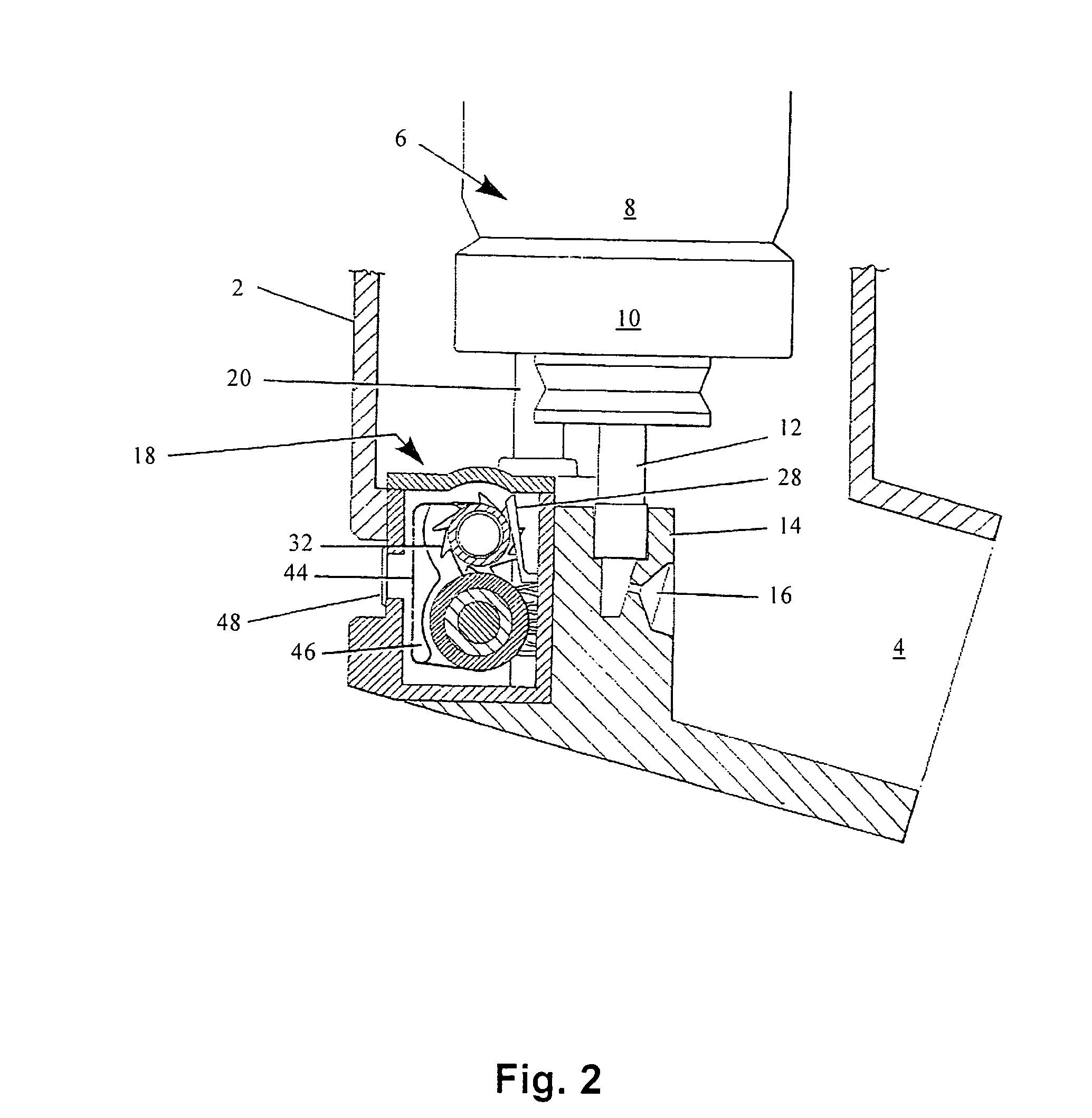

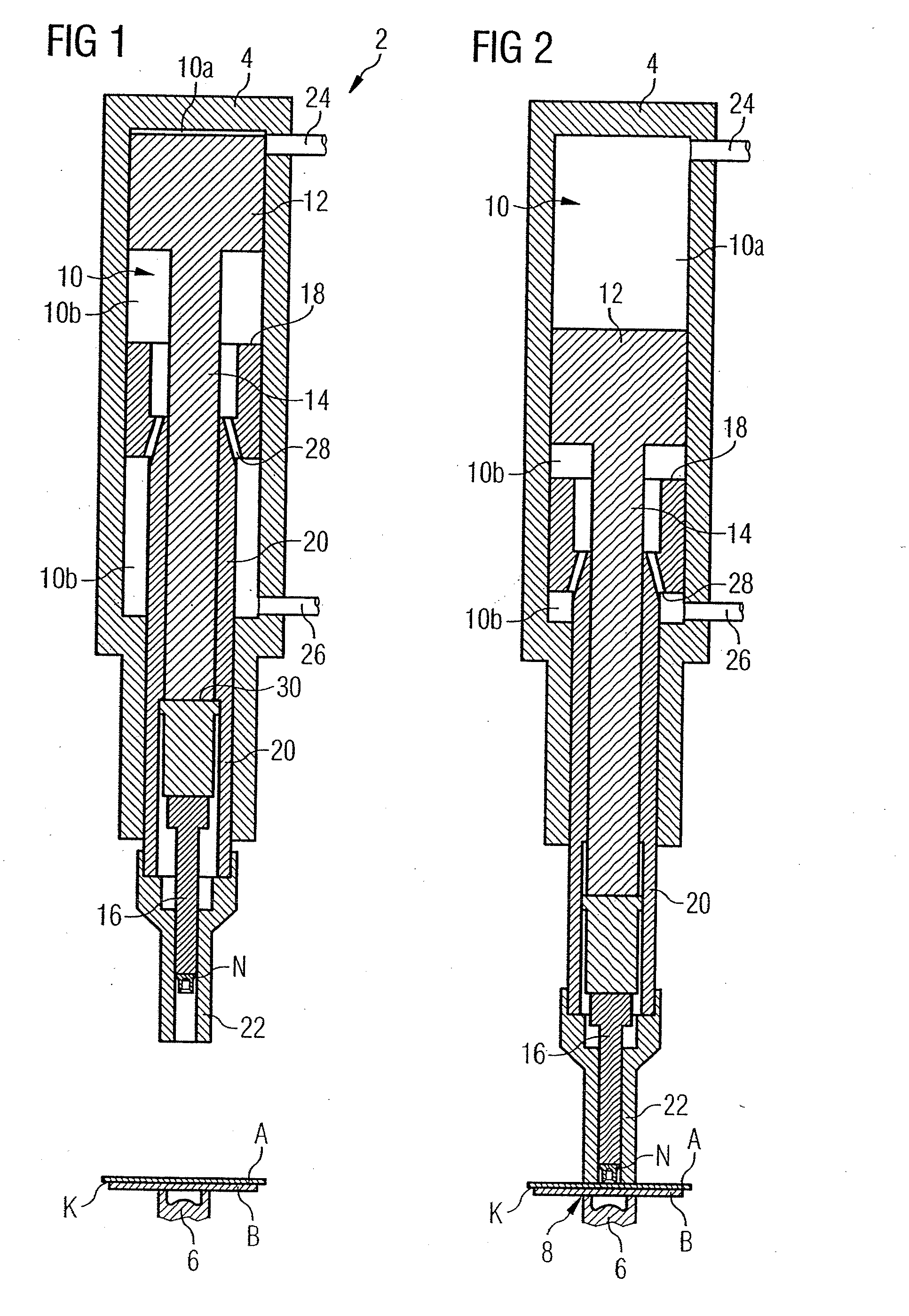

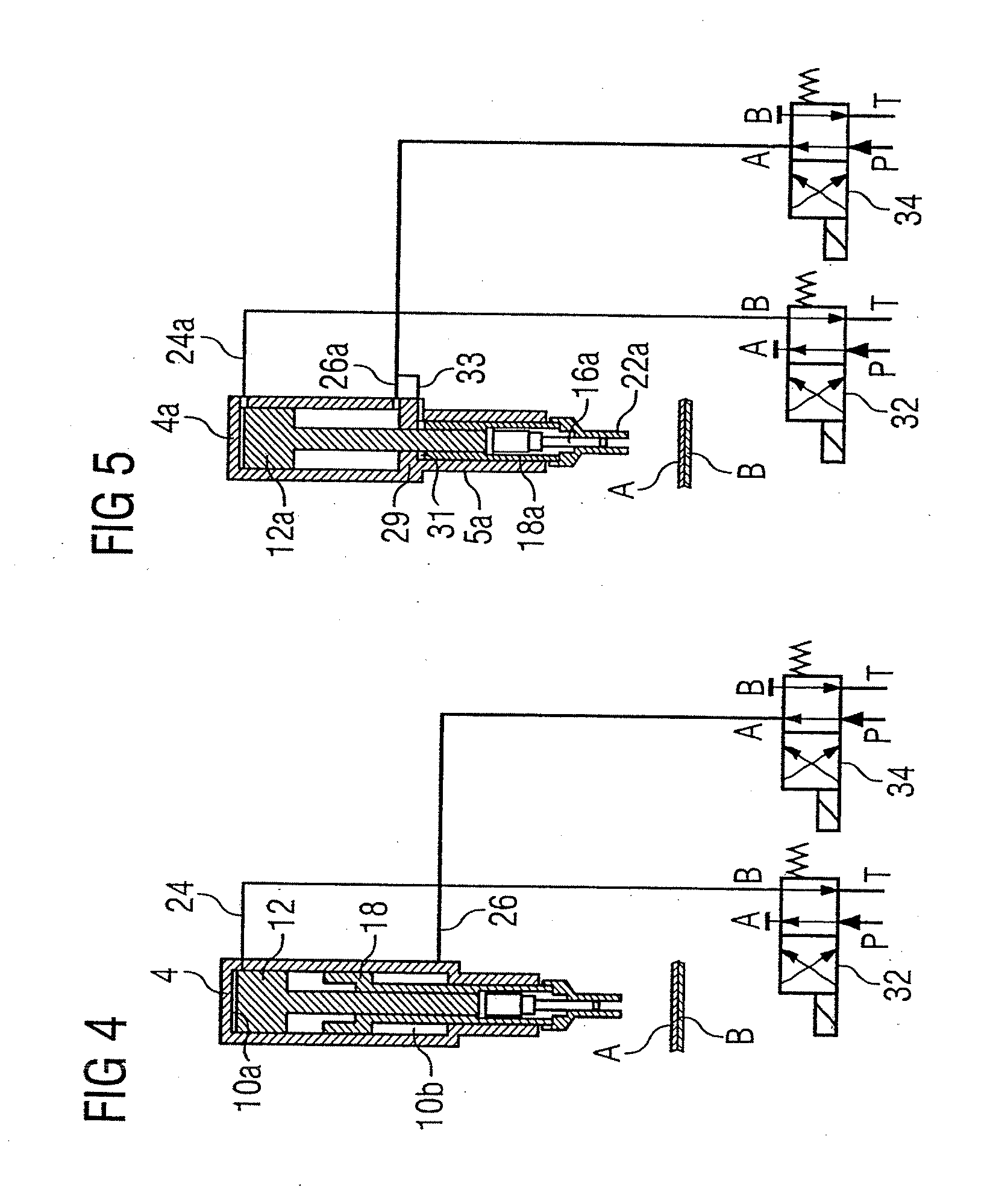

Joining Method and a Device for Operating a Fastening Tool

InactiveUS20070124911A1Quality improvementSufficient final strength of jointMetal working apparatusConnectionsEngineeringRivet

In a method for joining at least two plate-shaped workpieces by a fastening tool and a device for operating the fastening tool, the fastening tool comprises a punch for exerting a punch force to perform a joining operation and a clamp for exerting a clamping force upon the workpieces at the joining area. During the joining operation the punch exerts a high punch force to perform the joining operation and the clamp exerts substantially no clamping force to allow for free material deformation in the joining area. After the joining operation both the punch and the clamp exert high forces at the same time to reduce any material deformations of the workpieces and to provide for compression of the workpieces in the joining area. Preferably the invention is used in a riveting tool for setting self-piercing rivets; as an alternative it may be used in a clinching tool.

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

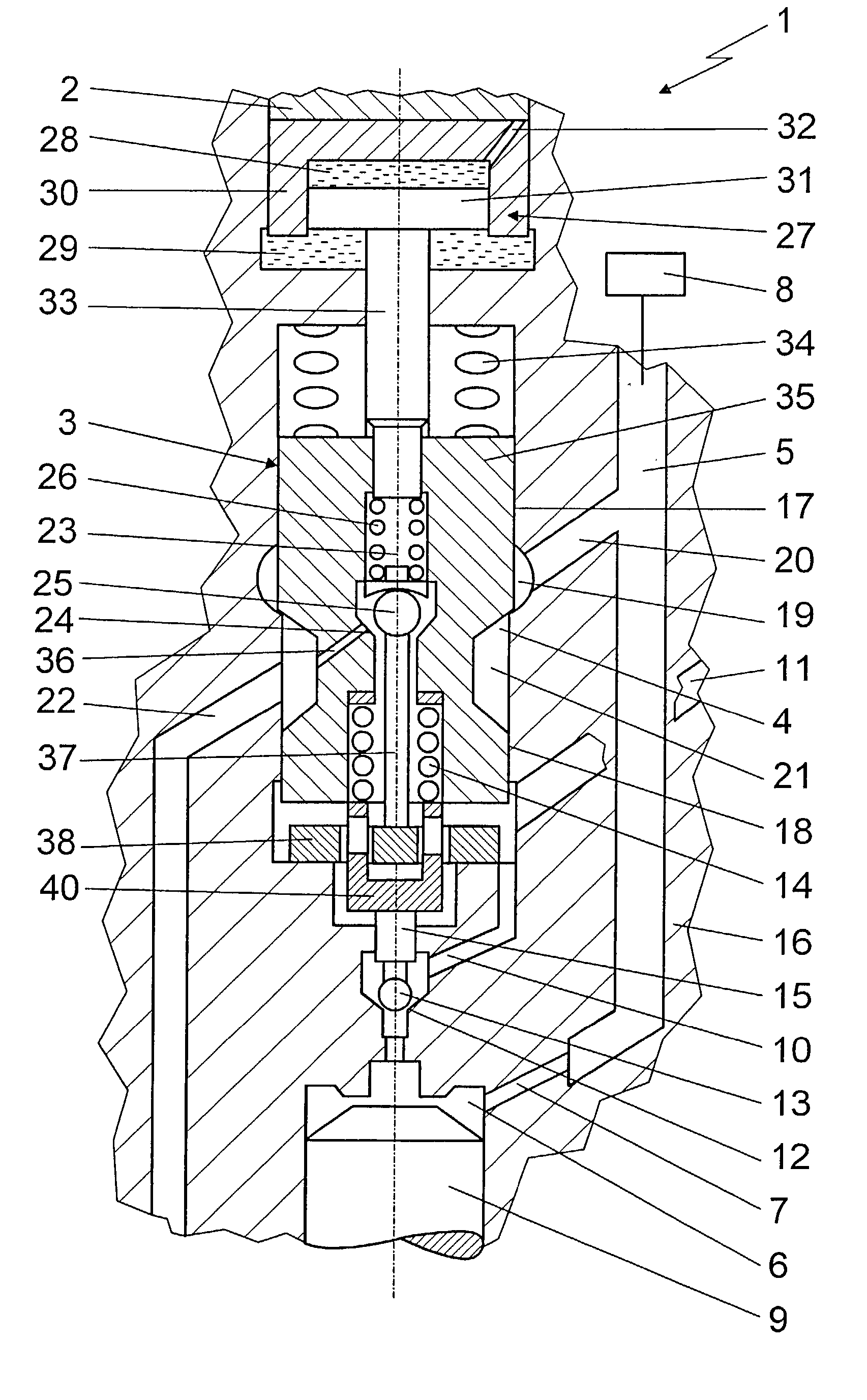

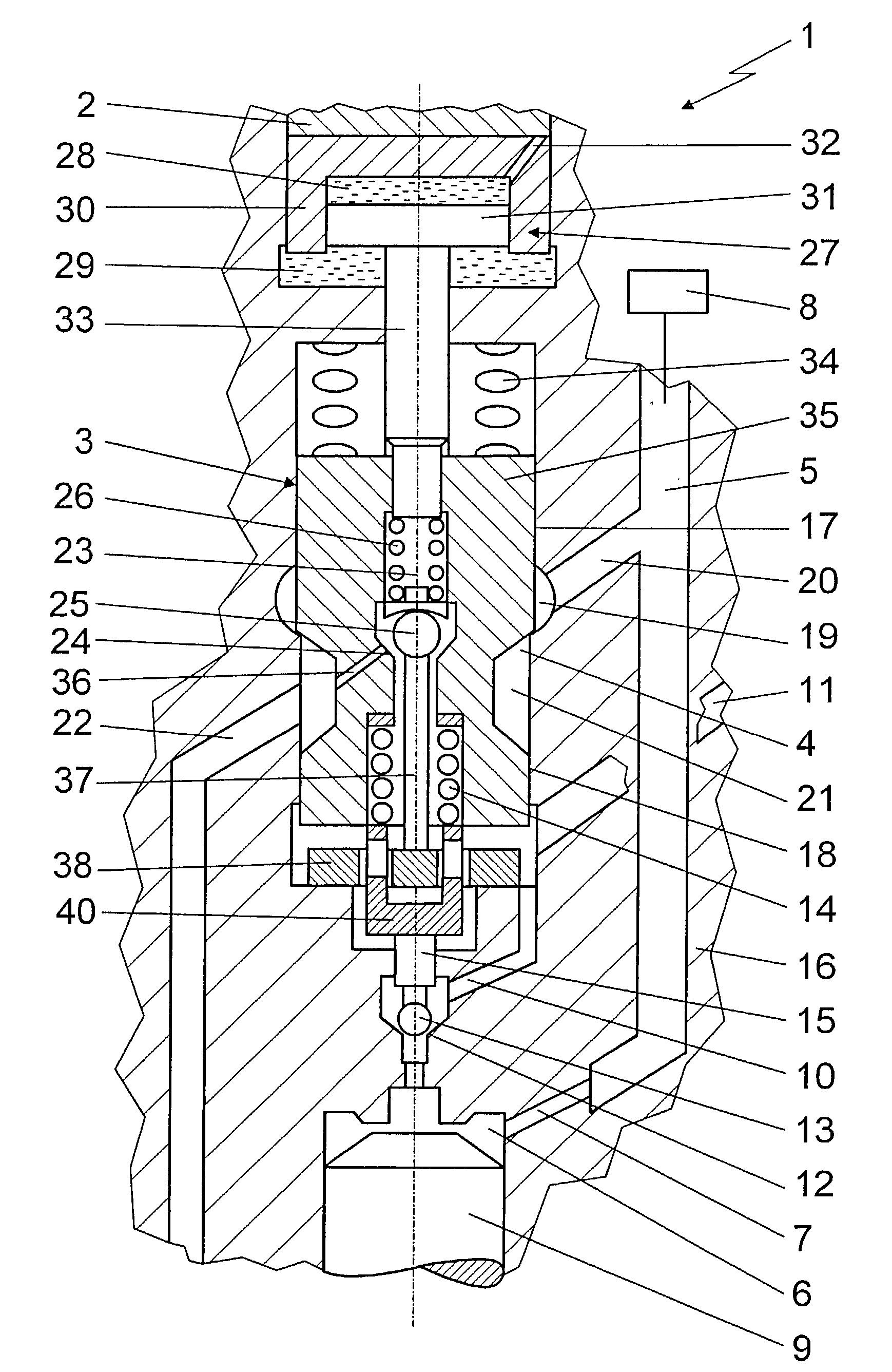

Fuel injection device for internal combustion engines

InactiveUS20020179730A1Proportion of hydrocarbon in the engine exhaust gas can be reduced considerablyIncrease pressureMachines/enginesFuel injecting pumpsCombustionControl room

A fuel injection device (1) for internal combustion engines, with an injection nozzle that can be supplied with fuel from a high-pressure fuel source (8) and with an actuating element (9) that opens and closes the injection nozzle as a function of the pressure in control chamber (6) is proposed. A high-pressure line (7) discharges into the control chamber (6), and an outflow conduit (10) leads away from the control chamber (6) and can be blocked by a closing element (13) of a valve member (3). A high-pressure delivery system (19, 20, 21, 22) that leads into a nozzle chamber can be blocked by a first valve seat (4) of the valve member (3), and the valve member (3) is movable by a defined stroke length by means of an actuator (2). As a function of this stroke length, the closing element (13) is movable between a closing position and an opening position, the latter relieving the control chamber (6) and allowing an injection (Drawing).

Owner:ROBERT BOSCH GMBH

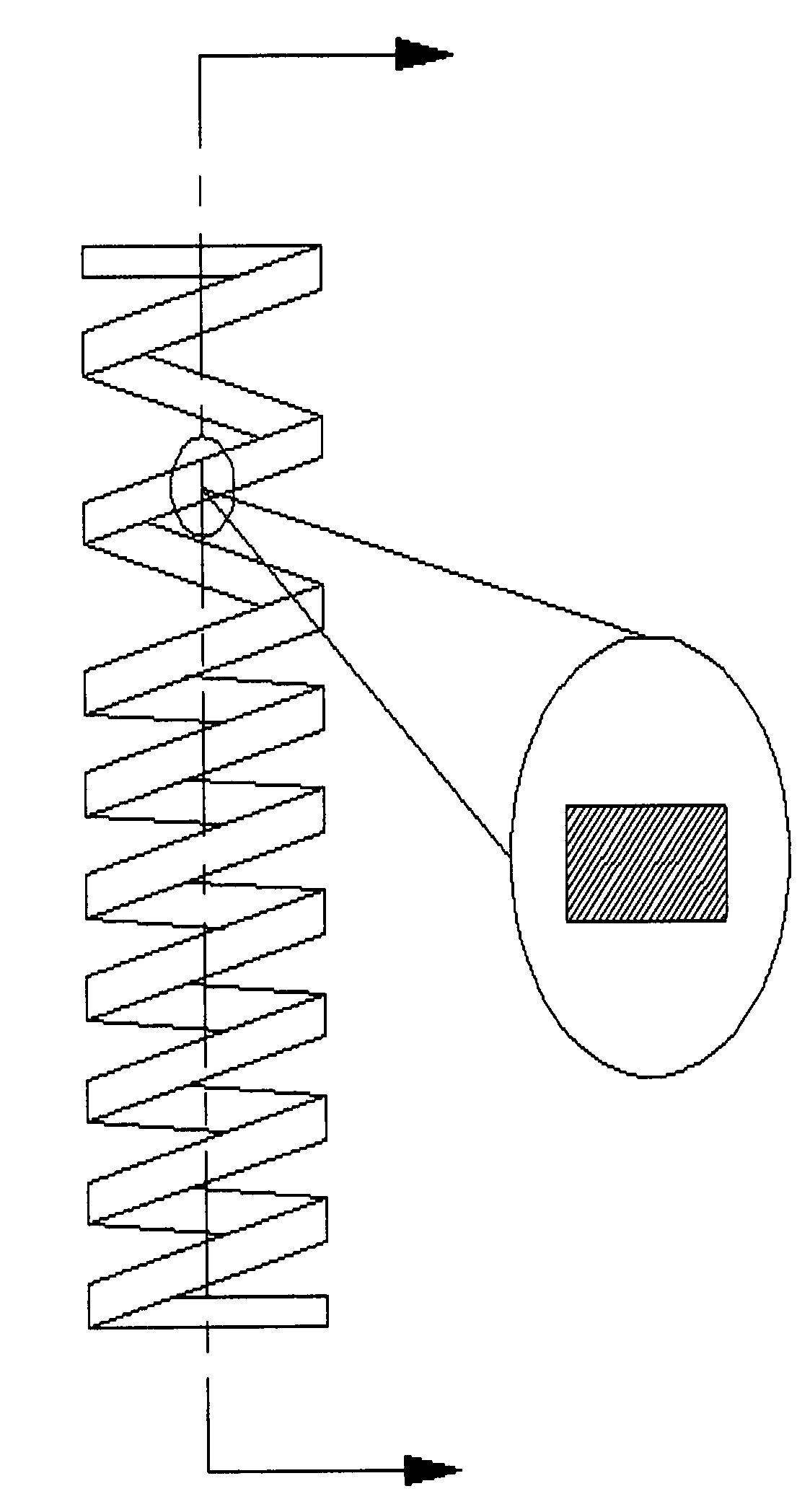

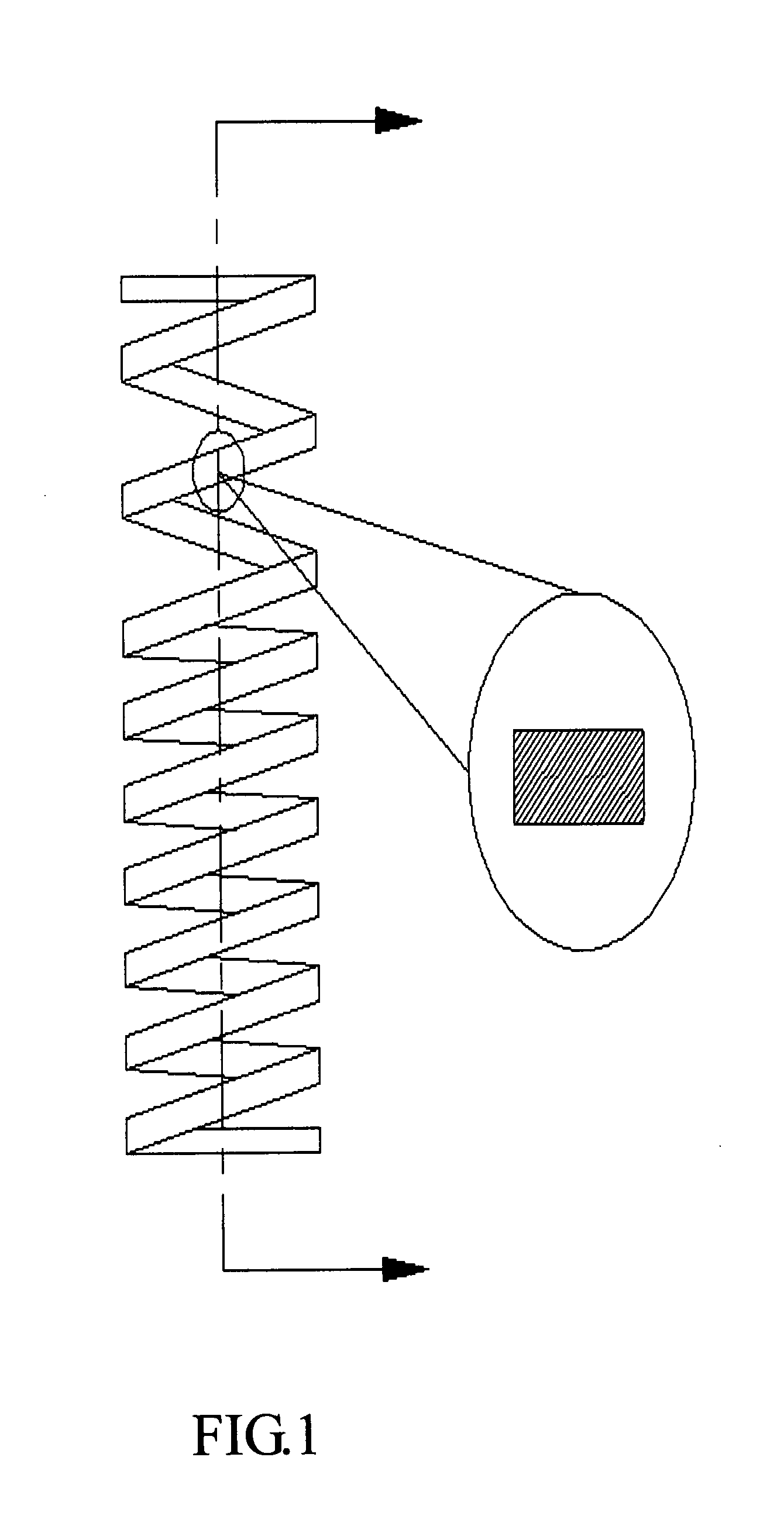

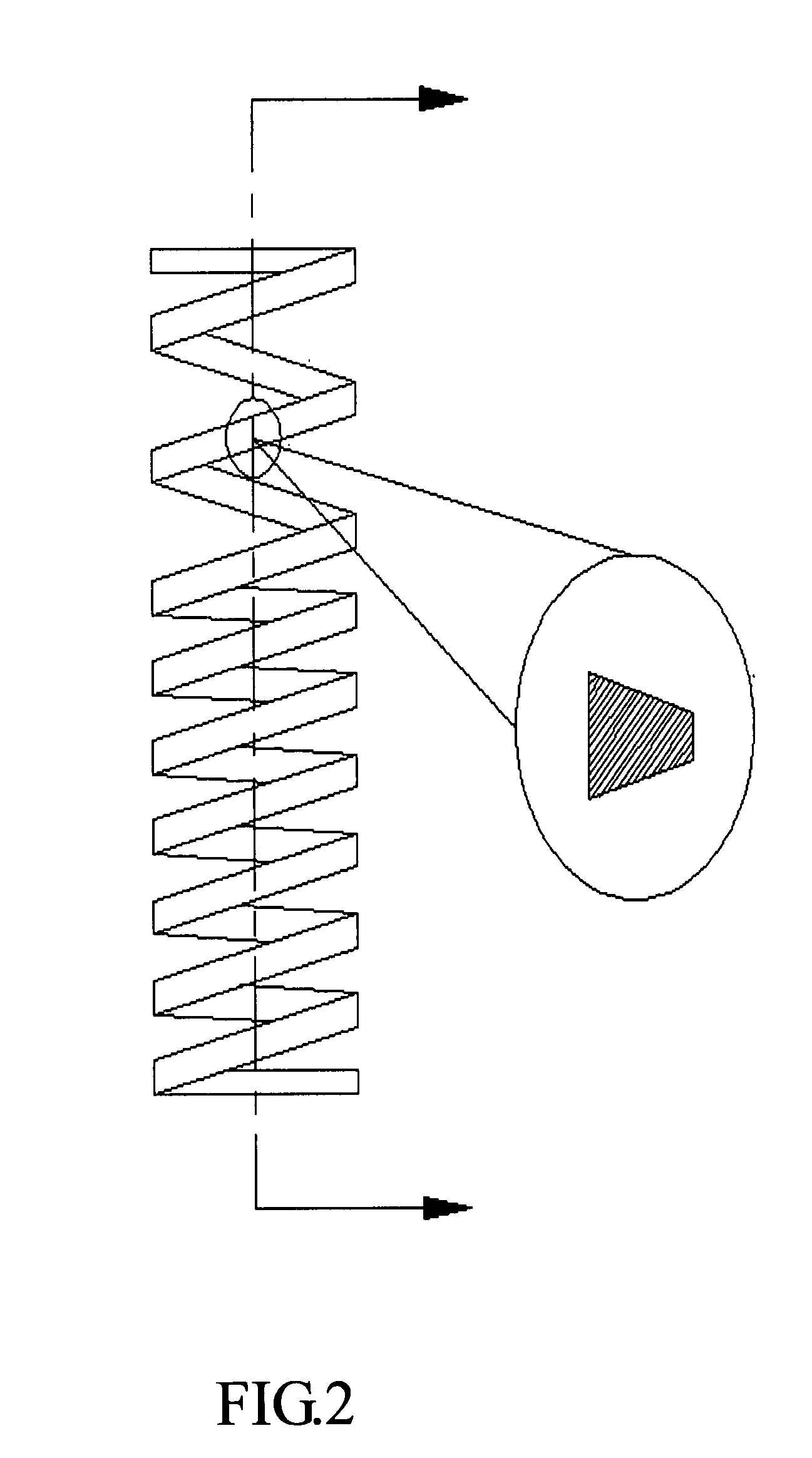

Spring formed with an abnormal-shaped cross section specially used as a vehicle shock absorber

InactiveUS20080191400A1Light weightLarge strokeSpringsResilient suspensionsAbnormal shapesAbnormal shaped

A spring formed with an abnormal-shape cross section (a non-circular cross section) specially used as a vehicle shock absorber is a string whose cross section is shaped rectangular, trapezoidal, single-edge arced or oval. Compared with a spring formed with a circular-shape cross section, the spring formed with one of foresaid abnormal-shape cross sections has some or all of the following functions: The stroke can be increased under the condition of a same free height; it can be prevented from broken after its load area is enlarged; it can reduce weight under the condition of a same stroke; it can enhance resistance to huge outer stress and thus prolong its service life and it can be received and positioned in a very small space.

Owner:LIU CHING LIAUG

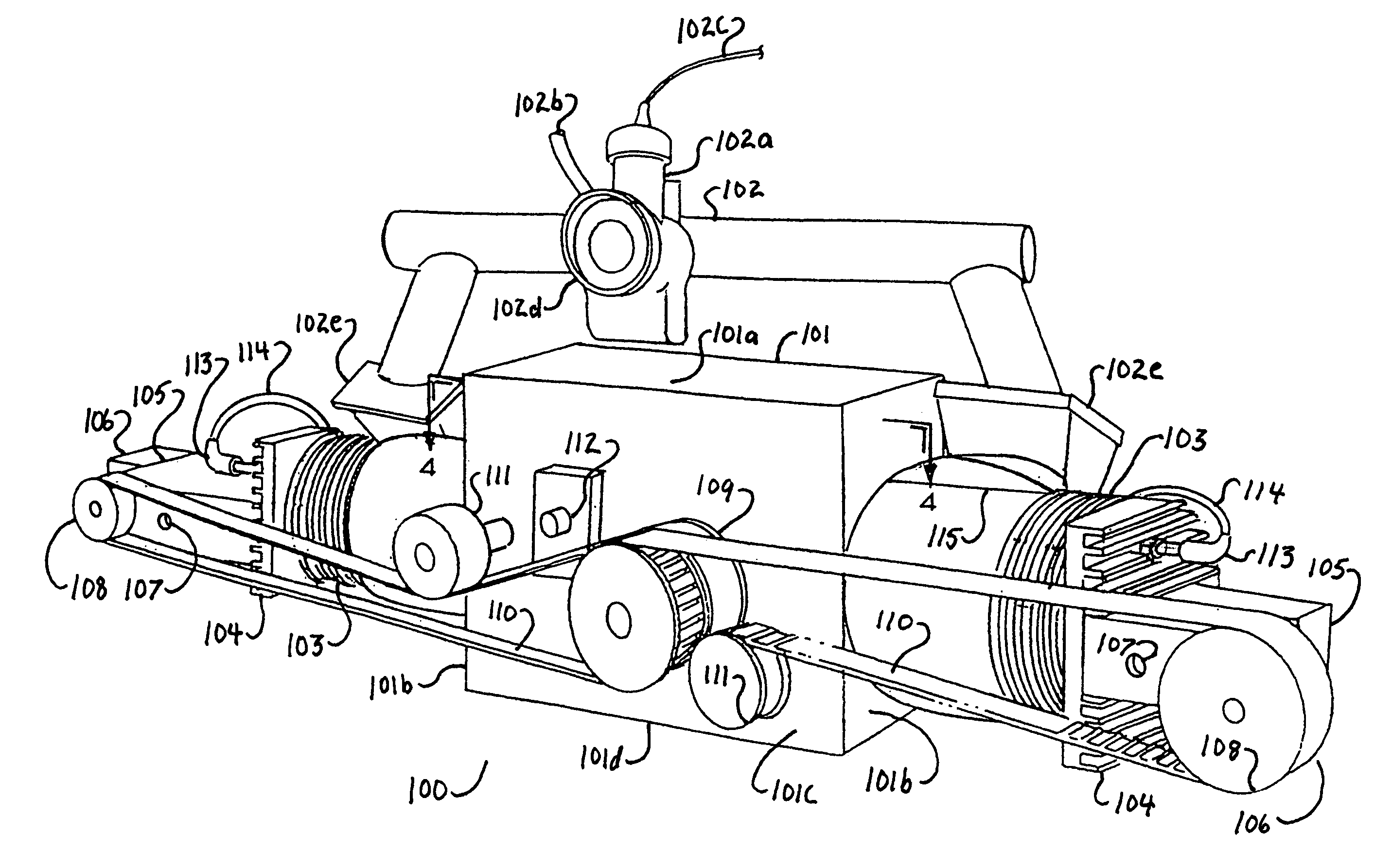

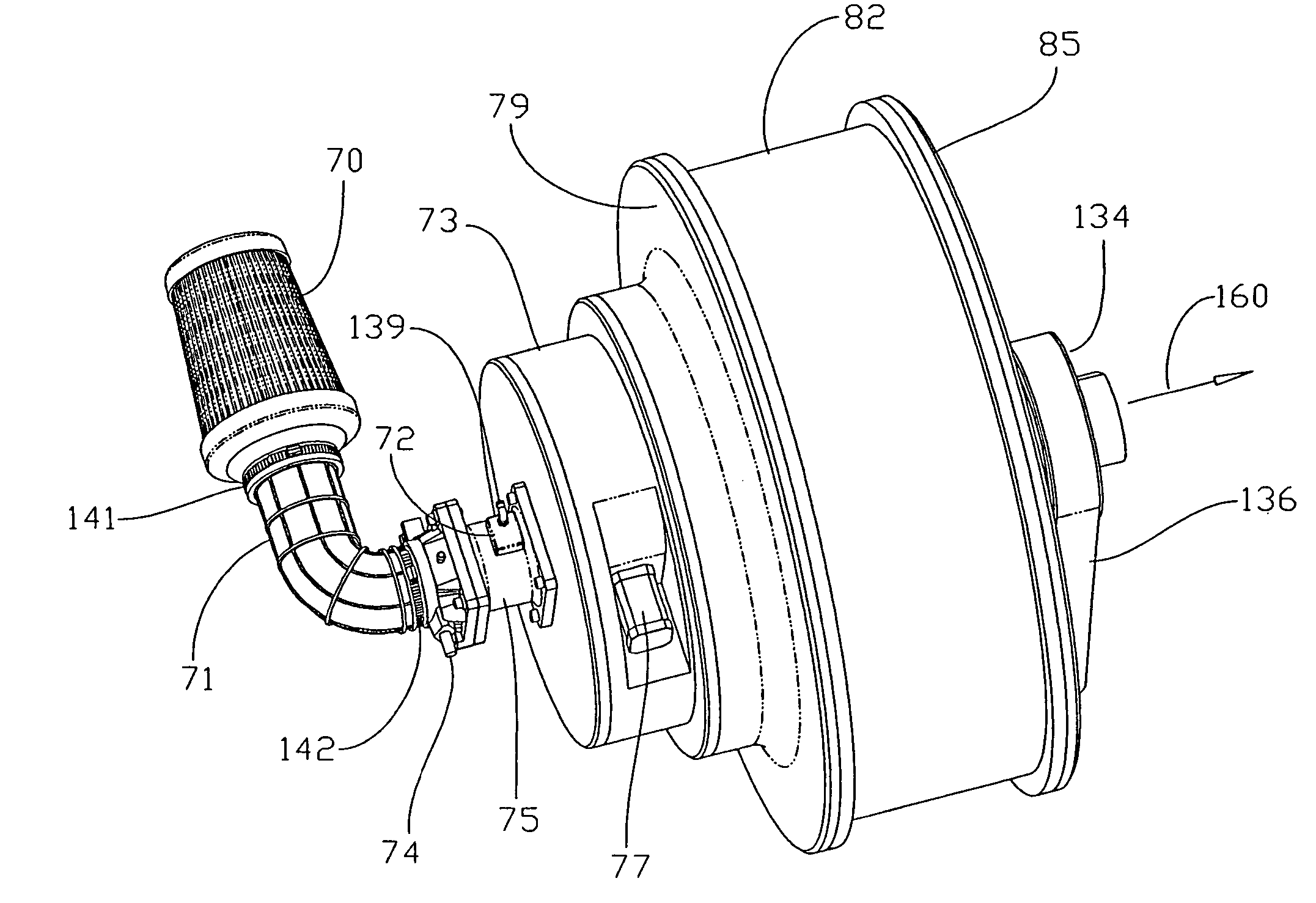

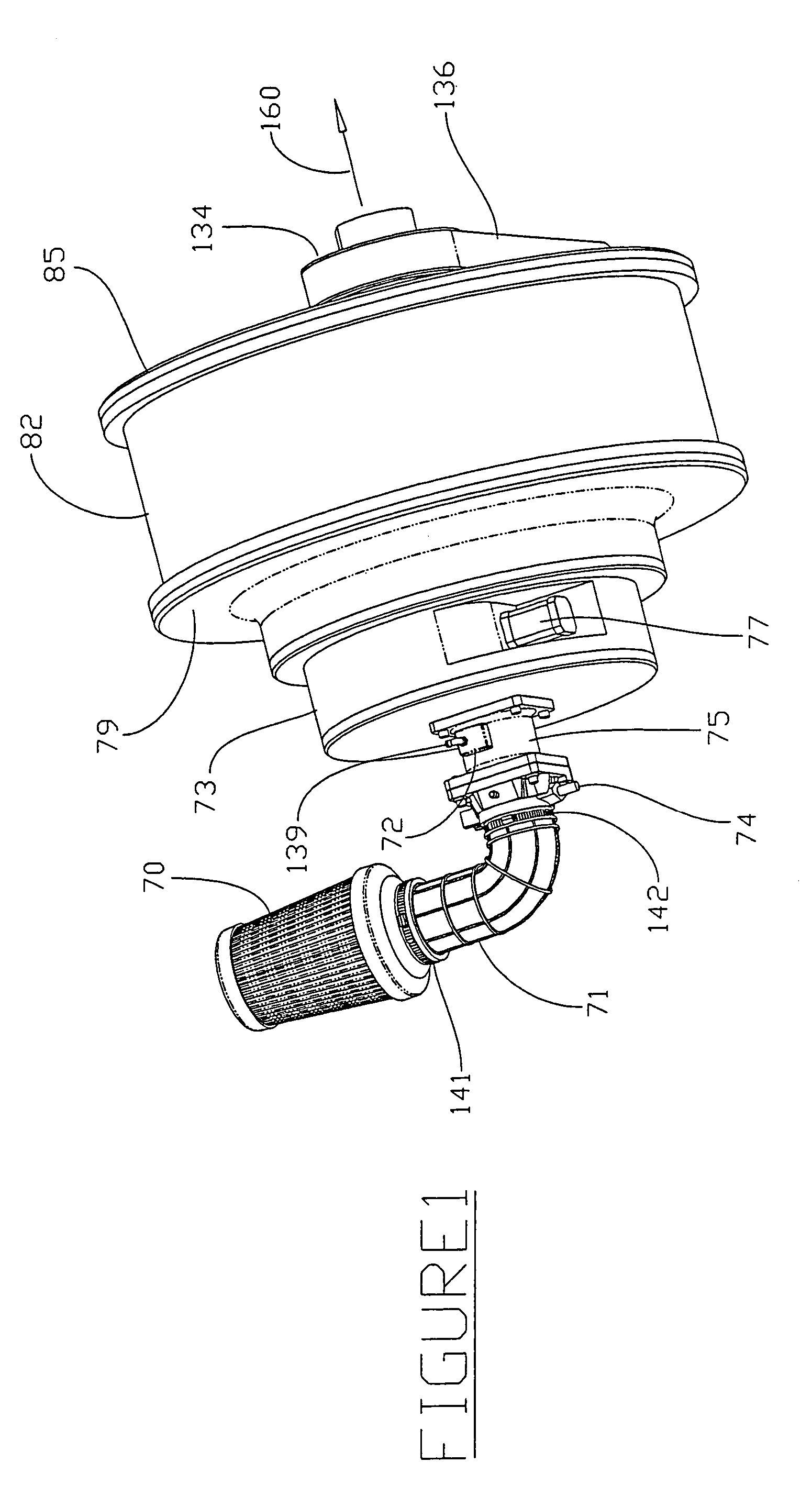

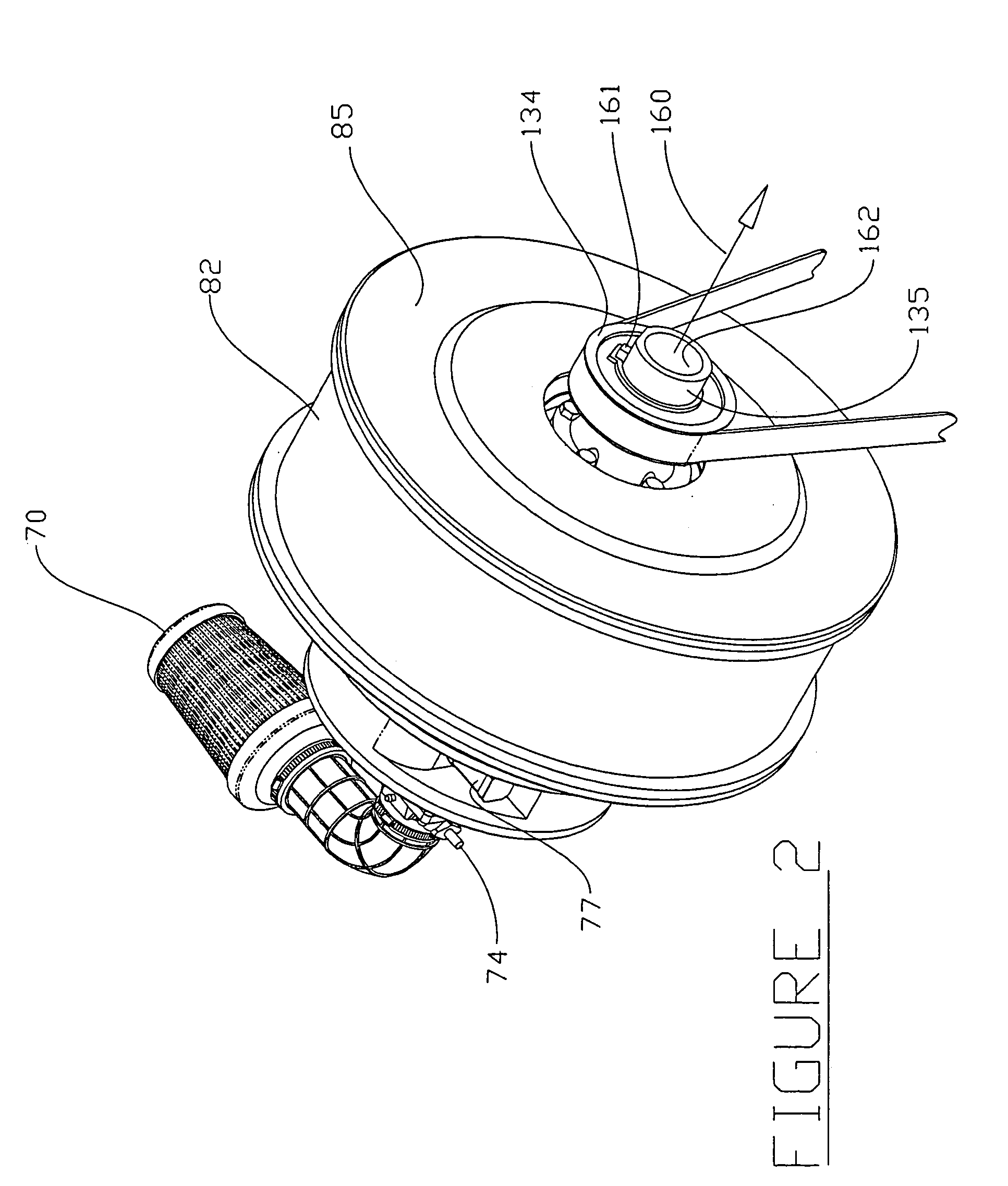

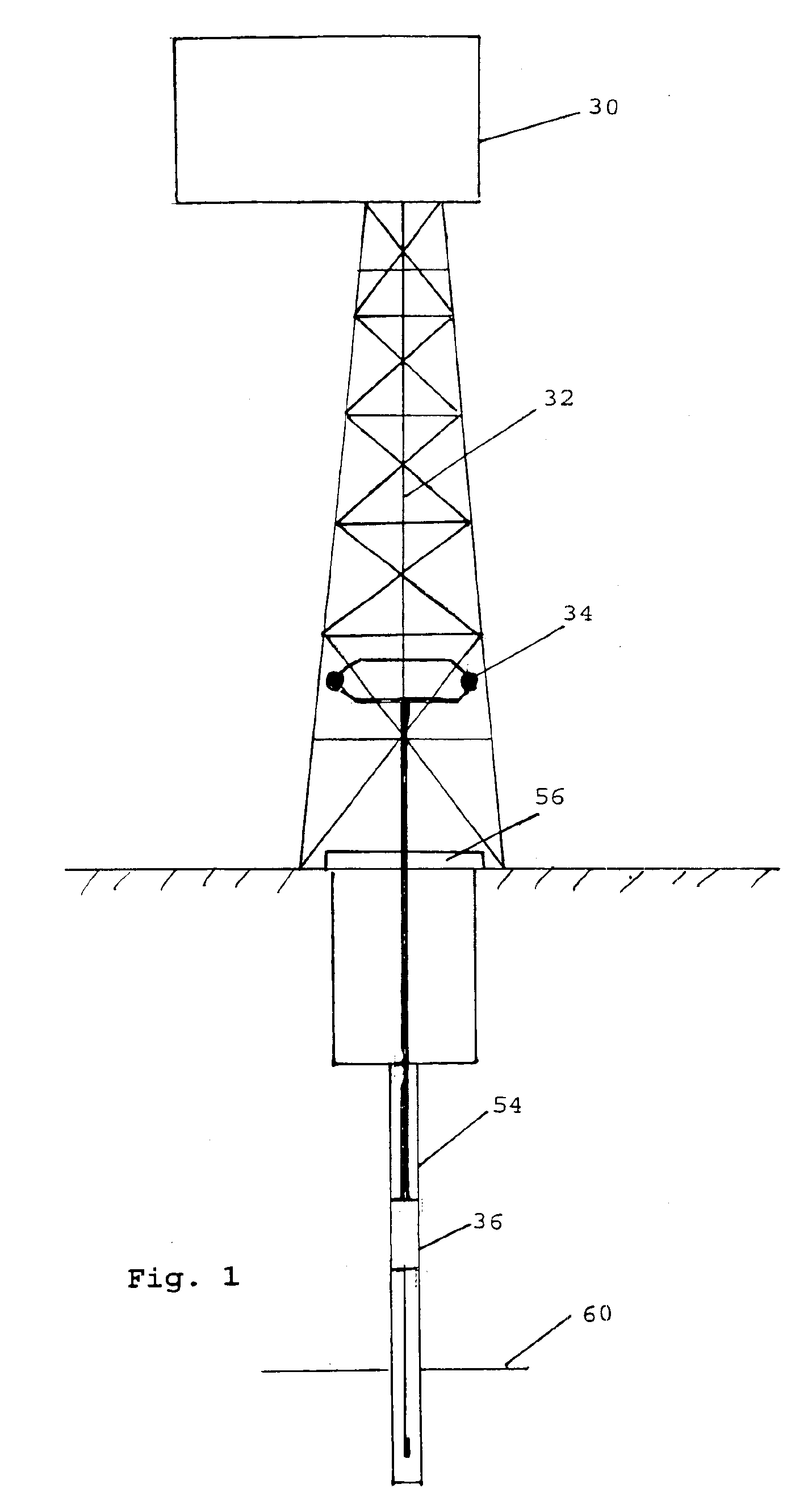

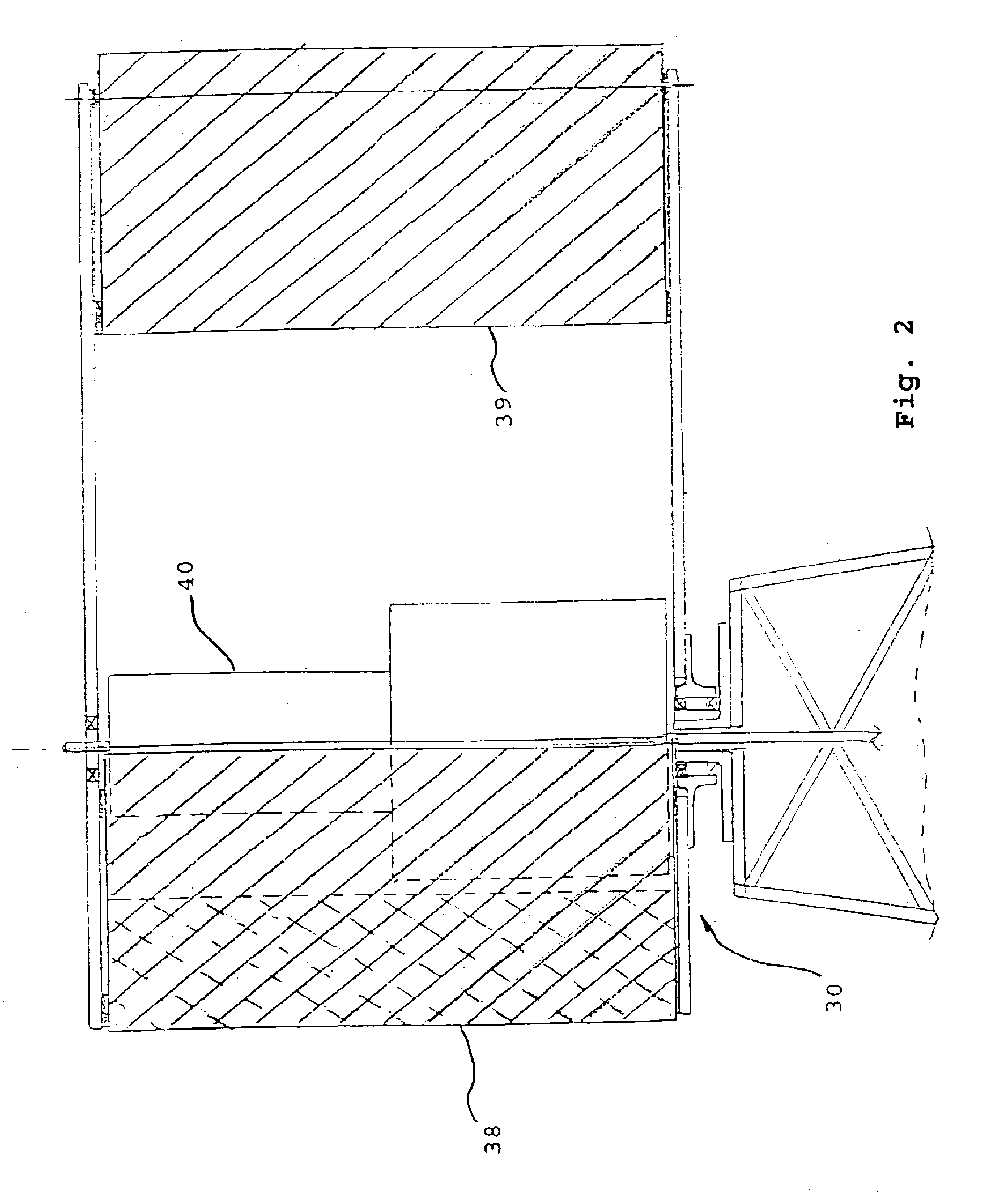

Wind driven high pressure water pump

InactiveUS6863505B2Improve efficiencyReduce windEnergy industryPump controlWind drivenPositive pressure

This invention relates to a wind mill which is designed to convert rotational energy to mechanical energy to drive one or more pistons to raise a liquid such as water to an elevated location if necessary at a positive pressure. In addition, the present invention may be adapted to pressurize a medium, such as a gas, for storage in a reservoir.

Owner:DIETZ JEREMY J

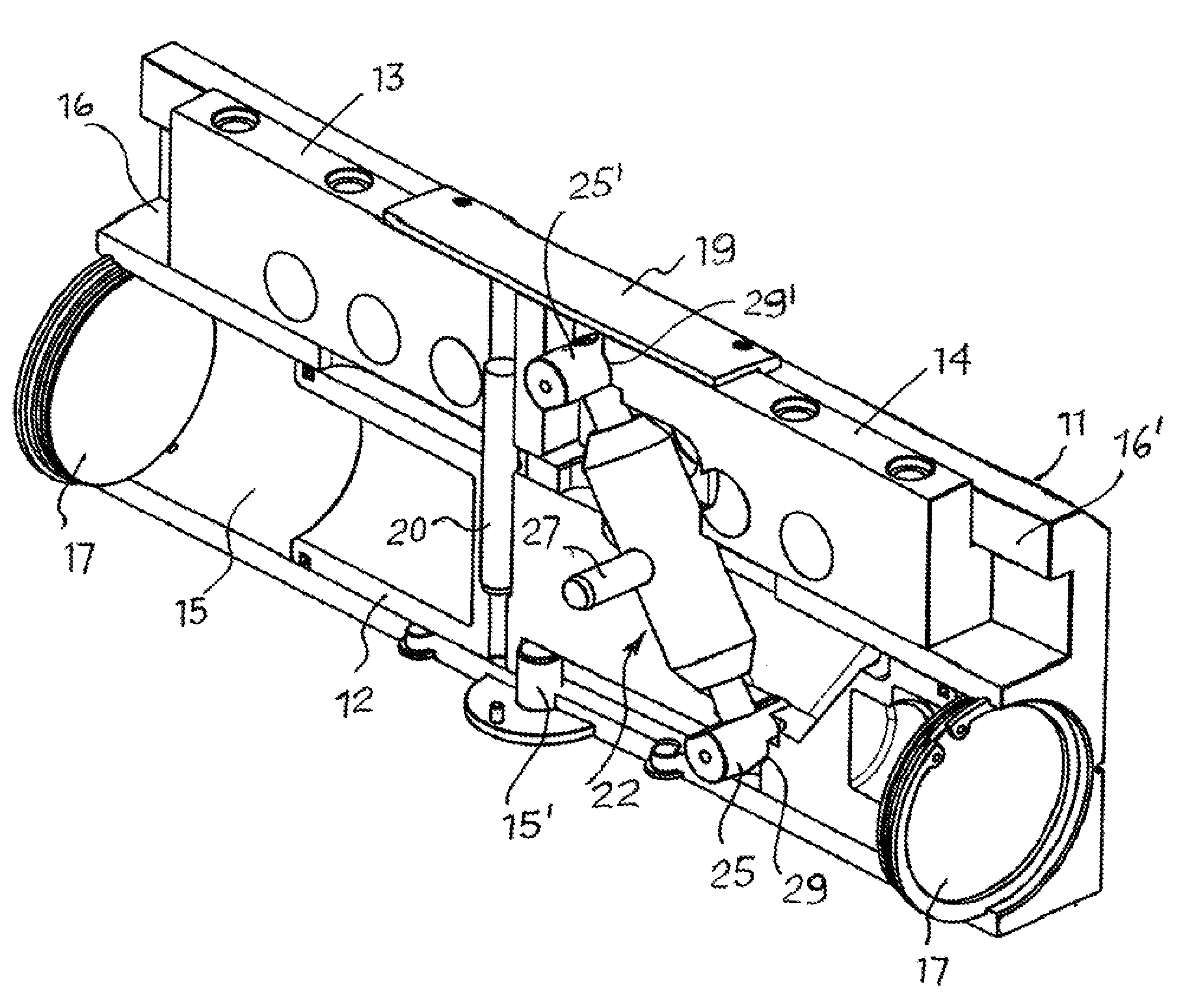

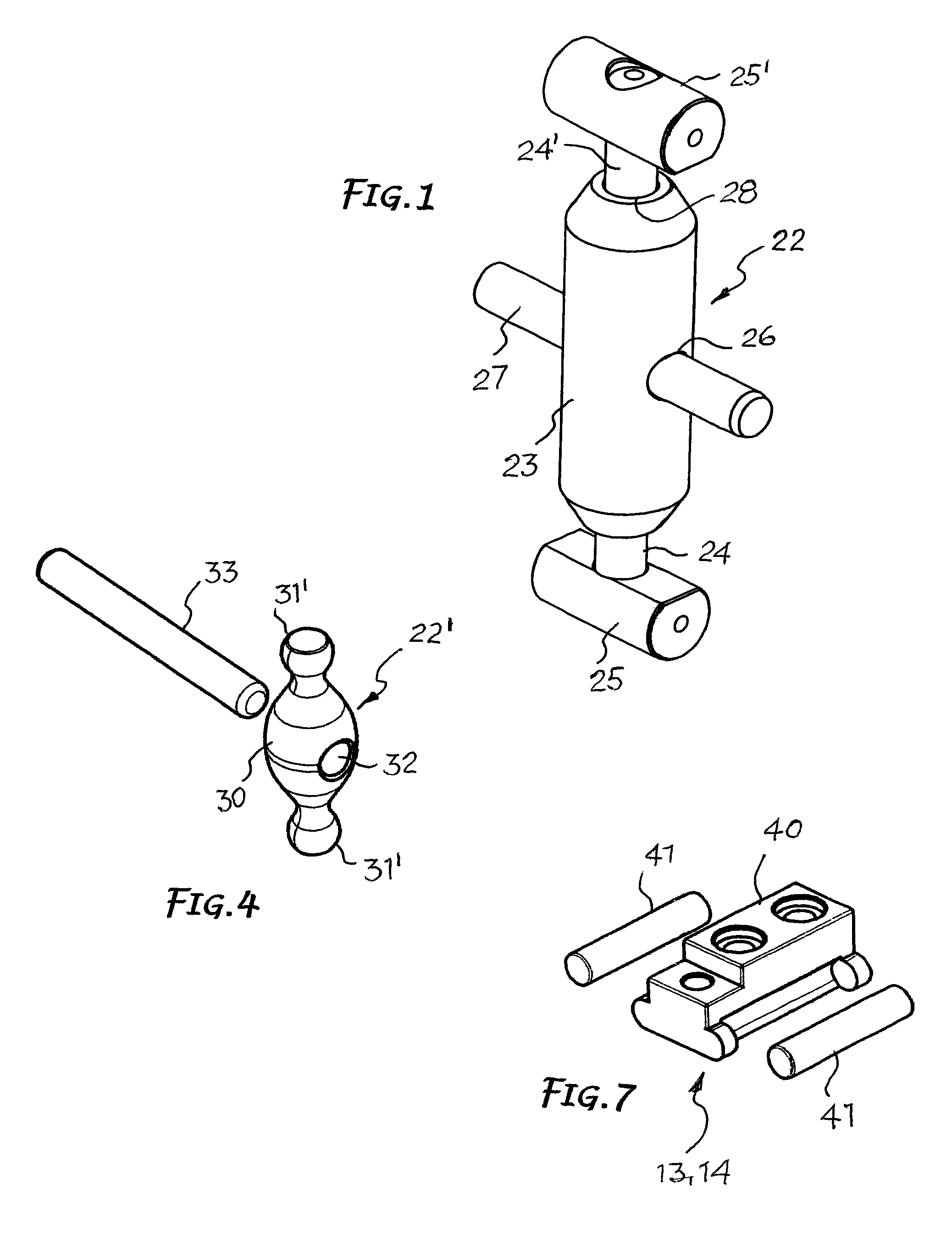

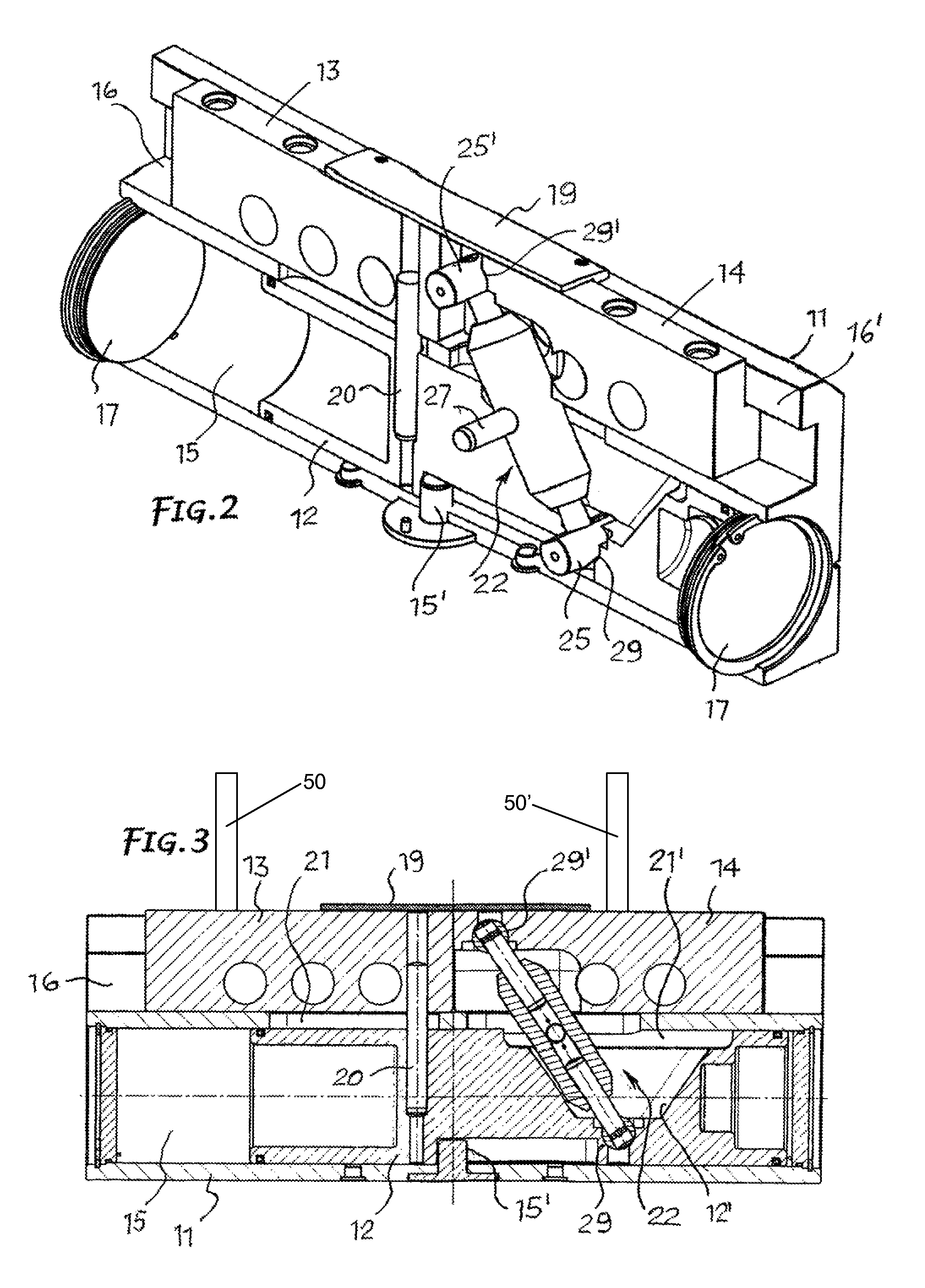

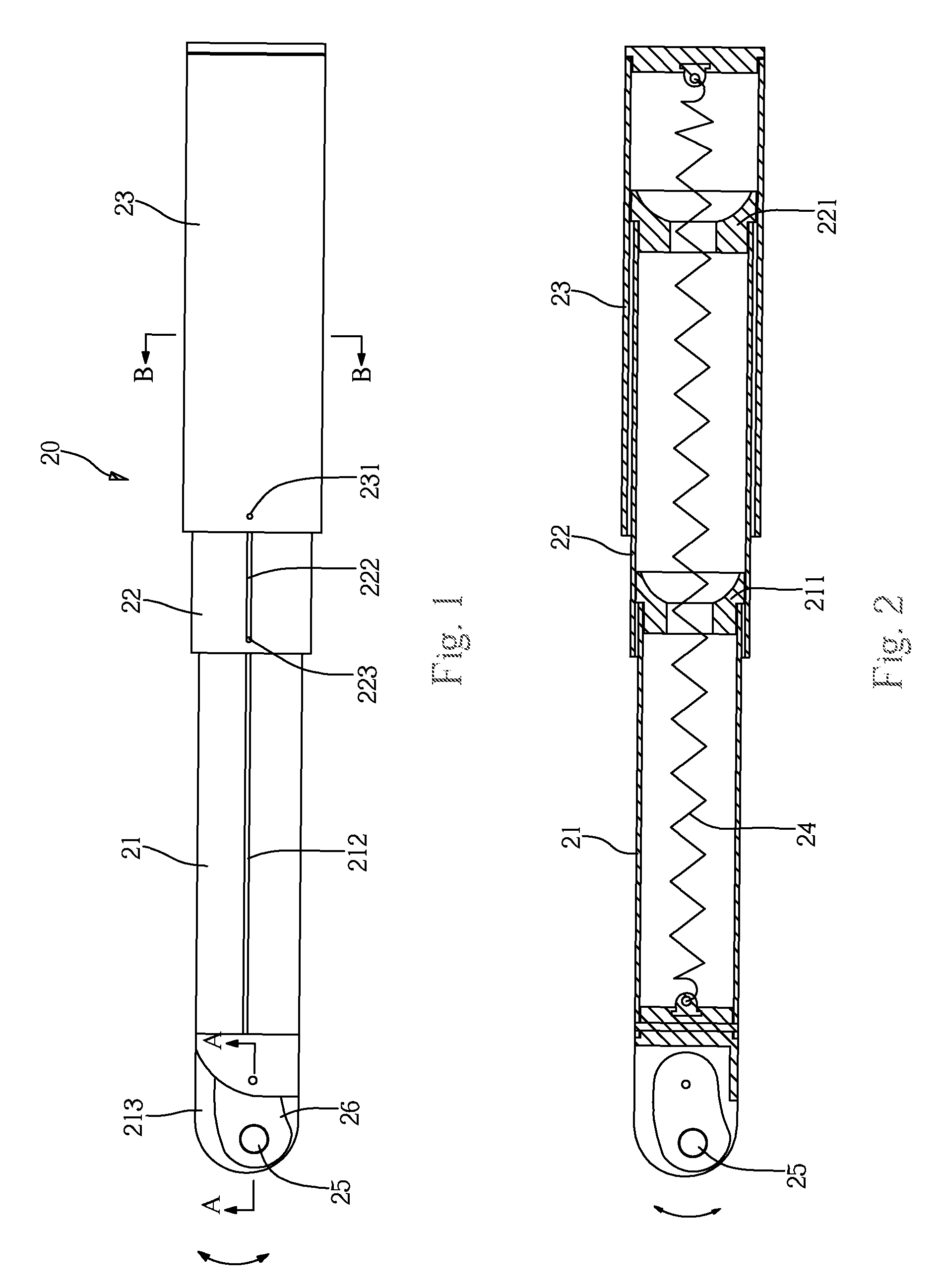

Parallel pneumatic gripper

InactiveUS7635154B2Variation in strokeIncrease the total strokeGripping headsLoad-engaging elementsEngineeringMechanical engineering

The invention concerns a parallel pneumatic gripper which includes a gripper body (11) forming a chamber (15), an alternate pneumatic piston (12) movable in the chamber, and two jaws (13, 14) controlled by the piston and movable in opposite directions. A first jaw (13) is rigidly attached to the piston (12) to follow its movements, whereas the second jaw (14) is connected to the piston (12) by an oscillating transmission element or lever (22, 22′) comprising an intermediate larger dimensioned cross section portion (23, 30) having a transversal bore to house the oscillating central fulcrum and two terminal heads with rolling surfaces (25, 25′; 31, 31′) designed to couple with corresponding seats provided respectively on the bottom of a flaring shaped in one side of the piston (12) and in the second jaw (14).

Owner:GIMATIC SRL

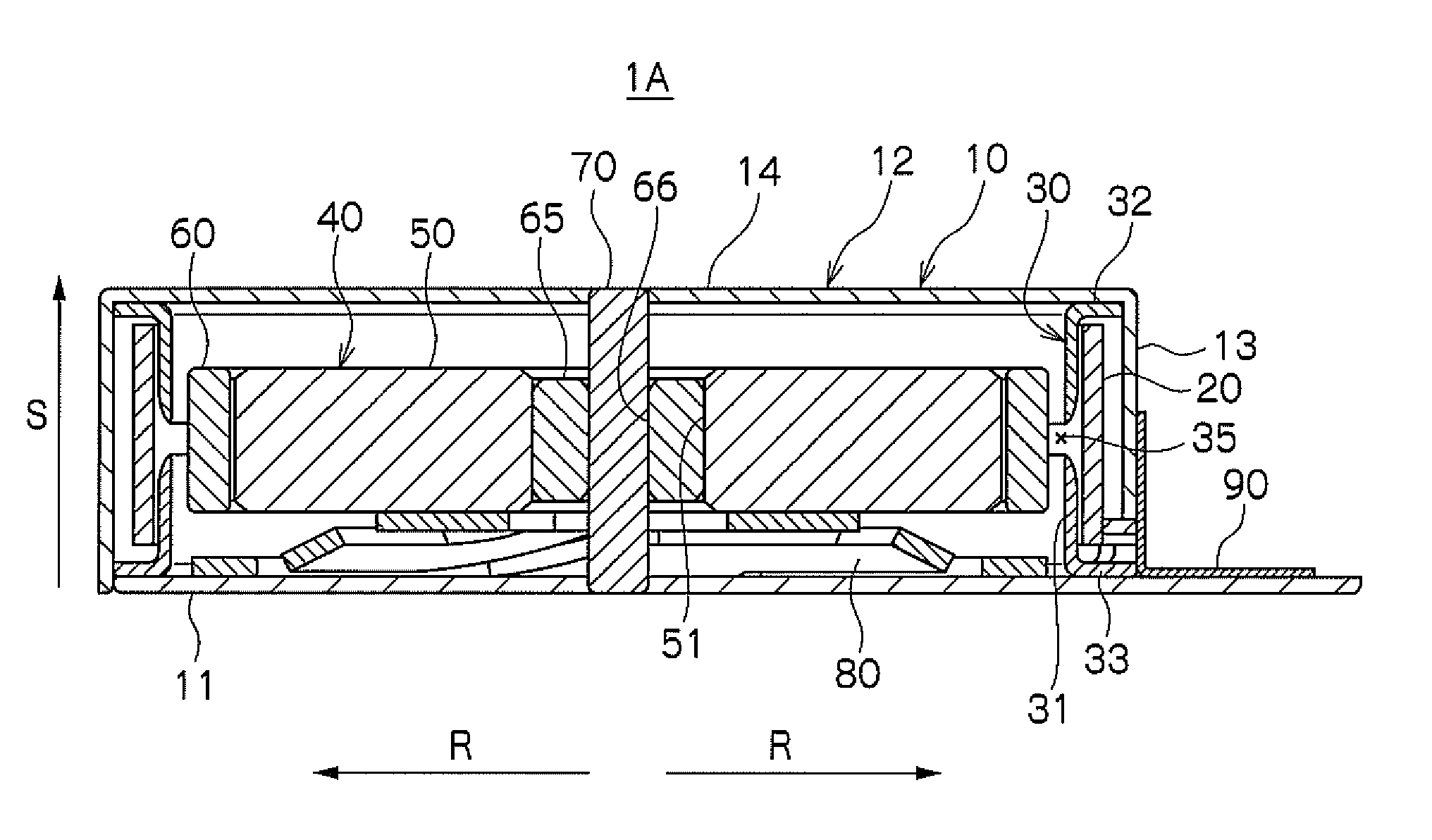

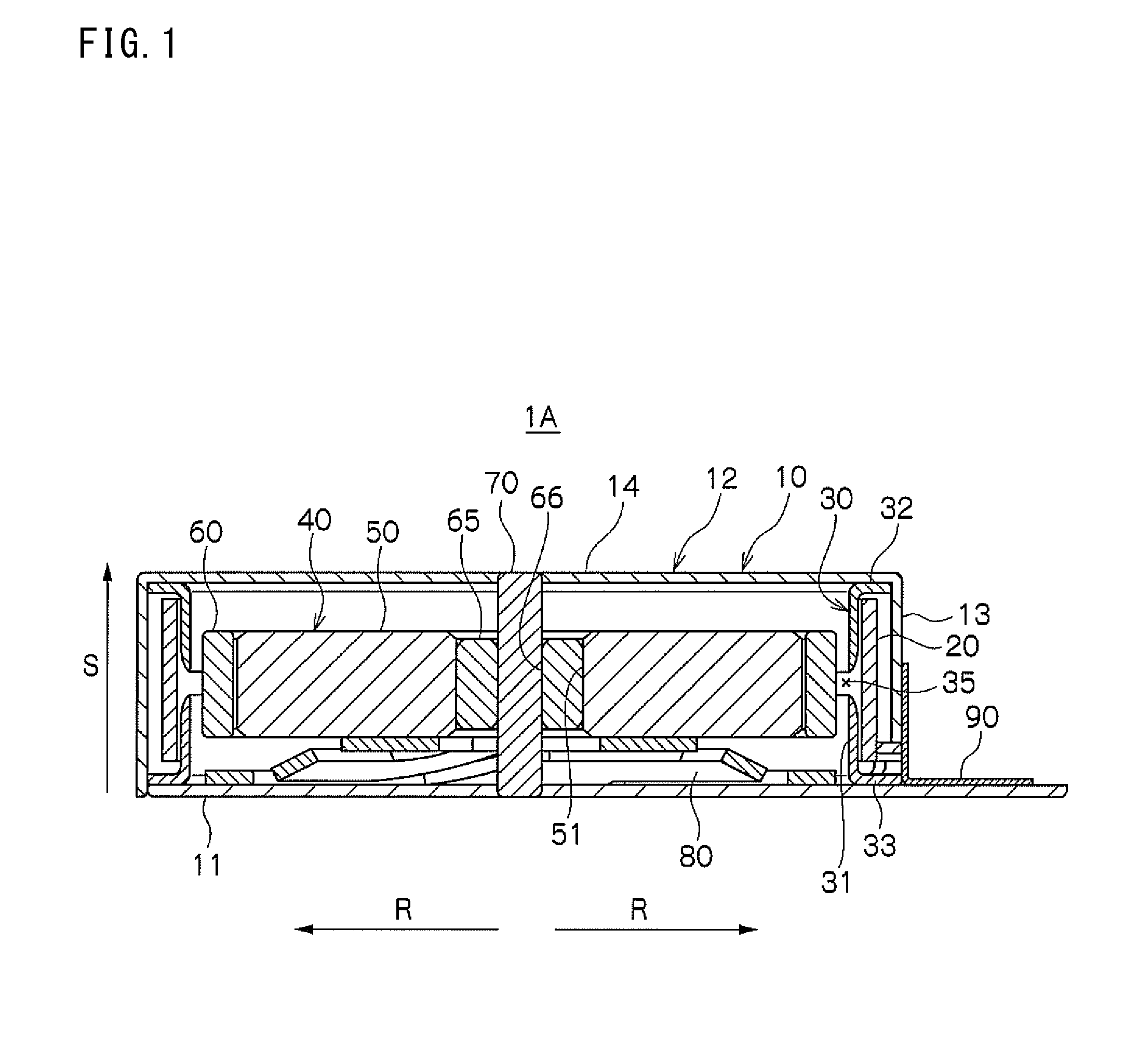

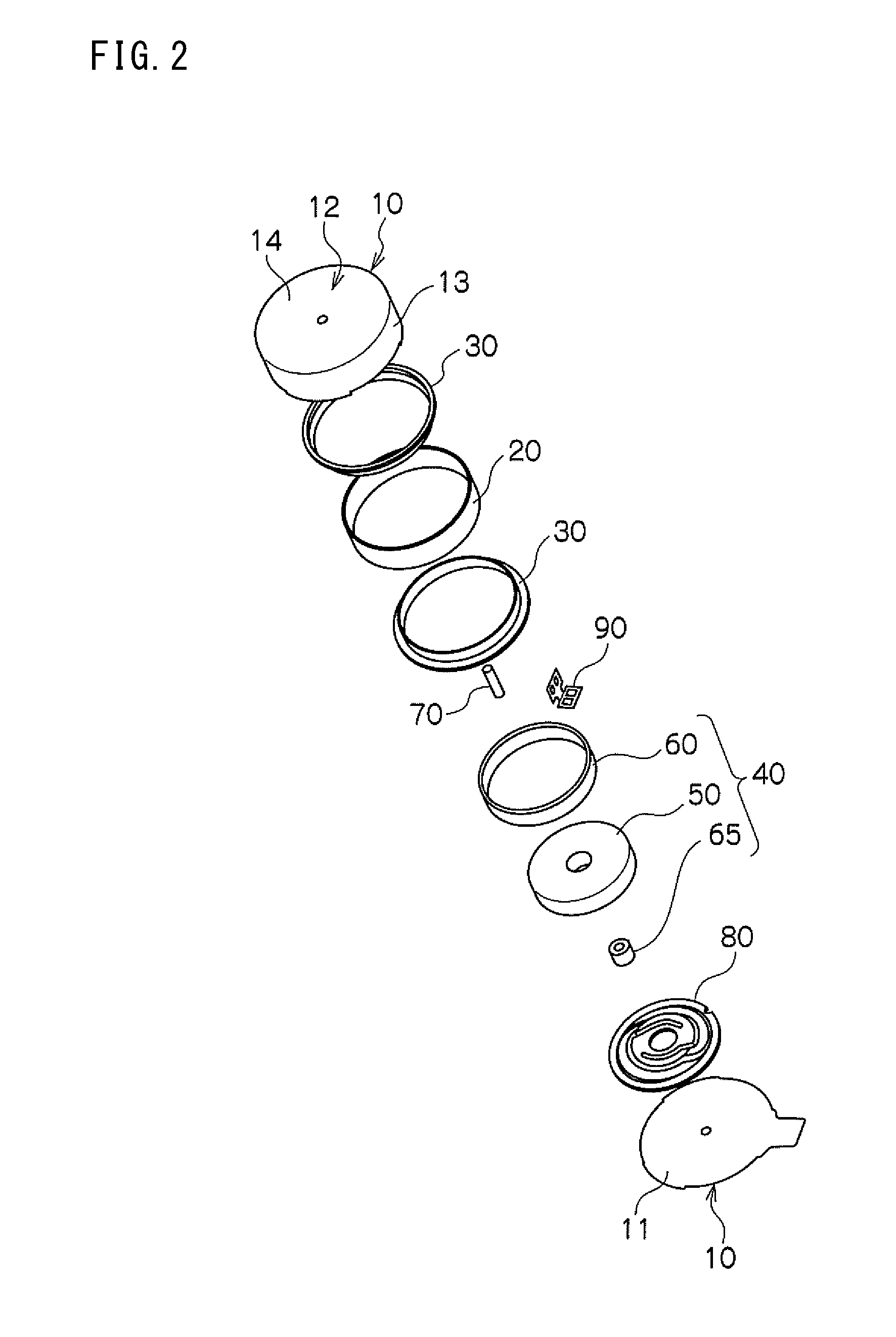

Vibration generator

A vibration generator includes a coil, a vibrating body, a spring, and a shaft. The coil is arranged to generate magnetic fields. The vibrating body includes a magnet and a weight. The vibrating body is arranged to be vibrated in a thrust direction by an interaction of magnetic fields generated from the magnet and magnetic fields generated from the coil. The spring is arranged to support the vibrating body at one thrust-direction side of the vibrating body. The shaft is extended in the thrust direction through the vibrating body. The shaft is arranged to allow the vibrating body to slide along the shaft in the thrust direction.

Owner:SANYO SEIMITSU

Drawer buffer and drawer slide rail with drawer buffer

A drawer Buffer includes: the base, cylinder and plate with the guide rod projected in the front end; the cylinder of which is fixed in the base and there is a projecting column on the front end of its piston rod; in the middle of the guide rod, there is a sliding chute for the move of piston rod; in the outer side of the guide rod, there is a guideway to coordinate with the projecting column, the front end of the guideway is linked with a positioning slot; on the plate, there is the guiding slot for traction and pushing the projecting column into the positioning slot; the section shape of the mentioned cylinder sleeve and piston rod of the cylinder is similar to the ellipse, the tail of the cylinder sleeve is linked with the head of piston rod via the spring. The buffer can be used with a drawer slide rail for drawer moving reposefully.

Owner:HSIEH YIN WANG +1

Bi-directional actuator utilizing both attractive and repulsive electrostatic forces

InactiveUS7705514B2Increase the total strokeSimple structurePiezoelectric/electrostrictive device detailsElectrostatic motorsEngineeringElectrostatic actuator

An electrostatic actuator comprising: first and second comb arrays of electrodes arranged on a base, the electrodes of the first and second comb arrays being interleaved; a third comb array of electrodes spring mounted over the first and second comb arrays, the electrodes of the third comb array being essentially aligned with the electrodes of the second comb array; means for applying a first voltage to the third comb array and a second voltage to the first and second comb arrays to generate an attractive force acting on the third comb array to move the third comb array toward the second comb array; and, means for applying the first voltage to the second and third comb arrays and the second voltage to the first comb array to generate a repulsive force acting on the third comb array to move the third comb array away from the second comb array.

Owner:HE +1

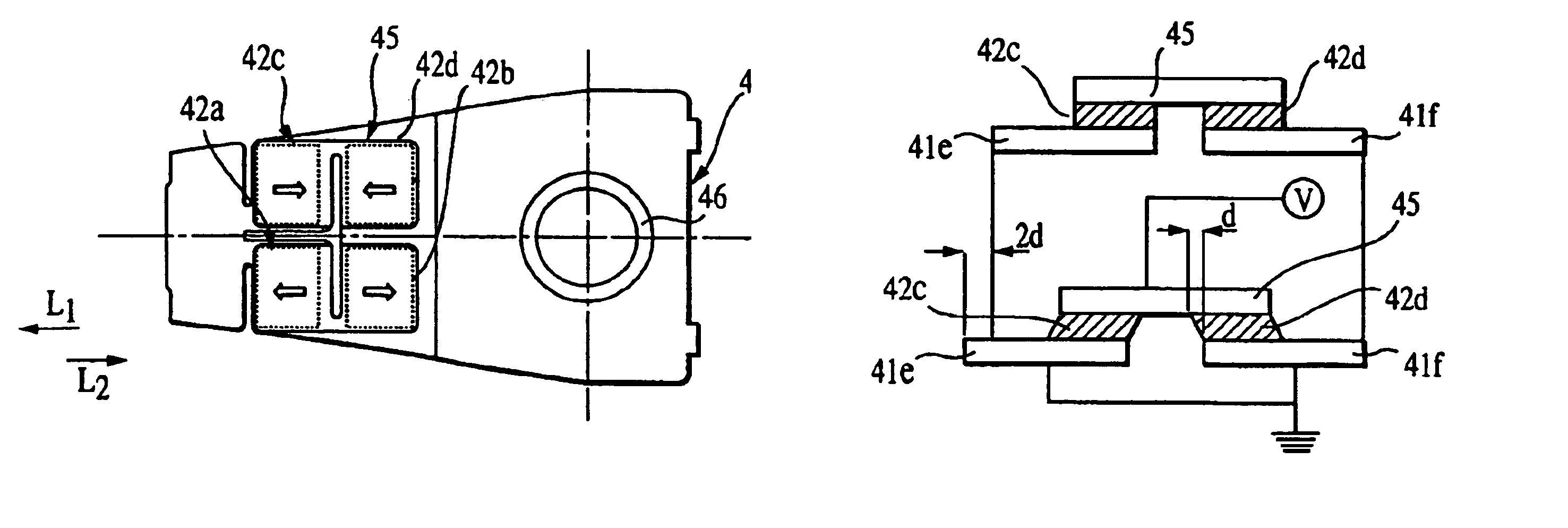

Disc drive magnetic head fine positioning mechanism including a base connecting a suspension to an arm, and having a piezoelectric drive element adjacent thereto

InactiveUS7061724B2Eliminate disadvantagesHigh dimensional accuracyTrack finding/aligningRecord information storageEngineeringDriven element

A fine positioning mechanism is provided in a disc drive for driving a head that records data onto and reproduces data from a disc. The mechanism includes a base fixed to an arm and a suspension, the base connecting the suspension to the arm, the arm swinging around a rotary shaft, and the suspension supporting the head. A drive part is located above the base, for deforming the base, the drive part including a shear type piezoelectric element that is polarized in a direction orthogonal to a thickness direction of the piezoelectric element, and deforms top and bottom surfaces of the piezoelectric element perpendicular to the thickness direction when voltage is applied to the piezoelectric element in the thickness direction.

Owner:TOSHIBA STORAGE DEVICE CORP

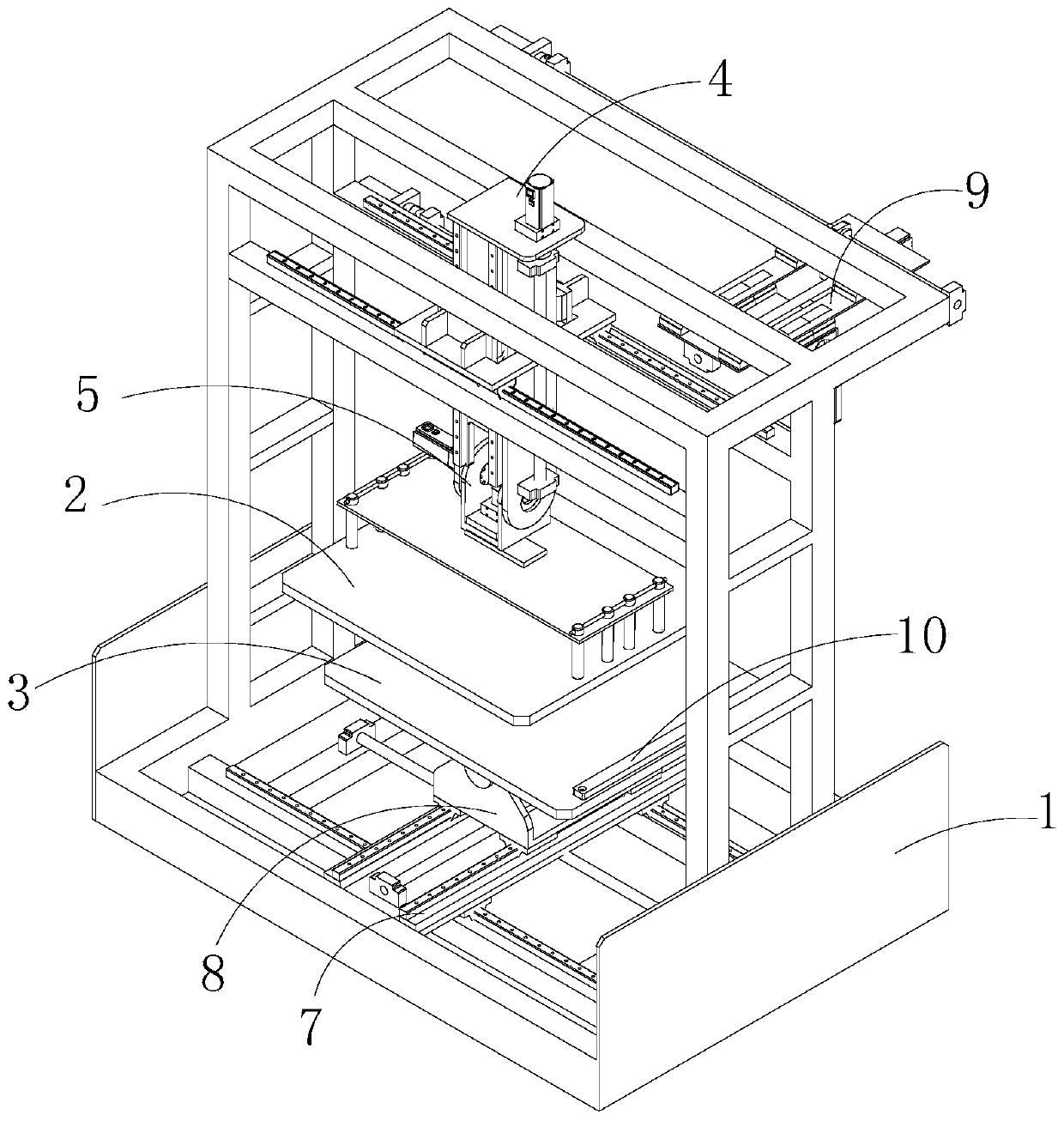

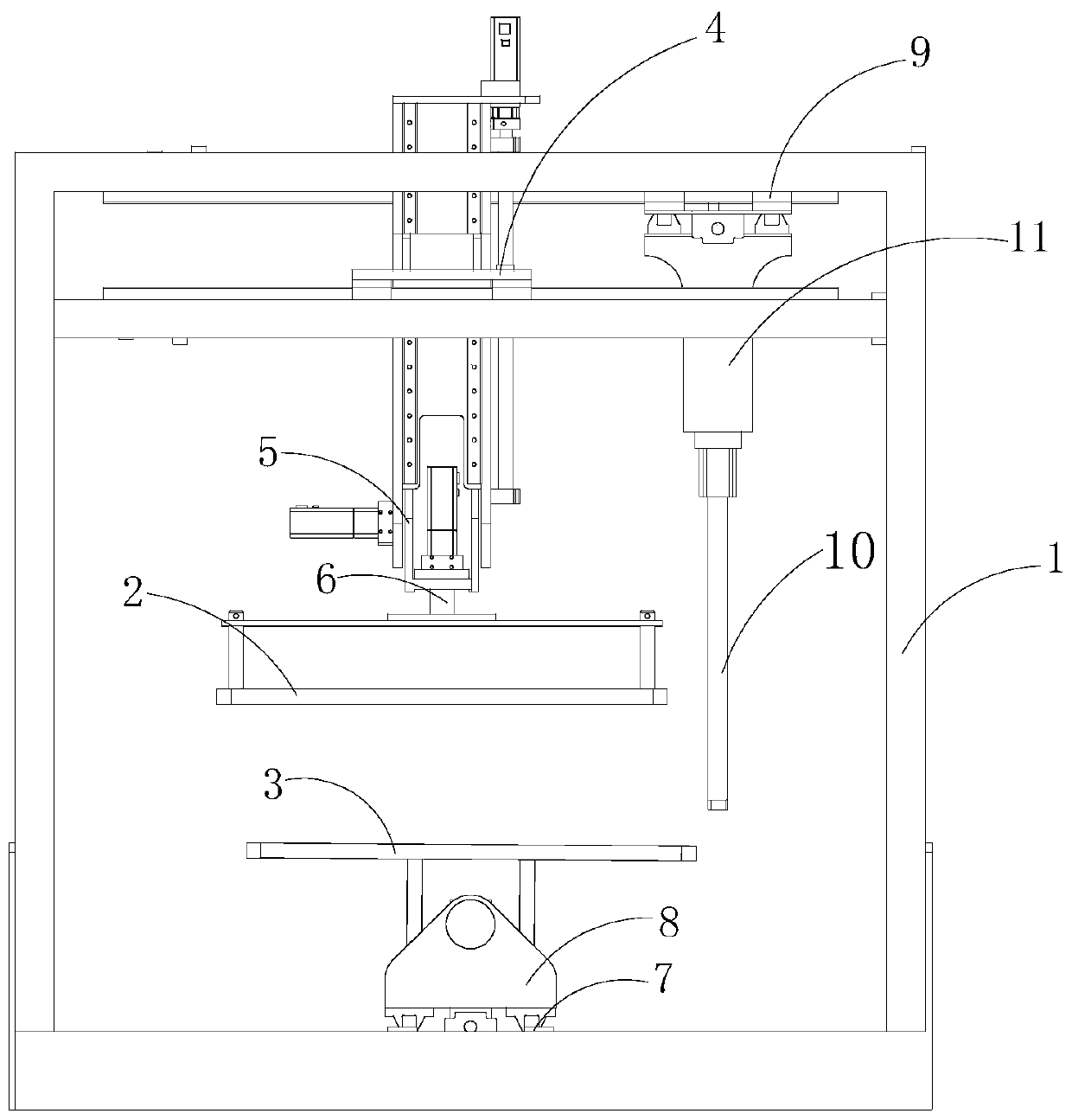

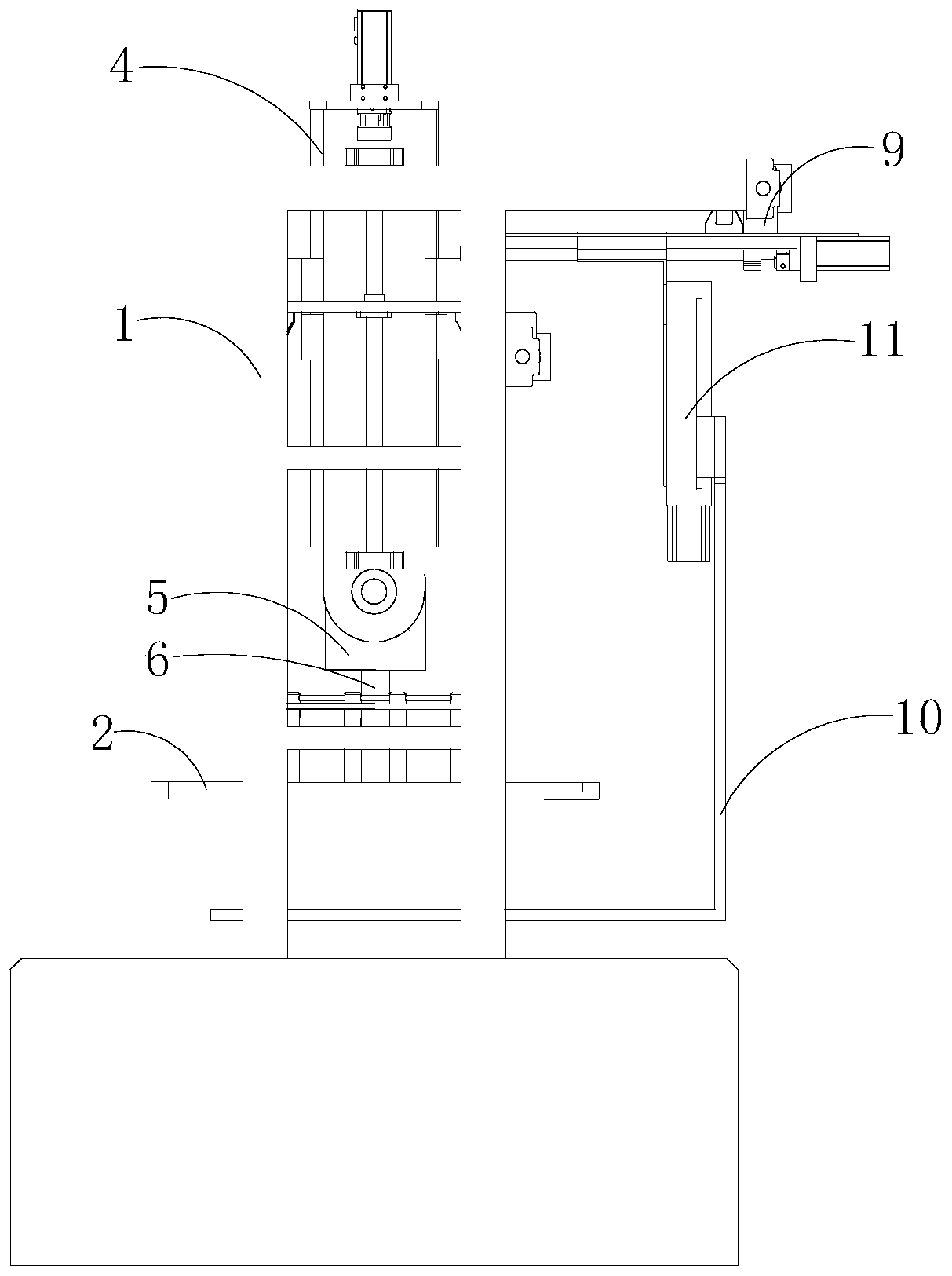

Wireless charging test bench for electric vehicle

PendingCN110988573ALong test distanceSmall sizeVehicle testingElectrical testingElectric vehicleInductive charging

The invention discloses a wireless charging test bench for an electric vehicle. The test bench comprises a rack, an upper flat plate and a lower flat plate which are mounted on the rack. The lower flat plate is used for placing a transmitting coil; the upper flat plate is used for placing a receiving coil; and the lower flat plate and the upper flat plate are both made of non-metal insulating materials. The upper flat plate and the lower flat plate can be installed on the rack in a sliding mode in an X-axis direction, at least one of the upper flat plate and the lower flat plate can slide in aY-axis direction, at least one of the upper flat plate and the lower flat plate can ascend or descend in a Z-axis direction, and at least one of the upper flat plate and the lower flat plate can be installed on the rack in a rotating mode around the vertical center line. One of the upper flat plate and the lower flat plate deflects around the X axis, and the other one deflects around the Y axis.The test bench can be used for testing items such as electromagnetic field distribution and size, transmission distance, transmission efficiency and the like between the transmitting and receiving coils as well as testing relative spatial position changes and position alignment between the transmitting and receiving coils and is particularly suitable for testing a static or dynamic wireless systemof an electric vehicle.

Owner:无锡市沃乐思科技有限公司 +1

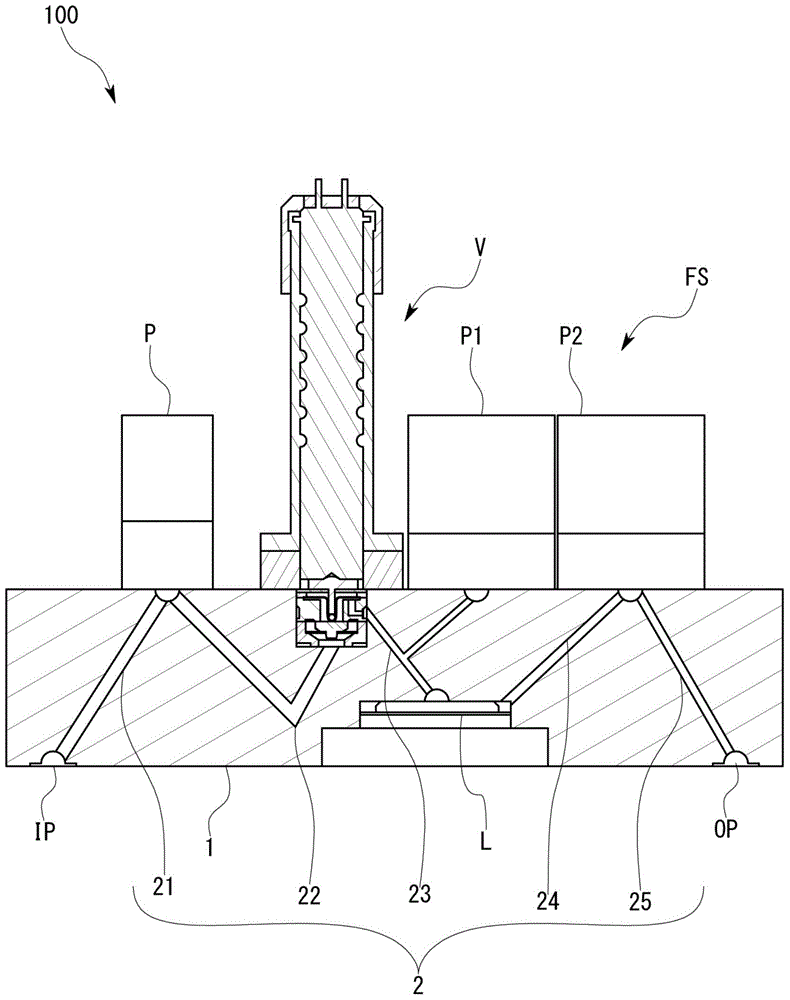

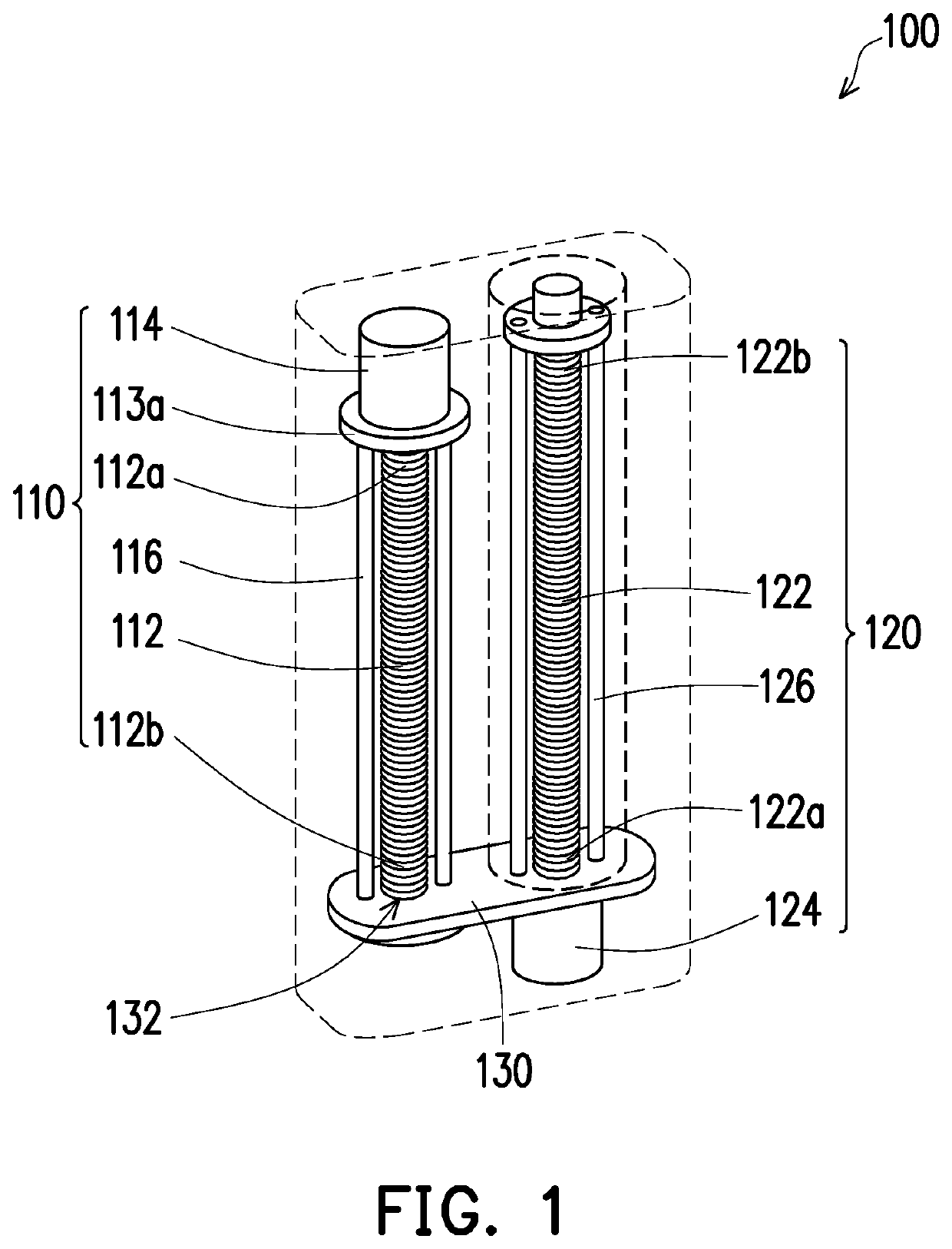

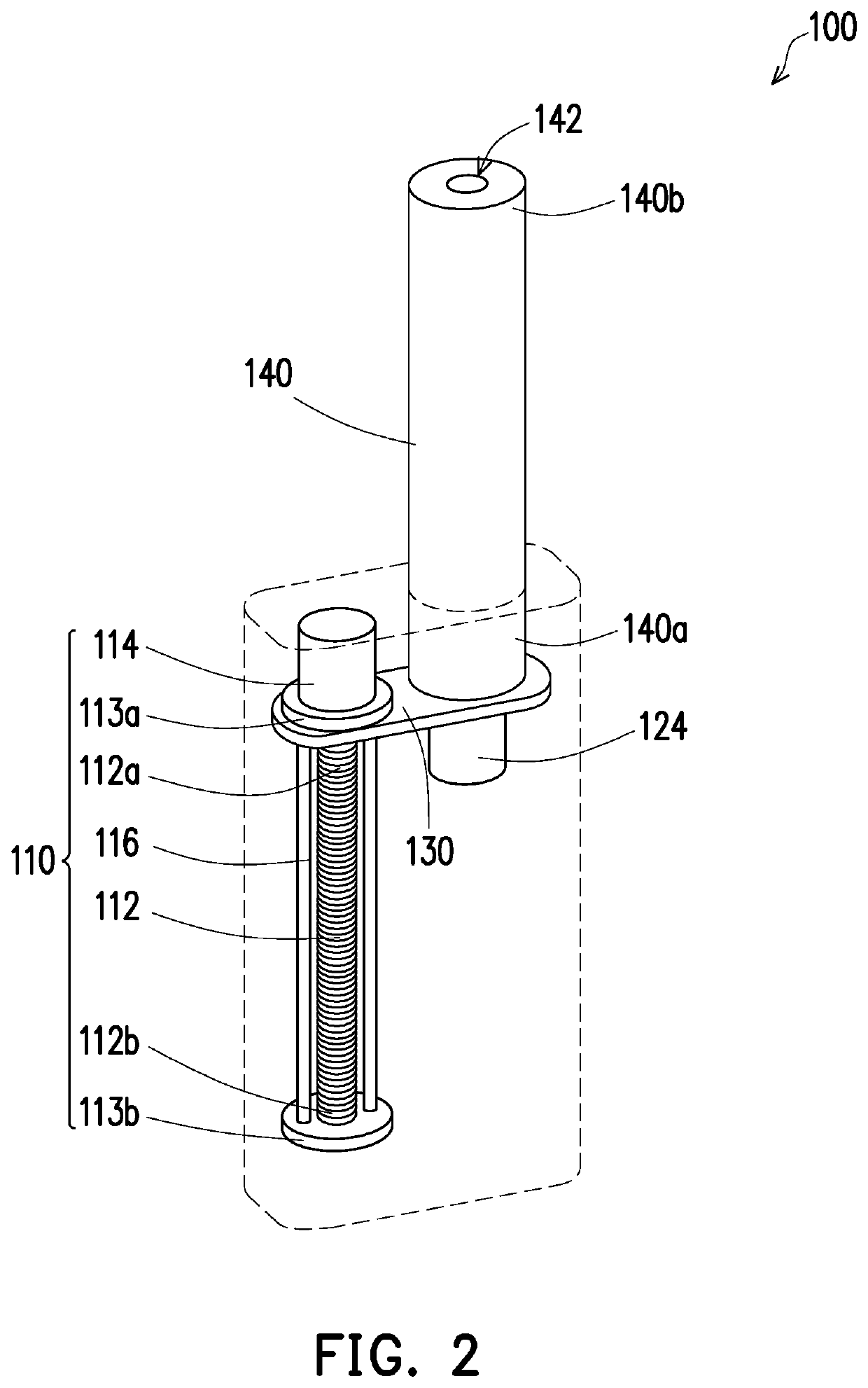

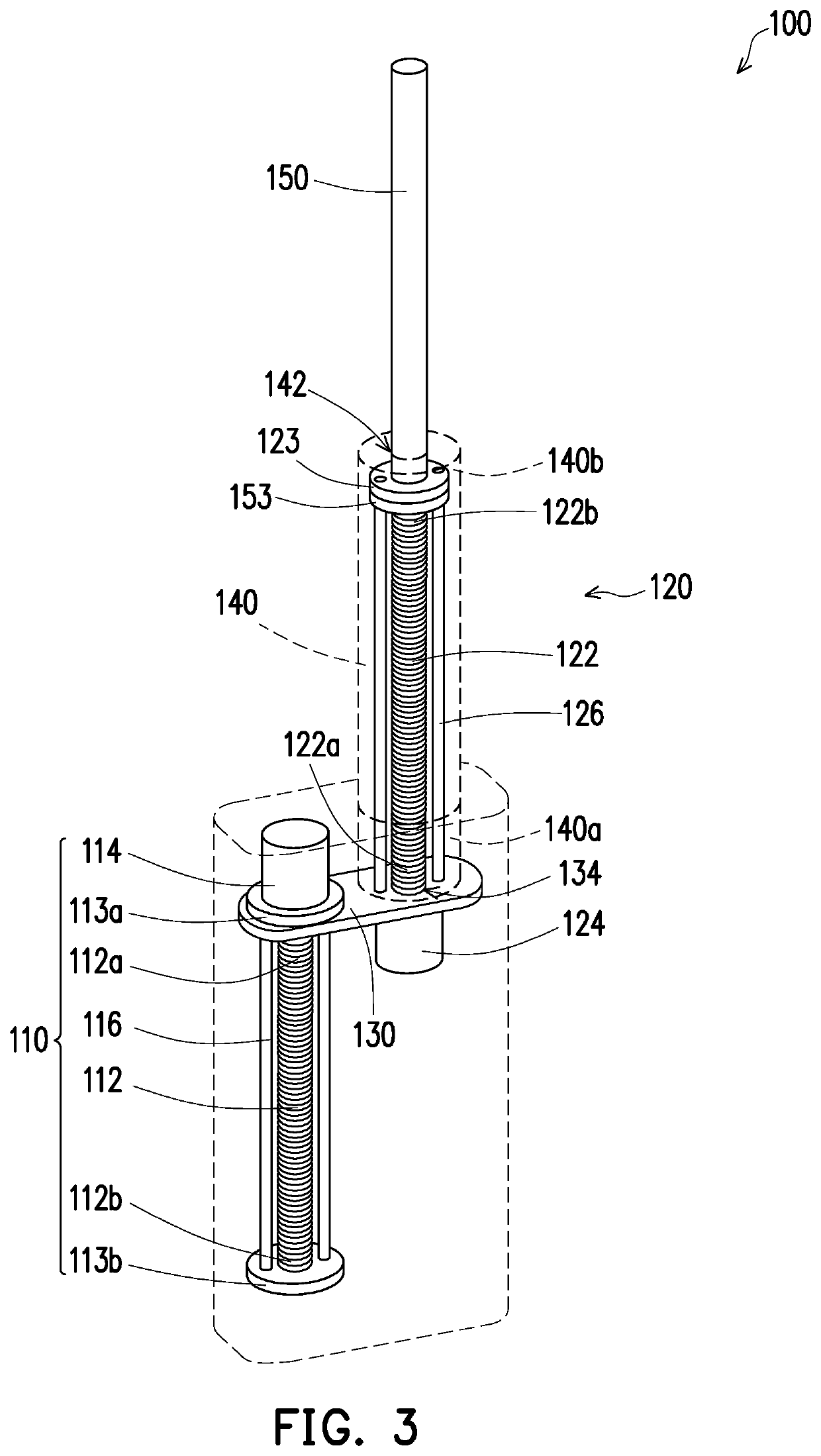

Telescopic adjuster

ActiveUS20190390752A1Effectively increasing a strokeControl the moving distanceGearingRod connectionsLinear actuatorControl theory

A telescopic adjuster including first and second linear actuators, a connecting platform and first and second telescopic levers is provided. The first linear actuator includes a first screw and a pair of first fixing rings. The first fixing rings are arranged at two respective ends of the first screw. The second linear actuator includes a second screw and a second fixing ring. The second fixing ring is arranged at the end of the second screw, relatively away from the connecting platform. The first and second linear actuators are arranged on the connecting platform in parallel. The first screw pushes the connecting platform to move along the first screw, and the first fixing rings limit a movement of the connecting platform. The first and second telescopic levers are coaxially arranged.

Owner:PEGATRON

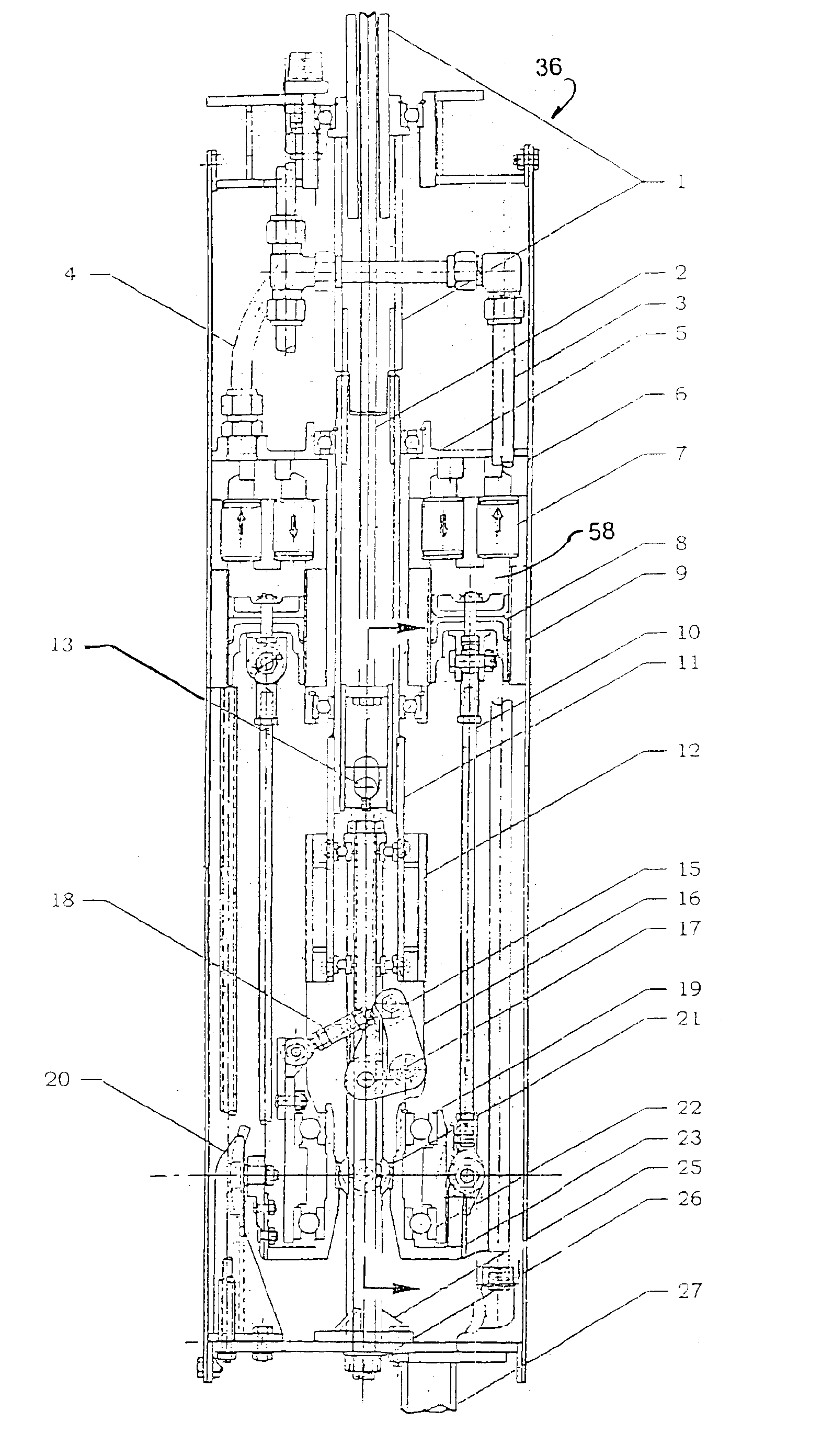

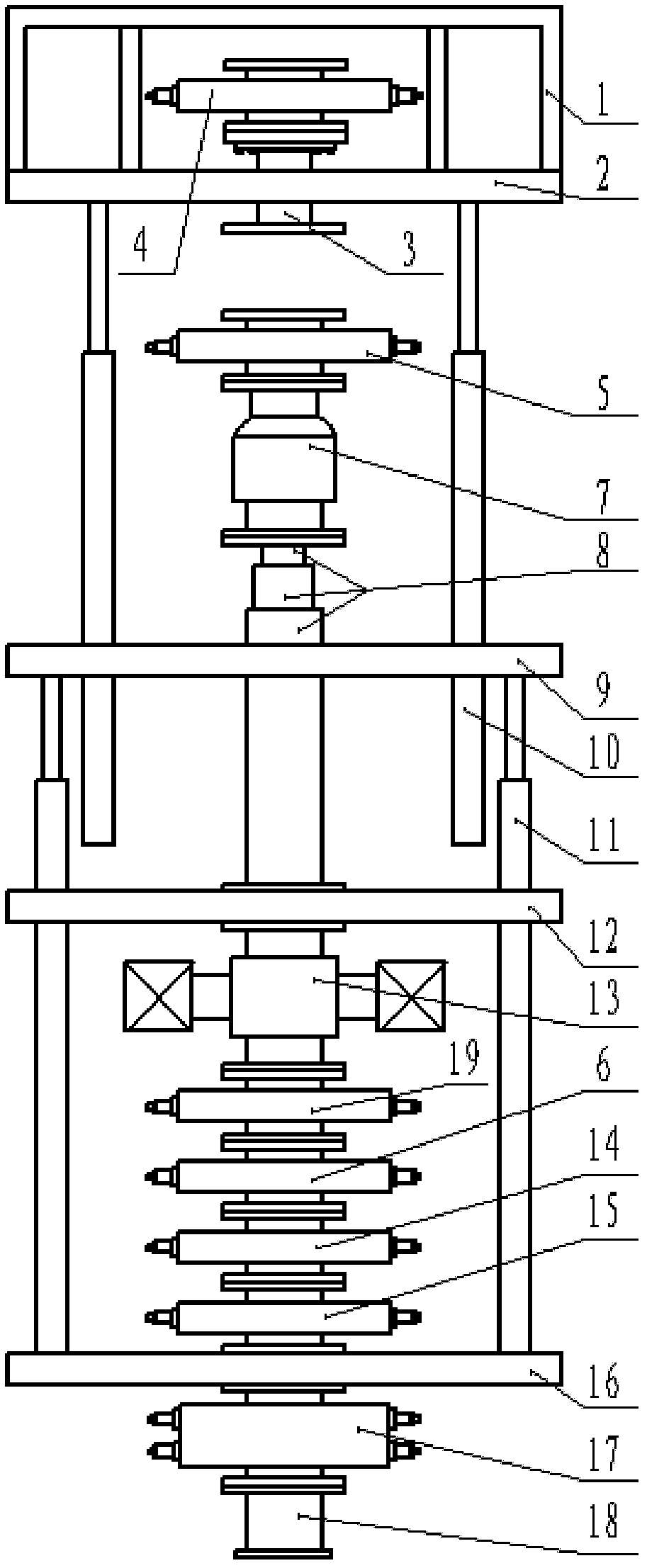

Long-stroke no-killing well working device of oil-water well

InactiveCN102561978AIncrease the total strokeImprove work efficiencyDrilling rodsCleaning apparatusWellheadTelescopic cylinder

The invention belongs to the field of machinery manufacture, in particular relates to a long-stroke no-killing well working device of an oil-water well. The long-stroke no-killing well working device of the oil-water well comprises a moving slips, an annular blowout preventer, a totally-enclosed blowout preventer, an upper half-enclosed blowout preventer, a lower half-enclosed blowout preventer, a hoisting hydraulic cylinder, a wellhead four-way, a cutting blowout preventer, a fixed slips, a double-disc blowout preventer, a reducing flange, an operating rod and a cleaning tool. The long-stroke no-killing well working device is characterized in that the device also comprises a flexible rod, a multistage hydraulic cylinder and a rotation flange. The stroke of operation is improved by using the multistage hydraulic cylinder and the flexible cylinder, and the moving slips can be rotatably moved by using the rotation flange to drive the operating rod and the cleaning tool to clear the fouling of an inner wall of the oil pipe in a rotating way. The device of the invention also can press a lower oil pipe under the condition of no-injection of the oil pipe. The device is convenient to operate, greatly improves the working efficiency and is favorable for generalization and application.

Owner:王秀忠

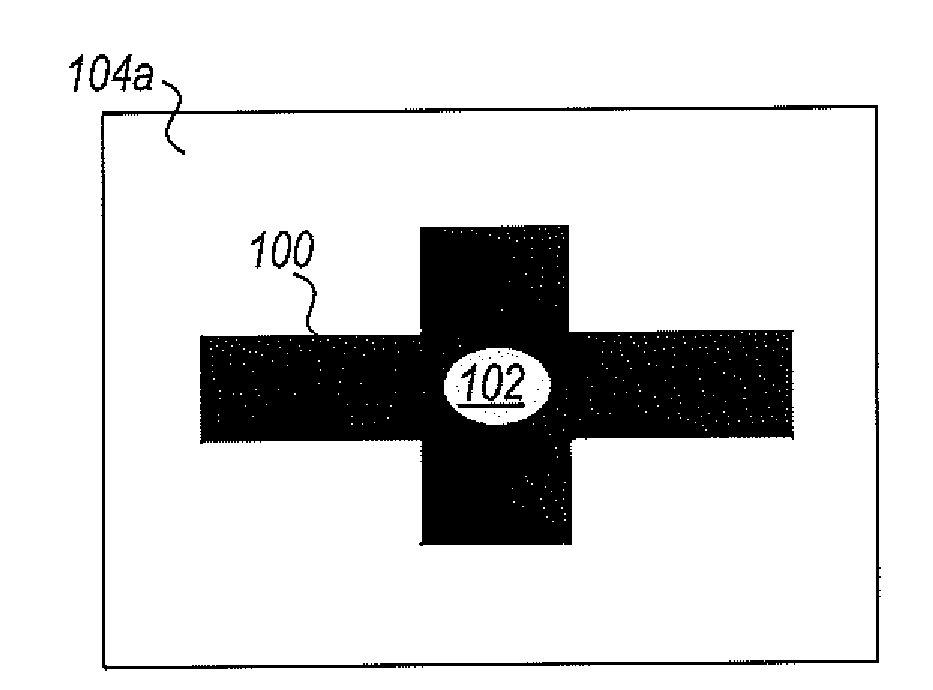

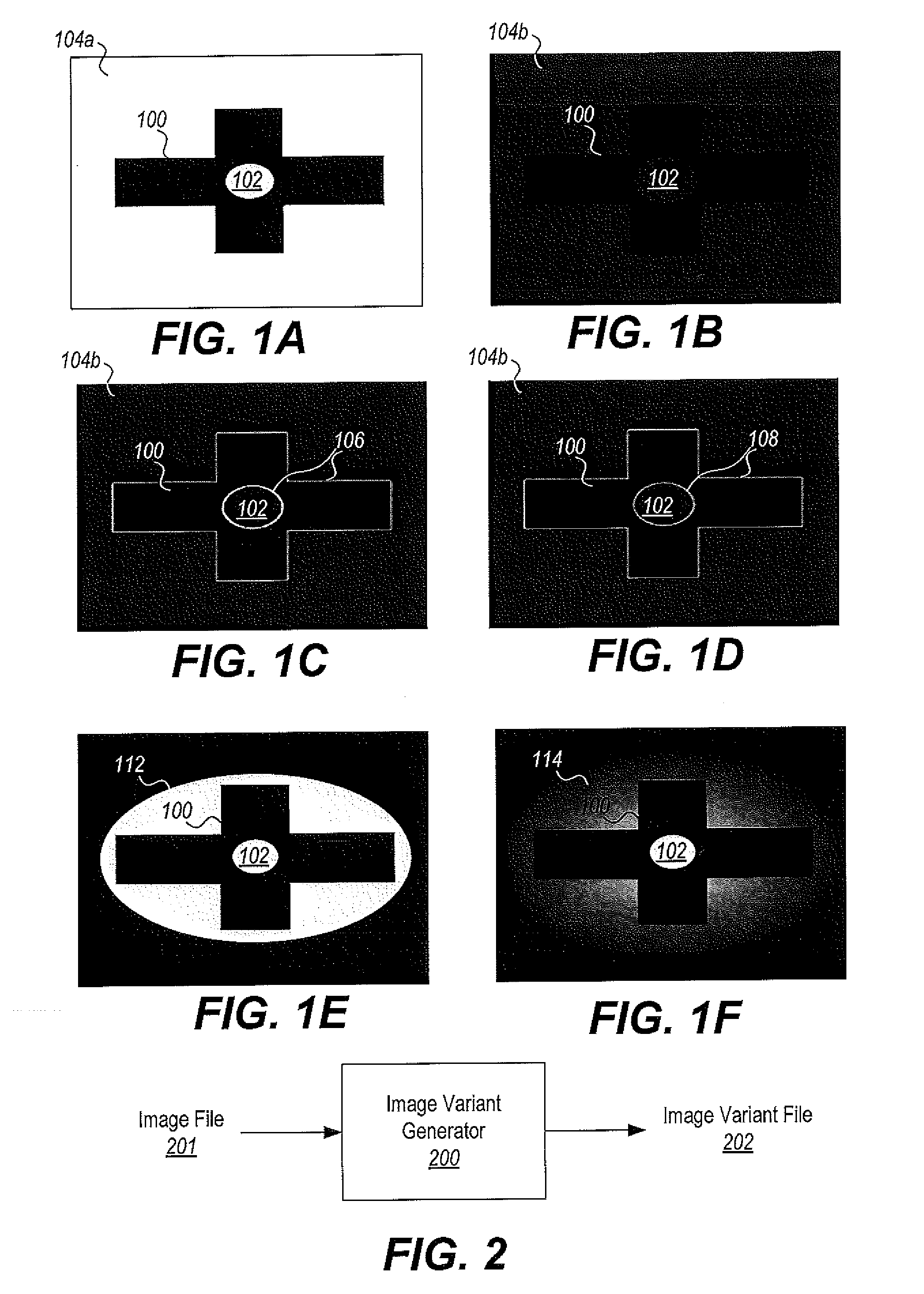

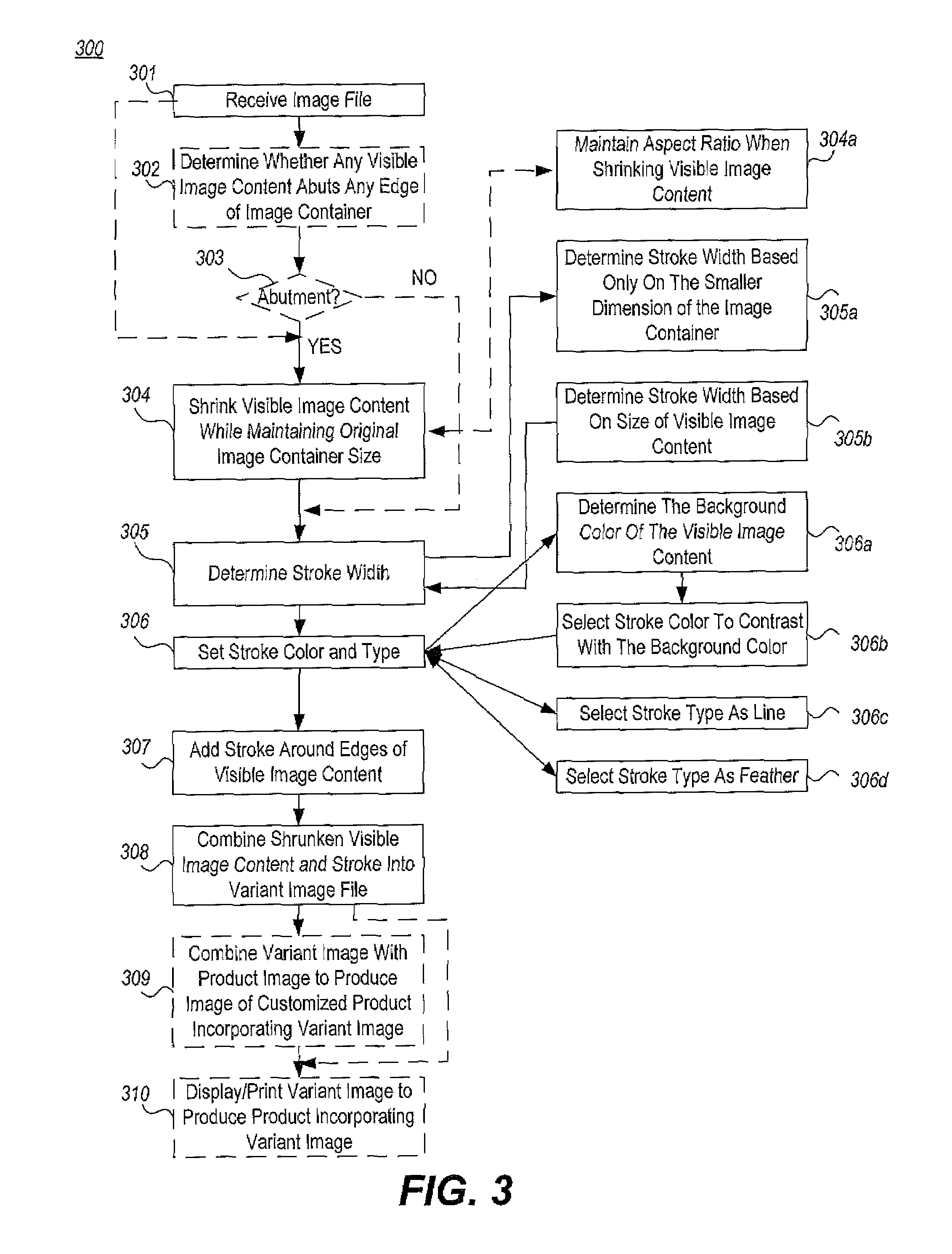

Creating images for displalying or printing on low-contrast background

InactiveUS20090189913A1Keep sizeIncrease the total strokeImage enhancementImage analysisElectronic documentComputer graphics (images)

Techniques for automatically adding special effects to an image to be overlaid on a low-contrast background are presented. A stroke or an intervening layer of a color contrasting with the background color is automatically added to provide a contrasting color around the edges of visible image content in an image container of an electronic document. The technique may be applied to entire libraries of images to generate variant images that are visually perceptible when displayed or printed on low-contrast background colors.

Owner:CIMPRESS SCHWEIZ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com