Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve whole yarn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method for increasing low-grade tobacco use value

A processing method for increasing low-grade tobacco use value includes the steps: moistening a tobacco group composed of low-grade tobacco to enable the water content to be 18-22%; storing for 1-24h, and entering a lining feeder to enable the tobacco water content to be 28-36%; using a burley tobacco curing machine to dry the tobacco under the conditions that the temperature is 70-1100 DEG C and the process flow is 1600kg / h to enable the water content of tobacco in a cooling area to be 4-7%, and entering a resurgence area to enable the tobacco water content to be 10-14%; entering a surface material feeder to enable the tobacco water content to be 18.5-21.5% after surface material feeding, storing for 1-4h, and shredding, wherein the tobacco water content is 17.5-20.5%; and drying the shredded tobacco through a sheet cut-tobacco dryer to enable the tobacco water content to be 12.5-13.5% after drying of cut tobacco. By means of the processing method, the use ratio of low-grade tobacco in third-grade and fourth-grade cigarettes can be evidently increased to be 8-20%, and cost of formula raw materials can be remarkably lowered.

Owner:CHINA TOBACCO ANHUI IND CO LTD

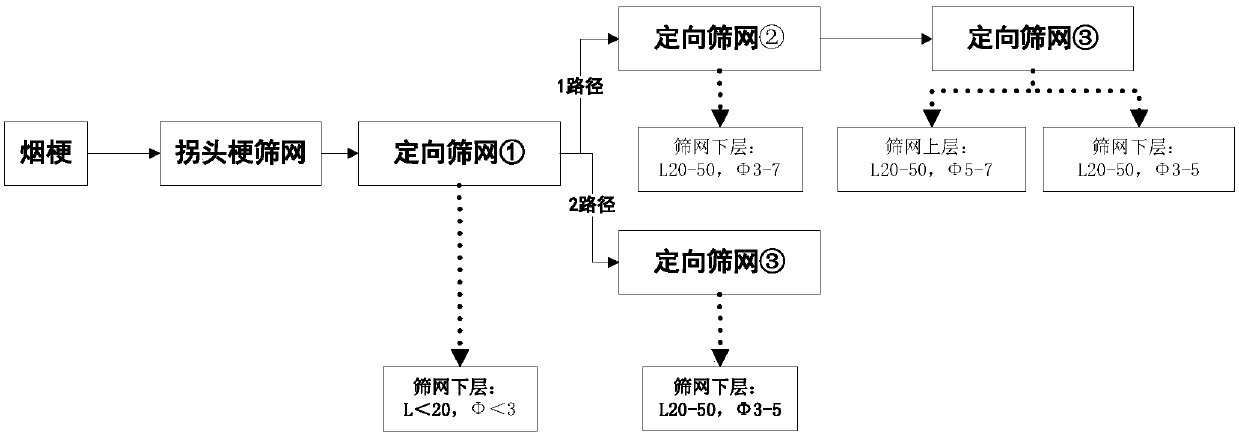

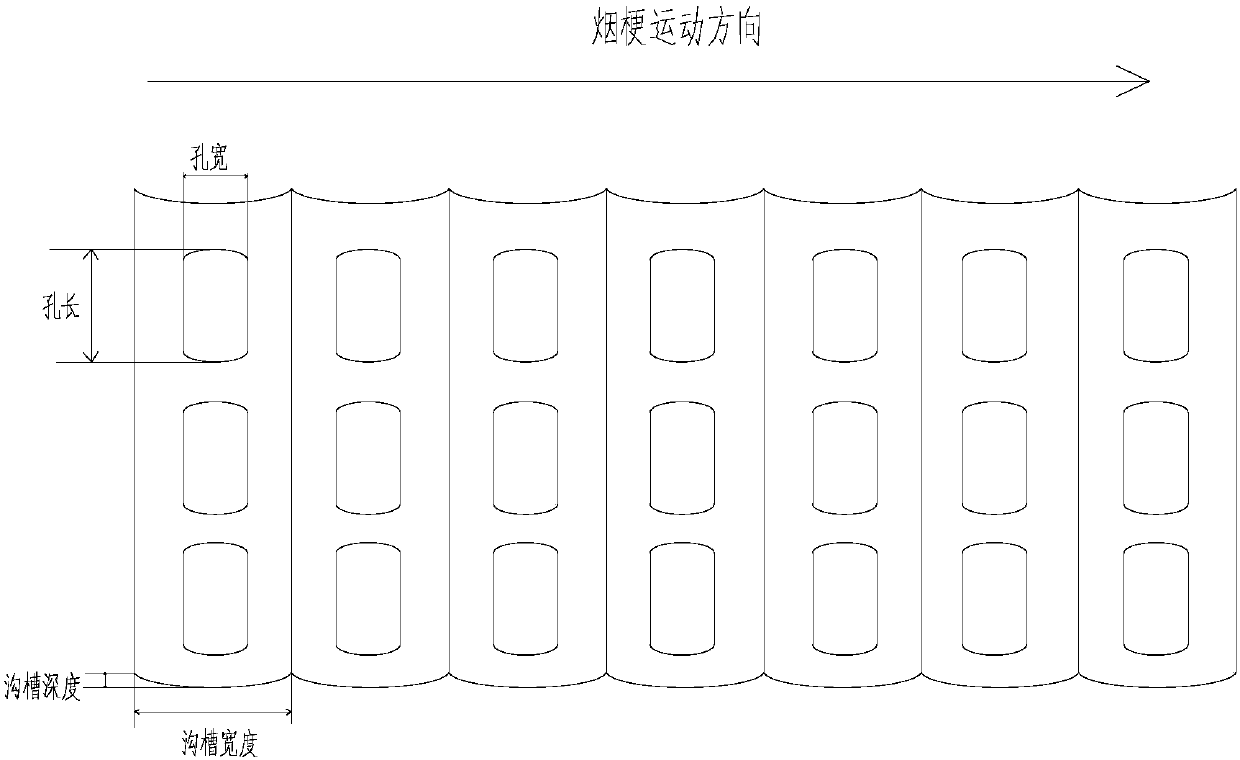

Tobacco stem sorting method suitable for different cigarettes

The invention provides a tobacco stem sorting method suitable for different cigarettes. The method comprises the following steps: (1) preliminary screening of tobacco stems; (2) first screening: screening the tobacco stems obtained by the preliminary screening in the step (1) by adopting a vibrating screen screening device with a directional screen (1); (3) second screening: dividing the tobacco stems obtained in the step (2) into two strands, wherein the first strand is screened by a vibrating screen screening device with a directional screen (2) and the second strand is screened by a vibrating screen screening device with a directional screen (3); (4) third screening: screening the tobacco stems screened by the vibrating screen screening device with the directional screen (2) in the step(3) by using a vibrating screen screening device with a directional screen (3); and (5) respective collecting, packaging and marking and storing of the screened tobacco stems. According to the methodprovided by the invention, process route selection can be carried out according to actually required tobacco stem types. According to the method provided by the invention, the incoming quality of thetobacco stems is improved, so that the cut tobacco stem forming quality is improved, the cigarette quality is improved, and the blending of fine cut cigarette stems can be realized.

Owner:HUBEI CHINA TOBACCO IND

Flash evaporation puffing and roller drying treatment process for stalk shreds

ActiveCN102488314AImprove processing resistanceIncrease the yield of shredded stemsTobacco preparationCooking & bakingEngineering

The invention provides a flash evaporation puffing and roller drying treatment process for stalk shreds. According to the treatment process, jet type stalk shred heating and humidifying equipment and steam-heated drum-type shred baking equipment are adopted, the filling value of the stalk shreds is increased from 5.6 cm<3> / g to 6.0 cm<3> / g, namely increased by 7.1%, the processing resistance of the stalk shreds is markedly increased, the stalk shred output rate is increased by 0.6%, the integral stalk shred rate is increased by 1.4%, the outlet water content of the dried stalk shreds is uniform, the water content fluctuation is controlled within a range of + / -0.4%, the woody gas influence caused by stalk shreds in the cigarette product is effectively avoided, and at the same time, the dried stalk shreds are better in water content uniformity and lower in water content fluctuation.

Owner:HONGTA TOBACCO GRP

Processing method of high-grade tobacco expansion shreds

InactiveCN103005663AGood colorImprove whole yarn rateTobacco preparationFluidized bed dryingCO2 content

The invention discloses a processing method of high-grade tobacco expansion shreds. The method comprises the following steps of A, dampening cut tobacco shreds through a CO2 expansion line until the moisture content is 20 to 25 percent; B, dipping the cut tobacco shreds in a CO2 dipping tank, wherein the dipping time is 10 to 80 seconds, the CO2 draining time is 120 to 350 seconds, and the CO2 content in the dipped tobacco shreds is 2 to 6 percent; C, drying and expanding the tobacco shreds in a fluidized bed, wherein the process flow rate of the fluidized bed is 2,500kg / h, the temperature of the first area is 100 to 1,400 DEG C, the temperature of the second area and the third area is normal temperature, the steam flow is 600 to 900kg / h, and the moisture content of the dried and expanded tobacco shreds is 12.5 to 13.0 percent; and D, adding a characteristic aroma into the shreds by using an aroma adding machine. The expansion shreds manufactured by the process are relatively good in color and luster, lemon yellow and high in expansion shred finishing rate, the fill value is slightly lower than that of the expansion shreds manufactured in the prior art, the internal quality is obviously improved, and volatile and semi-volatile aromatic component loss is low.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Circulation method for preparing expanded cut tobacco

ActiveCN101617854AHigh energy consumptionReduce energy consumptionTobacco preparationFinal product manufactureVacuum pumpingProcess engineering

The invention discloses a circulation method for preparing expanded cut tobacco, comprising the following steps: (1) putting cut tobacco into a preheated impregnating tank, then carrying out vacuum-pumping; (2) spraying liquid expanding agent to the cut tobacco; (3) filling gas expanding agent to the impregnating tank; (4) impregnating; (5) first, recycling the liquid expanding agent, then recycling the gas expanding agent; and (6) expanding the impregnated cut tobacco, and carrying out operations in step (2) or / and step (3) by the liquid expanding agent and the gas expanding agent recycled in step (5). The method of the invention has mild condition and greatly reduced requirement for devices, by fully recycling the expanding agents, the cost is lowered, the complete set of devices has low energy consumption and high automation, continuous mass production can be carried out, all performance indexes of the obtained expanded cut tobacco are high, the expanded efficiency of the cut tobacco is high, and the recycling rate of the expanding agents is high.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

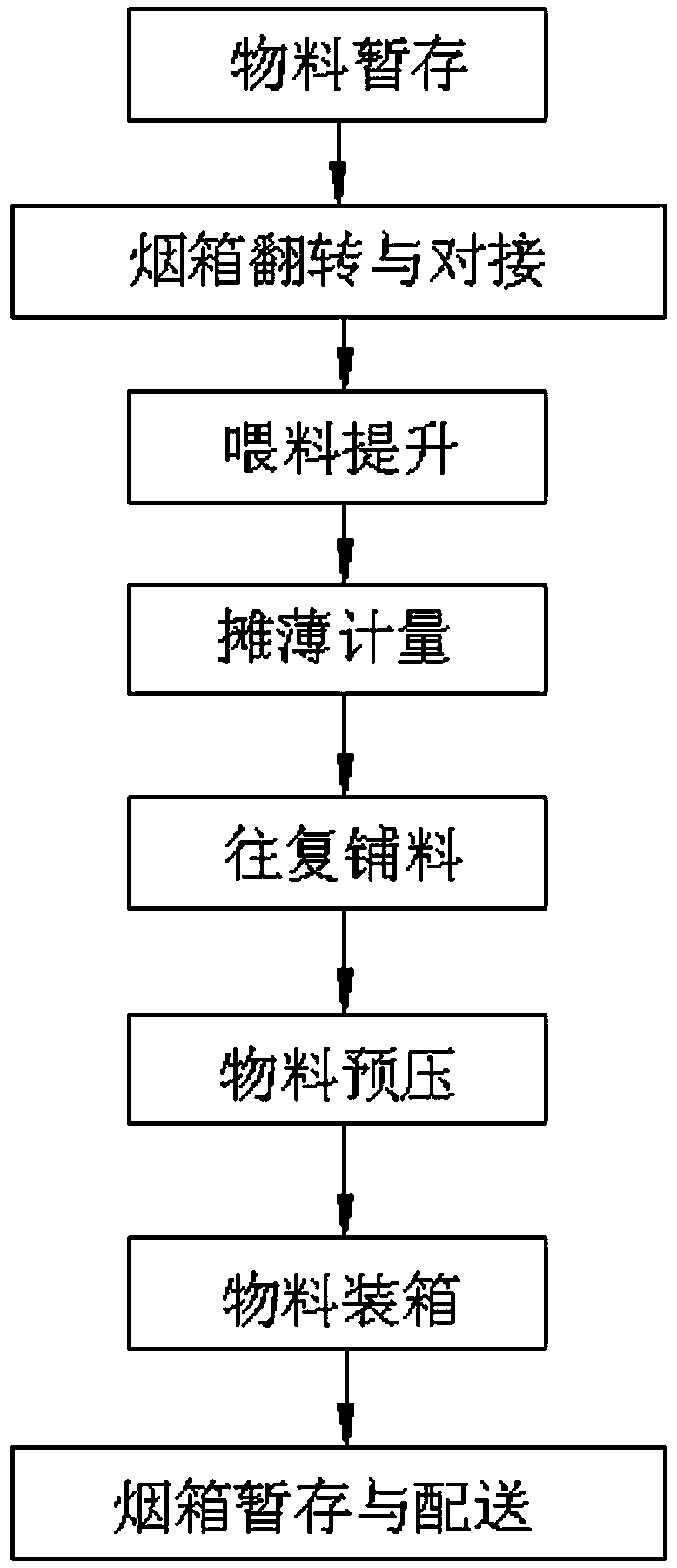

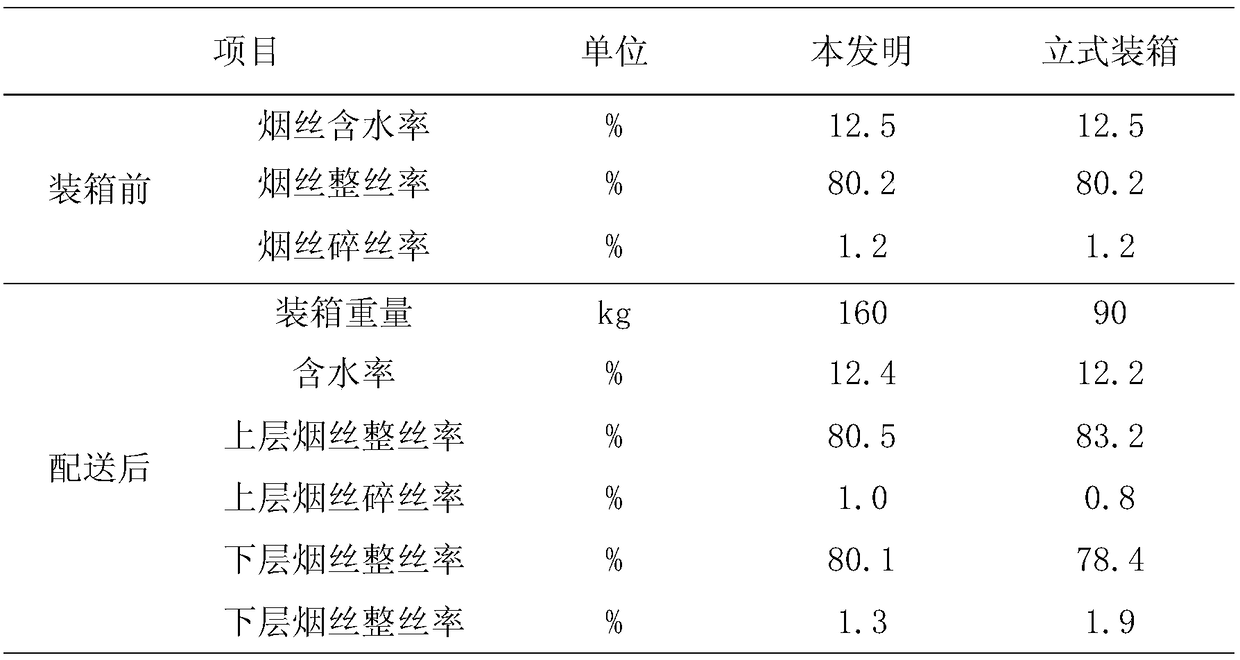

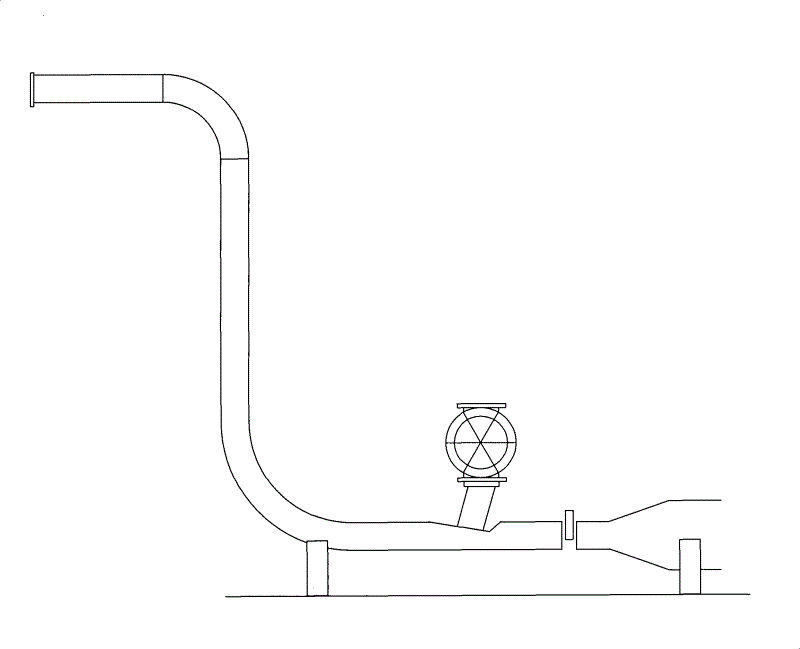

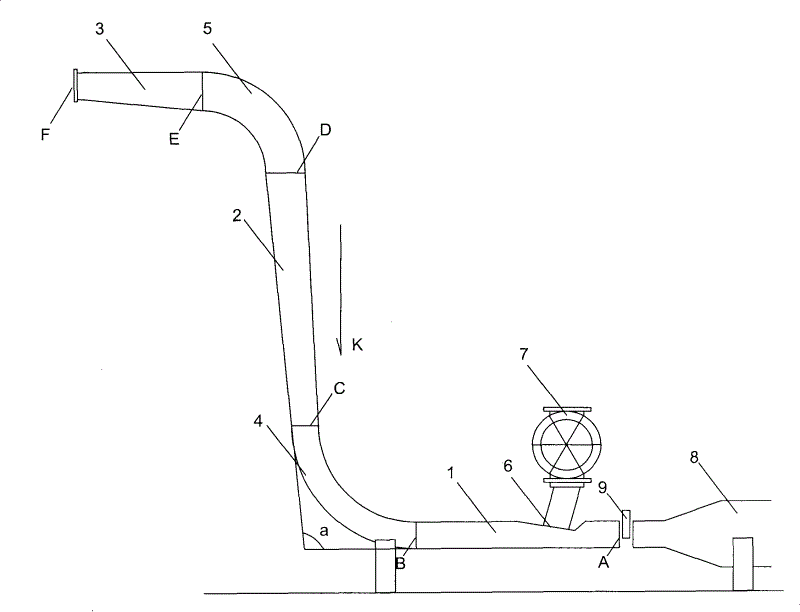

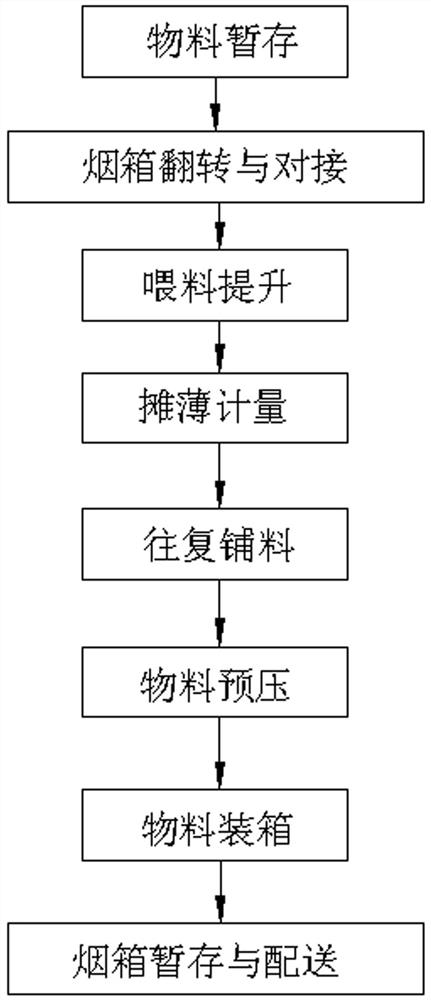

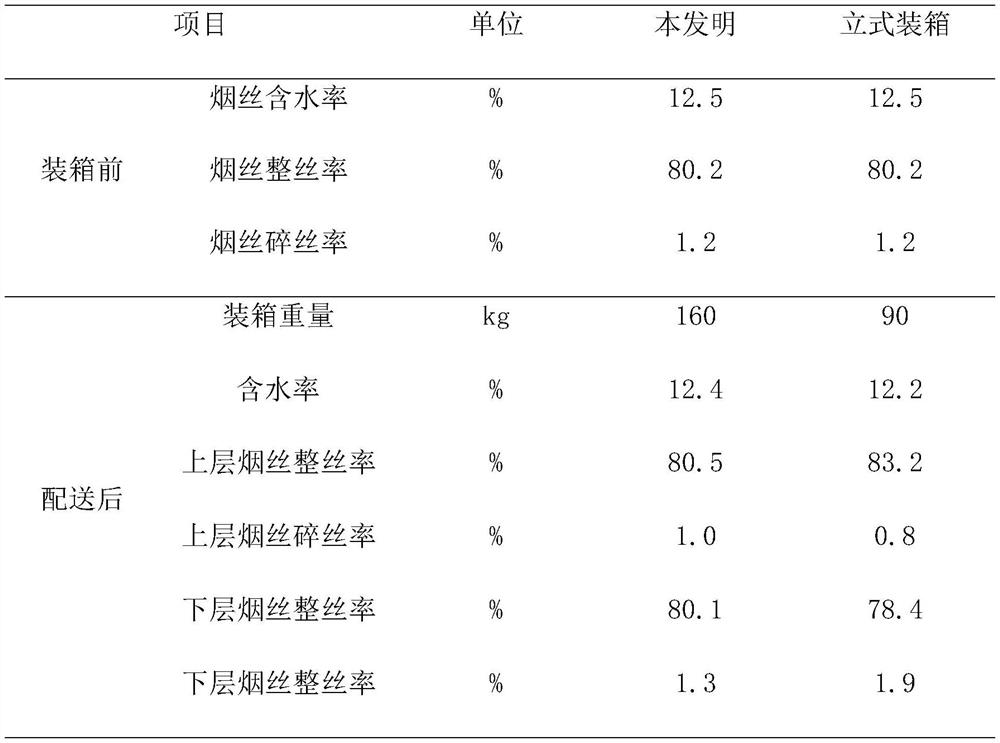

Prepressing and boxing process for filamentous tobacco materials

ActiveCN108910185ASolve the problem of pile upGuaranteed uniformityIndividual articlesProcess equipmentButt joint

The invention discloses a prepressing and boxing process for filamentous tobacco materials. The process comprises the production flow of material temporary storage-tobacco box overturning and butt joint-feed lifting-thinning and metering-reciprocating pavement-material prepressing-material boxing-tobacco temporary storage and distribution; a traditional vertical boxing process is improved; the boxing uniformity and the boxing density of tobacco materials in boxes can be improved; the transportation cost is reduced; the field requirement is low; the process equipment floor area and the factorybuilding design requirements are reduced; the equipment cost is indirectly reduced; the tobacco shredding rate can be effectively reduced; and the process is suitable for boxing and distribution of such tobacco materials as shredded tobaccos, expansion shredded tobaccos, sheet shredded tobaccos and cut stems, and is wide in application range.

Owner:CHINA TOBACCO HENAN IND

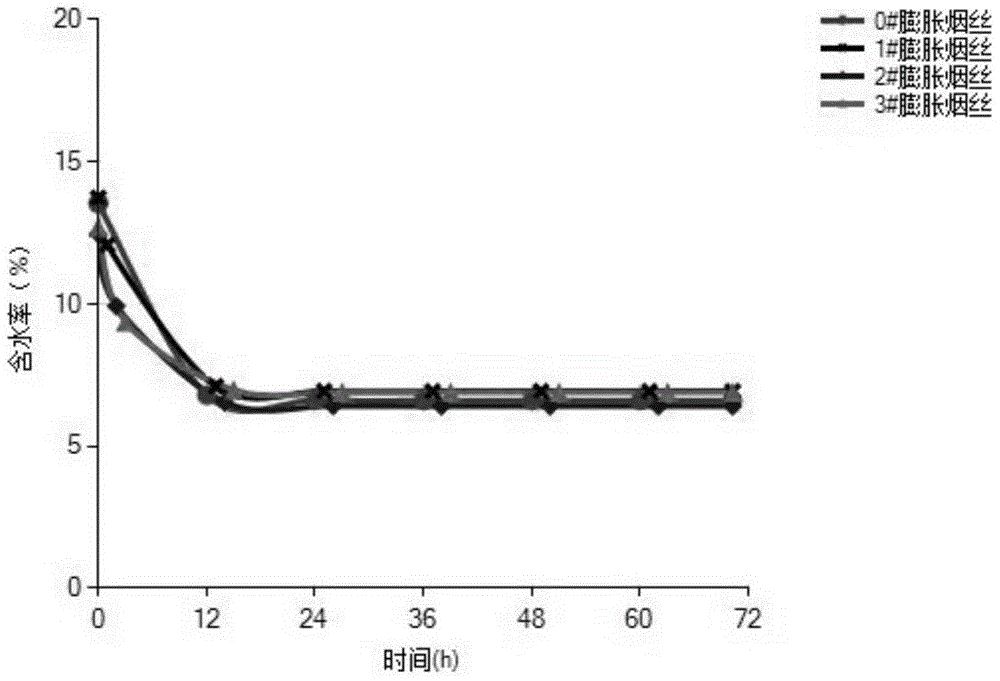

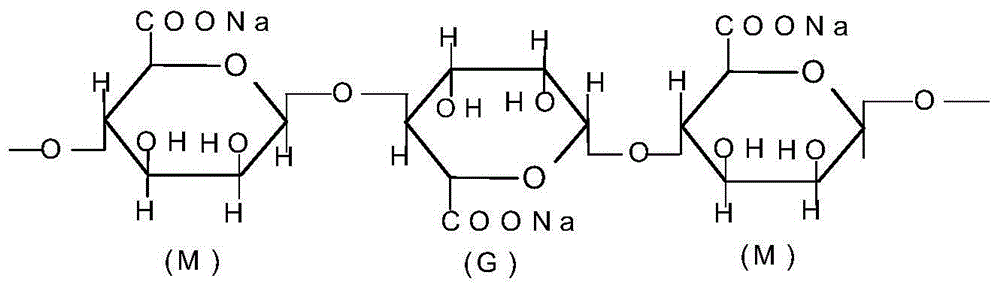

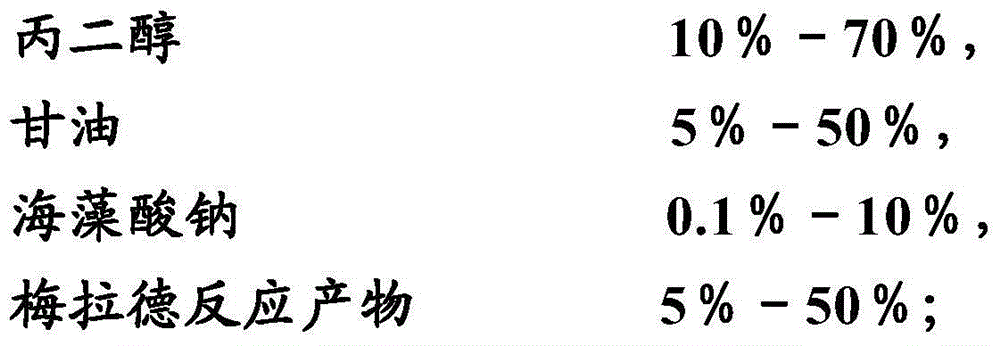

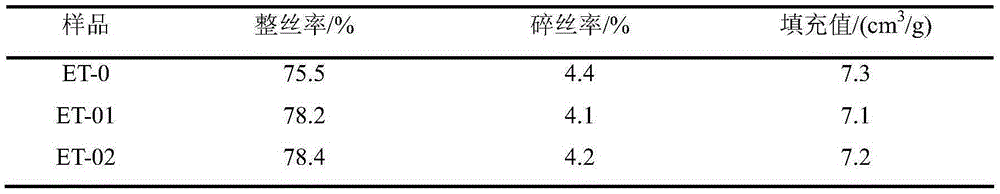

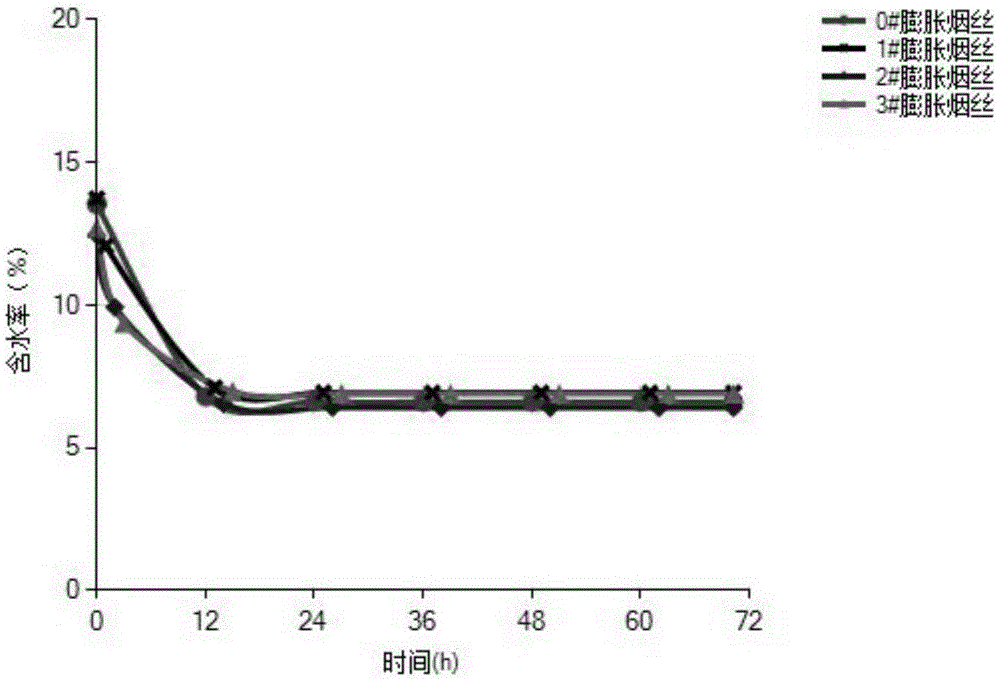

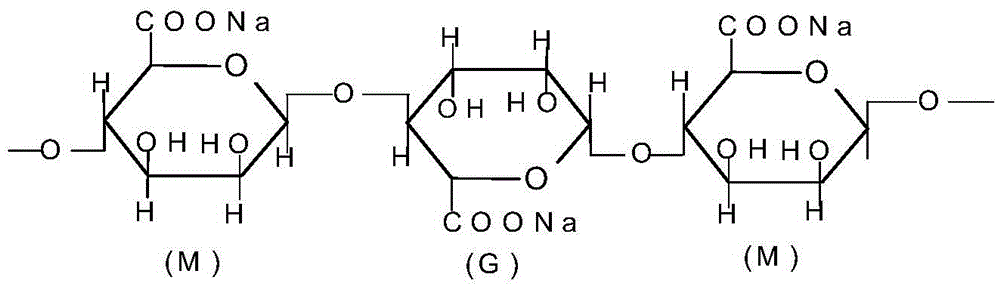

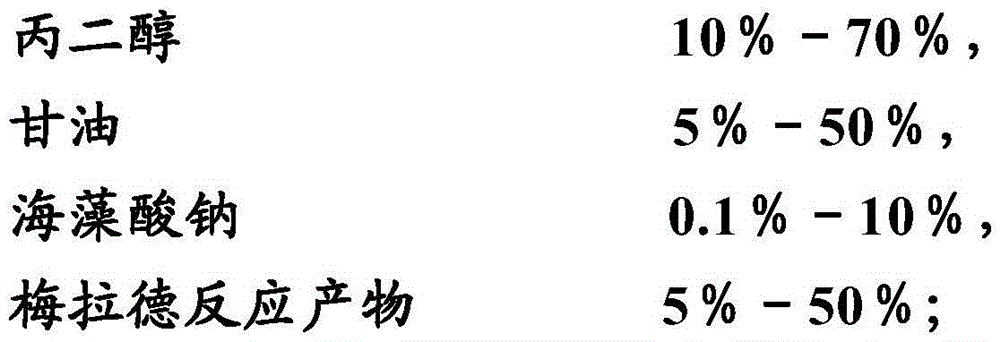

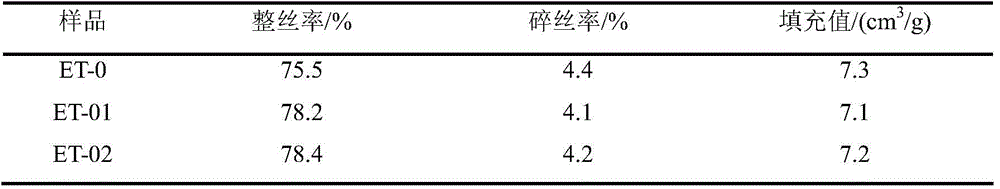

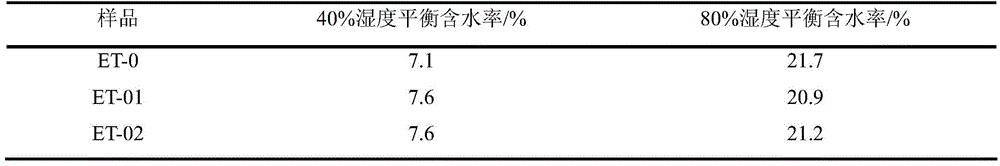

Additive for improving quality of CO2 expanded cut tobacco and application of additive in cigarettes

The invention belongs to the field of cigarette processing and relates to an additive for improving the quality of CO2 expanded cut tobacco and an application of the additive in cigarettes. Concretely, the additive contains propylene glycol and / or glycerinum, sodium alginate and a maillard reaction product. The invention also relates to an application of the additive in preparation of tobacco products such as cigarettes. The additive is sprayed on cut tobacco, and then, the cut tobacco is subjected to CO2 expansion, so that the loss of fragrant components and relevant components in the cut tobacco in a CO2 expansion process can be effectively reduced, and furthermore, the sensory quality and physical wettability of the expanded cut tobacco are improved. The additive disclosed by the invention can also be used for effectively reducing the crushed cut tobacco in the expansion process, reducing the cut tobacco crushing rate and increasing the complete cut tobacco rate and the filling value and has relatively high production and application values.

Owner:CHINA TOBACCO FUJIAN IND +1

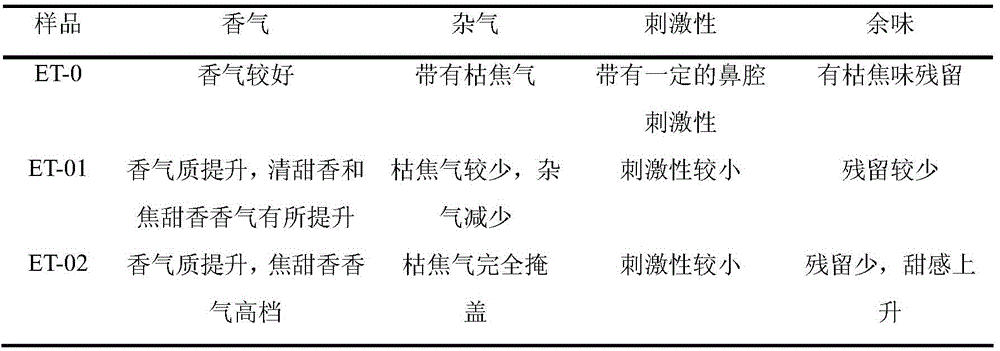

Method for enabling carbon dioxide expanded tobacco to highlight sweet aroma style

ActiveCN105394805AImprove processing resistanceImprove whole yarn rateTobacco preparationTobacco treatmentMaillard reactionDistillation

The invention discloses a method for enabling carbon dioxide expanded tobacco to highlight the sweet aroma style. The method is characterized by comprising the steps that before tobacco leaf expansion, primary feed liquid is added into tobacco leaves, then carbon dioxide expansion is performed after tobacco leaves are shredded, and finally secondary feed liquid is added into the expanded tobacco shreds, wherein the primary feed liquid is water solutions of monosaccharide, disaccharide and polysaccharide, and the secondary feed liquid is prepared from heterocyclic oxygen spice, heterocyclic nitrogen spice, sweet aroma style tobacco essence molecule distillation light component, a sweet aroma style Maillard reaction product, tobacco source low molecular weight monomer spice and a fruit extract. The method can improve the physical structure of expanded tobacco and reduce technological residues, and can specifically compensate for aroma substance losses caused by expansion, add high-quality aroma in expanded tobacco, cover offensive odor, reduce irritation and reduce dryness sensation.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

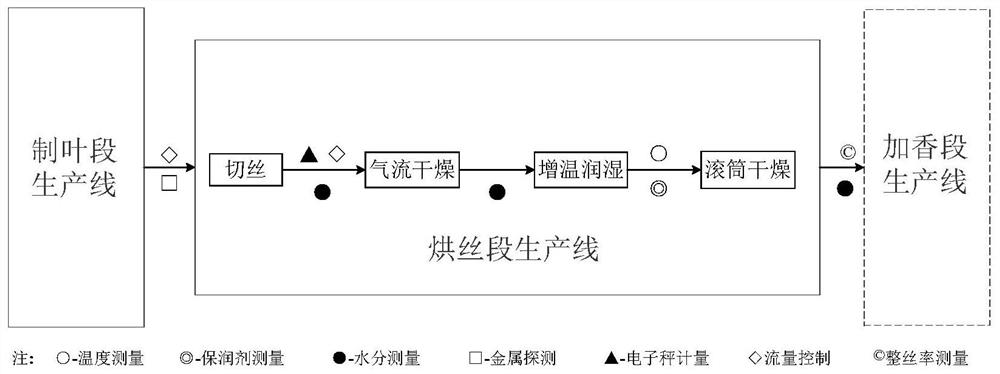

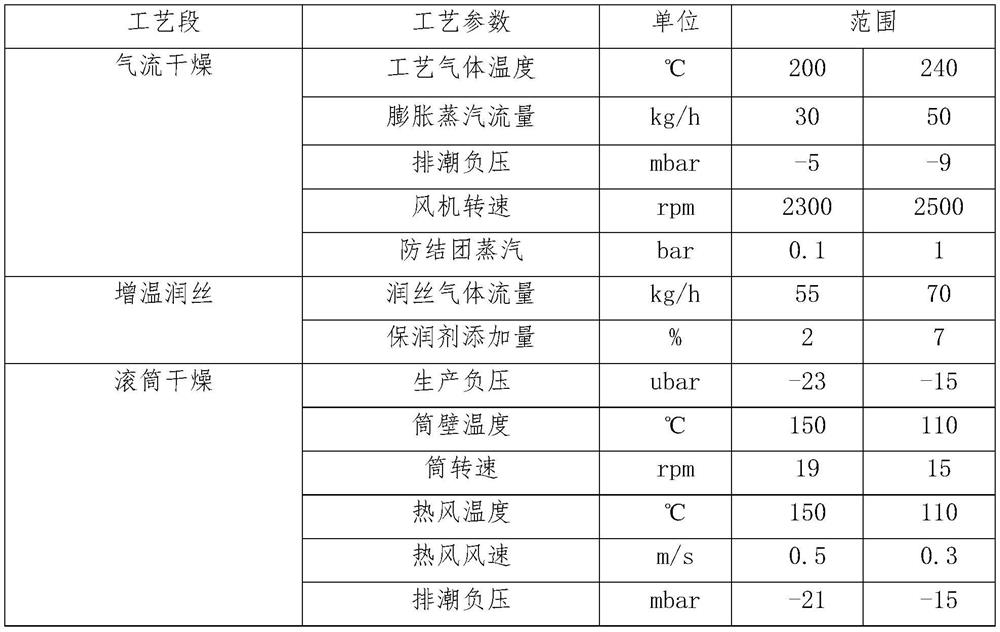

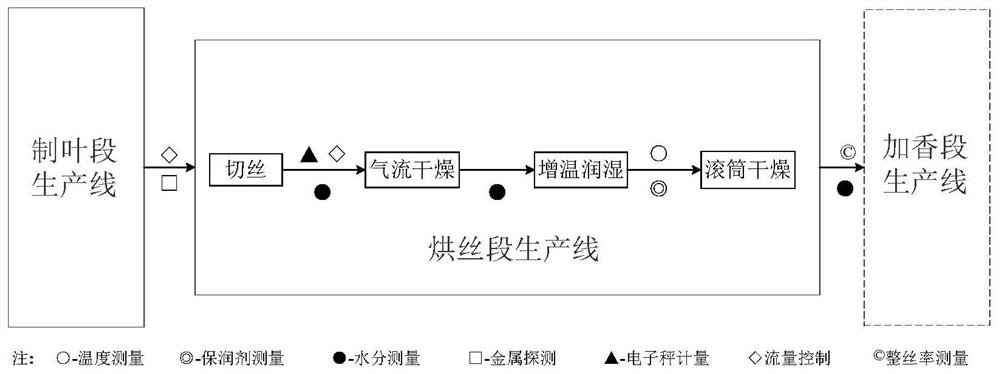

Novel online drying method for heating cigarette tobacco shreds

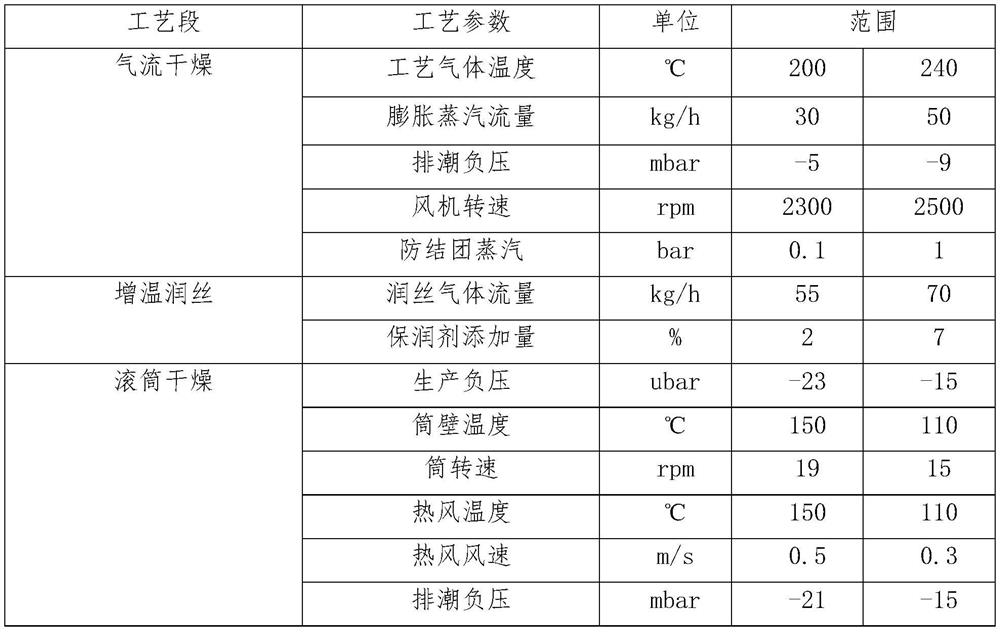

The invention aims to provide a novel online drying method for heating cigarette tobacco shreds. The method comprises the following two steps of 1) increasing the moisture of natural tobacco leaves to 18.5-20.5% through a leaf making section, shredding, and controlling the width of the tobacco shreds to 0.9-1.1 mm; (2) carrying out high-temperature airflow drying treatment on the tobacco shreds to reduce the moisture content of the tobacco shreds to 9.5-10.5%, (3) carrying out temperature increasing and tobacco shred moistening treatment on the tobacco shreds to increase the temperature of the tobacco shreds to 86+ / -3 DEG C and control the content of a humectant in the tobacco shreds to 2-6%, and (4) carrying out roller drying treatment on the tobacco shreds to reduce the moisture content to 3% or below.

Owner:CHINA TOBACCO ZHEJIANG IND

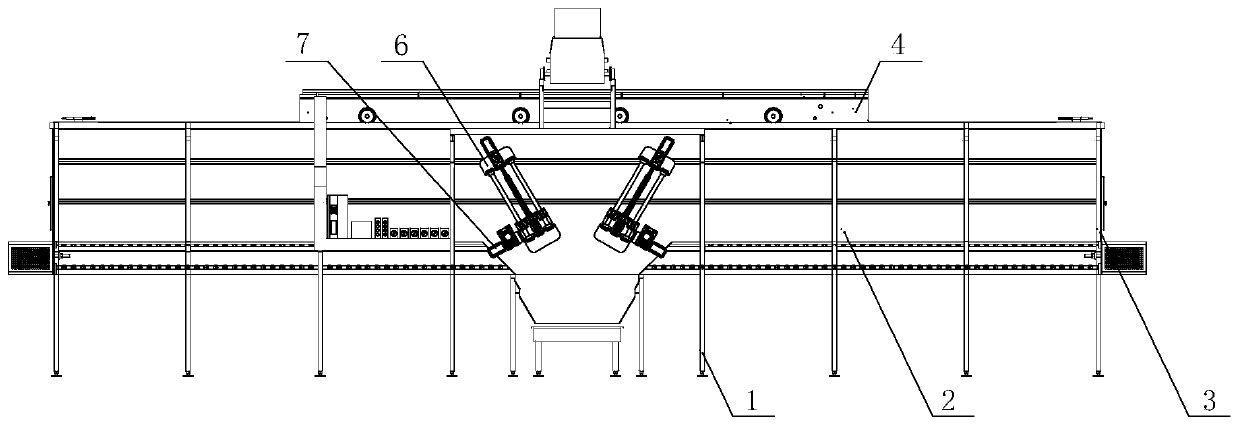

Sectioning type waste cigarette treating device

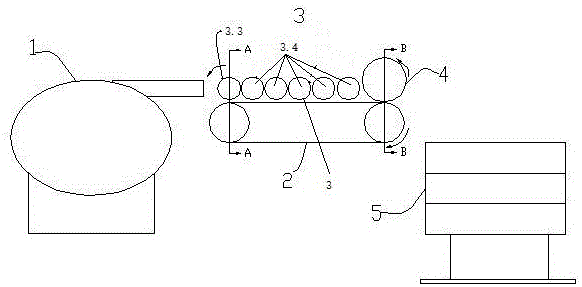

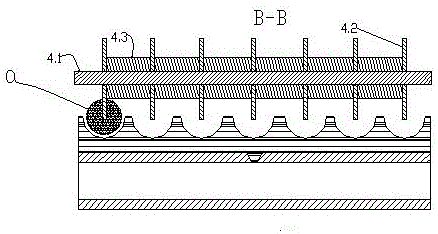

InactiveCN105852204APlay the role of orientationImprove whole yarn rateSievingConveyorsDrive wheelEngineering

A cut-away waste cigarette processing device, including a smoke conveying device, a smoke compressing device, and a tobacco cutting device, characterized in that the smoke compressing device is installed above the smoke conveying device, and the smoke cutting device is installed above the smoke conveying device and the tobacco compressing device. At the rear of the smoke device, the smoke delivery device is a belt conveyor or a belt conveyor or a chain plate conveyor, including a driving wheel, a conveyor belt and a driven wheel. The driving wheel and the driven wheel are connected by a conveyor belt. The advantages of the present invention: 1) , The waste cigarettes fall into the groove on the conveyor belt, and the groove plays a role in positioning and guiding the cigarettes, so the blade can cut the waste cigarettes from the middle at one time, so there is less paper scraps in the shredded tobacco; 2 ), because the waste cigarettes are only cut once, and the next process does not whip or hard damage the cigarettes, so the recovered shredded tobacco has a high whole shred rate, which greatly improves the comprehensive recycling rate of shredded tobacco.

Owner:CHANGDE RUIHUA MFG

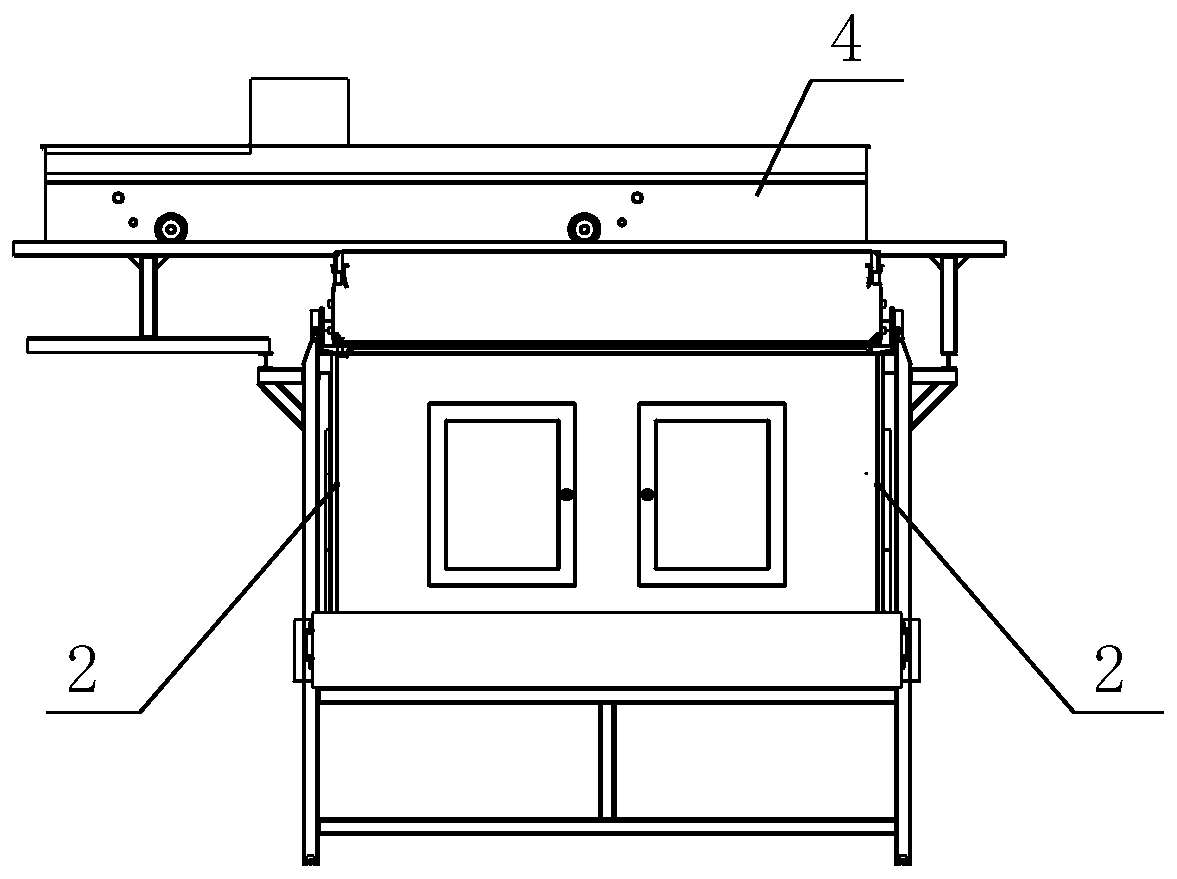

Lateral box turning-over method for double-layer cigarette box and box turning-over system

PendingCN109160300AImprove work efficiencyReduce lossLifting devicesBottle emptyingEngineeringManipulator

The invention discloses a lateral box turning-over method for a double-layer cigarette box and a box turning-over system. A cigarette box input mechanism, an unstacking mechanism, a conveying mechanism, a stacking mechanism and an output mechanism are arranged, and a box turning-over mechanism is arranged on one side of the conveying mechanism, so that the box turning-over system capable of integrating unstacking, transferring, box turning-over and stacking and realizing continuous and automatic box turning-over is constituted; a series of continuous processes of cigarette box transferring, cigarette box unstacking, clamping-holding box turning-over, cleaning of the empty boxes and covering stacking can be completed, and the continuous lateral box turning-over process of the cigarette boxes is achieved; continuous automatic unstacking, automatic box turning-over and automatic stacking can be achieved, the working efficiency of the whole box turning-over system is improved greatly, andthe stable and reliable effects are achieved; and meanwhile, frequent use of a traditional manipulator is replaced, the equipment loss can be lowered, and the equipment maintenance cost is indirectlylowered.

Owner:CHINA TOBACCO HENAN IND

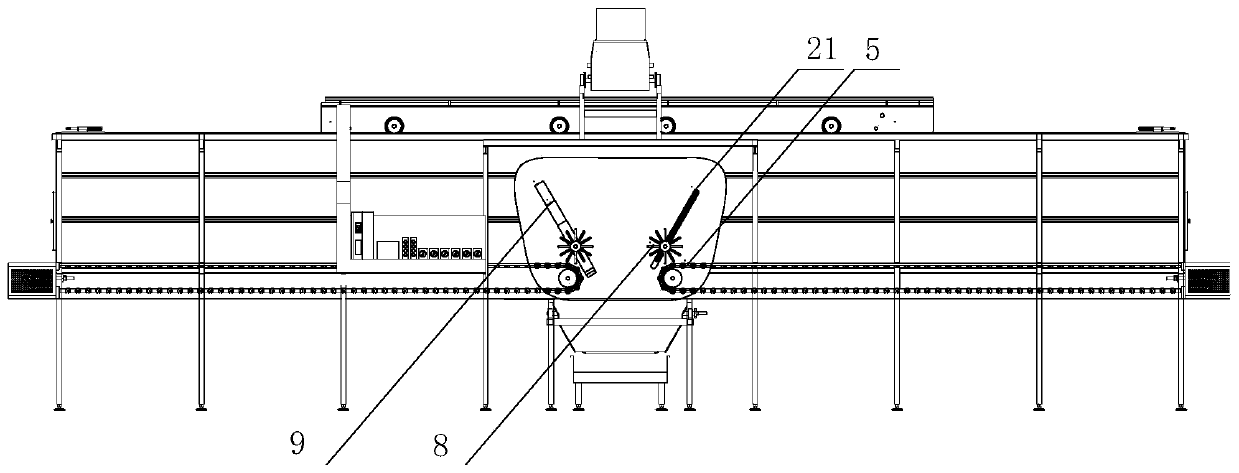

Anti-crushing loosening device for discharging of tobacco storage cabinet

PendingCN110589522AImprove porosity efficiencyReduce breakage rateConveyorsLoading/unloadingEngineeringMechanical engineering

The invention relates to an anti-crushing loosening device for discharging of a tobacco storage cabinet. The anti-crushing loosening device comprises raking mechanisms, lifting mechanisms and rotatingmechanisms, wherein the two ends of the roller shaft of each raking mechanism are respectively connected with a lifting sliding table on the corresponding lifting mechanism; one end of each roller shaft is connected with the corresponding rotating mechanism; and the lifting mechanisms are arranged on a side plate of the tobacco storage cabinet. According to the anti-crushing loosening device, thelifting mechanisms drive the raking mechanisms to reciprocate up and down, and three raking thorn rollers do not need to be arranged in the height direction of a discharge opening, so that high material crushing rate caused by positive and negative stirring, repeated stirring and continuous stirring is avoided, the tobacco crushing rate is reduced, the whole tobacco shredding rate and the fillingvalue are improved, the cost is saved, and the internal quality of cigarettes is improved; and the roller shafts of the raking mechanisms are driven to rotate by the rotating mechanisms, and the raking mechanisms rotate while reciprocating up and down, so that the material raking and loosening efficiency is high.

Owner:WUHAN YANCHENG TECH CO LTD

Circulation method for preparing expanded cut tobacco

ActiveCN101617854BImprove whole yarn rateIncrease elasticityTobacco preparationFinal product manufactureVacuum pumpingProcess engineering

The invention discloses a circulation method for preparing expanded cut tobacco, comprising the following steps: (1) putting cut tobacco into a preheated impregnating tank, then carrying out vacuum-pumping; (2) spraying liquid expanding agent to the cut tobacco; (3) filling gas expanding agent to the impregnating tank; (4) impregnating; (5) first, recycling the liquid expanding agent, then recycling the gas expanding agent; and (6) expanding the impregnated cut tobacco, and carrying out operations in step (2) or / and step (3) by the liquid expanding agent and the gas expanding agent recycled in step (5). The method of the invention has mild condition and greatly reduced requirement for devices, by fully recycling the expanding agents, the cost is lowered, the complete set of devices has low energy consumption and high automation, continuous mass production can be carried out, all performance indexes of the obtained expanded cut tobacco are high, the expanded efficiency of the cut tobacco is high, and the recycling rate of the expanding agents is high.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

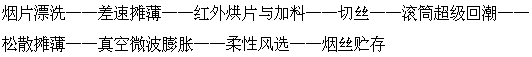

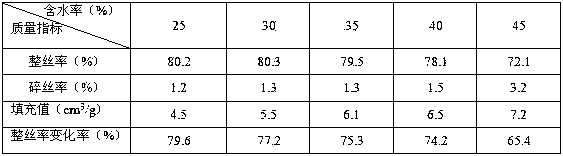

Tobacco shred expanding process adopting water as medium

The invention provides a tobacco shred expanding process adopting water as a medium. The process comprises the following steps: after loosening, enabling redried tobacco strips to be subjected to continuous rinsing for 10-30 s in the medium, namely, water, so as to obtain tobacco strips with the water content being 40-50%, carrying out redrying and casing in a mesh belt, carrying out strip bakingby adopting infrared rays to enable the water content to achieve 18-20%, carrying out shredding, carrying out super resurgence so as to realize temperature increase and humidity increase on the tobacco shreds and improve the water content of the tobacco shreds to 30-40%, carrying out instantaneous heating by adopting vacuum microwave in an expanding device, so as to sufficiently gasify water in tobacco shred cells, enable water vapor to rush out of the cells and further to sufficiently expand the tobacco shreds and obtain tobacco shreds with the water content being 12-13% and the filling valuebeing 5.5 cm<3> / g-7.0 cm<3> / g, carrying out flexible winnowing, and storing the expanded tobacco shreds for later use.

Owner:CHINA TOBACCO HENAN IND

A kind of online drying method of heating cigarette cut tobacco

The object of the present invention is to provide a novel online drying method for heated cigarette cut tobacco, which comprises the following two steps: step 1) increasing the moisture content of natural tobacco leaves to 18.5-20.5% through the leaf making section, cutting into shreds, and shredding the width of the shredded tobacco. Controlling to 0.9 to 1.1 mm; Step 2) Drying the cut tobacco with high-temperature air flow to reduce the moisture content of the cut tobacco to 9.5-10.5%; Step 3) Carrying out a warming and moistening treatment for the cut tobacco, increasing the temperature of the cut tobacco to 86°C±3, and controlling The content of the humectant in the cut tobacco is 2-6%; step 4) the cut tobacco is subjected to drum drying treatment to reduce the moisture content to below 3%.

Owner:CHINA TOBACCO ZHEJIANG IND

Tobacco shred immersion method and device

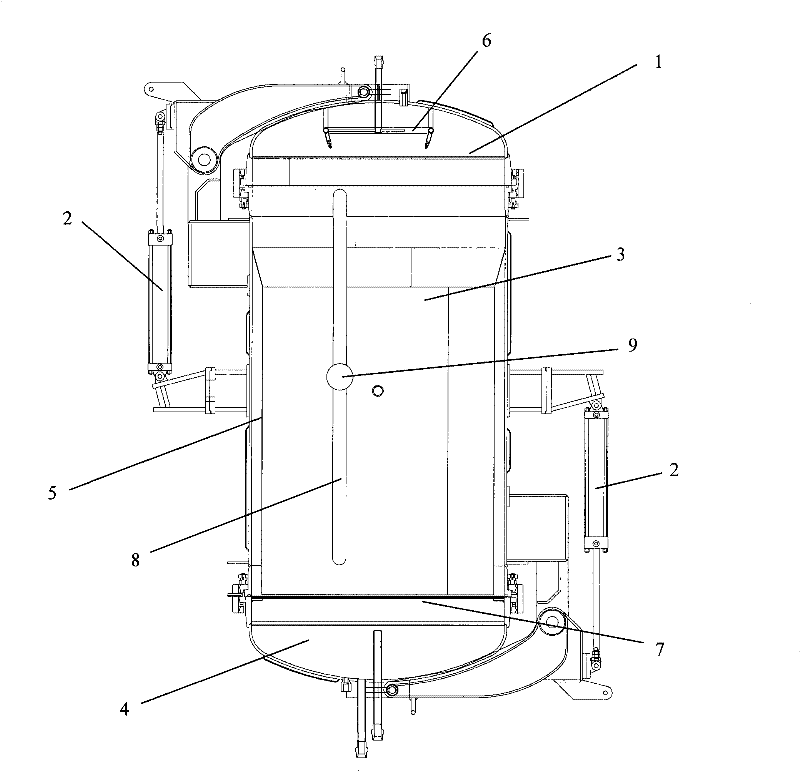

ActiveCN101744359BHigh energy consumptionReduce energy consumptionTobacco preparationLiquid stateAgricultural engineering

The invention relates to a tobacco shred immersion method and a device; the method comprises: (1) the tobacco shred is arranged in a pre-heating immersion device and then vacuumizing is carried out; (2) swelling agent with liquid state is sprayed on the tobacco shred; (3) swelling agent with gas state is filled in the immersion device; (4) immersion is carried out. The immersion device provided by the invention comprises a tank body, an upper tank cover, a lower tank cover and a hydraulic pressure opening device, a spraying device is arranged in the upper tank cover, wherein the tank body is provided with two layers of sleeves, a screen cloth is formed on the inner wall of the inner layer sleeve, and the pore diameter of the screen cloth is 1.5mm. The invention has simple structure and convenient operation, can achieve good immersion effect to the tobacco shred and can realize continuous immersion of the tobacco shred.

Owner:BEIJING INST OF AEROSPACE TESTING TECH +1

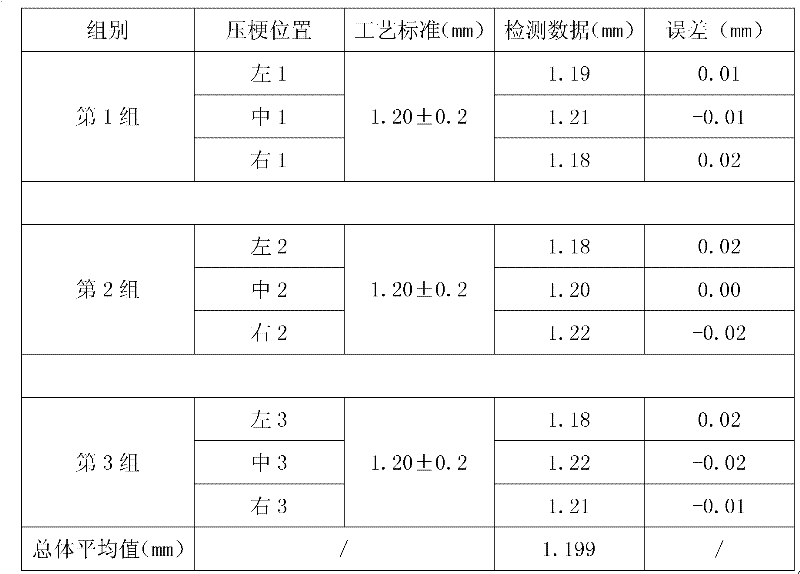

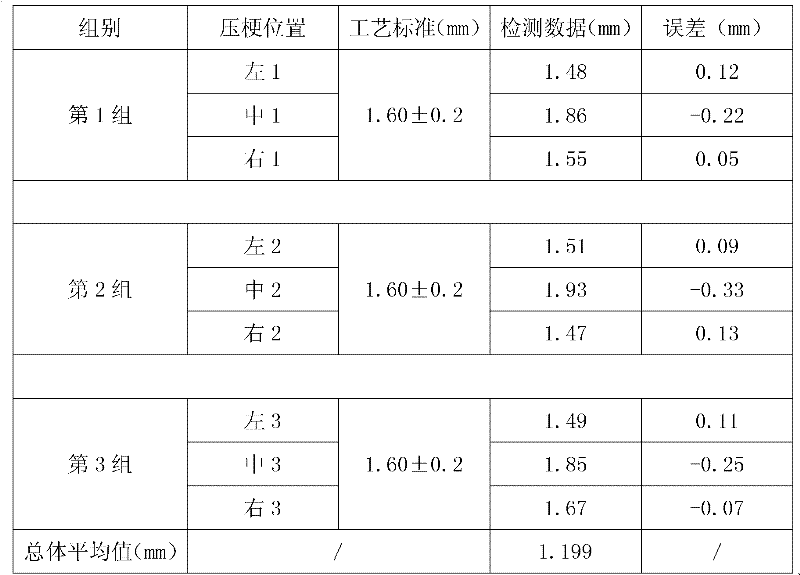

Method for detecting thickness of flattened stems

ActiveCN102162714BAccurate detectionImprove whole yarn rateMechanical thickness measurementsVernier scaleCalipers

The invention provides a method for detecting the thickness of a flattened stem, belonging to a method for detecting the thickness of a stem flattened by a stem flattener by utilizing fuses. The method comprises the following steps: selecting 9-30 fuses in certain size and length, and making marks, wherein the diameter and length of each fuse respectively range from 1.00mm to 3.50mm and 10cm to 30cm; under normal production conditions, respectively putting 3-10 fuses at the left part, middle part and right part of a feeding hole of a stem flattener, and taking the fuses out of a discharge hole of the stem flattener after extrusion; using a vernier caliper to test the thickness of each fuse, and respectively calculating the average thickness of each of the left, middle and right groups of fuses; and repeating the above steps 3-5 times, then calculating the total average thickness according to the average thickness of the three groups of fuses during each testing, and polishing a rollerof the stem flattener if either the average thickness of each of the left, middle and right groups of fuses or the total average thickness exceeds the requirement of the process standard. The method has the advantages of rapid and accurate detection of thickness of the flattened stem and high detection efficiency.

Owner:CHONGQING CHINA TOBACCO IND CO LTD +1

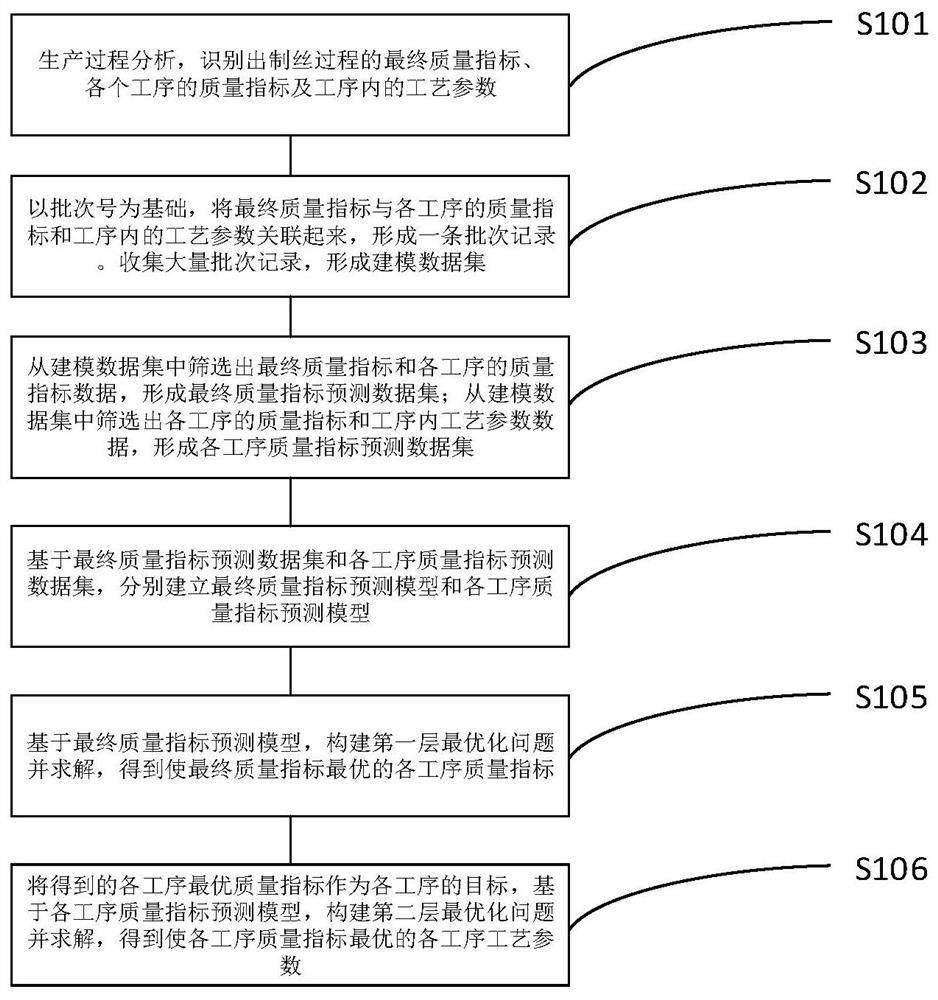

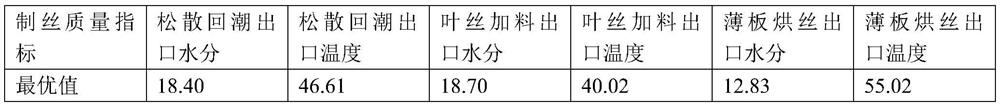

A process parameter optimization method for multi-process industrial production process

ActiveCN112036701BReduce the number of input variablesIncrease credibilityTobacco preparationArtificial lifeData setProcess engineering

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

A way to improve co 2 Additives for Expanded Cut Tobacco Quality and Its Application in Cigarettes

The invention belongs to the field of cigarette processing and relates to a method for improving CO 2 Additives for expanded cut tobacco quality and their application in cigarettes. Specifically, the additives include propylene glycol and / or glycerin, sodium alginate, and Maillard reaction products. The invention also relates to the use of said additive in the manufacture of tobacco products such as cigarettes. The additive is sprayed on the shredded tobacco, and then the shredded tobacco is subjected to CO 2 Expansion, can effectively reduce CO 2 The loss of tobacco aroma components and related components during the expansion process improves the sensory quality and physical moisturizing performance of expanded tobacco. The additive of the invention can also effectively reduce the shredded tobacco in the expansion process, reduce the shredded shredded ratio, increase the shredded shredded ratio and the filling value, and has high production and application value.

Owner:CHINA TOBACCO FUJIAN IND +1

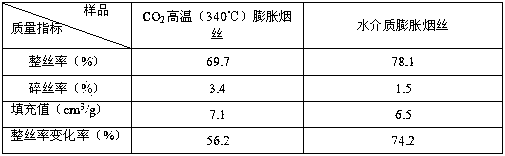

Medium and low temperature CO2 expansion process for shredded tobacco

The invention belongs to a low-temperature CO2 expansion process for shredded tobacco, comprising the following steps: ① immerse shredded tobacco with a moisture content of 18% to 20% in liquid CO2 for 60 to 100 seconds to obtain shredded tobacco with dry ice; ② immerse shredded tobacco with dry ice obtained in step ① After the shredded tobacco is loose, it enters the HT steam expansion device through quantitative feeding for pre-expansion; ③The pre-expanded shredded tobacco is sent to the air dryer for expansion and drying, and the flow rate of the hot air entering the air dryer is 21m / s~23m / s , The temperature is 200 ℃ ~ 230 ℃. Adopting the process of the present invention reduces the treatment intensity of the carbon dioxide process, reduces the fragmentation during the expansion process, improves the whole cut rate of the expanded cut tobacco, and the whole cut rate is 74% to 78%, reduces the broken shred rate, and the broken shred rate is 1.4% to 2.1%, Improve the change rate of the whole yarn rate, and the change rate of the whole yarn rate is 73% to 77%.

Owner:CHINA TOBACCO HENAN IND

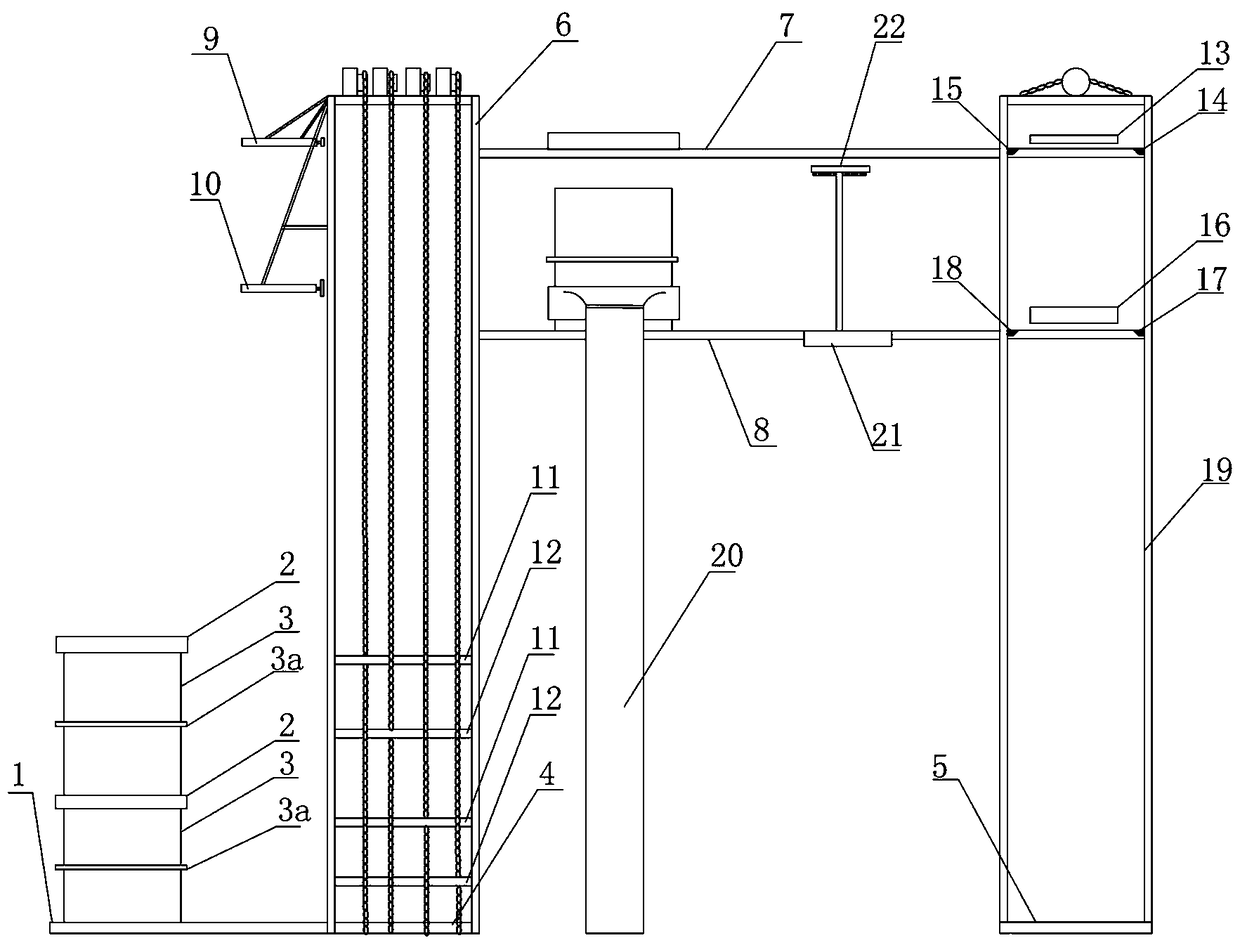

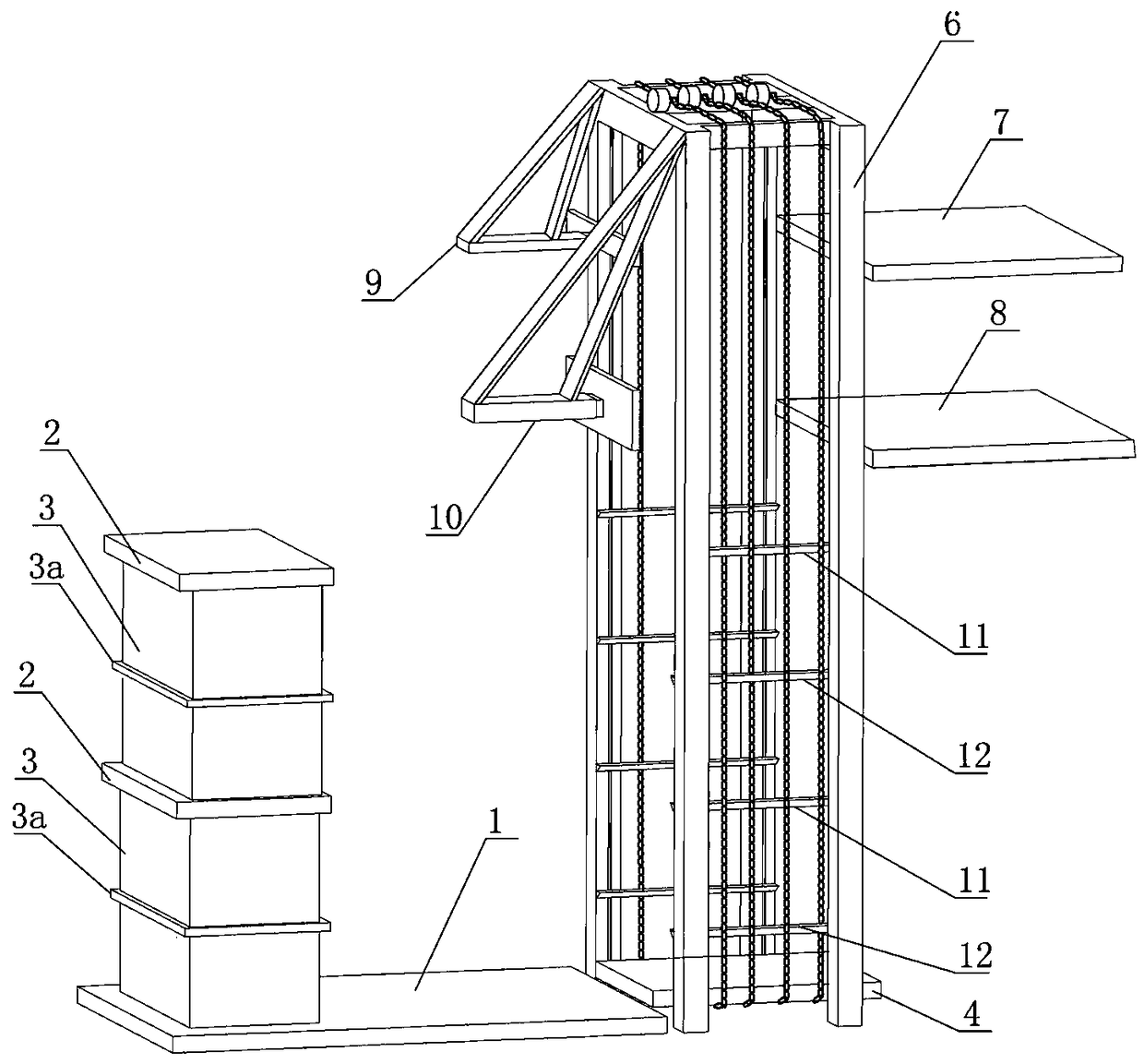

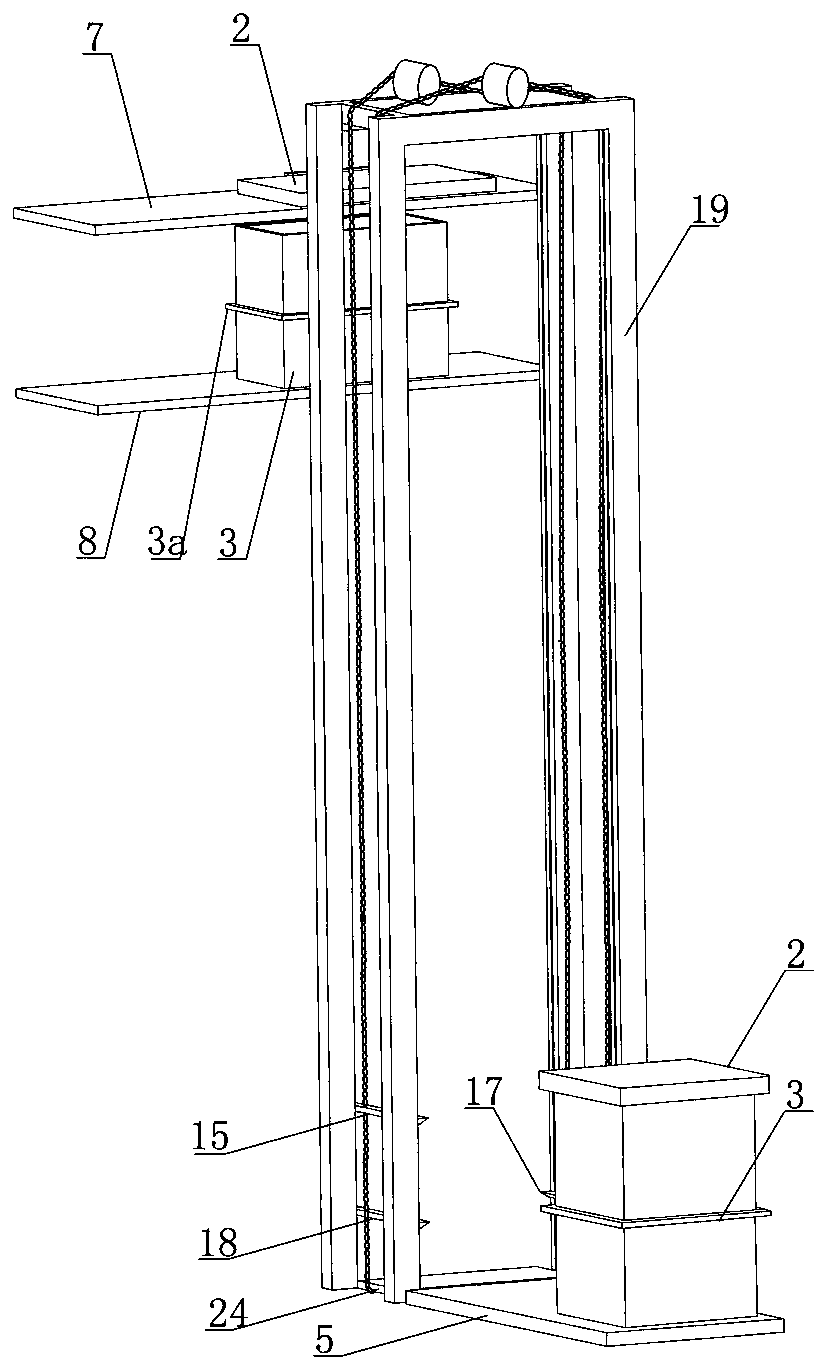

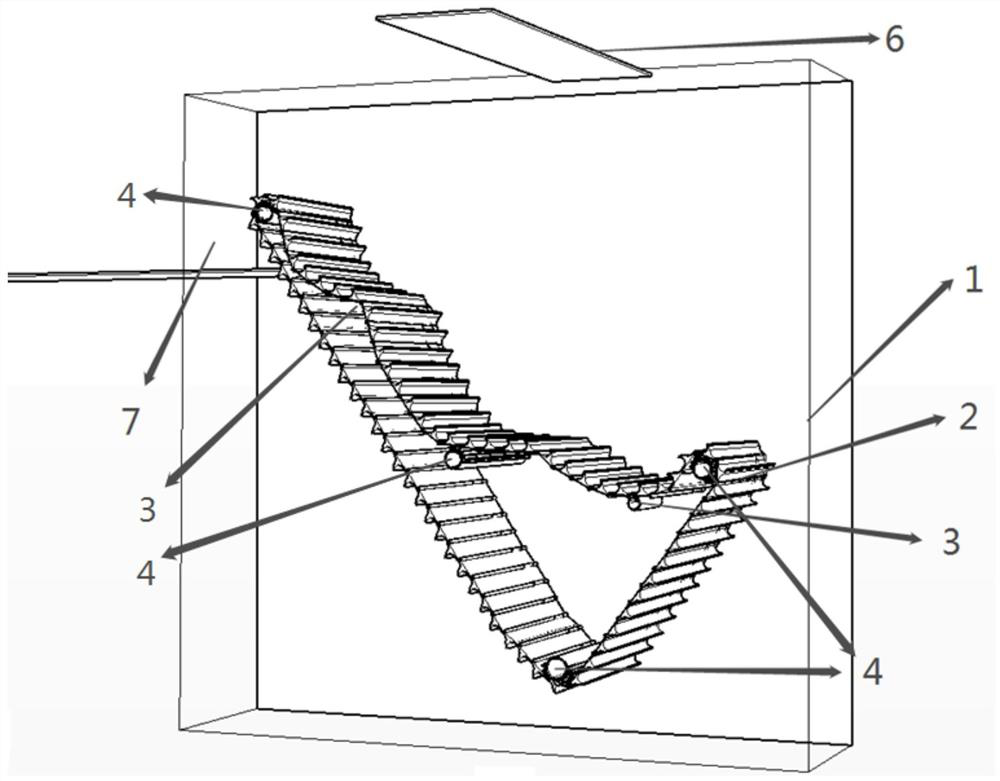

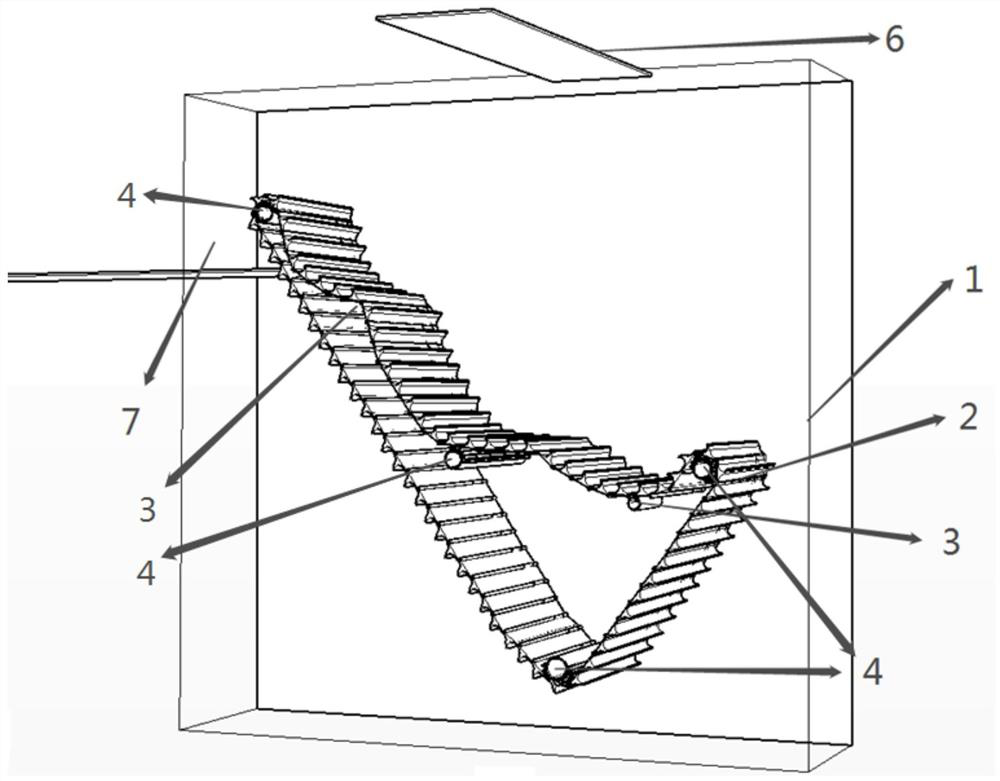

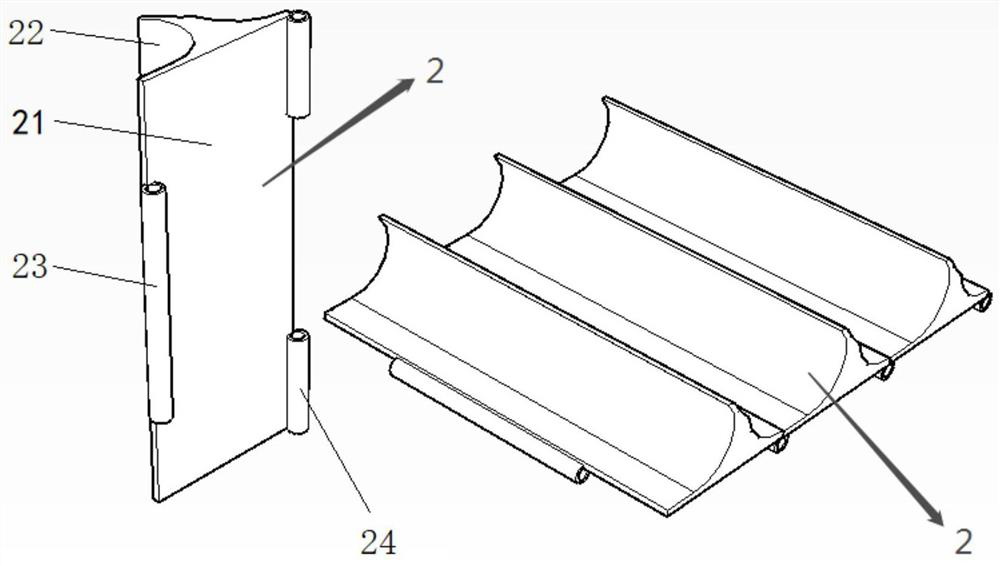

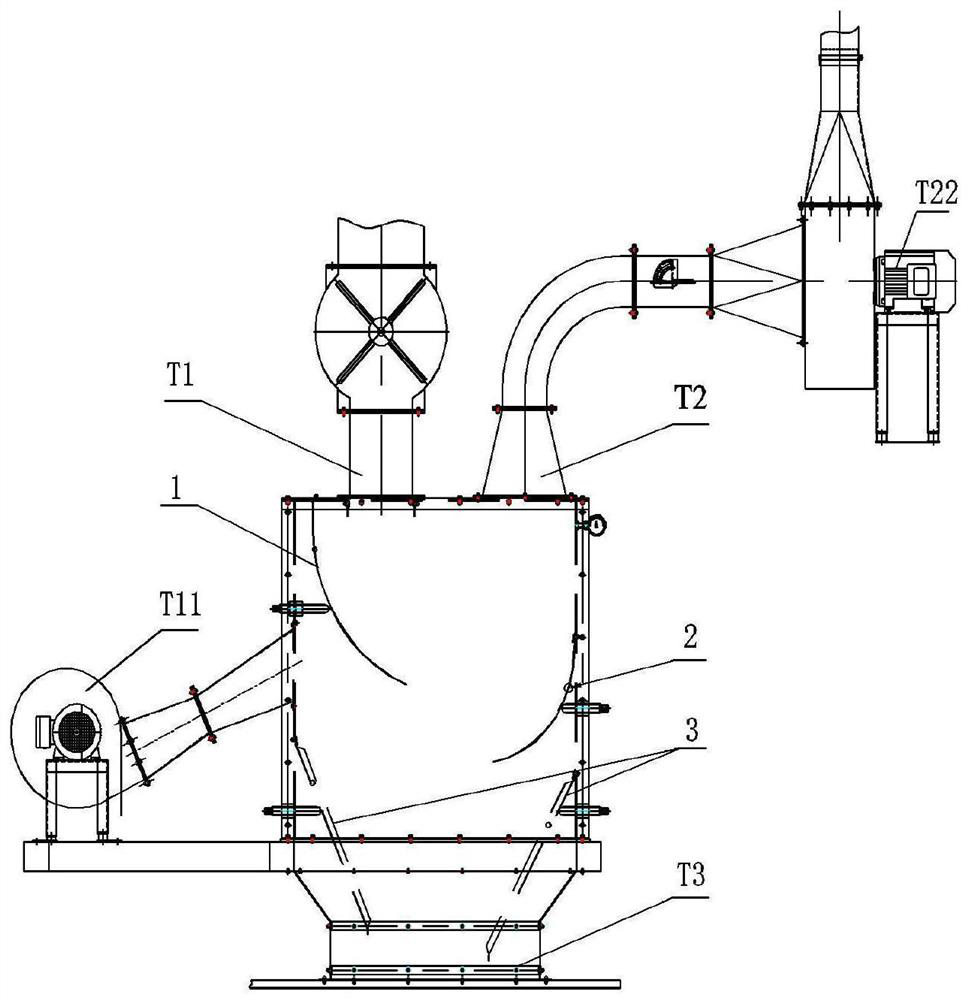

Tobacco stem directional arrangement feeding device suitable for stem cutting machine equipment

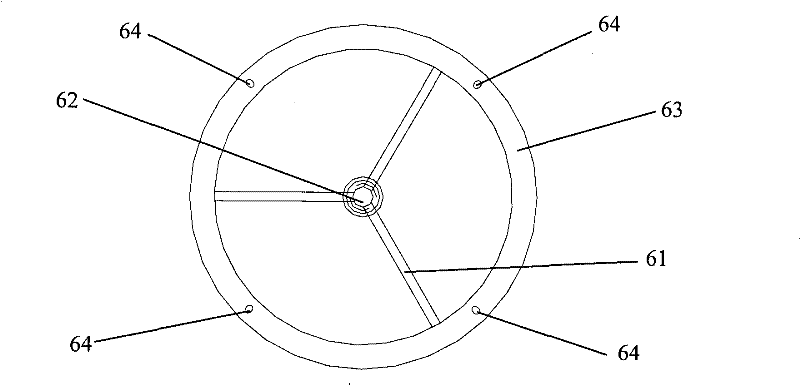

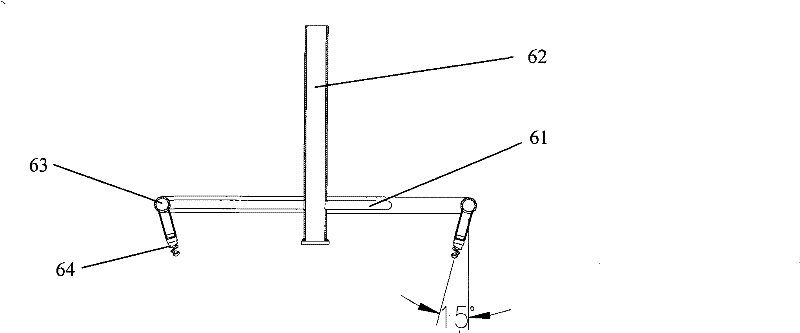

ActiveCN113633013AReduce drynessPrecisely control the feeding speedTobacco treatmentAgriculture gas emission reductionAgricultural engineeringStructural engineering

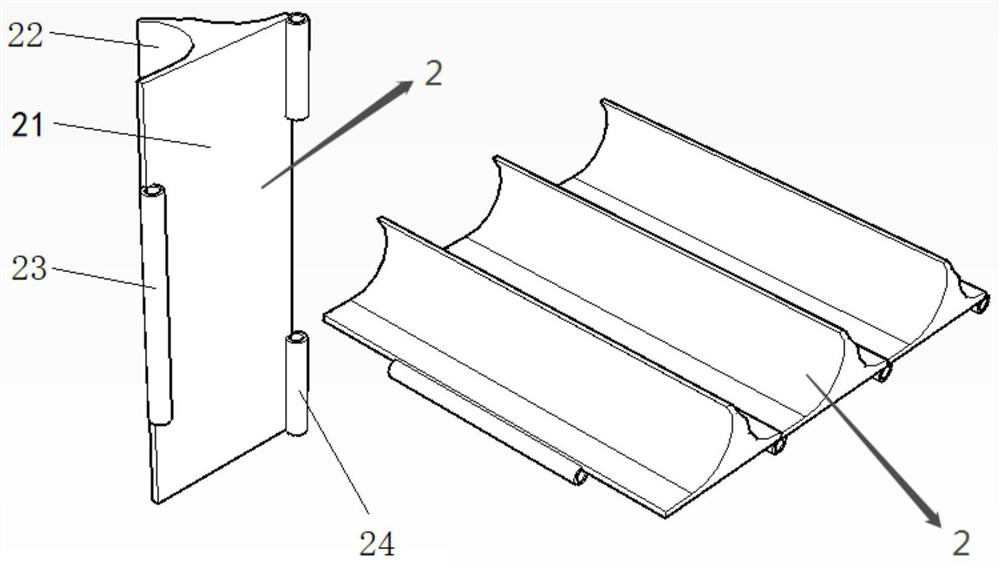

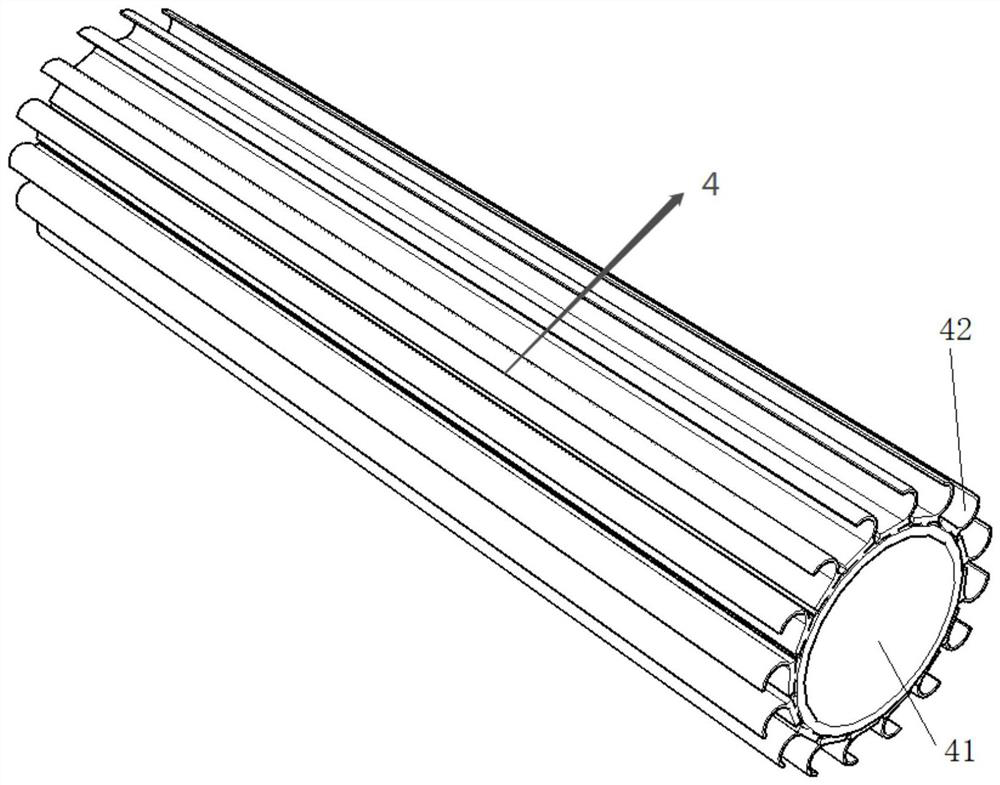

The invention discloses a tobacco stem directional arrangement feeding device suitable for stem cutting machine equipment. The device comprises a rectangular cubic shell (1), a row chain (2), a vibration mechanism (3), a transmission mechanism (4), a feed port (6) and a discharge port (7). The device is characterized in that: the row chain (2) comprises a bottom plate (21), an arc-shaped part (22), a first hinge sleeve (23) and second hinge sleeves (24), one side surface of the bottom plate is provided with the arc-shaped part, the first hinge sleeve is arranged at one end of the bottom plate, the second hinge sleeves are arranged at the other end of the bottom plate, a C-shaped groove is formed between arc-shaped parts of two adjacent hinges, and the first hinge sleeve is connected with the two spaced second hinge sleeves through pin shafts. According to the tobacco stem directional arrangement feeding device, the material passing effect is obviously improved, and after the tobacco stems pass through the feeding device, the arrangement of the incoming tobacco stems can be basically consistent with the cutting direction of a knife roll of a stem cutting machine.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

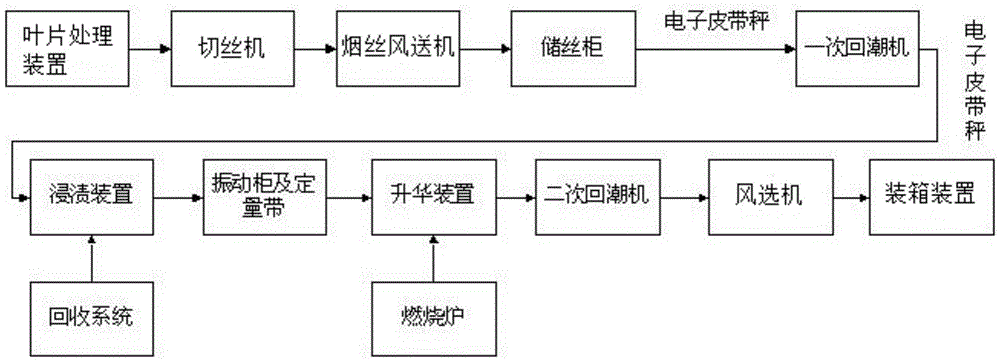

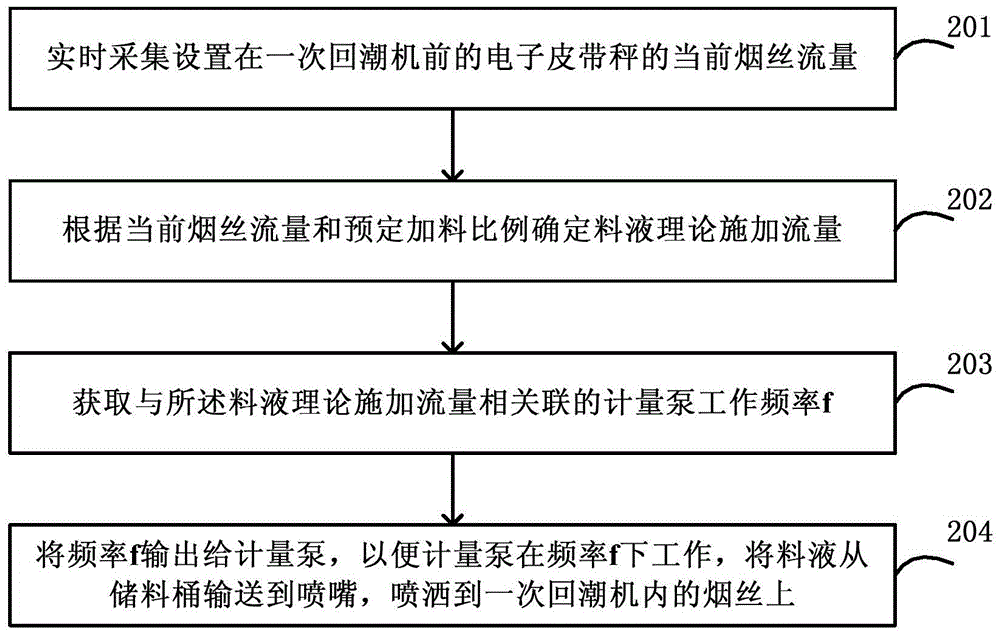

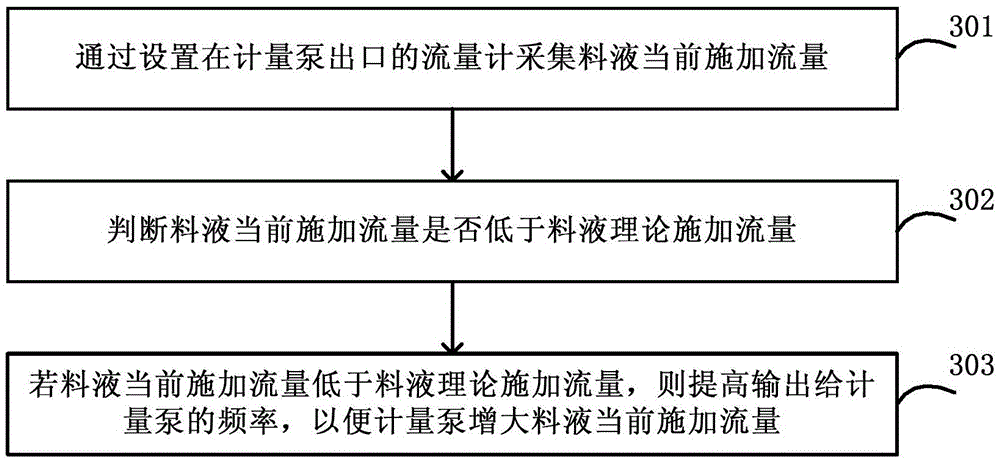

On-line feeding method and device, and expanded shredded tobacco production system

The invention discloses an online feeding method and device, and an expanded shredded tobacco production system. The method includes: collecting in real time the current cut tobacco flow rate of the electronic belt scale set in front of the primary dampening machine; according to the current cut tobacco flow rate and the predetermined feeding ratio K 0 Determine the theoretical applied flow rate of the material liquid; obtain the working frequency f of the metering pump associated with the theoretical applied flow rate of the material liquid; output the working frequency f to the metering pump so that the metering pump works at the working frequency f, and convert the theoretical The feed liquid with the applied flow rate is transported from the storage barrel to the nozzle, and sprayed on the shredded tobacco in the primary conditioning machine, wherein the feed liquid includes a humectant. The present invention installs the on-line feeding device at the primary dampening drum, which can reduce the loss of aroma components and other components of shredded tobacco during the expansion process under the premise of maintaining the normal expansion effect of shredded tobacco, thereby improving the sensory quality and physical moisture retention of shredded tobacco performance.

Owner:XIAMEN TOBACCO IND

A Tobacco Stem Directional Arrangement Feeding Device Applicable to Stem Cutting Machine Equipment

ActiveCN113633013BReduce drynessPrecisely control the feeding speedTobacco treatmentAgriculture gas emission reductionBiotechnologyStructural engineering

The invention discloses a tobacco stem directional arrangement feeding device suitable for a stem cutting machine, which comprises a rectangular cubic casing (1), chains (2), a vibrating mechanism (3), a transmission mechanism (4), The feed port (6) and the discharge port (7) are characterized in that the row chain (2) includes a bottom plate (21), an arc portion (22), a first hinge sleeve (23), a second hinge sleeve (24), one side of the bottom plate is provided with an arc portion, one end of the bottom plate is provided with a first hinge sleeve, and the other end is provided with a second hinge sleeve, and a C-shaped concave is formed between the arc portions of two adjacent hinges. slot, and the first hinge sleeve is connected with two spaced apart second hinge sleeves by a pin shaft. The feeding device for directional arrangement of tobacco stems of the present invention significantly improves the feeding effect, and after passing through the feeding device, the arrangement of incoming tobacco stems can be basically consistent with the cutting direction of the knife roller of the stem cutter.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

Improved novel tobacco shred expansion device

Owner:QINHUANGDAO TOBACCO MACHINERY

A kind of pre-pressing packing process of filamentous tobacco material

ActiveCN108910185BSolve the problem of pile upGuaranteed uniformityIndividual articlesAgricultural scienceProcess equipment

The invention discloses a process for pre-pressing and boxing filamentary tobacco materials, through material temporary storage-cigarette box flipping and docking-feeding lifting-thinning metering-reciprocating material spreading-material pre-pressing-material boxing-cigarette box The production process of temporary storage and distribution adopts the traditional vertical box packing process, which can not only improve the packing uniformity and packing density of tobacco materials in the box, reduce transportation costs, but also have low requirements on the site and reduce process equipment The floor area and factory design requirements can indirectly reduce the equipment cost, and can effectively reduce the shred rate. It is suitable for packing and distribution of tobacco materials such as shredded tobacco, expanded shredded tobacco, thin slices, and shredded stems. It has a wide range of applications.

Owner:CHINA TOBACCO HENAN IND

A method for making carbon dioxide-expanded shredded tobacco highlight the burnt-sweet flavor

ActiveCN105394805BImprove processing resistanceImprove whole yarn rateTobacco preparationTobacco treatmentMaillard reactionDistillation

The invention discloses a method for enabling carbon dioxide expanded tobacco to highlight the sweet aroma style. The method is characterized by comprising the steps that before tobacco leaf expansion, primary feed liquid is added into tobacco leaves, then carbon dioxide expansion is performed after tobacco leaves are shredded, and finally secondary feed liquid is added into the expanded tobacco shreds, wherein the primary feed liquid is water solutions of monosaccharide, disaccharide and polysaccharide, and the secondary feed liquid is prepared from heterocyclic oxygen spice, heterocyclic nitrogen spice, sweet aroma style tobacco essence molecule distillation light component, a sweet aroma style Maillard reaction product, tobacco source low molecular weight monomer spice and a fruit extract. The method can improve the physical structure of expanded tobacco and reduce technological residues, and can specifically compensate for aroma substance losses caused by expansion, add high-quality aroma in expanded tobacco, cover offensive odor, reduce irritation and reduce dryness sensation.

Owner:CHINA TOBACCO ANHUI IND CO LTD +1

Flash evaporation puffing and roller drying treatment process for stalk shreds

ActiveCN102488314BImprove processing resistanceIncrease the yield of shredded stemsTobacco preparationCooking & bakingEngineering

Owner:HONGTA TOBACCO GRP

Medium and low temperature CO2 expansion process for tobacco shred

The invention relates to a medium and low temperature CO2 expansion process for tobacco shred. The process includes the following steps that 1, the tobacco shred with the water content of 18-20% is soaked for 60-100 s in liquid-state CO2 to obtain dry ice tobacco shred; 2, the dry ice tobacco shred obtained in the step 1 is loosened and then quantitatively fed into an HT steam expansion device to be expanded in advance; 3, the tobacco shred expanded in advance is fed into a flash dryer to be expanded and dried, the flow rate of hot wind entering the flash dryer is 21-23 m / s, and the temperature of the hot wind is 200-230 DEG C. The treatment intensity of the CO2 process is reduced by adopting the process, the tobacco damage ratio in the expansion process is reduced, the proportion of whole shred of the expanded tobacco shred is improved to be 74-78%, the proportion of broken shred is reduced to be 1.4-2.1%, and the change rate of the proportion of whole shred is improved to be 73-77%.

Owner:CHINA TOBACCO HENAN IND

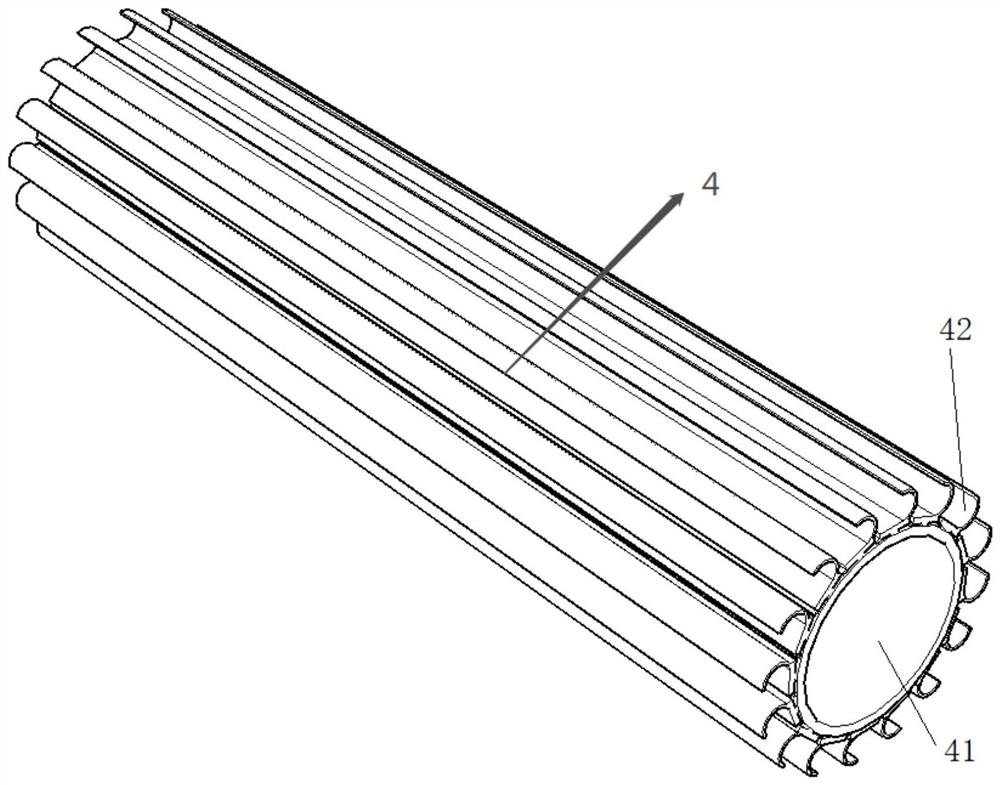

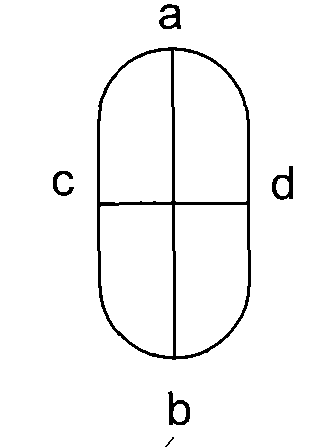

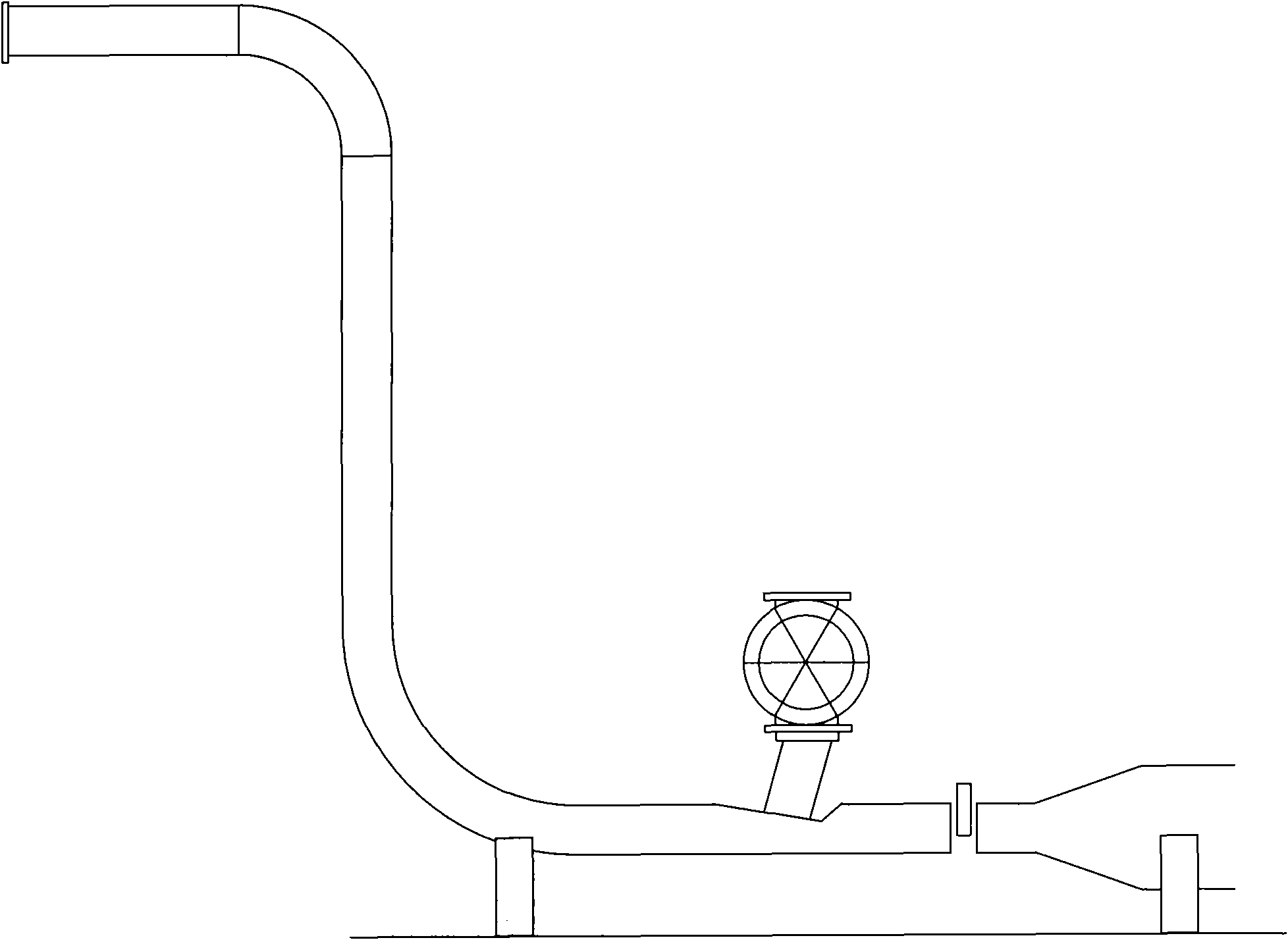

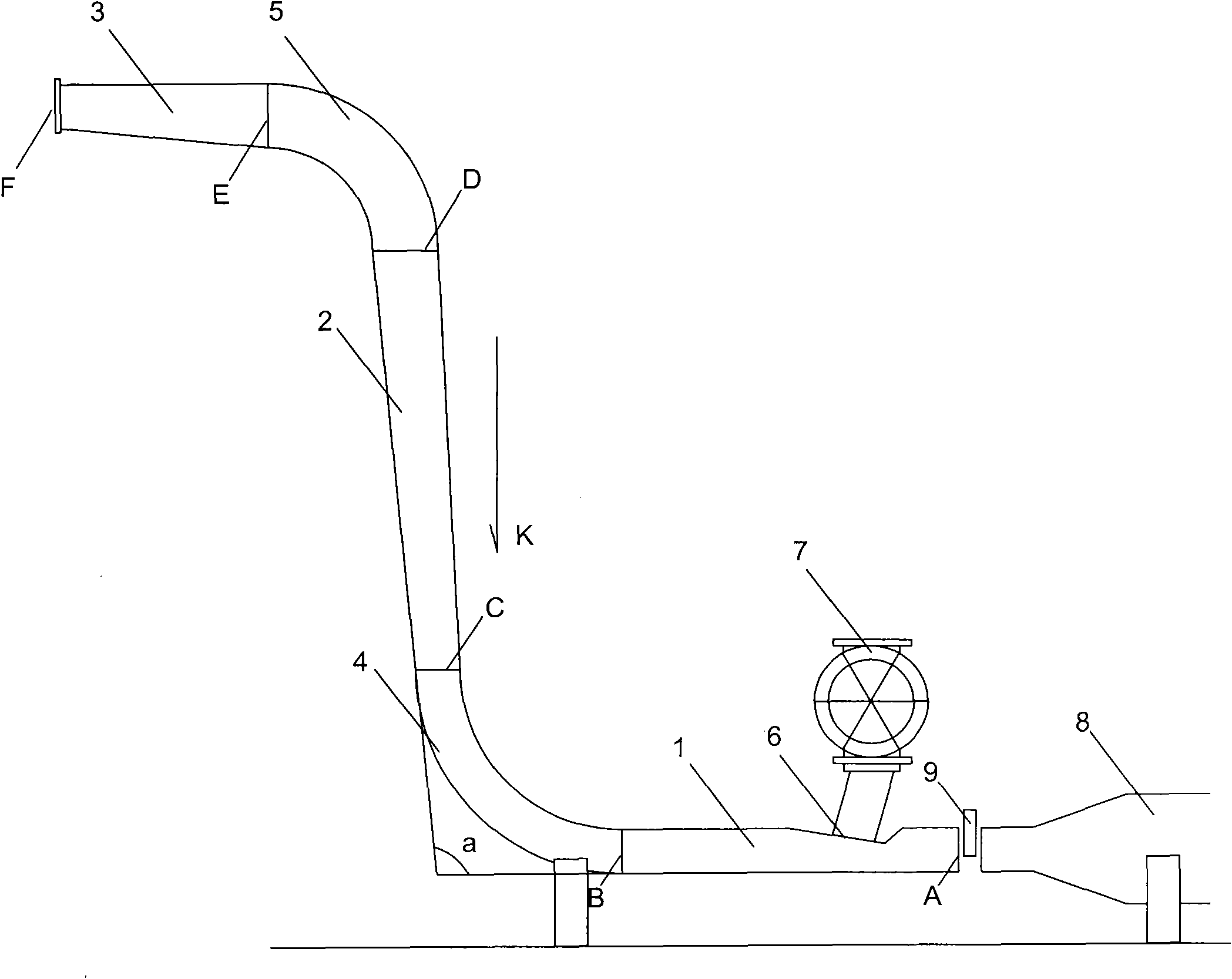

Improved novel tobacco shred expansion device

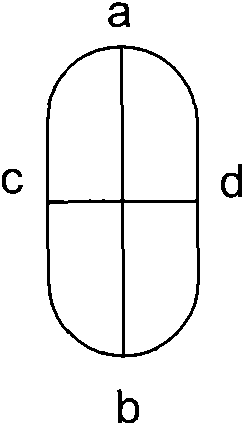

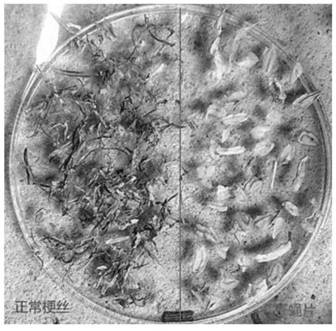

The invention relates to a tobacco leaf puffing treatment device for preparing tobaccos in a tobacco factory, in particular to an improved novel tobacco shred expansion device. By the expansion device, expansion treatment is carried out on tobacco shreds which are soaked by carbon dioxide liquid and form dry ice by high-temperature airflow. The improved novel tobacco shred expansion device is in a Z-shaped tubular structure with an inlet and an outlet which are horizontally arranged, the inlet is connected with a hot air conveying device, the outlet is connected with a tangential separator, the position of the inlet is also communicated with a feeding mechanism, and the whole range of the tubular structure adopts an oblong section, wherein the area of the oblong section of an upright tube section is gradually increased from an inlet end to an outlet end, the length of the longitudinal long axis of the oblong section is gradually increased, the length of the transverse short axis is unchanged, and hot air conveyed by the hot air conveying device is parallel to the direction of the transverse short axis in the direction of the inlet. The expansion device enhances the heat exchange effect of tobacco shreds in the expansion device greatly, also prevents the collision between the tobacco shreds and enhances the shred straightening rate.

Owner:QINHUANGDAO TOBACCO MACHINERY

Device and method for removing light and thin pieces in cut stems by using flow guide plate

ActiveCN112089089AEasy to separateSmall footprintTobacco treatmentGas current separationEngineeringMechanical engineering

The invention discloses a device for removing light and thin pieces in cut stems by using a flow guide plate. The device comprises a vertically-arranged separation cylinder (T), the cut stem flow guide plate (1) and a cut stem distribution plate (2), wherein the cut stem flow guide plate (1) and the cut stem distribution plate (2) are arranged in the separation cylinder (T). The invention furtherdiscloses a method for removing the light and thin pieces in the cut stems by using the device. By means of the device, the finished cut stems can be fully separated from the light and thin pieces. The device is designed for the first time, occupies a small area and is beneficial to industrial production.

Owner:CHINA TOBACCO YUNNAN IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com