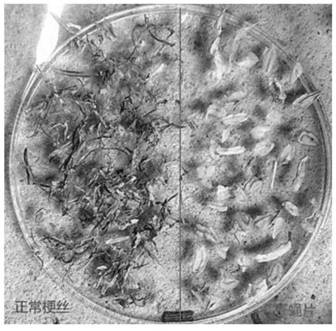

Device and method for removing light and thin pieces in cut stems by using flow guide plate

A technology of baffles and cut stems, which is used in the separation of solids from solids by air flow, chemical instruments and methods, applications, etc. Small land, good for industrial production and clever design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

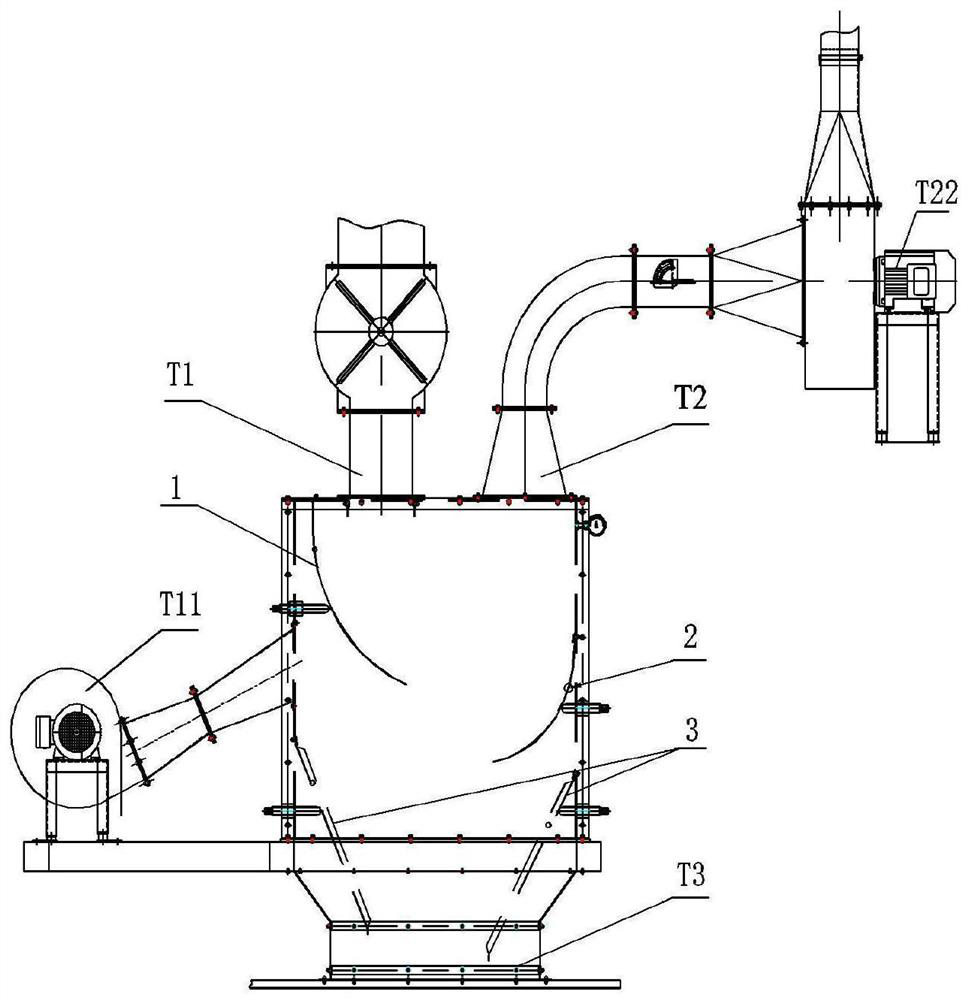

[0033] In order to make the purpose, technical solution and beneficial results of the present invention clearer, the implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings. However, the drawings and embodiments are not limitations to the technical solutions of the present invention, and any changes or improvements made based on the teachings of the present invention belong to the protection scope of the present invention.

[0034] Such as figure 2 As shown, a device using deflectors to remove light flakes from cut stems includes the steps of: a vertically placed cylindrical separation cylinder T and cut stem deflectors 1 arranged inside the separation cylinder T; The cut stem distribution plate 2; the upper part of the cut stem deflector 1 is the cut stem feed port T1 for guiding the cut stem coming in from the feed inlet T1, and the cut stem deflector 1 is provided at the bottom There is a posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com