Improved novel tobacco shred expansion device

An expansion device and a technology for shredded tobacco, which are applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems of collision of shredded tobacco, increase of friction machines, uneven wind speed, and no attention, etc. The effect of preventing collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention provides an improved shredded tobacco expansion device, which can make the shredded tobacco evenly transported along the center line of the expansion device, greatly improves the heat exchange effect of the shredded tobacco in the expansion device, and also reduces the collision probability between shredded tobacco , improve the whole cut rate of cut tobacco in the expansion process.

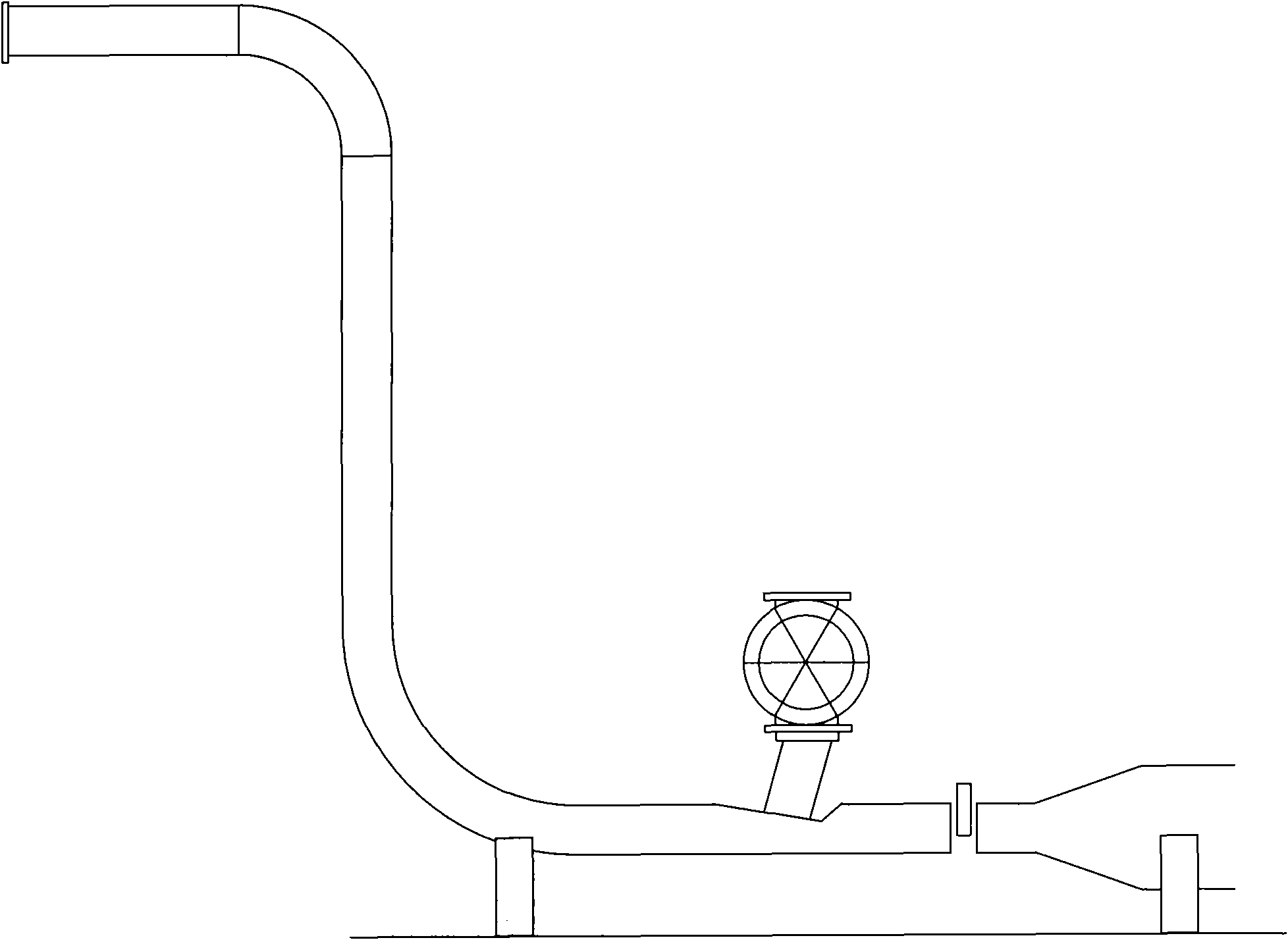

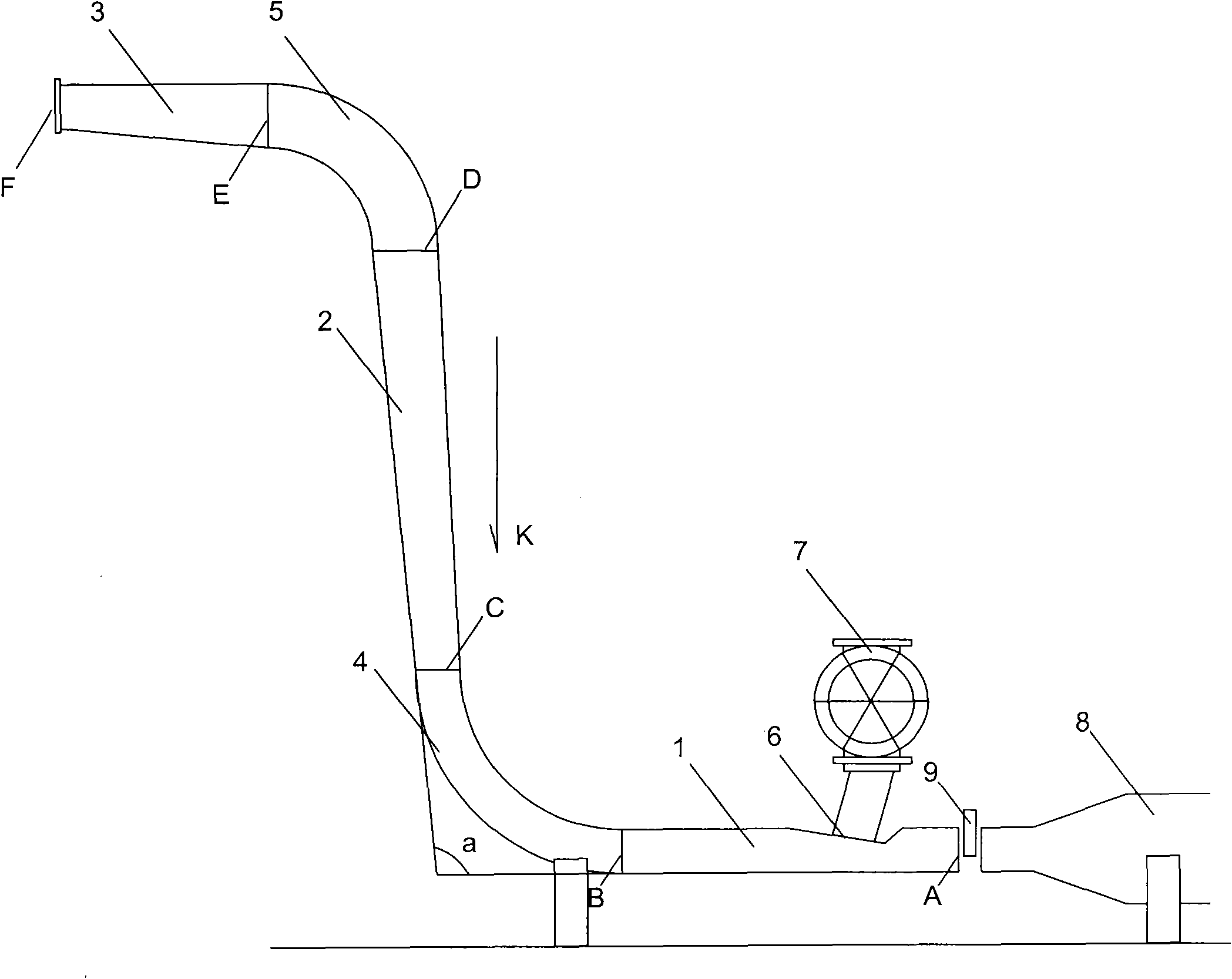

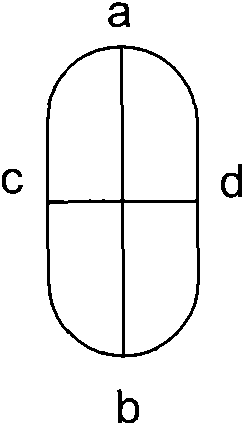

[0031] The invention provides an improved new shredded tobacco expansion device, the expansion device is a Z-shaped tubular structure with an inlet and an outlet arranged horizontally, a hot air conveying device is connected to the inlet, and a tangential separator is connected to the outlet , the entrance of the tubular structure is also communicated with the feeding mechanism, and the whole process of the tubular structure adopts an oblong cross-section (as shown in the attached manual image 3 As shown), the oblong cross-sectional area of the vertical pipe section of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com