Tobacco shred expanding process adopting water as medium

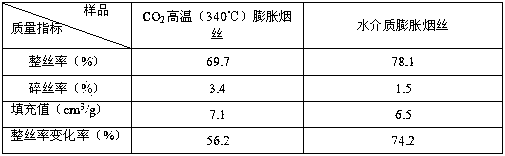

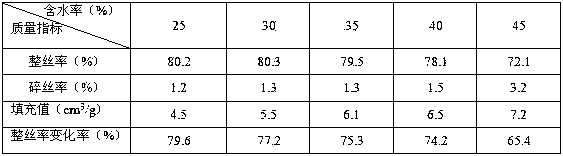

A shredded tobacco and medium technology, applied in the field of tobacco, can solve the problems of the loss of chemical components of shredded tobacco, low change rate of whole shredded ratio, and high production cost, and achieve the effects of widening the use range of raw materials, improving the taste, and increasing the use value of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

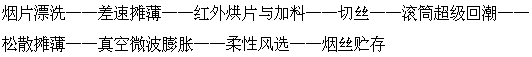

[0024] A cutting tobacco expansion process using water as the medium, the steps are as follows:

[0025] (1) Rinsing of tobacco slices: continuous rinsing of the loose recured tobacco slices into the washing tank after quantitative feeding, the water flow rate is 0.1m / s, the rinsing water temperature is 25°C, and the moisture content of the tobacco slices after rinsing is 45% (rinsing time 20s );

[0026] (2) Differential speed thinning: After the washed smoked sheets are filtered through the mesh belt, the material is thinned by differential feeding. The speed of the low-speed belt is 2m / s, and the speed of the high-speed belt is 4m / s. A leveling roller is used above the high-speed belt Dilute the material to a material thickness of 10mm;

[0027] (3) Infrared drying and feeding: the leaves are dried by infrared drying until the moisture content is 16% before feeding. The infrared wavelength is 6 μm, the infrared power is 18kw, the drying temperature is 70°C, and the drying ...

Embodiment 2

[0046] A cutting tobacco expansion process using water as the medium, the steps are as follows:

[0047] (1) Rinsing of tobacco slices: the loose recured tobacco slices are fed into the washing tank for continuous rinsing by quantitative feeding, the water flow rate is 0.05m / s, the rinsing water temperature is 30°C, and the moisture content of the rinsed tobacco slices is 40% (rinsing time 10s );

[0048] (2) Differential speed thinning: After the washed smoked sheets are filtered through the mesh belt, the material is thinned by differential feeding. The speed of the low-speed belt is 2m / s, and the speed of the high-speed belt is 4m / s. A leveling roller is used above the high-speed belt Dilute the material to a material thickness of 10mm;

[0049](3) Infrared drying and feeding: the leaves are dried by infrared drying until the moisture content is 15% before feeding. The infrared wavelength is 10 μm, the infrared power is 15kw, the drying temperature is 60°C, and the drying ...

Embodiment 3

[0056] A cutting tobacco expansion process using water as the medium, the steps are as follows:

[0057] (1) Rinsing of tobacco slices: the loose recured tobacco slices are fed into the washing tank for continuous rinsing by quantitative feeding, the water flow speed is 0.08m / s, the rinsing water temperature is 15°C, and the moisture content of the tobacco slices after rinsing is 50% (rinsing time 30s );

[0058] (2) Differential speed thinning: After the washed smoked sheets are filtered through the mesh belt, the material is thinned by differential feeding. The speed of the low-speed belt is 2m / s, and the speed of the high-speed belt is 4m / s. A leveling roller is used above the high-speed belt Dilute the material to a material thickness of 10mm;

[0059] (3) Infrared drying and feeding: the leaves are dried by infrared drying until the moisture content is 15% before feeding. The infrared wavelength is 2.5 μm, the infrared power is 20kw, the drying temperature is 80°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com