Additive for improving quality of CO2 expanded cut tobacco and application of additive in cigarettes

A technology of expanded shredded tobacco and additives, applied in the fields of application, tobacco, and prepared tobacco, can solve the problems of the influence of expanded shredded tobacco, and the fact that the physical moisture retention effect of expanded shredded tobacco has no relevant effect, so as to improve the whole shredded tobacco rate, improve the sensory quality and physical retention. Lubricant performance, loss reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

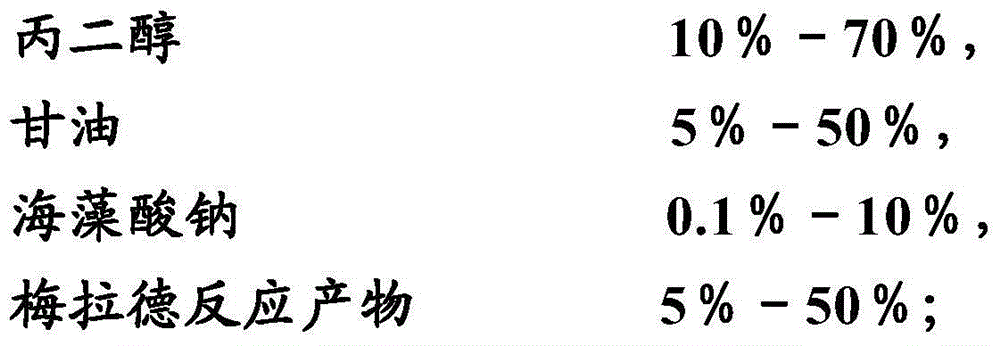

[0060] Preparation Example 1: Preparation of Maillard Reaction Product 1

[0061] Amino acids are: proline, glycine, alanine, the ratio is 1:1.5:1 (molar ratio).

[0062] Sugar is: glucose, fructose, the ratio is 1:3 (molar ratio).

[0063] The ratio of amino acid and sugar is 1:1 (molar ratio).

[0064] Preparation process: Mix sugar and amino acid evenly, add 10 times distilled water to dissolve to obtain a mixed solution, heat the solution to 90°C, react for 2 hours, and cool to obtain Maillard reaction product 1.

[0065] Used in Example 1 below.

preparation example 2

[0066] Preparation Example 2: Preparation of Maillard Reaction Product 2

[0067] The amino acids are: proline, glycine, the ratio is 1:2.5 (molar ratio).

[0068] Sugar is: glucose.

[0069] The ratio of amino acid and sugar is 1:5 (molar ratio).

[0070] Preparation process: Mix sugar and amino acid evenly, add 30 times distilled water to dissolve to obtain a mixed solution, heat the solution to 95°C, react for 8 hours, and cool to obtain Maillard reaction product 2.

preparation example 3

[0072] Preparation Example 3: Preparation of Maillard Reaction Product 3

[0073] The amino acids are: proline, alanine, the ratio is 1:4 (molar ratio).

[0074] Sugar is: glucose, fructose, the ratio is 1:5 (molar ratio).

[0075] The ratio of amino acid and sugar is 1:3 (molar ratio).

[0076] Preparation process: Mix sugar and amino acid evenly, add 50 times distilled water to dissolve to obtain a mixed solution, heat the solution to 93.5°C, react for 5 hours, and cool to obtain Maillard reaction product 3.

[0077] Used in Example 3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com