Method for enabling carbon dioxide expanded tobacco to highlight sweet aroma style

A technology of carbon dioxide and expanded cut tobacco, which is applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems such as the inability to reduce the crushing of expanded cut tobacco, the reduction of aroma of expanded cut tobacco, and the deterioration of taste sensation, so as to increase the high-quality coke sweet aroma, Compensate for the loss of aroma substances and the effect of reducing the rate of shredding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

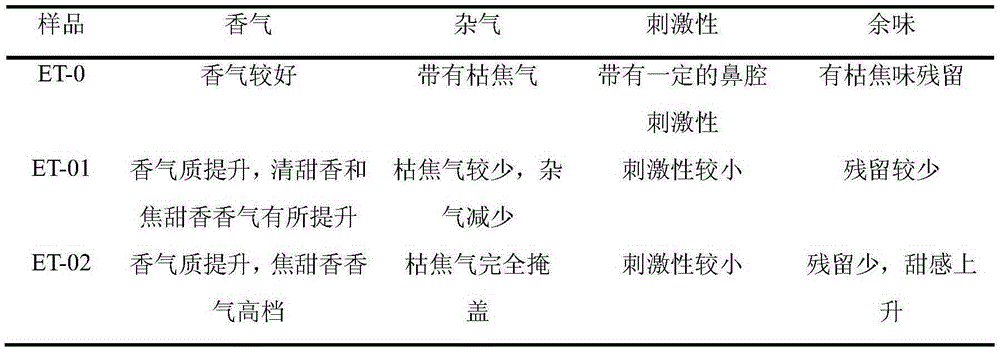

[0042] Add a feed liquid to the tobacco leaves before expansion, and its addition amount is 1% of the weight of the tobacco leaves. The composition of the feed liquid is as follows according to the mass ratio: 12% fructose, 2.5% maltose, 0.5% dextran, and 85% water. The final tobacco leaves are cut into shreds and then expanded with carbon dioxide to prepare expanded shredded tobacco.

[0043] Add secondary feed liquid in the shredded tobacco after expansion, its addition is 0.8% of the cut tobacco weight after expansion, and the composition of secondary feed liquid is as follows according to weight ratio: concentration is 1% (mass percentage, the same below) Zimbabwean tobacco essential oil molecule Distilled light fraction accounted for 2%, scopoletin ethanol solution accounted for 1%, concentration of 1% strawberry ketone ethanol solution accounted for 1%, concentration 1% of 2,3,5-collidine 1% ethanol solution of oxazine, 5% Maillard reaction product of burnt-sweet aroma s...

Embodiment 2

[0047] Add primary feed liquid in the tobacco leaf before expansion, and its addition is 2% of tobacco leaf weight, and the composition of primary feed liquid is as follows according to mass ratio: xylose 10%, maltose 2.5%, lentinan 0.5%, water 87% (weight Percentage), the shredded tobacco leaves after the addition are then expanded with carbon dioxide to prepare expanded shredded tobacco.

[0048] Add the secondary feed liquid to the expanded shredded tobacco in an amount of 1% of the weight of the expanded shredded tobacco. The composition of the secondary feed liquid is as follows according to the weight ratio: the molecular distillation light component of Hunan tobacco leaf essential oil with a concentration of 1% accounts for 2%. 1% ethanol solution of damascenone with a concentration of 2%, 1% ethanol solution of strawberry ketone with a concentration of 1%, 2,3,5-trimethylpyrazine ethanol solution with a concentration of 1% 0.5%, 1% burnt-sweet-flavored Maillard reactio...

Embodiment 3

[0051] Embodiment 3: Physical Structure Comparison of Expanded Shredded Tobacco

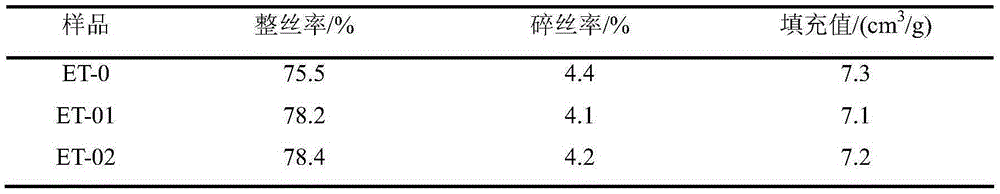

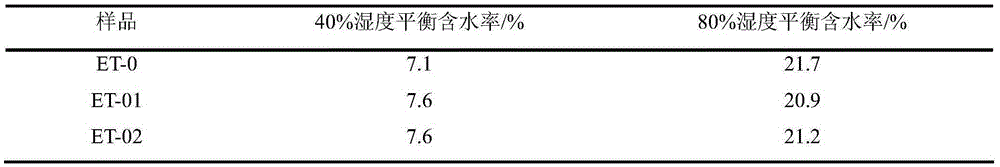

[0052] Compare the expanded shredded tobacco ET-01 and ET-02 prepared in the above examples with the blank expanded shredded tobacco sample ET-0, and compare their physical structure indicators. All the expanded shredded tobacco raw materials are the same leaf group formula, and the blank expanded shredded tobacco sample ET-0 Prepared for blank shredded tobacco without addition. Measure the filling value according to the industry standard YC / T152-2001, and measure the whole filament rate and broken filament rate according to YC / T178-2003. The results are shown in Table 1.

[0053] Table 1. Physical structure comparison of expanded cut tobacco ET-0, ET-01 and ET-02

[0054]

[0055] From the data in Table 1, it can be obtained that the whole shred rate of the expanded shredded tobacco prepared by the method of the present invention is obviously improved, the shredded shredded shredded ratio i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com