Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Improve water squeeze effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

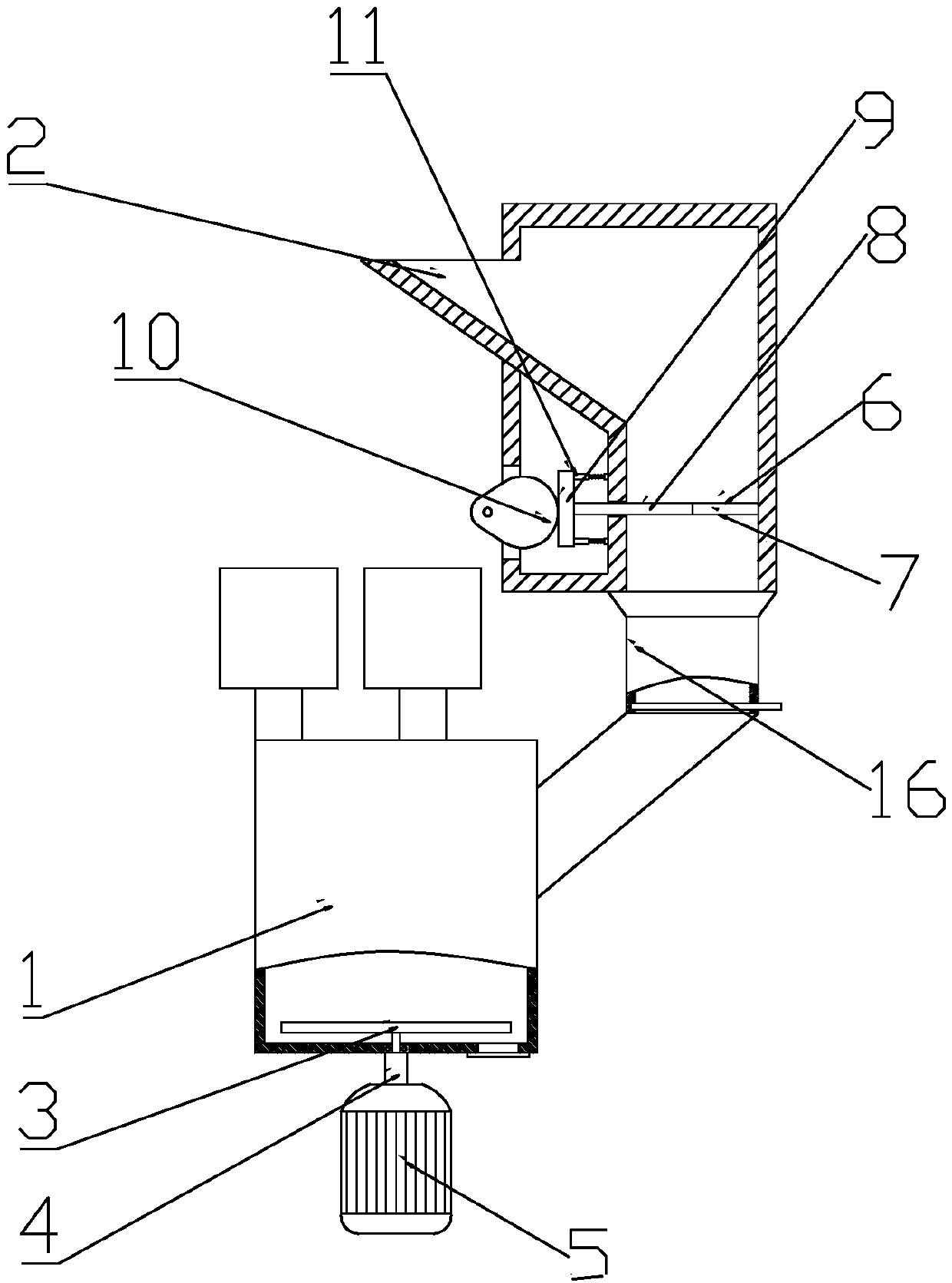

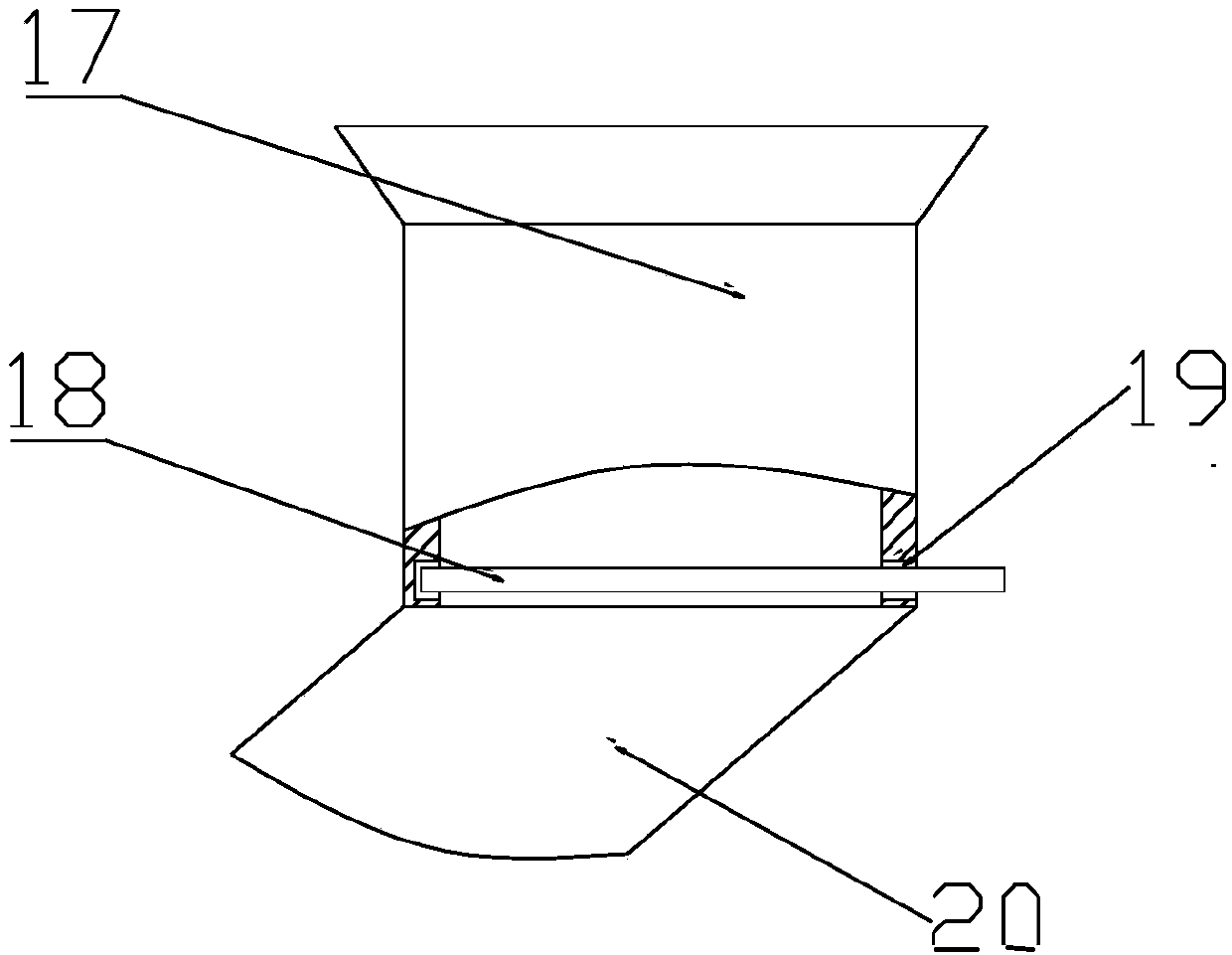

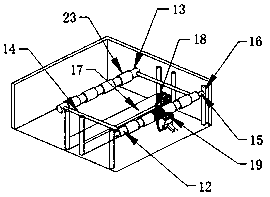

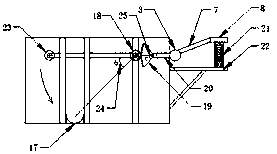

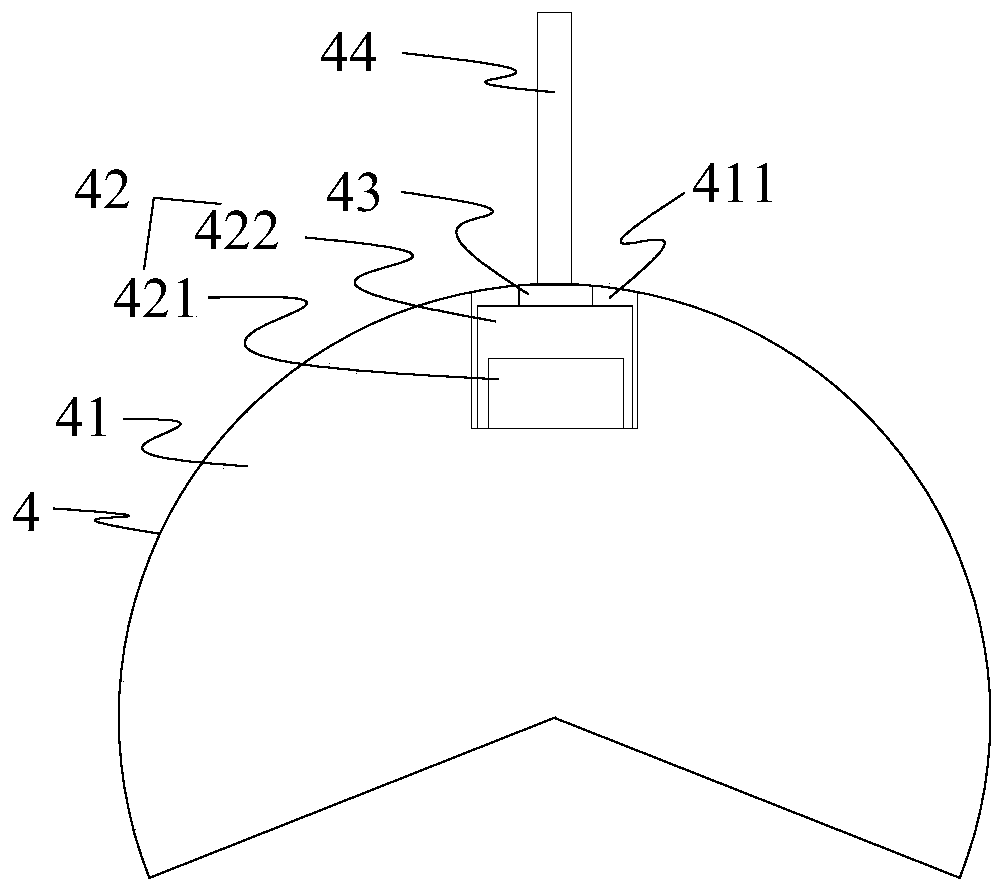

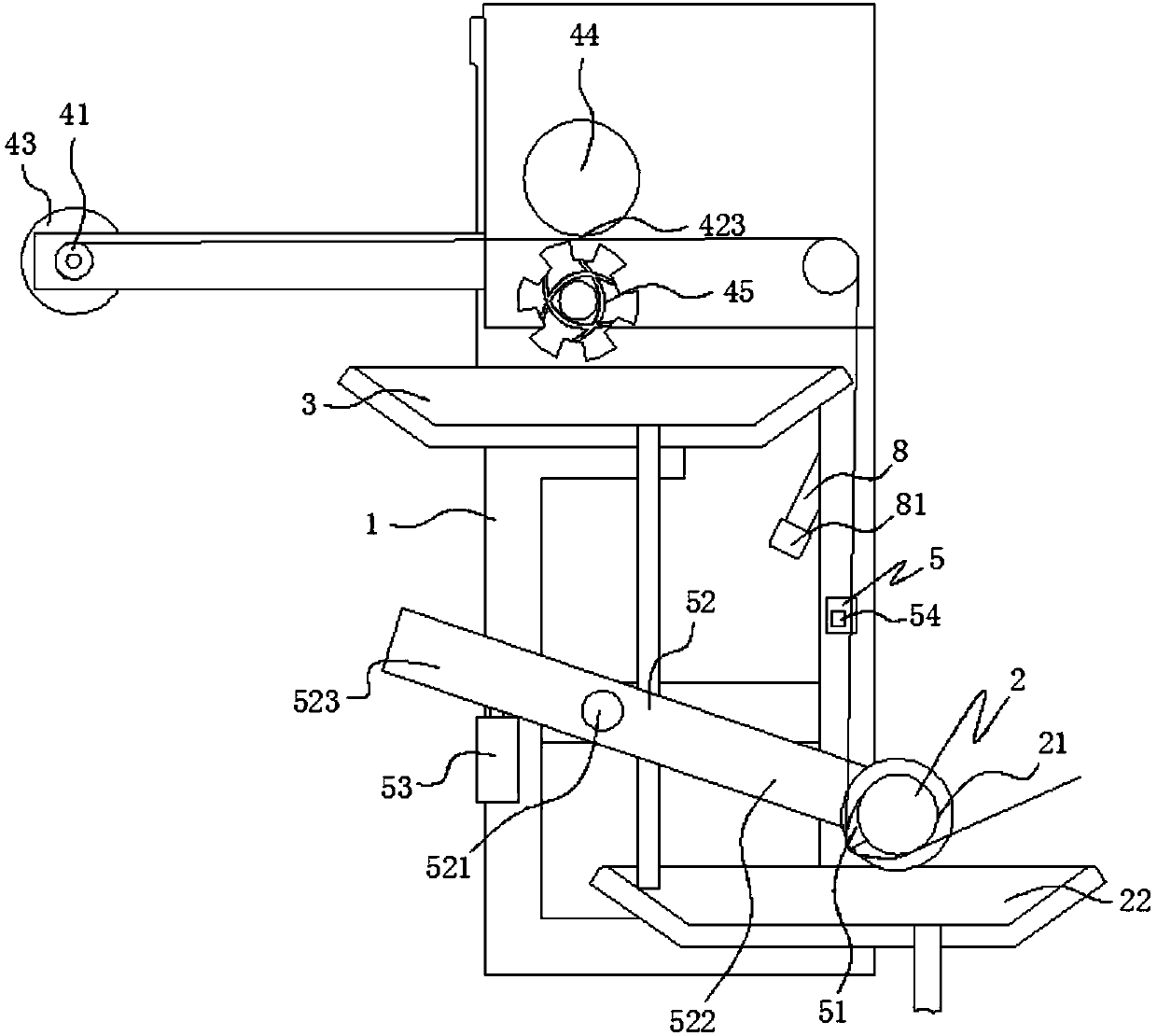

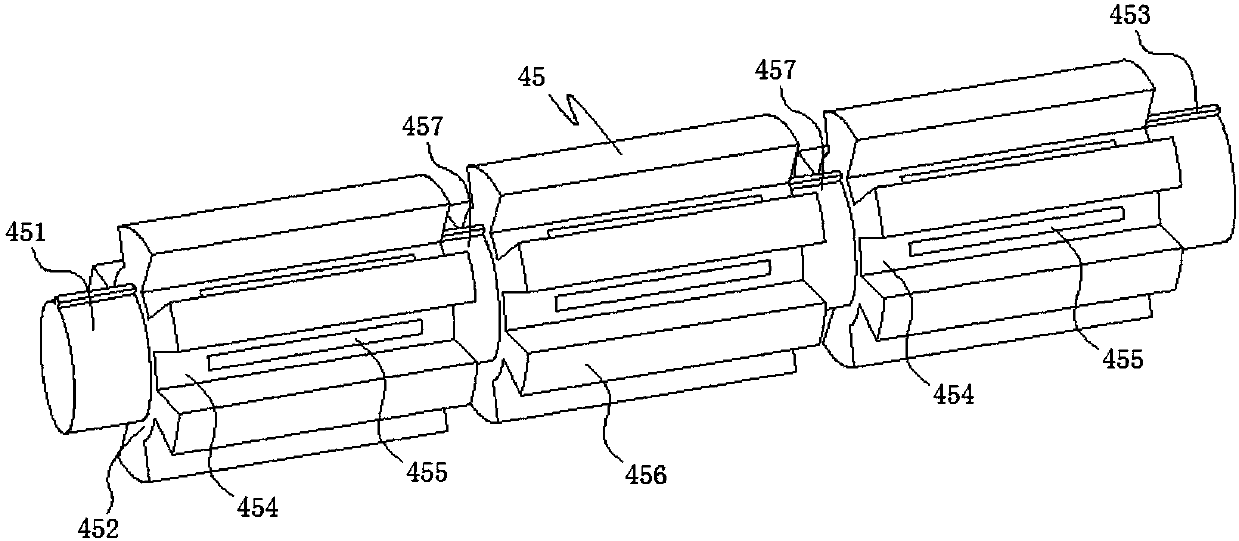

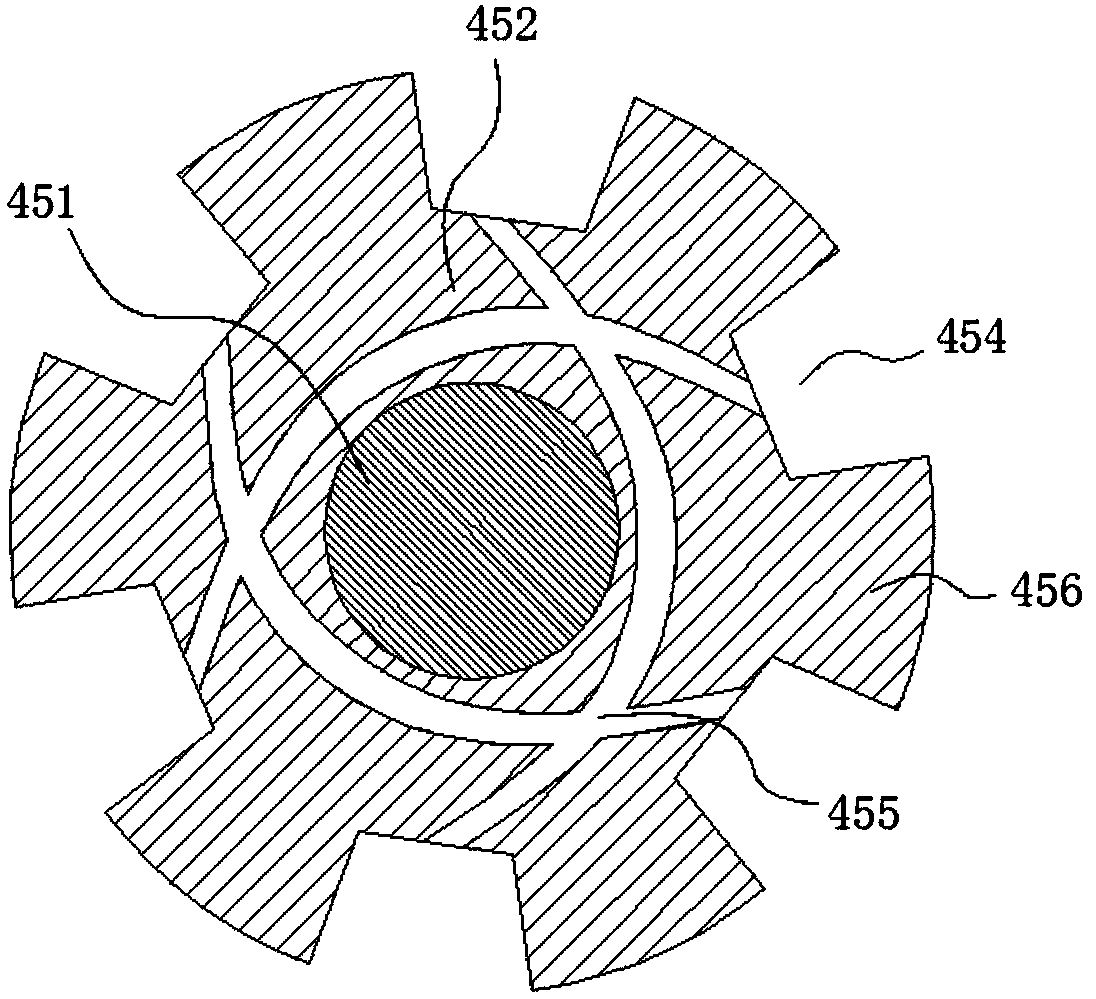

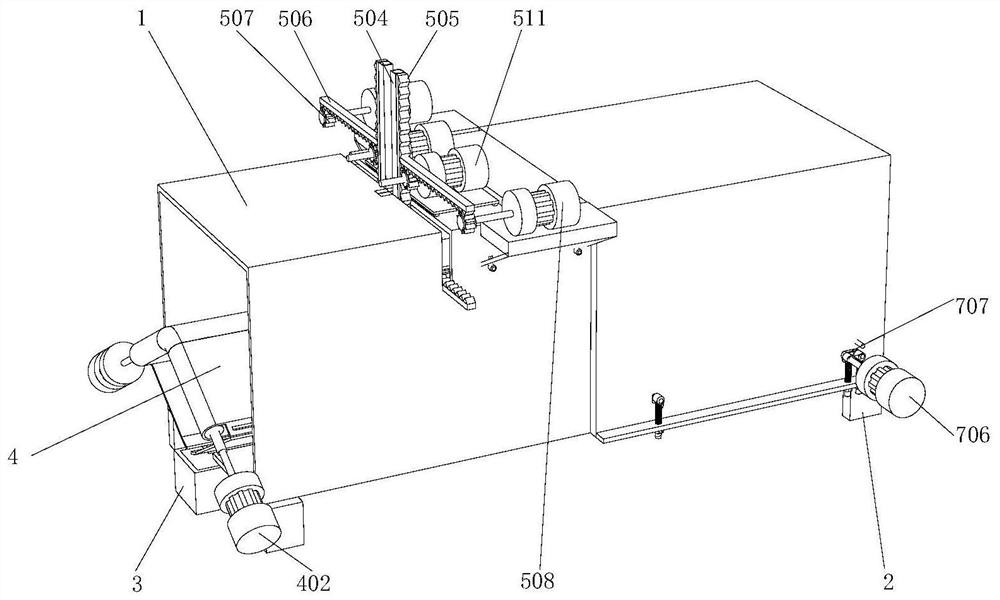

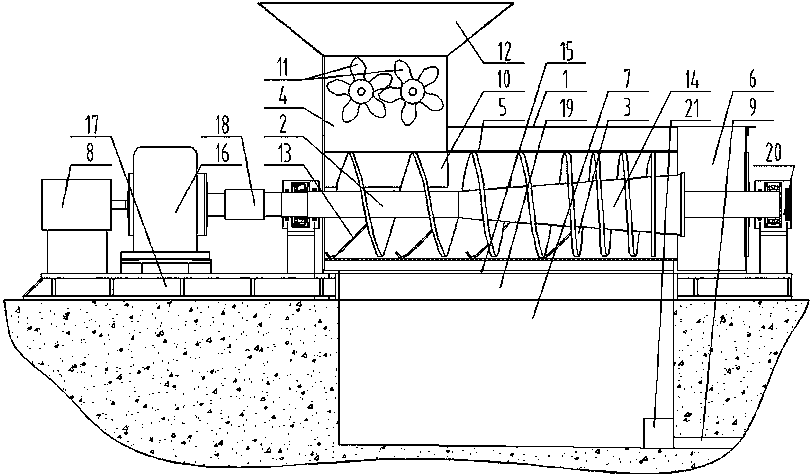

Feed mixing and crushing device for agriculture

PendingCN109589825AImprove qualityImprove water squeeze effectFeeding-stuffTransportation and packagingNutrientWater content

The invention relates to the technical field of agricultural machinery, in particular, to a feed mixing and crushing device for agriculture. The feed mixing and crushing device comprises a mixing box,a feeding cabin, a mixing blade, a mixing shaft, a motor and a quantitative cabin; the feeding cabin is arranged above the mixing box, the mixing blade is arranged inside the mixing box, the mixing blade is fixed on the top end of the mixing shaft by soldering, the mixing shaft stretches downward and is installed on the motor; a cutting mechanism is arranged inside the feeding cabin; the lower side of the feeding cabin is connected with green material quantitative mechanism; and the left side of the feeding cabin is provided with a water squeezing mechanism. The feed mixing and crushing device provided by the invention is simple in structure, low in cost, and convenient to transform the existing equipment, by squeezing water of green materials, weighing in a quantitative way, and then mixing with other additives, the problems that excessive water content in green material influences feed mixing and nutrient is lost are avoided, thus, the quality of mixed feed is effectively improved,and the practicability is good.

Owner:蔡亲军

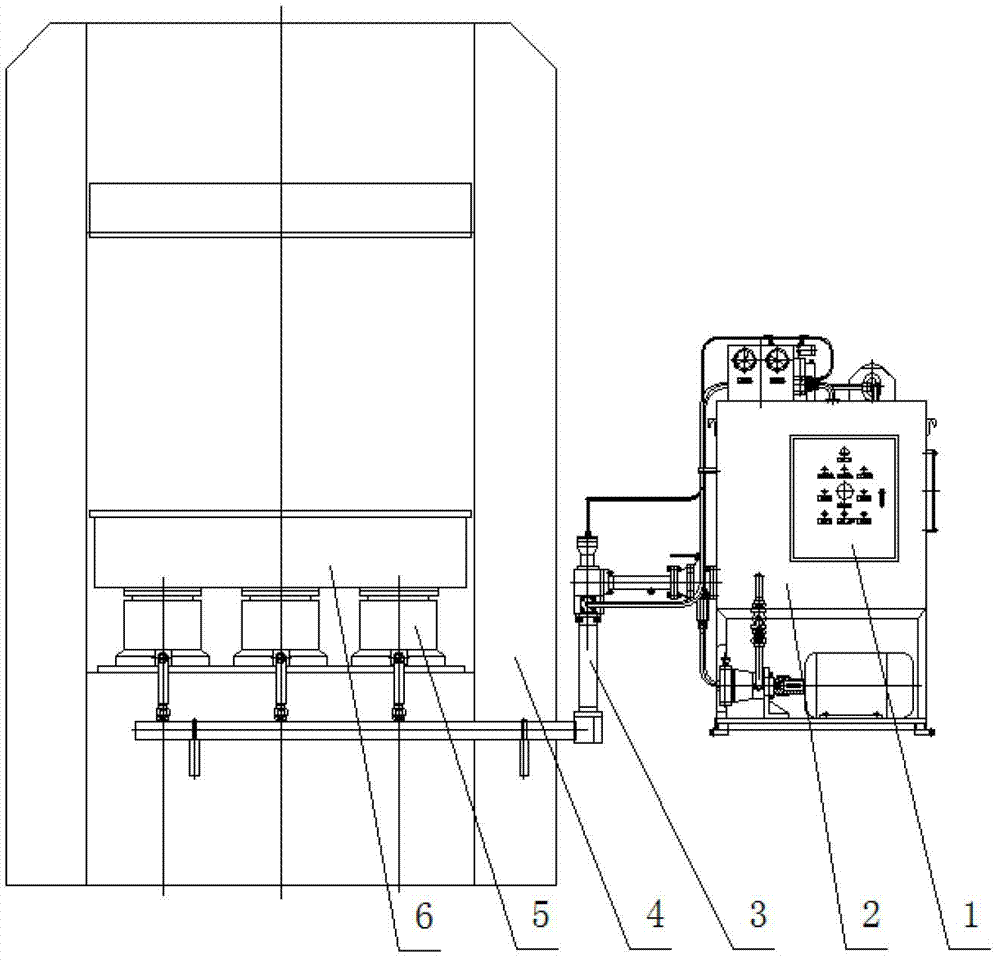

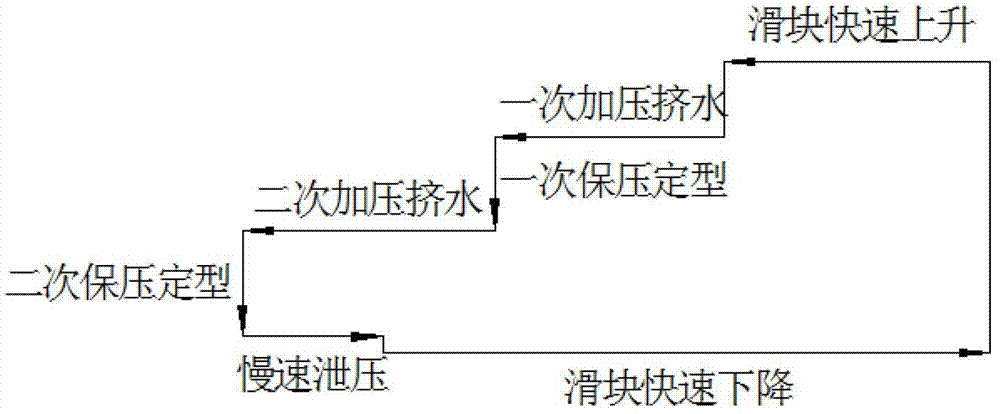

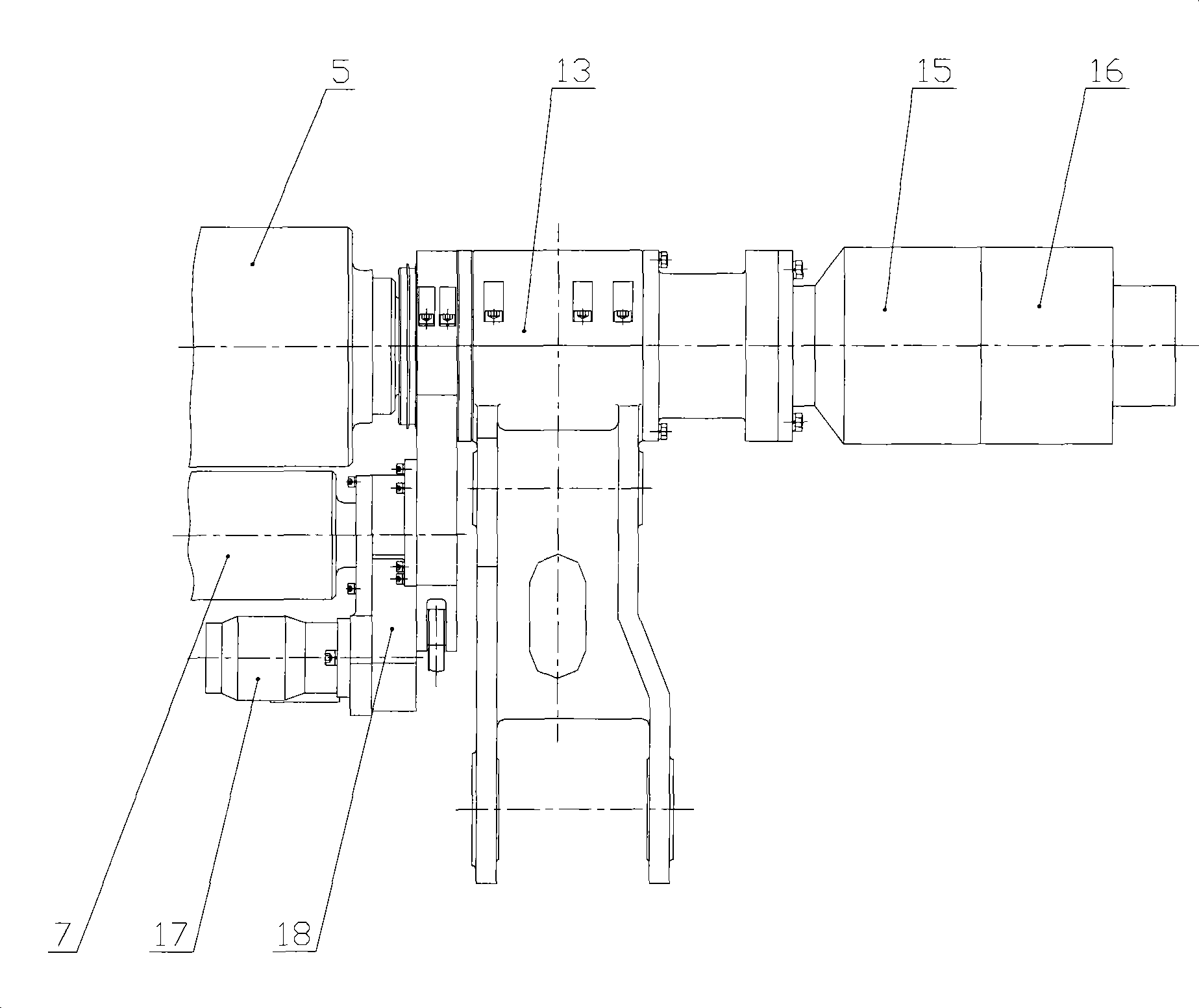

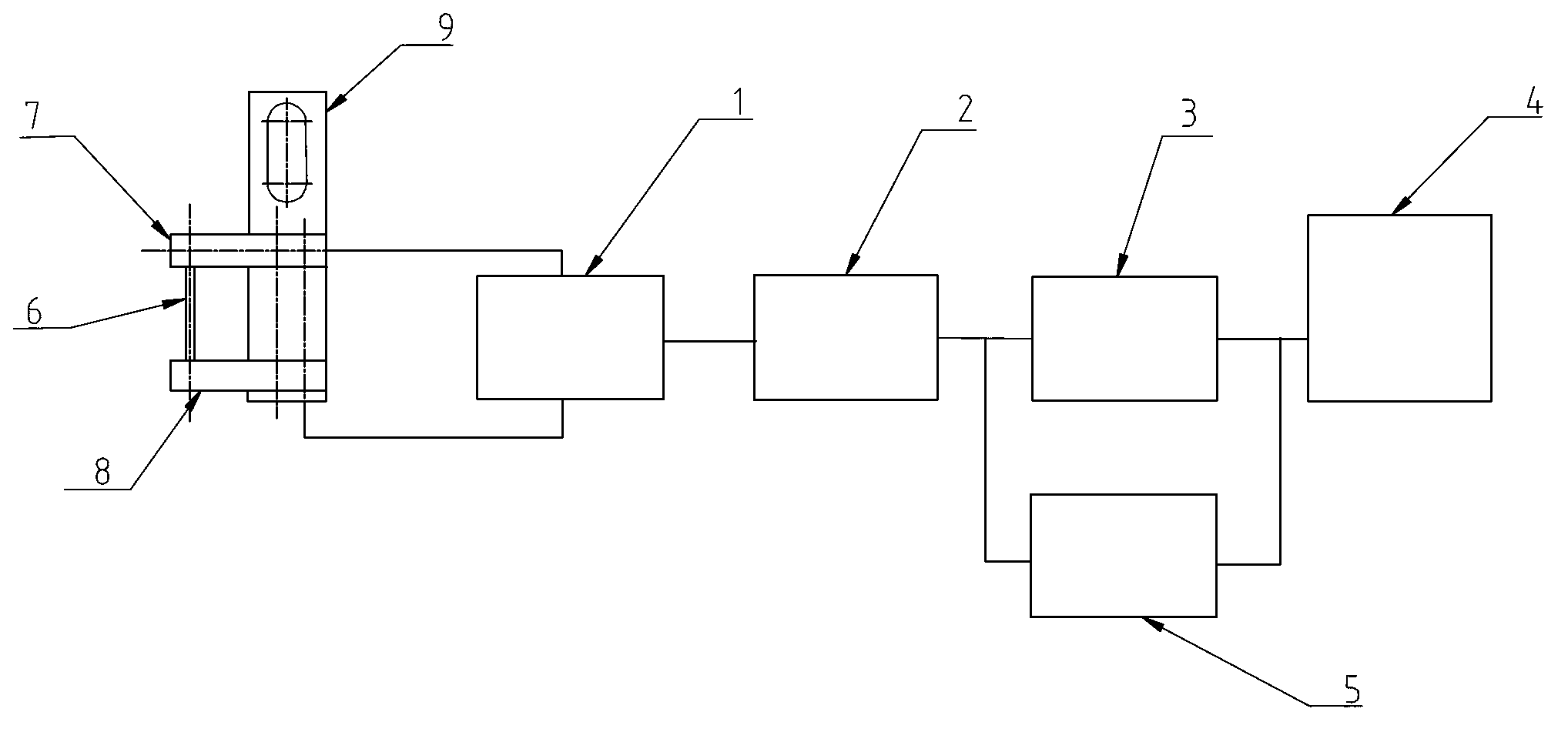

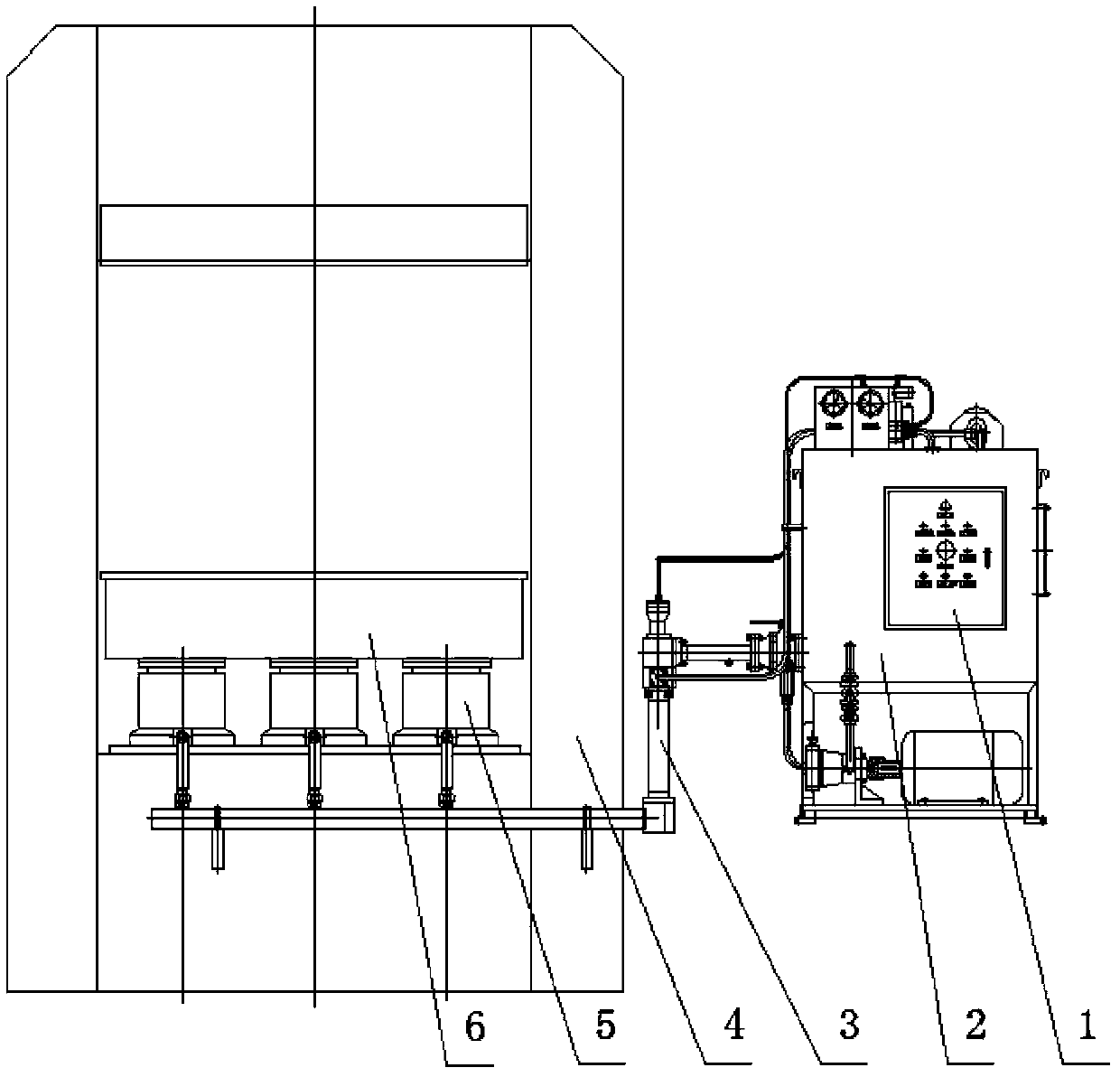

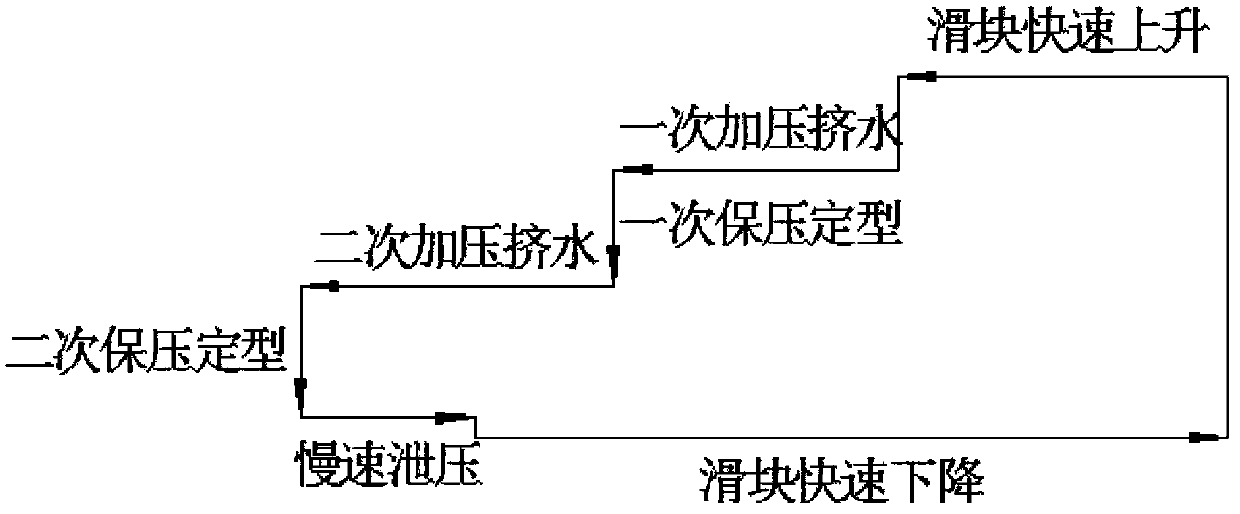

Hydraulic machine for rapid water squeezing and shaping

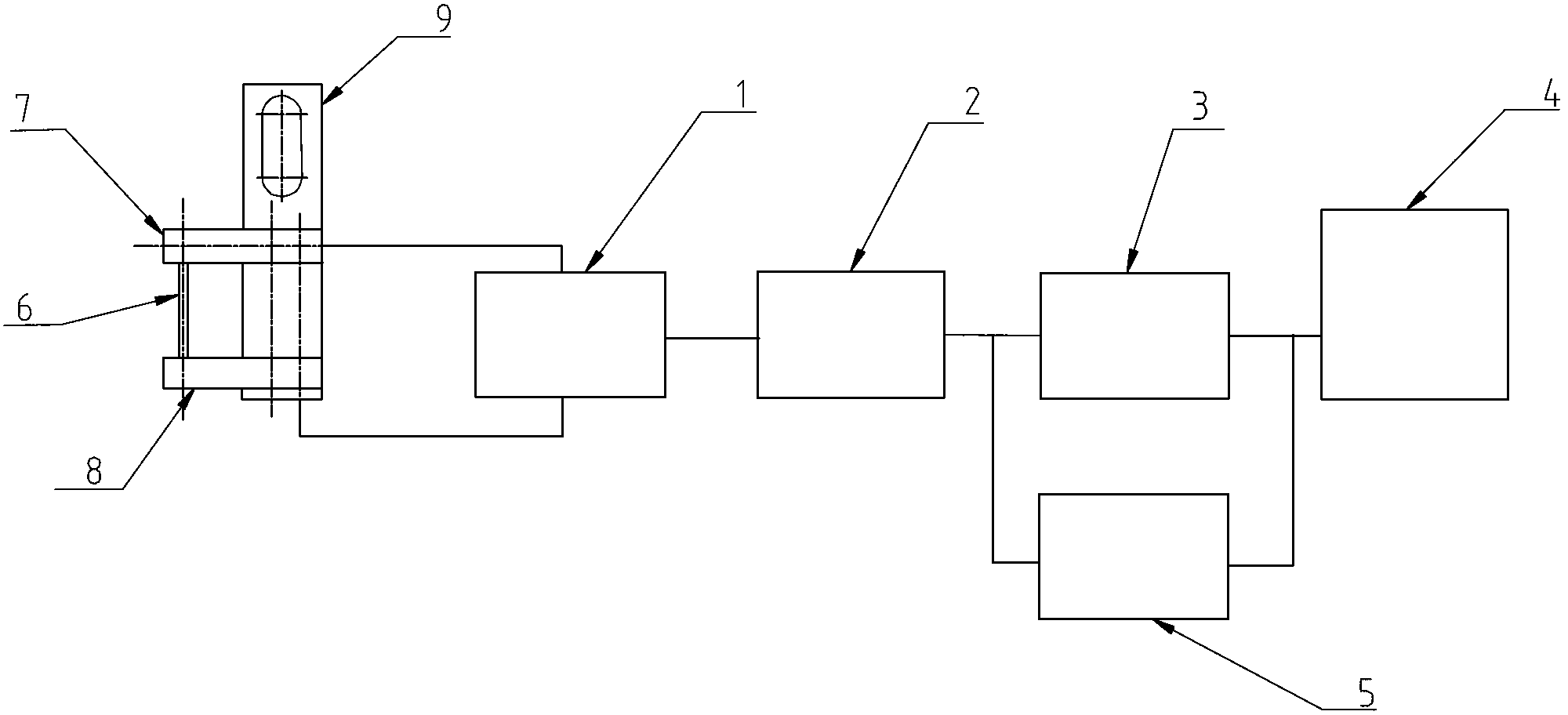

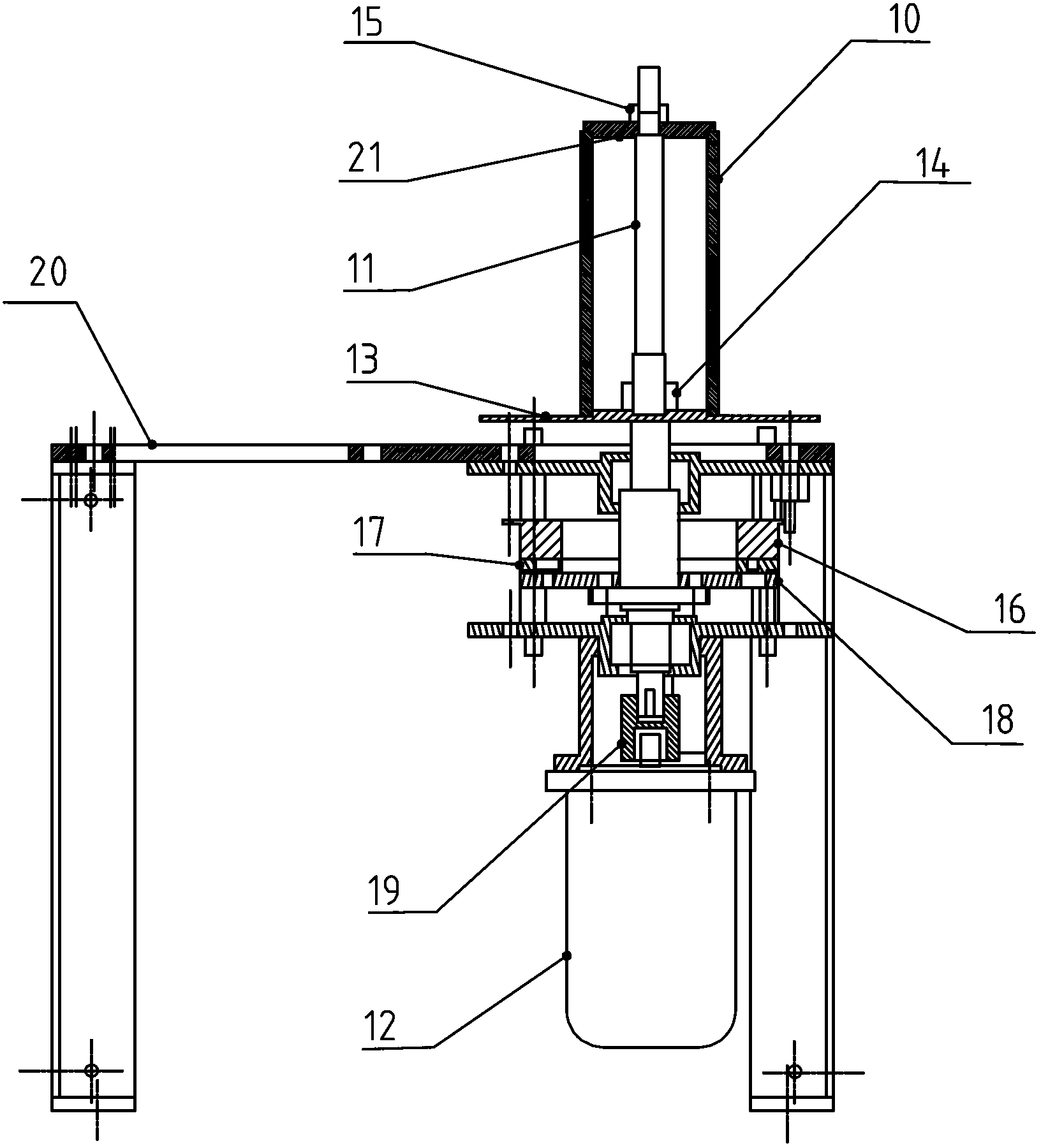

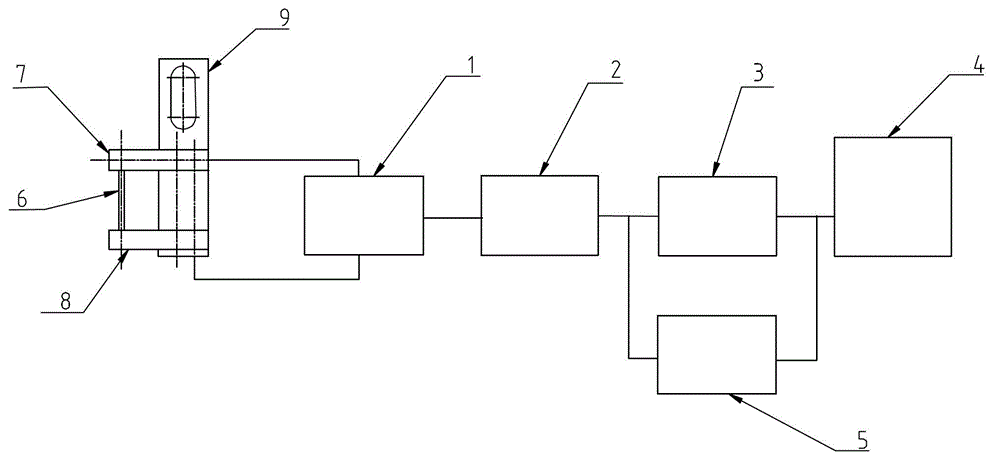

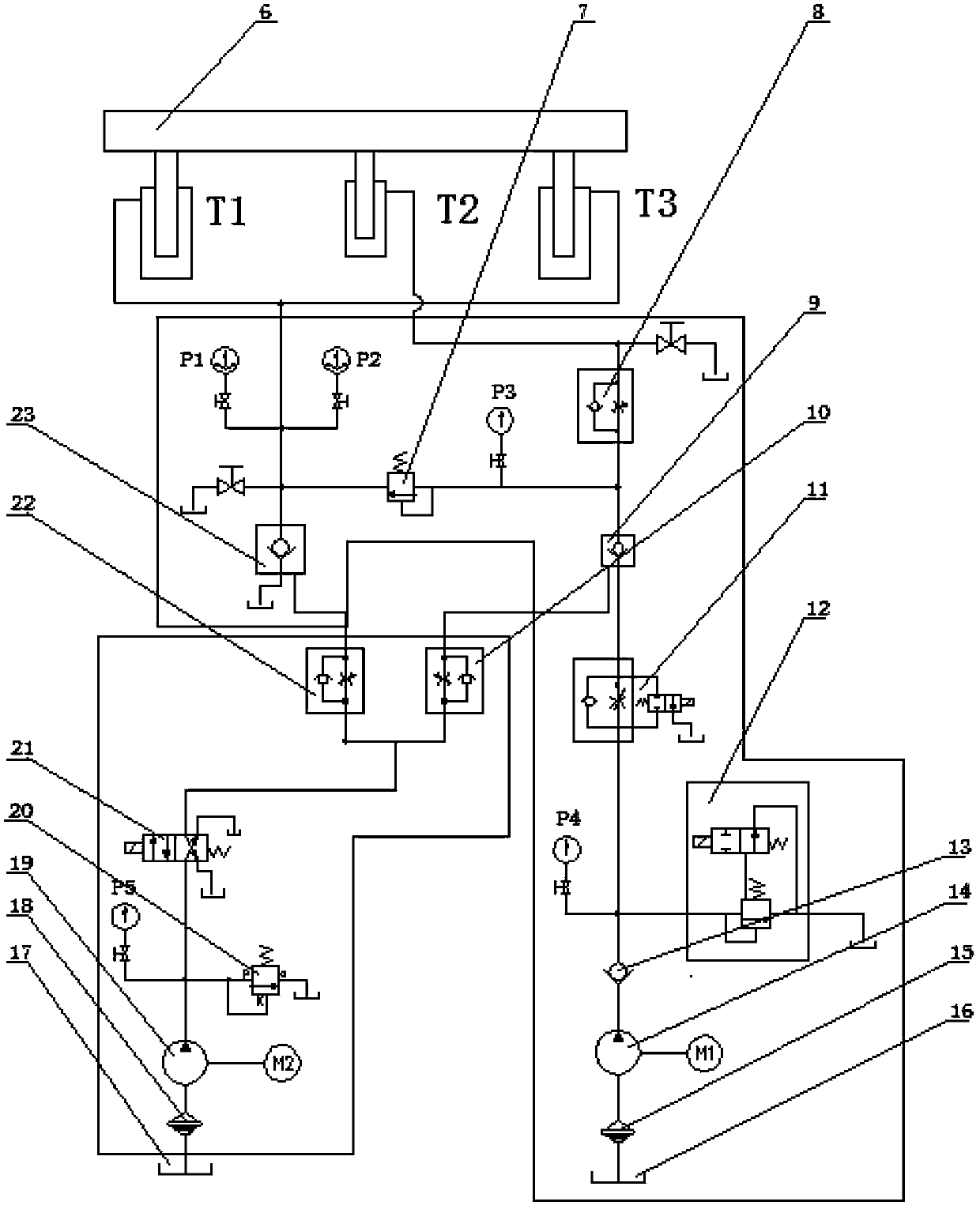

InactiveCN102922765AHigh speedIncrease pressureServomotor componentsServomotorsLow speedControl system

The invention relates to a hydraulic machine for rapid water squeezing and shaping. The hydraulic machine comprises a frame, sliding blocks, a plurality of oil cylinders, a hydraulic control system, an oil supply pipeline and an electric appliance control system, wherein the sliding blocks are mounted in the frame in parallel in a guiding manner; the oil cylinders are evenly distributed on the frame below the sliding blocks at intervals; the oil cylinders are connected with the hydraulic control system respectively through the oil supply pipeline; and the electric appliance control system controls each action of the hydraulic control system according to a predetermined command. The hydraulic machine is characterized in that the rapid raising, the pressurized water squeezing, the pressure-maintaining shaping, the low-speed decompressing and the rapid descending of the sliding blocks are carried out by utilizing a pressurization control return circuit and a decompression control return circuit respectively, wherein the pressurization control return circuit controls the rapid raising, the pressurized water squeezing, the pressure-maintaining shaping of the sliding blocks; and the decompression control return circuit controls the low-speed decompressing and the rapid descending of the sliding blocks. The hydraulic machine has the advantages of low cost, simple structure, convenience in repair, low operation cost, high working efficiency and excellent cost performance, thereby overcoming the defects of high-grade and low-grade water squeezing and shaping equipment.

Owner:天津市诺恩电器设备制造有限公司

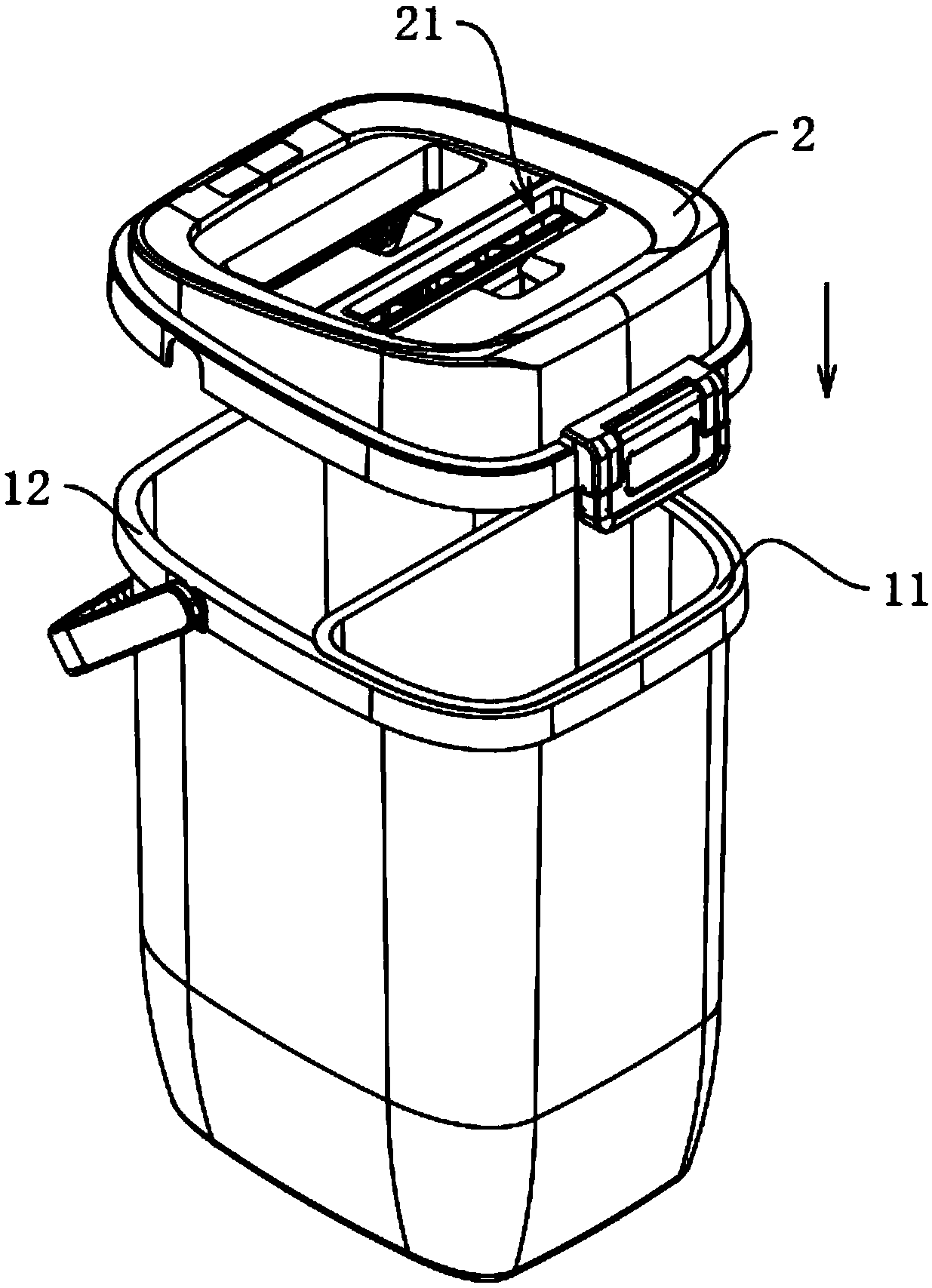

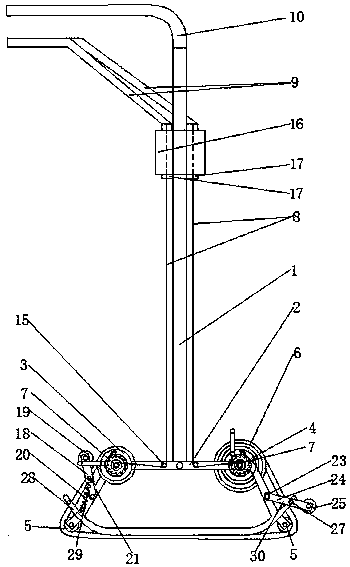

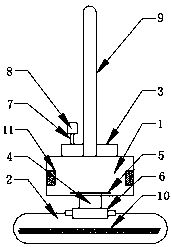

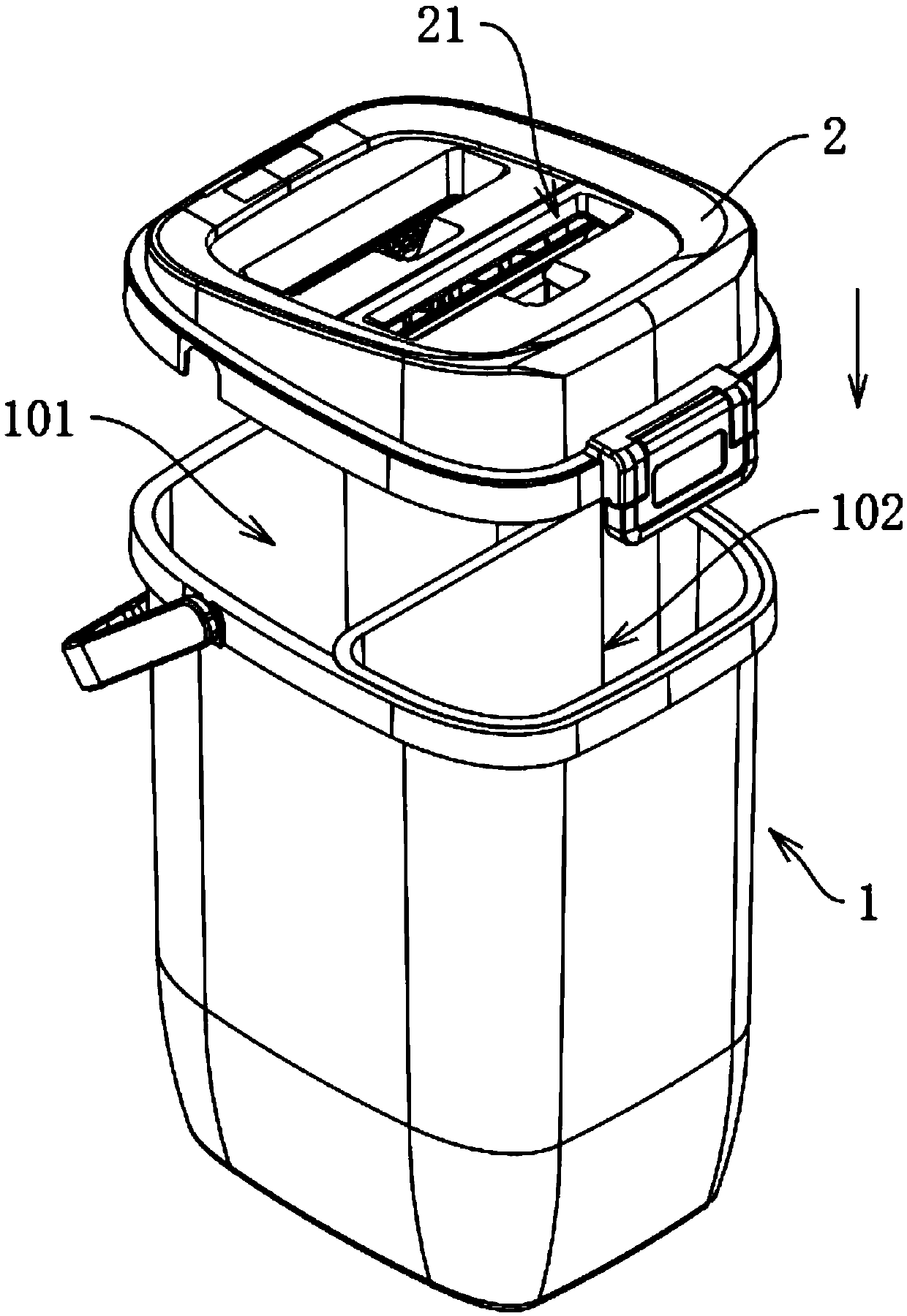

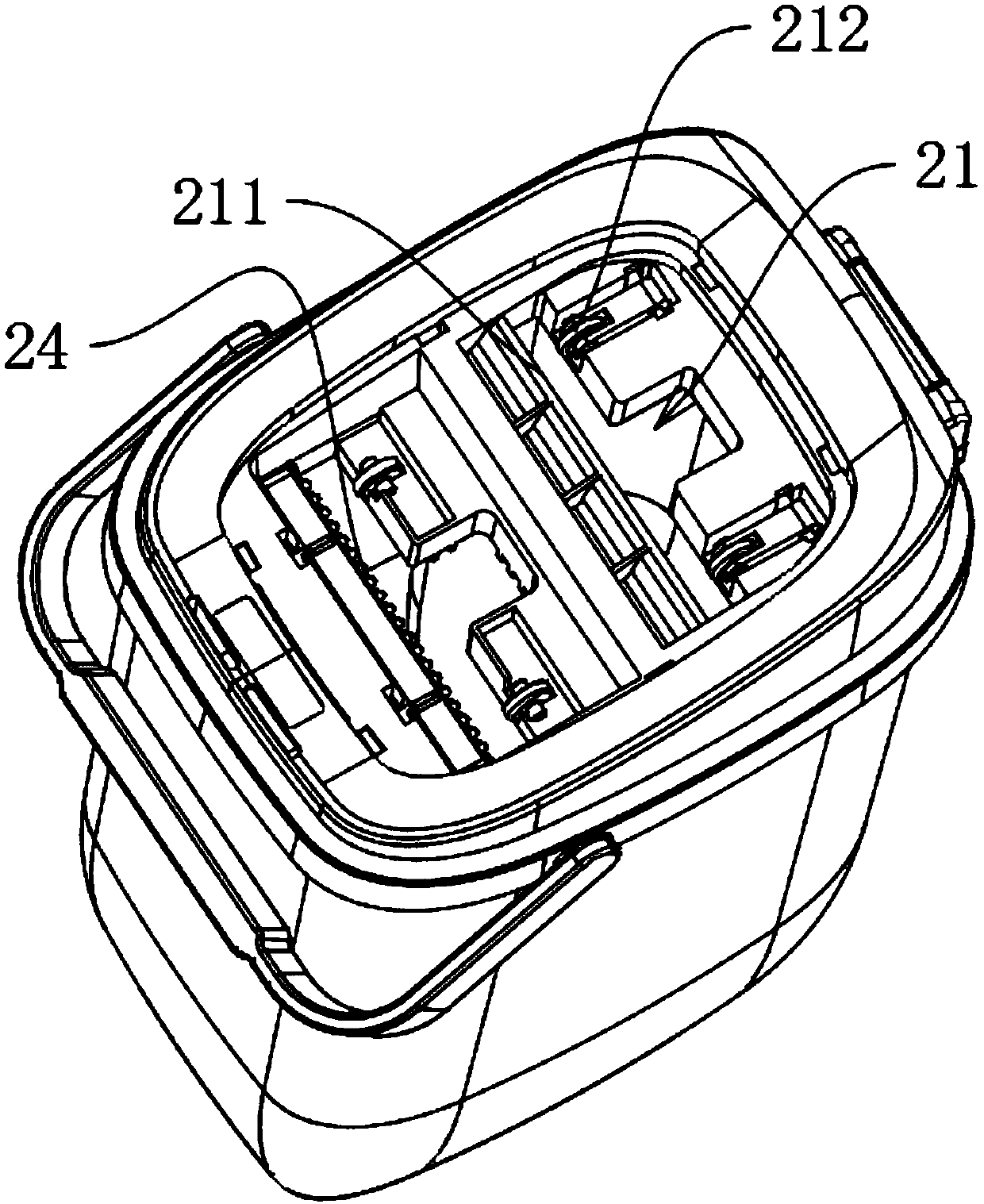

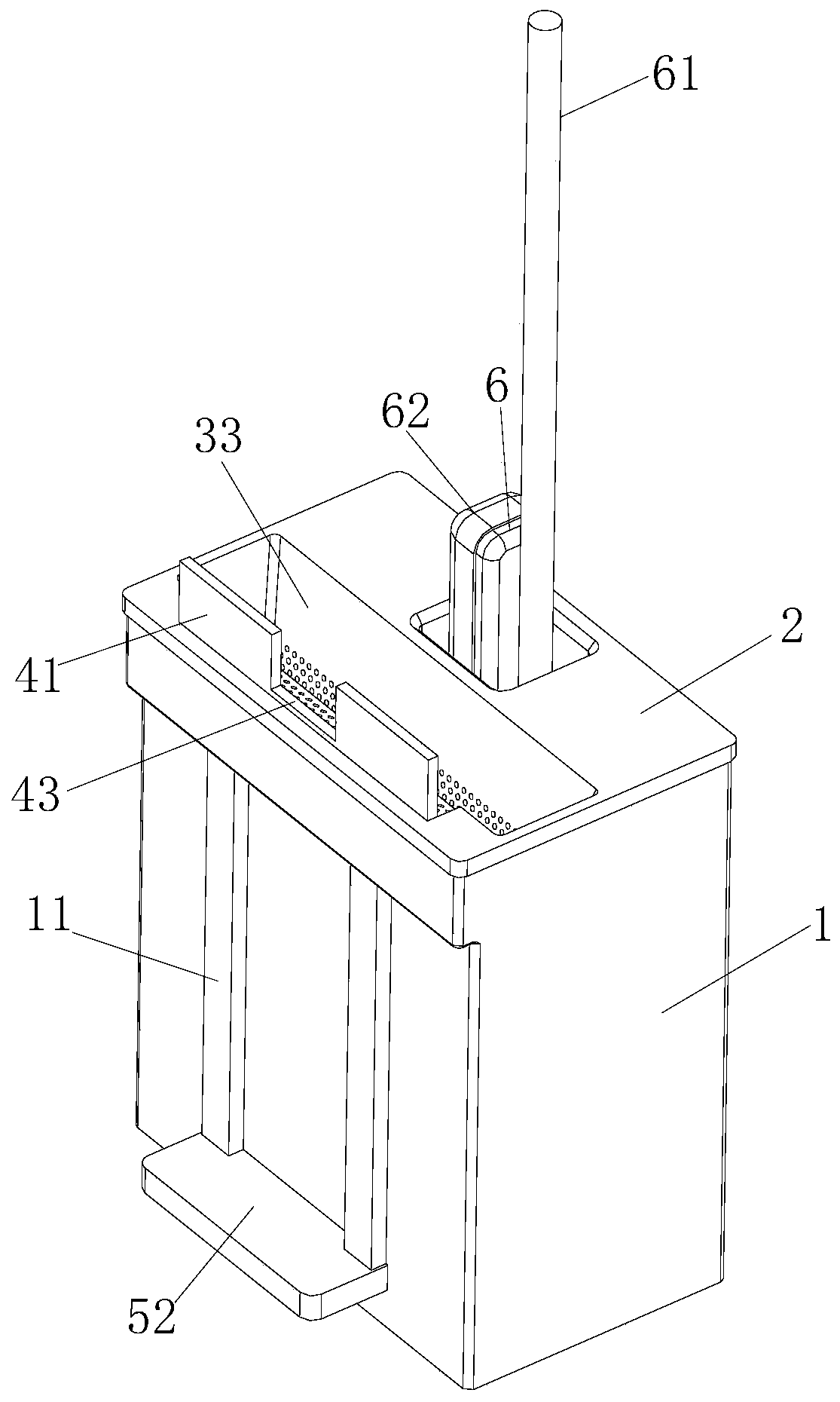

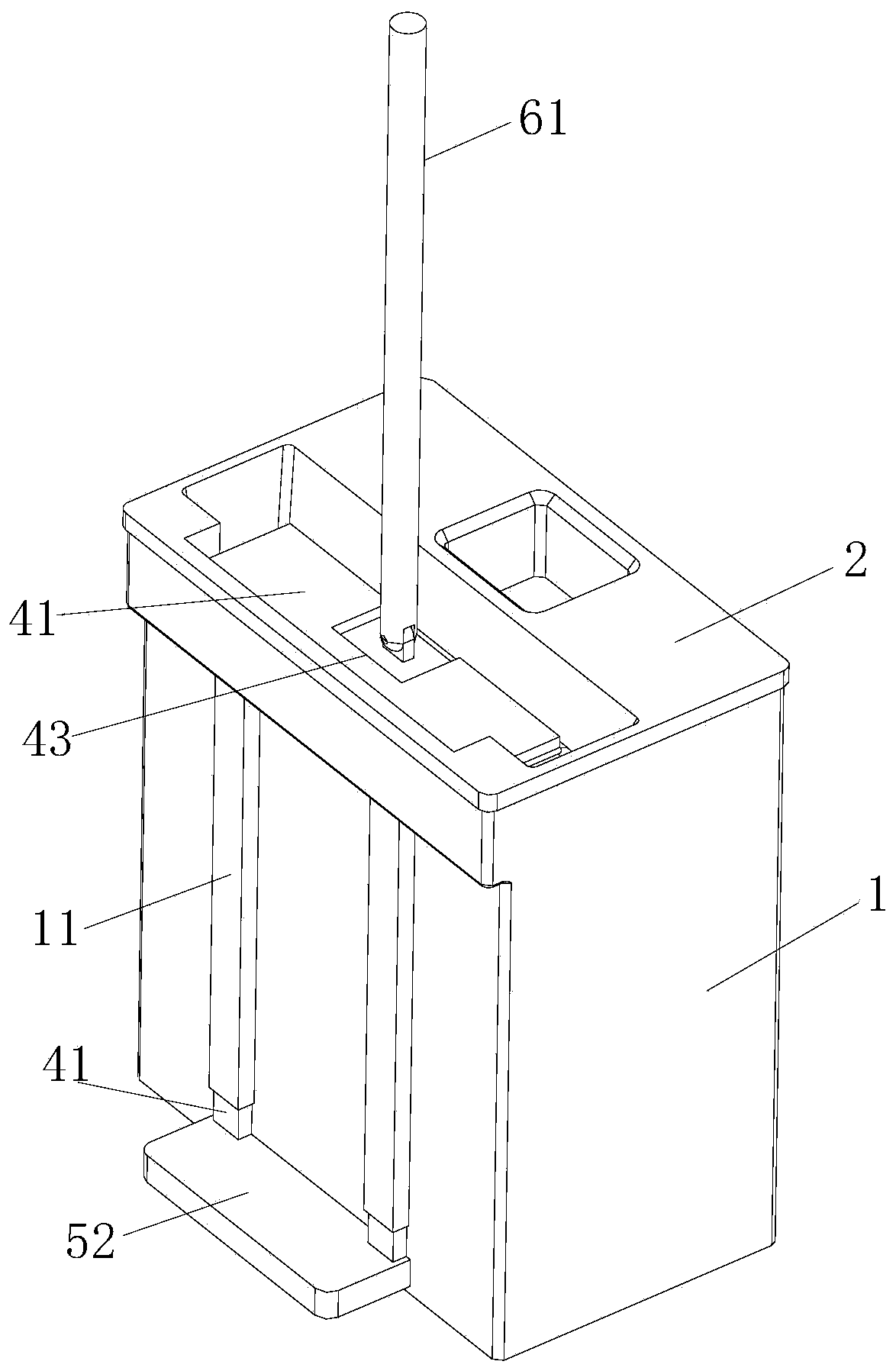

Mop bucket for flat-plate mop

PendingCN108714011AEasy to excavateAvoid affecting the drying effectCarpet cleanersFloor cleanersEngineeringWater diversion

The invention discloses a mop bucket for a flat-plate mop, belonging to the technical field of cleaning supplies. The mop bucket comprises a water squeezing bucket and a cleaning bucket, wherein the water squeezing bucket can be contained in the cleaning bucket and taken out; a water retaining cover is arranged on a wiper bucket; a wiper port is formed in the water retaining cover; a wiper strip and a popping-up piece opposite to the wiper strip are arranged at the wiper port; the wiper strip is fixed; an inclined water diversion slope is formed on the upper surface of the wiper strip; an upper drain outlet is formed in the bottom end of the water diversion slope; and the popping-up piece comprises a swing arm. The mop bucket disclosed by the invention comprises two separable buckets, theconvenience is improved, the wiper strip is integrally molded, the stability during water squeezing is ensured, the wiped water can be drained by the inclined wiper strip, the water is squeezed by enabling the swing arm to pop up the panel of the flat-plate mop, the fluctuation of the wiper strip can be alleviated, and the water squeezing effect is improved.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

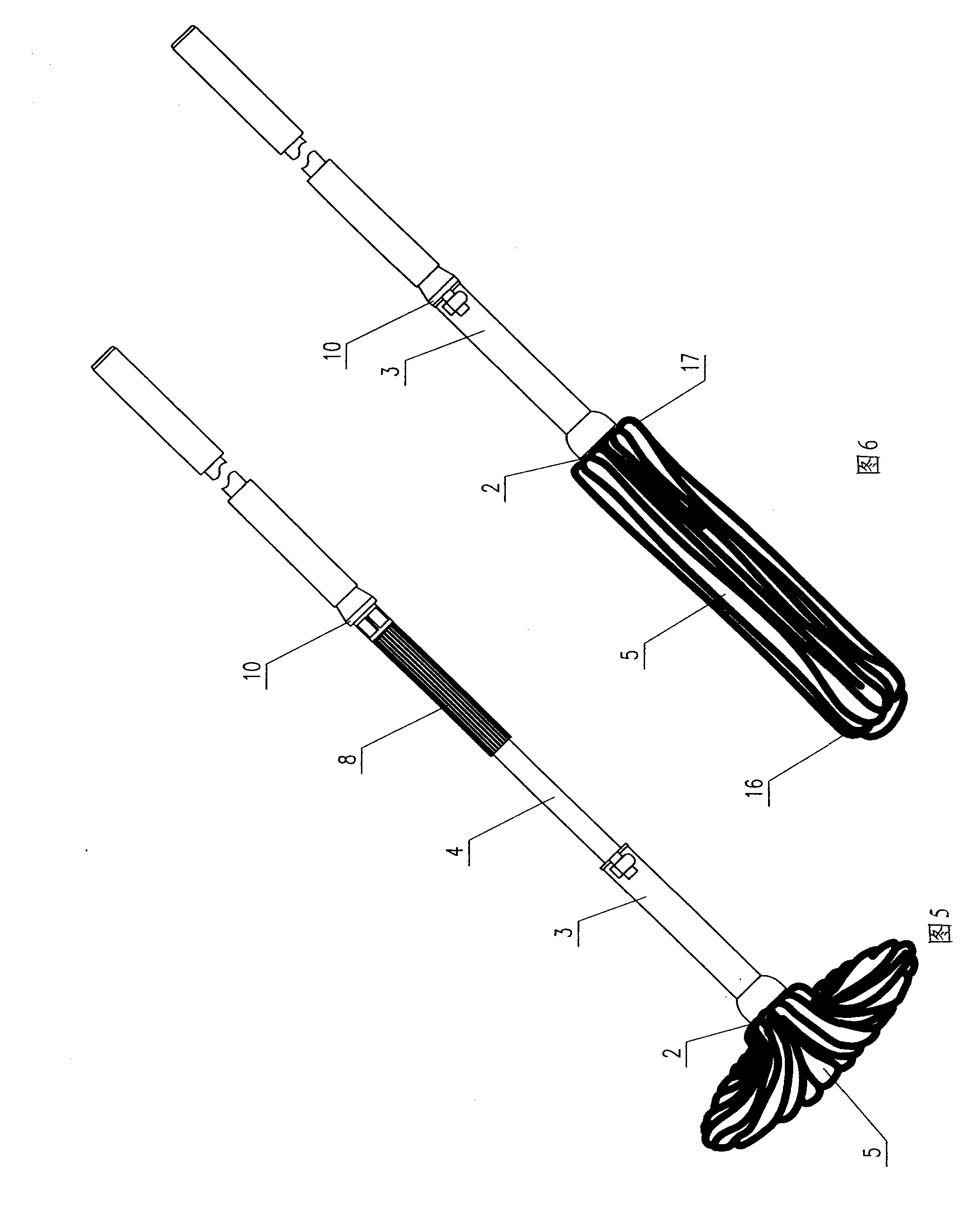

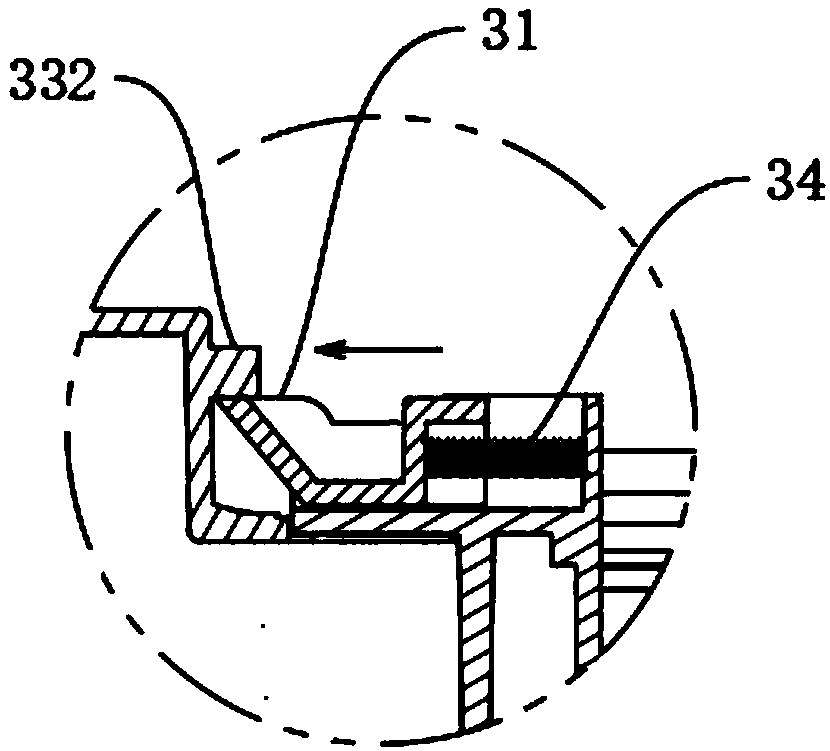

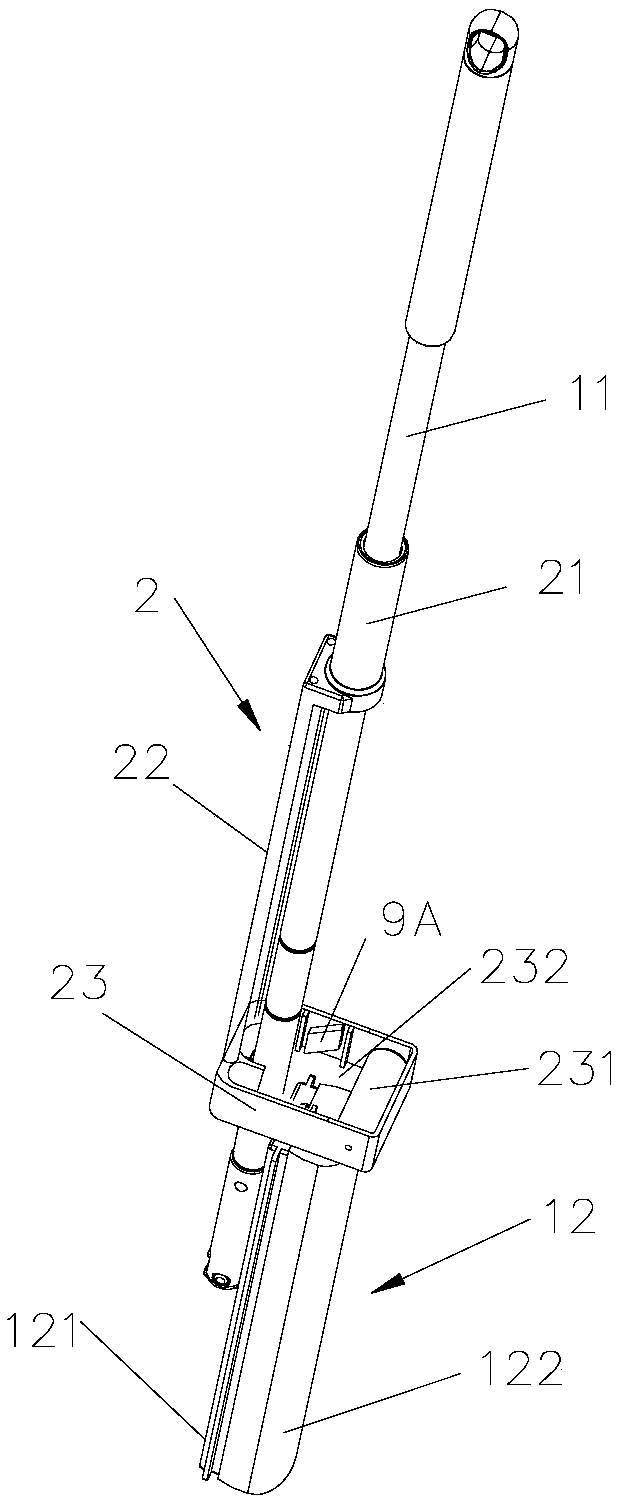

Wringing mop

InactiveCN101869460AOvercome the disadvantage of poor squeezing effectImprove water squeeze effectCarpet cleanersFloor cleanersEngineeringPiston

The invention relates to a wringing mop comprising a stick, a point-type fixing surface, a piston, a sliding sleeve, a ring-shaped fixing surface, a cylinder and a straight bag-shaped mop component, wherein the point-type fixing surface and the piston are fixedly connected to the front end of the stick; the sliding sleeve is sleeved on the stick in a way that the sliding sleeve is capable of axially moving on the stick; the ring-shaped fixing surface and the cylinder are sequentially and fixedly connected to the front end of the sliding sleeve, drain holes are formed on the cylinder, and the point-type fixing surface and the piston are capable of axially moving in the cylinder with the stroke thereof being started from the ring-shaped fixing surface; and the straight bag-shaped mop component is assembled from strings, the bottom end of the straight bag-shaped mop component is connected with the point-type fixing surface, and the opening end thereof is connected with the ring-shaped fixing surface. When the water is wrung from the mop, the mop component is located in the cylinder, and the stick is not located in the mop component, thus effectively improving the wringing efficiency.

Owner:陈光中

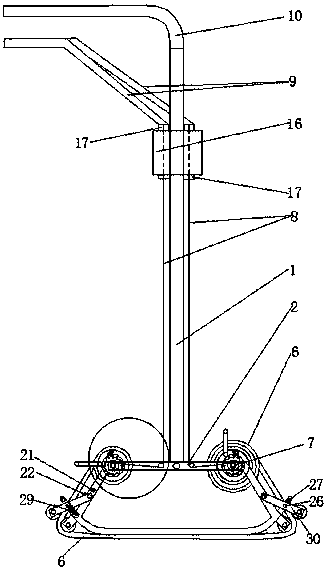

Self-squeezing mop

InactiveCN106974600ASimple structureSqueeze water smoothlyCarpet cleanersFloor cleanersClutchEngineering

The invention provides a self-squeezing mop, belonging to the technical field of cleaning supplies, for solving the technical problems in the prior art. The self-squeezing mop comprises a mop rod and a mop board on which mop cloth can be arranged, wherein the lower end of the mop rod is movably connected with the mop board, a water-squeezing sleeve capable of axially moving relative to the mop rod is arranged on the mop rod, a clutch type maintaining mechanism capable of enabling the mop board to be always static relative to the mop rod when the water-squeezing sleeve squeezes water of the mop cloth on the mop board is arranged between the mop rod and the mop board, and a control mechanism capable of enabling the water-squeezing sleeve to move axially relative to the mop rod so that the clutch type maintaining mechanism enables the mop board to be static relative to the mop rod or releases the state of the mop board relative to the mop rod is arranged between the water-squeezing sleeve and the mop rod. The self-squeezing mop realizes smooth water squeezing, the water-squeezing sleeve can rotate circumferentially, and thus the cleaning effect is good.

Owner:JIAXING J CREATION INTELLIGENT ELECTRIC APPLIANCE CO LTD

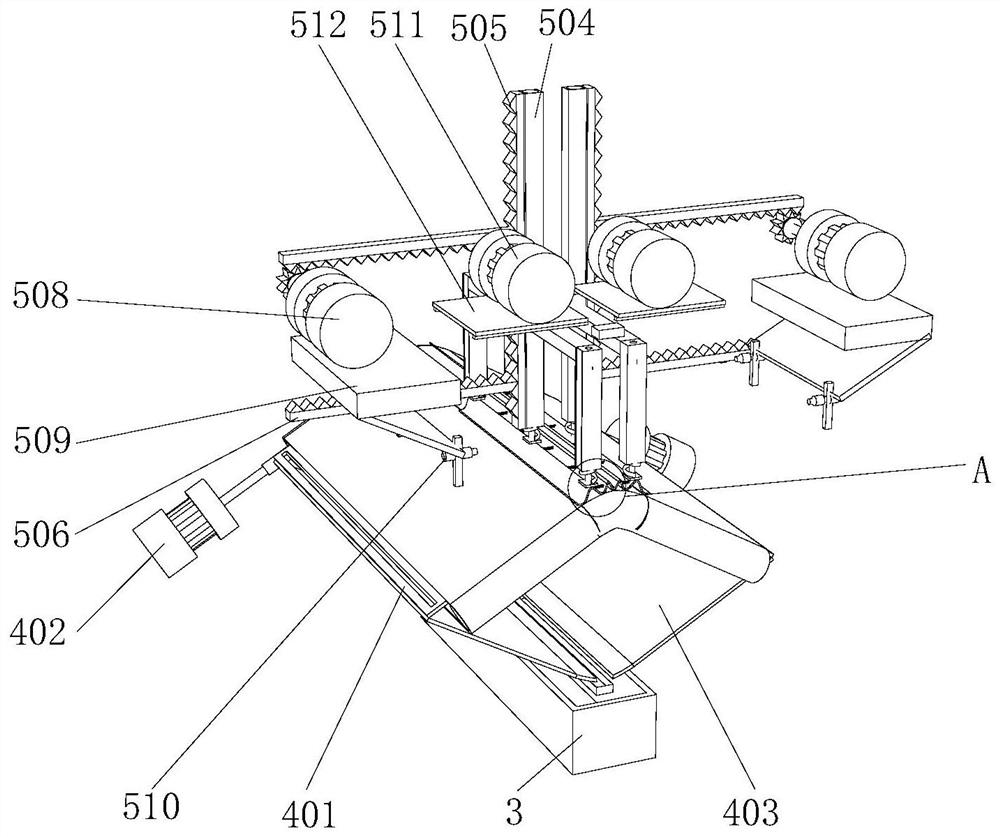

Five-roller type samming machine

InactiveCN101440414AImprove water squeeze effectEnergy savingLeather manufacturingRocker armEnergy analysis

The invention discloses a five-roll wringing-flattening machine, which comprises a rack oil cylinder, a linkage mechanism connected with the rack oil cylinder, a feed-roll support arranged on the linkage mechanism, two felt-roll oil cylinders, felt-roll rocker arms connected with the felt-roll oil cylinders, a knife-roll oil cylinder, as well as a knife-roll rocker arm connected with the knife-roll oil cylinders, wherein a big rubber roll and a small rubber roll are arranged on the feed-roll support; an upper felt roll and a lower felt roll are arranged on the two felt-roll rocker arms respectively; and a knife roll is arranged on the knife-roll rocker arm. The machine can wring water twice and extend twice, and has the advantages of improving wringing effects and leather yield, saving a large amount of energy and greatly improving work efficiency.

Owner:湖州二轻机械有限公司

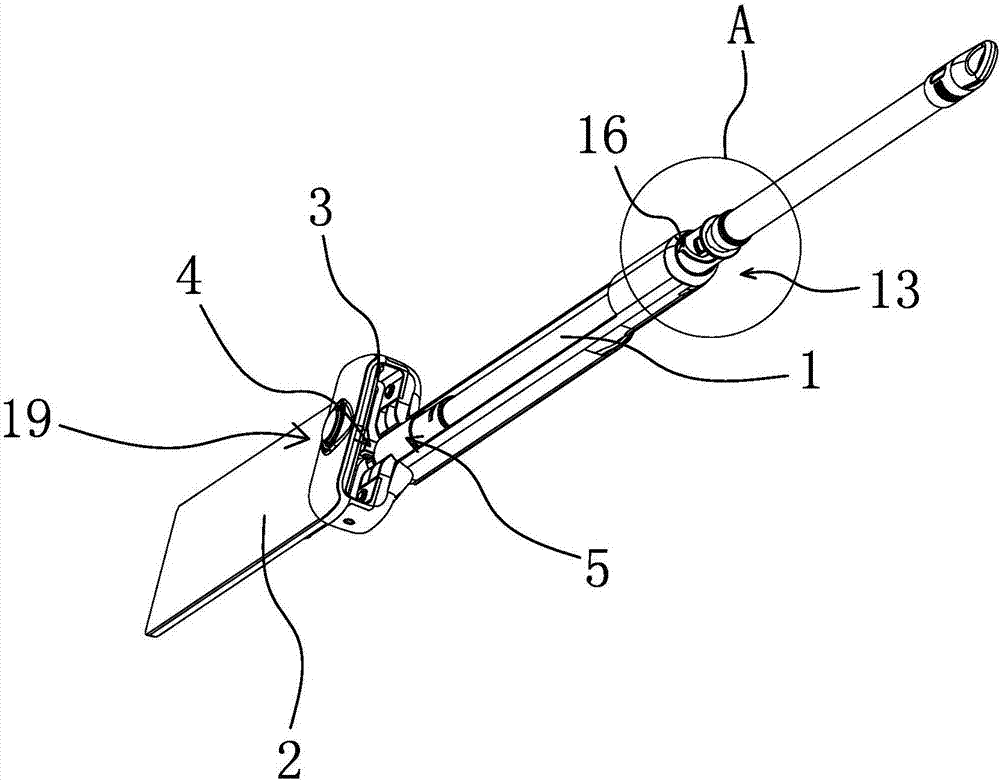

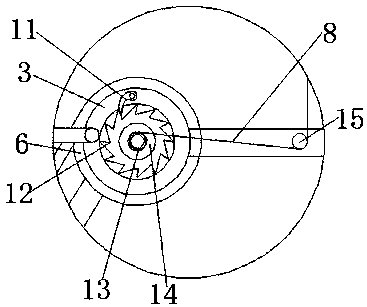

Scroll mop convenient to use

ActiveCN107890328AGuaranteed squeeze functionRealize water squeeze operationCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a scroll mop convenient to use. The scroll mop comprises a first bracket, wherein a second bracket is movably connected to the bottom end of the first bracket, a lint use roller and a lint storage roller are respectively arranged at the left and right ends of the upper part of the second bracket, rollers are connected to the left and right ends of the lower part of the second bracket, the lint storage roller is wound with multiple cycles of floor mopping lint, the floor mopping lint winds out of the lint storage roller, passes through the rollers and the bottom of the second bracket and then winds the lint use roller; cloth exchanging mechanisms are arranged in the lint use roller and the lint storage roller and are connected with a lifting handle through steel wires; and a first water extruding device and a second water extruding device are respectively arranged at the left and right parts of the second bracket. The scroll mop has the characteristics that the adsorption capacity is very strong, and wiping cloth is convenient to clean.

Owner:GUIZHOU UNIV

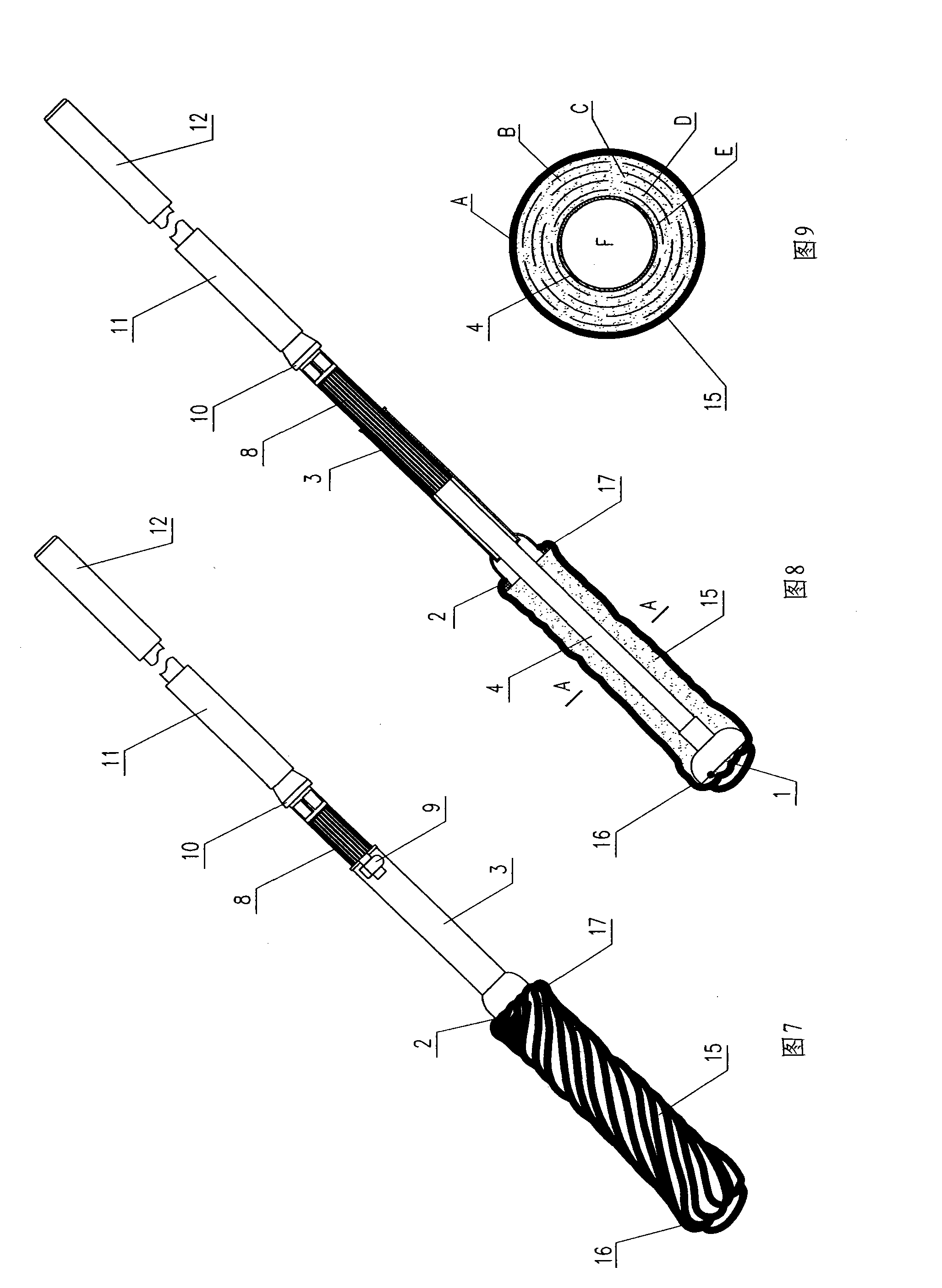

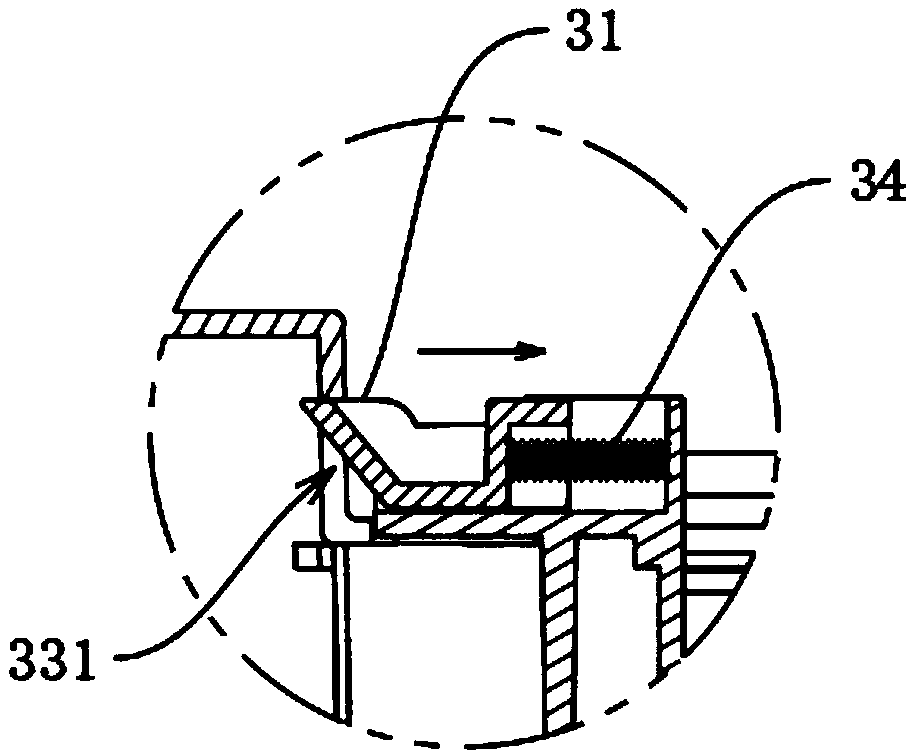

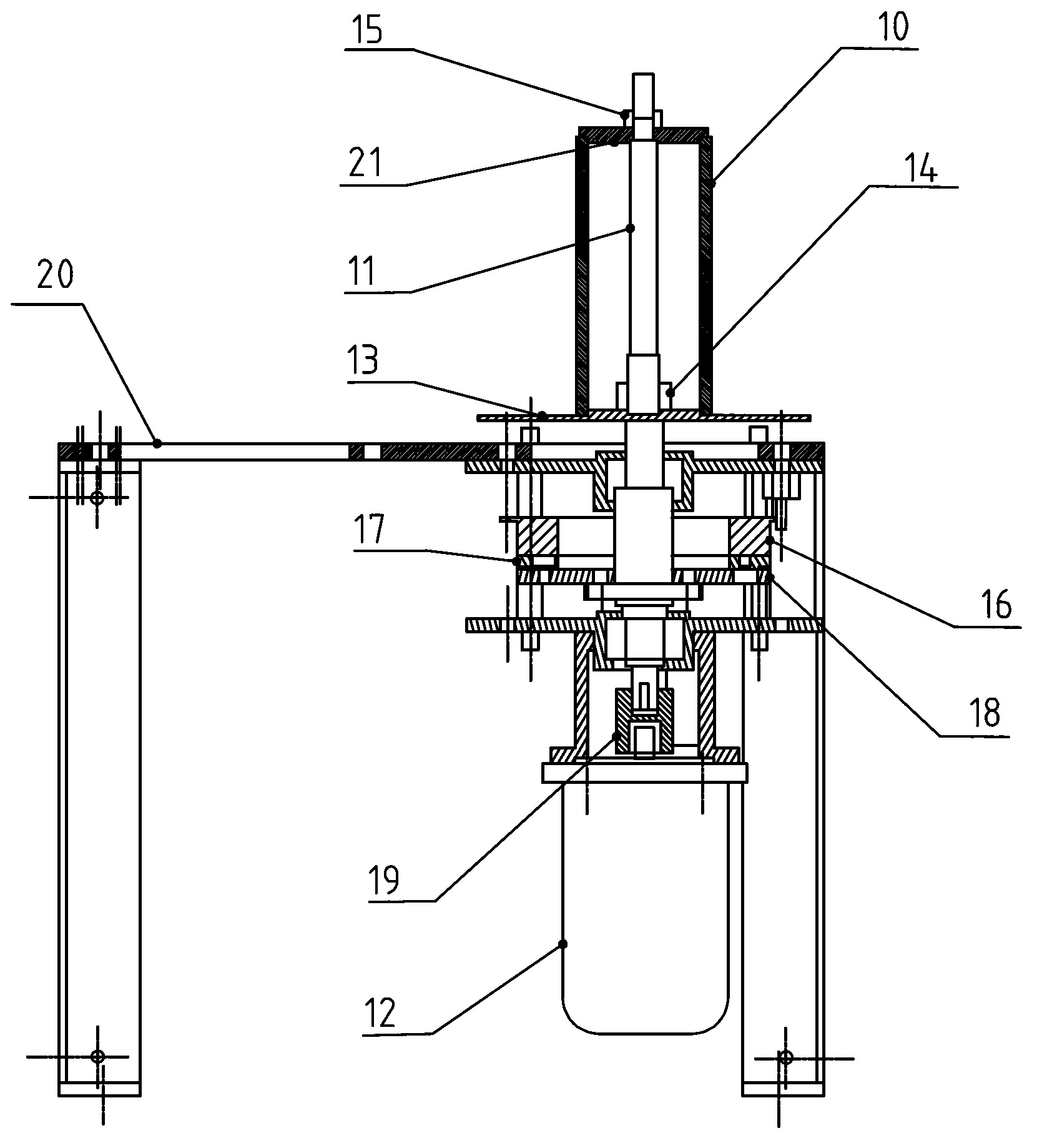

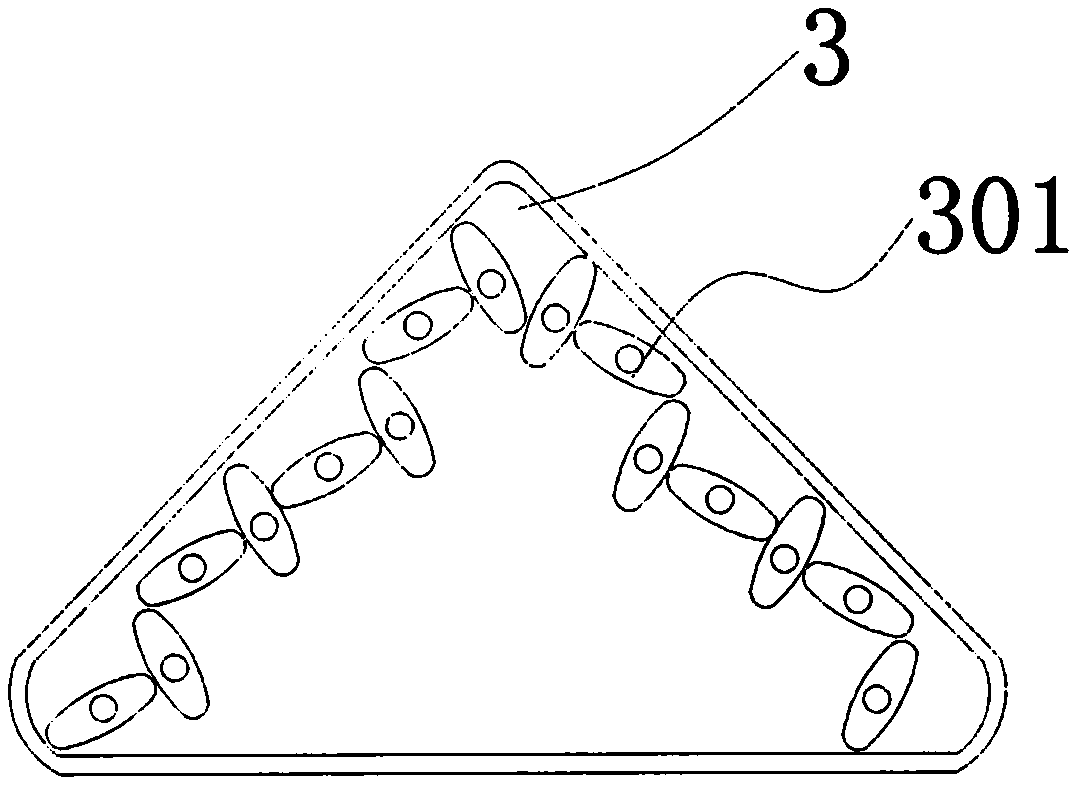

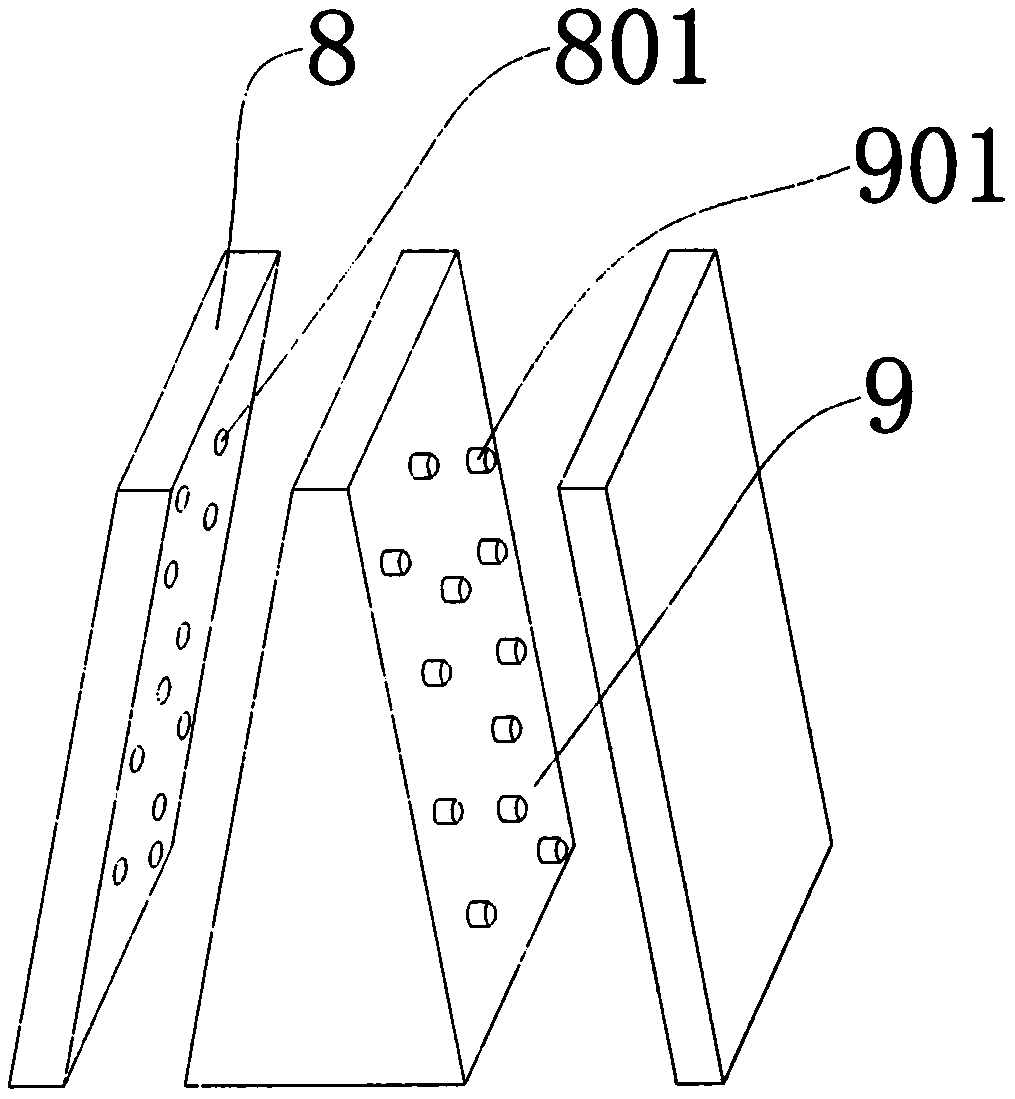

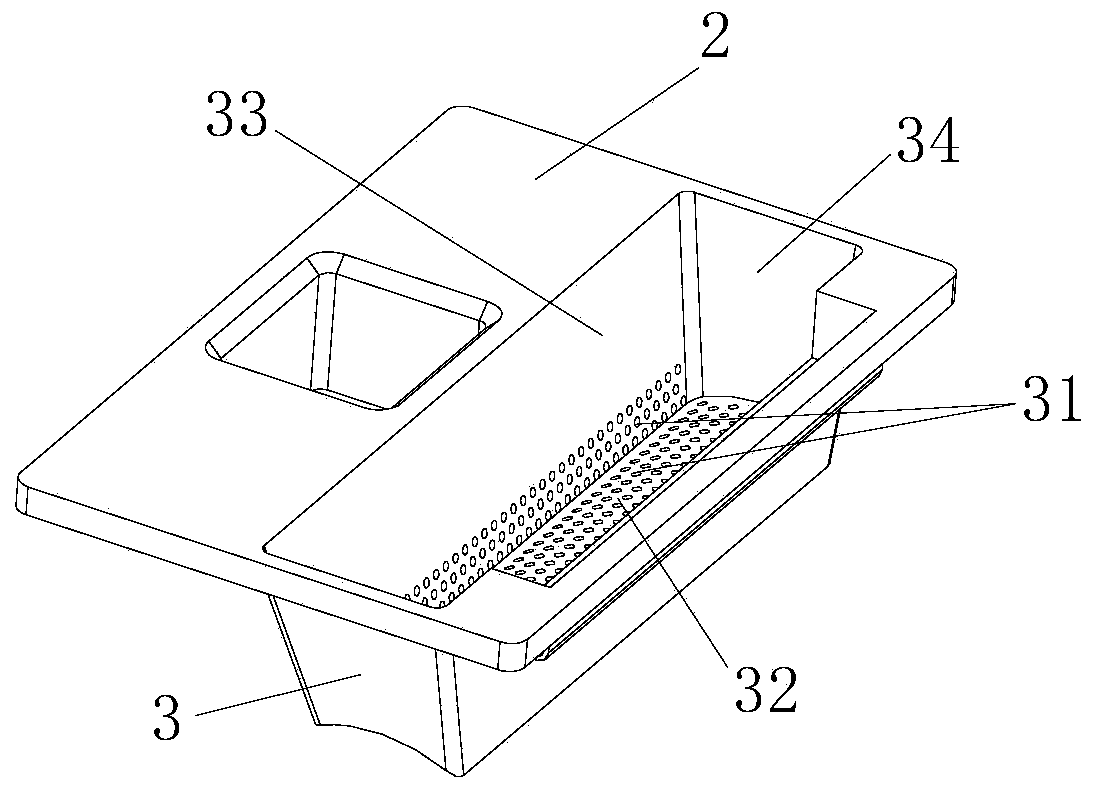

Water squeezing module used for horizontal plate mop, and horizontal plate mop bucket provided with water squeezing module

PendingCN108814486AImprove water squeeze effectEasy to useCarpet cleanersFloor cleanersMarine engineering

The invention discloses a water squeezing module used for a horizontal plate mop, and a horizontal plate mop bucket provided with the water squeezing module, belonging to the technical field of cleaning supplies. For the water squeezing module used for the horizontal plate mop, the water squeezing module is provided with a quick disassembly mechanism (3), the water squeezing module is detachably mounted to the horizontal plate mop bucket (1) through the quick disassembly mechanism, the water squeezing module comprises a water squeezing hole (2) allowing the horizontal plate mop to pass through, and a water squeezing part (22) positioned on one side of a wiping object of the horizontal plate mop and being capable of forming squeezing for the wiping object is arranged in the water squeezinghole. The water squeezing module convenient to detach is arranged, a collodion mop water squeezing module or cloth mop water squeezing module can be mounted according to the demands, so that the watersqueezing module can be suitable for horizontal plate mops of different types, the use is simple and convenient, due to the modularization, the space needed for storage is reduced, in addition, afterbeing damaged, the water squeezing structure can be independently replaced, and thus the cost is saved.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

Double-sided flat mop

PendingCN110025272APrevent disengagementAvoid offsetCarpet cleanersFloor cleanersMechanical engineeringEngineering

Owner:刘凯

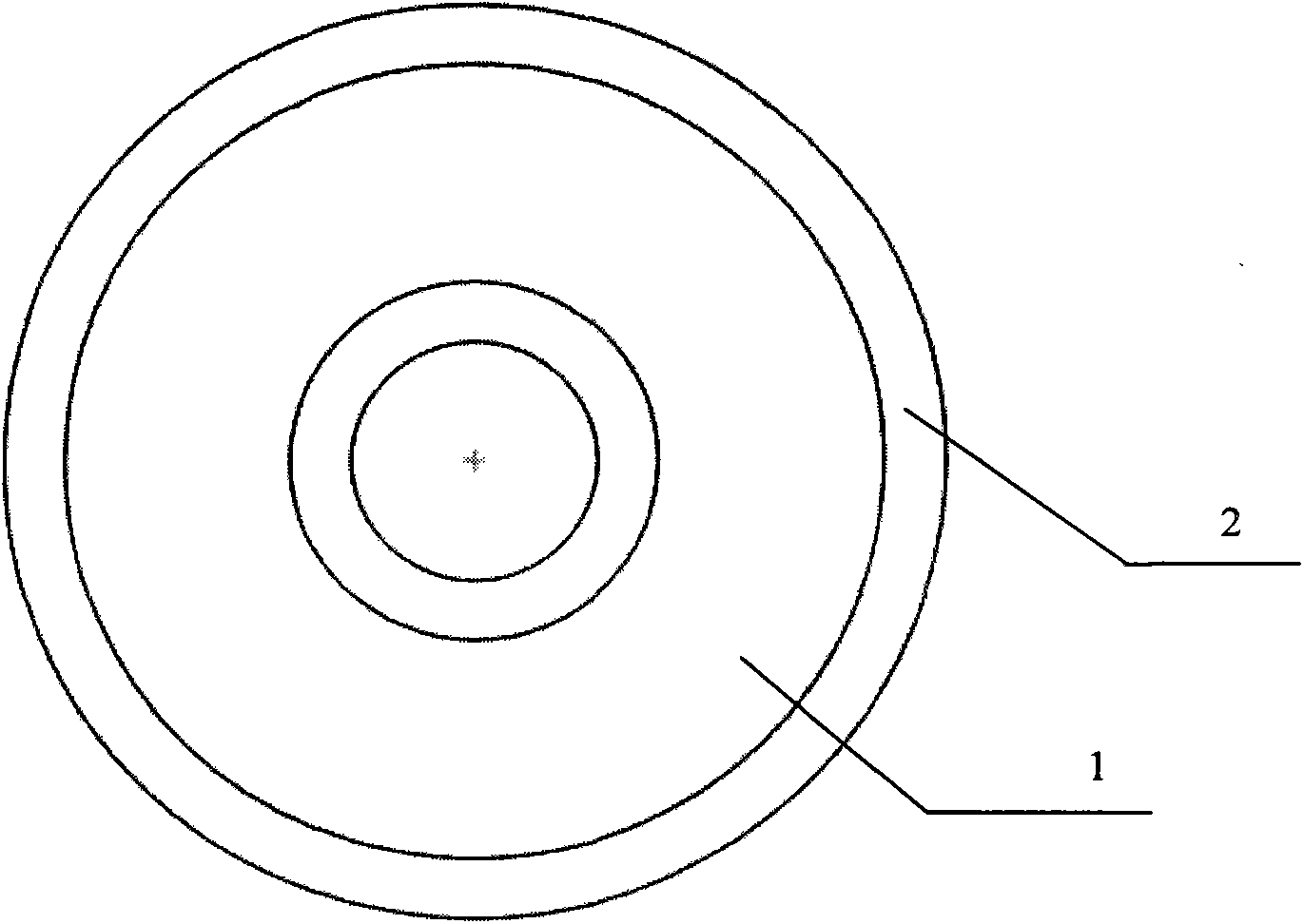

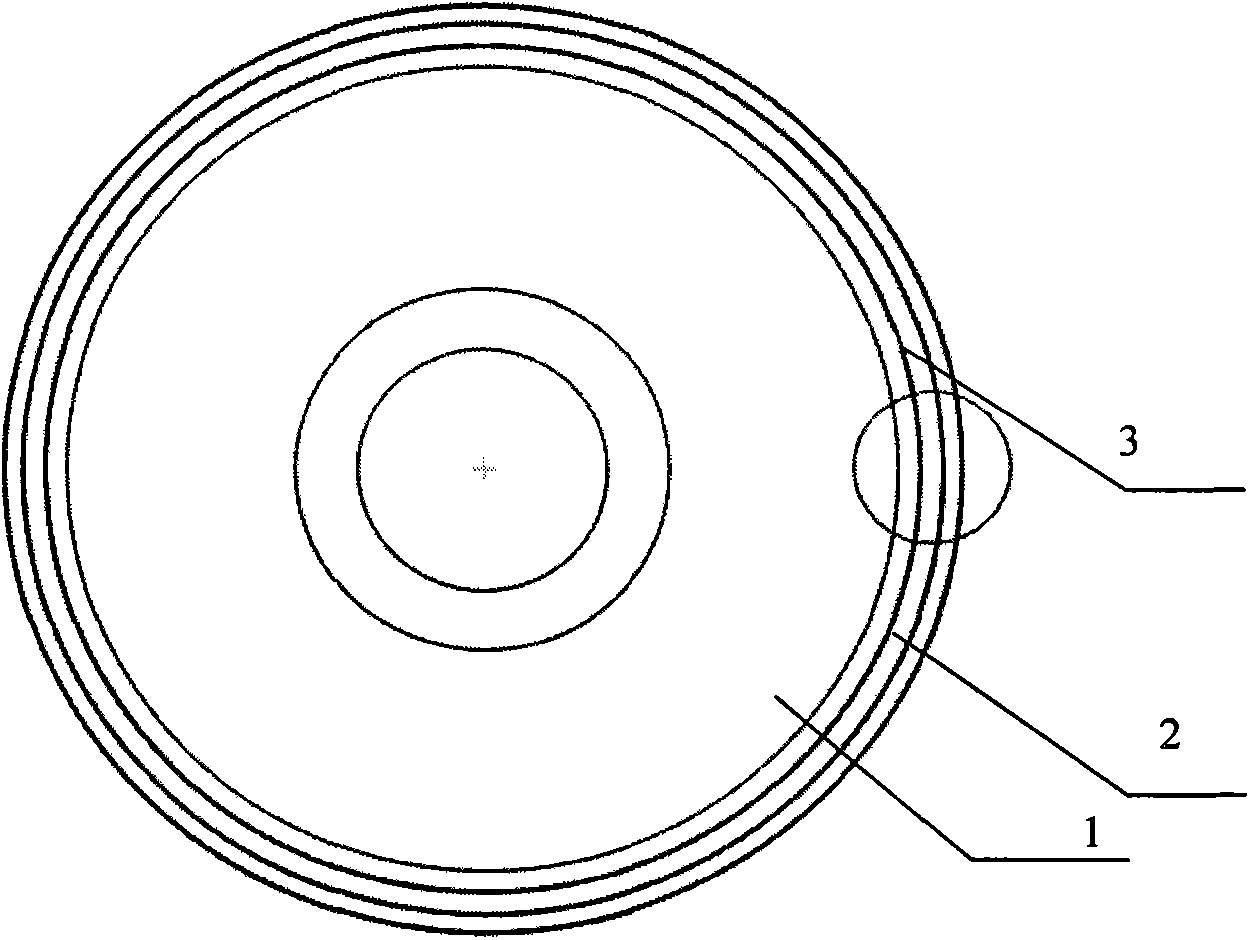

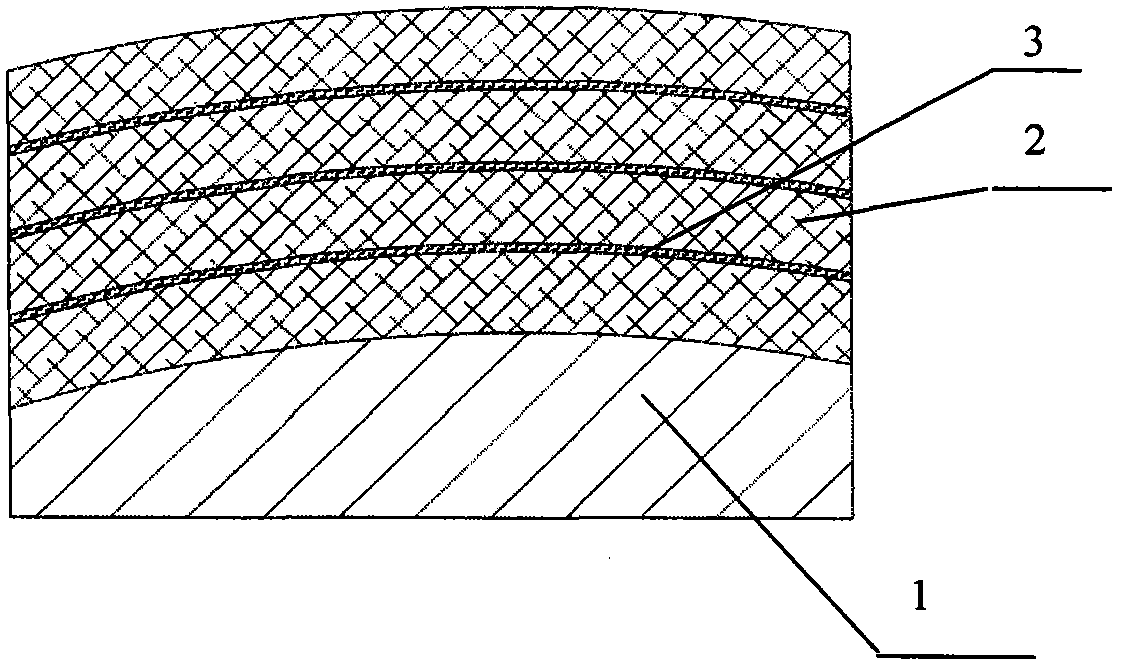

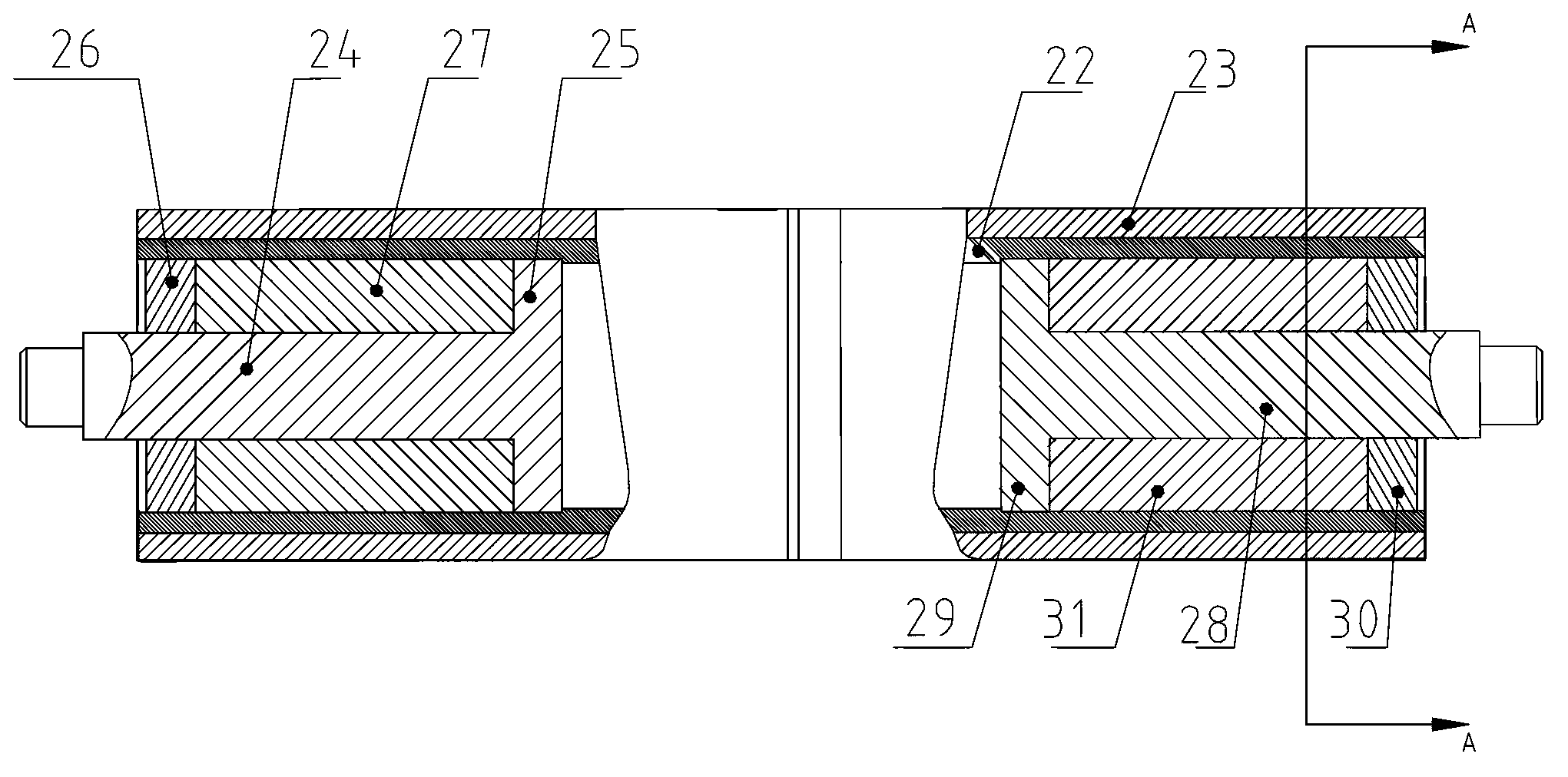

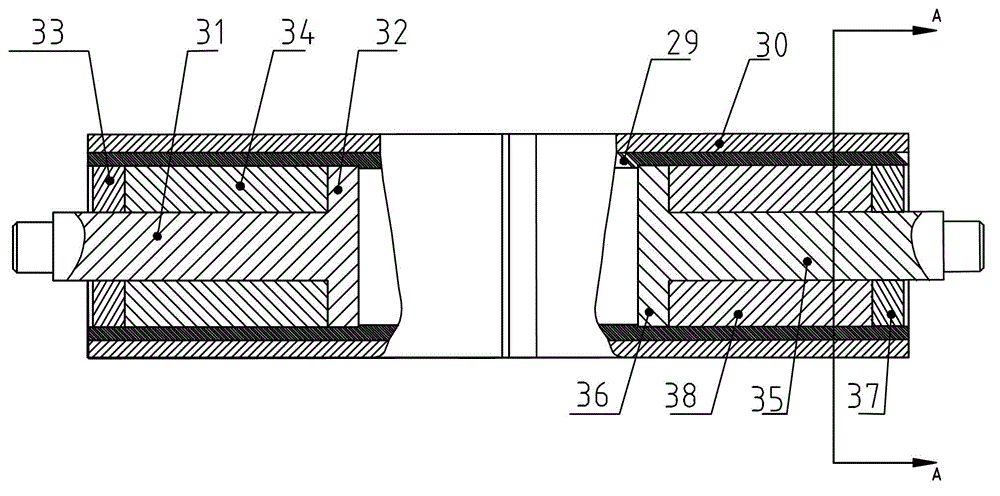

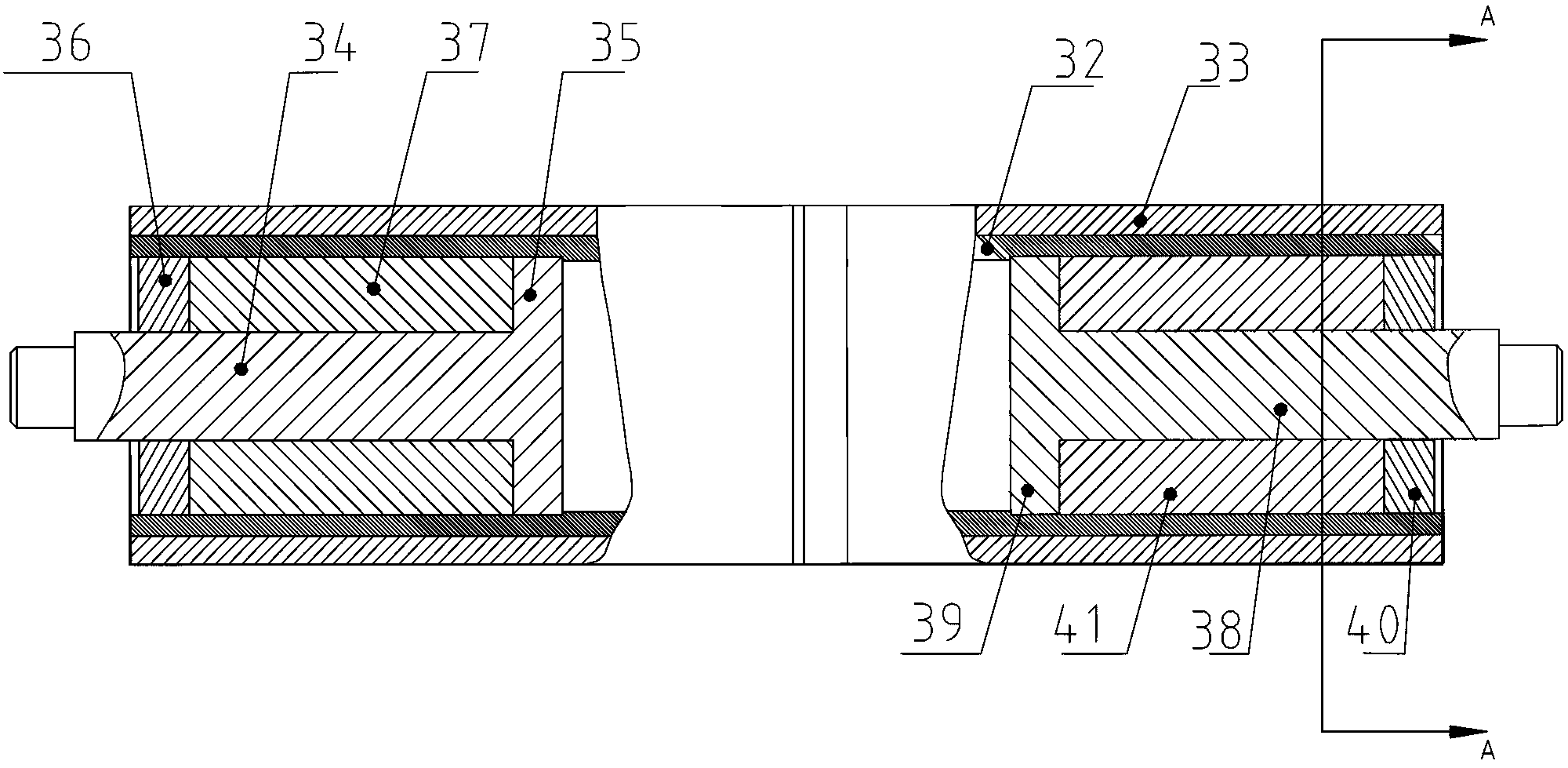

High linear pressure water-squeezing big roller and manufacturing method thereof

InactiveCN103590209AReduce the probability of wire breakageImprove water squeeze effectLiquid/gas/vapor removal by squeezing rollersAbrasive blastingVulcanization

The invention belongs to a high linear pressure big roller and a manufacturing method of the high linear pressure big roller. The high linear pressure big roller comprises a central spindle and a rubber layer covering the exterior of the central spindle. Six nylon reinforcement layers are added into the rubber layer to enhance the displacement prevention capability of the rubber layer and improve the tear-resistant performance of the rubber layer. The central spindle is an iron core, and the nylon reinforcement layers are made of nylon 66 cord fabrics. The manufacturing process comprises conducting abrasive blasting, cleaning, adhesive brushing, drying and mucilage brushing on the central spindle in sequence; after mucilage is dry, cord fabric straps and the rubber layer are wound around the central spindle through a winding type forming machine for forming, and then the central spindle is sequentially subjected to iron wire winding, vulcanization, iron wire dismantling, turning, inspection and warehousing to obtain the high linear pressure big roller. The actual service life of the rubber covered roller is up to six months according to manufacturers.

Owner:北京华腾橡塑乳胶制品有限公司

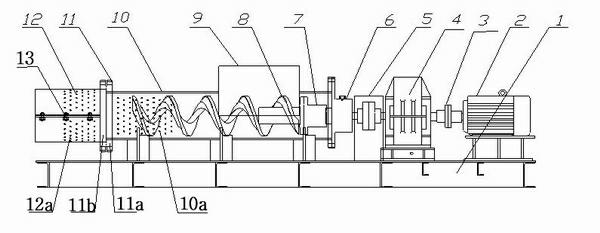

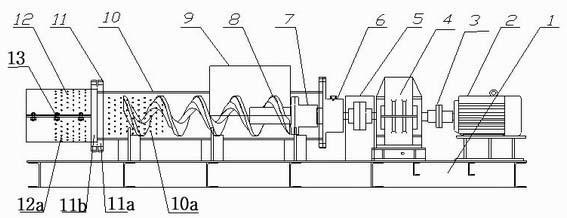

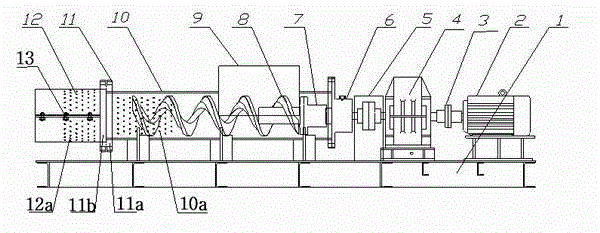

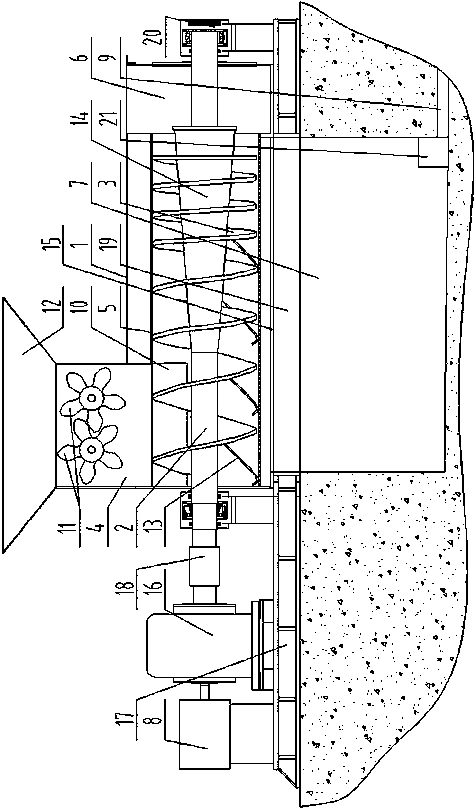

Device for wringing papermaking waste residues

A device for wringing papermaking waste residues belongs to the technical field of devices for wringing the papermaking waste residues, and comprises a base, wherein an electric motor, a transmission gear which is connected with the electric motor through a first coupling and a bearing base which is connected with the transmission gear through a second coupling are sequentially arranged on the base through a support, the other end of the bearing base is provided and connected with a shaftless spiral body in a matching way through a third coupling, a feed bin is arranged above one end of the shaftless spiral body in a matching way, which is close to the bearing base, a shaftless spiral body shell is arranged outside the shaftless spiral body, and is connected with a material seal shell through a flange, and drain holes are respectively arranged on the shaftless spiral body shell and the material seal shell in a matching way. The device adopts the technology, has a simple structure, thematerial extruding strength is increased, and the wringing effect is improved; and one end of the shaftless spiral body shell is connected with the material seal shell, the material traveling distance and the material forward resistance are increased, the extruding force on the material is improved, the wringing effect is enhanced, and the continuity and stability of the wringing process are protected.

Owner:仁精科技(昆山)有限公司

Wringing mop bucket for flat mop

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

Plain-weave plastic braiding machine

The invention discloses a plain-weave plastic braiding machine which is characterized by comprising a shedding mechanism, a water jet weft insertion mechanism, a weft beating-up mechanism, a let-off mechanism, a take-up mechanism and an auxiliary mechanism; the take-up mechanism comprises a wringing roller, the wringing roller comprises a rubber roller inner barrel and a coating layer arranged on the outer barrel wall of the rubber roller inner barrel, a spindle nose is arranged at the two ends of the roller tube inner barrel respectively, each spindle nose is fixedly arranged on the inner barrel wall of the rubber roller inner barrel through a spindle nose inner support disc and a spindle nose outer support disc, a plurality of radial reinforcing ribs are arranged between the spindle nose inner support disc and the spindle nose outer support disc, one end of each reinforcing rib is fixedly arranged on one spindle nose, the other end of each reinforcing rib is fixedly arranged on the inner barrel wall of the rubber roller inner barrel, in the length range of being 350-450 mm from the each end part of the coating layer, the diameter of the coating layer is reduced gradually from the middle part to the end parts, and the diameter of the end part is smaller than the diameter of the middle part by 1-1.5 mm. The plain-weave plastic braiding machine is suitable for weaving wide and heavy fabric and is also beneficial to further improving and guaranteeing the quality of plastic fabric.

Owner:青岛东佳机械制造有限公司

A sauerkraut squeezing device

ActiveCN110250550BSqueeze water with high efficiencyIncrease contact areaFood shapingEngineeringMechanical engineering

The invention provides a sauerkraut squeezing device, which comprises an outer casing, a shaking mechanism and a conveying mechanism. At the opening, an extruding mechanism is arranged below the conveying mechanism. The extruding mechanism includes an extruding inclined plate, an extruding middle plate and a limiting plate. Both the extruding inclined plate and the limiting plate are arranged on one side of the extruding middle plate. The extruding inclined plate and the limiting plate are not located on the same side. The extrusion mechanism and the transmission mechanism provided can squeeze the sauerkraut with high efficiency, and in the process of squeezing the water, the inwardly inclined extrusion slant plate cooperates with the extrusion middle plate to increase the distance between the sauerkraut and the extrusion mechanism. At the same time, by cooperating with the setting of the water squeezing hole and the water squeezing convex plate, the squeezing force in the process of squeezing sauerkraut can be increased, and the water squeezing effect can be further increased.

Owner:甘肃圆根香生物科技股份有限公司

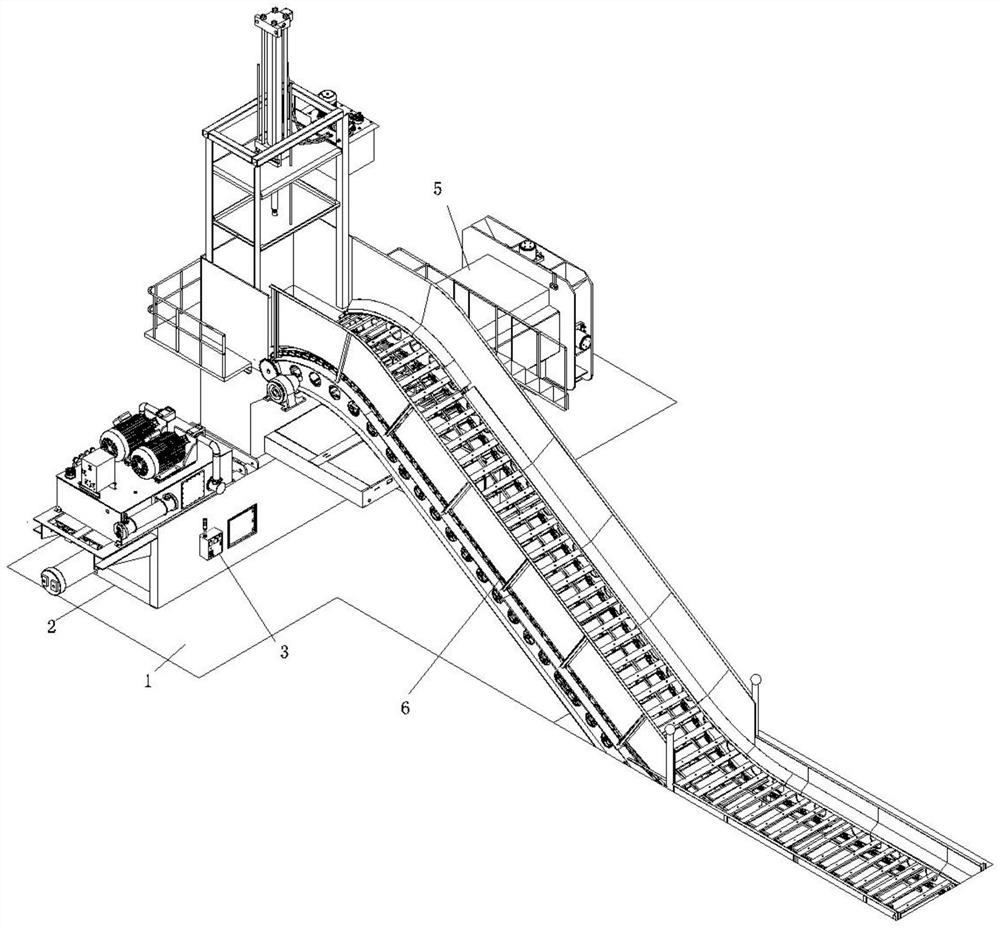

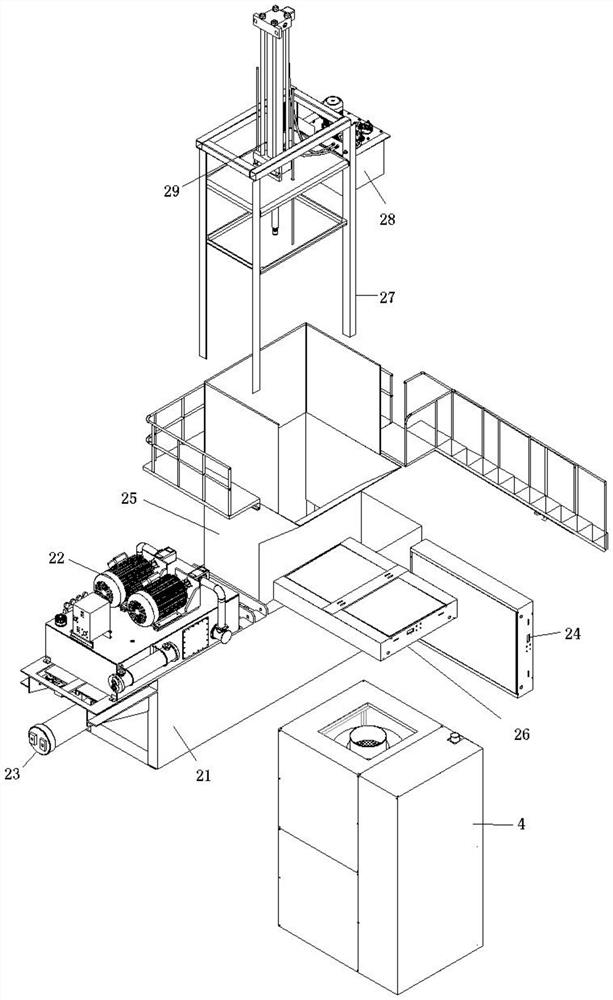

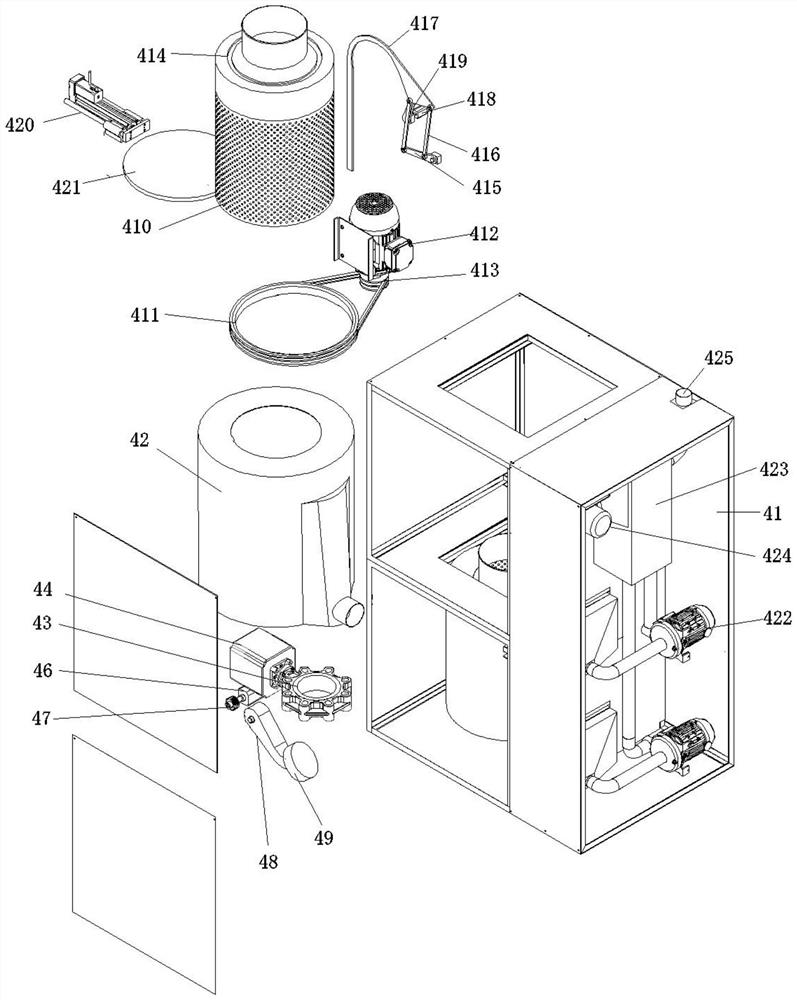

Compaction equipment in plastic film cleaning and recycling production line

The invention relates to the technical field of plastic film recycling, and discloses a compacting device in a plastic film cleaning and recycling production line, which comprises a base, a water squeezing mechanism, a controller, a smashing mechanism and a conveying belt, the water squeezing mechanism is arranged on the left side of the top end of the base in the front-back direction. The controller is mounted on the outer side of the water squeezing mechanism; the smashing mechanism is arranged at the top end of the base in the front-back direction and located on the rear side of the water squeezing mechanism. The conveying belt is arranged on the right side of the top end of the base. According to the compaction equipment in the plastic film cleaning and recycling production line, the water squeezing effect on plastic film particles and the scattering effect after water squeezing can be improved, the dehydration performance of the cleaned plastic film particles is improved, and the subsequent drying operation efficiency is indirectly improved; and fine plastic film particles in waste water discharged after extrusion and dehydration can be recycled, pollution caused by the discharged waste water is avoided, the recycling effect of the plastic film is improved, and the device is more environmentally friendly.

Owner:郭懒懒

Squeezing device for papermaking

InactiveCN112211026AImprove water squeeze effectImprove water absorptionPress sectionWater savingPapermaking

The invention provides a squeezing device for papermaking, and relates to the technical field of papermaking. The squeezing device for papermaking comprises a shell, a driving motor, a shaft, a hose,a first water squeezing mechanism and second water squeezing mechanisms, and the first water squeezing mechanism is arranged at the bottom end of the shell. Water in a water squeezing device is discharged through the first water squeezing mechanism, the top end of the first water squeezing mechanism is fixedly connected with the top end in the shell, and the shaft penetrates through the central axis of the first water squeezing mechanism and is fixedly connected with the first water squeezing mechanism. A driving motor is arranged on the left side of the first water squeezing mechanism, the output end of the driving motor is fixedly connected with the shaft, the hose is fixedly connected to the bottom end of the right side of the first water saving mechanism, and the second water squeezingmechanisms are arranged on the left side and the right side of the first water saving mechanism and movably connected with the first water squeezing mechanism. The squeezing device solves the problemthat the squeezing efficiency of a squeezing device is affected due to the fact that water can be thrown out and fall on squeezed paper blanks in the rolling process of a rolling shaft after the paper blanks are squeezed through the rolling shaft.

Owner:俞大陆

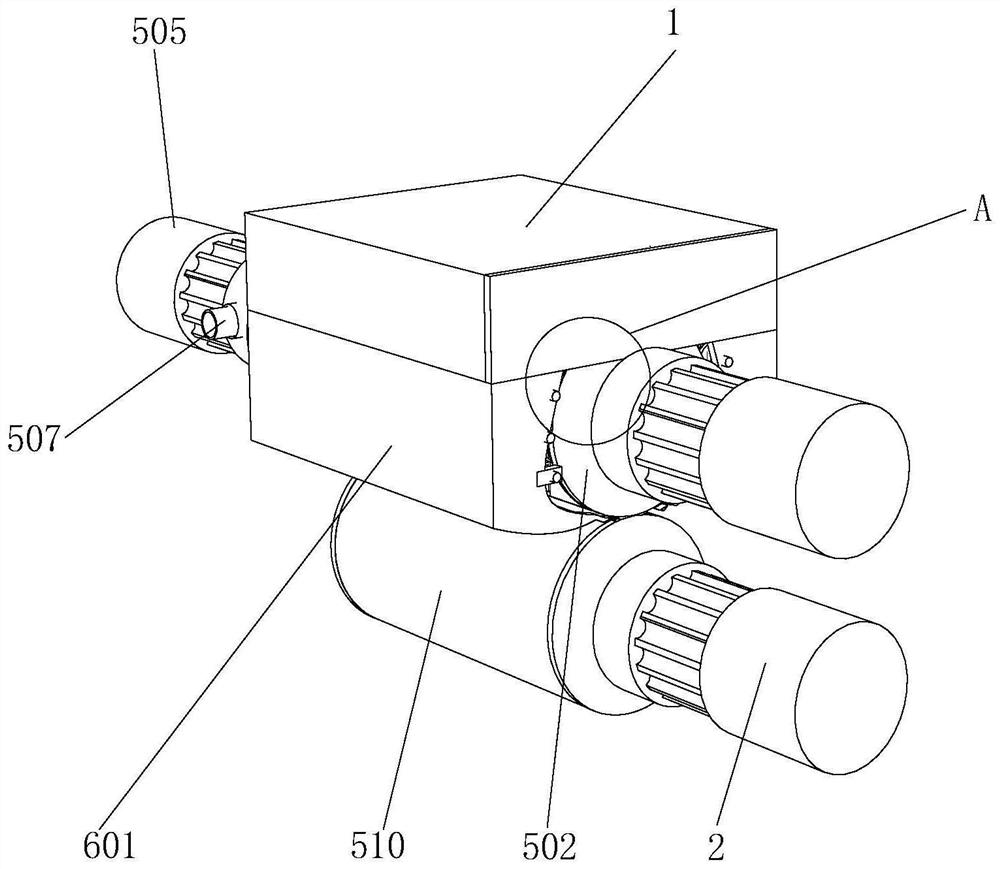

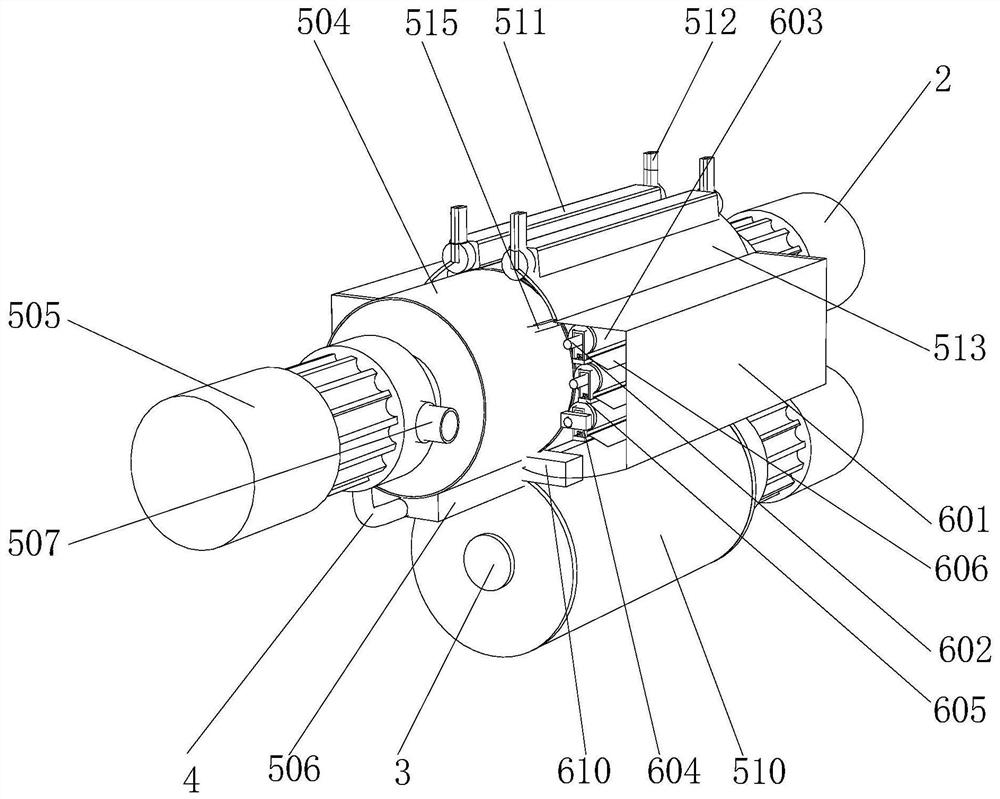

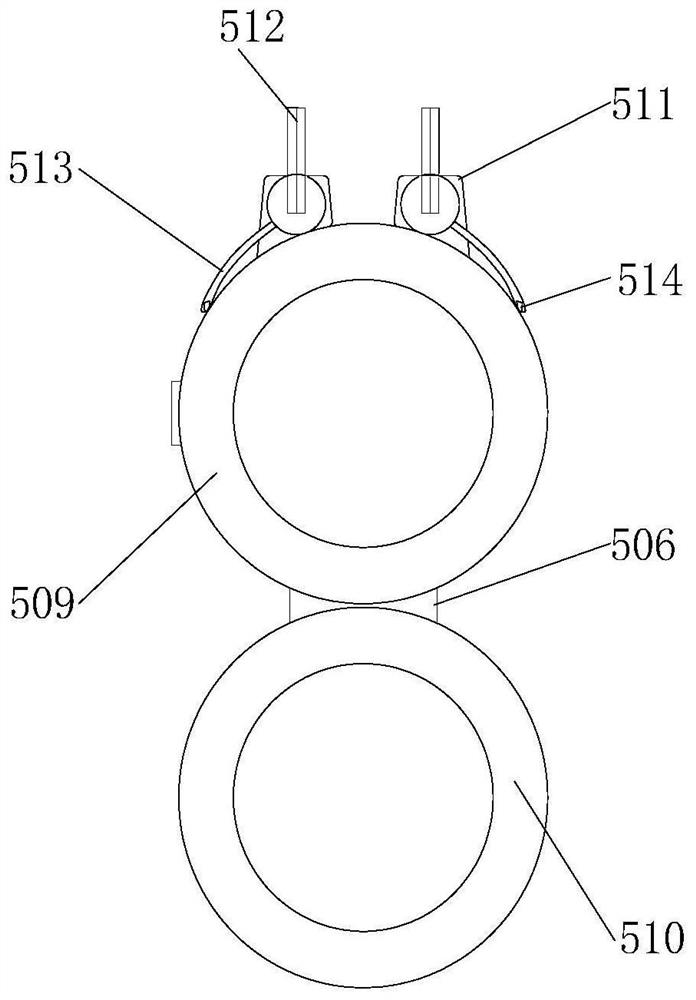

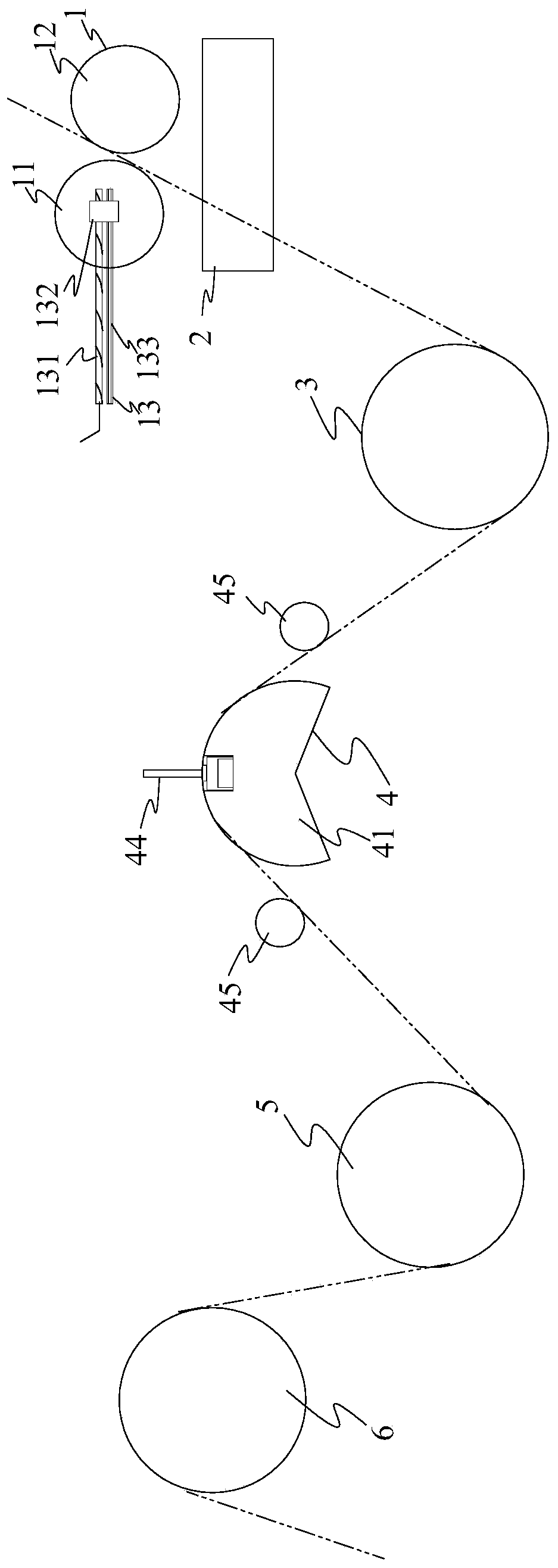

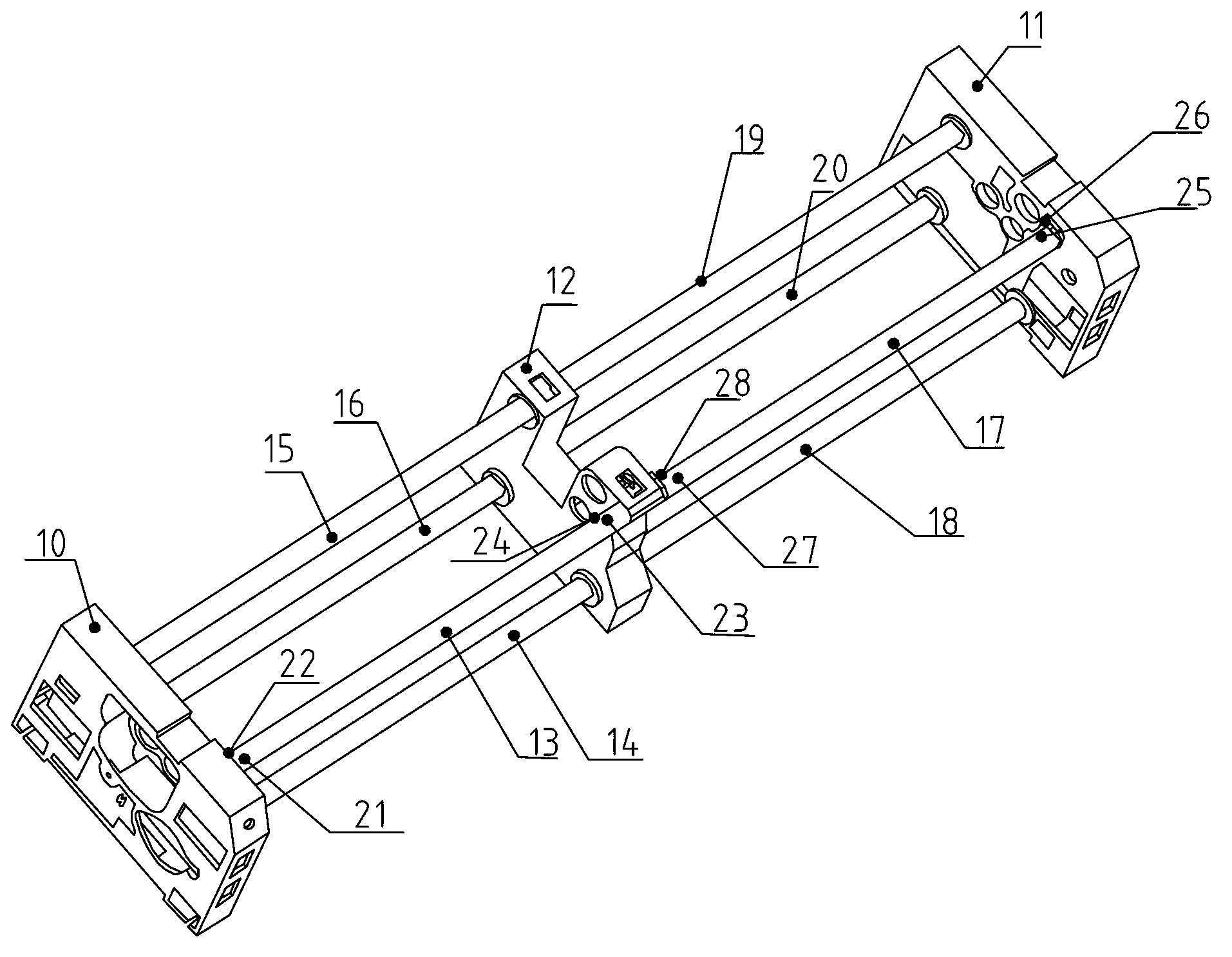

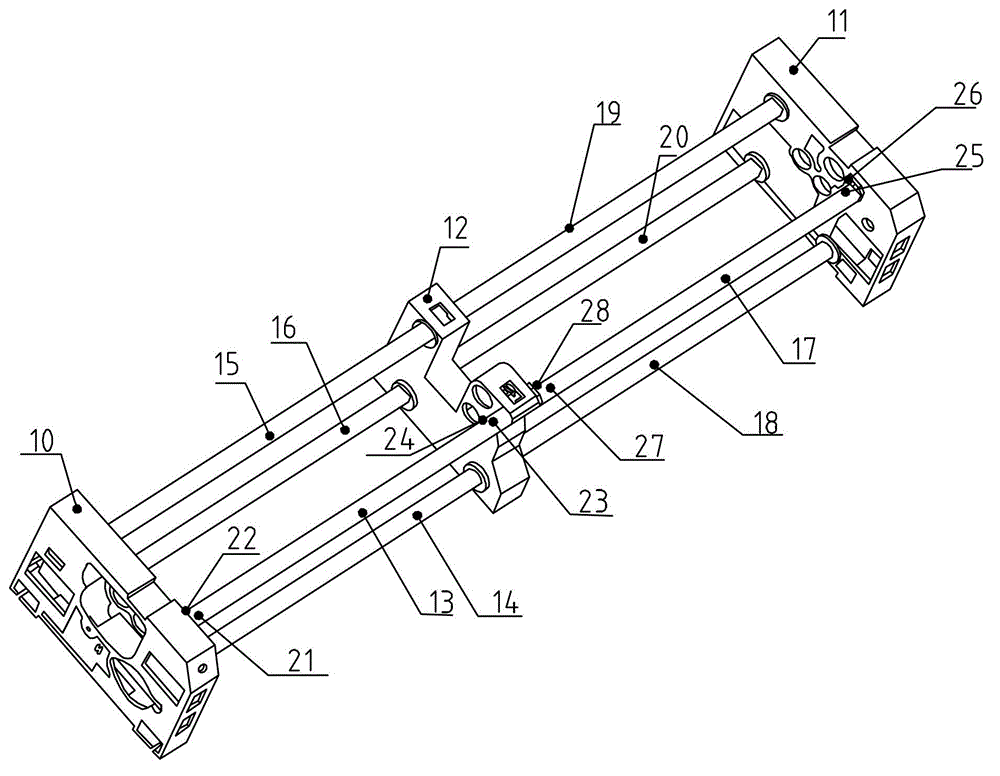

One-drawing and splitting structure of a sunshade net wire drawing machine

ActiveCN108973069BSqueeze water to achieveSatisfy water squeeze needsFilament/thread formingElectric machineryStructural engineering

The invention discloses a pulling and splitting structure of a sunshade net wire drawing machine, which includes a water squeezing roller group, a negative pressure moisture absorption device cooperated with the water squeezing roller group, a first traction roller cooperated with the negative pressure moisture absorption device, and The first traction roller cooperates with the splitting structure, the second traction roller cooperates with the splitting mechanism, the third traction roller cooperates with the second traction roller and the traction motor; the water squeezing roller group is used to cooperate with the cooling water tank of the wire drawing machine. Realize squeezing water from the flat film cooled by the cooling water tank; the first traction roller, the second traction roller and the third traction roller are respectively connected to the traction motor. The invention adopts the above structure to realize squeezing of the flat film after the cooling water tank is cooled; a fine-tuning mechanism is used to adjust the distance between the first water squeezing roller and the second water squeezing roller, which can meet the water squeezing needs of flat films of different thicknesses, and more It is beneficial to improve the water squeezing effect and prevent damage caused by squeezing the flat film.

Owner:安徽省塑格昂控股有限公司

Plastic knitting machine

InactiveCN102839490AIncrease widthAdapt to weaving requirementsLoomsElectrical resistance and conductancePower flow

The invention discloses a plastic knitting machine, which is characterized by including a shedding mechanism, a water jet weft insertion mechanism, a beating-up mechanism, a let-off mechanism, a winding mechanism and an auxiliary mechanism. The auxiliary mechanism includes a frame mechanism and an electronic weft cutter. The electronic weft cutter comprises a main controller, a current relay, a current transformer, a first copper terminal, a second copper terminal and a resistance wire for thermally cutting off a weft yarn; the main controller is connected with the current relay; the current relay is connected with the current transformer; the current transformer is connected with the first copper terminal and the second copper terminal; and the resistance wire has one end connected with the first copper terminal and the other end connected with the second copper terminal. The frame mechanism includes a left wall plate, a right wall plate and spacers; a middle wall plate is arranged between the left and the right wall plate; the left wall plate is connected with the middle wall plate through a first spacer group; and the right wall plate is connected with the middle wall plate through a second spacer group. The plastic knitting machine is not only suitable for knitting wide and heavy fabrics, but also in favor of further improvement and guarantee on the quality of plastic fabrics.

Owner:青岛东佳纺机(集团)有限公司 +1

Device for wringing papermaking waste residues

A device for wringing papermaking waste residues belongs to the technical field of devices for wringing the papermaking waste residues, and comprises a base, wherein an electric motor, a transmission gear which is connected with the electric motor through a first coupling and a bearing base which is connected with the transmission gear through a second coupling are sequentially arranged on the base through a support, the other end of the bearing base is provided and connected with a shaftless spiral body in a matching way through a third coupling, a feed bin is arranged above one end of the shaftless spiral body in a matching way, which is close to the bearing base, a shaftless spiral body shell is arranged outside the shaftless spiral body, and is connected with a material seal shell through a flange, and drain holes are respectively arranged on the shaftless spiral body shell and the material seal shell in a matching way. The device adopts the technology, has a simple structure, thematerial extruding strength is increased, and the wringing effect is improved; and one end of the shaftless spiral body shell is connected with the material seal shell, the material traveling distance and the material forward resistance are increased, the extruding force on the material is improved, the wringing effect is enhanced, and the continuity and stability of the wringing process are protected.

Owner:仁精科技(昆山)有限公司

Plain weave plastic loom

The invention discloses a plain weave plastic loom, which comprises an open mechanism, a water jet weft insertion mechanism, a weft beating-up mechanism, a warp feeding mechanism, a take-up mechanism and an auxiliary mechanism. The loom is characterized in that the auxiliary mechanism comprises a frame mechanism, an electronic weft-yarn cutter device and an electronic weft feeding device; the electronic weft-yarn cutter device comprises a main controller, a current relay, a current transformer, a No.1 copper terminal, a No.2 copper terminal and a resistance wire for burning off weft yarns; the electronic weft feeding device comprises a weft-yarn table component, a weft-yarn tube, a vertical drive shaft, a weft feeding motor and an electromagnetic brake component; a tray driven by the drive shaft is arranged at the upper part of a tabletop; the weft-yarn tube is placed on the tray and rotates together along with the tray; the electromagnetic brake component comprises a brake fixed tray and a friction disk; and the fixed tray is fixed at the bottom of the tabletop; the friction disk is positioned under the fixed tray and is fixedly connected with the drive shaft. The plain weave plastic loom can be not only suitable for weaving wide heavy fabrics, but also favorable for further improving and ensuring the quality of plastic fabrics.

Owner:青岛东佳机械制造有限公司

Plastic knitting machine

The invention discloses a plastic knitting machine, which is characterized by including a shedding mechanism, a water jet weft insertion mechanism, a beating-up mechanism, a let-off mechanism, a winding mechanism and an auxiliary mechanism. The auxiliary mechanism includes a frame mechanism and an electronic weft cutter. The electronic weft cutter comprises a main controller, a current relay, a current transformer, a first copper terminal, a second copper terminal and a resistance wire for thermally cutting off a weft yarn; the main controller is connected with the current relay; the current relay is connected with the current transformer; the current transformer is connected with the first copper terminal and the second copper terminal; and the resistance wire has one end connected with the first copper terminal and the other end connected with the second copper terminal. The frame mechanism includes a left wall plate, a right wall plate and spacers; a middle wall plate is arranged between the left and the right wall plate; the left wall plate is connected with the middle wall plate through a first spacer group; and the right wall plate is connected with the middle wall plate through a second spacer group. The plastic knitting machine is not only suitable for knitting wide and heavy fabrics, but also in favor of further improvement and guarantee on the quality of plastic fabrics.

Owner:青岛东佳纺机(集团)有限公司 +1

A printing and dyeing process having a low decolourization ratio

ActiveCN107893338AReduce moisture contentNot easy to fadeSingeingLiquid/gas/vapor removal by squeezing rollersCooking & bakingPulp and paper industry

A printing and dyeing process having a low decolourization ratio is disclosed. The process includes (1) a singeing step; (2) a dyeing step, namely a step of adding gray cloth into a dyeing pool and dyeing the gray cloth; (3) a squeeze drying step, namely a step of subjecting the dyed cloth to squeezing treatment by adopting a squeeze drying device, and then performing scotching treatment; and (4)a drying step, namely a step of subjecting the cloth to pre-baking treatment at 70-80 DEG C for 1-5 min before drying, the cooling the cloth to 40-60 DEG C, maintaining the temperature for 5-8 min, then raising the temperature to 120-150 DEG C, and baking the cloth for 3-8 min. The printed and dyed cloth is squeezed to remove water by the squeeze drying device so as to reduce the water content ofthe cloth before drying operation and to increase the drying efficiency, thus increasing the overall treatment efficiency. Pre-baking is performed before drying, and therefore the adhesion degree of dyeing liquid is increased, the cloth is not too hard and softness of the cloth is ensured.

Owner:沛县新丝路纺织有限公司

A leather multi-stage squeezing device

ActiveCN112029915BEasy squeezeImprove squeeze efficiencyLeather pressing/rollingSkins/hides/leather/fur manufacturing apparatusStructural engineeringMechanical engineering

The invention provides a leather multi-stage squeezing device, which relates to the technical field of leather processing. The multi-stage water squeezing device for leather includes a casing, a bracket, a water collecting tank, a first transmission device, a water squeezing mechanism, an arc-shaped inclined plate, a flattening mechanism, an adjustment device, a bracket fixedly connected to the bottom of the casing, and a casing. A water collecting tank is arranged between the bottom bracket on the left end, and the water collecting tank is flexibly connected with the casing. The inside of the casing is provided with a first transmission device near the bottom. The left and right sides of the first transmission device are fixedly connected with the inner wall of the casing. The first transmission device There is a water squeezing mechanism on the top, and an arc-shaped sloping plate is installed on the right end of the first transmission device. Both sides of the arc-shaped sloping plate are fixedly connected with the inside of the casing. Adjusting device, the adjusting device slides through the bottom ends of both sides of the casing and is connected with the casing, thereby solving the problems of low water squeezing efficiency during the leather squeezing process and the secondary adsorption of the squeezed water by the leather.

Owner:台州玉釉新材料科技有限公司

Hydraulic machine for rapid water squeezing and shaping

InactiveCN102922765BHigh speedIncrease pressureServomotor componentsServomotorsLow speedControl system

The invention relates to a hydraulic machine for rapid water squeezing and shaping. The hydraulic machine comprises a frame, sliding blocks, a plurality of oil cylinders, a hydraulic control system, an oil supply pipeline and an electric appliance control system, wherein the sliding blocks are mounted in the frame in parallel in a guiding manner; the oil cylinders are evenly distributed on the frame below the sliding blocks at intervals; the oil cylinders are connected with the hydraulic control system respectively through the oil supply pipeline; and the electric appliance control system controls each action of the hydraulic control system according to a predetermined command. The hydraulic machine is characterized in that the rapid raising, the pressurized water squeezing, the pressure-maintaining shaping, the low-speed decompressing and the rapid descending of the sliding blocks are carried out by utilizing a pressurization control return circuit and a decompression control return circuit respectively, wherein the pressurization control return circuit controls the rapid raising, the pressurized water squeezing, the pressure-maintaining shaping of the sliding blocks; and the decompression control return circuit controls the low-speed decompressing and the rapid descending of the sliding blocks. The hydraulic machine has the advantages of low cost, simple structure, convenience in repair, low operation cost, high working efficiency and excellent cost performance, thereby overcoming the defects of high-grade and low-grade water squeezing and shaping equipment.

Owner:天津市诺恩电器设备制造有限公司

Plastic knitting machine

The invention discloses a plastic knitting machine, which is characterized by including a shedding mechanism, a water jet weft insertion mechanism, a beating-up mechanism, a let-off mechanism, a winding mechanism and an auxiliary mechanism. The auxiliary mechanism comprises a frame mechanism and an electronic weft feeder. The electronic weft feeder comprises a weft table assembly, weft drums, a vertical transmission shaft, a weft feeding motor and an electromagnetic brake assembly. The frame mechanism comprises a left wall plate, a right wall plate, a middle wall plate, and first and second spacer groups; the left wall plate is connected with the middle wall plate through the first spacer group; and the right wall plate is connected with the middle wall plate through the second spacer group. The winding mechanism comprises a water squeezing roller; the water squeezing roller includes a rubber roller inner cylinder, and a kiss-coating layer disposed at the outer cylinder wall of the rubber roller inner cylinder; each of two ends of the rubber roller inner cylinder is provided with an axle head; and each axle head is fixed on the inner cylinder wall of the rubber roller inner cylinder through an axle head internal support disc and an axle head external support disc. The plastic knitting machine is not only suitable for knitting wide and heavy fabrics, but also in favor of further improvement and guarantee on the quality of plastic fabrics.

Owner:青岛东佳纺机(集团)有限公司 +1

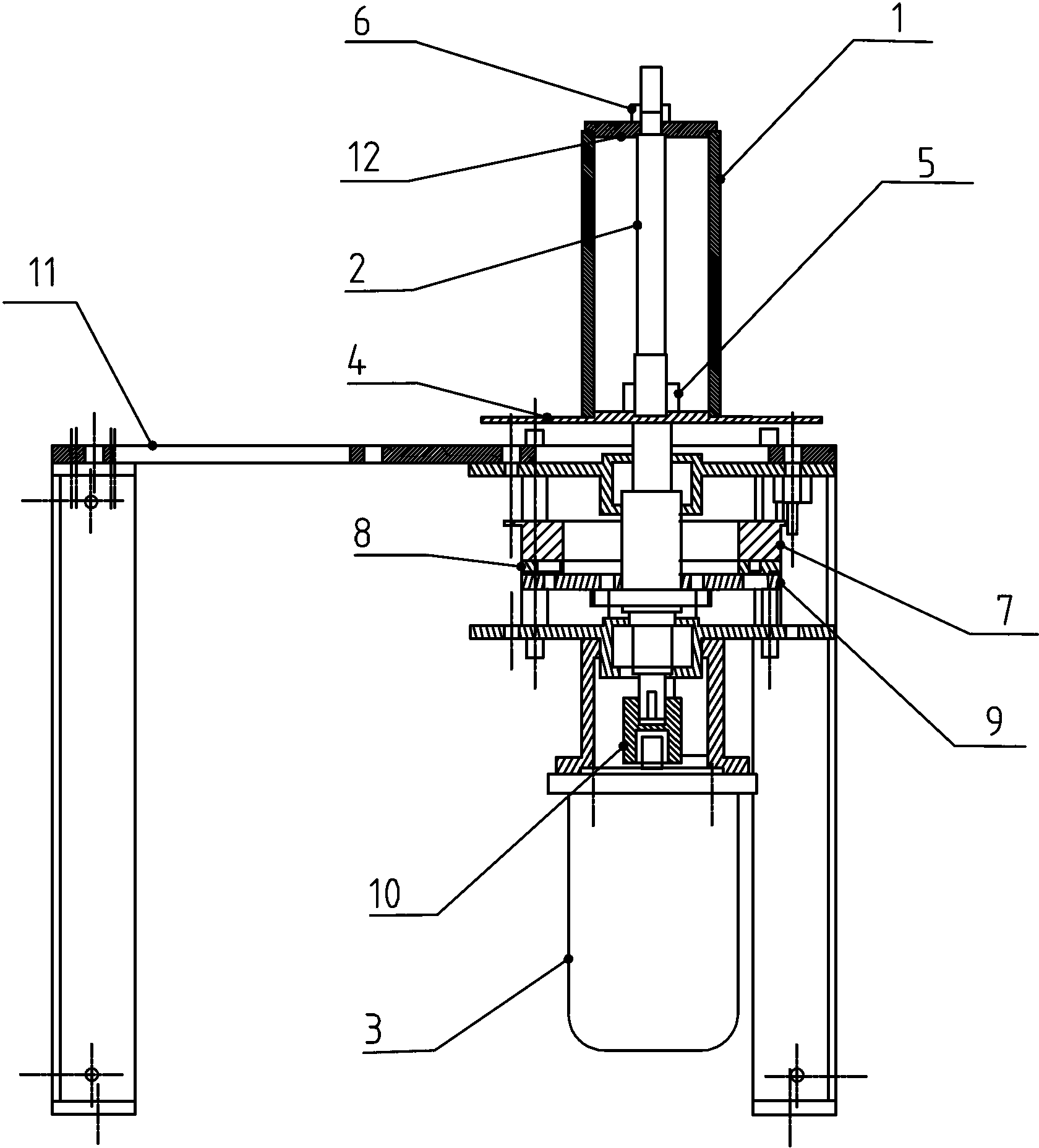

Slag extruding machine of sisal hemp leaf slag-juice separation production line

The invention discloses a slag extruding machine of a sisal hemp leaf slag-juice separation production line. The slag extruding machine is characterized in that a feeding port is formed in one end ofthe top of a water extruding tank, the other end of the top of the water extruding tank is provided with a discharging port, a partition plate located between the feeding port A and the discharging port in the water extruding tank divides the water extruding tank into a water extruding groove and a slag discharging groove, a water extruding pipe is fixedly connected in the water extruding groove,the pipe wall of the water extruding pipe is a mesh plate with a plurality of water filtering holes uniformly distributed, a notch is formed in the position, correspondingly located below the feedingport A, of the top of the water extruding pipe to form a feeding port B, a slag extruding roller is rotationally connected into the water extruding pipe, a water extruding plate of a spiral structureis arranged on the surface of the slag extruding roller in the axial direction of the slag extruding roller, and a liquid discharge port is formed in the position, on one side of the water extruding groove, of the bottom of the water extruding tank. According to the structure, the slag extruding machine of the sisal hemp leaf slag-juice separation production line has the effects that by means of the mechanical extrusion force, leaf pulp is extruded, so that juice in the leaf pulp is extruded as much as possible, then the recovery amount of the sisal juice is improved, and the extruded slag canbe further collected.

Owner:JIANGSU HIMALAYA NATURAL FIBER PROD

Foamed cotton mop with guiding structure

PendingCN110859559AImprove water squeeze effectEasy to operateCarpet cleanersFloor cleanersEngineeringMechanical engineering

Owner:NINGBO DERUNTANG INTELLIGENT TECH CO LTD

Plain-weave plastic braiding machine

The invention discloses a plain-weave plastic braiding machine which is characterized by comprising a shedding mechanism, a water jet weft insertion mechanism, a weft beating-up mechanism, a let-off mechanism, a take-up mechanism and an auxiliary mechanism; the take-up mechanism comprises a wringing roller, the wringing roller comprises a rubber roller inner barrel and a coating layer arranged onthe outer barrel wall of the rubber roller inner barrel, a spindle nose is arranged at the two ends of the roller tube inner barrel respectively, each spindle nose is fixedly arranged on the inner barrel wall of the rubber roller inner barrel through a spindle nose inner support disc and a spindle nose outer support disc, a plurality of radial reinforcing ribs are arranged between the spindle nose inner support disc and the spindle nose outer support disc, one end of each reinforcing rib is fixedly arranged on one spindle nose, the other end of each reinforcing rib is fixedly arranged on the inner barrel wall of the rubber roller inner barrel, in the length range of being 350-450 mm from the each end part of the coating layer, the diameter of the coating layer is reduced gradually from the middle part to the end parts, and the diameter of the end part is smaller than the diameter of the middle part by 1-1.5 mm. The plain-weave plastic braiding machine is suitable for weaving wide and heavy fabric and is also beneficial to further improving and guaranteeing the quality of plastic fabric.

Owner:青岛东佳机械制造有限公司

Pickle water squeezing device

ActiveCN110250550AQuickly achieve water squeeze effectImprove work efficiencyFood shapingEngineeringMechanical engineering

Owner:甘肃圆根香生物科技股份有限公司

Water squeezing device of foam cotton head mop

Owner:NINGBO DERUNTANG INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com