Hydraulic machine for rapid water squeezing and shaping

A hydraulic machine, fast technology, applied in the field of hydraulic pressure, can solve the problems that are not suitable for the development needs of small and medium-sized enterprises, restrict the development needs of enterprises, and the complex structure of high-end products, and achieve the effect of improving the water squeezing effect, ensuring the quality of water squeezing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

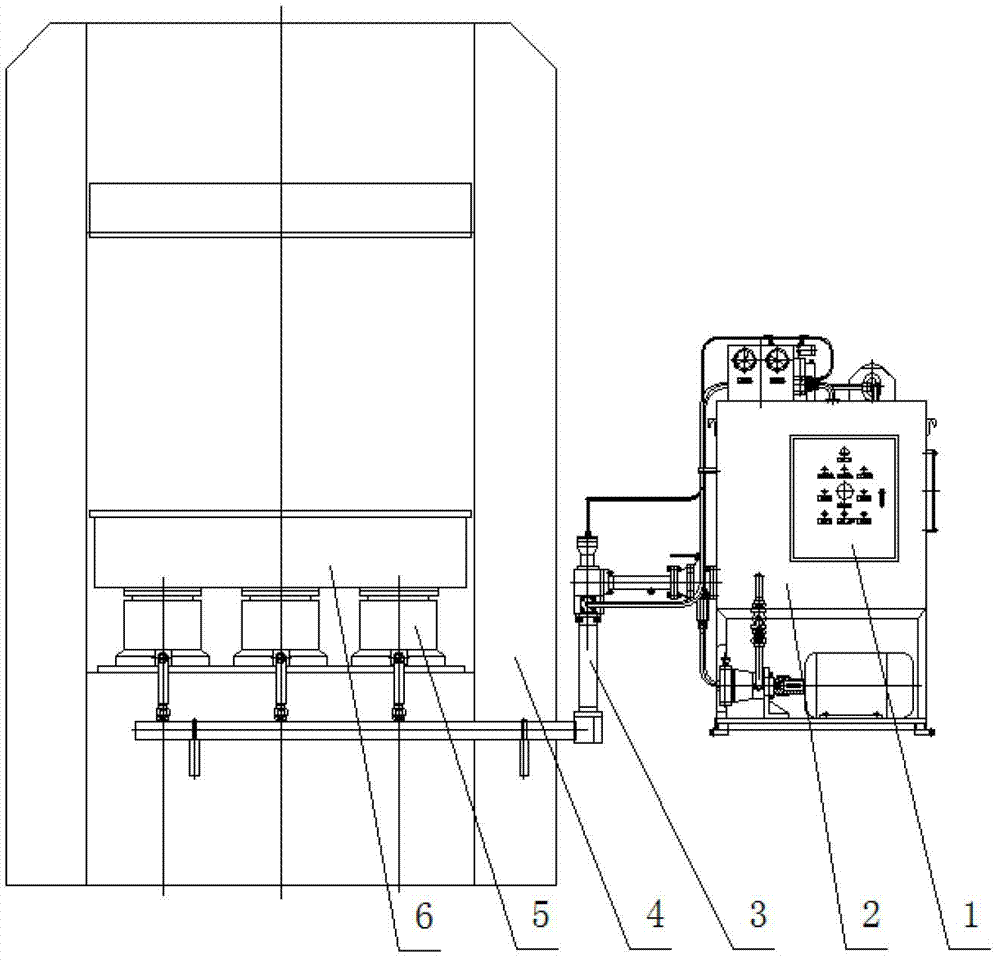

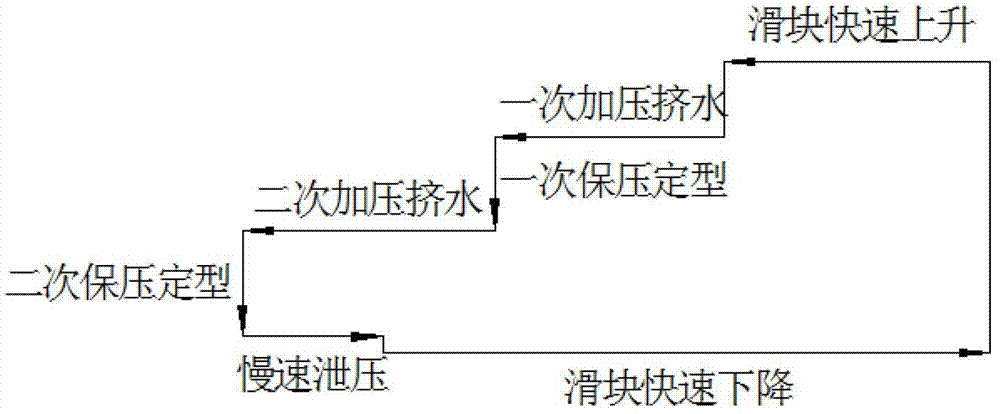

[0020] A hydraulic press for rapid water extrusion (such as figure 1 shown), including frame 4, slide block 6, oil cylinder 5, hydraulic control system 2, oil supply pipeline 3 and electrical control system 1, slide blocks are installed in parallel guides in the frame, and the frame below the slide block Oil cylinders are evenly distributed on the top, and the oil cylinders are respectively connected with the hydraulic control system through oil supply pipelines. The electrical control system controls each action of the hydraulic control system according to preset instructions. The working form of the hydraulic press is to lift the material, pressurize the water, keep the pressure and set the shape.

[0021] The technical scheme of the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com