Five-roller type samming machine

A technology of leveling and spreading machine, applied in the field of leather extrusion leveling and spreading processing machinery, can solve the problems of poor second stretching effect of the machine, poor water squeezing effect, and reduced work efficiency, etc., to improve the extrusion stretching effect, squeeze Water effect improvement, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

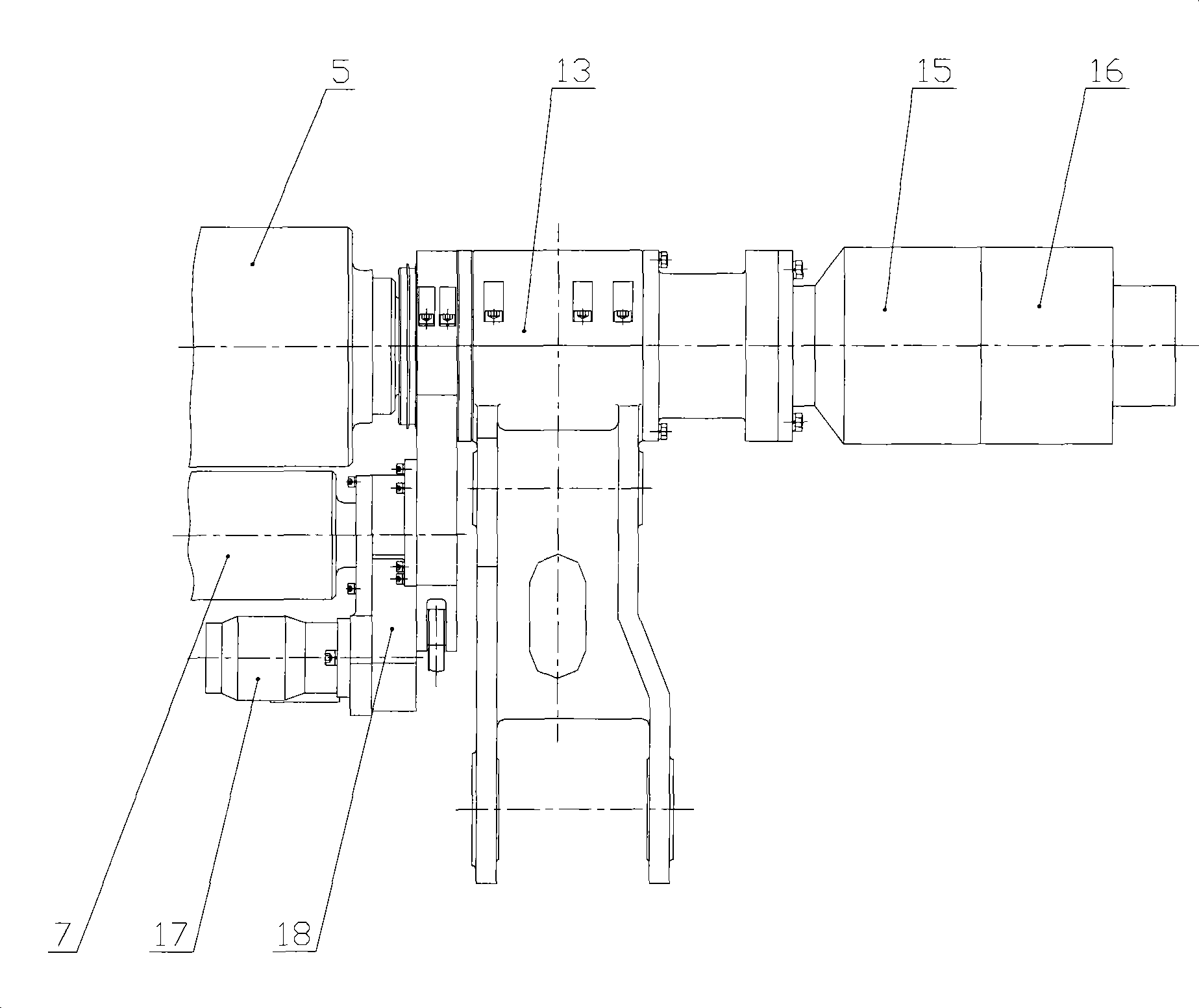

[0016] refer to figure 1 , a five-roller extrusion horizontal stretching machine, including a rack cylinder 11, a connecting rod mechanism 12 connected to the rack cylinder 11, a feed roller support 13 arranged on the connecting rod mechanism 12, two felt roller cylinders 1, connected to the The felt roller rocker arm 2 on the felt roller oil cylinder 1, the knife roller oil cylinder 9, the knife roller rocker arm 8 connected on the knife roller oil cylinder 9, the large rubber roller 5 and the small rubber roller 7 are installed on the feed roller support 13 An upper felt roller 3 and a lower felt roller 4 are installed on the two felt roller rocking arms 2 respectively, and a knife roller 6 is installed on the knife roller rocking arm 8 . Above-mentioned feed roller support 13, rack oil cylinder 11, connecting rod mechanism 12, two felt roller oil cylinders 1, two felt roller rocking arms 2, knife roller oil cylinder 9 and knife roller rocking arm 8 are all fixed on the wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com